Experimental Study on the Stability and Distribution of Air Voids in Fresh Fly Ash Concrete

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Mix Proportions

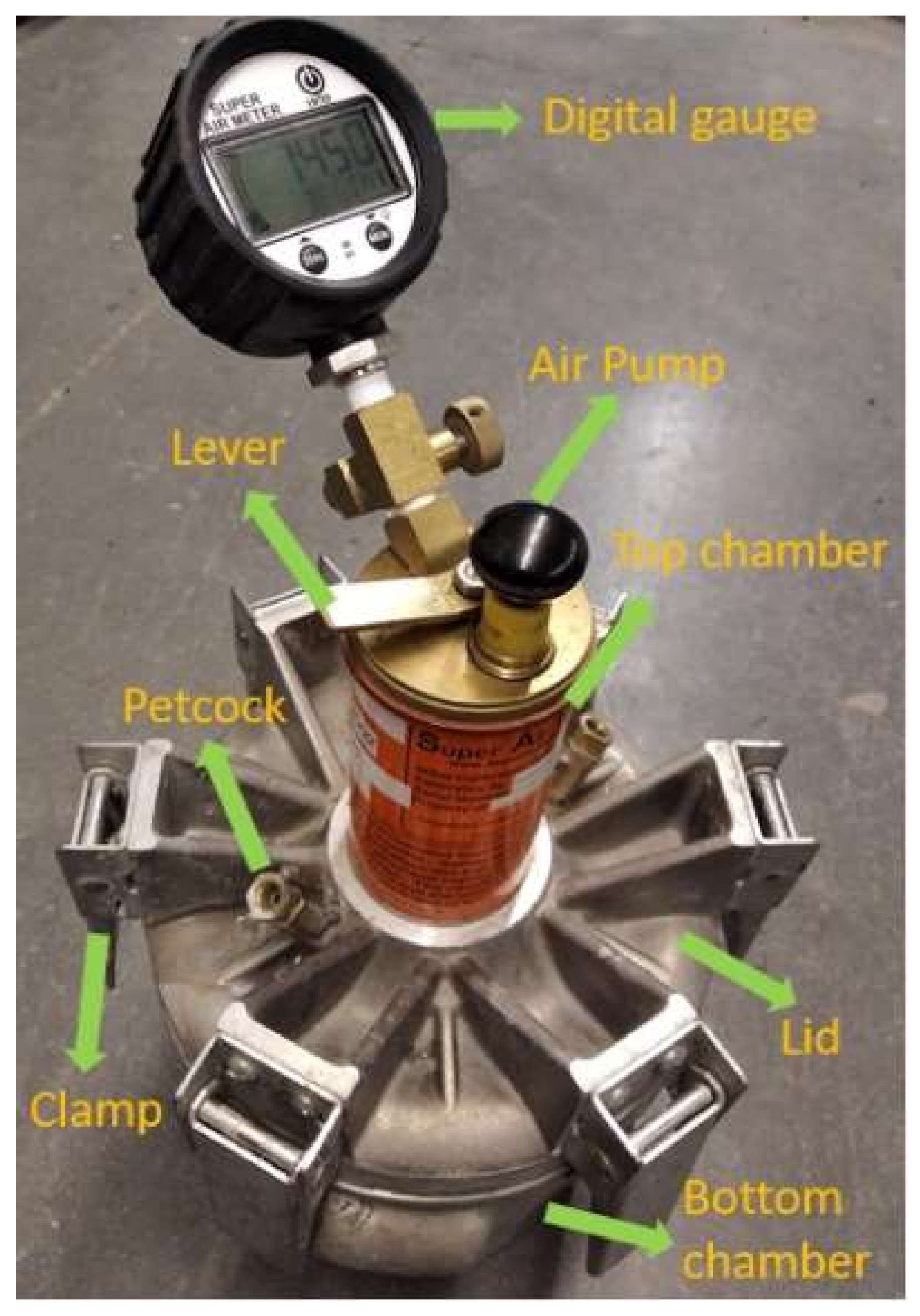

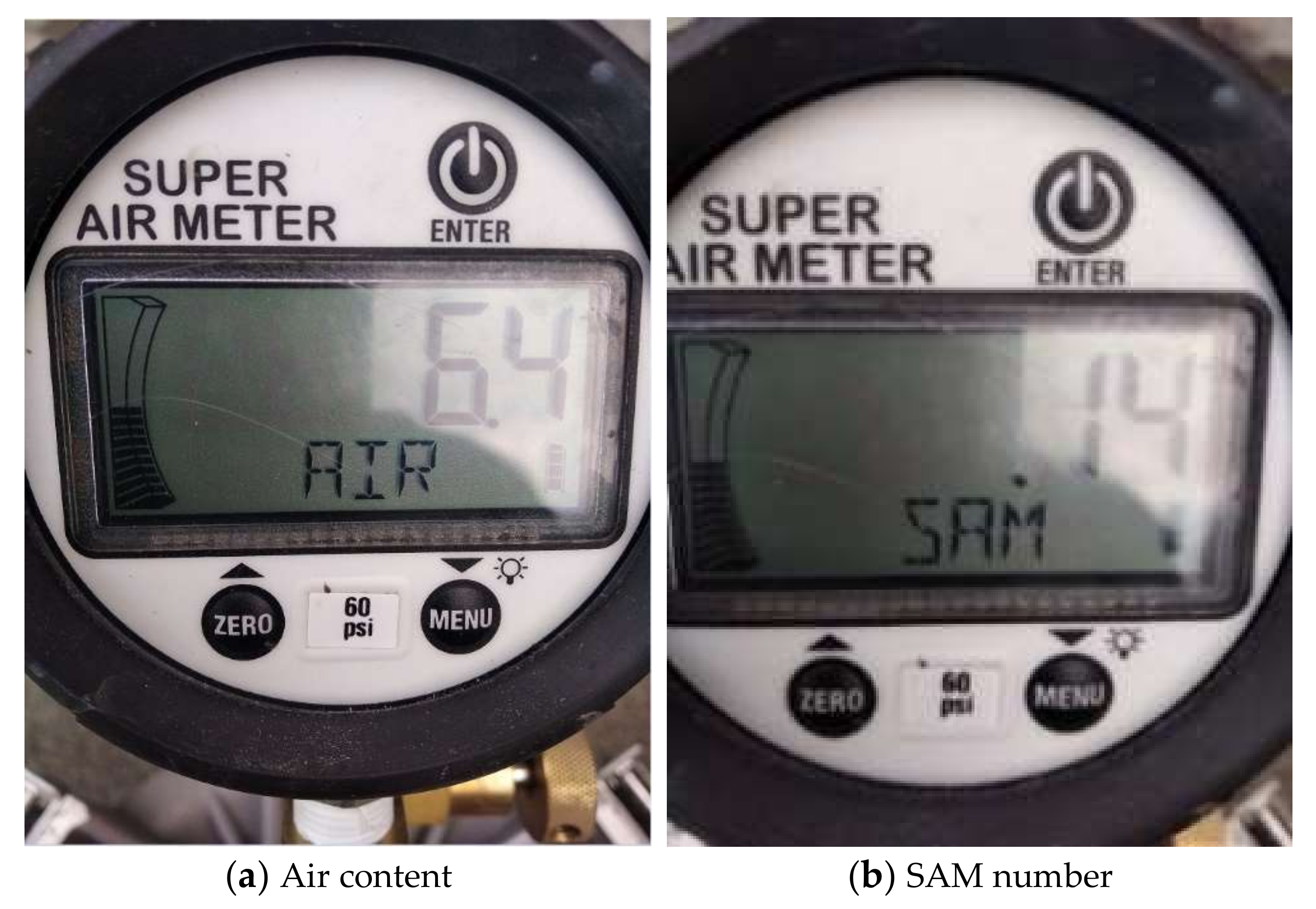

2.3. Test Methods

3. Results and Discussion

3.1. Fresh Properties

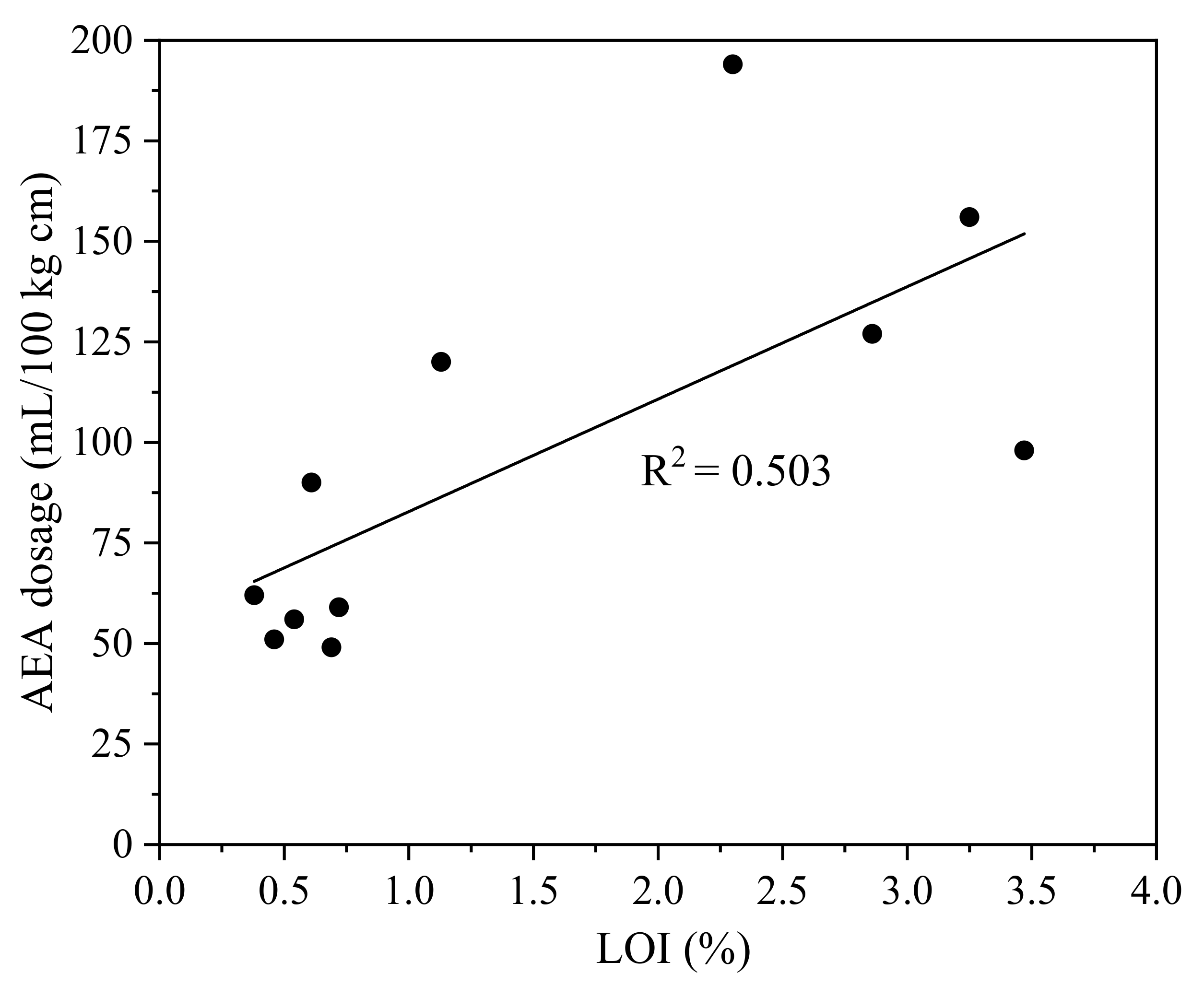

3.2. AEA Dosage Demand

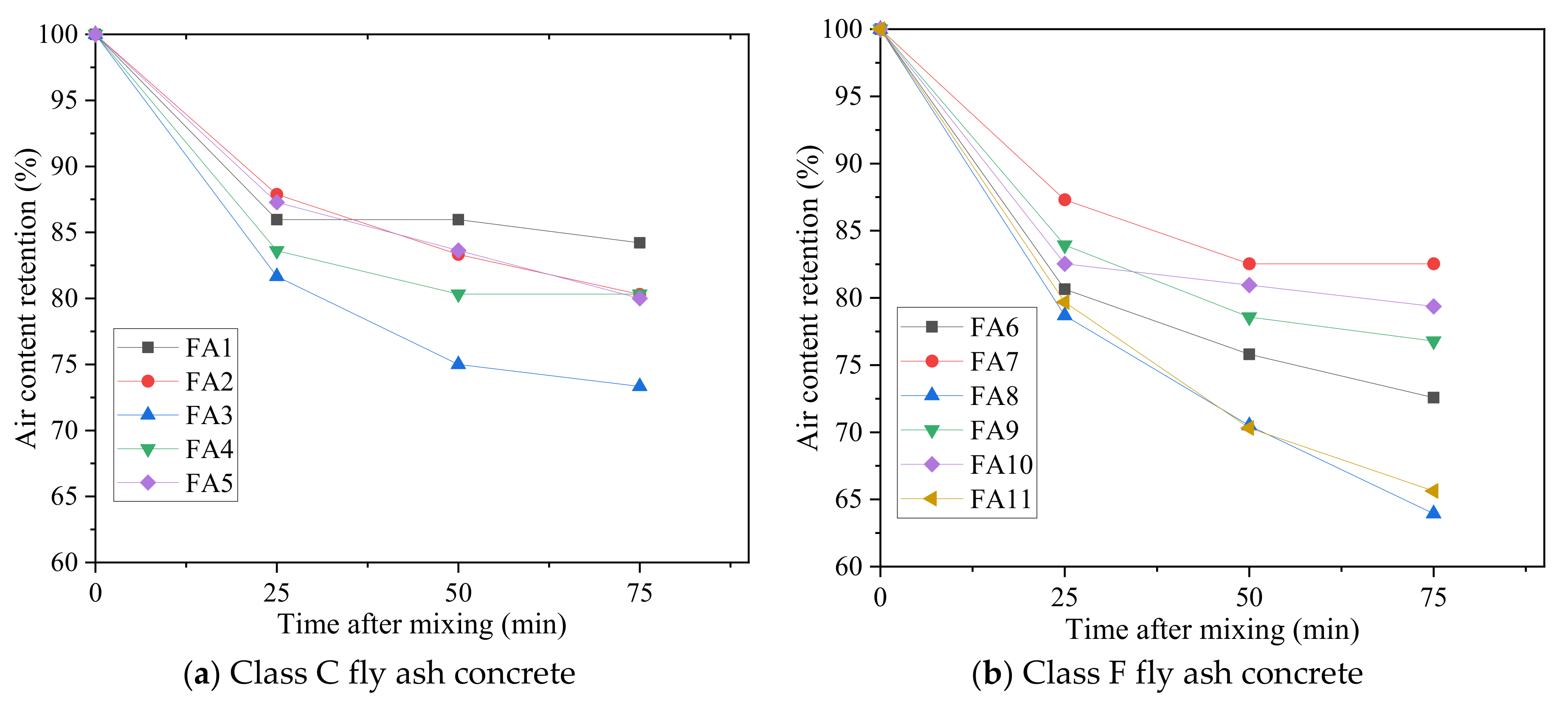

3.3. Air Void Stability and Distribution

4. Conclusions

- (1)

- There was no significant correlation between the LOI of fly ash and the AEA requirement for the initial air content of 6 ± 1%.

- (2)

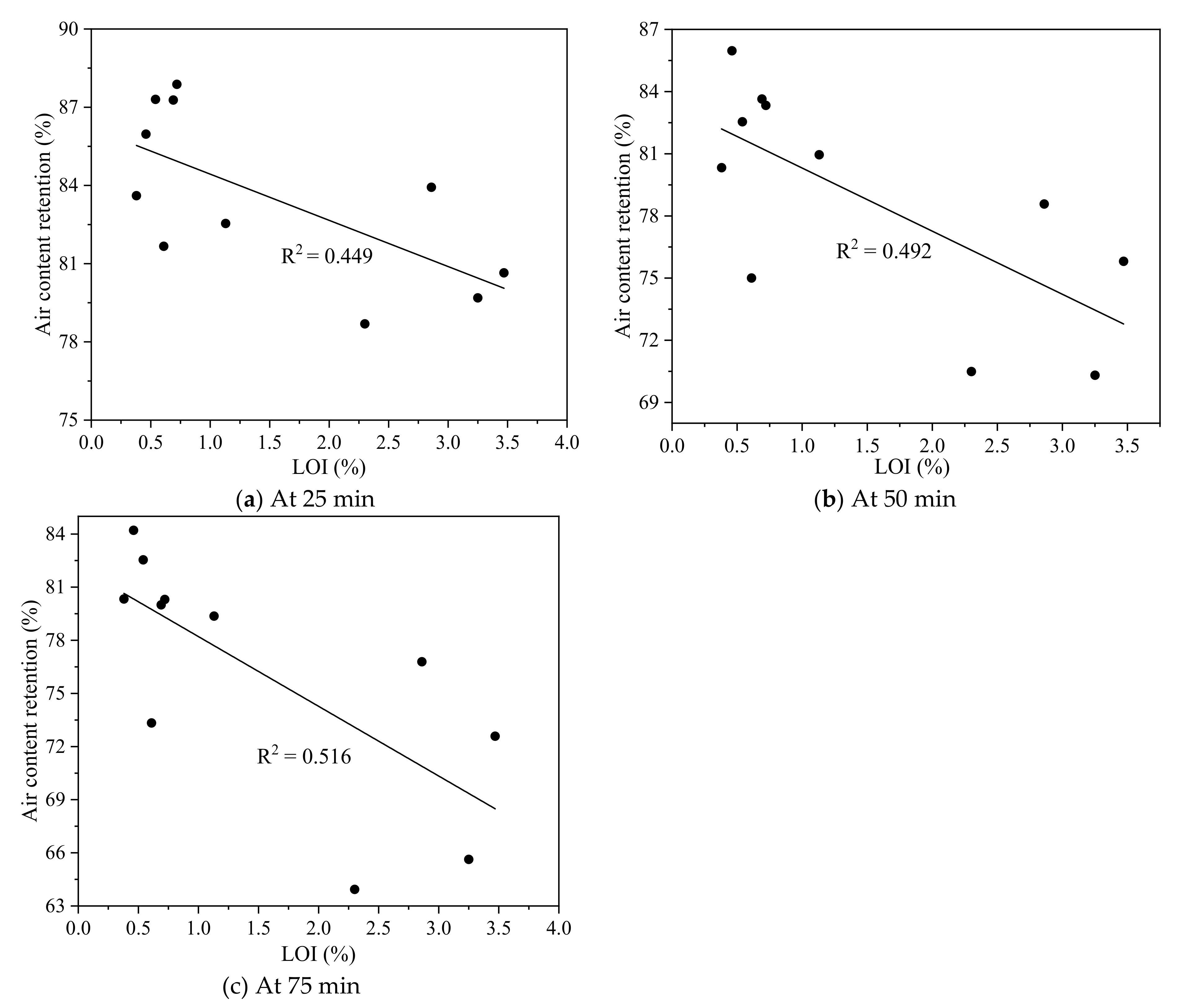

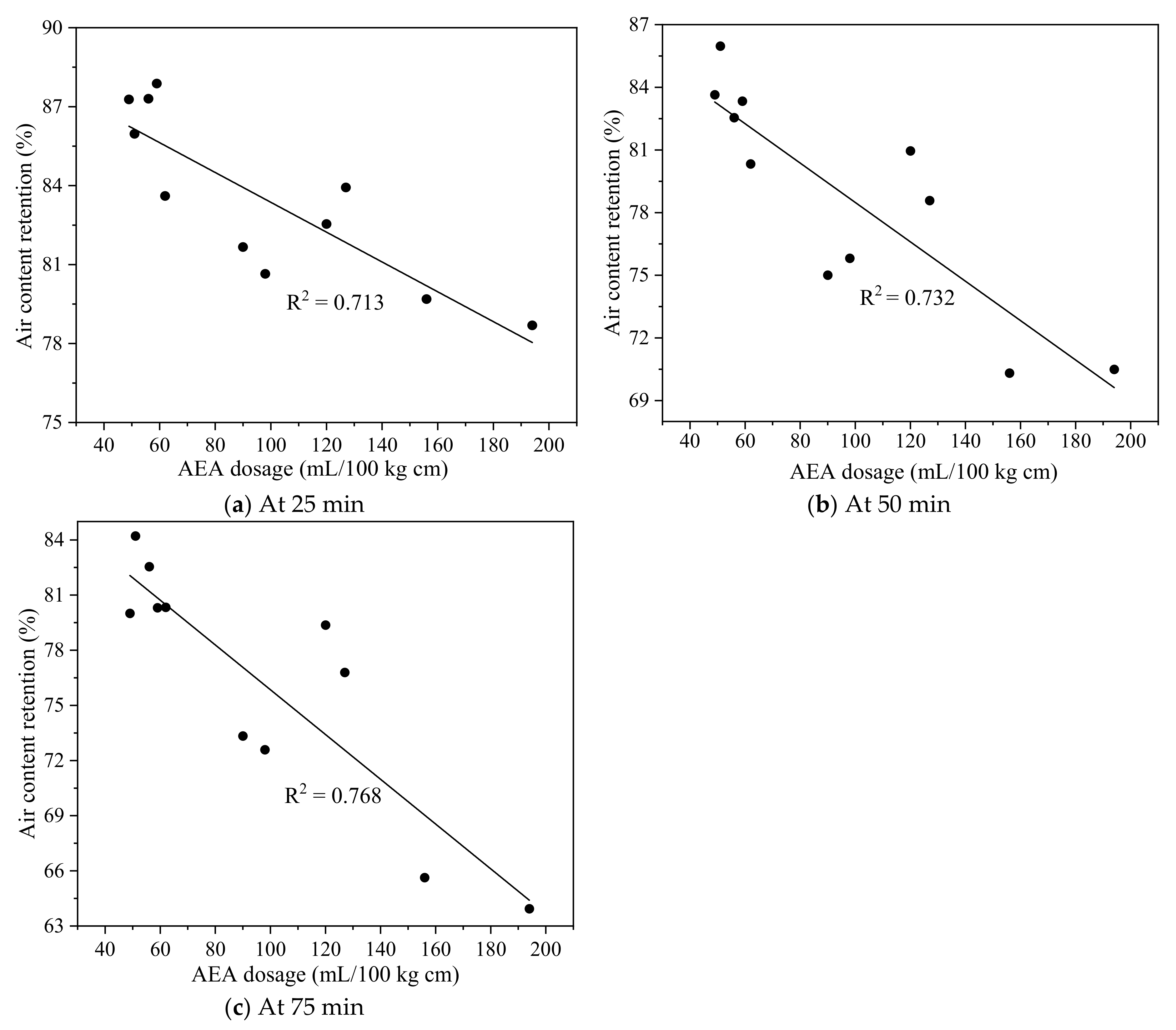

- Overall, Class F fly ash concrete had a worse air content retention than Class C fly ash concrete. Compared with LOI, AEA demand had a stronger correlation with air content retention.

- (3)

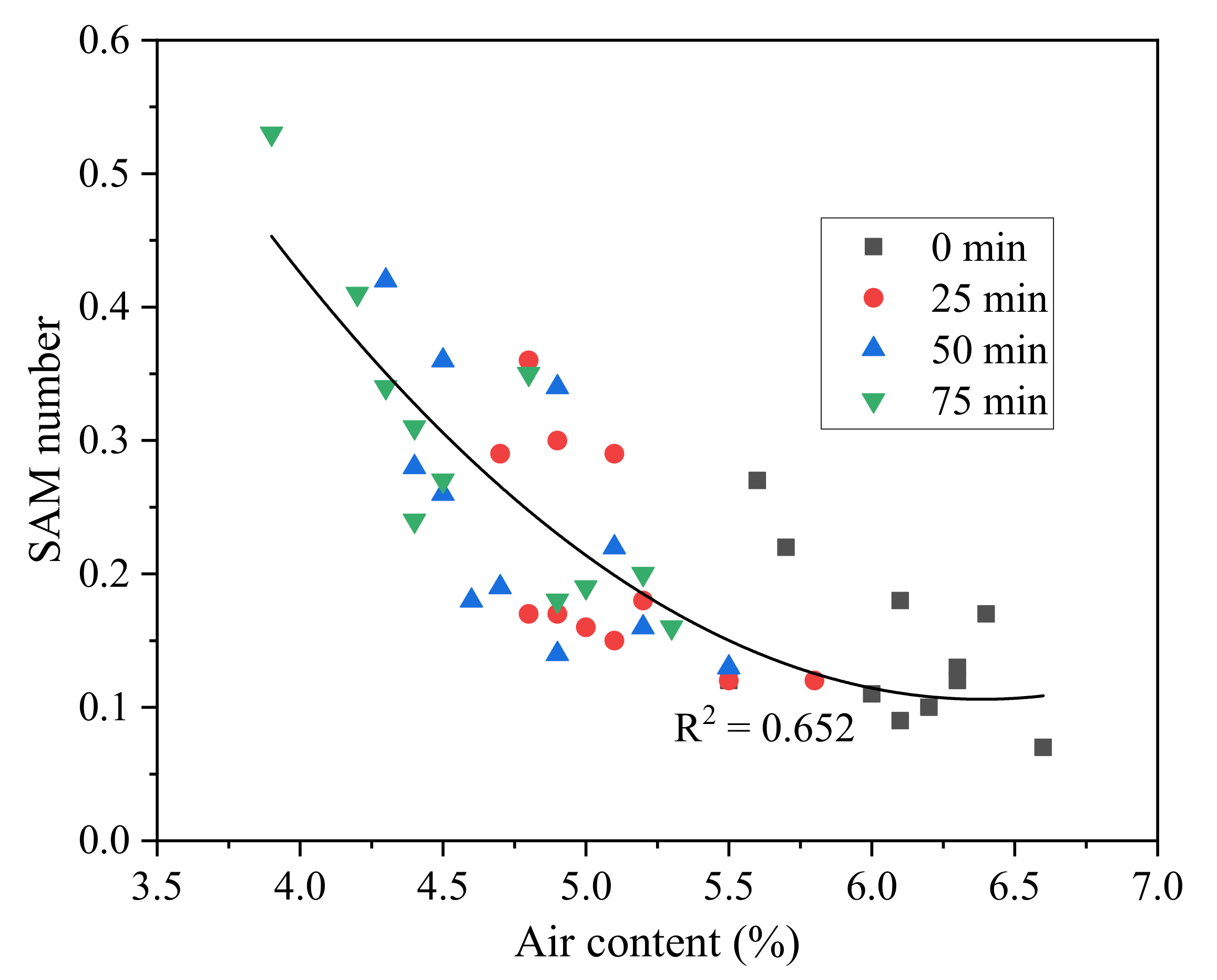

- Most of the fly ash concrete mixtures had an SAM number below 0.2 right after mixing, indicating that it was feasible to produce fly ash concrete with a high-quality air void system, but the SAM number showed an increasing trend with sampling time, which indicated the coarsening of the air void system. Thus, sampling time had a relatively large effect on measuring air content and SAM number for fly ash concrete. The air content and SAM number obtained right after mixing were not necessarily the same as the measured results after 75 min.

- (4)

- The correlation between air content in fresh concrete and SAM number showed that increasing the air content could reduce the SAM number and, thus, achieve a lower spacing of air voids.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, P.; Li, D.; Qiao, Y.; Zhang, S.; Sun, C.; Zhao, T. Effect of air entrainment on the mechanical properties, chloride migration, and microstructure of ordinary concrete and fly ash concrete. J. Mater. Civ. Eng. 2018, 30, 4018265. [Google Scholar] [CrossRef]

- Wang, R.; Hu, Z.; Li, Y.; Wang, K.; Zhang, H. Review on the deterioration and approaches to enhance the durability of concrete in the freeze–thaw environment. Constr. Build. Mater. 2022, 321, 126371. [Google Scholar] [CrossRef]

- ASTM C231/C231M-17a; Standard Test Method for Air Content of Freshly Mixed Concrete by the Pressure Method. American Society for Testing and Materials (ASTM) International: West Conshohocken, PA, USA, 2017.

- ASTM C138/C138M-13; Standard Test Method for Density (Unit Weight), Yield, and Air Content (Gravimetric) of Concrete. American Society for Testing and Materials (ASTM) International: West Conshohocken, PA, USA, 2013.

- ASTM C173/C173M-16; Standard Test Method for Air Content of Freshly Mixed Concrete by the Volumetric Method; American Society for Testing and Materials (ASTM) International: West Conshohocken, PA, USA, 2016.

- Yuan, J.; Wu, Y.; Zhang, J. Characterization of air voids and frost resistance of concrete based on industrial computerized tomographical technology. Constr. Build. Mater. 2018, 168, 975–983. [Google Scholar] [CrossRef]

- ASTM C666/C666M-15; Standard Test Method for Resistance of Concrete to Rapid Freezing and Thawing; American Society for Testing and Materials (ASTM) International: West Conshohocken, PA, USA, 2015.

- Freeman, J.M. Stability and Quality of Air Void Systems in Concretes with Superplasticizers. Master’s Thesis, Oklahoma State University, Stillwater, OK, USA, 2012. [Google Scholar]

- Ashraf, W.; Glinicki, M.A.; Olek, J. Statistical analysis and probabilistic design approach for freeze–thaw performance of ordinary Portland Cement concrete. J. Mater. Civ. Eng. 2018, 30, 04018294. [Google Scholar] [CrossRef]

- ASTM C457/C457M-16; Standard Test Method for Microscopical Determination of Parameters of the Air-Void System in Hardened Concrete. American Society for Testing and Materials (ASTM) International: West Conshohocken, PA, USA, 2016.

- Jakobsen, U.H.; Pade, C.; Thaulow, N.; Brown, D.; Sahu, S.; Magnusson, O.; Buck, S.; Schutter, G. Automated air void analysis of hardened concrete—A Round Robin study. Cem. Concr. Res. 2006, 36, 1444–1452. [Google Scholar] [CrossRef]

- Ojala, T.; Chen, Y.; Punkki, J.; Al-Neshawy, F. Characteristics of Entrained Air Voids in Hardened Concrete with the Method of Digital Image Analysis Coupled with Schwartz-Saltykov Conversion. Materials 2021, 14, 2439. [Google Scholar] [CrossRef]

- Molendowska, A.; Wawrzeńczyk, J.; Kowalczyk, H. Development of the Measuring Techniques for Estimating the Air Void System Parameters in Concrete Using 2D Analysis Method. Materials 2020, 13, 428. [Google Scholar] [CrossRef] [Green Version]

- Guo, S.; Dai, Q.; Sun, X.; Sun, Y.; Liu, Z. Ultrasonic Techniques for Air Void Size Distribution and Property Evaluation in Both Early-Age and Hardened Concrete Samples. Appl. Sci. 2017, 7, 290. [Google Scholar] [CrossRef] [Green Version]

- Guo, S.; Dai, Q.; Sun, X.; Sun, Y. Ultrasonic scattering measurement of air void size distribution in hardened concrete samples. Constr. Build. Mater. 2016, 113, 415–422. [Google Scholar] [CrossRef]

- Krstic, M.; Davalos, J.F.; Rossi, E.; Figueiredo, S.C.; Copuroglu, O. Freeze–Thaw Resistance and Air-Void Analysis of Concrete with Recycled Glass–Pozzolan Using X-ray Micro-Tomography. Materials 2021, 14, 154. [Google Scholar] [CrossRef]

- Song, Y.; Shen, C.; Damiani, R.M.; Lange, D.A. Image-based restoration of the concrete void system using 2D-to-3D unfolding technique. Constr. Build. Mater. 2021, 270, 121476. [Google Scholar] [CrossRef]

- Suárez, F.; Conchillo, J.J.; Gálvez, J.C.; Casati, M.J. Macro Photography as an Alternative to the Stereoscopic Microscope in the Standard Test Method for Microscopical Characterisation of the Air-Void System in Hardened Concrete: Equipment and Methodology. Materials 2018, 11, 1515. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tao, J.; Gong, H.; Wang, F.; Luo, X.; Qiu, X.; Huang, Y. Automated Image Segmentation of Air Voids in Hardened Concrete Surface Using Photometric Stereo Method. Int. J. Pavement Eng. 2021, 24, 1–18. [Google Scholar] [CrossRef]

- Tao, J.; Gong, H.; Wang, F.; Luo, X.; Qiu, X.; Liu, J. Deep Learning Based Automated Segmentation of Air-Void System in Hardened Concrete Surface Using Three Dimensional Reconstructed Images. Constr. Build. Mater. 2022, 324, 126717. [Google Scholar] [CrossRef]

- Magura, D.D. Evaluation of the air void analyzer. Concr. Int. 1996, 18, 55–59. [Google Scholar]

- AASHTO TP 75-08; Standard Test Method for Air-Void Characteristics of Freshly Mixed Concrete by Buoyancy Change. American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2008.

- Distlehorst, J.A.; Kurgan, G.J. Development of Precision Statement for Determining Air Void Characteristics of Fresh Concrete with Use of Air Void Analyzer. Transp. Res. Rec. 2007, 2020, 45–49. [Google Scholar] [CrossRef]

- Ley, T.; Tabb, B. Development of a Robust Field Technique to Quantify the Air-Void Distribution in Fresh Concrete; Report No. OTCREOS9.1-31-F; Oklahoma Transportation Center: Stillwater, OK, USA, 2013. [Google Scholar]

- AASHTO TP 118–17; Characterization of the Air-Void System of Freshly Mixed Concrete by the Sequential Pressure Method. American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2017.

- Ley, M.T.; Welcher, D.; Peery, J.; Khatibmasjedi, S.; LeFlore, J. Determining the air-void distribution in fresh concrete with the Sequential Air Method. Constr. Build. Mater. 2017, 150, 723–737. [Google Scholar] [CrossRef]

- Hall, H.; Ley, M.T.; Welchel, D.; Peery, J.; Leflore, J.; Khatibmasjedi, M.; Gudimettla, J.M.; Praul, M. Field and Laboratory Validation of the Sequential Air Method. Mater. Struct. 2020, 53, 14. [Google Scholar] [CrossRef]

- Becker, H.H.; Ley, M.T.; Welchel, D.; Peery, J.; Leflore, J.; Brorsen, B.W.; Khatibmasjedi, M. Determining the Air Void Efficiency of Fresh Concrete Mixtures with the Sequential Air Method. Constr. Build. Mater. 2021, 288, 122865. [Google Scholar] [CrossRef]

- Dąbrowski, M.; Glinicki, M.A.; Dziedzic, K.; Antolik, A. Validation of Sequential Pressure Method for Evaluation of the Content of Microvoids in Air Entrained Concrete. Constr. Build. Mater. 2019, 227, 116633. [Google Scholar] [CrossRef]

- Schrader, Y. An Investigation into the Effects of Fly Ash on Freeze-Thaw Durability Prediction. Master’s Thesis, University of Arkansas, Fayetteville, AR, USA, 2020. [Google Scholar]

- American Concrete Institute (ACI) Committee 201. Guide to Durable Concrete; ACI Committee: Farmington Hills, MI, USA, 2016. [Google Scholar]

- Metha, P.K. High-performance, high-volume fly ash concrete for sustainable development. In Proceedings of the International Workshop on Sustainable Development and Concrete Technology, Beijing, China, 20–21 May 2004; pp. 3–14. [Google Scholar]

- Hemalatha, T.; Ramaswamy, A. A review on fly ash characteristics—Towards promoting high volume utilization in developing sustainable concrete. J. Clean. Prod. 2017, 147, 546–559. [Google Scholar] [CrossRef]

- Thomas, M. Optimizing the Use of Fly Ash in Concrete; The Portland Cement Association: Skokie, IL, USA, 2007; Volume 24, pp. 1–24. [Google Scholar]

- ASTM C618-19; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. American Society for Testing and Materials (ASTM) International: West Conshohocken, PA, USA, 2019.

- Gebler, S.; Klieger, P. Effect of fly ash on the air-void stability of concrete. In Proceedings of the International Conference on Using Fly Ash, Silica Fume, Slag and Other Mineral By-products in Concrete, Montebello, QC, Canada, July–August 1983; American Concrete Institute: Detroit, MI, USA, 1983; Volume 79, pp. 103–142. [Google Scholar]

- Zhang, D.S. Air Entrainment in Fresh Concrete with PFA. Cem. Concr. Compos. 1996, 18, 409–416. [Google Scholar] [CrossRef]

- Spörel, F.; Uebachs, S.; Brameshuber, W. Investigations on the influence of fly ash on the formation and stability of artificially entrained air voids in concrete. Mater. Struct. 2009, 42, 227–240. [Google Scholar] [CrossRef]

- Ley, M.T.; Harris, N.J.; Folliard, K.J.; Hover, K.C. Investigation of Air-Entraining Admixture Dosage in Fly Ash Concrete. ACI Mater. J. 2008, 105, 494–498. [Google Scholar] [CrossRef]

- Shon, C.S.; Abdigaliyev, A.; Bagitova, S.; Chung, C.W.; Kim, D. Determination of air-void system and modified frost resistance number for freeze-thaw resistance evaluation of ternary blended concrete made of ordinary Portland cement/silica fume/class F fly ash. Cold Reg. Sci. Technol. 2018, 155, 127–136. [Google Scholar] [CrossRef]

- Pedersen, K.; Jensen, A.; Skjothrasmussen, M.; Damjohansen, K. A review of the interference of carbon containing fly ash with air entrainment in concrete. Prog. Energy Combust. Sci. 2008, 34, 135–154. [Google Scholar] [CrossRef]

- Dubovoy, V.S.; Gebler, S.H.; Klieger, P. Cement-alkali Level as It Affects Air-void Stability, Freeze-thaw Resistance, and Deicer Scaling Resistance of Concrete; Portland Cement Association: Skokie, IL, USA, 2002. [Google Scholar]

- Plante, P.; Pigeon, M.; Foy, C. The influence of water-reducers on the production and stability of the air void system in concrete. Cem. Concr. Res. 1989, 19, 621–633. [Google Scholar] [CrossRef]

- Pigeon, M.; Plante, P.; Pleau, R.; Banthia, N. Influence of soluble alkalies on the production and stability of the air-void system in superplasticized and nonsuperplasticized concrete. ACI Mater. J. 1992, 89, 24–31. [Google Scholar] [CrossRef]

- ASTM C150/C150M–19a; Standard Specification for Portland Cement. American Society for Testing and Materials (ASTM) International: West Conshohocken, PA, USA, 2019.

- ASTM C33/C33M-18; Standard Specification for Concrete Aggregates. American Society for Testing and Materials (ASTM) International: West Conshohocken, PA, USA, 2018.

- ASTM C494/C494M-15a; Standard Specification for Chemical Admixtures for Concrete. American Society for Testing and Materials (ASTM) International: West Conshohocken, PA, USA, 2015.

- ASTM C260/C260M-10a; Standard Specification for Air-Entraining Admixtures for Concrete. American Society for Testing and Materials (ASTM) International: West Conshohocken, PA, USA, 2016.

- ASTM C192/C192M-14; Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory. American Society for Testing and Materials (ASTM) International: West Conshohocken, PA, USA, 2014.

- ASTM C143/C143M-20; Standard Test Method for Slump of Hydraulic-Cement Concrete. American Society for Testing and Materials (ASTM) International: West Conshohocken, PA, USA, 2020.

- Khayat, K.H.; Assaad, J. Air-Void Stability in Self-Consolidating Concrete. ACI Mater. J. 2002, 99, 408–416. [Google Scholar] [CrossRef]

- Lamond, J.F.; Pielert, J.H. Significance of Tests and Properties of Concrete and Concrete-Making Materials; ASTM International: West Conshohocken, PA, USA, 2006. [Google Scholar]

- Fan, M.; Brown, R.C. Comparison of the loss-on-ignition and thermogravimetric analysis techniques in measuring unburned carbon in coal fly ash. Energy Fuels 2001, 15, 1414–1417. [Google Scholar] [CrossRef]

- Brown, R.C.; Dykstra, J. Systematic Errors in the Use of Loss-on-Ignition to Measure Unburned Carbon in Fly Ash. Fuel 1995, 74, 570–574. [Google Scholar] [CrossRef]

- Burris, S.C.; Li, D.; Riley, J.T. Comparison of Heating Losses and Macro Thermogravimetric Analysis Procedures for Estimating Unburned Carbon in Combustion Residues. Energy Fuel 2005, 19, 1493–1502. [Google Scholar] [CrossRef]

- Du, L.; Folliard, K.J. Mechanisms of air entrainment in concrete. Cem. Concr. Res. 2005, 35, 1463–1471. [Google Scholar] [CrossRef]

- Ghafari, E.; Ghahari, S.; Feys, D.; Khayat, K.; Baig, A.; Ferron, R. Admixture compatibility with natural supplementary cementitious materials. Cem. Concr. Compos. 2020, 112, 103683. [Google Scholar] [CrossRef]

- Puthipad, N.; Ouchi, M.; Attachaiyawuth, A. Effects of fly ash, mixing procedure and type of air-entraining agent on coalescence of entrained air bubbles in mortar of self-compacting concrete at fresh state. Constr. Build. Mater. 2018, 180, 437–444. [Google Scholar] [CrossRef]

- Zeng, X.; Lan, X.; Zhu, H.; Liu, H.; Umar, H.A.; Xie, Y.; Long, G.; Ma, C. A Review on Bubble Stability in Fresh Concrete: Mechanisms and Main Factors. Materials 2020, 13, 1820. [Google Scholar] [CrossRef] [Green Version]

- Plante, P.; Pigeon, M.; Saucier, F. Air-void stability, Part II: Influence of superplasticizers and cement. ACI Mater. J. 1989, 86, 581–589. [Google Scholar] [CrossRef]

- Saucier, F.; Pigeon, M.; Plante, P. Air-Void Stability, Part III. Field Tests of Superplasticized Concretes. ACI Mater. J. 1990, 87, 3–11. [Google Scholar] [CrossRef]

- Glinicki, M.A.; Zieliński, M. Air void system in concrete containing circulating fluidized bed combustion fly ash. Mater. Struct. 2008, 41, 681–687. [Google Scholar] [CrossRef]

- Lane, D.S. Laboratory Investigation of Air-Void Systems Produced by Air-Entraining Admixtures in Fresh and Hardened Mortar; Report No. VTRC 06-R27; Virginia Transportation Research Council (VTRC): Charlottesville, VA, USA, 2006. [Google Scholar]

- Puthipad, N.; Ouchi, M.; Rath, S.; Attachaiyawuth, A. Enhancement in Self-Compactability and Stability in Volume of Entrained Air in Self-Compacting Concrete with High Volume Fly Ash. Constr. Build. Mater. 2016, 128, 349–360. [Google Scholar] [CrossRef]

- Wang, L.; Huang, Y.; Zhao, F.; Huo, T.; Chen, E.; Tang, S. Comparison between the Influence of Finely Ground Phosphorous Slag and Fly Ash on Frost Resistance, Pore Structures and Fractal Features of Hydraulic Concrete. Fractal Fract. 2022, 6, 598. [Google Scholar] [CrossRef]

- Wang, L.; He, T.; Zhou, Y.; Tang, S.; Tan, J.; Liu, Z.; Su, J. The influence of fiber type and length on the cracking resistance, durability and pore structure of face slab concrete. Constr. Build. Mater. 2021, 282, 122706. [Google Scholar] [CrossRef]

| Material | CaO | Al2O3 | SiO2 | Fe2O3 | K2O | Na2O | SO3 | MgO | LOI | Specific Gravity |

|---|---|---|---|---|---|---|---|---|---|---|

| Cement | 63.57 | 4.35 | 20.63 | 3.14 | 0.48 | 0.21 | 2.74 | 3.2 | 1.68 | 3.15 |

| Materials | FA1 | FA2 | FA3 | FA4 | FA5 | FA6 | FA7 | FA8 | FA9 | FA10 | FA11 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Class | C | C | C | C | C | F | F | F | F | F | F |

| Specific gravity | 2.71 | 2.58 | 2.64 | 2.75 | 2.65 | 2.50 | 2.61 | 2.54 | 2.55 | 2.57 | 2.48 |

| Fineness (Retained on No. 325 sieve, %) | 22.3 | 19.6 | 13.0 | 20.9 | 25.4 | 19.2 | 26.1 | 14.7 | 18.5 | 11.8 | 16.4 |

| Sieve (mm) | Fine Aggregate (wt.% Passing) | Sieve (mm) | Coarse Aggregate (wt.% Passing) |

|---|---|---|---|

| 9.53 | 100 | 50.8 | 100 |

| 4.75 | 99 | 38.1 | 100 |

| 2.36 | 88 | 25.4 | 100 |

| 1.18 | 71 | 19.05 | 96 |

| 0.6 | 45 | 12.7 | 47 |

| 0.3 | 20 | 9.525 | 33 |

| 0.15 | 6 | 4.75 | 8 |

| 0.075 | 1.2 | 2.36 | 3 |

| Cement (kg/m3) | Fly Ash (kg/m3) | Water (kg/m3) | Coarse Aggregate (kg/m3) | Fine Aggregate (kg/m3) | SP (mL/100 kg cm) | AEA (mL/100 kg cm) |

|---|---|---|---|---|---|---|

| 280 | 70 | 140 | 1050 | 780 | 90 | 49~194 |

| Fly Ash Concrete | Slump (mm) | Type B | SAM | |

|---|---|---|---|---|

| Air Content (%) | Air Content (%) | SAM Number | ||

| FA1 | 160 ± 3.1 | 5.9 ± 0.22 | 5.7 ± 0.16 | 0.22 ± 0.02 |

| FA2 | 169 ± 4.6 | 6.7 ± 0.08 | 6.6 ± 0.14 | 0.07 ± 0.01 |

| FA3 | 158 ± 5.2 | 6.0 ± 0.14 | 6.0 ± 0.26 | 0.11 ± 0.03 |

| FA4 | 172 ± 2.9 | 6.4 ± 0.17 | 6.1 ± 0.29 | 0.09 ± 0.02 |

| FA5 | 153 ± 5.6 | 5.8 ± 0.26 | 5.5 ± 0.14 | 0.12 ± 0.03 |

| FA6 | 155 ± 4.5 | 6.5 ± 0.16 | 6.2 ± 0.08 | 0.10 ± 0.02 |

| FA7 | 159 ± 6.2 | 6.2 ± 0.22 | 6.3 ± 0.25 | 0.13 ± 0.04 |

| FA8 | 167 ± 5.9 | 6.4 ± 0.08 | 6.1 ± 0.18 | 0.18 ± 0.04 |

| FA9 | 163 ± 6.6 | 5.8 ± 0.16 | 5.6 ± 0.08 | 0.27 ± 0.06 |

| FA10 | 166 ± 4.2 | 5.9 ± 0.14 | 6.3 ± 0.24 | 0.12 ± 0.03 |

| FA11 | 162 ± 7.3 | 6.3 ± 0.28 | 6.4 ± 0.16 | 0.17 ± 0.05 |

| Fly Ash Concrete | LOI of Fly Ash | AEA Dosage (mL/100 kg cm) |

|---|---|---|

| FA1 | 0.46 | 51 |

| FA2 | 0.72 | 59 |

| FA3 | 0.61 | 90 |

| FA4 | 0.38 | 62 |

| FA5 | 0.69 | 49 |

| FA6 | 3.47 | 98 |

| FA7 | 0.54 | 56 |

| FA8 | 2.30 | 194 |

| FA9 | 2.86 | 127 |

| FA10 | 1.13 | 120 |

| FA11 | 3.25 | 156 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Lu, H.; Xiao, R.; Hu, W.; Huang, B. Experimental Study on the Stability and Distribution of Air Voids in Fresh Fly Ash Concrete. Materials 2022, 15, 8332. https://doi.org/10.3390/ma15238332

Wang Y, Lu H, Xiao R, Hu W, Huang B. Experimental Study on the Stability and Distribution of Air Voids in Fresh Fly Ash Concrete. Materials. 2022; 15(23):8332. https://doi.org/10.3390/ma15238332

Chicago/Turabian StyleWang, Yanhai, Hang Lu, Rui Xiao, Wei Hu, and Baoshan Huang. 2022. "Experimental Study on the Stability and Distribution of Air Voids in Fresh Fly Ash Concrete" Materials 15, no. 23: 8332. https://doi.org/10.3390/ma15238332

APA StyleWang, Y., Lu, H., Xiao, R., Hu, W., & Huang, B. (2022). Experimental Study on the Stability and Distribution of Air Voids in Fresh Fly Ash Concrete. Materials, 15(23), 8332. https://doi.org/10.3390/ma15238332