Thermo-Mechanical Processing as Method Decreasing Delta-Ferrite and Improving the Impact Toughness of the Novel 12% Cr Steels with Low N and High B Contents

Abstract

:1. Introduction

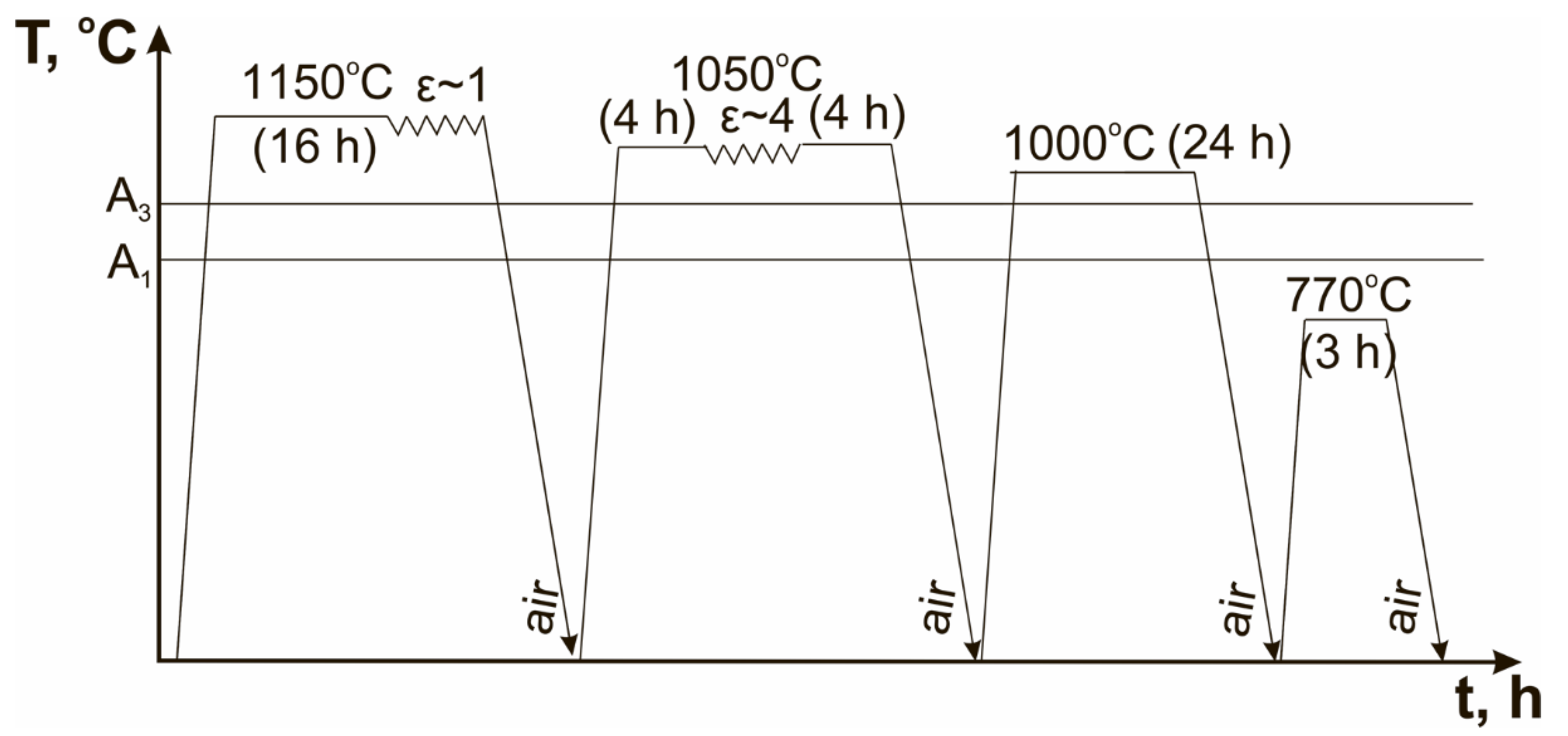

2. Materials and Methods

3. Results and Discussion

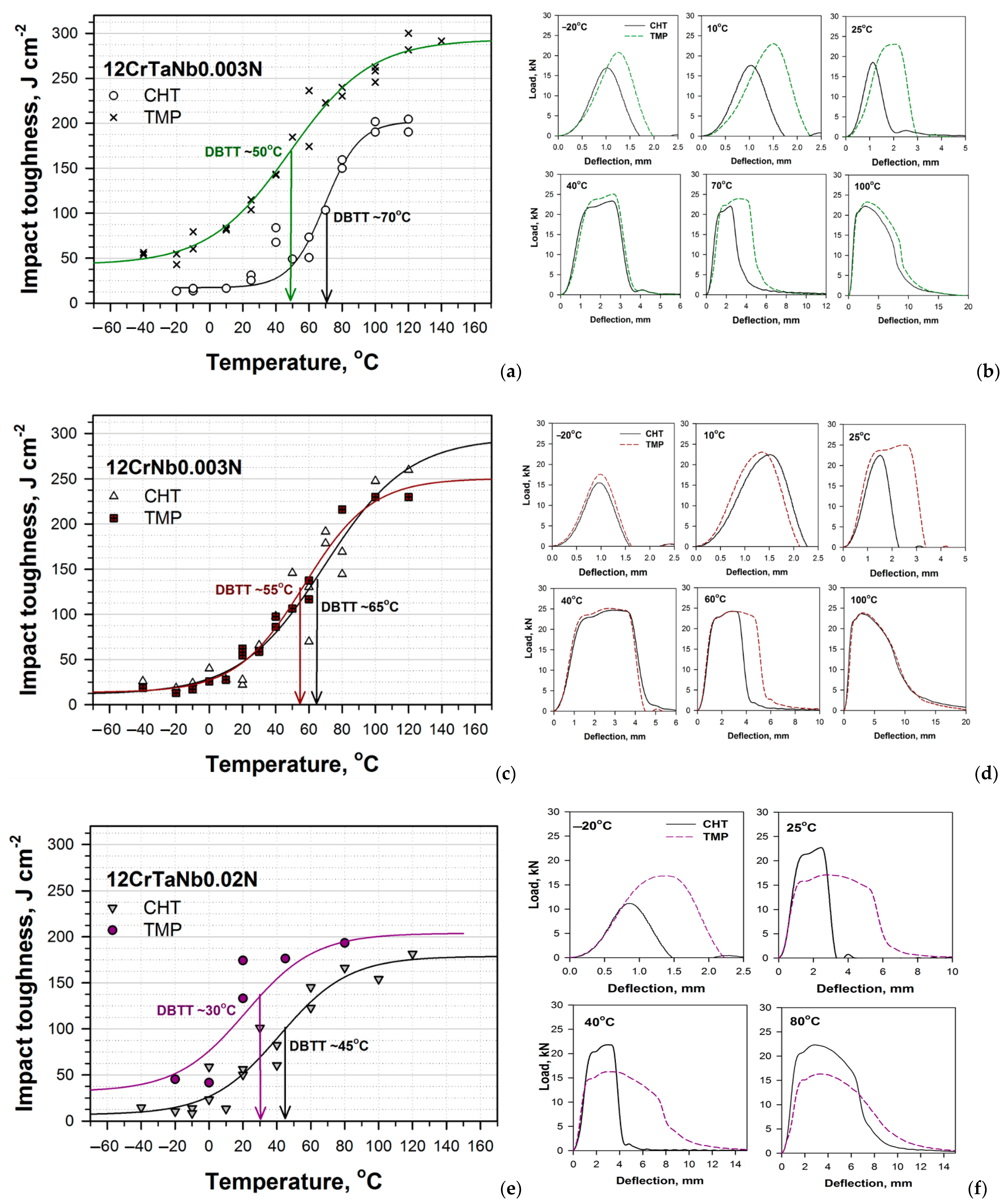

3.1. Impact Tests

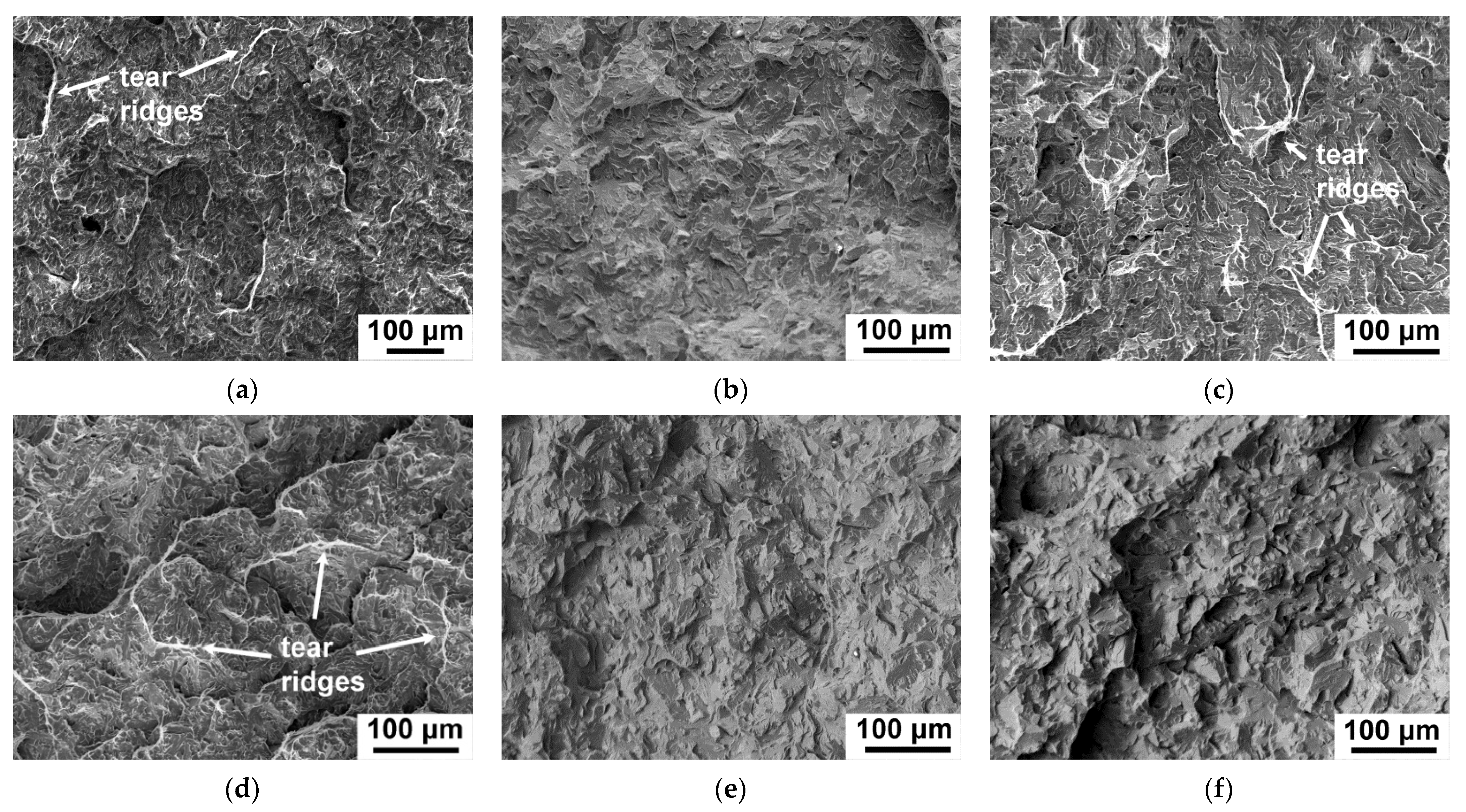

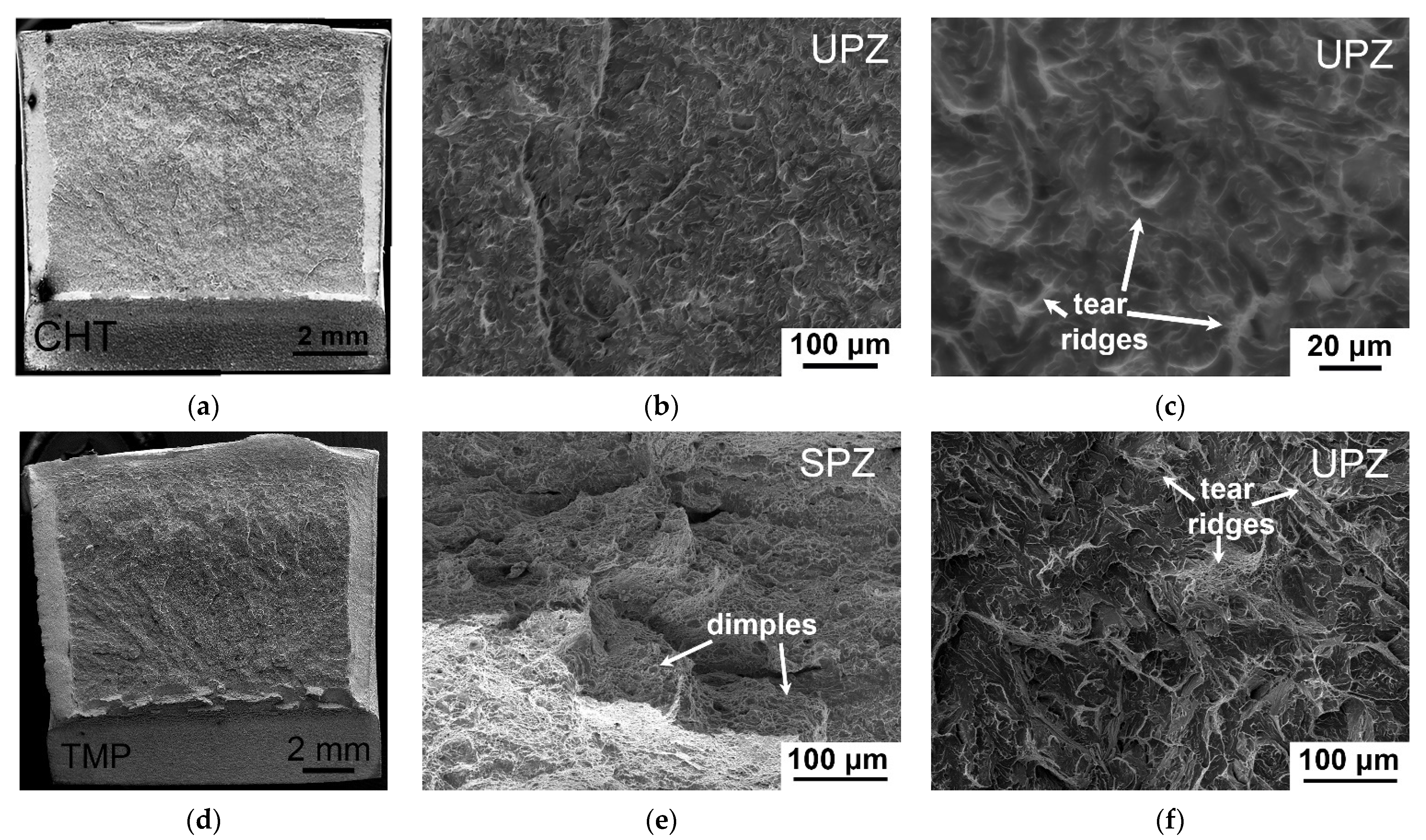

3.2. Fractography after Impact Tests

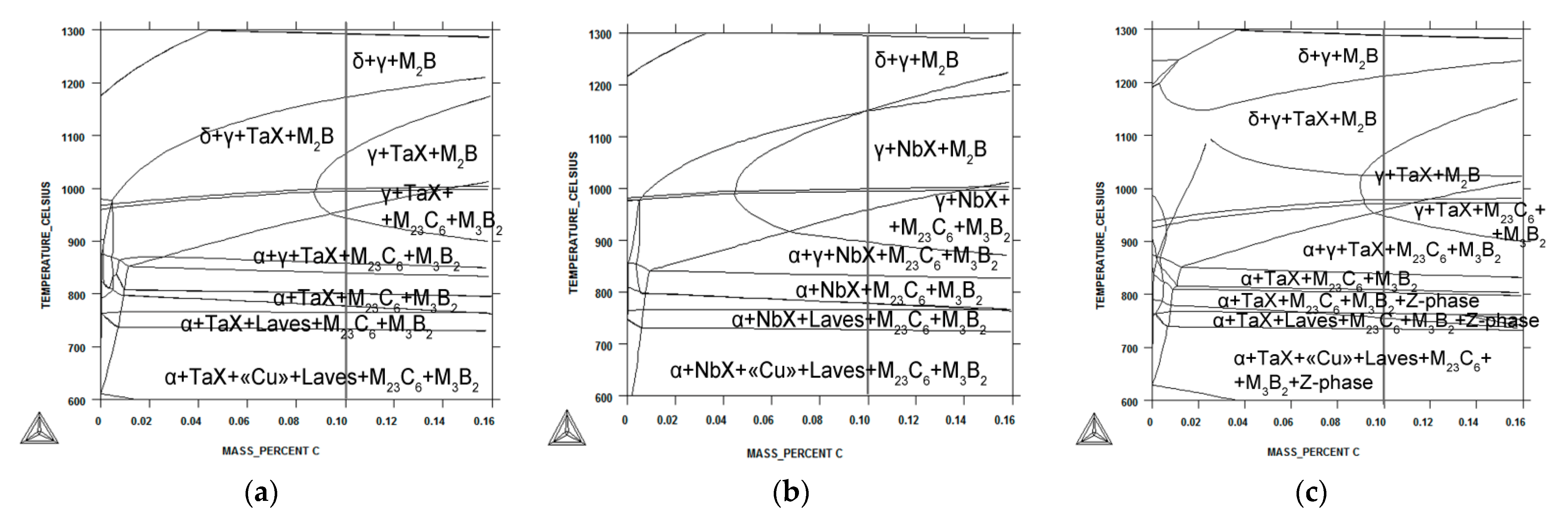

3.3. Phase Equilibrium Modeling

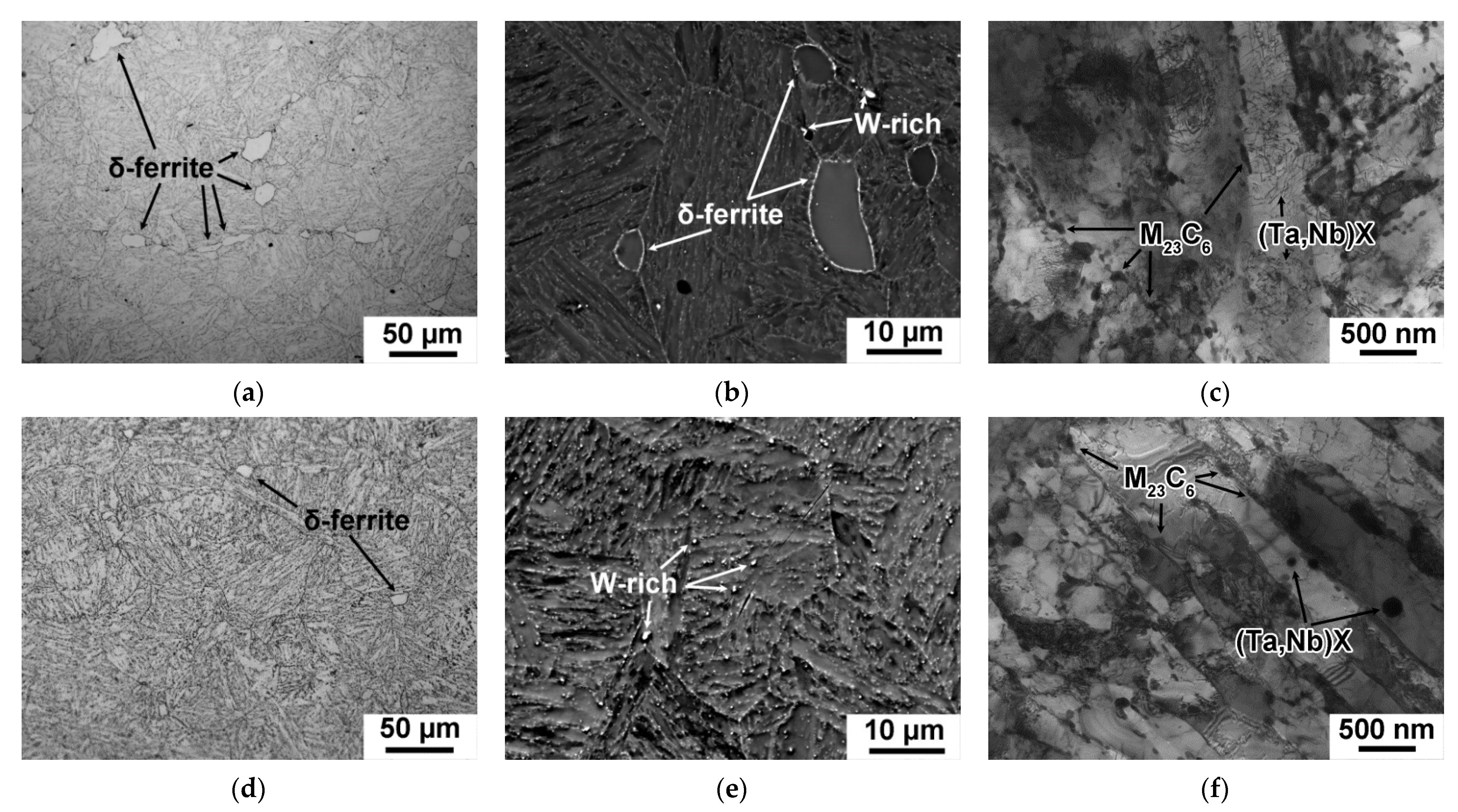

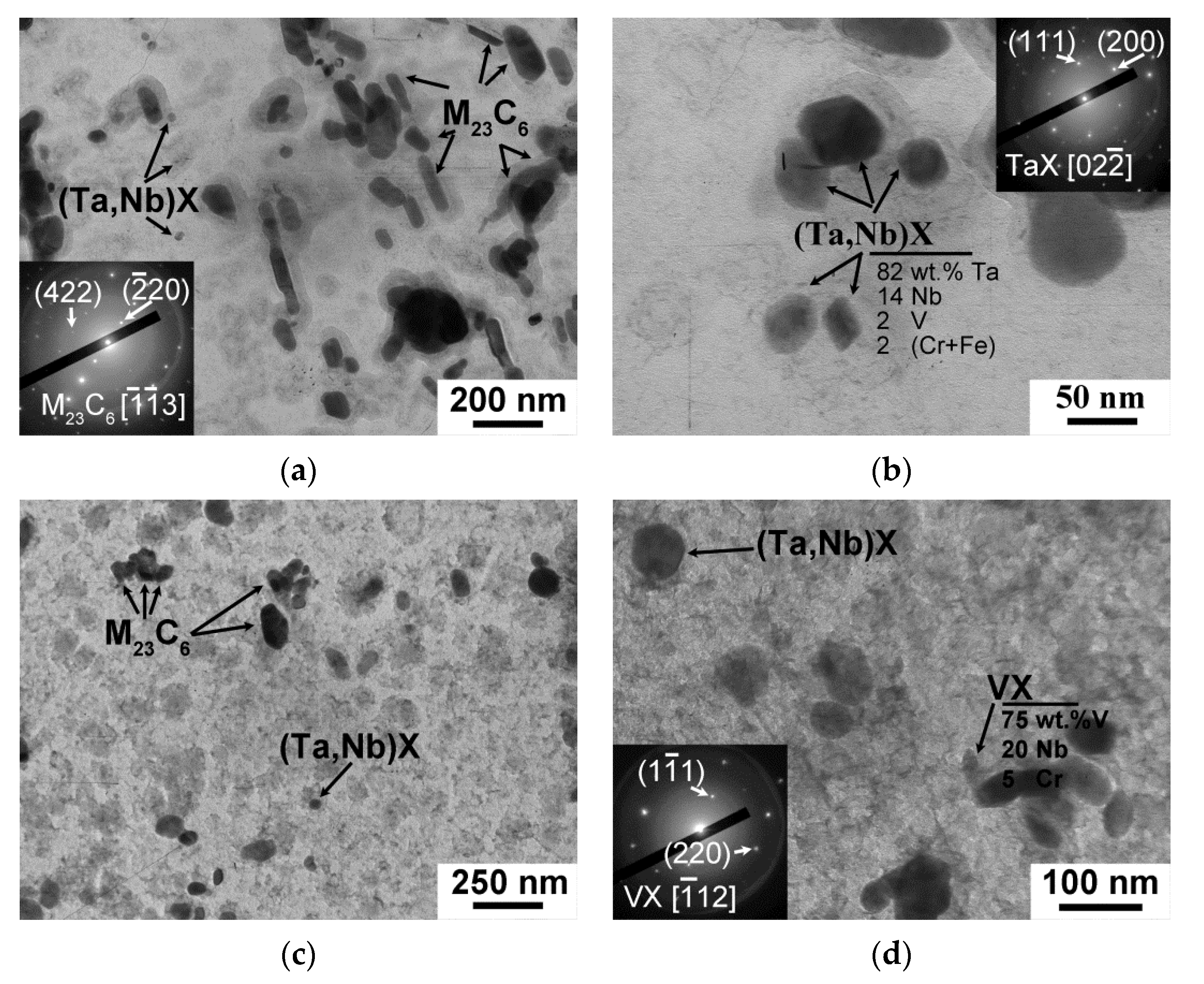

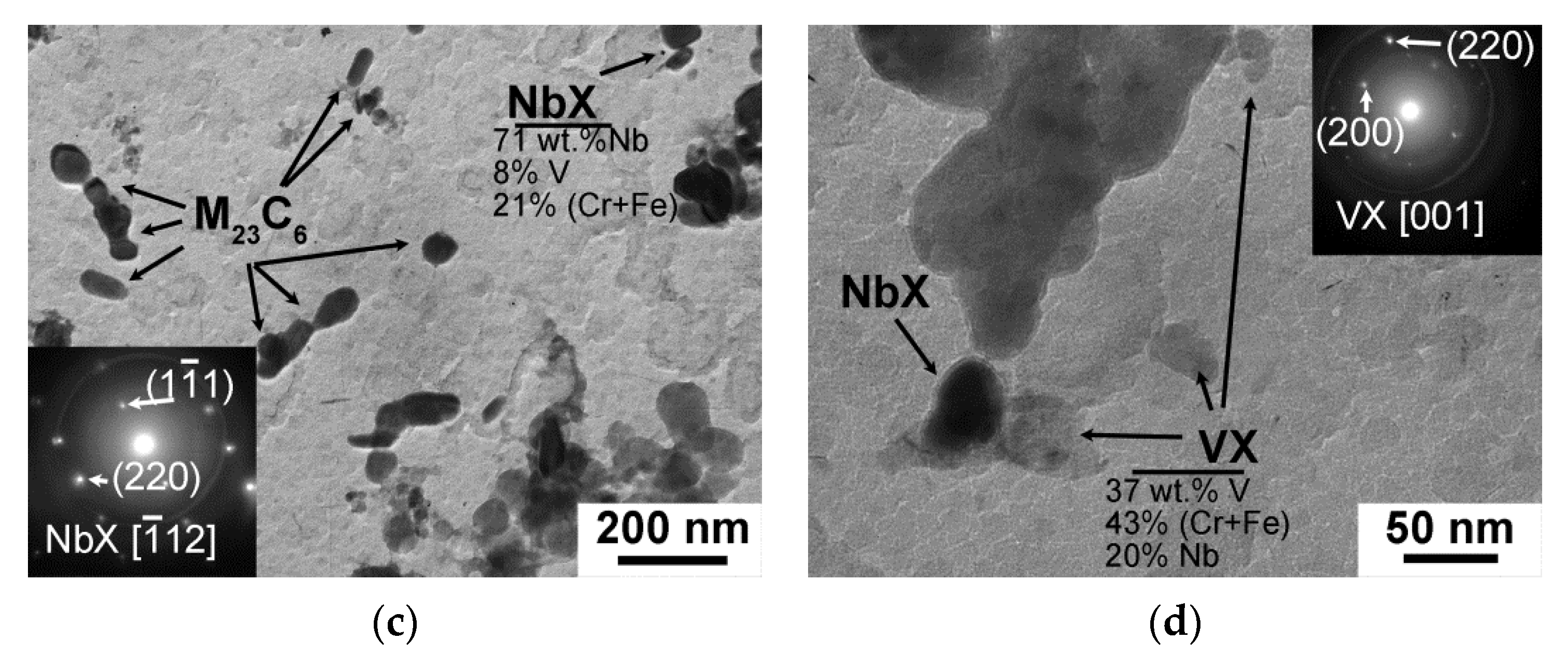

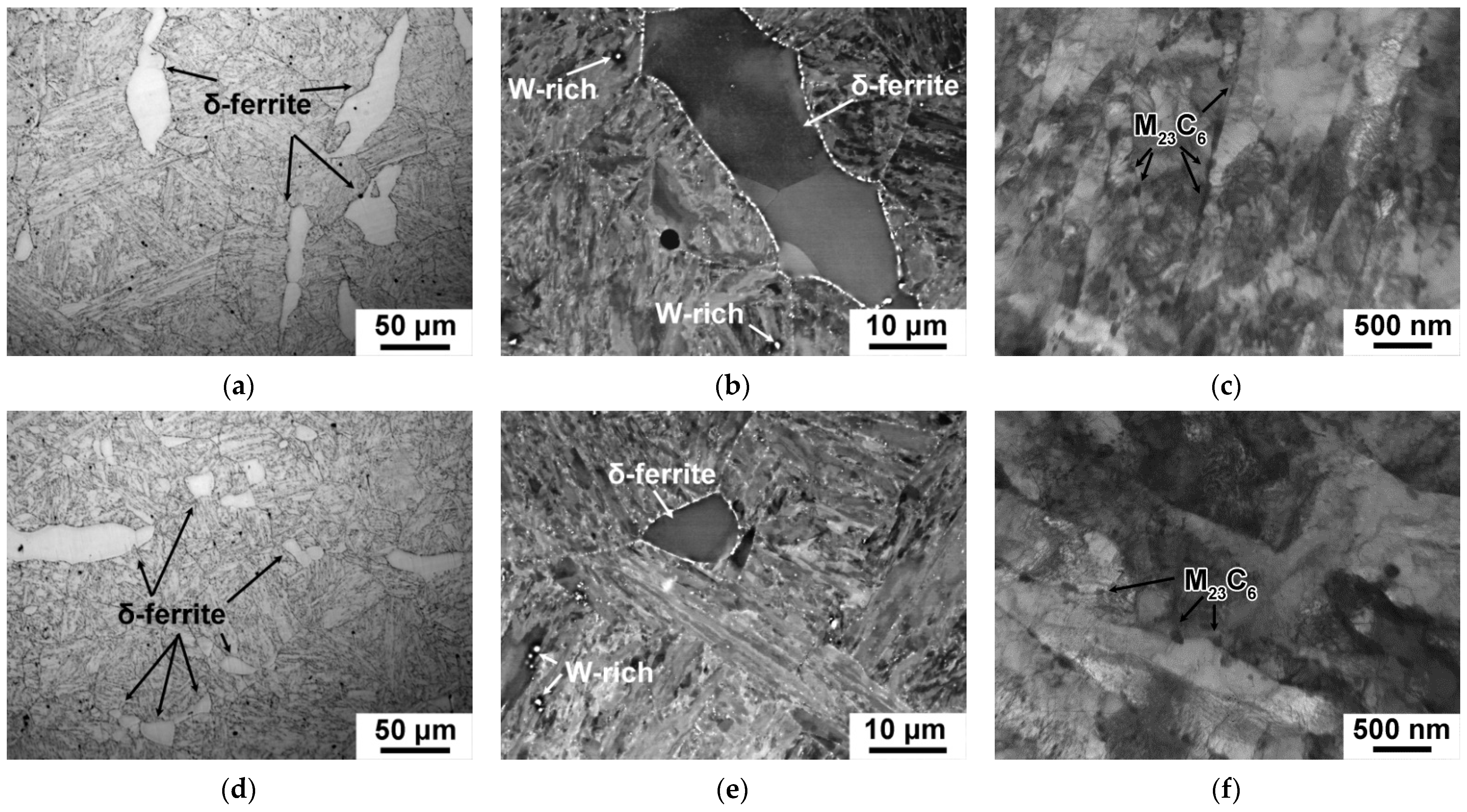

3.4. Structure of the 12CrTaNb0.003N Steel Subjected to CHT and TMP

- (a)

- a decrease in the fraction of delta-ferrite to 1%;

- (b)

- a decrease in the mean size of PAGs to 40 μm;

- (c)

- an increase in the mean size of M23C6 carbides up to 65 nm together with a decrease in the particle number density to 1.5 μm−1;

- (d)

- an additional precipitation of VX carbonitrides with the mean size of 30 nm and volume fraction of 0.04%.

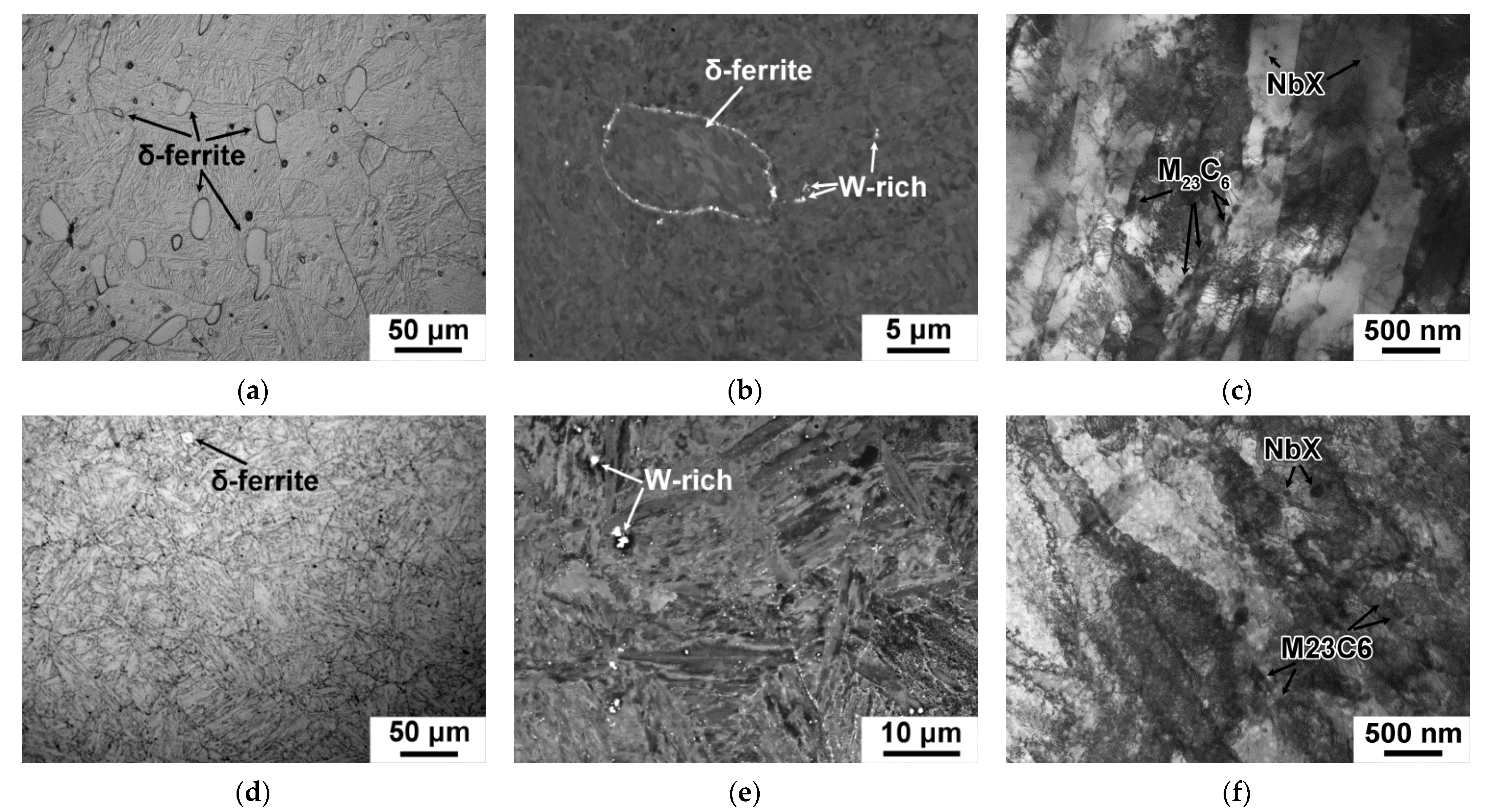

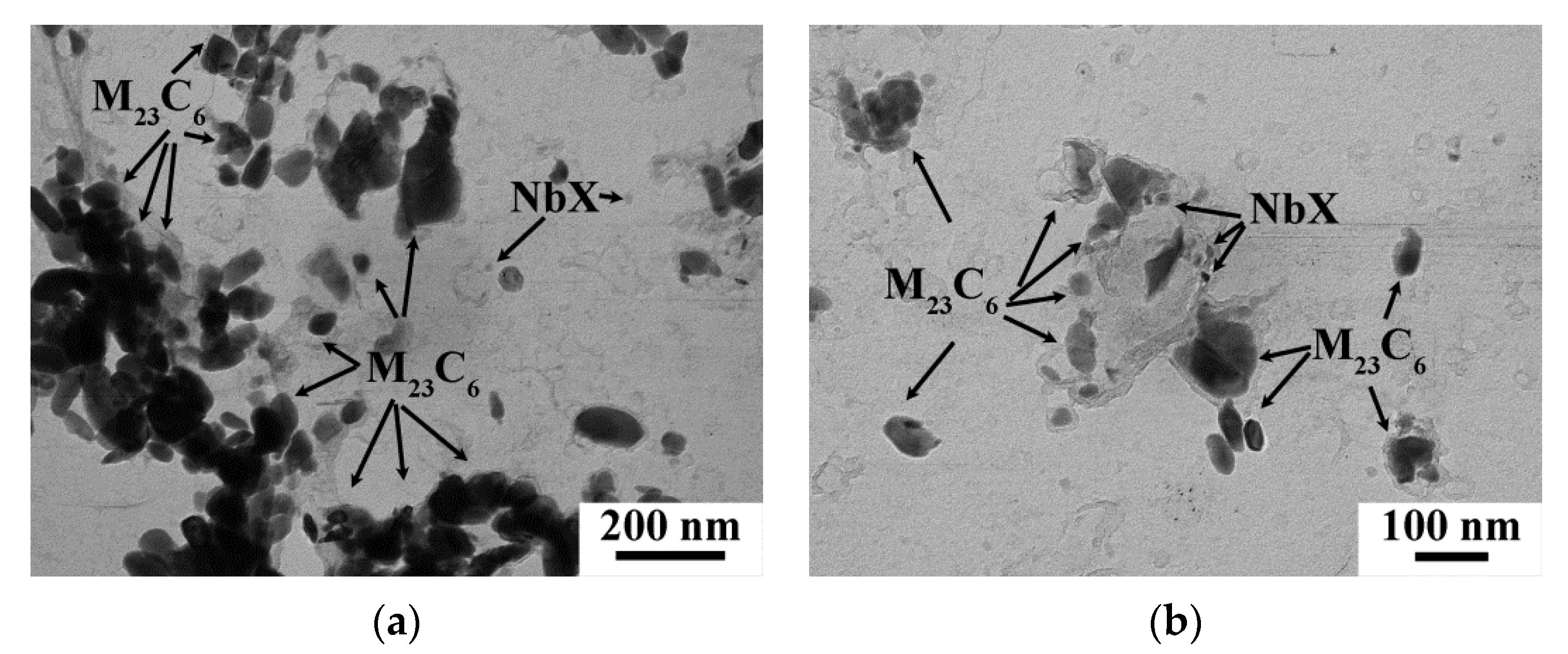

3.5. Structure of the 12CrNb0.003N Steel Subjected to CHT and TMP

- (a)

- a decrease in the delta-ferrite amounted to an almost full disappearance;

- (b)

- an additional precipitation of VX carbonitrides with the mean size of 12 nm and volume fraction of 0.03%.

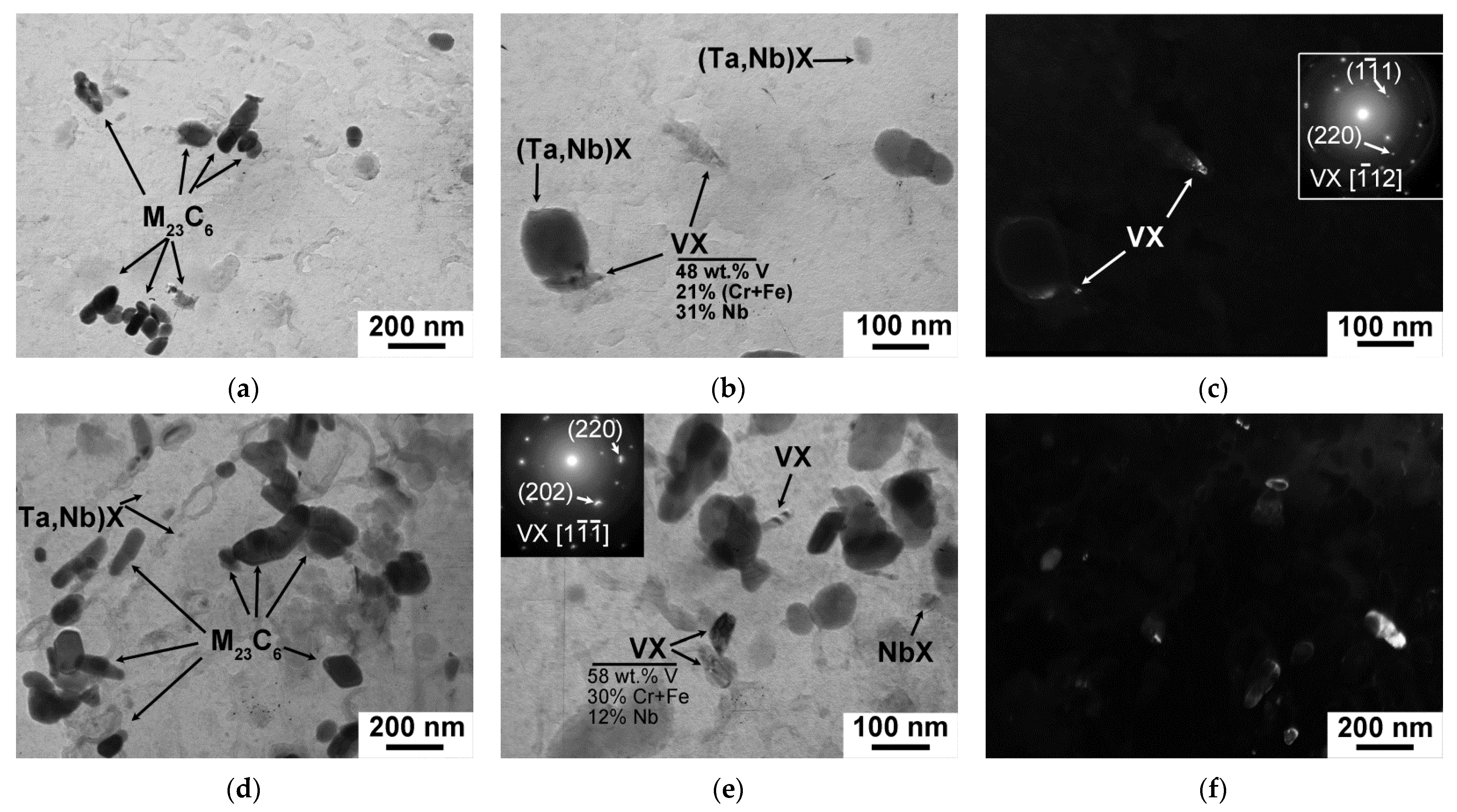

3.6. Structure of the 12CrTaNb0.02N Steel Subjected to CHT and TMP

- (a)

- a decrease in the delta-ferrite amount to 10%;

- (b)

- a decrease in the mean size of PAGs to 43 μm.

3.7. The Relationship between the Microstructural Characteristics and Impact Toughness

4. Conclusions

- The TMP positively affects the impact toughness of all different 12% Cr steels. This reduces the DBTT by 10–20 K for all 12% Cr steels. For the 12% Cr steels containing Ta, the TMP shifts all entire Charpy energy curves to higher values by 30–50 J cm−2, including the lower and upper shelf energies.

- At room temperature, the Charpy energy of all 12% Cr steels exposed to the TMP comprises of more than 60 J cm−2, which is feasible for commercial application as a structural material for fossil power plants. Moreover, the 12% Cr steels containing Ta retain 40 J cm−2 Charpy energy even at the temperatures lower than −20 °C.

- The TMP provides the almost full dissolution of delta-ferrite in the 12% Cr steel with ultra-low N content and decreased the fraction of delta-ferrite (about 10%) in the 12CrTaNb0.02N steel.

- In the 12% Cr steels containing Ta, the TMP leads to a decrease in the mean size of PAGs by 20–26%. For the 12% Cr steels with ultra-low N content, the TMP causes the changes in the dispersion of M23C6 carbides and MX carbonitrides.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kern, T.-U.; Staubli, M.; Scarlin, B. The European Efforts in Material Development for 650 °C USC power plants—COST522. ISIJ Int. 2002, 42, 1515–1519. [Google Scholar] [CrossRef]

- Abe, F.; Kern, T.-U.; Viswanathan, R. Creep-Resistant Steels; Woodhead Publishing: Cambridge, MA, USA, 2008; p. 678. [Google Scholar]

- Abe, F.; Tabuchi, M.; Tsukamoto, S. Alloy Design of MARBN for Boiler and Turbine Applications at 650 °C. Mater. High Temp. 2021, 38, 306–321. [Google Scholar] [CrossRef]

- Maruyama, K.; Sekido, N.; Yoshimi, K. Changes in strengthening mechanisms in creep of 9Cr-1.8W-0.5Mo-VNb steel tested over wide ranges of creep conditions. Int. J. Press. Vessel. Pip. 2021, 190, 104312. [Google Scholar] [CrossRef]

- Sawada, K.; Kimura, K.; Abe, F.; Taniuchi, Y.; Sekido, K.; Nojima, T.; Ohba, T.; Kushima, H.; Miyazaki, H.; Hongo, H.; et al. Catalog of NIMS creep data sheets. Sci. Technol. Adv. Mater. 2019, 20, 1131–1149. [Google Scholar] [CrossRef] [Green Version]

- Abe, F. Progress in Creep-Resistant Steels for High Efficiency Coal-Fired Power Plants. J. Press. Vessel. Technol. 2016, 138, 040804. [Google Scholar] [CrossRef]

- Kaibyshev, R.; Mishnev, R.; Fedoseeva, A.; Dudova, N. The Role of Microstructure in Creep Strength of 9–12% Cr Steels. Mater. Sci. Forum 2016, 879, 36–41. [Google Scholar] [CrossRef]

- Fedoseeva, A.; Nikitin, I.; Dudova, N.; Kaibyshev, R. On effect of rhenium on mechanical properties of a high-Cr creep-resistant steel. Mater. Lett. 2019, 236, 81–84. [Google Scholar] [CrossRef]

- Sklenička, V.; Kuchařová, K.; Kvapilová, M.; Kloc, L.; Dvořák, J.; Král, P. High-Temperature Creep Tests of Two Creep-Resistant Materials at Constant Stress and Constant Load. Key Eng. Mater. 2019, 827, 246–251. [Google Scholar] [CrossRef]

- Fedoseeva, A.E.; Kozlov, P.A.; Dudko, V.A.; Skorobogatykh, V.N.; Shchenkova, I.A.; Kaibyshev, R.O. Microstructural changes in steel 10Kh9V2MFBR during creep for 40,000 hours at 600 °C. Phys. Met. Metallogr. 2015, 116, 1047–1056. [Google Scholar] [CrossRef]

- Wang, P.; Lu, S.; Xiao, N.; Li, D.; Li, Y. Effect of delta ferrite on impact properties of low carbon 13Cr–4Ni martensitic stainless steel. Mater. Sci. Eng. A 2010, 527, 3210–3216. [Google Scholar] [CrossRef]

- Niessen, F.; Tiedje, N.S.; Hald, J. Kinetics modeling of delta-ferrite formation and retainment during casting of supermartensitic stainless steel. Mater. Des. 2017, 118, 138–145. [Google Scholar] [CrossRef] [Green Version]

- Hald, J. Microstructure and long-term creep properties of 9–12% Cr steels. Int. J. Press. Vessel. Pip. 2008, 85, 30–37. [Google Scholar] [CrossRef]

- Danielsen, H.K.; Di Nunzio, P.E.; Hald, J. Kinetics of Z-Phase Precipitation in 9 to 12 pct Cr Steels. Met. Mater. Trans. A 2013, 44, 2445–2452. [Google Scholar] [CrossRef] [Green Version]

- Danielsen, H.K. Review of Z phase precipitation in 9–12 wt-% Cr steels. Mater. Sci. Technol. 2015, 32, 126–137. [Google Scholar] [CrossRef] [Green Version]

- Sawada, K.; Kushima, H.; Kimura, K. Z-phase Formation during Creep and Aging in 9–12% Cr Heat Resistant Steels. ISIJ Int. 2006, 46, 769–775. [Google Scholar] [CrossRef] [Green Version]

- Kocer, C.; Abe, T.; Soon, A. The Z-phase in 9–12% Cr ferritic steels: A phase stability analysis. Mater. Sci. Eng. A 2009, 505, 1–5. [Google Scholar] [CrossRef]

- Fedoseeva, A.; Nikitin, I.; Dudova, N.; Kaibyshev, R. Strain-induced Z-phase formation in a 9% Cr-3% Co martensitic steel during creep at elevated temperature. Mater. Sci. Eng. A 2018, 724, 29–36. [Google Scholar] [CrossRef]

- Nikitin, I.; Fedoseeva, A.; Kaibyshev, R. Strengthening mechanisms of creep-resistant 12% Cr–3% Co steel with low N and high B contents. J. Mater. Sci. 2020, 55, 7530–7545. [Google Scholar] [CrossRef]

- Fedoseeva, A.E.; Nikitin, I.S.; Dudova, N.R.; Kaibyshev, R.O. Analysis of Mechanical Properties for the Heat Resistant Co-Modified 12 and 9% Cr Steels. Phys. Met. Met. 2020, 121, 1233–1239. [Google Scholar] [CrossRef]

- Borisova, J.; Dudko, V.; Mishnev, R.; Kaibyshev, R. Effect of Laves Phase on Ductile-Brittle Transition of 12 Pct Cr Steel. Met. Mater. Trans. A 2019, 50, 3528–3543. [Google Scholar] [CrossRef]

- Chatterjee, A.; Chakrabarti, D.; Moitra, A.; Mitra, R.; Bhaduri, A. Effect of normalization temperatures on ductile–brittle transition temperature of a modified 9Cr–1Mo steel. Mater. Sci. Eng. A 2014, 618, 219–231. [Google Scholar] [CrossRef]

- Cui, C.; Gao, X.; Su, G.; Gao, C.; Liu, Z.; Misra, R.D.K. Effect of thermal treatment on the evolution of delta ferrite in 11Cr–3Co–2.3W steel. Mater. Sci. Technol. 2018, 34, 2087–2096. [Google Scholar] [CrossRef]

- Liu, Y.; Sun, J.; Li, J.; Jiang, B.; Zhang, C. Investigation of forging process for eliminating delta ferrites in USC unites last stage blades steel 10Cr12Ni3Mo2VN. Procedia Eng. 2017, 207, 1797–1802. [Google Scholar] [CrossRef]

- Li, J.; Cheng, L.; Zhang, P.; Wang, L.; Li, H. Effect of delta ferrites on the anisotropy of impact toughness in martensitic heat-resistant steel. J. Mater. Res. Technol. 2019, 8, 1781–1788. [Google Scholar] [CrossRef]

- Pandey, C.; Mahapatra, M.M.; Kumar, P.; Saini, N.; Thakre, J.G.; Vidyarthy, R.; Narang, H. A brief study on δ-ferrite evolution in dissimilar P91 and P92 steel weld joint and their effect on mechanical properties. Arch. Civ. Mech. Eng. 2018, 18, 713–722. [Google Scholar] [CrossRef]

- Bashu, S.; Singh, K.; Rawat, M. Effect of heat treatment on mechanical properties and fracture behaviour of a 12CrMoV steel. Mater. Sci. Eng. A 1990, 127, 7–15. [Google Scholar] [CrossRef]

- Carrouge, D.; Bhadeshia, H.; Woollin, P. Effect of δ-ferrite on impact properties of supermartensitic stainless steel heat affected zones. Sci. Technol. Weld. Join. 2004, 9, 377–389. [Google Scholar] [CrossRef]

- Alkan, G.; Chae, D.; Kim, S.-J. Effect of δ ferrite on impact property of hot-rolled 12Cr–Ni steel. Sci. Technol. Weld. Join. 2013, 9, 377–389. [Google Scholar] [CrossRef]

- Schäfer, L. Influence of delta ferrite and dendritic carbides on the impact and tensile properties of a martensitic chromium steel. J. Nucl. Mater. 1998, 258–263, 1336–1339. [Google Scholar] [CrossRef]

- Dudko, V.; Fedoseeva, A.; Kaibyshev, R. Ductile-brittle transition in a 9% Cr heat-resistant steel. Mater. Sci. Eng. A 2017, 682, 73–84. [Google Scholar] [CrossRef]

- Fedoseeva, A.; Dudova, N.; Kaibyshev, R. Role of Tungsten in the Tempered Martensite Embrittlement of a Modified 9 Pct Cr Steel. Met. Mater. Trans. A 2017, 48, 982–998. [Google Scholar] [CrossRef]

- Fedoseeva, A.; Nikitin, I.; Dudova, N.; Hald, J.; Kaibyshev, R. Effect of the Thermo-Mechanical Processing on the Impact Toughness of a 12% Cr Martensitic Steel with Co, Cu, W, Mo and Ta Doping. Metals 2022, 12, 3. [Google Scholar] [CrossRef]

- Fedoseeva, A.; Kaibyshev, R. Impact toughness of a 12% Cr martensitic steel: Conventional heat treatment vs. thermomechanical processing. Mater. Lett. 2022; submitted. [Google Scholar]

- ASTM E 23-12c; Standard Test Methods for Notched Bar Impact Testing of Metallic Materials. ASTM: West Conshohocken, PA, USA, 2013; Volume i, pp. 1–25.

- Lubimyi, N.S.; Polshin, A.A.; Gerasimov, M.D.; Tikhonov, A.A.; Antsiferov, S.I.; Chetverikov, B.S.; Ryazantsev, V.G.; Brazhnik, J.; Ridvanov, I. Justification of the Use of Composite Metal-Metal-Polymer Parts for Functional Structures. Polymers 2022, 14, 352. [Google Scholar] [CrossRef] [PubMed]

- Mullet, C.; Kinson, J.; Ferjutz, K.; Lampman, H.; Riddlebaugh, M.J. ASM Handbook: Mechanical Testing and Evaluation 8; ASM International: New York, NY, USA, 2000; p. 2235. [Google Scholar]

- Bergquist, E.-L. Consumable and Welding Modified 9Cr-1Mo Steel. Svetsaran 1999, 1–2, 22–25. [Google Scholar]

- Chaouadi, R.; Fabry, A. On the utilization of the instrumented Charpy impact test for characterizing the flow and fracture behavior of reactor pressure vessel steels. Eur. Struct. Integr. Soc. 2002, 30, 103–117. [Google Scholar] [CrossRef]

- Dudova, N.; Mishnev, R.; Kaibyshev, R. Creep behavior of a 10% Cr heat-resistant martensitic steel with low nitrogen and high boron contents at 650 °C. Mater. Sci. Eng. A 2019, 766, 138353. [Google Scholar] [CrossRef]

- Fedoseeva, A.; Nikitin, I.; Tkachev, E.; Mishnev, R.; Dudova, N.; Kaibyshev, R. Effect of Alloying on the Nucleation and Growth of Laves Phase in the 9–10% Cr-3% Co Martensitic Steels during Creep. Metals 2020, 11, 60. [Google Scholar] [CrossRef]

| Ingots | Fe | C | Cr | Co | Mo | W | V | Nb | Ta | Cu | B | N |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 12CrTaNb0.003N | bal | 0.1 | 11.4 | 3.0 | 0.6 | 2.5 | 0.2 | 0.04 | 0.07 | 0.8 | 0.010 | 0.003 |

| 12CrNb0.003N | bal | 0.1 | 11.3 | 3.9 | 0.6 | 2.4 | 0.2 | 0.07 | - | 0.8 | 0.010 | 0.003 |

| 12CrTaNb0.02N | bal | 0.1 | 11.9 | 3.0 | 0.6 | 2.2 | 0.3 | 0.05 | 0.07 | 0.8 | 0.012 | 0.02 |

| Test Temperature, °C | 12CrTaNb0.003N | 12CrNb0.003N | 12CrTaNb0.02N | |||

|---|---|---|---|---|---|---|

| CHT | TMP | CHT | TMP | CHT | TMP | |

| −20 | 6.3 | 26.3 | 15.7 | 7.2 | 8.2 | 12.4 |

| 0 | 6.2 | 26.3 | 16.0 | 6.9 | 6.9 | 20.1 |

| 10 | 7.7 | 31.5 | 16.1 | 15.2 | - | - |

| 25 | 8.9 | 51.4 | 16.2 | 43.1 | 37.0 | 35.3 |

| 40 | 40.1 | 50.1 | 49.2 | 46.9 | 41.6 | 37.9 |

| 60 | 36.4 | 61.9 | 48.6 | 47.7 | 40.6 | - |

| 80 | 42.6 | 57.8 | 47.1 | 48.9 | 41.8 | 38.0 |

| 100 | 44.6 | 50.2 | 45.5 | 46.7 | 41.5 | - |

| 120 | 45.0 | 50.1 | 47.1 | 46.6 | 39.6 | - |

| Test Temperature, °C | 12CrTaNb0.003N | 12CrNb0.003N | 12CrTaNb0.02N | |||

|---|---|---|---|---|---|---|

| CHT | TMP | CHT | TMP | CHT | TMP | |

| −20 | 5.3 | 11.0 | 3.9 | 4.9 | 13.8 | 8.2 |

| 0 | 5.5 | 9.7 | 7.1 | 5.3 | 4.5 | 10.2 |

| 10 | 5.6 | 11.5 | 6.4 | 10.2 | - | - |

| 25 | 11.5 | 17.6 | 6.5 | 12.1 | 12.3 | 52.9 |

| 40 | 14.1 | 38.1 | 35.5 | 33.7 | 25.1 | 76.7 |

| 60 | 22.4 | 118.7 | 29.2 | 64.2 | 83.3 | - |

| 80 | 76.3 | 110.4 | 87.0 | 129.6 | 94.5 | 80.0 |

| 100 | 107.9 | 133.8 | 153.0 | 148.0 | 80.4 | - |

| 120 | 122.1 | 169.1 | 161.4 | 147.1 | 113.7 | - |

| Test Temperature, °C | 12CrTaNb0.003N | 12CrNb0.003N | 12CrTaNb0.02N | |||

|---|---|---|---|---|---|---|

| CHT | TMP | CHT | TMP | CHT | TMP | |

| −20 | 775.4 | 970.7 | 757.5 | 805.2 | 511.7 | 774.0 |

| 0 | 780.2 | 975.5 | 1071.6 | 763.5 | 732.7 | 764.4 |

| 10 | 806.1 | 1082.2 | 1030.4 | 1058.8 | - | - |

| 25 | 852.9 | 1098.7 | 1030.4 | 1147.7 | 1041.8 | 786.9 |

| 40 | 1059.2 | 1081.3 | 1131.7 | 1152.8 | 1001.0 | 747.0 |

| 60 | 1008.8 | 1071.6 | 1113.4 | 1110.6 | 1088.6 | - |

| 80 | 1033.6 | 1052.8 | 1102.8 | 1120.2 | 1023.9 | 750.2 |

| 100 | 1022.6 | 1034.0 | 1084.0 | 1095.0 | 954.7 | - |

| 120 | 1004.2 | 1028.1 | 1070.2 | 1076.7 | 1055.1 | - |

| 12CrTaNb0.003N | 12CrNb0.003N | 12CrTaNb0.02N | ||||

|---|---|---|---|---|---|---|

| CHT | TMP | CHT | TMP | CHT | TMP | |

| IZ | 0.26 | 0.24 | 0.20 | 0.24 | 0.27 | 0.26 |

| SPZ | - | 0.93 | - | 0.73 | 0.32 | 1.04 |

| UPZ | 7.23 | 6.66 | 7.69 | 6.45 | 6.94 | 4.25 |

| AZ | 0.30 | - | - | 0.53 | 1.0 | 2.2 |

| Temperature, °C | 12CrTaNb0.003N | 12CrNb0.003N | 12CrTaNb0.02N |

|---|---|---|---|

| A1 | 850 | 840 | 840 |

| A3 | 920 | 900 | 960 |

| A4 | 1080 | 1130 | 1050 |

| Treatment | Structure | Particles | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| PAG * Size, μm | δ-Ferrite Fraction, % | Lath Width, μm | ρdisl, ×1014 m−2 | Size, nm | Volume Fraction (by Thermo-Calc), % | |||||

| M23C6 | TaX | VX | W-Rich | M23C6 | TaX | |||||

| CHT | 48 ± 4 | 10 ± 2 | 0.29 ± 0.05 | 2.0 ± 0.1 | 50 ± 5 | 50 ± 5 | - | 600 ± 50 | 2.25 | 0.08 |

| TMP | 40 ± 4 | 1 ± 0.2 | 0.28 ± 0.05 | 2.2 ± 0.1 | 64 ± 5 | 89 ± 5 | 30 ± 5 | 650 ± 50 | 2.25 | 0.08 |

| Treatment | Structure | Particles | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| PAG * size, μm | δ-Ferrite Fraction, % | Lath Width, μm | ρdisl, ×1014 m−2 | Size, nm | Volume Fraction (by Thermo-Calc), % | |||||

| M23C6 | NbX | VX | W-Rich | M23C6 | NbX | |||||

| CHT | 51 ± 4 | 6 ± 2 | 0.31 ± 0.05 | 1.5 ± 0.1 | 51 ± 5 | 29 ± 5 | - | 700 ± 50 | 1.60 | 0.08 |

| TMP | 50 ± 4 | 0.5 ± 0.2 | 0.27 ± 0.05 | 2.1 ± 0.1 | 54 ± 5 | 20 ± 5 | 12 ± 5 | 600 ± 50 | 1.60 | 0.08 |

| Treatment | Structure | Particles | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| PAG * Size, μm | δ-Ferrite Fraction, % | Lath Width, μm | ρdisl, ×1014 m−2 | Size, nm | Volume Fraction (by Thermo-Calc), % | ||||||

| M23C6 | TaX | VX | W-Rich | M23C6 | TaX | VX | |||||

| CHT | 58 ± 4 | 15 ± 2 | 0.35 ± 0.05 | 1.4 ± 0.1 | 64 ± 5 | 78 ± 5 | 26 ± 5 | 700 ± 50 | 1.77 | 0.08 | 0.21 |

| TMP | 43 ± 4 | 10 ± 2 | 0.40 ± 0.05 | 1.9 ± 0.1 | 68 ± 5 | 80 ± 5 | 34 ± 5 | 800 ± 50 | 1.77 | 0.08 | 0.21 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fedoseeva, A.; Dolzhenko, A.; Kaibyshev, R. Thermo-Mechanical Processing as Method Decreasing Delta-Ferrite and Improving the Impact Toughness of the Novel 12% Cr Steels with Low N and High B Contents. Materials 2022, 15, 8861. https://doi.org/10.3390/ma15248861

Fedoseeva A, Dolzhenko A, Kaibyshev R. Thermo-Mechanical Processing as Method Decreasing Delta-Ferrite and Improving the Impact Toughness of the Novel 12% Cr Steels with Low N and High B Contents. Materials. 2022; 15(24):8861. https://doi.org/10.3390/ma15248861

Chicago/Turabian StyleFedoseeva, Alexandra, Anastasiia Dolzhenko, and Rustam Kaibyshev. 2022. "Thermo-Mechanical Processing as Method Decreasing Delta-Ferrite and Improving the Impact Toughness of the Novel 12% Cr Steels with Low N and High B Contents" Materials 15, no. 24: 8861. https://doi.org/10.3390/ma15248861