Tribological Properties of Carbon Fiber-Reinforced PEEK against 304 Stainless Steel with Reticulate Surface Texture

Abstract

:1. Introduction

2. Experiments

2.1. Sample Preparation

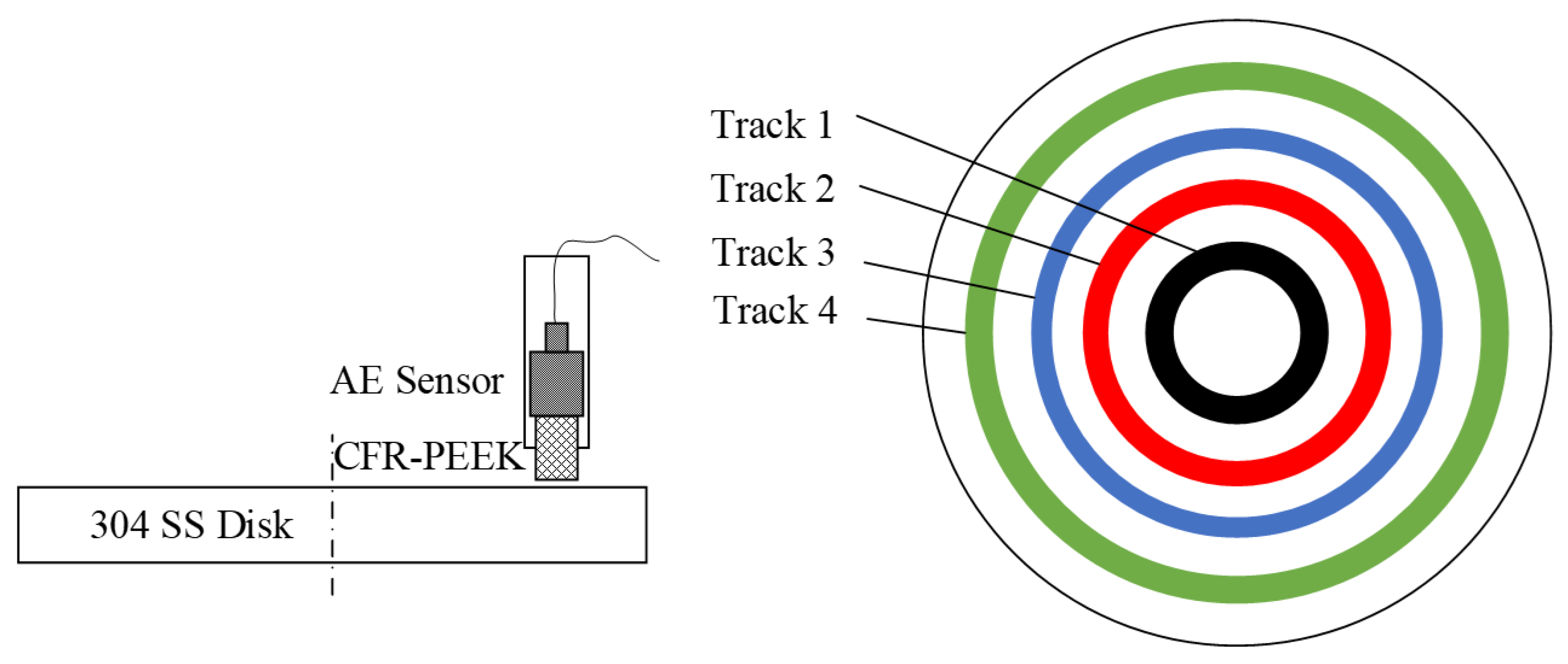

2.2. Tribology Test Method

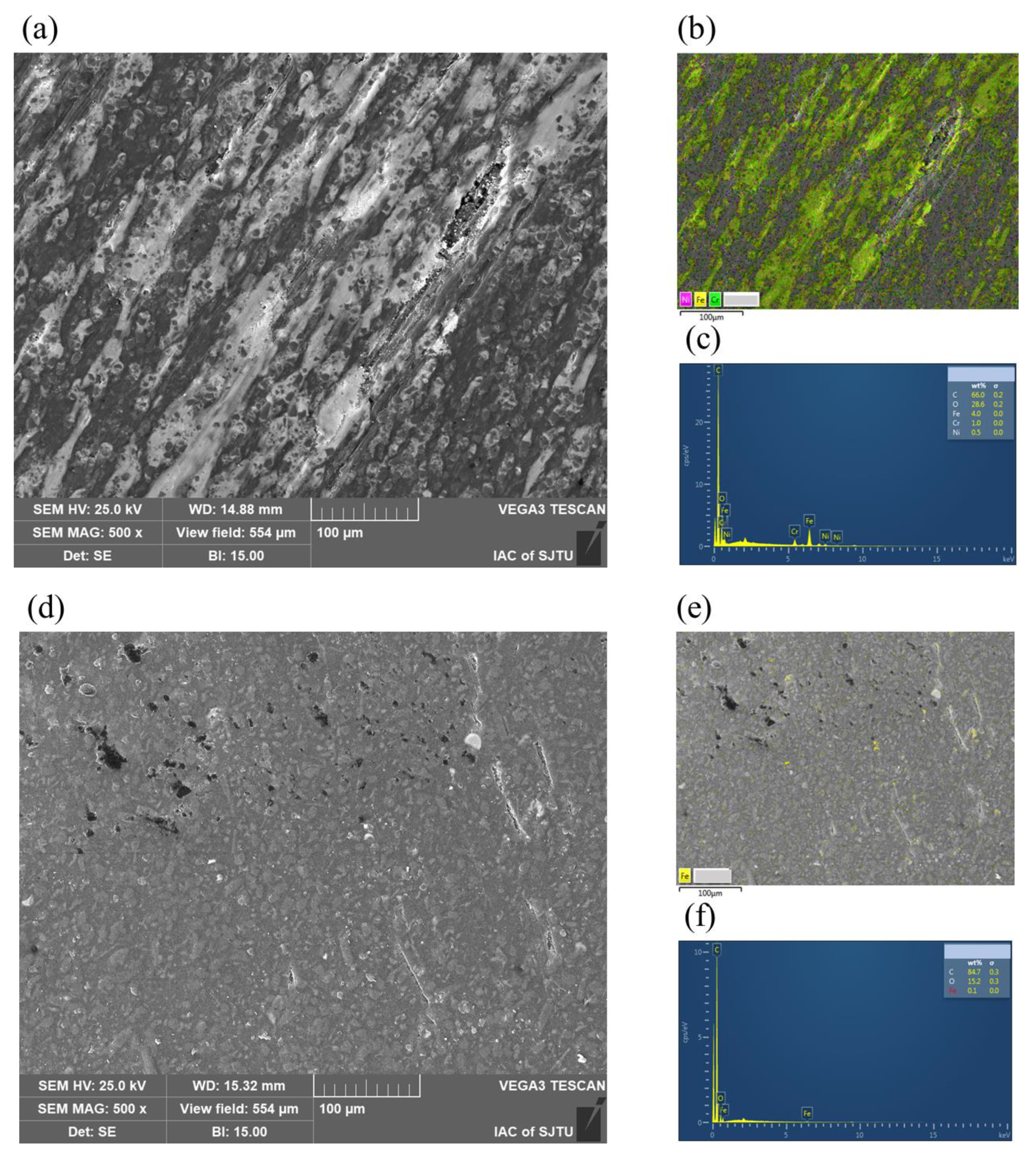

2.3. Surface Morphology and Transfer Film of Stainless Steel

3. Results and Discussion

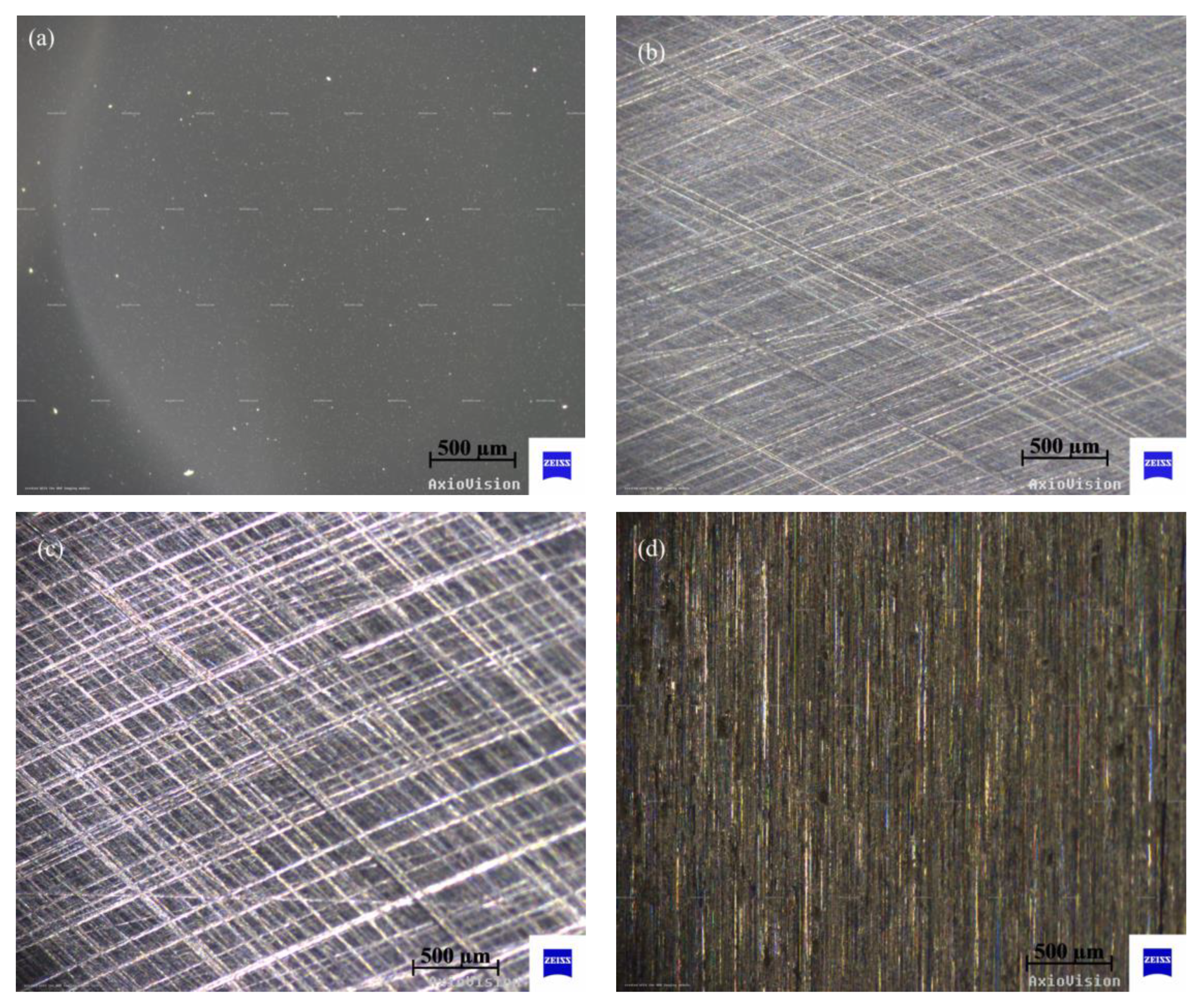

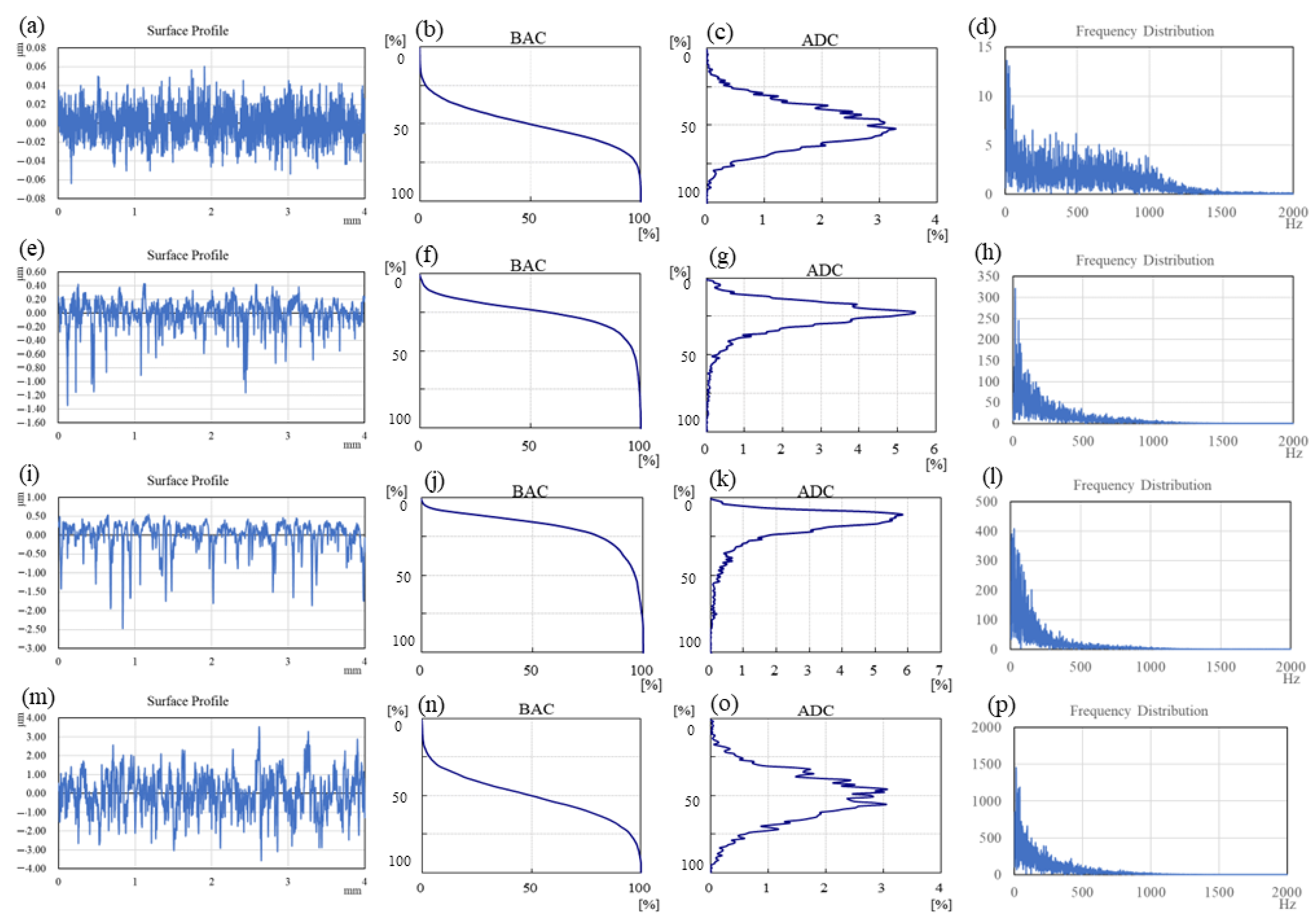

3.1. Surface Characteristics

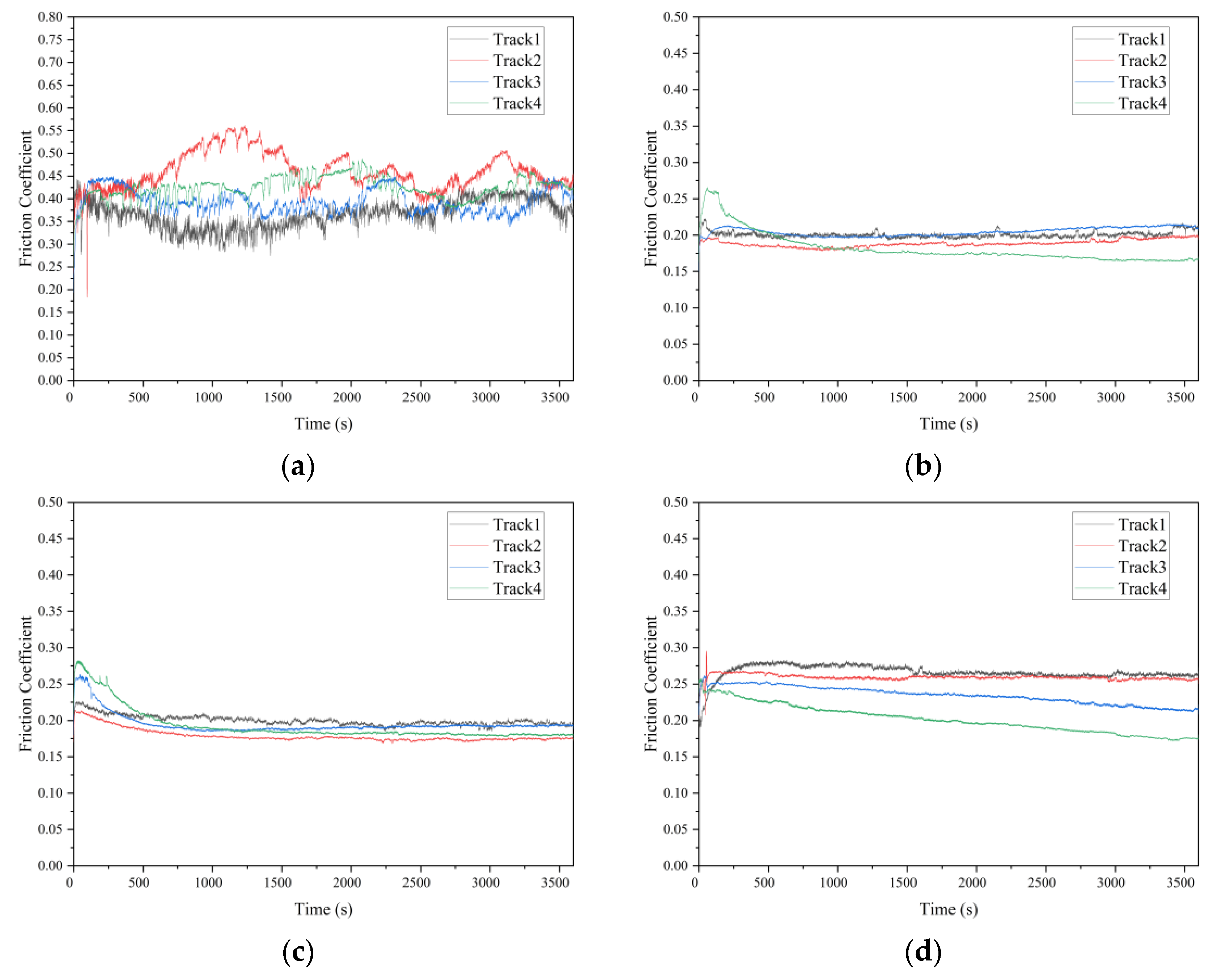

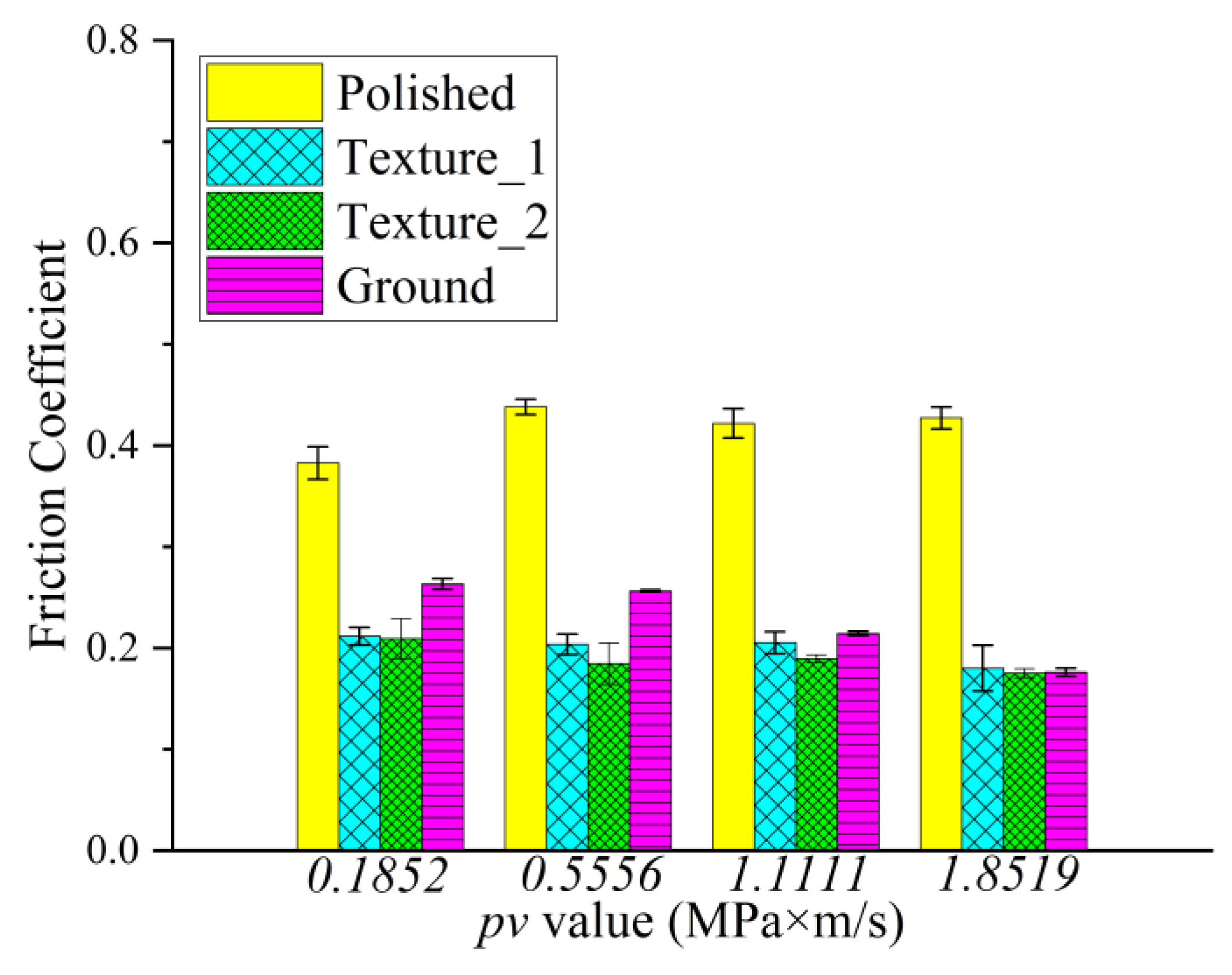

3.2. Frictional Behaviors

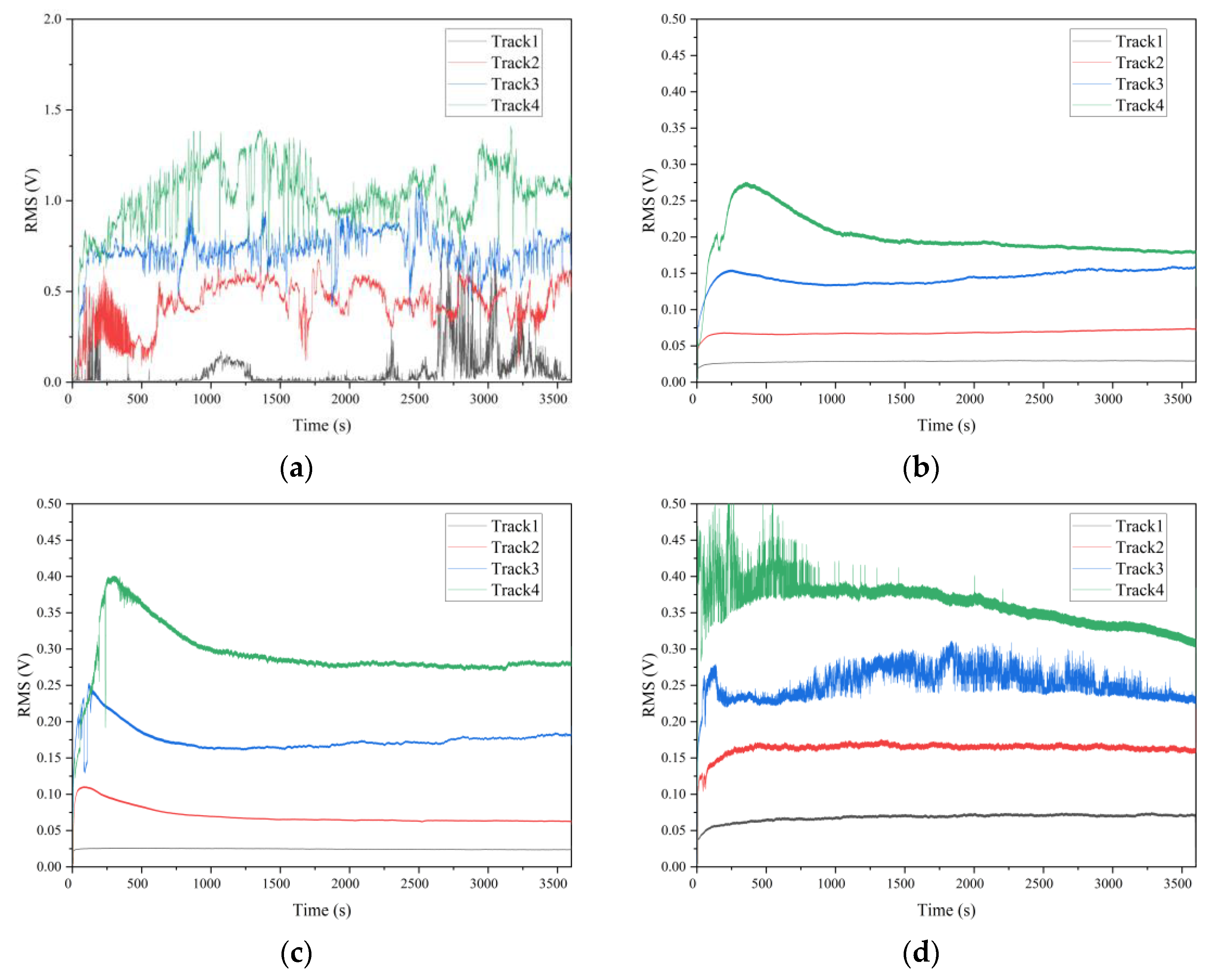

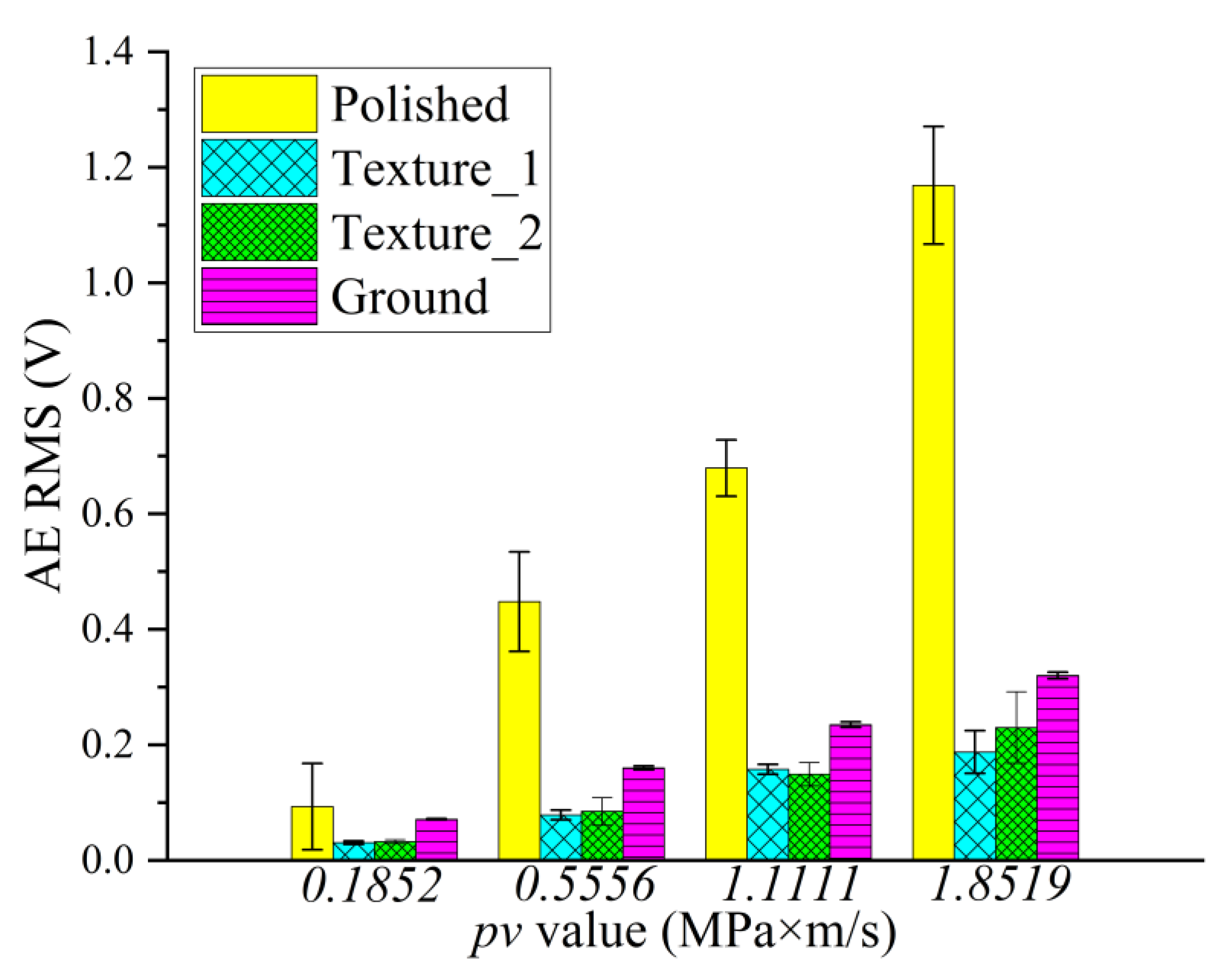

3.3. AE Signals

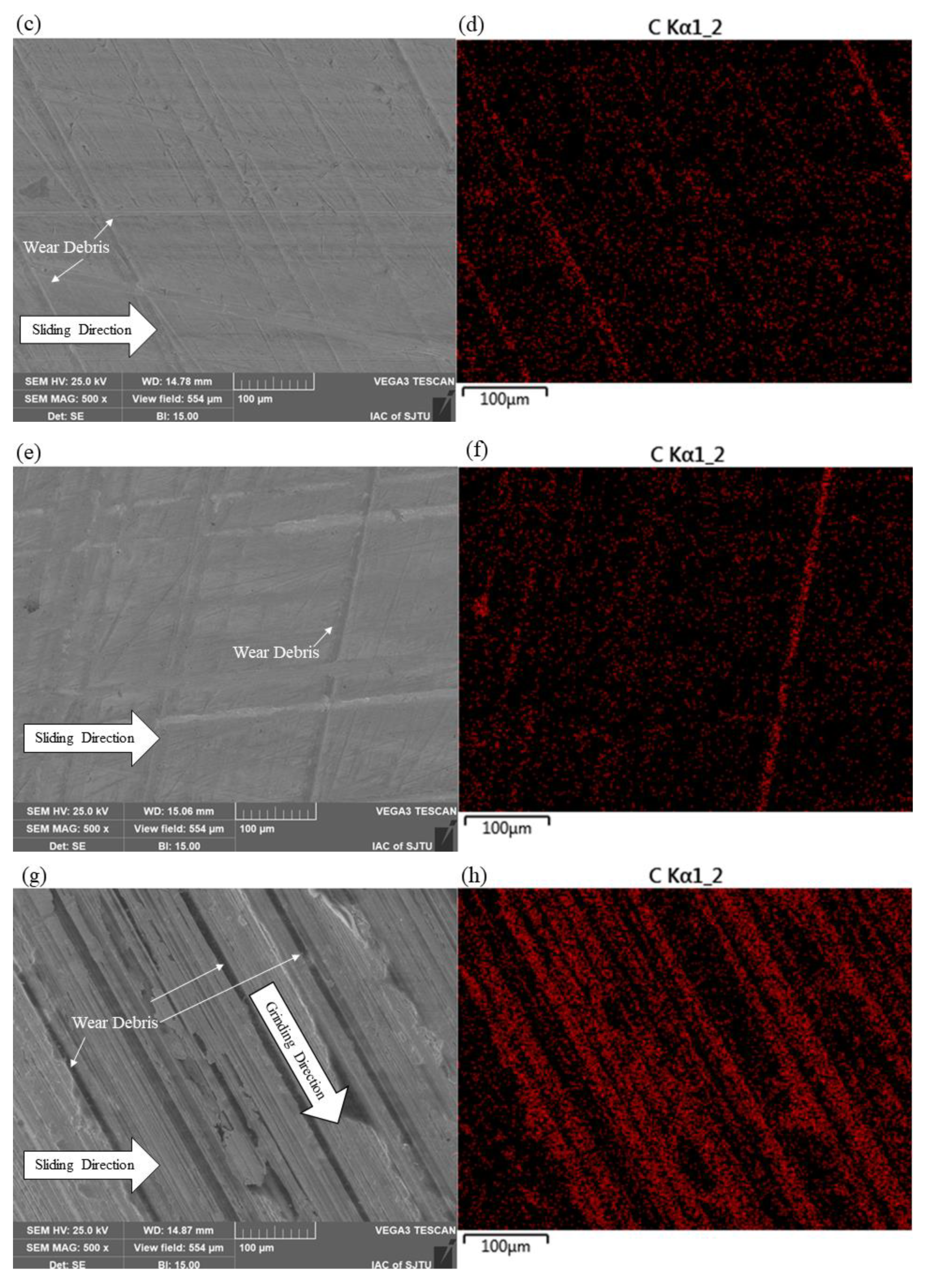

3.4. Surface Morphology and Transfer Film

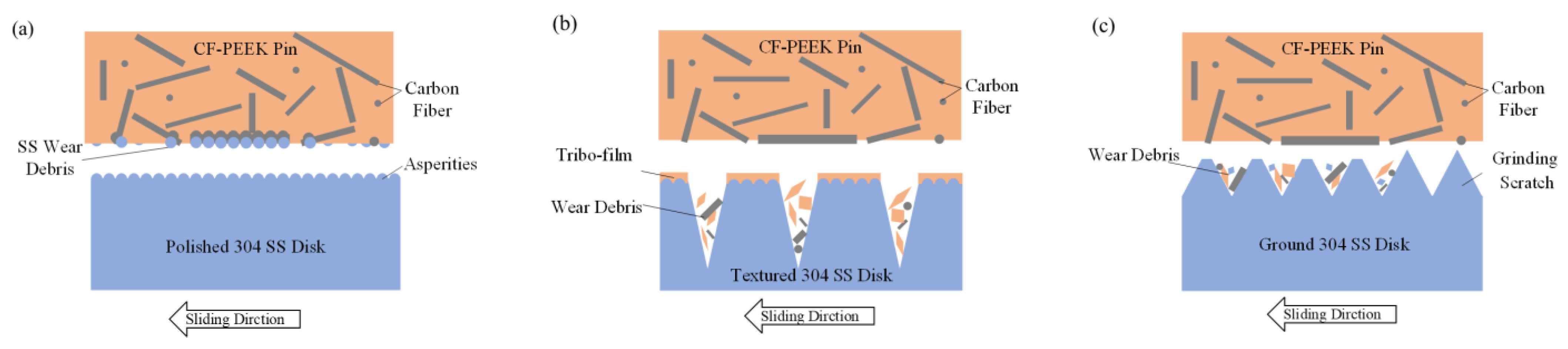

3.5. Influence of Morphology on Tribology Behavior

4. Conclusions

- (1)

- The reticular texture on the SS surface fabricated by the plane honing process can reduce the friction coefficient against CF-PEEK significantly under dry friction conditions from approximately 0.40 to about 0.20, compared with the polished SS surface. It is revealed and proven with EDS that the abrasive wear mechanism dominates the three-body contact of the polished SS disk against the CF-PEEK pin, with hard SS particles between the interface accumulating near the CF strips on the pin.

- (2)

- The AE RMS value increases significantly with increasing pv value for polished, textured and ground surfaces, indicating an increase in elastic–plastic deformation and wear rates. The AE RMS value of the polished SS disk is the highest, while that of the textured SS disk is the lowest, indicating that the smooth contact surface suffers sever elastic–plastic deformation and abrasive wear, which verifies the antiwear property of the textured SS surface.

- (3)

- The ground SS surface shows a low friction coefficient under a large pv value, due to the peaks on the ground SS surface being smoothed by CF-PEEK during the friction test with a high wear rate of the CF-PEEK counterparts. The distribution of peaks and valleys on the ground SS disk surface becomes asymmetric, similar to the two textured surfaces, resulting in a reduction in the friction coefficient.

- (4)

- The reduction of the friction coefficient with CF-PEEK against textured SS disks can be attributed to diminution of the CF wear debris and SS particles, which are scraped off by groove edges and trapped by groove valleys, reducing the three-body abrasive wear, and promotion of PEEK particles transferred to a tribofilm on the SS surface due to the flank surface effect of the grooved plateau under adhesive wear. The results show that the plane honing technique has the potential to be applied to the runner fabrication of thrust bearings facing the possible risk of dry friction.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dua, R.; Rashad, Z.; Spears, J.; Dunn, G.; Maxwell, M. Applications of 3D-Printed PEEK via Fused Filament Fabrication: A Systematic Review. Polymers 2021, 13, 4046. [Google Scholar] [CrossRef] [PubMed]

- Najeeb, S.; Zafar, M.S.; Khurshid, Z.; Siddiqui, F. Applications of polyetheretherketone (PEEK) in oral implantology and prosthodontics. J. Prosthodont. Res. 2016, 60, 12–19. [Google Scholar] [CrossRef] [PubMed]

- Panayotov, I.V.; Orti, V.; Cuisinier, F.; Yachouh, J. Polyetheretherketone (PEEK) for medical applications. J. Mater. Sci.-Mater. Med. 2016, 27, 118. [Google Scholar] [CrossRef]

- Nunez, E.E.; Gheisari, R.; Polycarpou, A.A. Tribology review of blended bulk polymers and their coatings for high-load bearing applications. Tribol. Int. 2019, 129, 92–111. [Google Scholar] [CrossRef]

- Davim, J.P.; Cardoso, R. Effect of the reinforcement (carbon or glass fibres) on friction and wear behaviour of the PEEK against steel surface at long dry sliding. Wear 2009, 266, 795–799. [Google Scholar] [CrossRef]

- Sandler, J.; Werner, P.; Shaffer, M.S.P.; Demchuk, V.; Altstädt, V.; Windle, A.H. Carbon-nanofibre-reinforced poly(ether ether ketone) composites. Compos. Part A Appl. Sci. Manuf. 2002, 33, 1033–1039. [Google Scholar] [CrossRef]

- Etsion, I. Improving Tribological Performance of Mechanical Components by Laser Surface Texturing. Tribol. Lett. 2004, 17, 733–737. [Google Scholar] [CrossRef]

- Wang, M.L.; Zhang, C.T.; Wang, X.L. The Wear Behavior of Textured Steel Sliding against Polymers. Materials 2017, 10, 330. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, J.; Liu, S.; Yu, A.; Xiang, S. Effect of laser surface texture on CuSn6 bronze sliding against PTFE material under dry friction. Tribol. Int. 2018, 118, 37–45. [Google Scholar] [CrossRef]

- Wu, W.; Shao, T.; Chen, G. Influence of groove surface texture on temperature rise under dry sliding friction. Sci. China Technol. Sci. 2016, 59, 183–190. [Google Scholar] [CrossRef]

- Menezes, P.L.; Kishore Kailas, S.V.; Lovell, M.R. The role of surface texture on friction and transfer layer formation during repeated sliding of Al–4Mg against steel. Wear 2011, 271, 1785–1793. [Google Scholar] [CrossRef]

- Conradi, M.; Kocijan, A.; Klobčar, D.; Podgornik, B. Tribological response of laser-textured Ti6Al4V alloy under dry conditions and lubricated with Hank’s solution. Tribol. Int. 2021, 160, 107049. [Google Scholar] [CrossRef]

- Kang, M.; Park, Y.M.; Kim, B.H.; Seo, Y.H. Micro- and nanoscale surface texturing effects on surface friction. Appl. Surf. Sci. 2015, 345, 344–348. [Google Scholar] [CrossRef]

- Dong, X.; Dong, C.; Wu, B. Insight into Surface Texture-Induced Dual Effects on Friction of WC-Co Dry Sliding Against Continuous Carbon Fiber-Reinforced Thermoplastic and Thermosetting Composites. Tribol. Trans. 2022. [Google Scholar] [CrossRef]

- Wang, B.; Zheng, M.; Zhang, W. Analysis and Prediction of Wear Performance of Different Topography Surface. Materials 2020, 13, 5056. [Google Scholar] [CrossRef] [PubMed]

- Cao, H.J.; Dong, X.; Qu, D.; Dong, C.Y.; Zhao, C.Y.; Sun, D.E.; Gu, L.; Wu, B. Transfer film growth of continuous carbon fiber reinforced thermoplastic poly(ether ether ketone) facilitated by surface texture during dry sliding. J. Mater. Sci. 2022, 57, 383–397. [Google Scholar] [CrossRef]

- Wang, M.L. The tribological performance of engineered micro-surface topography by picosecond laser on PEEK. Ind. Lubr. Tribol. 2020, 72, 172–179. [Google Scholar] [CrossRef]

- Hammouti, S.; Pascale-Hamri, A.; Faure, N.; Beaugiraud, B.; Guibert, M.; Mauclair, C.; Benayoun, S.; Valette, S. Wear rate control of peek surfaces modified by femtosecond laser. Appl. Surf. Sci. 2015, 357, 1541–1551. [Google Scholar] [CrossRef]

- Pawlus, P.; Reizer, R. Functional importance of honed cylinder liner surface texture: A review. Tribol. Int. 2022, 167, 107409. [Google Scholar] [CrossRef]

- Hu, Y.; Meng, X.; Xie, Y.; Fan, J. Study on the frictional performance of slide and plateau honed cylinder liners during running-in. Ind. Lubr. Tribol. 2017, 69, 282–299. [Google Scholar] [CrossRef]

- Woś, P.; Michalski, J. Effect of Initial Cylinder Liner Honing Surface Roughness on Aircraft Piston Engine Performances. Tribol. Lett. 2011, 41, 555–567. [Google Scholar] [CrossRef] [Green Version]

- Federici, M.; Menapace, C.; Moscatelli, A.; Gialanella, S.; Straffelini, G. Effect of roughness on the wear behavior of HVOF coatings dry sliding against a friction material. Wear 2016, 368–369, 326–334. [Google Scholar] [CrossRef]

- Li, P.; Ju, P.; Ji, L.; Li, H.; Liu, X.; Chen, L.; Zhou, H.; Chen, J. Toward Robust Macroscale Superlubricity on Engineering Steel Substrate. Adv. Mater. 2020, 32, 2002039. [Google Scholar] [CrossRef] [PubMed]

- Wei, J.; Lin, B.; Wang, H.; Sui, T.; Yan, S.; Zhao, F.; Wang, A.; Fang, S. Friction and wear characteristics of carbon fiber reinforced silicon carbide ceramic matrix (Cf/SiC) composite and zirconia (ZrO2) ceramic under dry condition. Tribol. Int. 2018, 119, 45–54. [Google Scholar] [CrossRef]

- Chang, B.N.; Gu, J.F.; Long, Z.Q.; Li, Z.; Ruan, S.L.; Shen, C.Y. Effects of temperature and fiber orientation on the tensile behavior of short carbon fiber reinforced PEEK composites. Polym. Compos. 2021, 42, 597–607. [Google Scholar] [CrossRef]

- Hu, S.; Huang, W.; Shi, X.; Peng, Z.; Liu, X.; Wang, Y. Bi-Gaussian stratified effect of rough surfaces on acoustic emission under a dry sliding friction. Tribol. Int. 2018, 119, 308–315. [Google Scholar] [CrossRef]

- Geng, Z.; Puhan, D.; Reddyhoff, T. Using acoustic emission to characterize friction and wear in dry sliding steel contacts. Tribol. Int. 2019, 134, 394–407. [Google Scholar] [CrossRef] [Green Version]

- Wang, D.W.; Mo, J.L.; Zhu, Z.Y.; Ouyang, H.; Zhu, M.H.; Zhou, Z.R. Debris trapping and space-varying contact via surface texturing for enhanced noise performance. Wear 2018, 396–397, 86–97. [Google Scholar] [CrossRef]

| Properties | Modulus of Elasticity (MPa) | Ball Indentation Hardness (MPa) | Density (g/cm3) | Melting Point (°C) | Glass Transition Temperature (°C) | Thermal Conductivity (W/m × K) |

|---|---|---|---|---|---|---|

| CF-PEEK | 6000 | 298 | 1.38 | 341 | 147 | 0.66 |

| Parameters | nw/rpm | np/rpm | e/mm | r/mm | d1/mm | d2/mm | d3/mm |

|---|---|---|---|---|---|---|---|

| Texture_1 | 20 | 51 | 30 | 50 | 250 | 50 | 60 |

| Texture_2 | 20 | 201 | 30 | 50 | 250 | 50 | 60 |

| Track Number | Unit | 1 | 2 | 3 | 4 |

|---|---|---|---|---|---|

| Diameter of the tracks | mm | 20 | 30 | 40 | 50 |

| Sliding velocity | m/s | 0.2618 | 0.3927 | 0.5236 | 0.6545 |

| Sliding distance | m | 942 | 1414 | 1885 | 2356 |

| Applied load | N | 20.00 | 40.00 | 60.00 | 80.00 |

| Specific pressure | MPa | 0.7074 | 1.4147 | 2.1221 | 2.8294 |

| pv value | MPa∙m/s | 0.1852 | 0.5556 | 1.1111 | 1.8519 |

| Parameters | Polished | Textured_1 | Textured_2 | Ground |

|---|---|---|---|---|

| Rpk/μm | 0.015 | 0.161 | 0.130 | 1.002 |

| Rk/μm | 0.04 | 0.345 | 0.566 | 2.679 |

| Rvk/μm | 0.016 | 0.438 | 0.916 | 1.347 |

| Mr1/% | 9.013 | 7.913 | 2.938 | 8.544 |

| Mr2/% | 90.475 | 83.409 | 79.800 | 87.813 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, Z.; Zhang, X.; Hou, Z.; Yao, Z.; Shen, H. Tribological Properties of Carbon Fiber-Reinforced PEEK against 304 Stainless Steel with Reticulate Surface Texture. Materials 2022, 15, 8789. https://doi.org/10.3390/ma15248789

Jin Z, Zhang X, Hou Z, Yao Z, Shen H. Tribological Properties of Carbon Fiber-Reinforced PEEK against 304 Stainless Steel with Reticulate Surface Texture. Materials. 2022; 15(24):8789. https://doi.org/10.3390/ma15248789

Chicago/Turabian StyleJin, Zhiyi, Xifang Zhang, Zhibao Hou, Zhenqiang Yao, and Hong Shen. 2022. "Tribological Properties of Carbon Fiber-Reinforced PEEK against 304 Stainless Steel with Reticulate Surface Texture" Materials 15, no. 24: 8789. https://doi.org/10.3390/ma15248789

APA StyleJin, Z., Zhang, X., Hou, Z., Yao, Z., & Shen, H. (2022). Tribological Properties of Carbon Fiber-Reinforced PEEK against 304 Stainless Steel with Reticulate Surface Texture. Materials, 15(24), 8789. https://doi.org/10.3390/ma15248789