Effect of Elevated Temperature and Annealing Time on Mechanical Properties of Ti/Cu Bimetal

Abstract

1. Introduction

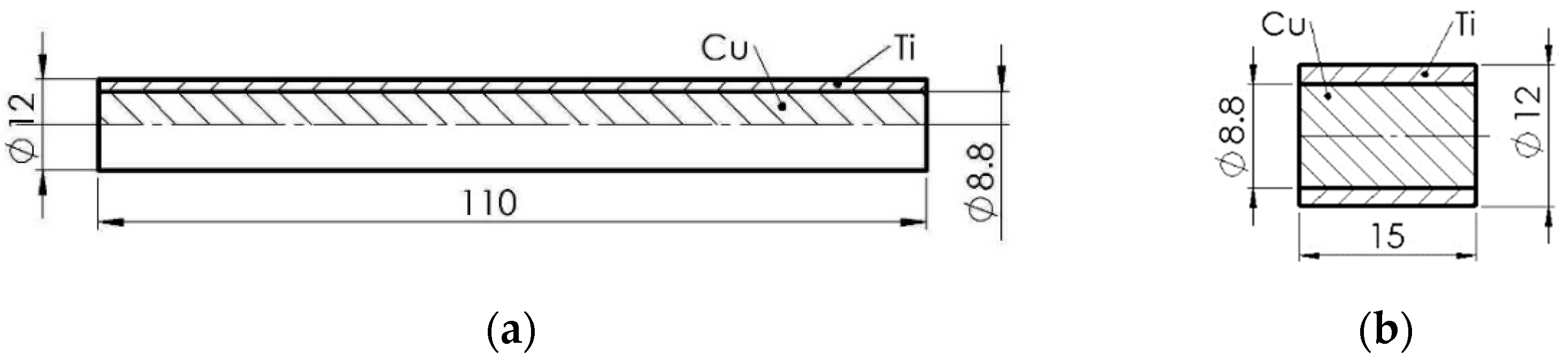

2. Experimental Procedure

Materials and Specimens

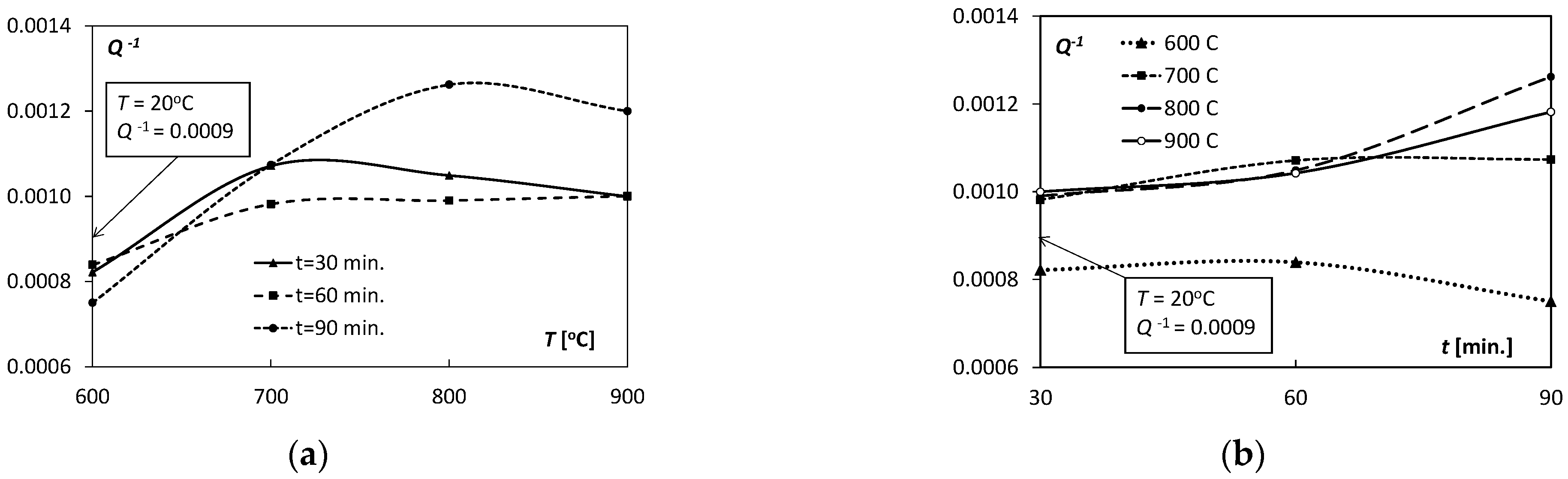

3. Elastic Properties of Ti/Cu Bimetal after Thermal Action

Results of Impulse Excitation Tests and Discussion

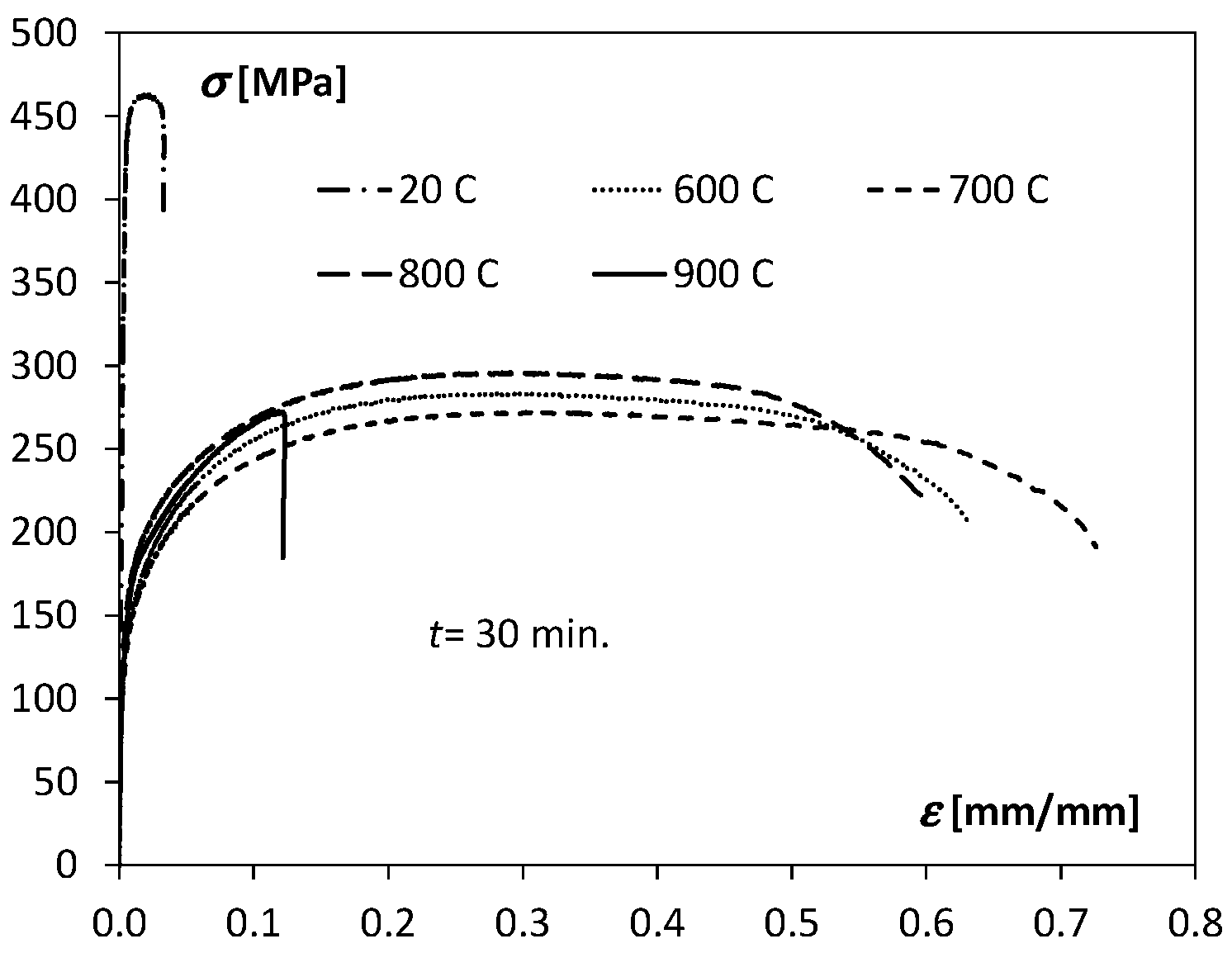

4. Tensile Tests of Specimens after Thermal Action

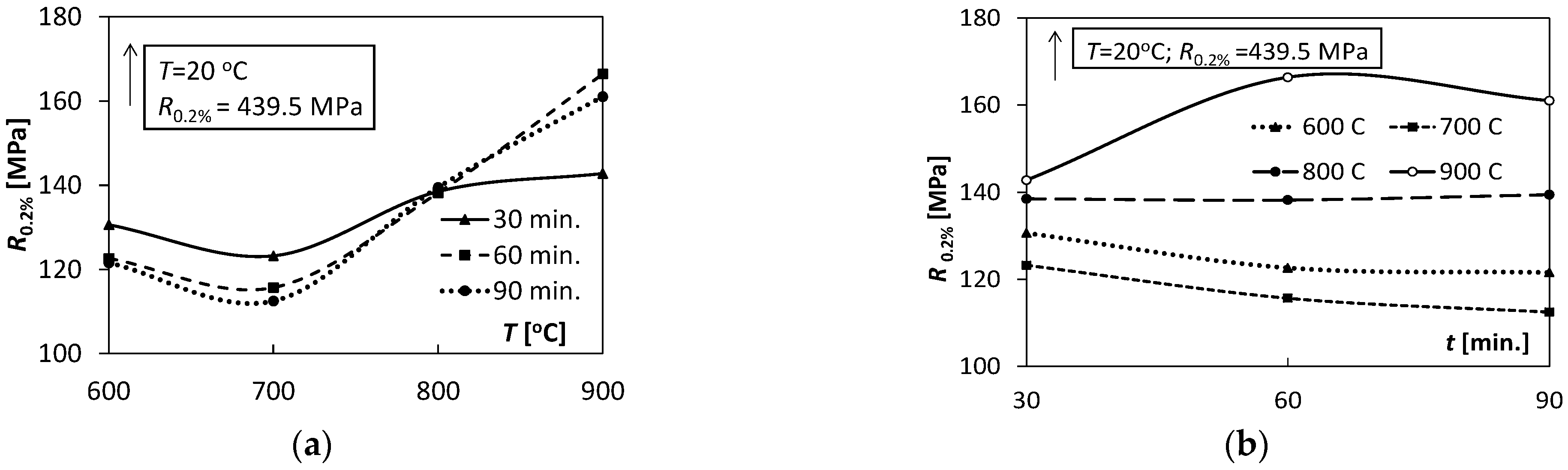

Results of Tensile Tests and Discussion

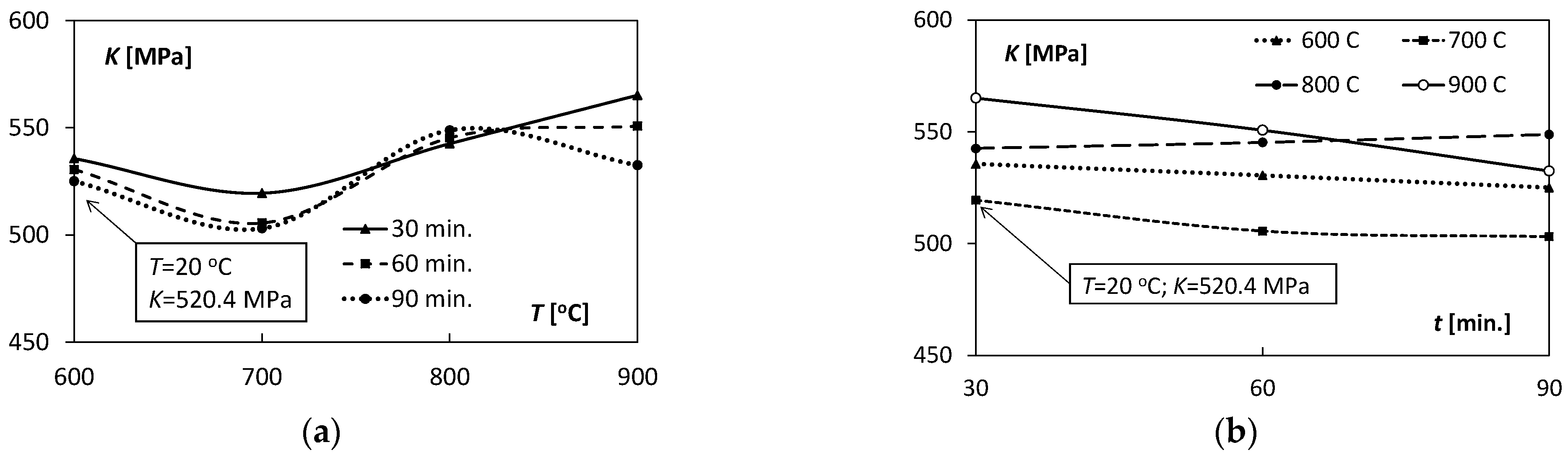

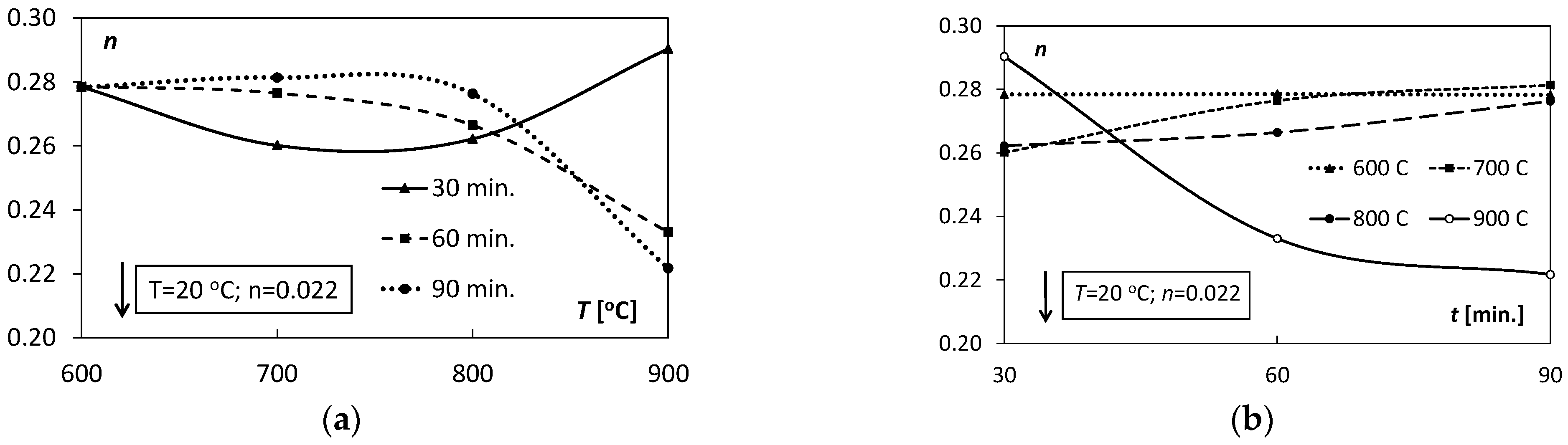

5. Hardening of Ti/Cu Bimetal

6. SEM Assessment of Ti–Cu Interface

7. Conclusions

- In the tested temperature range, the highest value of Young’s modulus E of the Ti/Cu bimetal occurred for T = 900 °C. It was 118 GPa for an annealing time of 90 min, while in the temperature range of 600–800 °C, its increase was insignificant and was in the range of 110–111 GPa. The annealing time had the most significant impact on the samples exposed to the temperature of 900 °C, characterized by an increase from 114 GPa to 118 GPa in the range of 30–90 min. Inverse relations occurred about the internal friction parameter Q−1 ranging in the temperature range of 600–700 °C. The highest value of the parameter was recorded in the case of t = 90 min;

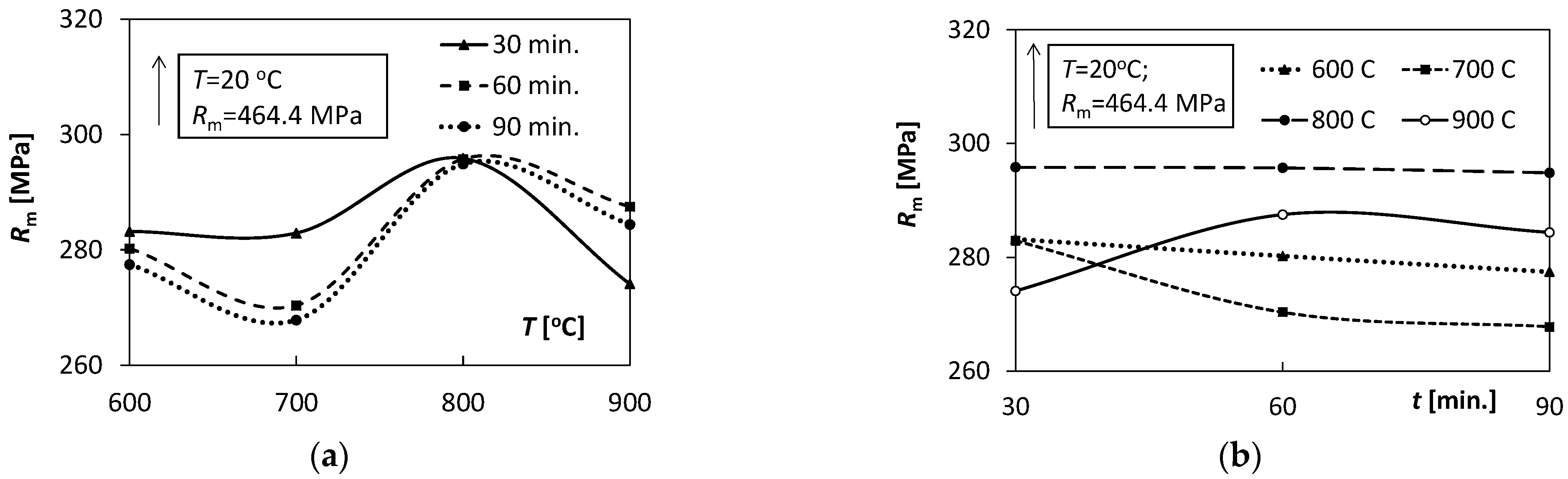

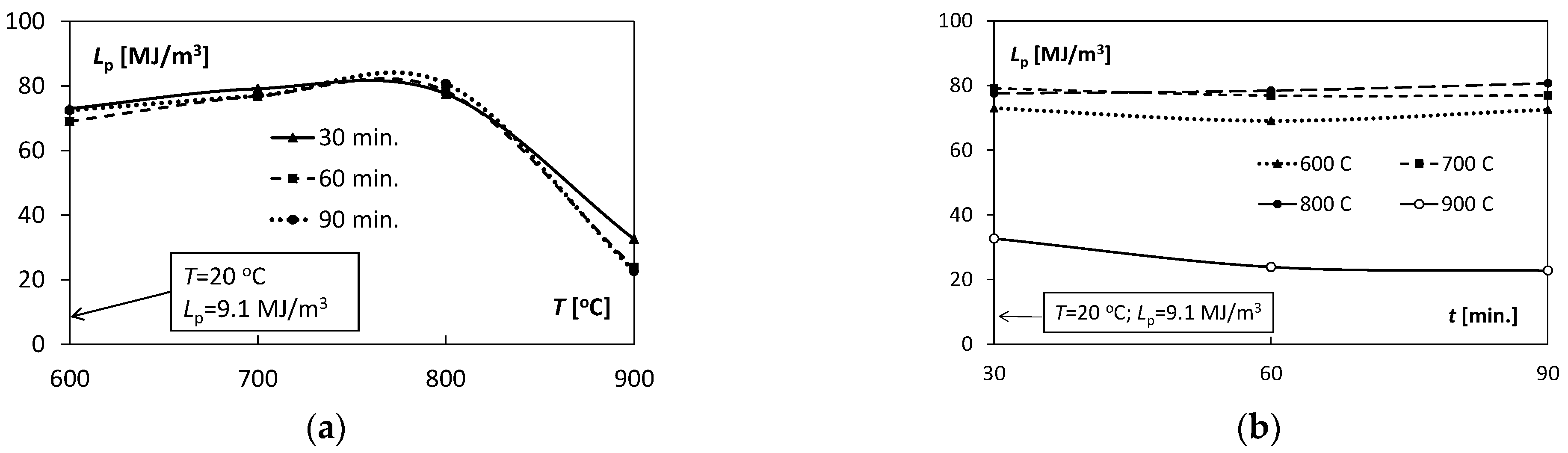

- All samples of Ti/Cu subjected to the thermal factor showed several times decreased values of strength parameters concerning the virgin samples. The tensile strength Rm decreased from the level of 464.4 MPa to the value of 284.4 MPa with the temperature increase at T = 900 °C and t = 90 min. At the same time, the energy demand necessary for uniform plastic deformation (Lp) of the samples increased by about ten times, from 9.1 MJ/m3 to 80.7 MJ/m3. At the temperature of 900 °C and for t = 90 minutes, the Lp value decreased by 58.0 MJ/m3 as the consequence of structural changes in the Ti/Cu bimetal. It was observed that even a 30-min overheating of the bimetal at 600 °C caused significant deterioration of the strength properties and the ability to work under load;

- Increasing the holding time from 30 min to 90 min had the most substantial influence on the hardening factor n of samples annealed at 900 °C and caused its value to drop from 0.290 to 0.222. For the remaining temperatures in the range of 600–800 °C, the increase of the n coefficient was insignificant;

- The heating of the Ti/Cu bimetal to the temperature of 900 °C caused, in the range of the tested annealing times, dangerous structural changes, causing destructive processes leading to the reconstruction of the internal structure, brittleness of the titanium layer, formation of gaps on the interface, and finally delamination.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Uścinowicz, R. Deformation Processes of Metal Layered Composites; Publishing House of the Bialystok University of Technology: Białystok, Poland, 2015. (In Polish) [Google Scholar]

- Sanjurjo, A.; Wood, B.J.; Lau, K.H.; Tong, G.T.; Choi, D.K.; McKubre, M.C.H.; Song, H.K.; Church, N. Titanium-Based Coatings on Copper by Chemical Vapor Deposition in Fluidized Bed Reactors. Surf. Coat. Technol. 1991, 49, 110–115. [Google Scholar] [CrossRef]

- Chawla, S.L.; Gupta, R.K. Materials Selection for Corrosion Control; ASM International, Ed.; ASM International: Novelty, OH, USA, 1993; ISBN 9780871704740. [Google Scholar]

- O’Brien, T.F.; Bommaraju, T.V.; Hine, F. Handbook of Chlor-Alkali Technology: Volume II: Brine Treatment and Cell Operation; Springer Science & Business Media: New York, NY, USA, 2007; ISBN 0306486245. [Google Scholar]

- Bockris, J. Comprehensive Treatise of Electrochemistry Volume 2; Electrochemical Processing: New York, NY, USA, 1981. [Google Scholar]

- Titanium-Clad Copper Electrodes, New Products from Dymax Corp. Met. Finish. 2008, 106, 98–99. [CrossRef]

- Du, X.; Yang, Q.; Chen, Y.; Yang, Y.; Zhang, Z. Galvanic Corrosion Behavior of Copper/Titanium Galvanic Couple in Artificial Seawater. Trans. Nonferrous Met. Soc. China 2014, 24, 570–581. [Google Scholar] [CrossRef]

- Titanium-Clad Copper Bus Bar. Developments, New Equipment, Processes, and Materials. Met. Finish. 1999, 97, 67. [CrossRef]

- Shmorgun, V.; Slautin, O.; Arisova, V.; Evstropov, D. Phase Composition Study of Diffusion Zone in the Composite of the Copper-Titanium System. Izv. Volg STU Volgogr. 2013, 6, 32–35. (In Russian) [Google Scholar]

- Bateni, M.R.; Szpunar, J.A.; Ashrafizadeh, F.; Zandrahimi, M. The Effect of Novel Ti-Cu Intermetallic Compound Coatings on Tribological Properties of Copper. Surfaces 2003, 10, 11. [Google Scholar]

- Bateni, M.R.; Mirdamadi, S.; Ashrafizadeh, F.; Szpunar, J.A.; Drew, R.A.L. Formation of Ti–Cu Intermetallic Coatings on Copper Substrate. Mater. Manuf. Process. 2001, 16, 219–228. [Google Scholar] [CrossRef]

- Pronichev, D.V.; Slautin, O.V.; Evstropov, D.A.; Taube, A.O.; Novikov, R.E. Study of the Thermophysical Properties of Intermetallic Composite Material Titanium-Copper. News Volgogr. State Tech. Univ. 2013, 15, 16–19. (In Russian) [Google Scholar]

- Zhu, Y.X.; Chen, W.; Tu, W.B.; Guo, Y.; Chen, L. Three-Dimensional Finite Element Modeling of Rotary-Draw Bending of Copper-Titanium Composite Tube. Int. J. Adv. Manuf. Technol. 2020, 106, 2377–2389. [Google Scholar] [CrossRef]

- Kahraman, N.; Gülenç, B. Microstructural and Mechanical Properties of Cu–Ti Plates Bonded through Explosive Welding Process. J. Mater. Process. Technol. 2005, 169, 67–71. [Google Scholar] [CrossRef]

- Paul, H.; Skuza, W.; Chulist, R.; Miszczyk, M.; Gałka, A.; Prażmowski, M.; Pstruś, J. The Effect of Interface Morphology on the Electro-Mechanical Properties of Ti/Cu Clad Composites Produced by Explosive Welding. Metall. Mater. Trans. A 2020, 51, 750–766. [Google Scholar] [CrossRef]

- Matsushita, T.; Noguchi, M.; Arimura, K. Hot Hydrostatic Extrusion of Ti/Cu-Alloy Composite Materials. J. Soc. Mater. Sci. Jpn. 1988, 37, 107–113. [Google Scholar] [CrossRef]

- Lee, J.S.; Son, H.T.; Oh, I.H.; Kang, C.S.; Yun, C.H.; Lim, S.C.; Kwon, H.C. Fabrication and Characterization of Ti-Cu Clad Materials by Indirect Extrusion. J. Mater. Process. Technol. 2007, 187–188, 653–656. [Google Scholar] [CrossRef]

- Paul, H.; Chulist, R.; Bobrowski, P.; Perzyński, K.; Madej, Ł.; Mania, I.; Miszczyk, M.; Cios, G. Microstructure and Properties of the Interfacial Region in Explosively Welded and Post-Annealed Titanium-Copper Sheets. Mater. Charact. 2020, 167, 110520. [Google Scholar] [CrossRef]

- Paul, H.; Chulist, R.; Miszczyk, M.; Lityńska-Dobrzyńska, L.; Cios, G.; Gałka, A.; Petrzak, P.; Szlezynger, M. Towards a Better Understanding of the Phase Transformations in Explosively Welded Copper to Titanium Sheets. Mater. Sci. Eng. A 2020, 784, 139285. [Google Scholar] [CrossRef]

- Zu, G.; Li, X.; Zhang, J.; Zhang, H. Interfacial Characterization and Mechanical Property of Ti/Cu Clad Sheet Produced by Explosive Welding and Annealing. J. Wuhan Univ. Technol.-Mater. Sci. Ed. 2015, 30, 1198–1203. [Google Scholar] [CrossRef]

- Mojżeszko, M.; Perzyński, K.; Sionkowski, M.; Paul, H.; Madej, Ł. Numerical Investigation of an Explosive Welding of Ti/Cu Plates Based on a Meshfree Method. Arch. Metall. Mater. 2020, 65, 707–711. [Google Scholar]

- Aydın, K.; Kaya, Y.; Kahraman, N. Experimental Study of Diffusion Welding/Bonding of Titanium to Copper. Mater. Des. 2012, 37, 356–368. [Google Scholar] [CrossRef]

- Hosseini, M.; Pardis, N.; Danesh Manesh, H.; Abbasi, M.; Kim, D.-I. Structural Characteristics of Cu/Ti Bimetal Composite Produced by Accumulative Roll-Bonding (ARB). Mater. Des. 2017, 113, 128–136. [Google Scholar] [CrossRef]

- Hosseini, M.; Danesh Manesh, H.; Eizadjou, M. Development of High-Strength, Good-Conductivity Cu/Ti Bulk Nano-Layered Composites by a Combined Roll-Bonding Process. J. Alloy. Compd. 2017, 701, 127–130. [Google Scholar] [CrossRef]

- Hosseini, M.; Danesh Manesh, H. Bond Strength Optimization of Ti/Cu/Ti Clad Composites Produced by Roll-Bonding. Mater. Des. 2015, 81, 122–132. [Google Scholar] [CrossRef]

- Uscinowicz, R. Experimental Study of the Hardening Process of Ti/Cu Bimetal during Compression Test. Mater. Today Commun. 2021, 28, 102687. [Google Scholar] [CrossRef]

- Senoo, M.; Suito, K.; Kobayashi, T.; Kubota, H. High Pressure Research on Solids (Current Japanese Materials Research); Elsevier Science: New York, NY, USA, 1995; ISBN 9780444823113. [Google Scholar]

- Mao, L.; Xie, L. Material Test Certificate NO: JP18-02-003; Shenzhen Jia Ping Titanium Industry Co., Ltd.: Shenzhen, China, 2018. [Google Scholar]

- ASTM E1876-15; Standard Test Method for Dynamic Youngs Modulus, Shear Modulus, and Poissons Ratio by Impulse Excitation of Vibration. ASTM International: West Conshohocken, PA, USA, 2015.

- Roebben, G.; Bollen, B.; Brebels, A.; Van Humbeeck, J.; Van Der Biest, O. Impulse Excitation Apparatus to Measure Resonant Frequencies, Elastic Moduli, and Internal Friction at Room and High Temperature. Rev. Sci. Instrum. 1997, 68, 4511–4515. [Google Scholar] [CrossRef]

- Roebben, G.; Basu, B.; Vleugels, J.; Van Humbeeck, J.; Van der Biest, O. Innovative Impulse Excitation Technique for High-Temperature Mechanical Spectroscopy. J. Alloy. Compd. 2000, 310, 284–287. [Google Scholar] [CrossRef]

- Raggio, L.I.; Etcheverry, J.; Sánchez, G.; Bonadeo, N. Error Analysis of the Impulse Excitation of Vibration Measurement of Acoustic Velocities in Steel Samples. Phys. Procedia 2010, 3, 297–303. [Google Scholar] [CrossRef][Green Version]

- Song, W.; Zhong, Y.; Xiang, J. Mechanical Parameters Identification for Laminated Composites Based on the Impulse Excitation Technique. Compos. Struct. 2017, 162, 255–260. [Google Scholar] [CrossRef]

- Uscinowicz, R. Characterization of Directional Elastoplastic Properties of Al/Cu Bimetallic Sheet. J. Mater. Eng. Perform. 2019, 28, 1350–1359. [Google Scholar] [CrossRef]

- Manual RFDA Basic, Version 1.1; IMCE NV: Genk, Belgium, 2014.

- Puškár, A. Internal Friction of Materials; Cambridge International Science Publishing Ltd.: Cambridge, UK, 2001. [Google Scholar]

- Blanter, M.S.; Golovin, I.S.; Neuhäuser, H.; Sinning, H.R. Internal Friction in Metallic Materials: A Handbook; Springer Series in Materials Science; Springer: Berlin/Heidelberg, Germany, 2007; ISBN 9783540687580. [Google Scholar]

- Davis, J.R. Tensile Testing, 2nd ed.; ASM International: Novelty, OH, USA, 2004; ISBN 978-1-61503-095-8. [Google Scholar]

- ASTM E8/E8M-11; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2011.

- Swift, H.W. Plastic Instability under Plane Stress. J. Mech. Phys. Solids 1952, 1, 1–18. [Google Scholar] [CrossRef]

- Iijima, Y.; Hoshino, K.; Hirano, K.-I. Diffusion of titanium in copper. Metall. Trans. A 1977, 8, 997–1001. [Google Scholar] [CrossRef]

- Jandaghi, M.R.; Saboori, A.; Khalaj, G.; Khanzadeh Ghareh Shiran, M. Microstructural Evolutions and Its Impact on the Corrosion Behaviour of Explosively Welded Al/Cu Bimetal. Metals 2020, 10, 634. [Google Scholar] [CrossRef]

- Pouraliakbar, H.; Khalaj, G.; Jandaghi, M.R.; Fadaei, A.; Ghareh-Shiran, M.K.; Shim, S.H.; Hong, S.I. Three-Layered SS321/AA1050/AA5083 Explosive Welds: Effect of PWHT on the Interface Evolution and Its Mechanical Strength. Int. J. Press. Vessel. Pip. 2020, 188, 104216. [Google Scholar] [CrossRef]

| Titanium Layer (Ti) (%), Grade TA2 | |||||||

| Ti | Fe | C | N | H | 0 | others | |

| 99.6 | 0.002 | 0.003 | 0.002 | 0.0005 | 0.001 | <0.4 | |

| Copper Layer (Cu) (%); Grade T2 | |||||||

| Cu + Ag | Bi | Sb | As | Fe | Pb | S | others |

| 99.9 | 0.03 | 0.002 | 0.004 | 0.005 | 0.004 | 0.005 | 0.05 |

| Temperatureof Annealing | Timeof Annealing | E | χf | Q−1 |

|---|---|---|---|---|

| T (°C) | t (min) | (Gpa) | (Hz) | - |

| 20 | – | 112.9 | 3493 | 8.65 × 10−4 |

| 600 | 30 | 110.1 | 3494 | 8.22 × 10−4 |

| 60 | 110.5 | 3545 | 8.39 × 10−4 | |

| 90 | 109.7 | 3576 | 7.50 × 10−4 | |

| 700 | 30 | 109.7 | 3534 | 1.07 × 10−3 |

| 60 | 110.1 | 3542 | 9.82 × 10−4 | |

| 90 | 111.0 | 3568 | 1.07 × 10−3 | |

| 800 | 30 | 111.3 | 3560 | 1.05 × 10−3 |

| 60 | 110.9 | 3585 | 9.90 × 10−4 | |

| 90 | 111.7 | 3625 | 1.26 × 10−3 | |

| 900 | 30 | 114.2 | 3537 | 1.00 × 10−3 |

| 60 | 116.4 | 3591 | 1.04 × 10−3 | |

| 90 | 118.1 | 3623 | 1.18 × 10−3 |

| Temperature of Annealing | Time of Annealing | Rp0.05 | Rp0.2 | Rm | Le | Lp | |

|---|---|---|---|---|---|---|---|

| T (°C) | t (min.) | (MPa) | (Mpa) | (MPa) | (mm/mm) | (MJ/m3) | (MJ/m3) |

| 20 | 374.6 | 439.5 | 464.4 | 0.02 | 0.96 | 9.1 | |

| 600 | 30 | 109.2 | 130.7 | 283.2 | 0.28 | 0.36 | 73.0 |

| 60 | 97.7 | 122.7 | 280.2 | 0.27 | 0.36 | 69.1 | |

| 90 | 97.8 | 121.6 | 277.5 | 0.28 | 0.35 | 72.5 | |

| 700 | 30 | 100.6 | 123.3 | 282.9 | 0.31 | 0.37 | 79.2 |

| 60 | 92.6 | 115.7 | 270.3 | 0.31 | 0.33 | 76.9 | |

| 90 | 88.2 | 112.5 | 267.8 | 0.31 | 0.32 | 77.0 | |

| 800 | 30 | 111.4 | 138.5 | 295.9 | 0.29 | 0.40 | 77.5 |

| 60 | 113.5 | 138.2 | 295.7 | 0.29 | 0.39 | 78.4 | |

| 90 | 113.5 | 139.5 | 294.9 | 0.29 | 0.39 | 80.7 | |

| 900 | 30 | 115.6 | 142.8 | 274.1 | 0.13 | 0.32 | 32.6 |

| 60 | 129.8 | 166.4 | 287.5 | 0.09 | 0.36 | 23.8 | |

| 90 | 124.7 | 161.1 | 284.4 | 0.08 | 0.34 | 22.7 |

| Temperature of Annealing | Time of Annealing | K | n | |

|---|---|---|---|---|

| T (°C) | t (min) | (MPa) | - | (mm/mm) |

| 20 | 520.4 | 0.022 | 5.19 × 10-3 | |

| 600 | 30 | 535.7 | 0.278 | 1.74 × 10-3 |

| 60 | 530.5 | 0.279 | 1.60 × 10-3 | |

| 90 | 525.1 | 0.278 | 1.76 × 10-3 | |

| 700 | 30 | 519.5 | 0.260 | 9.59 × 10-4 |

| 60 | 505.6 | 0.276 | 2.22 × 10-3 | |

| 90 | 503.1 | 0.281 | 2.72 × 10-3 | |

| 800 | 30 | 542.6 | 0.262 | 3.56 × 10-3 |

| 60 | 545.3 | 0.266 | 3.86 × 10-3 | |

| 90 | 548.9 | 0.276 | 4.70 × 10-3 | |

| 900 | 30 | 565.2 | 0.290 | 6.59 × 10-3 |

| 60 | 550.8 | 0.233 | 2.67 × 10-3 | |

| 90 | 532.6 | 0.222 | 9.78 × 10-4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Uścinowicz, R. Effect of Elevated Temperature and Annealing Time on Mechanical Properties of Ti/Cu Bimetal. Materials 2022, 15, 8707. https://doi.org/10.3390/ma15238707

Uścinowicz R. Effect of Elevated Temperature and Annealing Time on Mechanical Properties of Ti/Cu Bimetal. Materials. 2022; 15(23):8707. https://doi.org/10.3390/ma15238707

Chicago/Turabian StyleUścinowicz, Robert. 2022. "Effect of Elevated Temperature and Annealing Time on Mechanical Properties of Ti/Cu Bimetal" Materials 15, no. 23: 8707. https://doi.org/10.3390/ma15238707

APA StyleUścinowicz, R. (2022). Effect of Elevated Temperature and Annealing Time on Mechanical Properties of Ti/Cu Bimetal. Materials, 15(23), 8707. https://doi.org/10.3390/ma15238707