Application of ECC as a Repair/Retrofit and Pavement/Bridge Deck Material for Sustainable Structures: A Review

Abstract

:1. Introduction

2. Use of ECC as a Repair and Retrofit Material

3. Use of ECC as Pavement and Bridge Deck

4. Effective Properties Providing ECC Application for Repair/Retrofit and Pavement/Bridge Deck

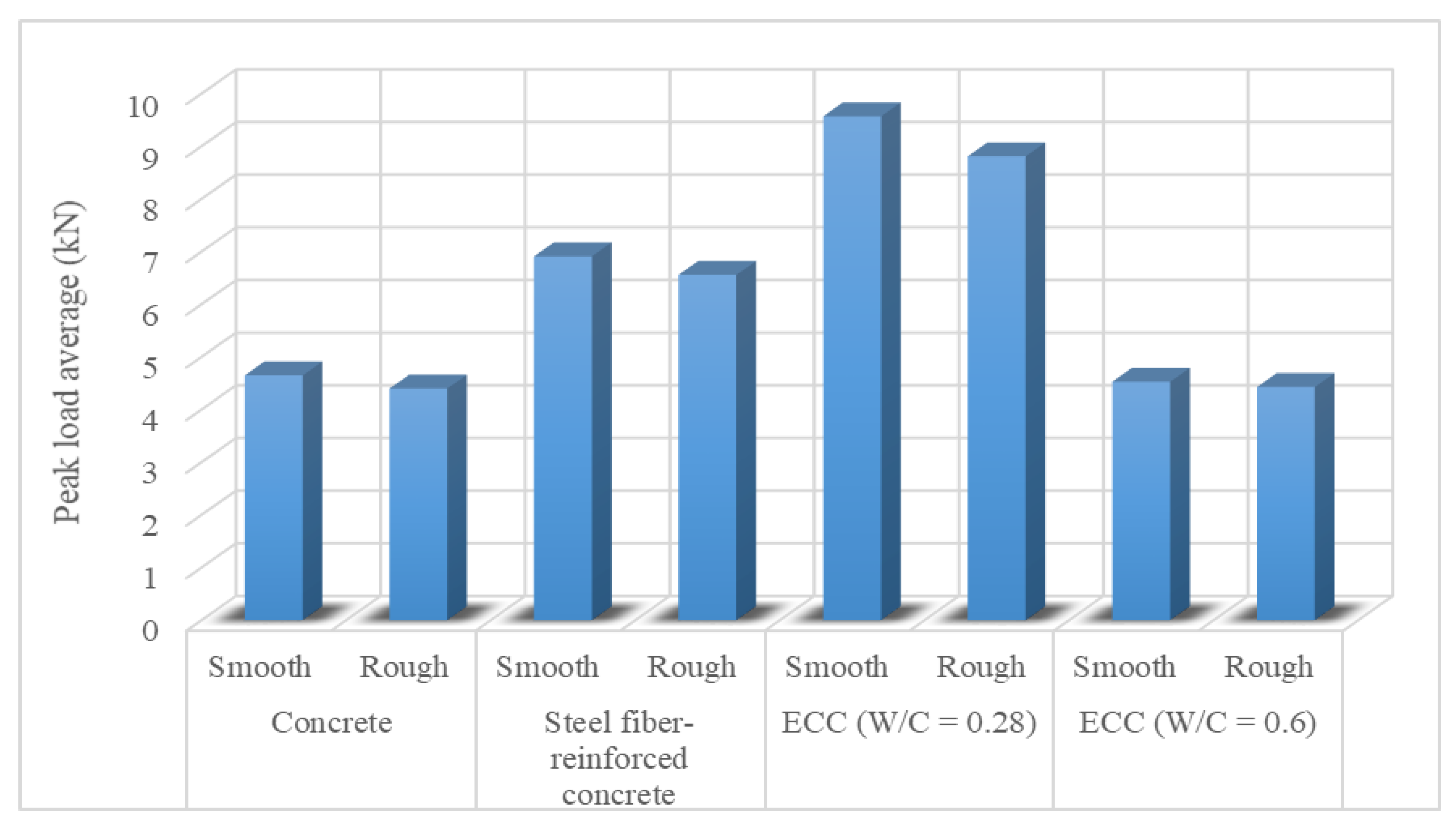

4.1. Bond Behavior of ECC

4.2. Self-Healing Property of ECC

5. Conclusions

- For repair/retrofit use, the fracture behavior performance of ECC is better than concrete and steel fiber-reinforced concrete thanks to the kink-crack trapping mechanism. The tensile bond strength and ductility performance of ECC are satisfying because of the uniquely large inelastic strain capacity. This makes ECC a suitable alternative for the repair of reinforced concrete structures, such as water tanks, where superior cracking and leakage are crucial.

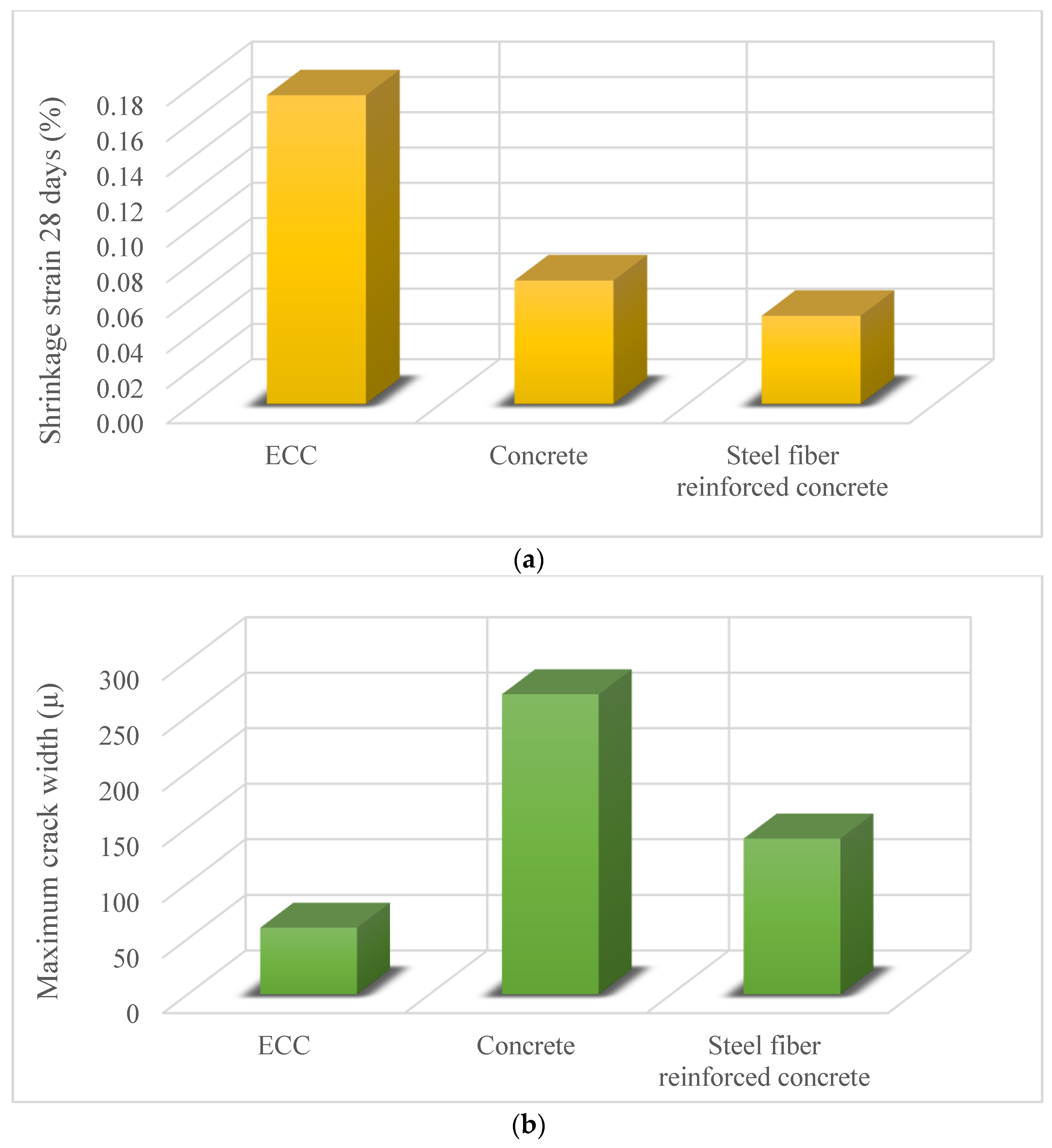

- ECC can be a solution to the high-early-strength and drying shrinkage problems frequently encountered in the use of repair materials. ECC outperforms concrete and steel fiber-reinforced concrete in terms of cracking and interface delamination.

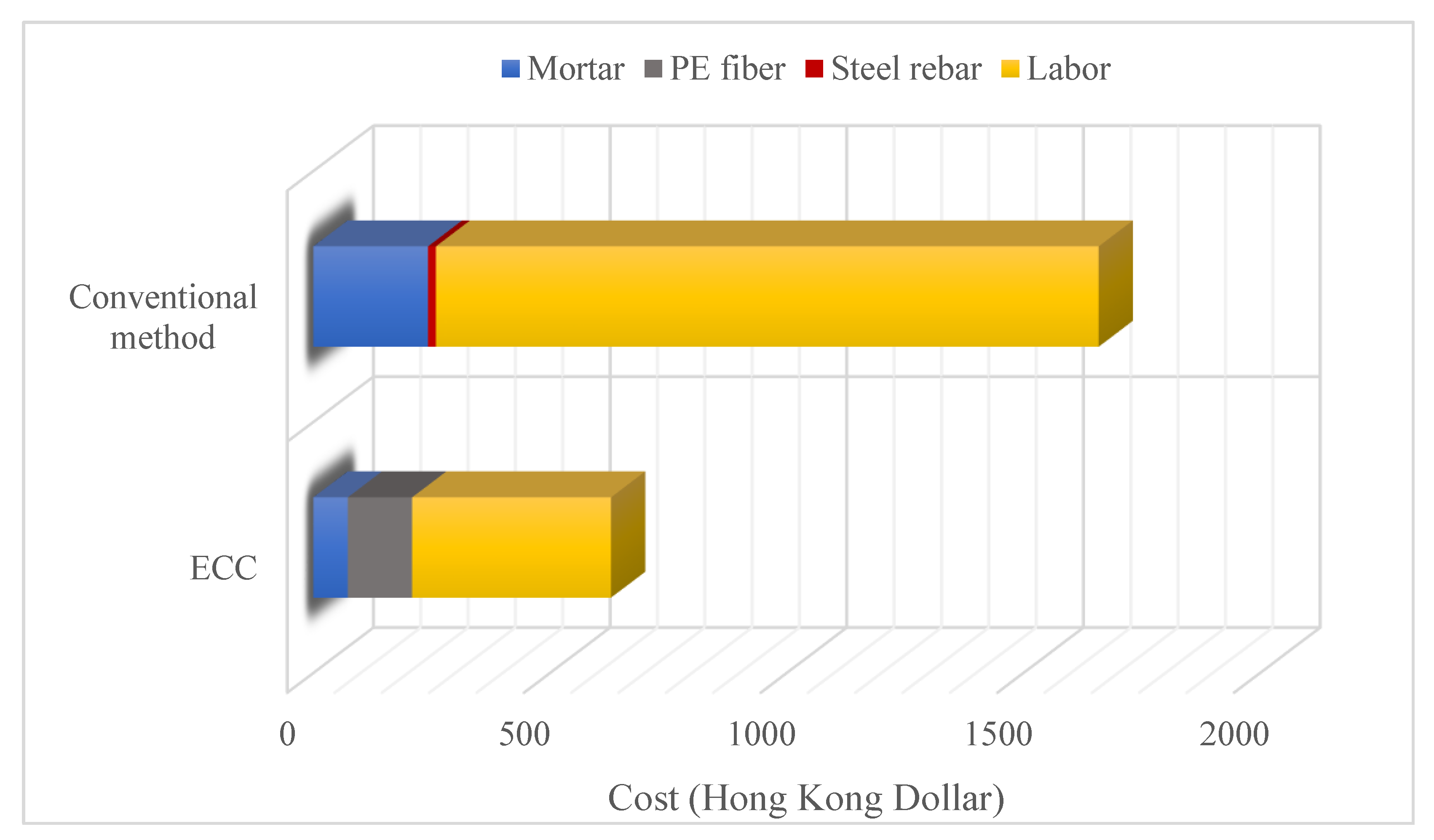

- ECC could be used in steel corrosion and beam-column joints for repair/retrofit. The repair cost using ECC is cheaper than the cost of concrete, equalling approximately 38% of the cost of concrete.

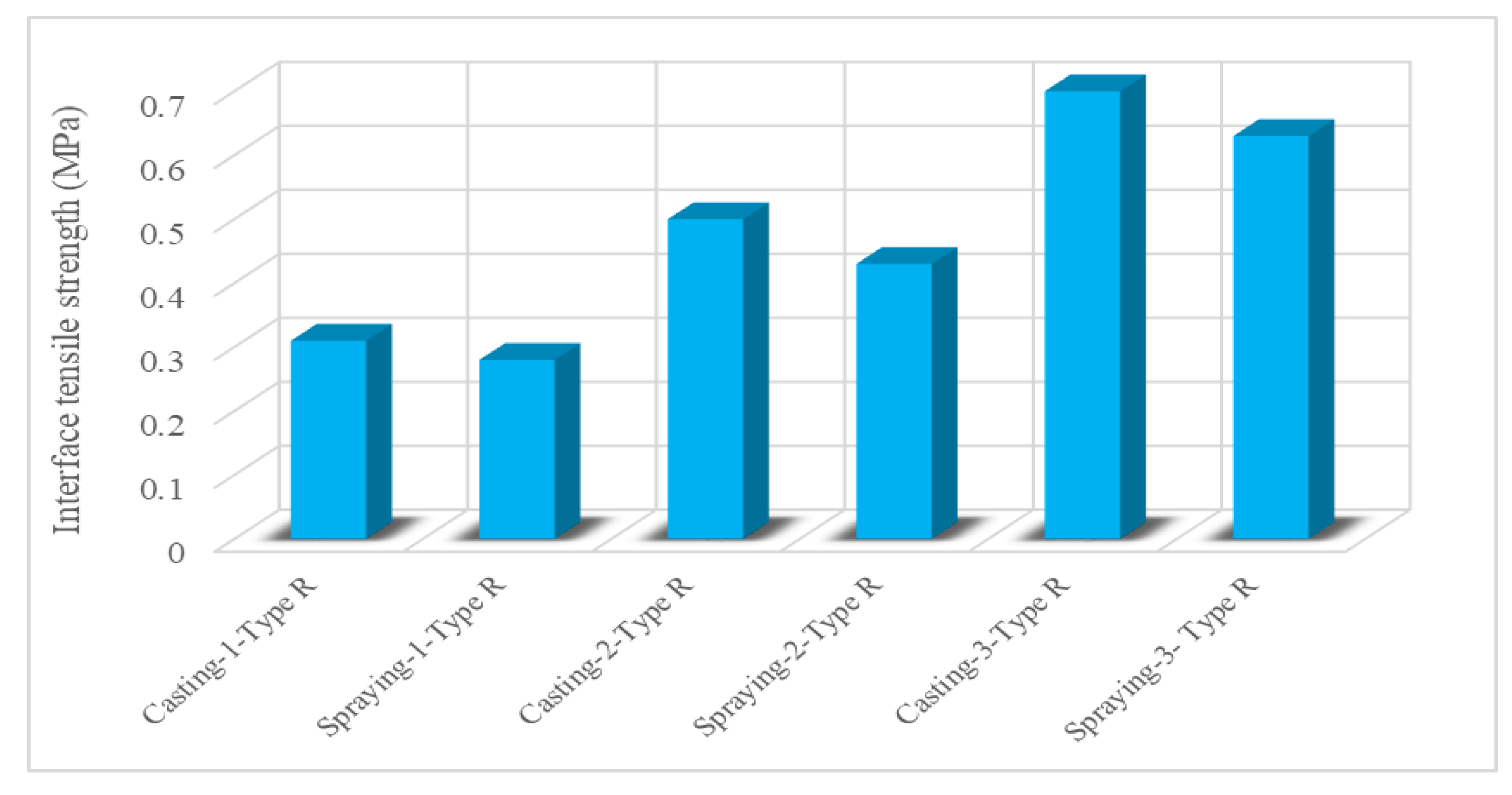

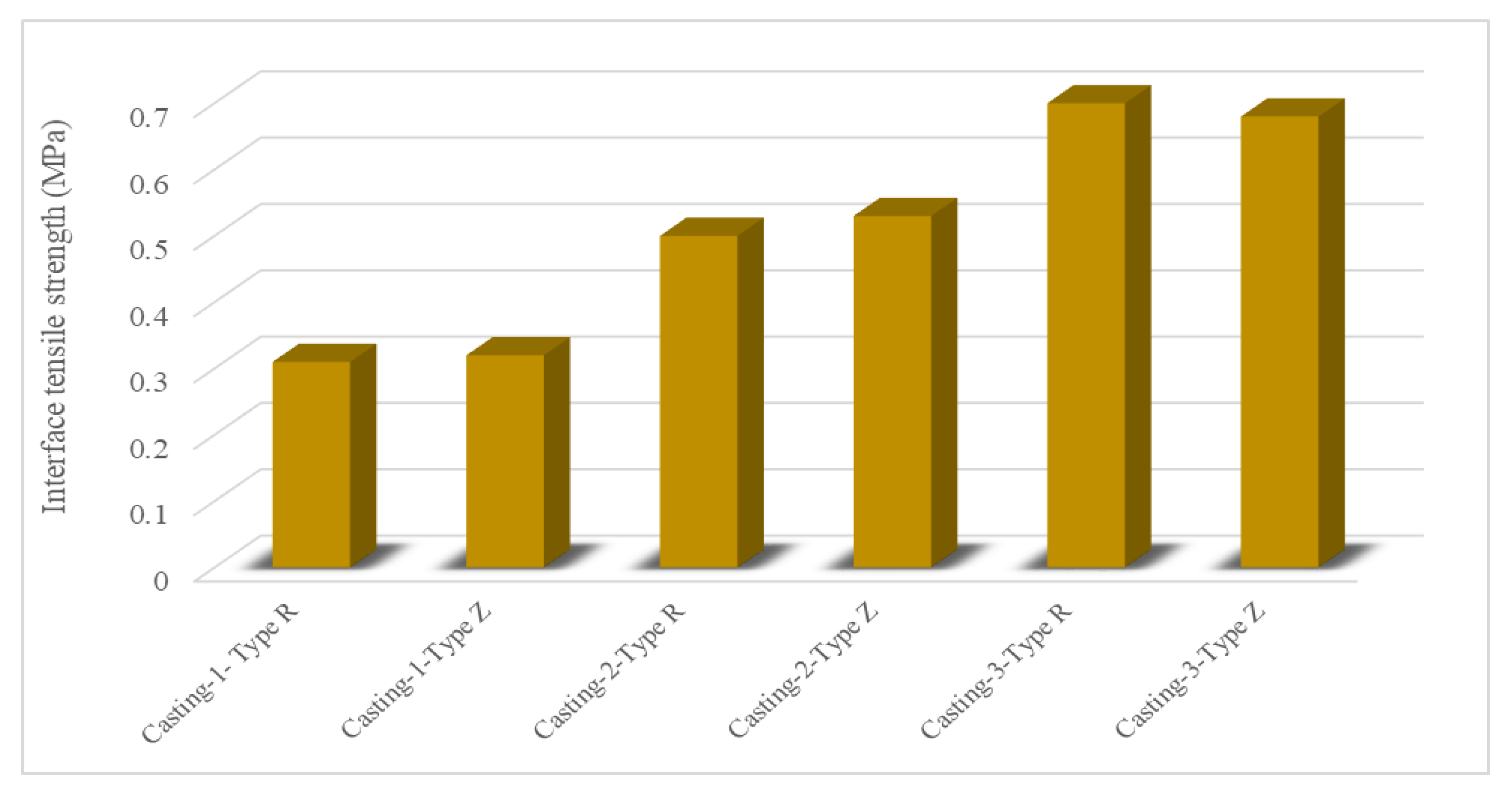

- ECC is convenient for different repair applications such as cast, sprayed, and trenchless rehabilitation. Crucially, ECC can also be used for trenchless rehabilitation of infrastructure, which is a more effective approach than open-cut.

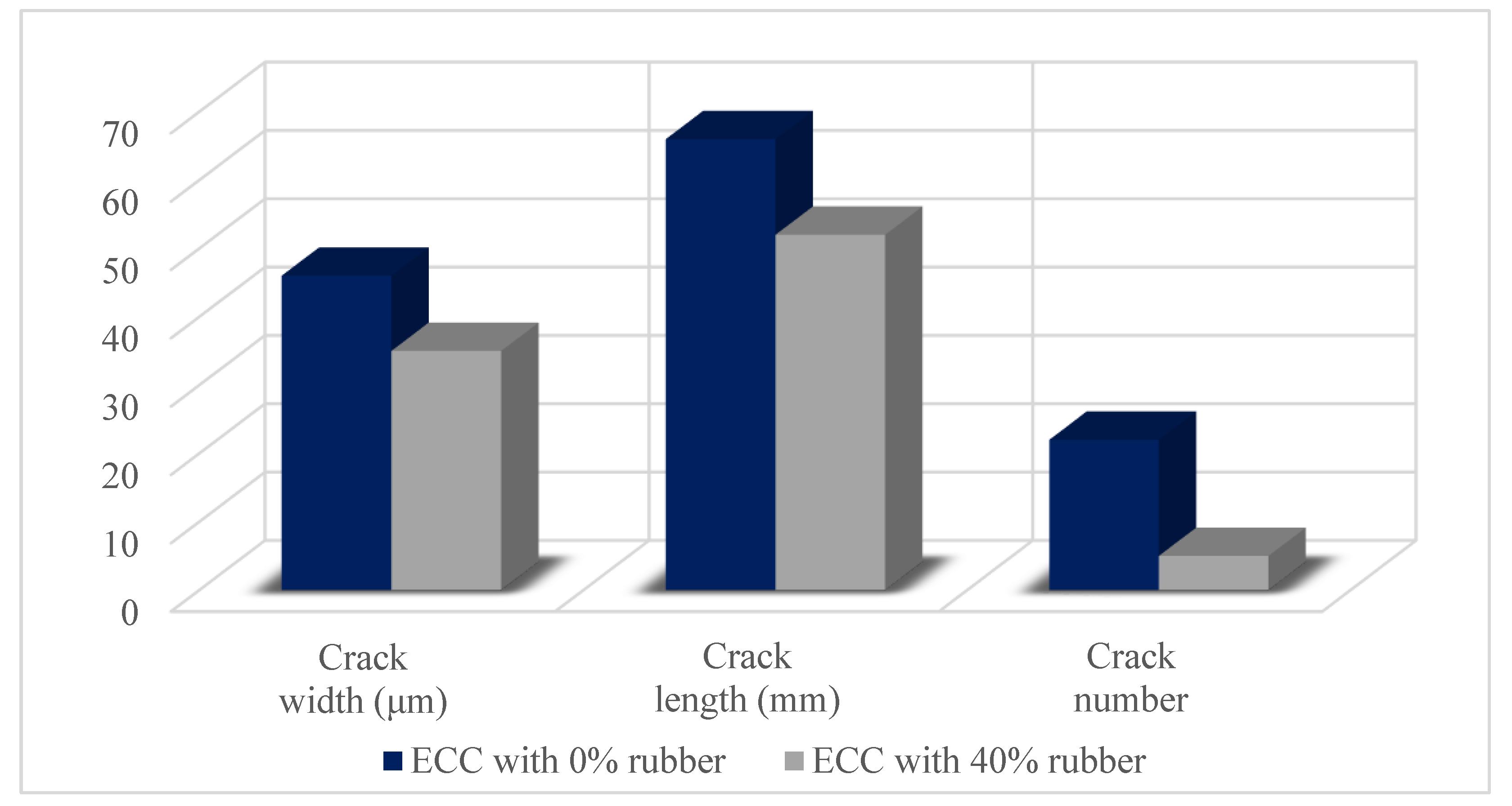

- ECC enables the use of different materials, such as recycled, bacteria, superelastic shape memory alloy, and sulfoaluminate cement. The utilization of tire rubber enhances ductility and durability, but the tensile and compressive strength of ECC with tire rubber decreases. The use of waste materials is also crucial for sustainability.

- For pavement/bridge deck use, the life cycle cost of ECC is lower than conventional concrete and hot mix asphalt because of reduced energy consumption and greenhouse gas emissions.

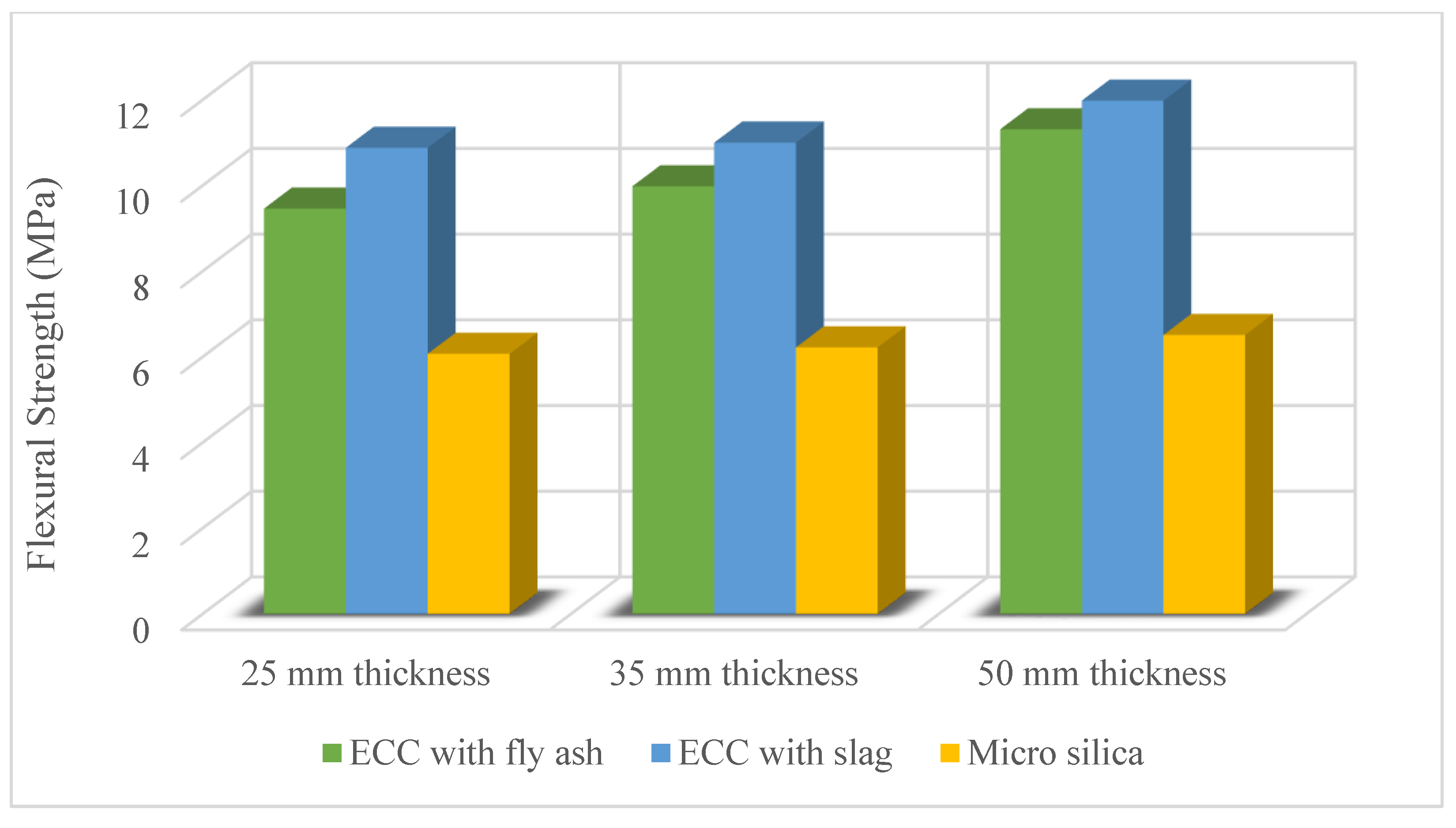

- The overlay performance of ECC is quite adequate. ECC with 25 mm thickness is better than micro-silica concrete with 50 mm thickness. Therefore, the economic life cycle analysis of ECC pavement is more sustainable than concrete overlay.

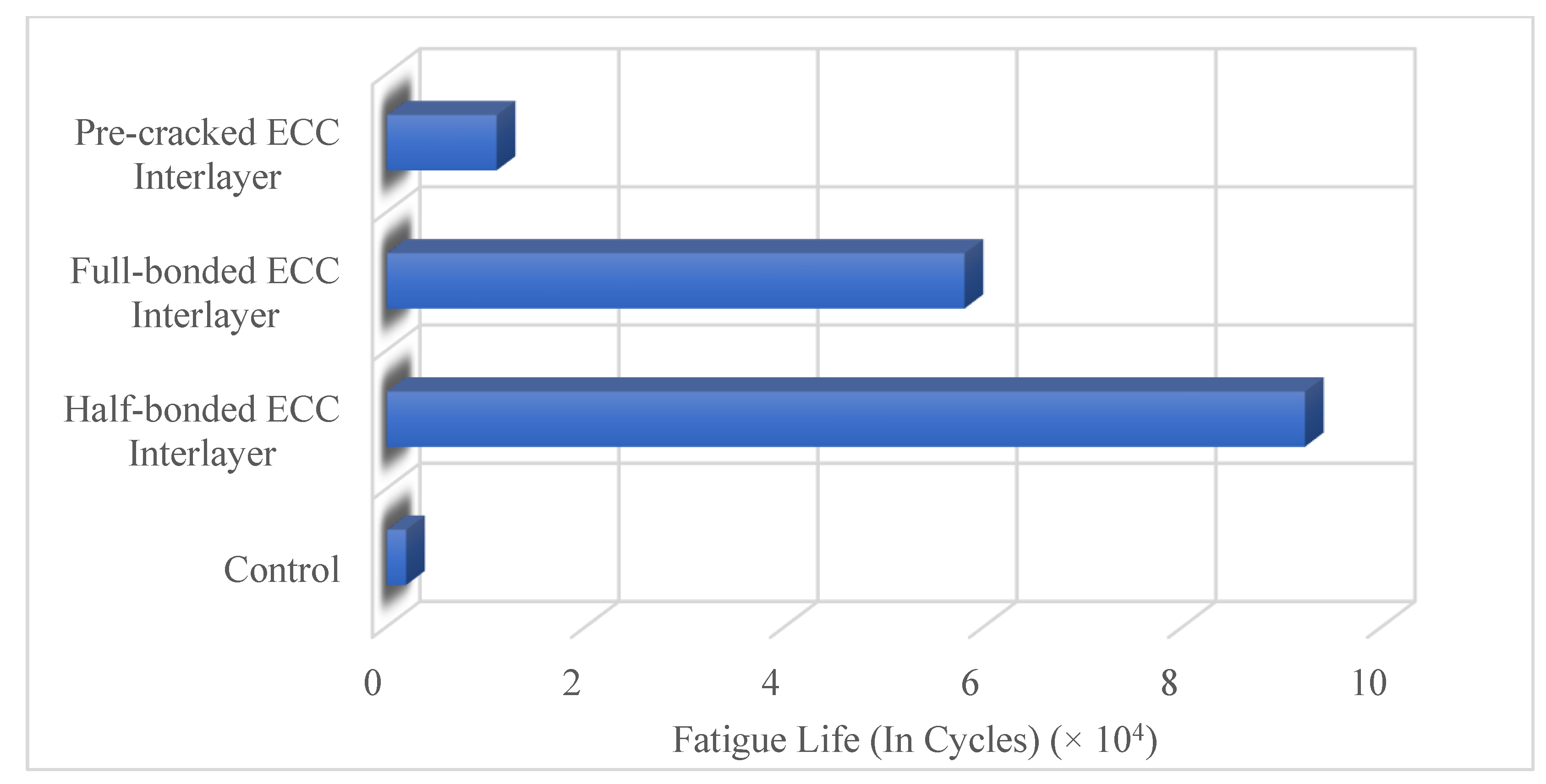

- ECC can be used as pavement, pavement overlay, tunnel pavement, airfield pavement, and bridge deck, and it also satisfies the specific requirements for these uses. ECC mitigates reflective cracks, and enhances load-bearing capacity and fatigue life. In addition, abrasion resistance and acoustic wave attenuation performance are sufficient level.

- ECC has superior bonding behavior properties. Bond behavior of ECC-steel bar, ECC overlay-conventional concrete substrate, and the tensile performance of ECC-concrete interface is satisfactory. Furthermore, bonding performance of ECCunder different conditions such as freeze-thawing and high temperatures is adequate.

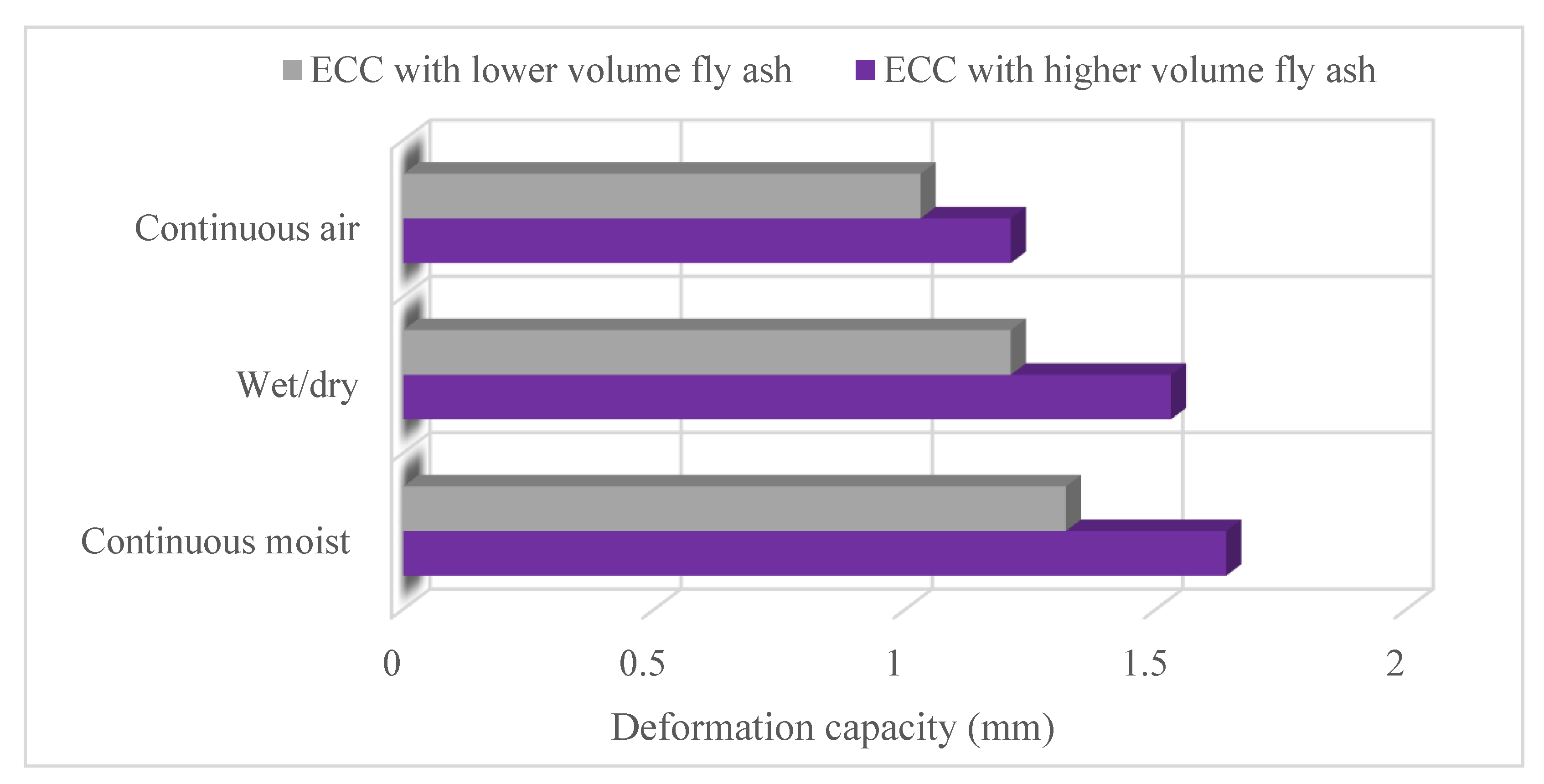

- ECC has also outstanding self-healing properties. High amounts of industrial waste (fly ash, etc.) positively affect the self-healing properties of ECC. Flexural loading on the self-healing properties of ECC and self-healing on the flexural fatigue performance of ECC are satisfactory.

- ECC is a more sustainable material than other materials because it can solve the durability problems of structures effectively, requires fewer repairs, and has a longer service life.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhu, H.; Yu, K.; Li, V.C. Sprayable Engineered Cementitious Composites (ECC) Using Calcined Clay Limestone Cement (LC3) and PP Fiber. Cem. Concr. Compos. 2021, 115, 103868. [Google Scholar] [CrossRef]

- Li, V.C. Engineered Cementitious Composites (ECC): Bendable Concrete for Sustainable and Resilient Infrastructure; Springer: Berlin/Heidelberg, Germany, 2019; pp. 1–419. [Google Scholar]

- Roghanian, N.; Banthia, N. Development of a sustainable coating and repair material to prevent bio-corrosion in concrete sewer and waste-water pipes. Cem. Concr. Compos. 2019, 100, 99–107. [Google Scholar] [CrossRef]

- Chen, W.; Feng, K.; Wang, Y.; Lin, Y.; Qian, H. Evaluation of Self-Healing Performance of a Smart Composite Material (SMA-ECC). Constr. Build. Mater. 2021, 290, 123216. [Google Scholar] [CrossRef]

- Erdoğan, T.Y. Beton; ODTÜ Gelistirme Vakfı Yayıncılık ve İletişim; Odtü Metu Press: Ankara, Turkey, 2007. [Google Scholar]

- Wang, B.; Xu, S.; Liu, F. Evaluation of tensile bonding strength between UHTCC repair materials and concrete substrate. Constr. Build. Mater. 2016, 112, 595–606. [Google Scholar] [CrossRef]

- Ahmadi, A.; Kianoush, M.R.; Moslemi, M.; Lachemi, M.; Siad, H.; Booya, E. Investigation on Repair of Tension Cracks in Reinforced Concrete Panels. Eng. Struct. 2021, 245, 112974. [Google Scholar] [CrossRef]

- Sierra-Beltran, M.G.; Jonkers, H.; Schlangen, E. Characterization of sustainable bio-based mortar for concrete repair. Constr. Build. Mater. 2014, 67, 344–352. [Google Scholar] [CrossRef]

- Koch, G.H.; Brongers, M.P.H.; Thompson, N.G.; Virmani, Y.P.; Payer, J.H. Corrosion Costs and Preventive Strategies in the United States; U.S. Federal Highway Administration, Office of Infrastructure Research and Development: Washington, DC, USA, 2002. [Google Scholar]

- Li, W.; Zhao, J.; Huang, X.; Zheng, J.; Shi, T.; Shumuye, E.D. Mechanical Properties of SAC-ECC Reinforced with Fiber-Reinforced Polymer Mesh. Constr. Build. Mater. 2022, 344, 128279. [Google Scholar] [CrossRef]

- Li, M.; Li, V.C. Influence of Material Ductility on Performance of Concrete Repair. ACI Mater. J. 2009, 106, 419–428. [Google Scholar]

- Tanaka, Y.; Kawano, H.; Watanabe, H.; Nakajo, T. Study on Cover Depth for Prestressed Concrete Bridges in Airborne-Chloride Environments. PCI J. 2006, 51, 42–53. [Google Scholar] [CrossRef]

- Lim, C.; Jeong, Y.; Kim, J.; Kwon, M. Experimental Study of Reinforced Concrete Beam-Column Joint Retrofitted by CFRP Grid with ECC and High Strength Mortar. Constr. Build. Mater. 2022, 340, 127694. [Google Scholar] [CrossRef]

- Chen, Y.; Yu, J.; Leung, C.K. Use of high strength Strain-Hardening Cementitious Composites for flexural repair of concrete structures with significant steel corrosion. Constr. Build. Mater. 2018, 167, 325–337. [Google Scholar] [CrossRef]

- Huang, X.; Ranade, R.; Ni, W.; Li, V.C. On the use of recycled tire rubber to develop low E-modulus ECC for durable concrete repairs. Constr. Build. Mater. 2013, 46, 134–141. [Google Scholar] [CrossRef]

- Mather, B.; Warner, J. Why Do Concrete Repairs Fail. Interview Held at Univ. of Wisconsin. 2003. Available online: http://aec.engr.wisc.edu/resources/rsrc07.html (accessed on 1 November 2003).

- Emberson, N.K.; Mays, G.C. Significance of property mismatch in the patch repair of structural concrete Part 1: Properties of repair systems. Mag. Concr. Res. 1990, 42, 147–160. [Google Scholar] [CrossRef]

- Emmons, P.H. Concrete Repair and Maintenance Illustrated: Problem Analysis, Repair Strategy, and Techniques; John Wiley & Sons: Hoboken, NJ, USA, 1992. [Google Scholar]

- Li, M.; Li, V.C. Behavior of ECC/Concrete Layered Repair System Under Drying Shrinkage Conditions / Das Verhalten Eines Geschichteten Instandsetzungssystems Aus ECC Und Beton Unter Der Einwirkung von Trocknungsschwinden. Restor. Build. Monum. 2006, 12, 143–160. [Google Scholar] [CrossRef]

- Emmons, P.H.; Vaysburd, A.M.; McDonald, J.E. Rational Approach to Durable Concrete Repairs. Concr. Int. 1993, 15, 40–45. [Google Scholar]

- Li, M.; Li, V.C. High-Early-Strength Engineered Cementitious Composites for Fast, Durable Concrete Repair—Material Properties. ACI Mater. J. 2011, 108, 3–12. [Google Scholar] [CrossRef]

- Li, V.C.; Horii, H.; Kabele, P.; Kanda, T.; Lim, Y. Repair and retrofit with engineered cementitious composites. Eng. Fract. Mech. 2000, 65, 317–334. [Google Scholar] [CrossRef] [Green Version]

- Lim, Y.M.; Li, V.C. Durable Repair of Aged Infrastructures Using Trapping Mechanism of Engineered Cementitious Composites. Cem. Concr. Compos. 1997, 19, 373–385. [Google Scholar] [CrossRef]

- Ma, H.; Zhang, Z. Paving an engineered cementitious composite (ECC) overlay on concrete airfield pavement for reflective cracking resistance. Constr. Build. Mater. 2020, 252, 119048. [Google Scholar] [CrossRef]

- Kamada, T.; Li, V.C. The Effects of Surface Preparation on the Fracture Behavior of ECC/Concrete Repair System. Cem. Concr. Compos. 2000, 22, 423–431. [Google Scholar] [CrossRef]

- Kim, Y.Y.; Fischer, G.; Lim, Y.M.; Li, V.C. Mechanical Performance of Sprayed Engineered Cementitious Composite Using Wet-Mix Shotcreting Process for Repair Applications. ACI Mater. J. 2004, 101, 42–49. [Google Scholar] [CrossRef]

- Da Costa, F.; Righi, D.; Graeff, A.; Filho, L.D.S. Experimental study of some durability properties of ECC with a more environmentally sustainable rice husk ash and high tenacity polypropylene fibers. Constr. Build. Mater. 2019, 213, 505–513. [Google Scholar] [CrossRef]

- Tian, J.; Wu, X.; Wang, W.-W.; Hu, S.; Tan, X.; Du, Y.; Zheng, Y.; Sun, C. Experimental study and mechanics model of ECC-to-concrete bond interface under tensile loading. Compos. Struct. 2022, 285, 115203. [Google Scholar] [CrossRef]

- Li, V.C. On Engineered Cementitious Composites (ECC) A Review of the Material and Its Applications. J. Adv. Concr. Technol. 2003, 1, 215–230. [Google Scholar] [CrossRef] [Green Version]

- Şahmaran, M.; Li, V.C. Engineered Cementitious Composites: Can Composites Be Accepted as Crack-Free Concrete? Transp. Res. Rec. J. Transp. Res. Board 2010, 2164, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Li, V.C. High Performance Fiber Reinforced Cementitious Composites as Durable Material for Concrete Structure Repair / Faser Verstärkte, Zement Gebundene, Zusammen Gesetzte Hochleistungswerkstoffe Für Das Dauerhafte Instandsetzen von Betontragwerken. Restor. Build. Monum. 2004, 10, 163–180. [Google Scholar] [CrossRef]

- Said, S.H.; Razak, H.A.; Othman, I. Strength and Deformation Characteristics of Engineered Cementitious Composite Slabs with Different Polymer Fibres. J. Reinf. Plast. Compos. 2015, 34, 1950–1962. [Google Scholar] [CrossRef]

- Halvaei, M.; Jamshidi, M.; Latifi, M. Application of Low Modulus Polymeric Fibers in Engineered Cementitious Composites. J. Ind. Text. 2014, 43, 511–524. [Google Scholar] [CrossRef]

- Rathod, J.D.; Patodi, S.C. Interface Tailoring of Polyester-Type Fiber in Engineered Cementitious Composite Matrix against Pullout. ACI Mater. J. 2010, 107, 114–122. [Google Scholar] [CrossRef]

- Yücel, H.E.; Öz, H.; Güneş, M.; Kaya, Y. Rheological properties, strength characteristics and flexural performances of engineered cementitious composites incorporating synthetic wollastonite microfibers with two different high aspect ratios. Constr. Build. Mater. 2021, 306, 124921. [Google Scholar] [CrossRef]

- Dutkiewicz, M.; Yücel, H.E.; Yıldızhan, F. Evaluation of the Performance of Different Types of Fibrous Concretes Produced by Using Wollastonite. Materials 2022, 15, 6904. [Google Scholar] [CrossRef] [PubMed]

- Fu, C.; Chen, M.; Guo, R.; Qi, R. Green-Engineered Cementitious Composite Production with High-Strength Synthetic Fiber and Aggregate Replacement. Materials 2022, 15, 3047. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Zhang, Z.; Yu, J.; Xiao, J.; Xu, Q. Using Green Supplementary Materials to Achieve More Ductile ECC. Materials 2019, 12, 858. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Şahmaran, M.; Lachemi, M.; Hossain, K.M.; Li, V.C. Internal curing of engineered cementitious composites for prevention of early age autogenous shrinkage cracking. Cem. Concr. Res. 2009, 39, 893–901. [Google Scholar] [CrossRef]

- Yang, Y.; Yang, E.-H.; Li, V. Autogenous healing of engineered cementitious composites at early age. Cem. Concr. Res. 2011, 41, 176–183. [Google Scholar] [CrossRef]

- Şahmaran, M.; Li, V.C. Durability properties of micro-cracked ECC containing high volumes fly ash. Cem. Concr. Res. 2009, 39, 1033–1043. [Google Scholar] [CrossRef]

- Zhou, Y.; Fu, H.; Li, P.; Zhao, D.; Sui, L.; Li, L. Bond behavior between steel bar and engineered cementitious composite (ECC) considering lateral FRP confinement: Test and modeling. Compos. Struct. 2019, 226, 111206. [Google Scholar] [CrossRef]

- Ding, Y.; Yu, K.; Li, M. A Review on High-Strength Engineered Cementitious Composites (HS-ECC): Design, Mechanical Property and Structural Application. Structures 2022, 35, 903–921. [Google Scholar] [CrossRef]

- Li, V.C.; Wang, S.; Wu, C. Tensile Strain-Hardening Behavior of Polyvinyl Alcohol Engineered Cementitious Composite (PVA-ECC). ACI Mater. J. 2001, 98, 483–492. [Google Scholar] [CrossRef]

- Gao, S.; Xie, P. Effect of Temperatures and Moisture Content on the Fracture Properties of Engineered Cementitious Composites (ECC). Materials 2022, 15, 2604. [Google Scholar] [CrossRef]

- Zhu, H.; Wang, T.; Wang, Y.; Li, V.C. Trenchless rehabilitation for concrete pipelines of water infrastructure: A review from the structural perspective. Cem. Concr. Compos. 2021, 123, 104193. [Google Scholar] [CrossRef]

- Zhu, H.; Zhang, D.; Li, V.C. Centrifugally Sprayed Engineered Cementitious Composites: Rheology, Mechanics, and Structural Retrofit for Concrete Pipes. Cem. Concr. Compos. 2022, 129, 104473. [Google Scholar] [CrossRef]

- Yucel, H.E.; Jashami, H.; Sahmaran, M.; Guler, M.; Yaman, I.O. Thin ECC Overlay Systems for Rehabilitation of Rigid Concrete Pavements. Mag. Concr. Res. 2013, 65, 108–120. [Google Scholar] [CrossRef]

- Li, X.; Li, M.; Song, G. Energy-Dissipating and Self-Repairing SMA-ECC Composite Material System. Smart Mater. Struct. 2015, 24, 025024. [Google Scholar] [CrossRef]

- Pan, B.; Liu, F.; Zhuge, Y.; Zeng, J.-J.; Liao, J. ECCs/UHPFRCCs with and without FRP reinforcement for structural strengthening/repairing: A state-of-the-art review. Constr. Build. Mater. 2021, 316, 125824. [Google Scholar] [CrossRef]

- Zhou, S.; Xie, L.; Jia, Y.; Wang, C. Review of Cementitious Composites Containing Polyethylene Fibers as Repairing Materials. Polymers 2020, 12, 2624. [Google Scholar] [CrossRef]

- Wu, J.; Liu, X.; Chew, S.H. Parametric Study on Cement-Based Soft-Hard-Soft (SHS) Multi-Layer Composite Pavement against Blast Load. Constr. Build. Mater. 2015, 98, 602–619. [Google Scholar] [CrossRef]

- Bawono, A.A.; Lechner, B.; Yang, E.-H. Skid resistance and surface water drainage performance of engineered cementitious composites for pavement applications. Cem. Concr. Compos. 2019, 104, 103387. [Google Scholar] [CrossRef]

- Zhang, H.; Keoleian, G.A.; Lepech, M.D. An Integrated Life Cycle Assessment and Life Cycle Analysis Model for Pavement Overlay Systems. Life Cycle Civ. Eng. 2008, 927–932. [Google Scholar] [CrossRef]

- Arce, G.A.; Noorvand, H.; Hassan, M.M.; Rupnow, T.; Dhakal, N. Feasibility of low fiber content PVA-ECC for jointless pavement application. Constr. Build. Mater. 2021, 268, 121131. [Google Scholar] [CrossRef]

- Bawono, A.A.; Tan, Z.H.; Hamdany, A.H.; NguyenDinh, N.; Qian, S.; Lechner, B.; Yang, E.-H. Bright and slip-proof engineered cementitious composites with visible light activated photo-catalysis property for pavement in tunnels. Cem. Concr. Compos. 2020, 114, 103788. [Google Scholar] [CrossRef]

- Das, A.; Bhuyan, M.R.; Khattak, M.J.; Zhang, Q. Mitigating reflective cracking in composite pavements through the use of a ductile concrete interlayer. Constr. Build. Mater. 2020, 259, 120383. [Google Scholar] [CrossRef]

- Yücel, H.E. Frost resistance of layered concrete systems incorporating ECC as overlay materials. Adv. Concr. Constr. 2021, 12, 227–241. [Google Scholar] [CrossRef]

- Qian, S.; Li, V.; Zhang, H.; Keoleian, G. Life cycle analysis of pavement overlays made with Engineered Cementitious Composites. Cem. Concr. Compos. 2013, 35, 78–88. [Google Scholar] [CrossRef]

- Pranav, S.; Lahoti, M.; Shan, X.; Yang, E.-H.; Muthukumar, G. Economic input-output LCA of precast corundum-blended ECC overlay pavement. Resour. Conserv. Recycl. 2022, 184, 106385. [Google Scholar] [CrossRef]

- Hungria, R.; Arce, G.; Hassan, M.; Anderson, M.; Mahdi, M.; Rupnow, T.; Bogus, S.M. Evaluation of novel jointless engineered cementitious composite ultrathin whitetopping (ECC-UTW) overlay. Constr. Build. Mater. 2020, 265, 120659. [Google Scholar] [CrossRef]

- Wu, C.; Pan, Y.; Ueda, T. Characterization of the Abrasion Resistance and the Acoustic Wave Attenuation of the Engineered Cementitious Composites for Runway Pavement. Constr. Build. Mater. 2018, 174, 537–546. [Google Scholar] [CrossRef]

- Pan, Y.; Wu, C.; Cheng, X.; Li, V.; He, L. Impact fatigue behaviour of GFRP mesh reinforced engineered cementitious composites for runway pavement. Constr. Build. Mater. 2020, 230, 116898. [Google Scholar] [CrossRef]

- Ma, H.; Zhang, Z.; Ding, B.; Tu, X. Investigation on the Adhesive Characteristics of Engineered Cementitious Composites (ECC) to Steel Bridge Deck. Constr. Build. Mater. 2018, 191, 679–691. [Google Scholar] [CrossRef]

- Chu, K.; Hossain, K.M.A.; Lachemi, M. Fatigue Behavior of GFRP-Reinforced ECC Link Slabs under Variable Stress Levels and Number of Cycles. Eng. Struct. 2020, 222, 111130. [Google Scholar] [CrossRef]

- Wu, S.; Yang, J.; Yang, R.; Zhu, J.; Sun, X. Self-healing acceleration and interface optimization of steel deck pavement with MgO and SAP. Constr. Build. Mater. 2021, 266, 121139. [Google Scholar] [CrossRef]

- Diab, A.M.; Elyamany, H.E.; Hussein, M.A.; Al Ashy, H.M. Bond behavior and assessment of design ultimate bond stress of normal and high strength concrete. Alex. Eng. J. 2014, 53, 355–371. [Google Scholar] [CrossRef]

- Şahmaran, M.; Yücel, H.E.; Yildirim, G.; Al-Emam, M.; Lachemi, M. Investigation of the Bond between Concrete Substrate and ECC Overlays. J. Mater. Civ. Eng. 2014, 26, 167–174. [Google Scholar] [CrossRef]

- Chang, H.; Feng, H.; Guo, Z.; Guo, A.; Wang, Y. Bond Properties of Magnesium Phosphate Cement-Based Engineered Cementitious Composite with Ordinary Concrete. Materials 2022, 15, 4851. [Google Scholar] [CrossRef]

- Zhang, P.; Shang, J.-Q.; Fan, J.-J.; Chen, Q.-Z.; Zhu, H.; Gao, D.-Y.; Sheikh, S.A. Experimental study on the shear performance of the CFRP plate-ECC-concrete composite interface. J. Build. Eng. 2022, 45, 103446. [Google Scholar] [CrossRef]

- Zhang, P.; Shang, J.-Q.; Fan, J.-J.; Chen, Q.-Z.; Zhu, H.; Gao, D.-Y.; Sheikh, S.A. Experimental study on the bond behavior of the CFRP plate-ECC-concrete composite interface under freeze–thaw cycles. Constr. Build. Mater. 2022, 316, 125822. [Google Scholar] [CrossRef]

- Gao, S.; Zhao, X.; Qiao, J.; Guo, Y.; Hu, G. Study on the bonding properties of Engineered Cementitious Composites (ECC) and existing concrete exposed to high temperature. Constr. Build. Mater. 2019, 196, 330–344. [Google Scholar] [CrossRef]

- Rajczakowska, M.; Habermehl-Cwirzen, K.; Hedlund, H.; Cwirzen, A. Autogenous Self-Healing: A Better Solution for Concrete. J. Mater. Civ. Eng. 2019, 31, 03119001. [Google Scholar] [CrossRef]

- Herbert, E.N.; Li, V.C. Self-Healing of Microcracks in Engineered Cementitious Composites (ECC) Under a Natural Environment. Materials 2013, 6, 2831–2845. [Google Scholar] [CrossRef] [Green Version]

- Sahmaran, M.; Yildirim, G.; Erdem, T.K. Self-Healing Capability of Cementitious Composites Incorporating Different Supplementary Cementitious Materials. Cem. Concr. Compos. 2013, 35, 89–101. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Z.; Zhang, Q. Self-Healing Ability of Engineered Cementitious Composites (ECC) under Different Exposure Environments. Constr. Build. Mater. 2017, 156, 142–151. [Google Scholar] [CrossRef]

- Özbay, E.; Şahmaran, M.; Lachemi, M.; Yücel, H.E. Self-Healing of Microcracks in High-Volume Fly-Ash-Incorporated Engineered Cementitious Composites. ACI Mater. J. 2013, 110, 33–43. [Google Scholar] [CrossRef]

- Özbay, E.; Sahmaran, M.; Yücel, H.E.; Erdem, T.K.; Lachemi, M.; Li, V.C. Effect of Sustained Flexural Loading on Self-Healing of Engineered Cementitious Composites. J. Adv. Concr. Technol. 2013, 11, 167–179. [Google Scholar] [CrossRef] [Green Version]

- Qiu, J.; Aw-Yong, W.L.; Yang, E.-H. Effect of self-healing on fatigue of engineered cementitious composites (ECCs). Cem. Concr. Compos. 2018, 94, 145–152. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yücel, H.E.; Dutkiewicz, M.; Yıldızhan, F. Application of ECC as a Repair/Retrofit and Pavement/Bridge Deck Material for Sustainable Structures: A Review. Materials 2022, 15, 8752. https://doi.org/10.3390/ma15248752

Yücel HE, Dutkiewicz M, Yıldızhan F. Application of ECC as a Repair/Retrofit and Pavement/Bridge Deck Material for Sustainable Structures: A Review. Materials. 2022; 15(24):8752. https://doi.org/10.3390/ma15248752

Chicago/Turabian StyleYücel, Hasan Erhan, Maciej Dutkiewicz, and Fatih Yıldızhan. 2022. "Application of ECC as a Repair/Retrofit and Pavement/Bridge Deck Material for Sustainable Structures: A Review" Materials 15, no. 24: 8752. https://doi.org/10.3390/ma15248752

APA StyleYücel, H. E., Dutkiewicz, M., & Yıldızhan, F. (2022). Application of ECC as a Repair/Retrofit and Pavement/Bridge Deck Material for Sustainable Structures: A Review. Materials, 15(24), 8752. https://doi.org/10.3390/ma15248752