A Lightweight AlTiVNb High-Entropy Alloy Film with High Strength-Ductility Synergy and Corrosion Resistance

Abstract

:1. Introduction

2. Experimental Methods

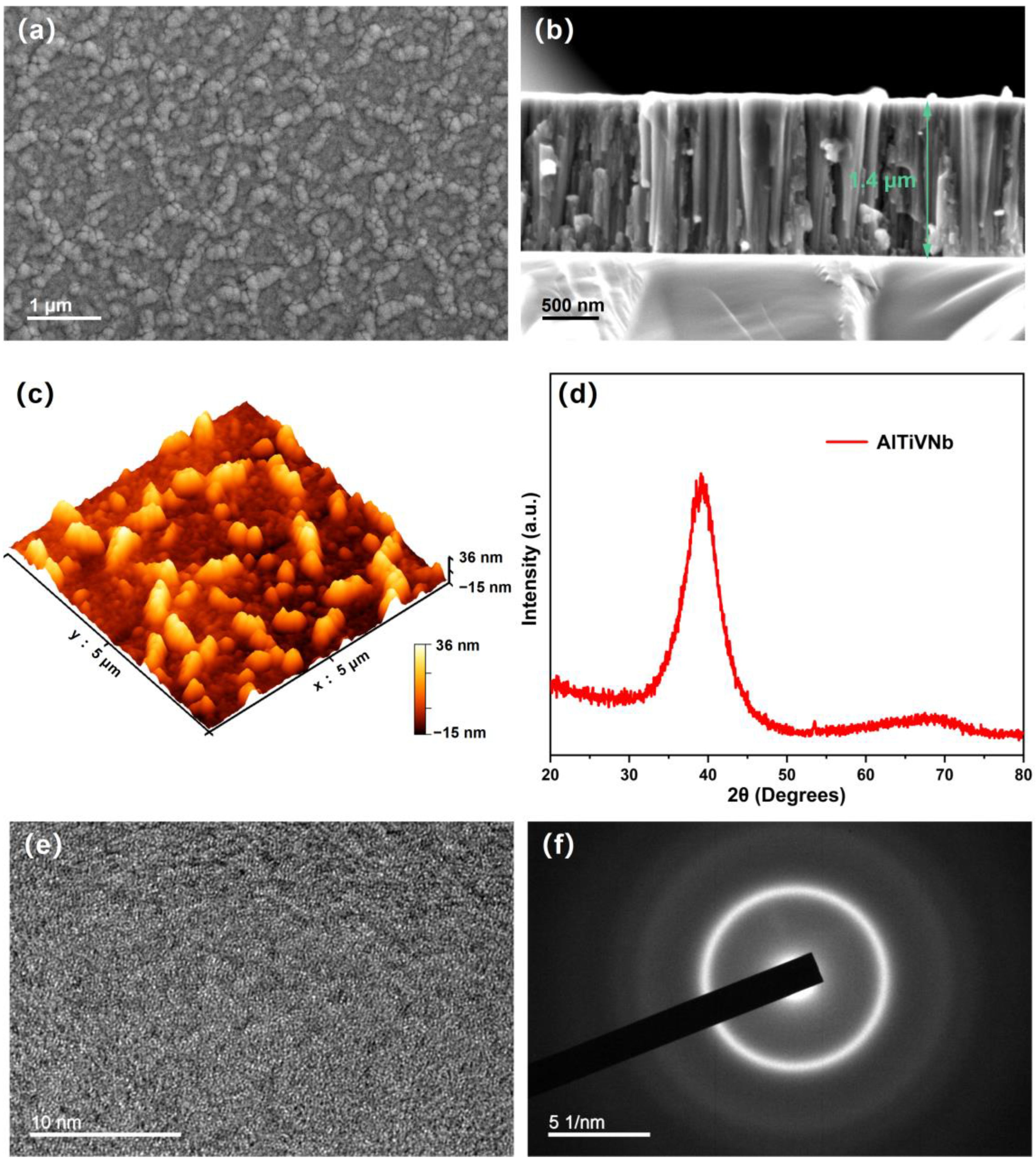

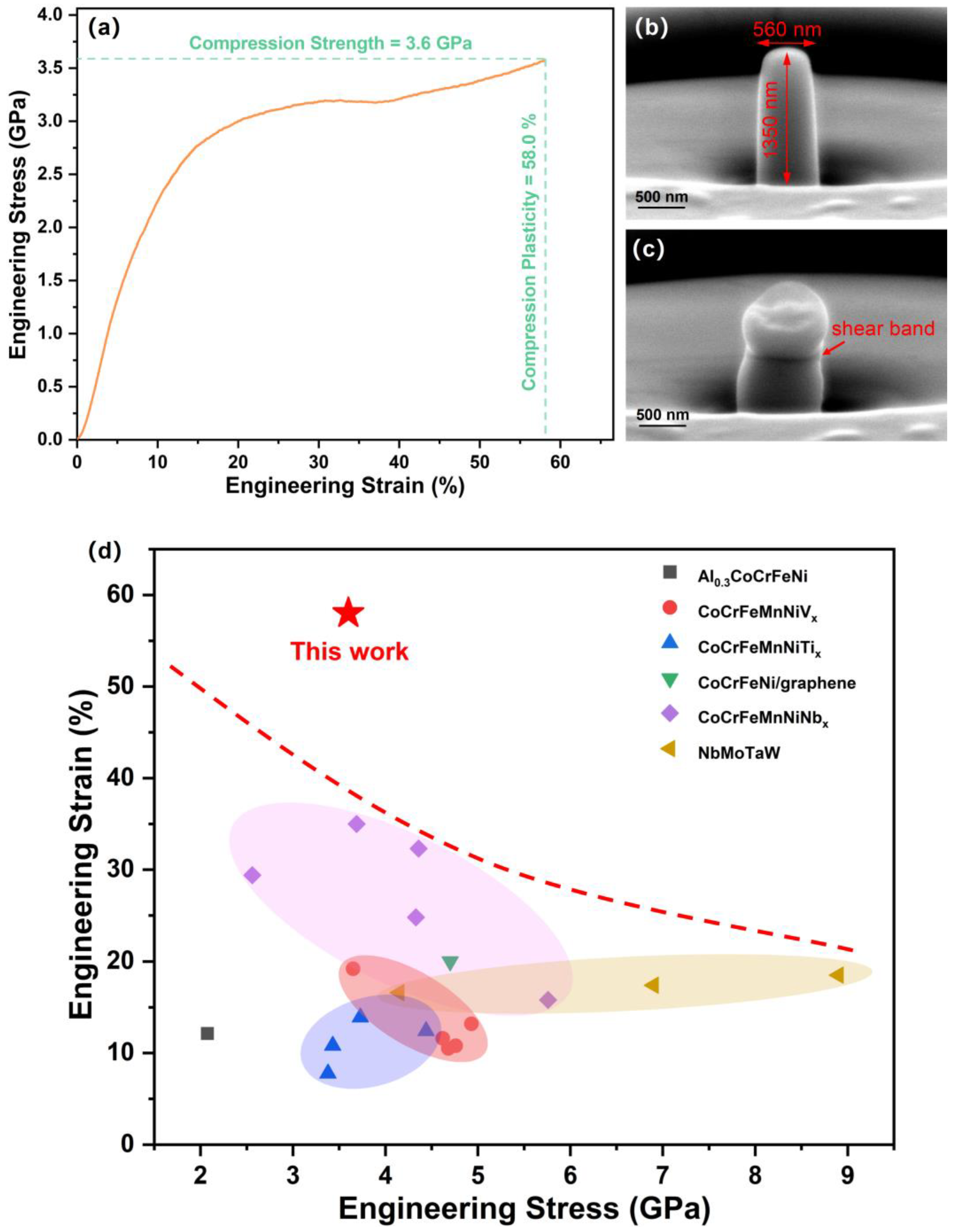

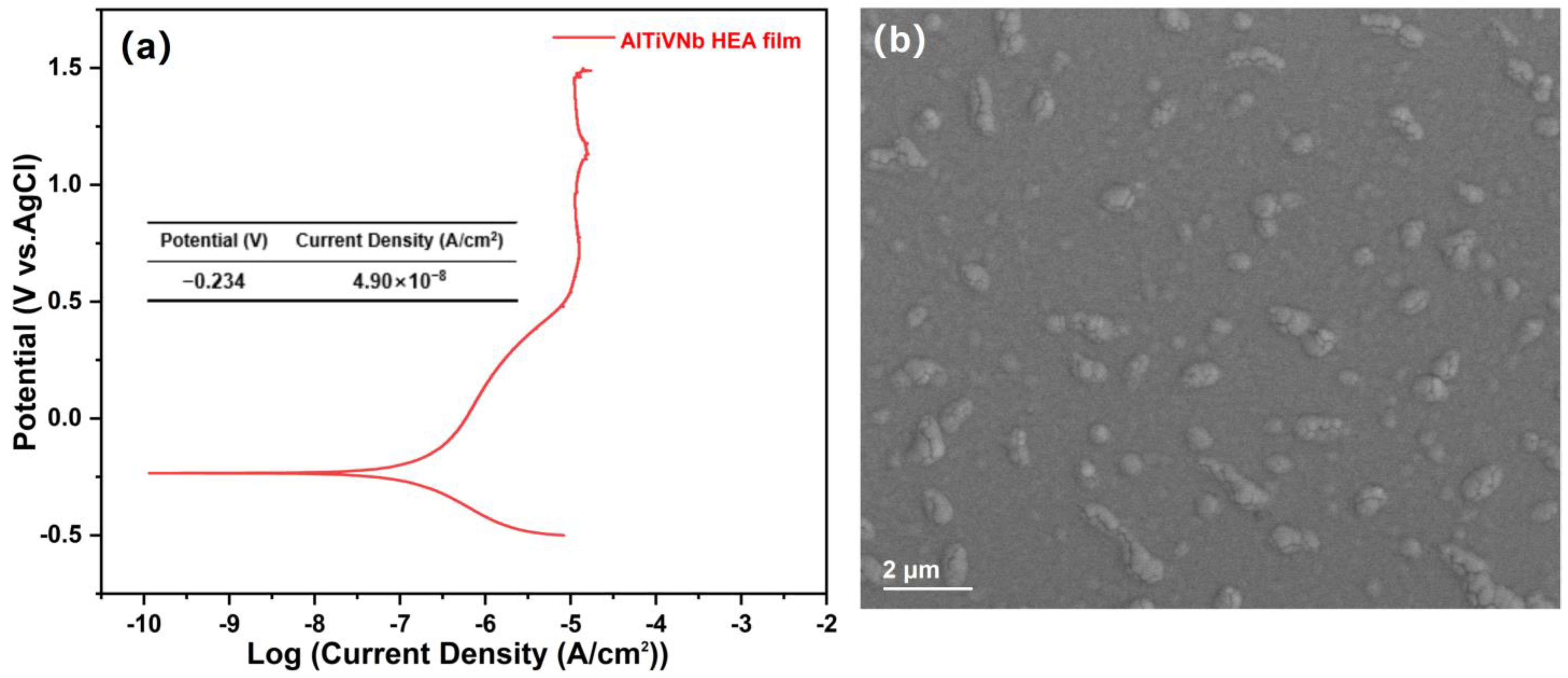

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.B. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 2004, 375–377, 213–218. [Google Scholar] [CrossRef]

- Feng, X.; Tang, G.; Sun, M.; Ma, X.; Wang, L.; Yukimura, K. Structure and properties of multi-targets magnetron sputtered ZrNbTaTiW multi-elements alloy thin films. Surf. Coat. Technol. 2013, 228, S424–S427. [Google Scholar] [CrossRef]

- Feng, X.B.; Fu, W.; Zhang, J.Y.; Zhao, J.T.; Li, J.; Wu, K.; Liu, G.; Sun, J. Effects of nanotwins on the mechanical properties of AlxCoCrFeNi high entropy alloy thin films. Scr. Mater. 2017, 139, 71–76. [Google Scholar] [CrossRef]

- Zhang, Y.; Zuo, T.T.; Tang, Z.; Gao, M.C.; Dahmen, K.A.; Liaw, P.K.; Lu, Z.P. Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 2014, 61, 1–93. [Google Scholar]

- Miracle, D.B.; Senkov, O.N. A critical review of highentropy alloys (HEAs) and related concepts. Acta Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef] [Green Version]

- Huang, X.; Miao, J.; Luo, A.A. Lightweight AlCrTiV high-entropy alloys with dual-phase microstructure via microalloying. J. Mater. Sci. 2019, 54, 2271–2277. [Google Scholar] [CrossRef]

- Stepanov, N.D.; Shaysultanov, D.G.; Salishchev, G.A.; Tikhonovsky, M.A. Structure and mechanical properties of a light-weight AlNbTiV high entropy alloy. Mater. Lett. 2015, 142, 153–155. [Google Scholar] [CrossRef]

- Tseng, K.K.; Yang, Y.C.; Juan, C.C.; Chin, T.S.; Tsai, C.W.; Yeh, J.W. A light-weight high-entropy alloy Al20Be20Fe10Si15Ti35. Sci. China Technol. Sci. 2018, 61, 184–188. [Google Scholar] [CrossRef]

- Youssef, K.M.; Zaddach, A.J.; Niu, C.N.; Irving, D.L.; Koch, C.C. A novel lowdensity, high-hardness, high-entropy alloy with close-packed single-phase nanocrystalline structures. Mater. Res. Lett. 2014, 3, 95–99. [Google Scholar] [CrossRef] [Green Version]

- Li, R.; Gao, J.C.; Fan, K. Study to microstructure and mechanical properties of Mg containing high entropy alloys. Mater. Sci. Forum. 2010, 650, 265–271. [Google Scholar] [CrossRef]

- Chen, T.K.; Shun, T.T.; Yeh, J.W.; Wong, M.S. Nanostructured nitride films of multi-element high-entropy alloys by reactive DC sputtering. Surf. Coat. Technol. 2004, 188–189, 193–200. [Google Scholar] [CrossRef]

- Kim, H.; Nam, S.; Roh, A.; Son, M.; Ham, M.H.; Kim, J.H.; Choi, H. Mechanical and electrical properties of NbMoTaW refractory high-entropy alloy thin films. Int. J. Refract. Met. Hard Mater. 2019, 80, 286–291. [Google Scholar] [CrossRef]

- Hsueh, H.T.; Shen, W.J.; Tsai, M.H.; Yeh, J.W. Effect of nitrogen content and substrate bias on mechanical and corrosion properties of high-entropy films (AlCrSiTiZr)100-xNx. Surf. Coat. Technol. 2012, 206, 4106–4112. [Google Scholar] [CrossRef]

- Sheng, W.J.; Yang, X.; Wang, C.; Zhang, Y. Nano-crystalliza-tion of high-entropy amorphous NbTiAlSiWxNy films prepared by magnetron sputtering. Entropy 2016, 18, 226. [Google Scholar] [CrossRef]

- Tsai, D.C.; Chang, Z.C.; Kuo, B.H.; Shiao, M.H.; Chang, S.Y.; Shieu, F.S. Structural morphology and characterization of (AlCrMoTaTi)N coating deposited via magnetron sputtering. Appl. Surf. Sci. 2013, 282, 789–797. [Google Scholar] [CrossRef]

- Feng, X.; Zhang, J.; Wu, K.; Liang, X.; Liu, G.; Sun, J. Ultrastrong Al(0.1)CoCrFeNi high-entropy alloys at small scales: Effects of stacking faults vs. nanotwins. Nanoscale 2018, 10, 13329–13334. [Google Scholar] [CrossRef]

- Zheng, S.; Cai, Z.; Pu, J.; Zeng, C.; Wang, L. Passivation behavior of VAlTiCrSi amorphous high-entropy alloy film with a high corrosion-resistance in artificial sea water. Appl. Surf. Sci. 2021, 542, 148520. [Google Scholar] [CrossRef]

- Surjadi, J.U.; Feng, X.; Zhou, W.; Lu, Y. Optimizing film thickness to delay strut fracture in high-entropy alloy composite microlattices. Int. J. Extrem. Manuf. 2021, 3, 025101. [Google Scholar] [CrossRef]

- Feng, X.; Surjadi, J.U.; Fan, R.; Li, X.; Zhou, W.; Zhao, S.; Lu, Y. Microalloyed medium-entropy alloy (MEA) composite nanolattices with ultrahigh toughness and cyclability. Mater. Today 2021, 42, 10–16. [Google Scholar] [CrossRef]

- Zheng, S.; Cai, Z.; Pu, J.; Zeng, C.; Chen, S.; Chen, R.; Wang, L. A feasible method for the fabrication of VAlTiCrSi amorphous high entropy alloy film with outstanding anti-corrosion property. Appl. Surf. Sci. 2019, 483, 870–874. [Google Scholar] [CrossRef]

- Braeckman, B.R.; Depla, D. Structure formation and properties of sputter deposited NbxCoCrCuFeNi high entropy alloy thin films. J. Alloy Comp. 2015, 646, 810–815. [Google Scholar] [CrossRef]

- Feng, C.S.; Lu, T.W.; Wang, T.L.; Lin, M.Z.; Hou, J.H.; Lu, W.J.; Liao, W.B. A novel high-entropy amorphous thin film with high electrical resistivity and outstanding corrosion resistance. Acta Metall. Sin. Engl. Lett. 2021, 34, 1537–1545. [Google Scholar] [CrossRef]

- Waleed, M.; John, A.; Vladimir, V. Corrosion performance and mechanical properties of FeCrSiNb amorphous equiatomic HEA thin film. Surf. Coat. Technol. 2021, 422, 127486. [Google Scholar]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Senkov, O.N.; Senkova, S.V.; Woodwart, C.; Miracle, D.B. Mechanical properties of low density, refractory multi-principal element alloys of the Cr-Nb-Ti-V-Zr system. Mater. Sci. Eng. A 2013, 565, 51–62. [Google Scholar] [CrossRef]

- Senkov, O.N.; Woodwart, C.; Miracle, D.B. Microstructure and Properties of Aluminum Containing Refractory High-Entropy Alloys. JOM 2014, 66, 2030–2042. [Google Scholar] [CrossRef]

- Razumov, N.; Makhmutov, T.; Kim, A.; Shemyakinsky, B.; Shakhmatov, A.; Popovich, V.; Popovich, A. Refractory CrMoNbWV High-Entropy Alloy Manufactured by Mechanical Alloying and Spark Plasma Sintering: Evolution of Microstructure and Properties. Materials 2021, 14, 621. [Google Scholar] [CrossRef]

- Ma, S.G.; Zhang, S.F.; Qiao, J.W.; Wang, Z.H.; Gao, M.C.; Jiao, Z.M.; Yang, H.J.; Zhang, Y. Superior high tensile elongation of a single-crystal CoCrFeNiAl0.3 highentropy alloy by Bridgman solidification. Intermetallics 2014, 54, 104–109. [Google Scholar] [CrossRef]

- Lu, T.W.; Feng, C.S.; Wang, Z.; Liao, K.W.; Liu, Z.Y.; Xie, Y.Z.; Hu, J.G.; Liao, W.B. Microstructures and mechanical properties of CoCrFeNiAl0.3 high-entropy alloy thin films by pulsed laser deposition. Appl. Surf. Sci. 2019, 494, 72–79. [Google Scholar] [CrossRef]

- Liao, W.B.; Zhang, H.; Liu, Z.Y.; Li, P.F.; Huang, J.J.; Yu, C.Y.; Lu, Y. High strength and deformation mechanisms of Al0. 3CoCrFeNi high-entropy alloy thin films fabricated by magnetron sputtering. Entropy 2019, 21, 146. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fang, S.; Wang, C.; Li, C.L.; Luan, J.H.; Jiao, Z.B.; Liu, C.T.; Hsueh, C.H. Microstructures and mechanical properties of CoCrFeMnNiVx high entropy alloy films. J. Alloy Comp. 2020, 820, 153388. [Google Scholar] [CrossRef]

- Hsu, Y.C.; Li, C.L.; Hsueh, C.H. Modifications of microstructures and mechanical properties of CoCrFeMnNi high entropy alloy films by adding Ti element. Surf. Coat. Tech. 2020, 399, 126149. [Google Scholar] [CrossRef]

- Feng, X.B.; Cao, K.; Huang, X.; Li, G.; Lu, Y. Nanolayered CoCrFeNi/Graphene Composites with High Strength and Crack Resistance. Nanomaterials 2022, 12, 2113. [Google Scholar] [CrossRef] [PubMed]

- Liang, Y.H.; Li, C.L.; Hsueh, C.H. Effects of Nb Addition on Microstructures and Mechanical Properties of Nbx-CoCrFeMnNi High Entropy Alloy Films. Coatings 2021, 11, 1539. [Google Scholar] [CrossRef]

- Zou, Y.; Ma, H.; Spolenak, R. Ultrastrong ductile and stable high-entropy alloys at small scales. Nat. Commun. 2015, 6, 1–8. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sun, B.A.; Yu, L.P.; Wang, G.; Tong, X.; Geng, C.; Wang, J.T.; Ren, J.L.; Wang, W.H. Chaotic dynamics in shear-band-mediated plasticity of metallic glasses. Phys. Rev. B 2020, 101, 224111. [Google Scholar] [CrossRef]

- Song, S.X.; Nieh, T.G. Direct measurements of shear band propagation in metallic glasses-an overview. Intermetallics 2011, 19, 1968–1977. [Google Scholar] [CrossRef]

- Greer, J.R.; De Hosson, J.T.M. Plasticity in small-sized metallic systems: Intrinsic versus extrinsic size effect. Prog. Mater. Sci. 2011, 56, 654–724. [Google Scholar] [CrossRef]

- Yang, Y.; Liu, C.T. Size effect on stability of shear-band propagation in bulk metallic glasses: An overview. J. Mater. Sci. 2012, 47, 55–67. [Google Scholar] [CrossRef]

- Greer, A.L.; Cheng, Y.Q.; Ma, E. Shear bands in metallic glasses. Mater. Sci. Engin. R 2013, 74, 71–132. [Google Scholar] [CrossRef]

- Inoue, A. High strength bulk amorphous alloys with low critical cooling rates (overview). Mater. Trans. 1995, 36, 866–875. [Google Scholar] [CrossRef]

- Lloyd, J.R.; Nakahara, S. Voids in thin as-deposited gold films prepared by vapor deposition. J. Vac. Sci. Technol. 1977, 14, 655–659. [Google Scholar] [CrossRef]

- Nakahara, S. Microporosity induced by nucleation and growth processes in crystalline and non-crystalline films. Thin Solid Film. 1977, 45, 421–432. [Google Scholar] [CrossRef]

- Thornton, J.A. The microstructure of sputter-deposited coatings. J. Vac. Sci. Technol. A 1986, 4, 3059–3065. [Google Scholar] [CrossRef]

- Donovan, T.M.; Heinemann, K. High-resolution electron microscope observation of voids in amorphous Ge. Phys. Rev. Lett. 1971, 27, 1794–1796. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, X.; Feng, C.; Lu, Y. A Lightweight AlTiVNb High-Entropy Alloy Film with High Strength-Ductility Synergy and Corrosion Resistance. Materials 2022, 15, 8568. https://doi.org/10.3390/ma15238568

Feng X, Feng C, Lu Y. A Lightweight AlTiVNb High-Entropy Alloy Film with High Strength-Ductility Synergy and Corrosion Resistance. Materials. 2022; 15(23):8568. https://doi.org/10.3390/ma15238568

Chicago/Turabian StyleFeng, Xiaobin, Chuangshi Feng, and Yang Lu. 2022. "A Lightweight AlTiVNb High-Entropy Alloy Film with High Strength-Ductility Synergy and Corrosion Resistance" Materials 15, no. 23: 8568. https://doi.org/10.3390/ma15238568

APA StyleFeng, X., Feng, C., & Lu, Y. (2022). A Lightweight AlTiVNb High-Entropy Alloy Film with High Strength-Ductility Synergy and Corrosion Resistance. Materials, 15(23), 8568. https://doi.org/10.3390/ma15238568