An Innovative Flexible-Honing Method with Dampers for Long-Life, Mass-Machining of Face Gears

Abstract

:1. Introduction

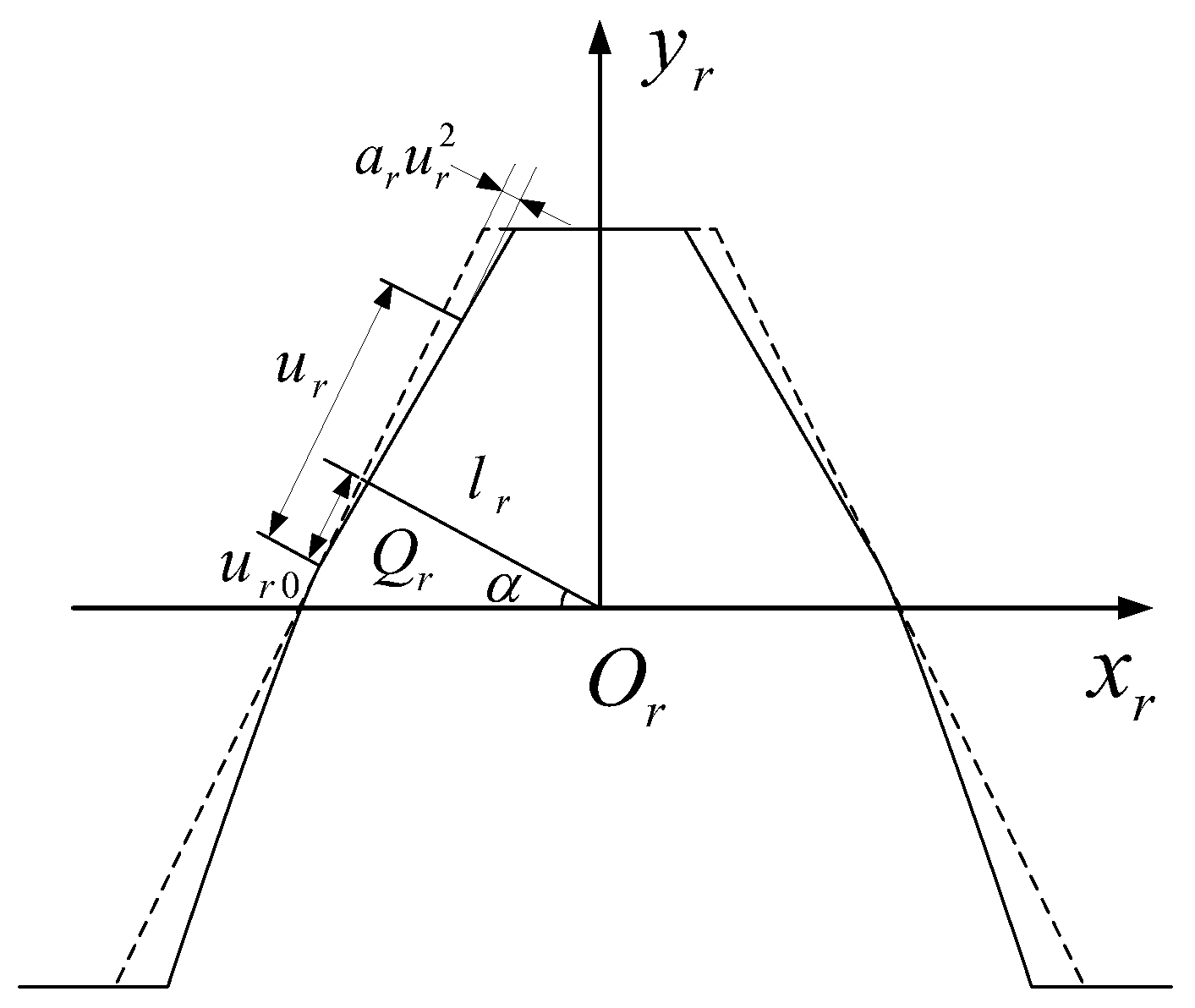

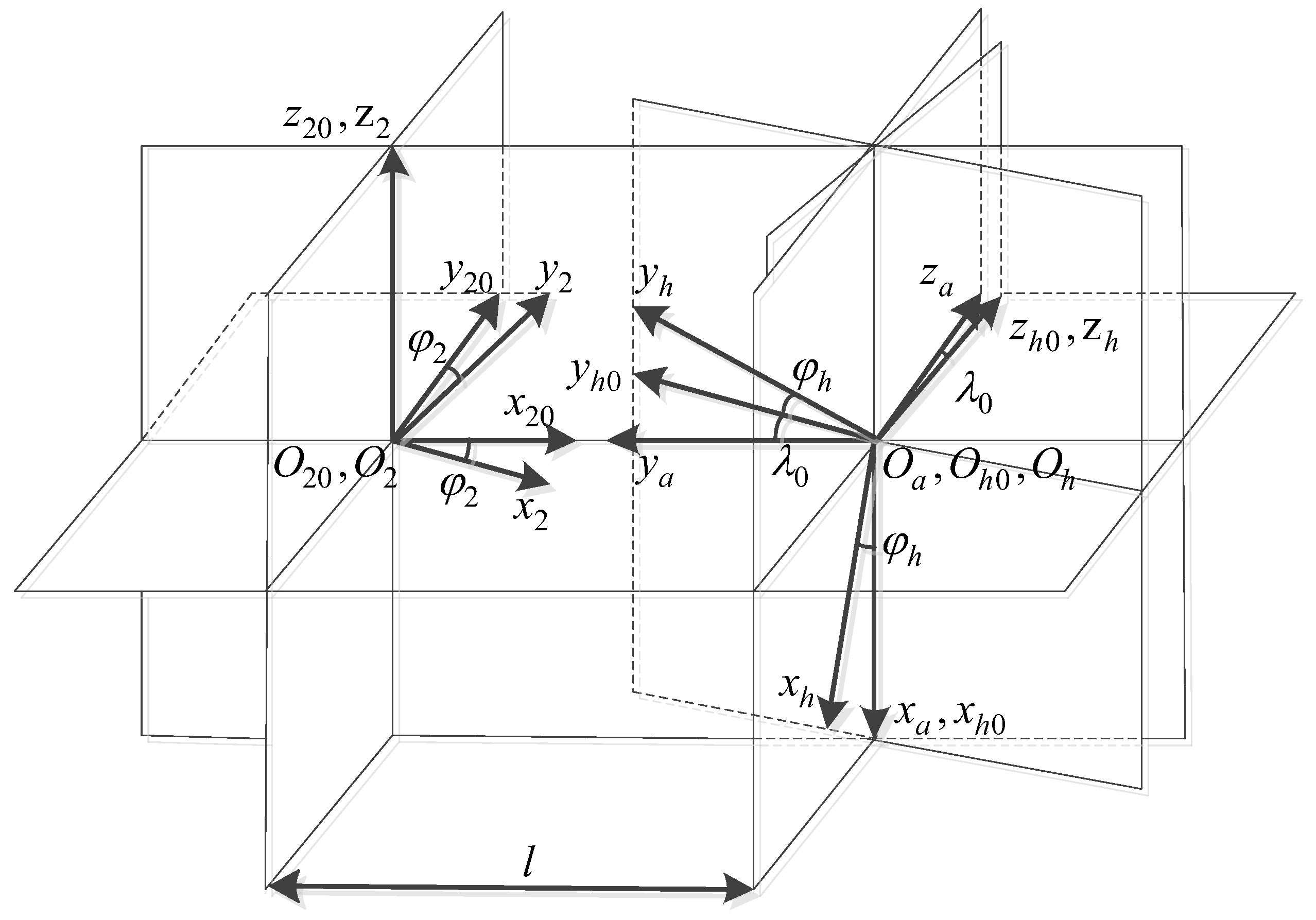

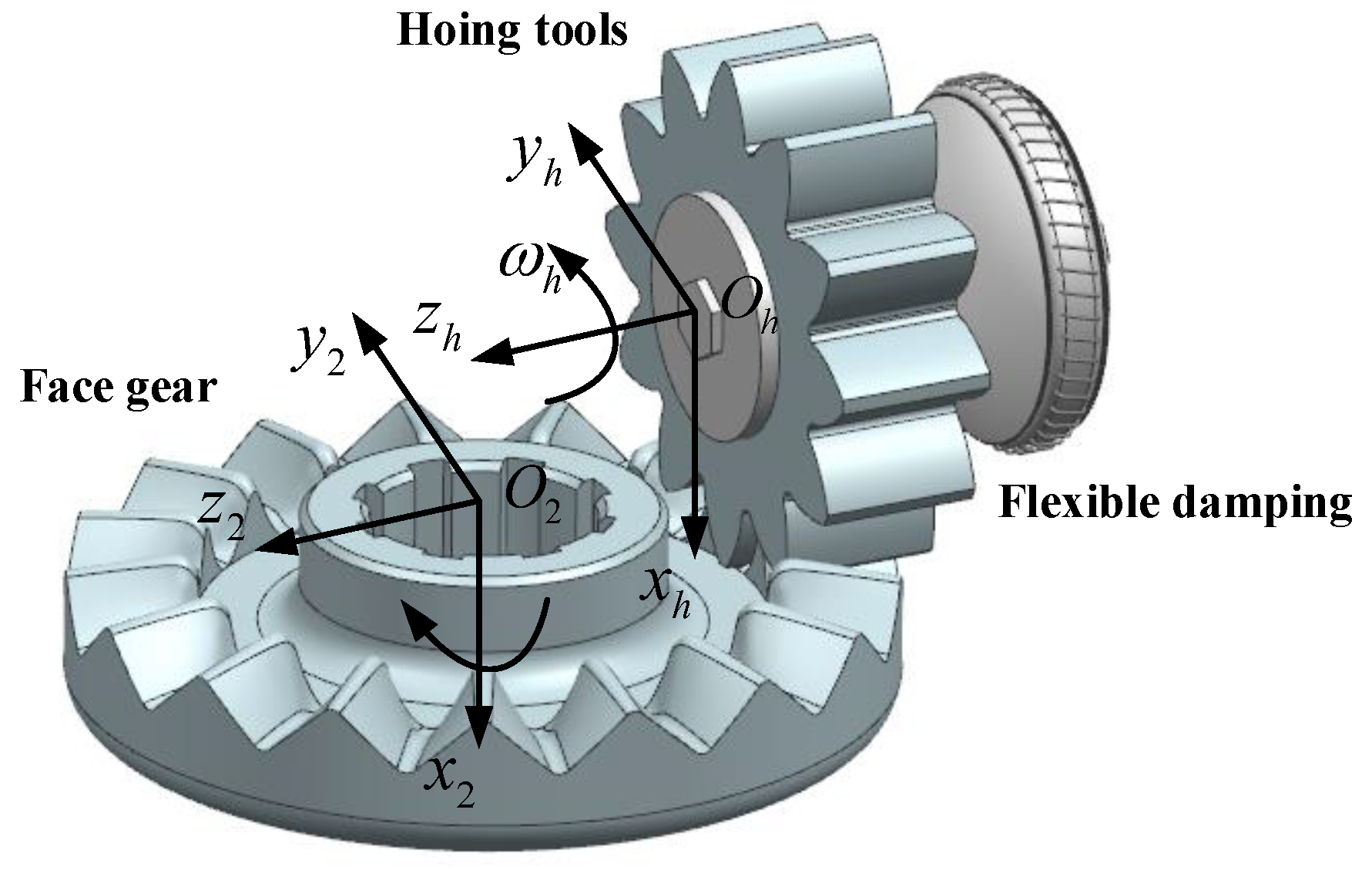

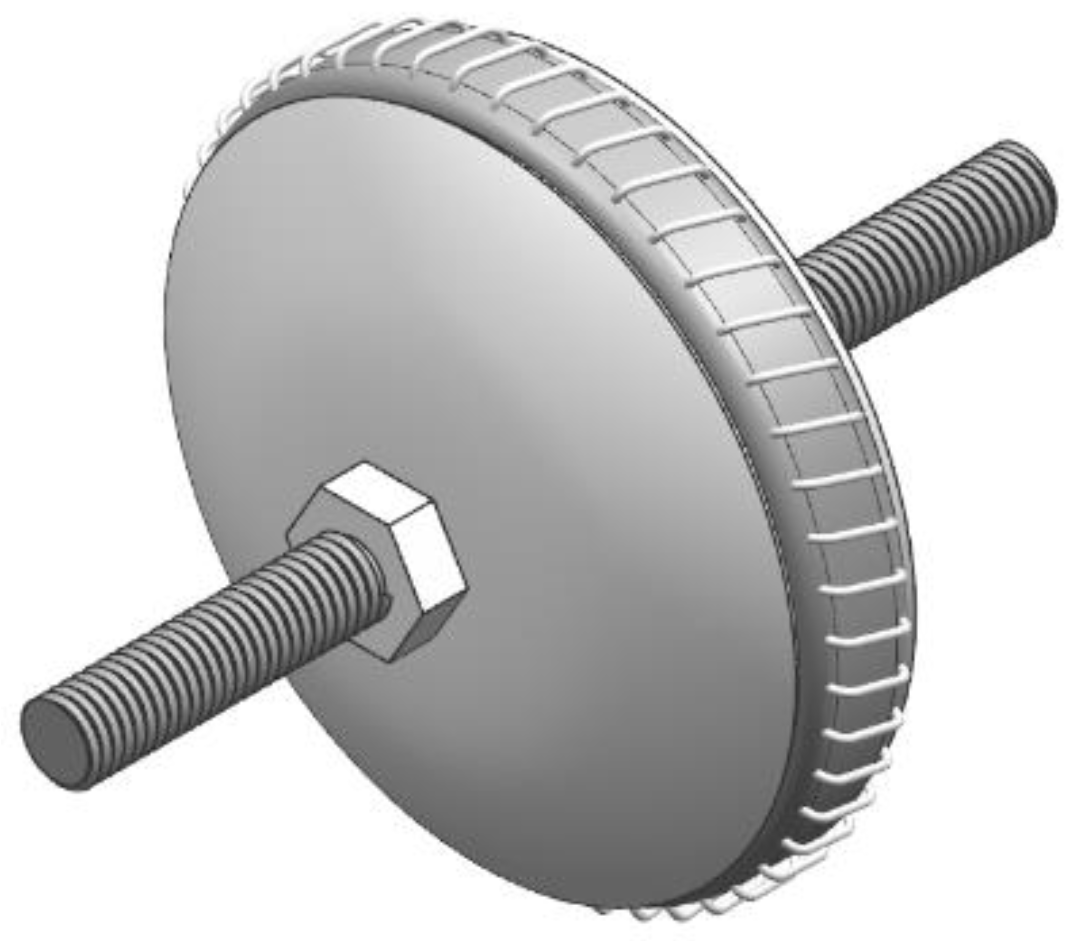

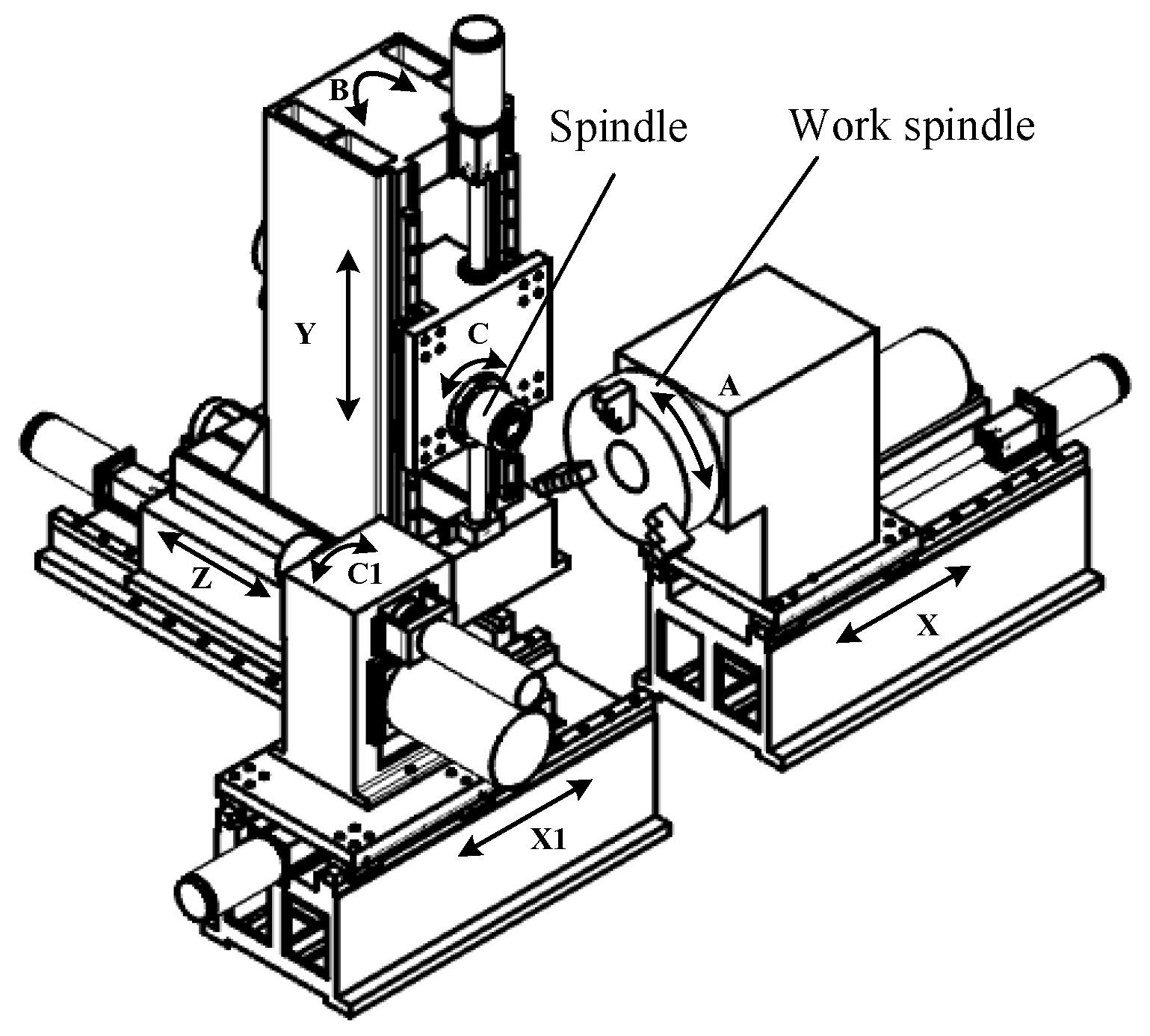

2. Principle of Face-Gear Honing

2.1. Tooth-Surface Equation for Face-Gear Honing

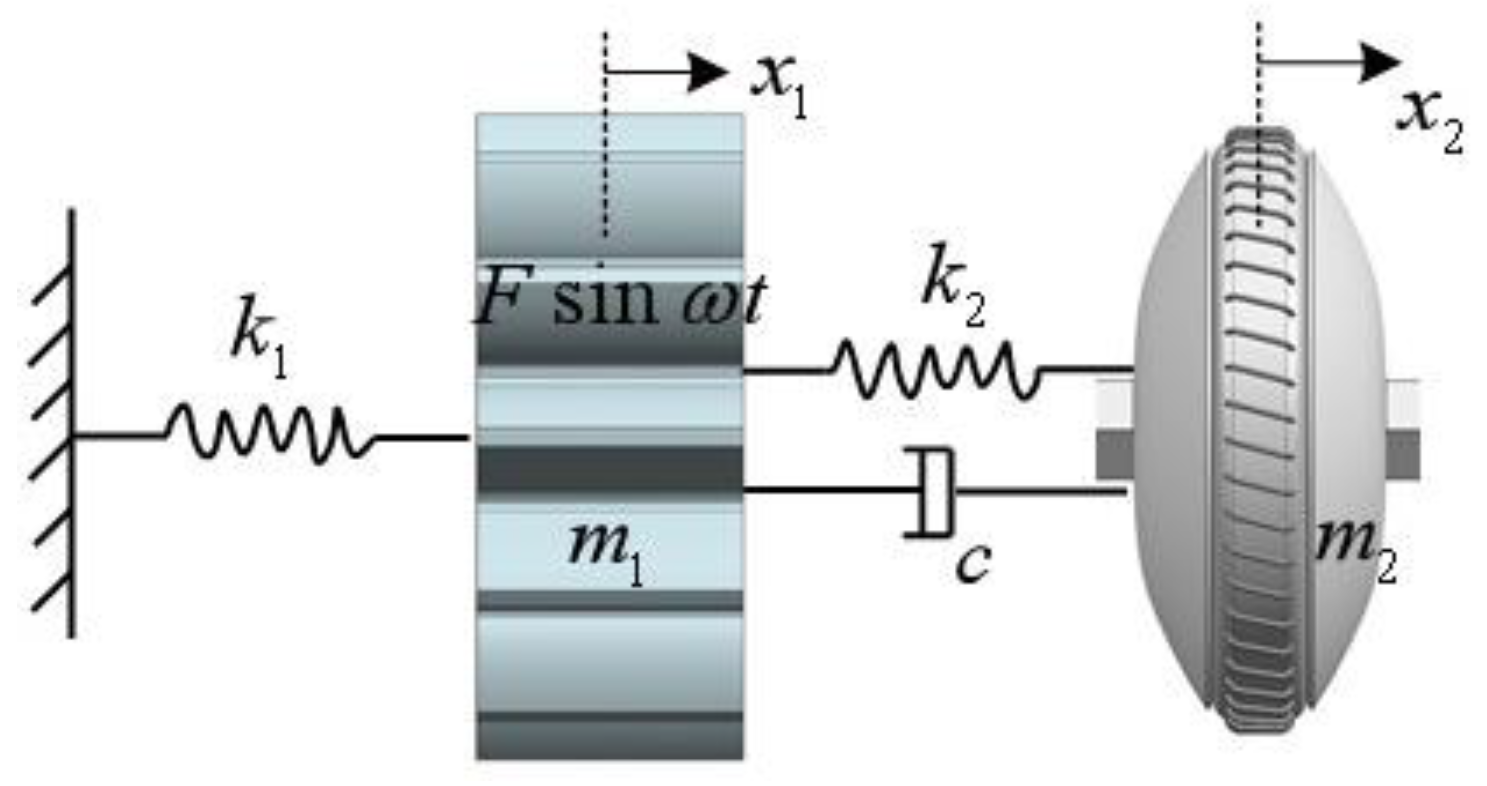

2.2. Mathematical Model of Face-Gear Flexible Honing

3. Roughness Analysis of Face-Gear Honing

3.1. Calculation of Honing Roughness of Face Gear

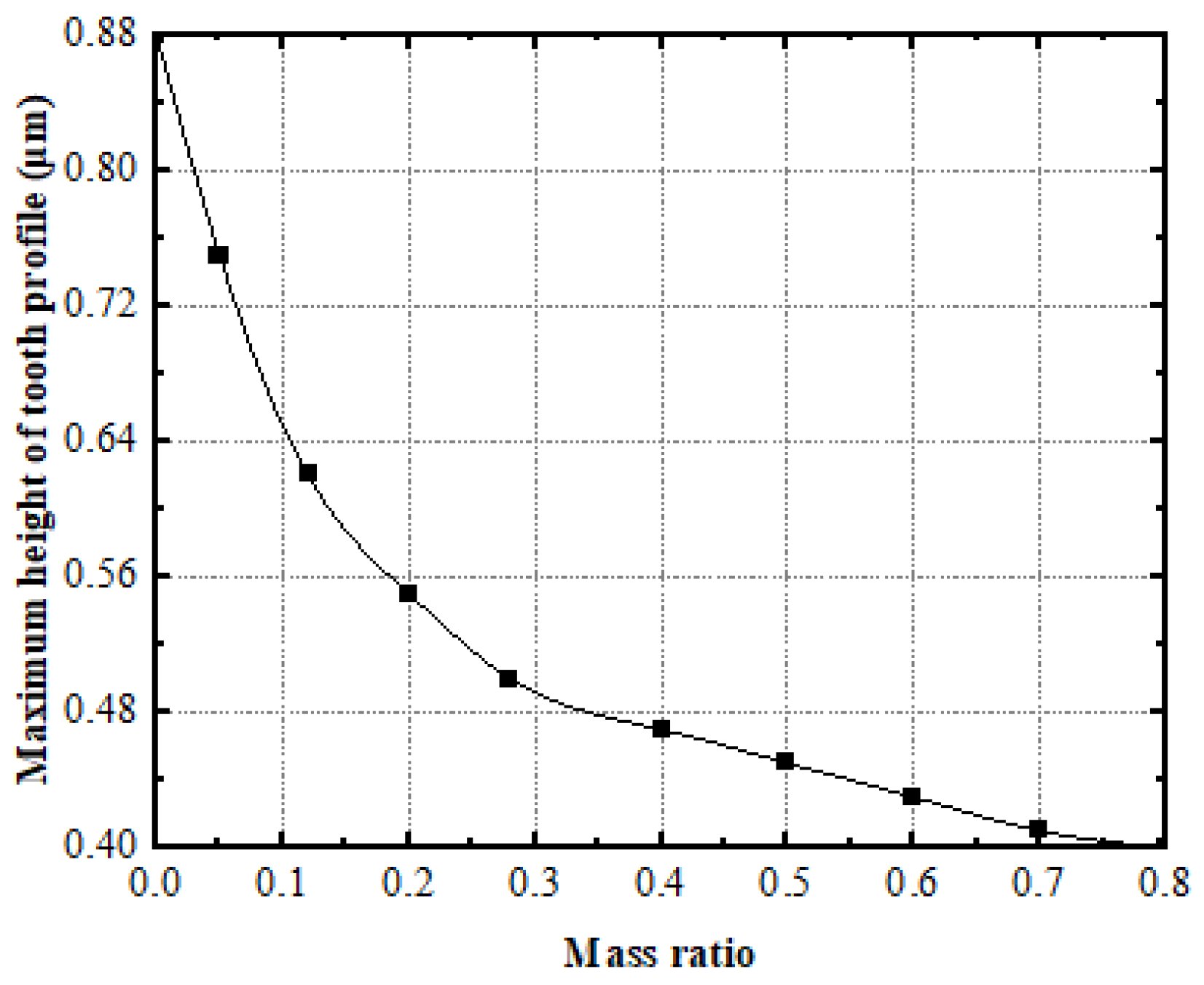

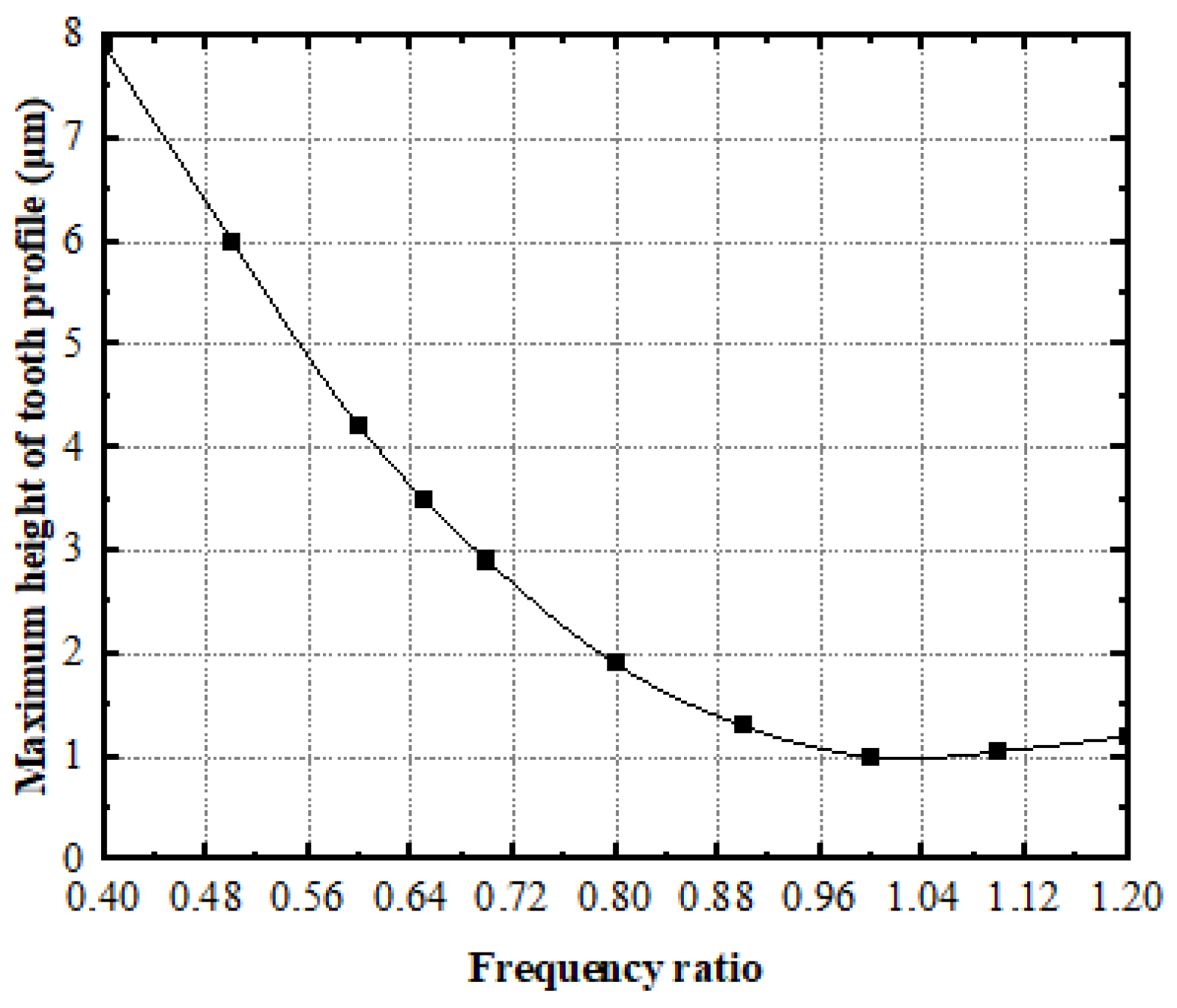

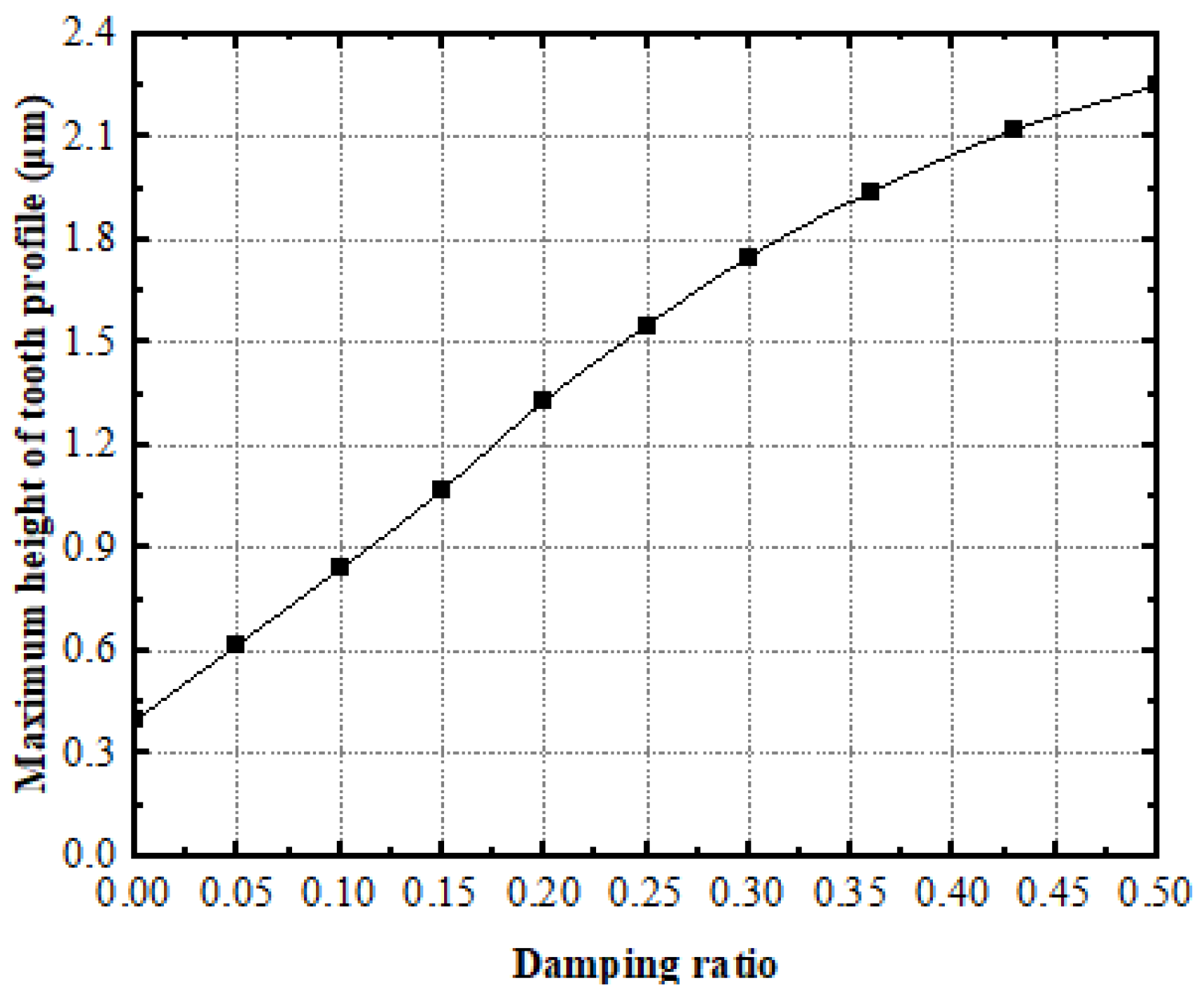

3.2. Analysis of the Effect of Vibration-Absorber Parameters on Honing-Tooth Surface Roughness

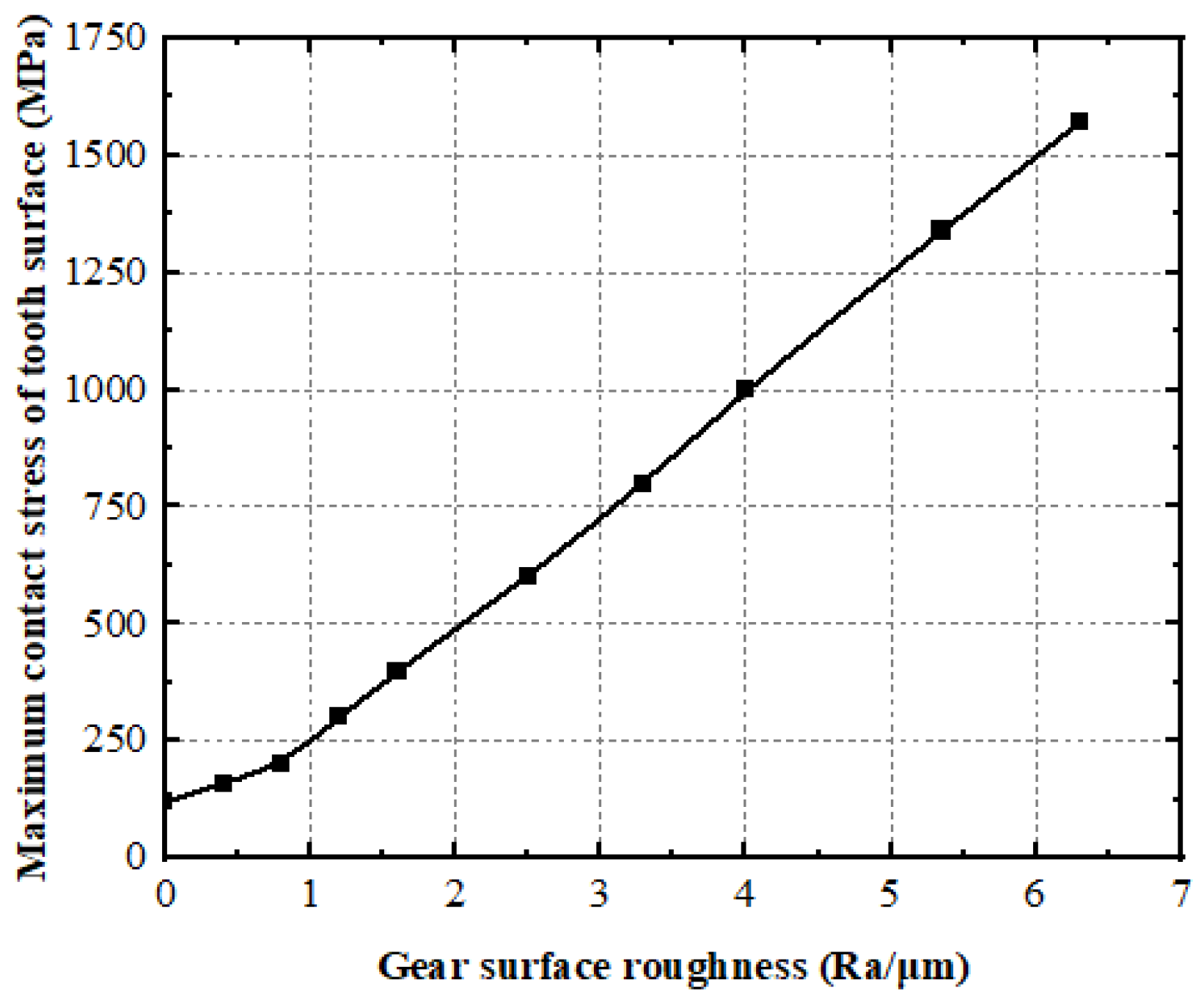

4. Influence Law of Roughness on Contact Stress of Face-Gear Tooth Surface

4.1. Calculation Method of Contact Stress on the Rough Tooth Surface of the Face Gear

4.2. Analysis of Contact-Stress Distribution on the Rough Tooth Surface of Face Gear

4.3. Determination of Damper Parameters

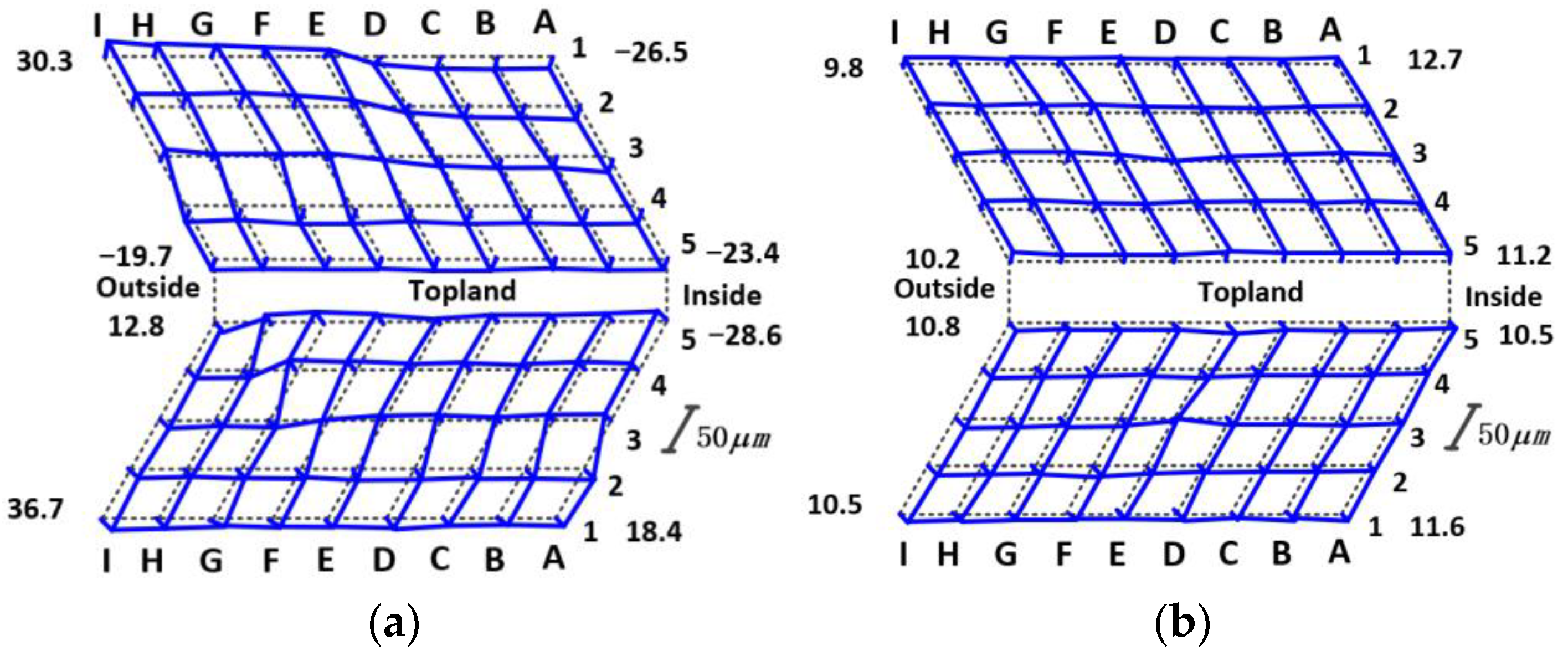

5. Experiment

6. Conclusions

- (1)

- According to the principle of honing, combined with flexible-honing tools, a mathematical analysis model of the flexible honing of face gears is established.

- (2)

- The influencing factors of the honing-tooth surface roughness are analyzed, and the effective regulation of the flexible-honing tool parameters on the tooth-surface roughness of the face gear is hooked up.

- (3)

- The calculation process of the contact stress is deduced, the contact stress distribution of the face gear is analyzed, and the parameters of flexible honing are determined.

- (4)

- The flexible-honing experiment is carried out to test the precision of the honed face gear. The test data exhibit that the precision of the honed face gear is improved. The experimental data confirm that the long-life mass-flexible-honing method is feasible.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Litvin, F.L.; Fuentes, A.; Zanzi, C.; Pontiggia, M. Design, generation, and stress analysis of two versions of geometry of face-gear drives. Mech. Mach. Theory. 2002, 37, 1179–1211. [Google Scholar] [CrossRef]

- Litvin, F.L.; Gonzalez-Perez, I.; Fuentes, A.; Vecchiato, D.; Hansen, B.D.; Binney, D. Design, generation and stress analysis of face-gear drive with helical pinion. Comput. Method Appl. M. 2005, 194, 3870–3901. [Google Scholar] [CrossRef]

- Gavrila, I.; Bolos, V. Experimental Research Concerning Relation between Contact Patch and Lapping Operation of Worm Face Gear. Procedia Tech. 2015, 19, 120–127. [Google Scholar] [CrossRef]

- Kawasaki, K.; Tsuji, I.; Gunbara, H. Geometric design of a face gear drive with a helical pinion. J. Mech. Sci. Technol. 2018, 32, 1653–1659. [Google Scholar] [CrossRef]

- Shen, Y.B.; Liu, X.; Li, D.Y.; Li, Z.P. A method for grinding face gear of double crowned tooth geometry on a multi-axis CNC machine. Mech. Mach. Theory 2018, 121, 460–474. [Google Scholar] [CrossRef]

- Shih, Y.P.; Sun, Z.H.; Wu, F.C. A disk tool cutting method for bevel gear manufacture on a five-axis machine. Int. J. Adv. Manuf. Tech. 2018, 94, 855–865. [Google Scholar] [CrossRef]

- Zschippang, H.A.; Weikert, S.; Küçük, K.A.; Wegener, K. Face-gear drive: Geometry generation and tooth contact analysis. Mech. Mach. Theory 2019, 142, 103576. [Google Scholar] [CrossRef]

- Zhou, R.C.; Zhao, N.; Li, W.; Li, W.; Li, R.; Guo, G.D.; Guo, H. A grinding method of face gear mating with a conical spur involute pinion. Mech. Mach. Theory 2019, 141, 226–244. [Google Scholar] [CrossRef]

- Wang, S.H.; Zhou, Y.S.; Tang, J.Y.; Tang, K.; Li, Z.M.Q. Digital tooth contact analysis of face gear drives with an accurate measurement model of face gear tooth surface inspected by CMMs. Mech. Mach. Theory 2022, 167, 104498. [Google Scholar] [CrossRef]

- Tang, Z.W.; Zhou, Y.S.; Wang, S.H.; Zhu, J.; Tang, J.Y. An innovative geometric error compensation of the multi-axis CNC machine tools with non-rotary cutters to the accurate worm grinding of spur face gears. Mech. Mach. Theory 2022, 169, 104664. [Google Scholar] [CrossRef]

- Zhou, Y.S.; Tang, Z.W.; Shi, X.L.; Tang, J.Y.; Li, Z.M.Q. Efficient and accurate worm grinding of spur face gears according to an advanced geometrical analysis and a closed-loop manufacturing process. J. Cent. South Univ. 2022, 29, 1–13. [Google Scholar] [CrossRef]

- Mo, S.; Ting, Z.; Jin, G.G.; Cao, X.L.; Gao, H.J. Analytical investigation on load sharing characteristics of herringbone planetary gear train with flexible support and floating sun gear. Mech. Mach. Theory 2020, 144, 103670. [Google Scholar]

- Inoue, T.; Kurokawa, S. Proposal of a face gear which generates virtual high mesh frequency by addition of grooves on the tooth flank, and the investigation via vibration simulator and actual samples. Precis. Eng. 2016, 47, 321–332. [Google Scholar] [CrossRef]

- Inoue, T.; Kurokawa, S. Influence of Waveform Components Derived from the Transmission Error of a Face Gear Pair on a Fishing Reel based on Tactile Sensibility. Precis. Eng. 2018, 51, 232–243. [Google Scholar] [CrossRef]

- Guo, H.; Zhang, S.Y.; Wu, T.P.; Zhao, N. An approximate design method of grinding worm with variable meshing angle and grinding experiments of face gear. Mech. Mach. Theory 2021, 166, 104461. [Google Scholar] [CrossRef]

- Zschippang, H.A.; Lanz, N.; Kucuk, K.A.; Weikert, S.; Wegener, K. Face-gear drive: Assessment of load sharing, transmission characteristics and root stress based on a quasi-static analysis. Mech. Mach. Theory 2020, 151, 103914. [Google Scholar] [CrossRef]

- Dong, J.X.; Hu, Z.H.; Tang, J.Y.; Wang, Z.W.; Chen, S.Y. Investigation of the Vibration Features and Dynamic Load Sharing Characteristics of Concentric Face Gear Torque Split Transmission. J. Comput. Nonlin. Dyn. 2021, 16, 071003. [Google Scholar] [CrossRef]

- Wang, Y.Z.; Hou, L.W.; Lan, Z.; Zhang, G.L. Precision grinding technology for complex surface aero face-gear. Int. J. Adv. Manuf. Tech. 2016, 86, 1263–1272. [Google Scholar] [CrossRef]

- Wang, Y.Z.; Lan, Z.; Hou, L.W.; Chu, X.M.; Yin, Y.Y. An efficient honing method for face gear with tooth profile modification. Int. J. Adv. Manuf. Tech. 2017, 90, 1155–1163. [Google Scholar] [CrossRef]

| Calculation Parameters | Value | Unit |

|---|---|---|

| Honing-tool radius of curvature | 25 | mm |

| Honing feed | 0.01 | mm |

| Honing excitation force | 40 | N |

| Honing-wheel stiffness | 3 × 108 | N/m |

| C | Mn | Si | S | P | Cr | Ni |

|---|---|---|---|---|---|---|

| 0.15~0.20 | 0.30~0.60 | 0.35 | 0.010 | 0.015 | 0.80~1.10 | 3.75~4.25 |

| Design Parameters | Numerical Value | Unit |

|---|---|---|

| Modulus | 3.5 | Mm |

| Number of face gears with enamel | 23 | — |

| Number of spur-equipment teeth | 23 | — |

| Angle of pressure | 25 | ° |

| Torque | 300 | Nm |

| Modulus of elasticity | 2 × 105 | MPa |

| Poisson’s ratio | 0.3 | — |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chu, X.; Zhou, Z.; Zeng, H.; Wang, Y.; Huang, Y. An Innovative Flexible-Honing Method with Dampers for Long-Life, Mass-Machining of Face Gears. Materials 2022, 15, 8573. https://doi.org/10.3390/ma15238573

Chu X, Zhou Z, Zeng H, Wang Y, Huang Y. An Innovative Flexible-Honing Method with Dampers for Long-Life, Mass-Machining of Face Gears. Materials. 2022; 15(23):8573. https://doi.org/10.3390/ma15238573

Chicago/Turabian StyleChu, Xiaomeng, Zhiji Zhou, Hong Zeng, Yanzhong Wang, and Yizhan Huang. 2022. "An Innovative Flexible-Honing Method with Dampers for Long-Life, Mass-Machining of Face Gears" Materials 15, no. 23: 8573. https://doi.org/10.3390/ma15238573

APA StyleChu, X., Zhou, Z., Zeng, H., Wang, Y., & Huang, Y. (2022). An Innovative Flexible-Honing Method with Dampers for Long-Life, Mass-Machining of Face Gears. Materials, 15(23), 8573. https://doi.org/10.3390/ma15238573