Preparation of Wide-Domain pH Color-Changing Nanocapsules and Application in Hydrogel Fibers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

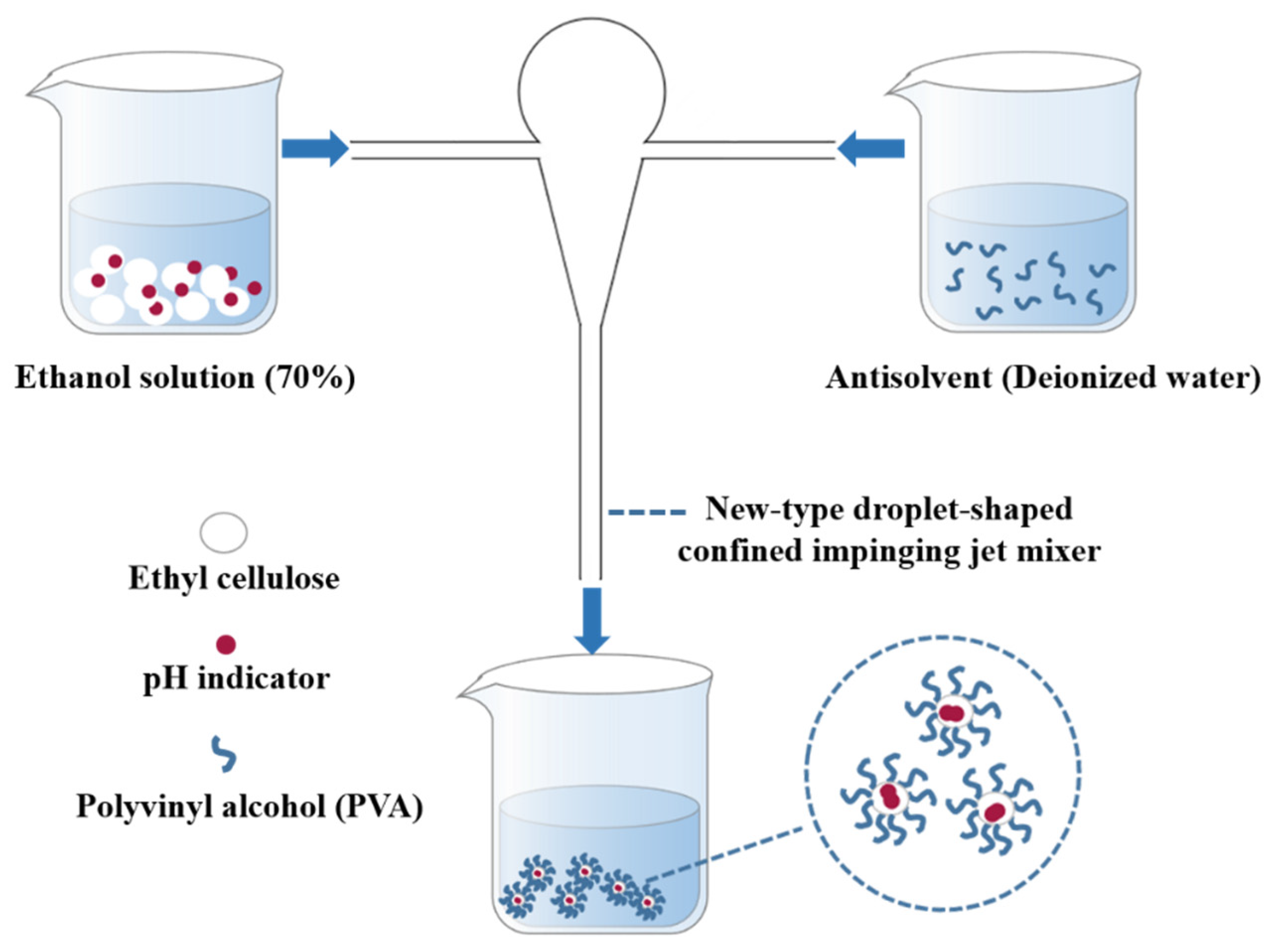

2.2. Preparation of Nanocapsules

2.3. Characterization Method

2.3.1. Scanning Electron Microscopy

2.3.2. Fourier Transform Infrared Spectroscopy (FTIR)

2.3.3. Particle Size and Distribution Test

2.3.4. Zeta Potential Test

2.3.5. Encapsulation Efficiency (EE%)

2.3.6. pH Color-Changing Responsiveness Test

2.3.7. Statistical Analysis

3. Results and Discussion

3.1. Formation Principle of the Nanocapsules

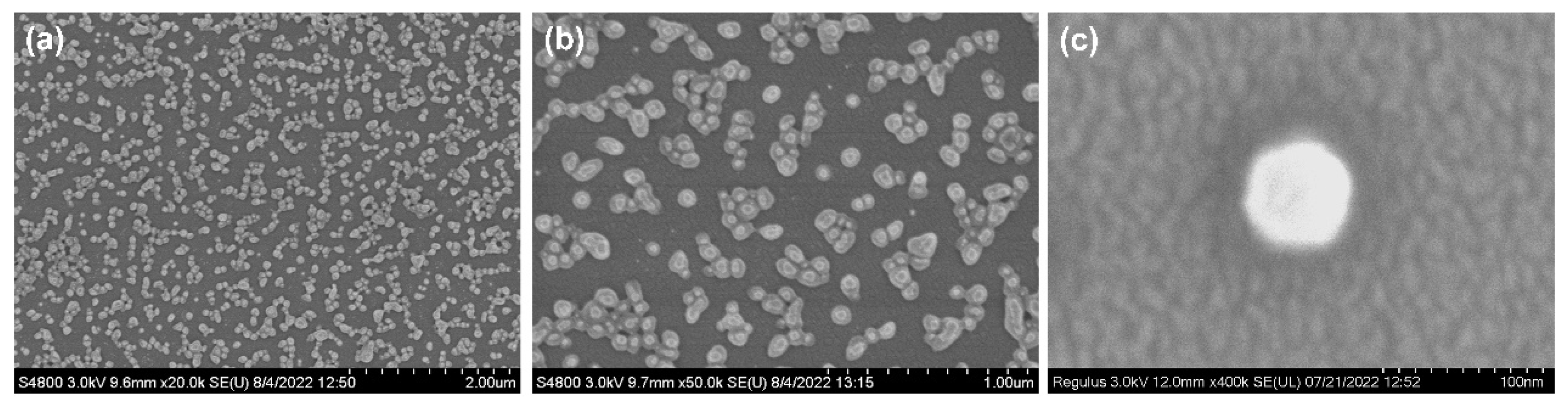

3.2. Microscopic Morphology and Structure

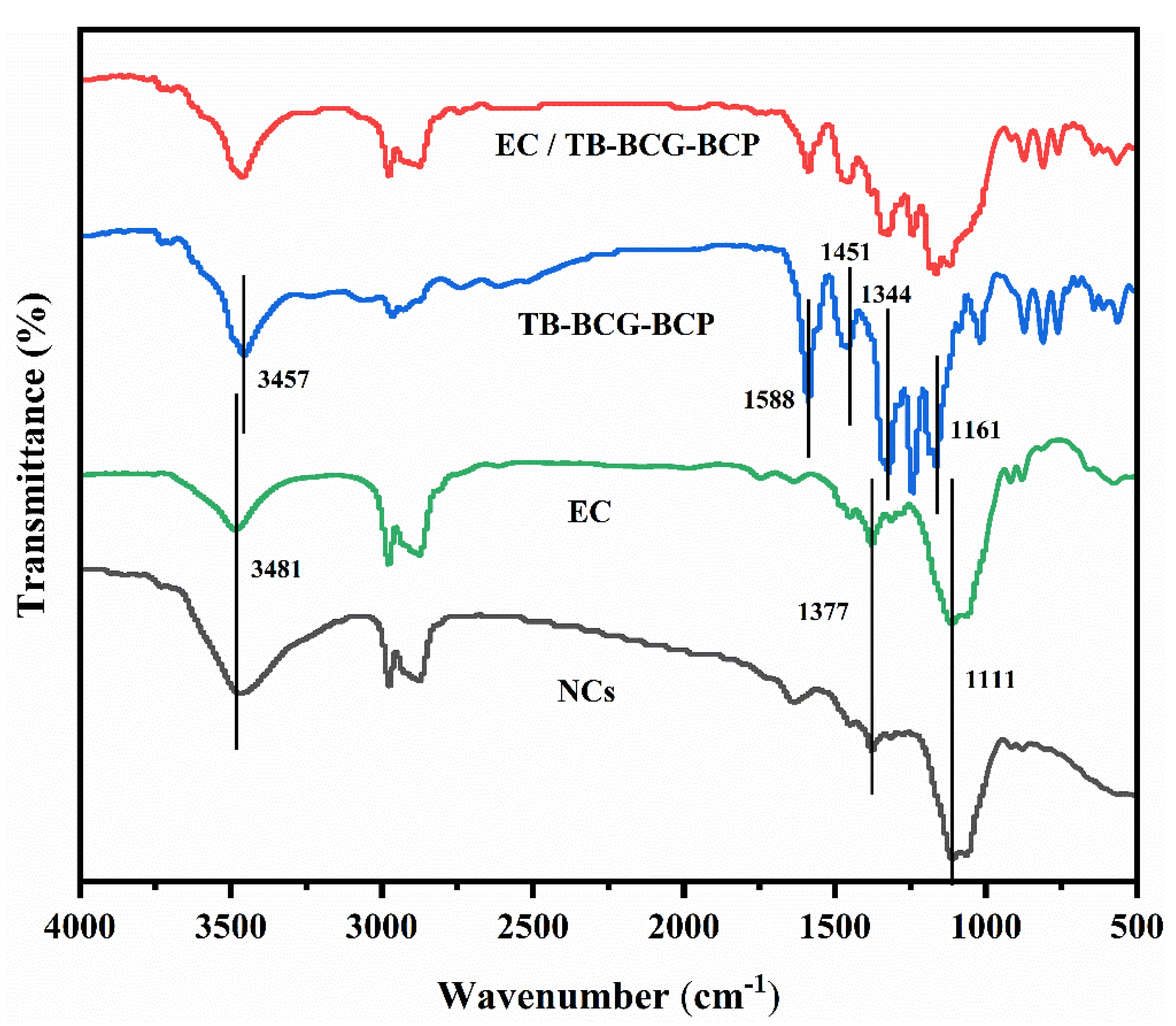

3.3. FTIR Analysis of the Nanocapsules

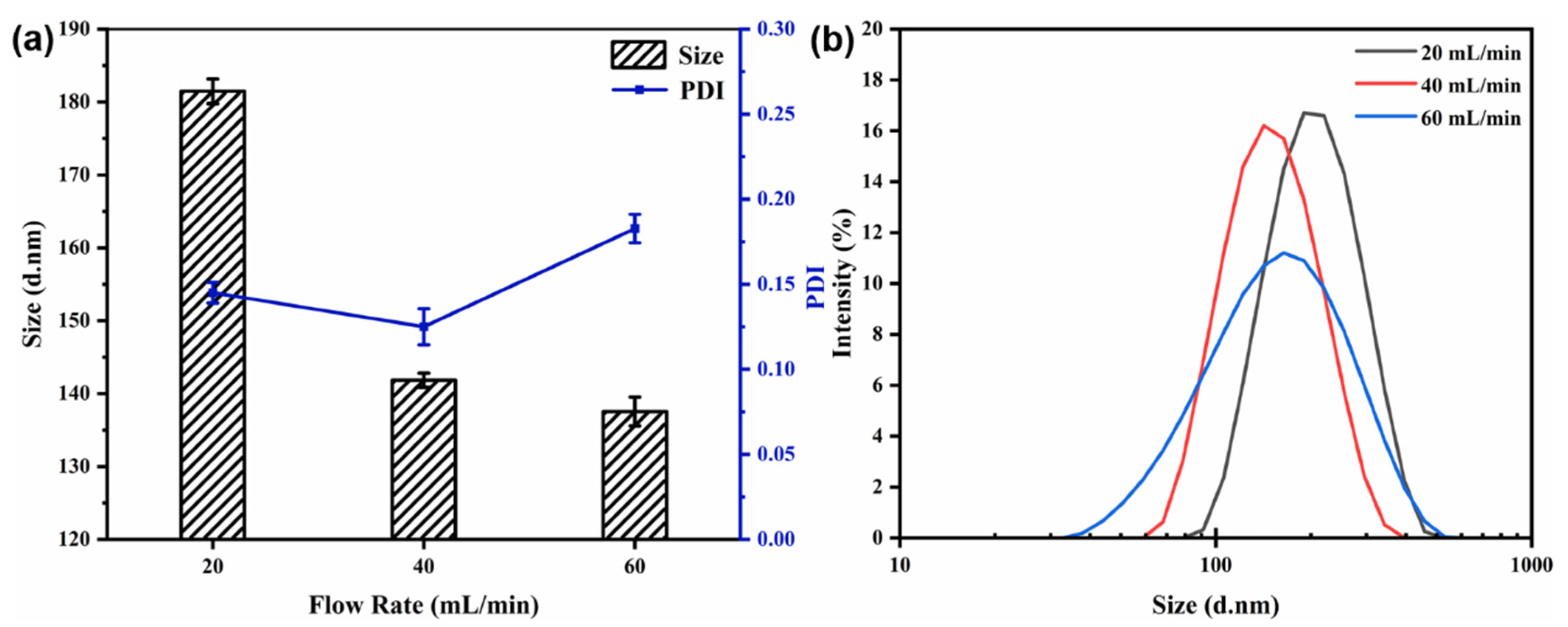

3.4. Particle Size and Distribution

3.4.1. Effect of the Flow Rate

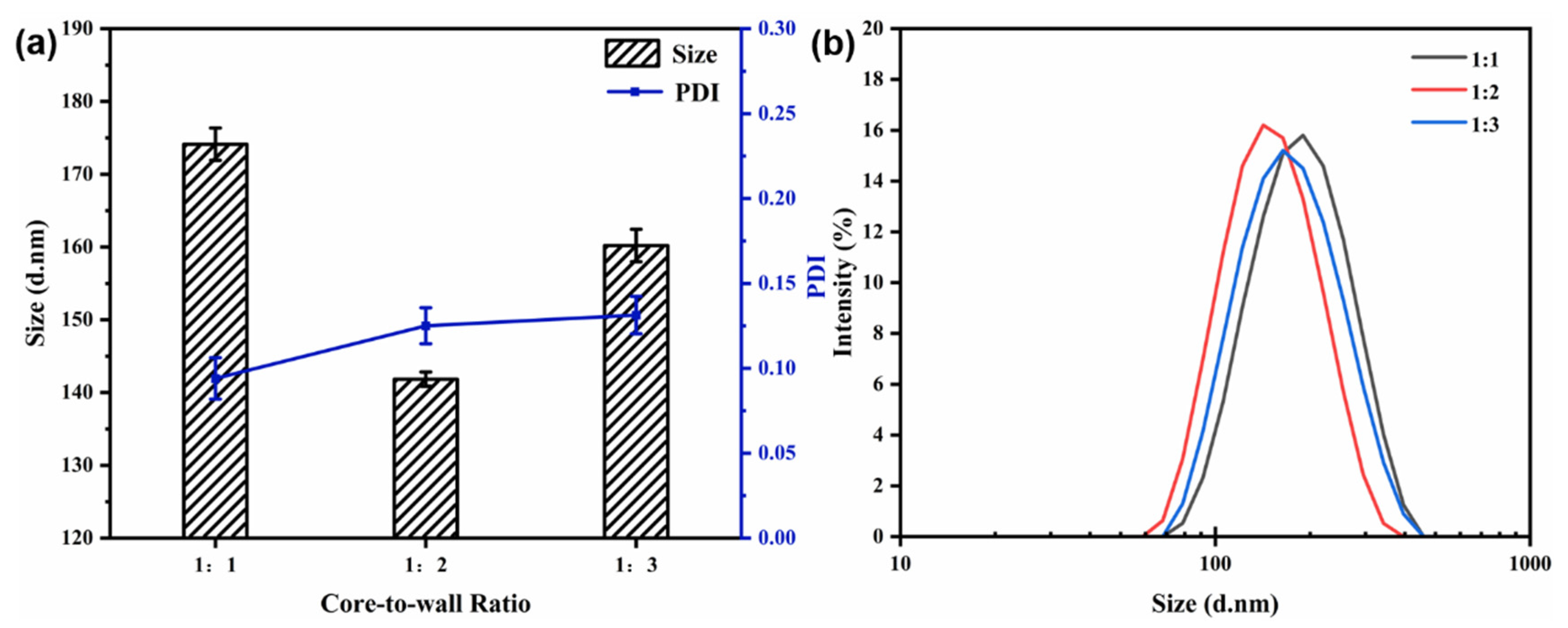

3.4.2. Effect of the Core-to-Wall Ratio

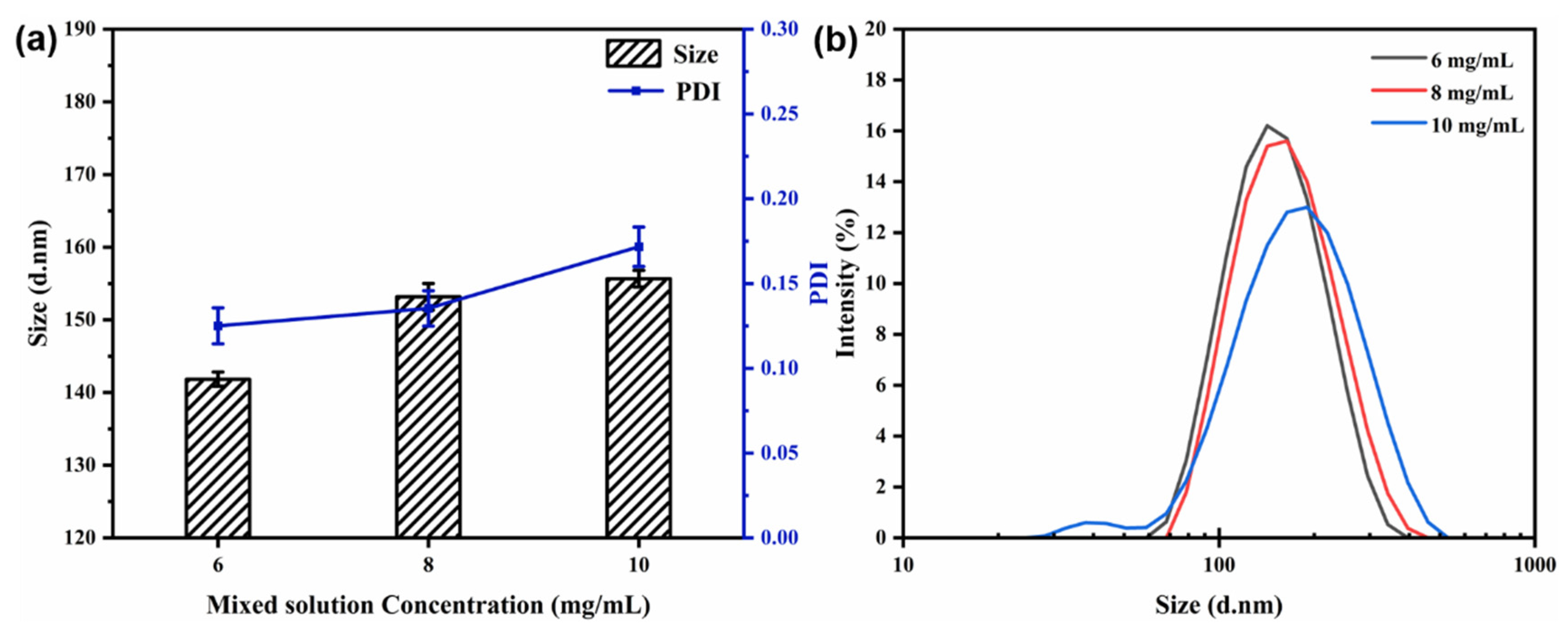

3.4.3. Effect of Mixed Solution Concentration

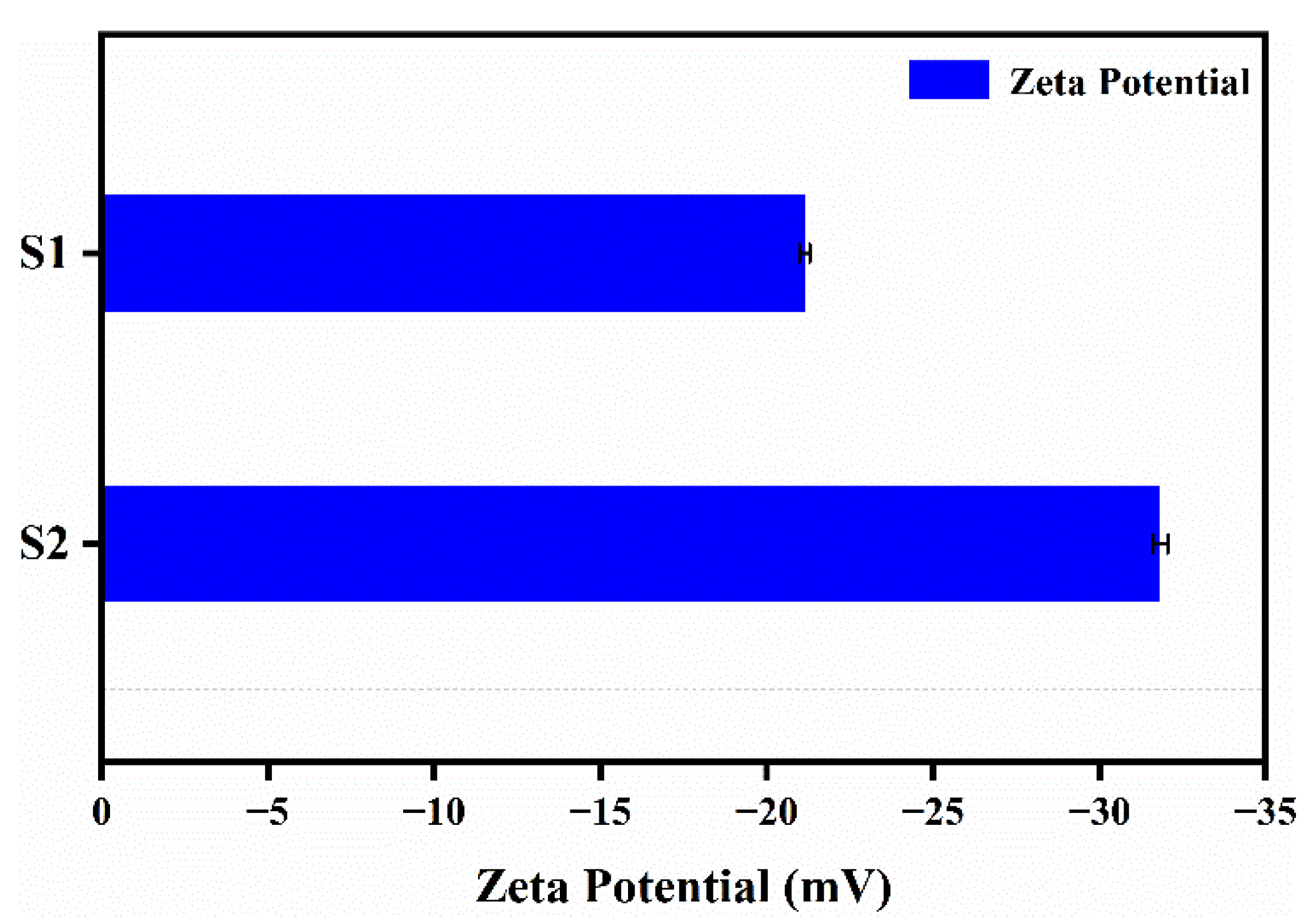

3.5. Dispersion Stability of Nanocapsules

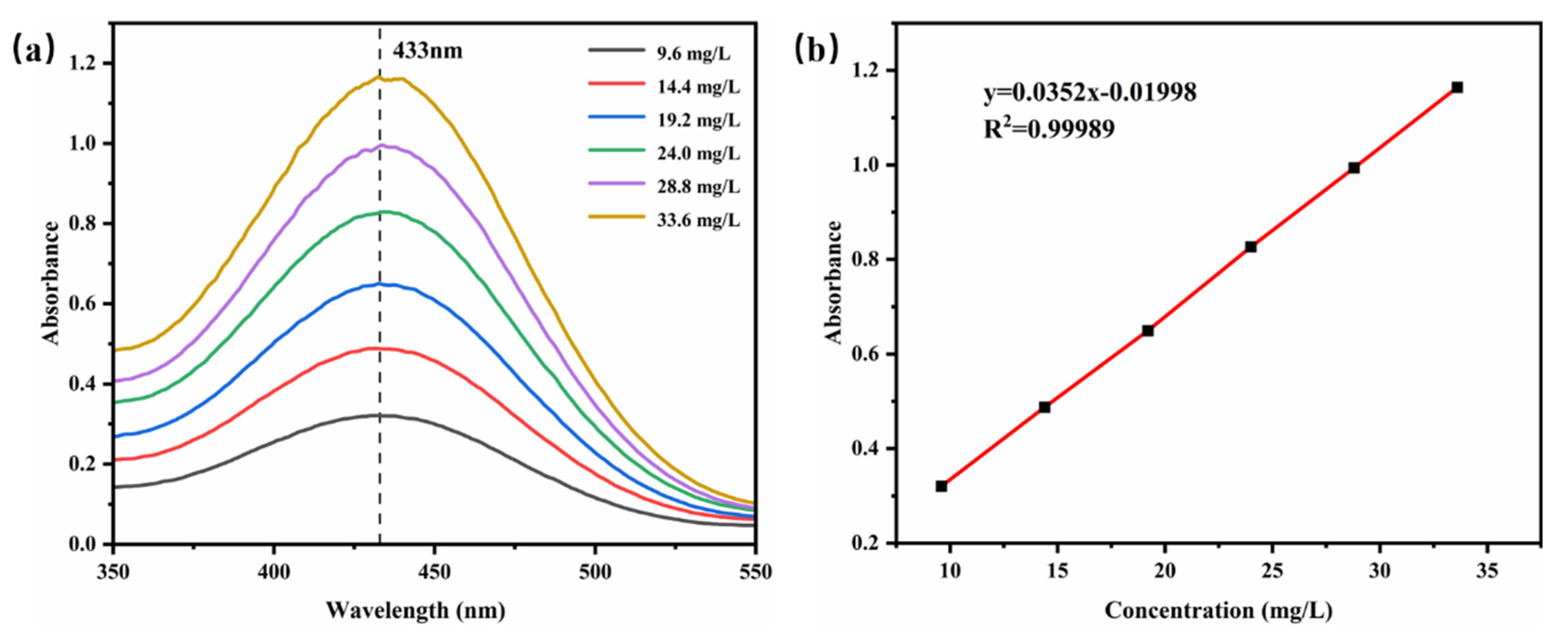

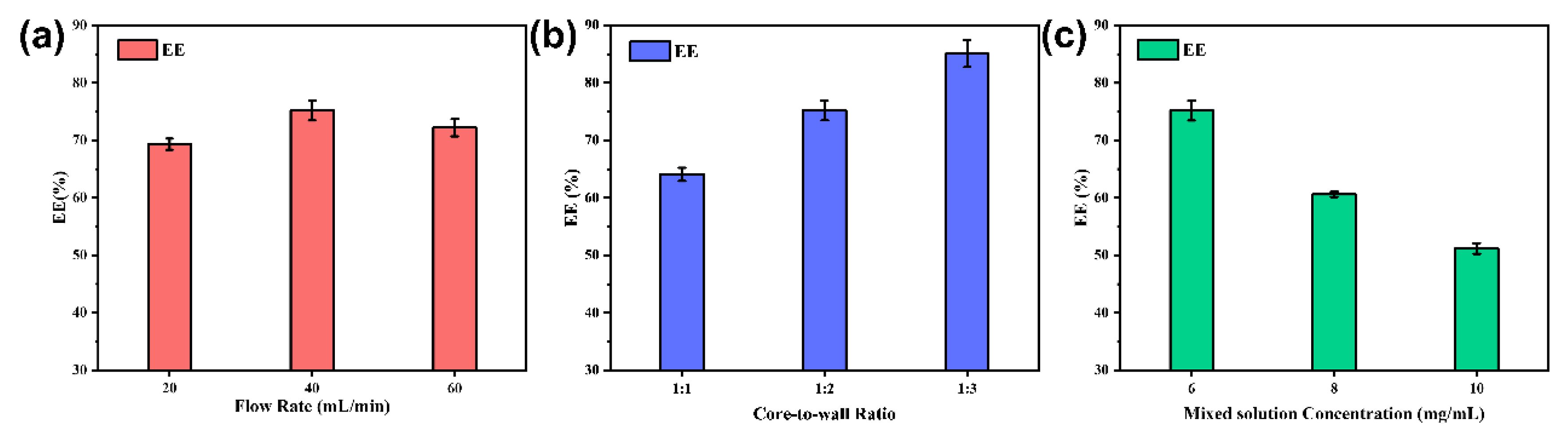

3.6. Encapsulation Efficiency (EE%)

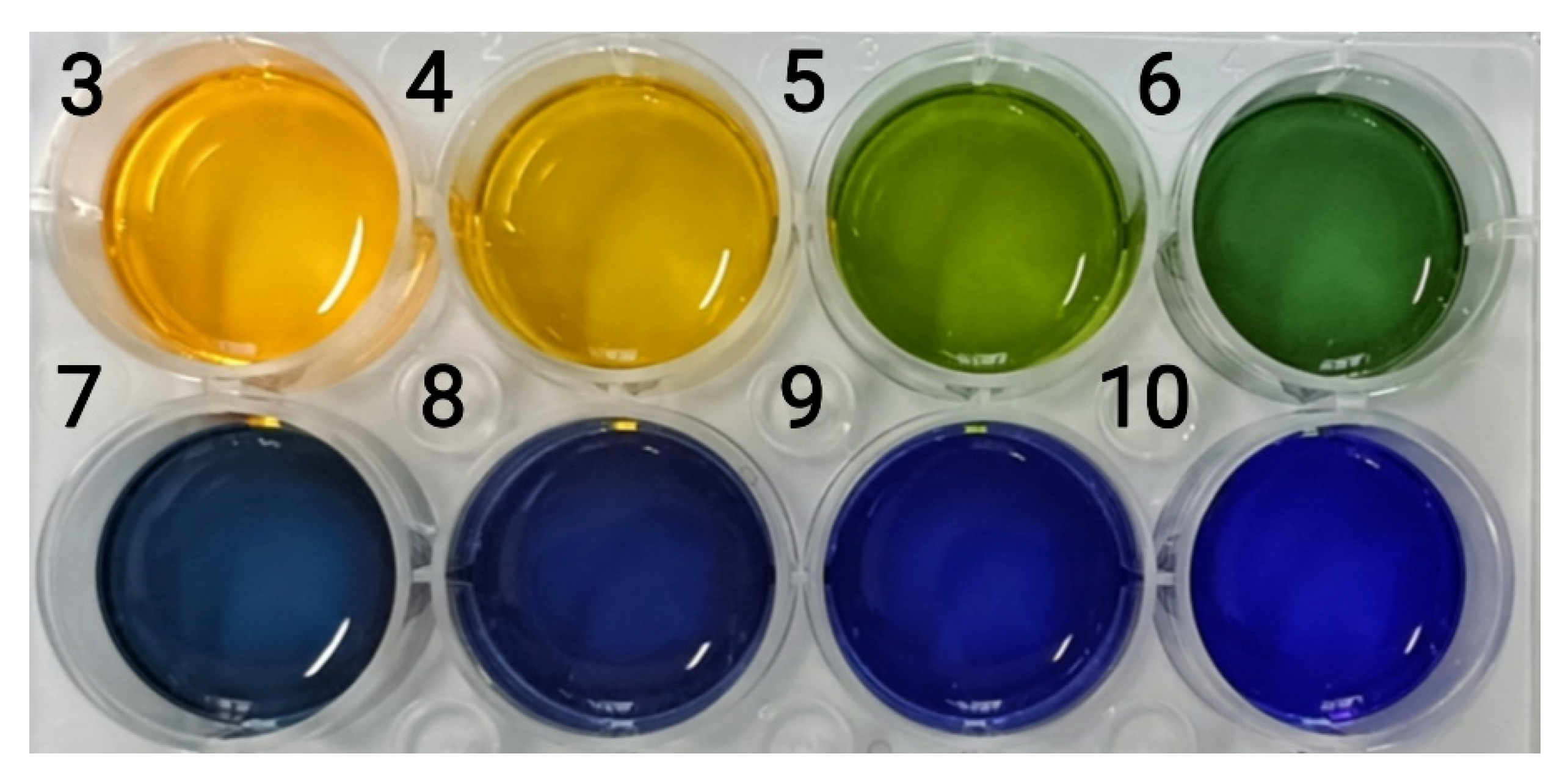

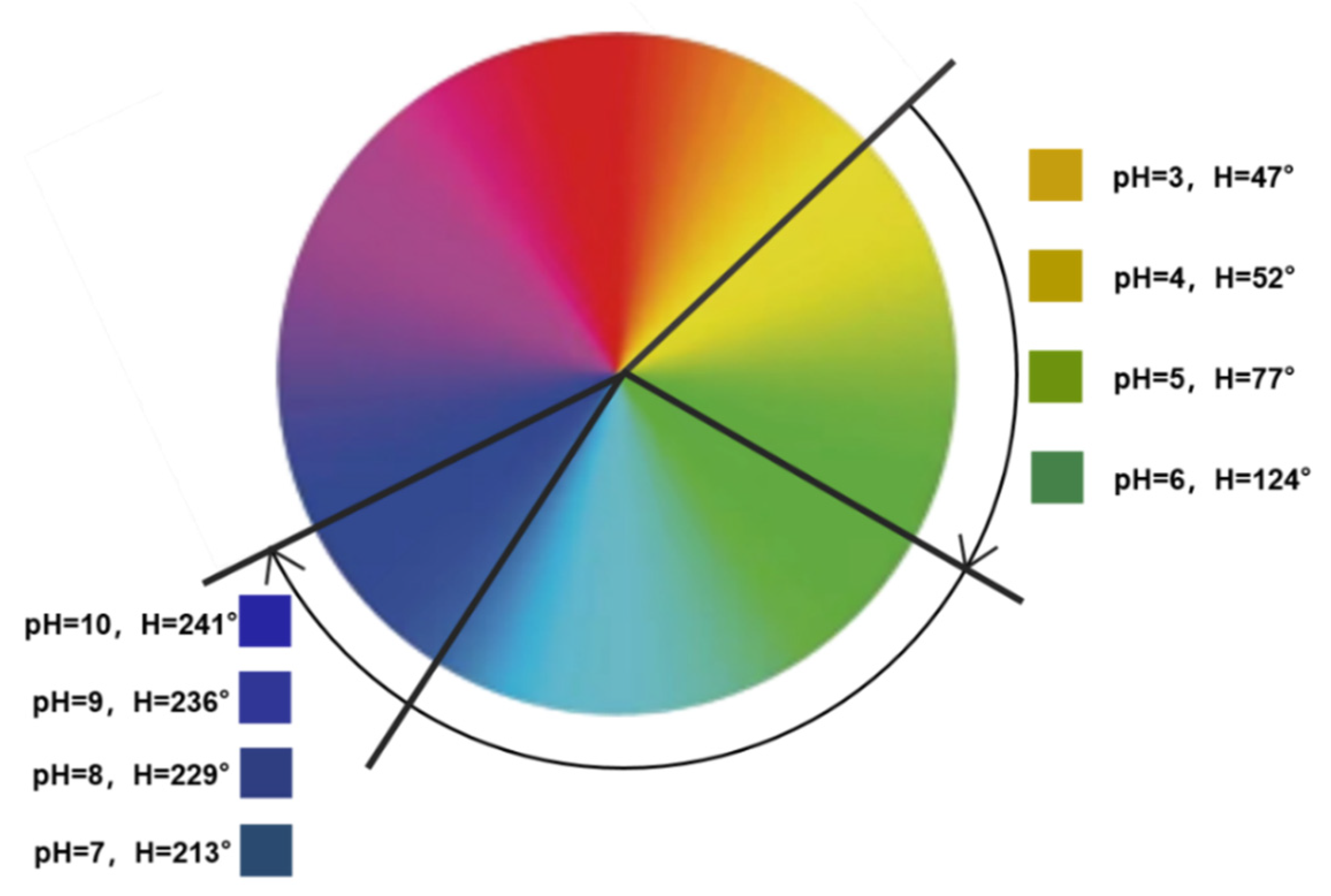

3.7. Color Responsiveness of pH

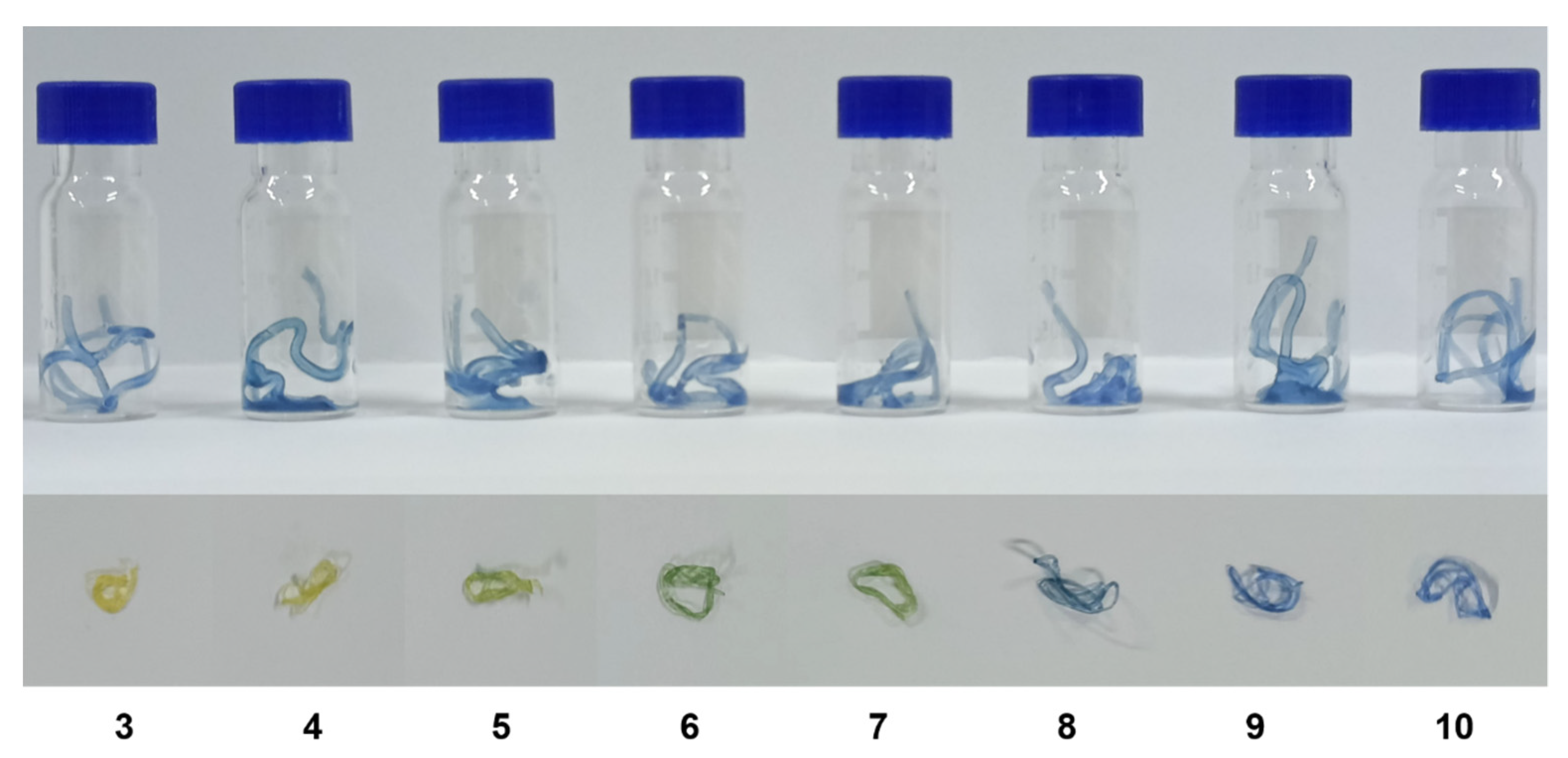

4. Application of Sodium Alginate Hydrogel Fibers

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Balbinot-Alfaro, E.; Craveiro, D.V.; Lima, K.O.; Costa, H.L.G.; Lopes, D.R.; Prentice, C. Intelligent Packaging with PH Indicator Potential. Food Eng. Rev. 2019, 11, 235–244. [Google Scholar] [CrossRef]

- Van der Schueren, L.; De Clerck, K. The Use of PH-Indicator Dyes for PH-Sensitive Textile Materials. Text. Res. J. 2010, 80, 590–603. [Google Scholar] [CrossRef]

- Liu, L.; Li, X.; Nagao, M.; Elias, A.; Narain, R.; Chung, H.-J. A PH-Indicating Colorimetric Tough Hydrogel Patch towards Applications in a Substrate for Smart Wound Dressings. Polymers 2017, 9, 558. [Google Scholar] [CrossRef] [Green Version]

- Carrillo-Carrion, C.; Parak, W.J. Multiplexed Fluorophore-Nanoparticle Hybrids for Extending the Range of PH Measurements. Small Methods 2017, 1, 1700153. [Google Scholar] [CrossRef]

- Zhang, J.; Tan, J.; Chen, X.; Yin, Y.; Wang, C. High Humidity-Sensitive Discoloration Materials Fabricated with PH Indicator Ingredients. Dyes Pigment. 2021, 195, 109740. [Google Scholar] [CrossRef]

- Jun-Ling, J.; Shui-Lin, C.; Xu-Jie, Y.; Lu-De, L.; Xin, W.; Li-Min, Y. The Dyeing of Nylon with a Microencapsulated Disperse Dye. Color. Technol. 2007, 123, 333–338. [Google Scholar] [CrossRef]

- Zhao, F.; Rao, B.; Xue, W.; Wang, F.; Li, C.; Lao, J.; Wang, L. The Development of Eco-Friendly Dye Microcapsules for Wool Fabric Dyeing Application. J. Polym. Environ. 2019, 27, 1202–1211. [Google Scholar] [CrossRef]

- Choi, I.; Lee, J.Y.; Lacroix, M.; Han, J. Intelligent PH Indicator Film Composed of Agar/Potato Starch and Anthocyanin Extracts from Purple Sweet Potato. Food Chem. 2017, 218, 122–128. [Google Scholar] [CrossRef]

- Qi, D.; Chen, Z.; Yang, L.; Cao, Z.; Wu, M. Improvement of Dispersion and Color Effect of Organic Pigments in Polymeric Films via Microencapsulation by the Miniemulsion Technique. Adv. Mater. Sci. Eng. 2013, 2013, 790321. [Google Scholar] [CrossRef] [Green Version]

- Hu, H.; Yang, C.; Li, M.; Shao, D.; Mao, H.-Q.; Leong, K.W. Flash Technology-Based Self-Assembly in Nanoformulation: Fabrication to Biomedical Applications. Mater. Today 2021, 42, 99–116. [Google Scholar] [CrossRef]

- Saad, W.S.; Prud’homme, R.K. Principles of Nanoparticle Formation by Flash Nanoprecipitation. Nano Today 2016, 11, 212–227. [Google Scholar] [CrossRef]

- Tao, J.; Chow, S.F.; Zheng, Y. Application of Flash Nanoprecipitation to Fabricate Poorly Water-Soluble Drug Nanoparticles. Acta Pharm. Sin. B 2019, 9, 4–18. [Google Scholar] [CrossRef]

- Han, J.; Zhu, Z.; Qian, H.; Wohl, A.R.; Beaman, C.J.; Hoye, T.R.; Macosko, C.W. A Simple Confined Impingement Jets Mixer for Flash Nanoprecipitation. J. Pharm. Sci. 2012, 101, 4018–4023. [Google Scholar] [CrossRef]

- Johnson, B.K.; Prud’homme, R.K. Chemical Processing and Micromixing in Confined Impinging Jets. AIChE J. 2003, 49, 2264–2282. [Google Scholar] [CrossRef]

- Li, Y.; Wang, J.; Wang, Y.; Cui, W. Advanced Electrospun Hydrogel Fibers for Wound Healing. Compos. Part B Eng. 2021, 223, 109101. [Google Scholar] [CrossRef]

- Ajmal, A.; Hollitt, C.; Frean, M.; Al-Sahaf, H. A Comparison of RGB and HSV Colour Spaces for Visual Attention Models. In Proceedings of the 2018 International Conference on Image and Vision Computing New Zealand (IVCNZ), Auckland, New Zealand, 19–21 November 2018; pp. 1–6. [Google Scholar]

- Maru, H.; Saito, S.; Kanai, H.; Nishimatsu, T. Photometry and Characterization on Brightness Sensation of Dyed Black Color Fabric for Objective Assessment of Fabric Appearance. J. Text. Eng. 2017, 63, 55–62. [Google Scholar] [CrossRef] [Green Version]

- Zhang, R.; Jingjing, Y.; Liu, N.; Gao, Y.; Mao, L. W/O Emulsions Featuring Ethylcellulose Structuring in the Water Phase, Interface and Oil Phase for Multiple Delivery. Carbohydr. Polym. 2022, 283, 119158. [Google Scholar] [CrossRef]

- Hasan, M.; Zafar, A.; Yousaf, M.; Gulzar, H.; Mehmood, K.; Hassan, S.G.; Saeed, A.; Yousaf, A.; Mazher, A.; Rongji, D.; et al. Synthesis of Loureirin B-Loaded Nanoliposomes for Pharmacokinetics in Rat Plasma. ACS Omega 2019, 4, 6914–6922. [Google Scholar] [CrossRef]

- Zulfiqar, H.; Zafar, A.; Rasheed, M.N.; Ali, Z.; Mehmood, K.; Mazher, A.; Hasan, M.; Mahmood, N. Synthesis of Silver Nanoparticles Using Fagonia Cretica and Their Antimicrobial Activities. Nanoscale Adv. 2019, 1, 1707–1713. [Google Scholar] [CrossRef] [Green Version]

- Hasan, M.; Ullah, I.; Zulfiqar, H.; Naeem, K.; Iqbal, A.; Gul, H.; Ashfaq, M.; Mahmood, N. Biological Entities as Chemical Reactors for Synthesis of Nanomaterials: Progress, Challenges and Future Perspective. Mater. Today Chem. 2018, 8, 13–28. [Google Scholar] [CrossRef]

- Lu, B.; Lv, X.; Le, Y. Chitosan-Modified PLGA Nanoparticles for Control-Released Drug Delivery. Polymers 2019, 11, 304. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Khorrami, S.; Zarrabi, A.; Khaleghi, M.; Danaei, M.; Mozafari, M. Selective Cytotoxicity of Green Synthesized Silver Nanoparticles against the MCF-7 Tumor Cell Line and Their Enhanced Antioxidant and Antimicrobial Properties. Int. J. Nanomed. 2018, 13, 8013–8024. [Google Scholar] [CrossRef] [Green Version]

- Tamayol, A.; Akbari, M.; Zilberman, Y.; Comotto, M.; Lesha, E.; Serex, L.; Bagherifard, S.; Chen, Y.; Fu, G.; Ameri, S.K.; et al. Flexible PH-Sensing Hydrogel Fibers for Epidermal Applications. Adv. Healthcare Mater. 2016, 5, 711–719. [Google Scholar] [CrossRef]

| pH | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|

| Colors displayed |  |  |  |  |  |  |  |  |

| H-value (°) | 54.0 | 61.6 | 67.8 | 92.5 | 95.4 | 207.1 | 213.7 | 218.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hou, X.; Zhao, H.; Zhang, K.-Q.; Meng, K. Preparation of Wide-Domain pH Color-Changing Nanocapsules and Application in Hydrogel Fibers. Materials 2022, 15, 8787. https://doi.org/10.3390/ma15248787

Hou X, Zhao H, Zhang K-Q, Meng K. Preparation of Wide-Domain pH Color-Changing Nanocapsules and Application in Hydrogel Fibers. Materials. 2022; 15(24):8787. https://doi.org/10.3390/ma15248787

Chicago/Turabian StyleHou, Xuemei, Huijing Zhao, Ke-Qin Zhang, and Kai Meng. 2022. "Preparation of Wide-Domain pH Color-Changing Nanocapsules and Application in Hydrogel Fibers" Materials 15, no. 24: 8787. https://doi.org/10.3390/ma15248787