Finite Element Simulation of Ultrasonic Scattering by Rough Flaws with Multi-Scale Distortions

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

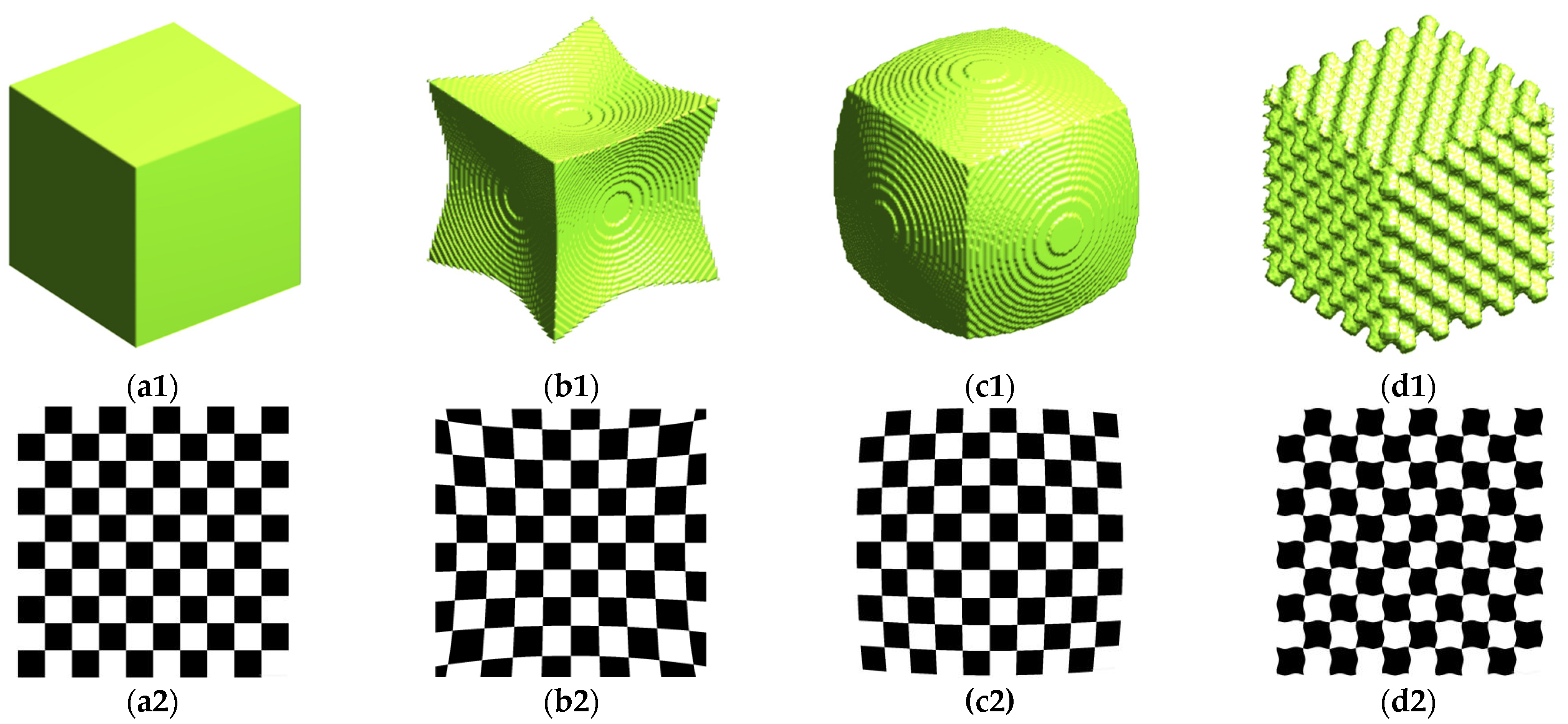

2.2. Generating Rough Flaws with Multi-Scale Distortions

2.3. Ultrasonic Finite Element Method

2.3.1. FE Simulation Setup

2.3.2. Model Verification

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Schmerr, L.W. Fundamentals of Ultrasonic Nondestructive Evaluation, 2nd ed.; Springer: Cham, Switzerland, 2016; pp. 419–523. [Google Scholar]

- Ogilvy, J.A. Theoretical Comparison of Ultrasonic Signal Amplitudes from Smooth and Rough Defects. NDT Int. 1986, 19, 371–385. [Google Scholar] [CrossRef]

- Ogilvy, J.A.; Culverwell, I.D. Elastic Model for Simulating Ultrasonic Inspection of Smooth and Rough Defects. Ultrasonics 1991, 29, 490–496. [Google Scholar] [CrossRef]

- Ogilvy, J.A. Model for the Ultrasonic Inspection of Rough Defects. Ultrasonics 1989, 27, 69–79. [Google Scholar] [CrossRef]

- Ogilvy, J.A. Computer Simulation of Acoustic Wave Scattering from Rough Surfaces. J. Phys. Appl. Phys. 1988, 21, 260–277. [Google Scholar] [CrossRef]

- Zhang, J.; Drinkwater, B.W.; Wilcox, P.D. Longitudinal Wave Scattering from Rough Crack-like Defects. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2011, 58, 2171–2180. [Google Scholar] [CrossRef]

- Pettit, J.R.; Walker, A.E.; Lowe, M.J.S. Improved Detection of Rough Defects for Ultrasonic Nondestructive Evaluation Inspections Based on Finite Element Modeling of Elastic Wave Scattering. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2015, 62, 1797–1808. [Google Scholar] [CrossRef] [Green Version]

- Jarvis, A.J.C.; Cegla, F.B. Application of the Distributed Point Source Method to Rough Surface Scattering and Ultrasonic Wall Thickness Measurement. J. Acoust. Soc. Am. 2012, 132, 1325. [Google Scholar] [CrossRef]

- Jarvis, A.J.C.; Cegla, F.B. Scattering of near Normal Incidence SH Waves by Sinusoidal and Rough Surfaces in 3-D: Comparison to the Scalar Wave Approximation. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2014, 61, 1179–1190. [Google Scholar] [CrossRef]

- Shi, F.; Lowe, M.J.S.; Xi, X.; Craster, R.V. Diffuse Scattered Field of Elastic Waves from Randomly Rough Surfaces Using an Analytical Kirchhoff Theory. J. Mech. Phys. Solids 2016, 92, 260–277. [Google Scholar] [CrossRef] [Green Version]

- Shi, F.; Choi, W.; Lowe, M.J.S.; Skelton, E.A.; Craster, R.V. The Validity of Kirchhoff Theory for Scattering of Elastic Waves from Rough Surfaces. Proc. R. Soc. Math. Phys. Eng. Sci. 2015, 471, 20140977. [Google Scholar] [CrossRef]

- Choi, W.; Shi, F.; Lowe, M.J.; Skelton, E.A.; Craster, R.V.; Daniels, W.L. Rough Surface Reconstruction of Real Surfaces for Numerical Simulations of Ultrasonic Wave Scattering. NDT E Int. 2018, 98, 27–36. [Google Scholar] [CrossRef] [Green Version]

- Wang, S.; Shen, J.; Kin Chan, W. Determination of the Fractal Scaling Parameter from Simulated Fractal-Regular Surface Profiles Based on the Weierstrass-Mandelbrot Function. J. Tribol. 2007, 129, 952–956. [Google Scholar] [CrossRef]

- Weng, J.; Cohen, P.; Herniou, M. Camera Calibration with Distortion Models and Accuracy Evaluation. IEEE Trans. Pattern Anal. Mach. Intell. 1992, 14, 965–980. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Shi, F.; Zhang, J.; Liu, Y. A New Calibration Model and Method of Camera Lens Distortion. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems, Beijing, China, 9 October 2006. [Google Scholar]

- Akca, E.; Gürsel, A. A Review on Superalloys and IN718 Nickel-Based INCONEL Superalloy. Period. Eng. Nat. Sci. PEN 2015, 3, 15–27. [Google Scholar] [CrossRef]

- Sawafuji, Y. Automatic Ultrasonic Testing of Non-Metallic Inclusions Detectable with Size of Several Tens of Micrometers Using a Double Probe Technique along the Longitudinal Axis of a Small-Diameter Bar. ISIJ Int. 2021, 61, 248–257. [Google Scholar] [CrossRef]

- Deutsch, W.A.K.; Joswig, M.; Kattwinkel, R.; Roye, W.; Maxam, K.; Ranzeng, M. Automated Ultrasonic Testing Systems for Bars and Tubes, Examples with Mono-Element and Phased Array Probes. In Proceedings of the ECNDT 2014, Prague, Czech Republic, 6 October 2014. [Google Scholar]

- Fan, Y.; Sinclair, A.N.; Honarvar, F. Ultrasonic Characterization of Continuously Cast Rod by Resonance Acoustic Spectroscopy. Nondestruct. Test. Eval. 2003, 19, 15–28. [Google Scholar] [CrossRef]

- Yi, L. The Development of the Automatic Ultrasonic Testing System for Bar Materials. Master’s Thesis, Chongqing University, Chongqing, China, 2006. [Google Scholar]

- Haldipur, P.; Margetan, F.J.; Thompson, R.B. Estimation of Single-Crystal Elastic Constants from Ultrasonic Measurements on Polycrystalline Specimens. AIP Conf. Proc. 2004, 700, 1061–1068. [Google Scholar] [CrossRef]

- Yang, S.; Yang, S.; Qu, J.; Du, J.; Gu, Y.; Zhao, P.; Wang, N. Inclusions in Wrought Superalloys: A Review. J. Iron Steel Res. Int. 2021, 28, 921–937. [Google Scholar] [CrossRef]

- Haldipur, P.; Margetan, F.J.; Thompson, R.B. Estimation of Single-Crystal Elastic Constants of Polycrystalline Materials from Back-Scattered Grain Noise. AIP Conf. Proc. 2006, 820, 1133–1140. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Zeng, Z.; Song, Y.; Li, X. Finite Element Simulation of Ultrasonic Scattering by Rough Flaws with Multi-Scale Distortions. Materials 2022, 15, 8633. https://doi.org/10.3390/ma15238633

Wang Z, Zeng Z, Song Y, Li X. Finite Element Simulation of Ultrasonic Scattering by Rough Flaws with Multi-Scale Distortions. Materials. 2022; 15(23):8633. https://doi.org/10.3390/ma15238633

Chicago/Turabian StyleWang, Zheng, Zhanhong Zeng, Yongfeng Song, and Xiongbing Li. 2022. "Finite Element Simulation of Ultrasonic Scattering by Rough Flaws with Multi-Scale Distortions" Materials 15, no. 23: 8633. https://doi.org/10.3390/ma15238633