Microstructure and Properties of Hollow Octet Nickel Lattice Materials

Abstract

1. Introduction

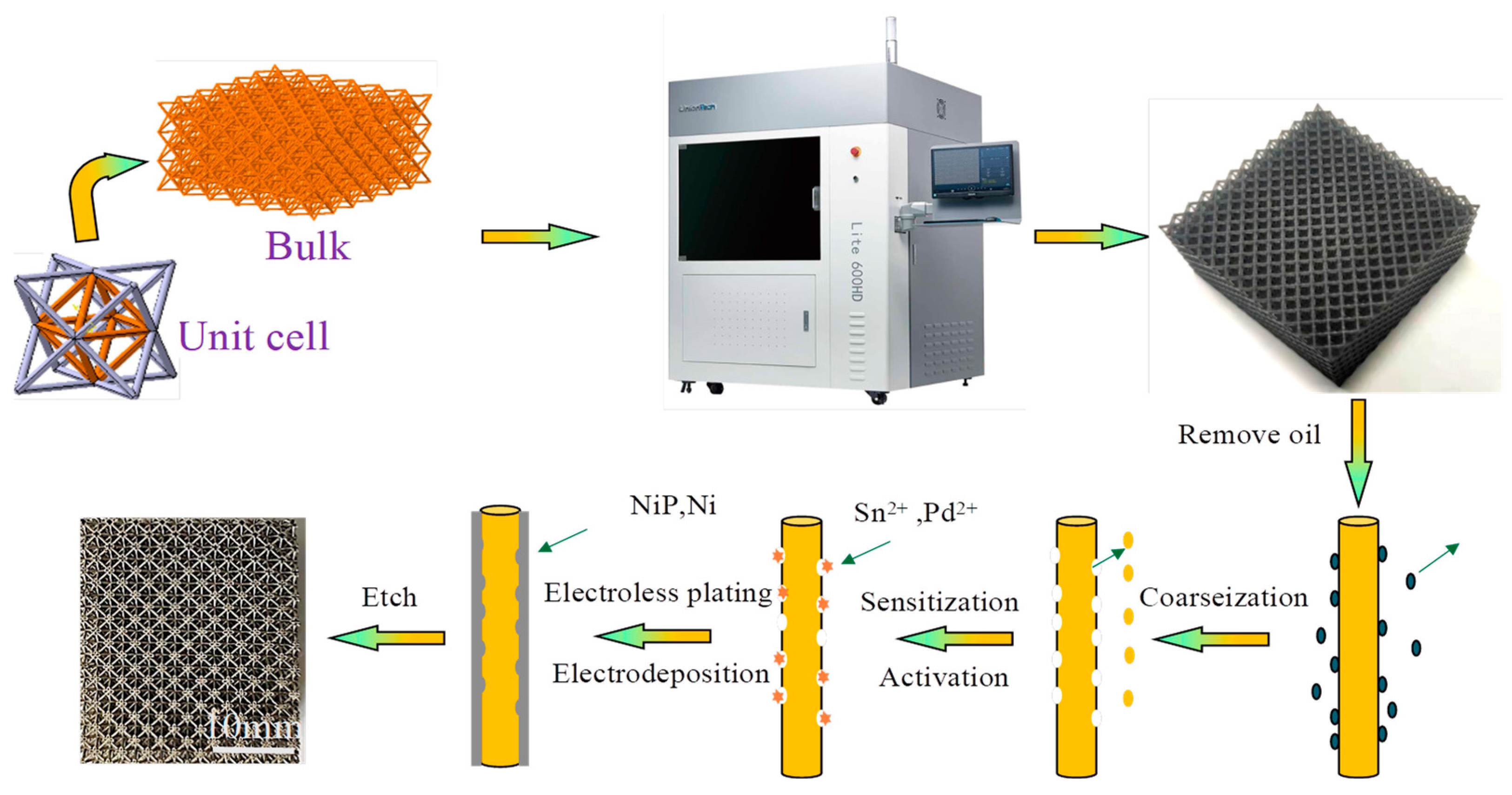

2. Materials and Methods

3. Results

3.1. Microstructure

3.2. Deformation Behavior

4. Discussion

4.1. Dependence of Relative Strength on the Relative Density

4.2. Dependence of Energy Absorption on Density

4.3. Dependence of Compression Stability of the Density

5. Conclusions

- (1)

- The grain sizes of electrodeposition Ni lattice materials were mainly concentrated between 150 and 500 nm, and it had (001) weak texture along the direction of thin film deposition

- (2)

- As the length-to-diameter ratio of the lattice increased, the stress–strain curve volatility of the lattice increased, and the lattice compressive deformation mode shifted from layer-by-layer and overall deformation to shear deformation in the 45° direction.

- (3)

- Hollow Octet lattices with different structural parameters have essentially the same compressive strength and elastic modulus at the same density. The strength and modulus of the lattice increased with the increase of density and belong to the transition region of stretch-dominated and bend-dominated of the Gibson–Ashby model.

- (4)

- The energy absorption capacity and compression stability decreased with the increase of the length-to-diameter ratio of the lattice rod because the macroporous lattice is prone to instability deformation and brittle fracture.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fleck, N.A.; Deshpande, V.S.; Ashby, M.F. Micro-architectured materials: Past, present and future. Proc. R. Soc. A 2010, 466, 2495–2516. [Google Scholar] [CrossRef]

- Nashar, M.A.; Sutradhar, A. Design of Hierarchical Architected Lattices for Enhanced Energy Absorption. Materials 2021, 14, 5384. [Google Scholar] [CrossRef] [PubMed]

- Andrews, E.W.; Tashi, T.; Jun, S. Failure modes in open-cell foams with hollow struts. Mater. Lett. 2008, 62, 4319–4321. [Google Scholar] [CrossRef]

- Xiong, J.; Mines, R.; Ghosh, R.; Vaziri, A.; Ma, L.; Ohrndorf, A.; Christ, H.J.; Wu, L. Advanced Micro-Lattice Materials. Adv. Eng. Mater. 2015, 17, 1253–1264. [Google Scholar] [CrossRef]

- Kladovasilakis, N.; Tsongas, K.; Karalekas, D.; Tzetzis, D. Architected Materials for Additive Manufacturing: A Comprehensive Review. Materials 2022, 15, 5919. [Google Scholar] [CrossRef]

- Chen, P.W.; Lin, Y.Y. Evaluation on crash worthiness and energy absorption of composite light airplane. Adv. Mech. Eng. 2018, 10, 1177. [Google Scholar] [CrossRef]

- Sharp, R.; Pelletier, M.H.; Walsh, W.R.; Kelly, C.N.; Gall, K. Corrosion Resistance of 3D Printed Ti6Al4V Gyroid Lattices with Varying Porosity. Materials 2022, 15, 4805. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Kim, I.Y.; Jeswiet, J. Conceptual and detailed design of an automotive engine cradle by using topology, shape, and size optimization. Struct. Multidiscip. Optim. 2015, 51, 547–564. [Google Scholar] [CrossRef]

- Hussain, S.; Ghopa, W.A.W.; Singh, S.S.K.; Azman, A.H.; Abdullah, S.; Harun, Z.; Hishamuddin, H. Vibration-Based Fatigue Analysis of Octet -Truss Lattice Infill Blades for Utilization in Turbine Rotors. Materials 2022, 15, 4888. [Google Scholar] [CrossRef]

- Rashed, M.G.; Ashraf, M.; Mines, R.A.W.; Hazell, P.J. Metallic microlattice materials: A current state of the art on manufacturing, mechanical properties and applications. Mater. Des. 2016, 95, 518–533. [Google Scholar] [CrossRef]

- Alkentar, R.; Máté, F.; Mankovits, T. Investigation of the Performance of Ti6Al4V Lattice Structures Designed for Biomedical Implants Using the Finite Element Method. Materials 2022, 15, 6335. [Google Scholar] [CrossRef] [PubMed]

- Liontas, R.; Greer, J.R. 3D nano-architected metallic glass: Size effect suppresses catastrophic failure. Acta Mater. 2017, 133, 393–407. [Google Scholar] [CrossRef]

- Maloney, K.J.; Roper, C.S.; Jacobsen, A.J.; Carter, W.B.; Valdevit, L.; Schaedler, T.A. Microlattices as architected thin films: Analysis of mechanical properties and high strain elastic recovery. APL Mater. 2013, 1, 962–965. [Google Scholar] [CrossRef]

- Zheng, X.; Lee, H.; Weisgraber, T.H.; Shusteff, M.; DeOtte, J.; Duoss, E.B.; Kuntz, J.D.; Biener, M.M.; Ge, Q.; Jackson, J.A.; et al. Ultralight, ultrastiff mechanical metamaterials. Science 2014, 344, 1373–1377. [Google Scholar] [CrossRef] [PubMed]

- Surjadi, J.U.; Gao, L.; Cao, K.; Fan, R.; Lu, Y. Mechanical enhancement of core-shell microlattices through high-entropy alloy coating. Sci. Rep. 2018, 8, 5442. [Google Scholar] [CrossRef]

- Richard, C.T.; Kwok, T.H. Analysis and Design of Lattice Structures for Rapid-Investment Casting. Materials 2021, 14, 4867. [Google Scholar] [CrossRef] [PubMed]

- Queheillalt, D.T.; Wadley, H.N.G. Cellular metal lattices with hollow trusses. Acta Mater. 2005, 53, 303–313. [Google Scholar] [CrossRef]

- Ren, H.; Shen, H.; Ning, J. Effect of Internal Microstructure Distribution on Quasi-Static Compression Behavior and Energy Absorption of Hollow Truss Structures. Materials 2020, 13, 5094. [Google Scholar] [CrossRef] [PubMed]

- Manuela, G.; Abdollah, S.; Sara, B. Ti-6Al-4V lattice structures produced by EBM: Heat treatment and mechanical properties. Procedia CIRP 2020, 88, 411–416. [Google Scholar]

- Zheng, X.; Smith, W.; Jackson, J.; Moran, B.; Cui, H.C.; Chen, D.; Ye, J.C.; Fang, N.; Rodriguez, N.; Weisgraber, T.; et al. Multiscale metallic metamaterials. Nat. Mater. 2016, 15, 1100–1106. [Google Scholar] [CrossRef]

- Torrents, A.; Schaedler, T.A.; Jacobsen, A.J.; Carter, W.B.; Valdevit, L. Characterization of nickel-based microlattice materials with structural hierarchy from the nanometer to the millimeter scale. Acta Mater. 2012, 60, 3511–3523. [Google Scholar] [CrossRef]

- Schaedler, T.A.; Jacobsen, A.J.; Torrents, A.; Sorensen, A.E.; Lian, J.; Greer, J.R.; Valdevit, L.; Carter, W.B. Ultralight metallic microlattices. Science 2011, 334, 962–965. [Google Scholar] [CrossRef] [PubMed]

- Rys, J.; Valdevit, L.; Schaedler, T.A.; Jacobsen, A.J.; William, B.C.; Julia, R.G. Fabrication and Deformation of Metallic Glass Micro-Lattices. Adv. Eng. Mater. 2014, 16, 889–896. [Google Scholar] [CrossRef]

- Meza, L.R.; Greer, J.R. Mechanical characterization of hollow ceramic nanolattices. J. Mater. Sci. 2014, 49, 2496–2508. [Google Scholar] [CrossRef]

- Meza, L.R.; Das, S.; Greer, J.R. Strong, lightweight, and recoverable three-dimensional ceramic nanolattices. Science 2014, 345, 1322–1326. [Google Scholar] [CrossRef] [PubMed]

- Meza, L.R.; Zelhofer, A.J.; Clarke, N.; Mateosa, A.J.; Kochmanna, D.M.; Greera, J.R. Resilient 3D hierarchical architected metamaterials. Proc. Natl. Acad. Sci. USA 2015, 112, 11502–11507. [Google Scholar] [CrossRef]

- Gu, X.W.; Greer, J.R. Ultra-strong architected Cu meso-lattices. Extrem. Mech. Lett. 2015, 2, 7–14. [Google Scholar]

- Surjadi, J.U.; Feng, X.; Fan, R.; Lin, W.T.; Li, X.C.; Lu, Y. Hollow medium-entropy alloy nanolattices with ultrahigh energy absorption and resilience. NPG Asia Mater. 2021, 13, 36. [Google Scholar] [CrossRef]

- Shi, J.; Liu, L. Creating hollow microlattice materials reinforced by carbon nanotubes for improved mechanical properties. Mater. Lett. 2019, 240, 205–208. [Google Scholar] [CrossRef]

- Montemayor, L.C.; Greer, J.R. Mechanical response of hollow metallic nanolattices: Combining structural and material size effects. J. Appl. Mech. 2015, 82, 07012. [Google Scholar] [CrossRef]

- Tobias, A.; Schaedler, T.A.; Ro, C.J.; Sorensen, A.E.; Eckel, S.Z.; Yang, S.S.; Carter, W.B.; Jacobsen, A.J. Designing metallic microlattices for energy absorber applications. Adv. Eng. Mater. 2014, 16, 276–283. [Google Scholar]

- Diamantopoulou, M.; Tancogne-Dejean, T.; Wheeler, J.M.; Mohr, D. Double-wall ceramic nanolattices: Increased stiffness and recoverabilityby design. Mater. Des. 2021, 208, 109928. [Google Scholar] [CrossRef]

- Valdevit, L.; Godfrey, S.W.; Schaedler, T.A.; Jacobsen, A.J.; Carter, W.B. Compressive strength of hollow microlattices: Experimental characterization, modeling, and optimal design. J. Mater. Res. 2013, 28, 2461–2473. [Google Scholar] [CrossRef]

- Deshpande, V.S.; Ashby, M.F.; Fleck, N.A. Foam topology binding versus stretching dominated architectures. Acta Mater. 2001, 49, 1035–1040. [Google Scholar] [CrossRef]

- Deshpande, V.S.; Fleck, N.A.; Ashby, M.F. Effective properties of the Octet -truss lattice material. J. Mech. Phys. Solids 2001, 49, 1747–1769. [Google Scholar] [CrossRef]

- Evans, A.G.; He, M.Y.; Deshpande, V.S.; Hutchinson, J.W.; Jacobsen, A.J.; Carter, W.B. Concepts for enhanced energy absorption using hollow micro-lattices. Int. J. Impact Eng. 2010, 37, 947–959. [Google Scholar] [CrossRef]

- Torrents, A.; Yang, H.; Mohamed, F.A. Effect of Annealing on Hardness and the Modulus of Elasticity in Bulk Nanocrystalline Nickel. Metall. Mater. Trans. A 2010, 41, 621–630. [Google Scholar] [CrossRef]

- Oudriss, A.; Savall, C.; Creus, J.; Feaugas, X.; Bouhattate, J. Grain Size and Grain-Boundaries Consequences on Diffusion and Trapping of Hydrogen in Pure Nickel. Acta Mater. 2012, 60, 6814–6828. [Google Scholar] [CrossRef]

- Ma, Q.; Clarke, D.R. Size dependent hardness of silver single crystals. J. Mater. Res. 1995, 10, 853–863. [Google Scholar] [CrossRef]

- Duan, F.H.; Lin, Y.; Pan, J. Ultrastrong nanotwinned pure nickel with extremely fine twin thickness. Sci. Adv. 2021, 7, 5113. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.J.; Feng, C.X.; Zhang, Z.J.; Qian, D.; Song, Z.X. Compressive Property of Additively-Manufactured Micro-Architectures with X-Type Lattice Unit Cell. Materials 2022, 15, 3815. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Schaedler, T.A.; Jacobsen, A.J.; Chen, X. Quasi-static energy absorption of hollow microlattice structures. Compos. Part B Eng. 2014, 67, 39–49. [Google Scholar] [CrossRef]

- Choi, D.H.; Min, G.L.; Han, S.C.; Jeonga, Y.C.; Cho, J.S.; Kang, K.J. Mechanical behavior of Microlattice with or without in-plane elements added on the outer faces. Int. J. Mech. Sci. 2018, 149, 311–325. [Google Scholar] [CrossRef]

- Gibson, L.J.; Ashby, M.F. Cellular Solids: Structure and Properties, 2nd ed.; Cambridge Solid State Science Series; Cambridge University Press: Cambridge, UK, 1997. [Google Scholar]

| Sample | Diameters | Length | Length-to-Diameter Ratio | Relative Density |

|---|---|---|---|---|

| A | 0.25 | 2.5 | 10 | 3.3% |

| B | 0.375 | 2.5 | 6.7 | 3.3% |

| C | 0.5 | 2.5 | 5 | 3.1% |

| D | 0.5 | 3.75 | 7.5 | 3.1% |

| E | 0.5 | 5 | 10 | 3.1% |

| F | 0.5 | 6.25 | 12.5 | 3.3% |

| G | 0.5 | 7.5 | 15 | 3% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, P.; Huang, D.; Zhang, Y.; Zhang, H.; Chen, W. Microstructure and Properties of Hollow Octet Nickel Lattice Materials. Materials 2022, 15, 8417. https://doi.org/10.3390/ma15238417

Zhao P, Huang D, Zhang Y, Zhang H, Chen W. Microstructure and Properties of Hollow Octet Nickel Lattice Materials. Materials. 2022; 15(23):8417. https://doi.org/10.3390/ma15238417

Chicago/Turabian StyleZhao, Peng, Deqing Huang, Yongfu Zhang, Hongmei Zhang, and Weiwei Chen. 2022. "Microstructure and Properties of Hollow Octet Nickel Lattice Materials" Materials 15, no. 23: 8417. https://doi.org/10.3390/ma15238417

APA StyleZhao, P., Huang, D., Zhang, Y., Zhang, H., & Chen, W. (2022). Microstructure and Properties of Hollow Octet Nickel Lattice Materials. Materials, 15(23), 8417. https://doi.org/10.3390/ma15238417