Effect of Hot Deformation Parameters on Heat-Treated Microstructures and Mechanical Properties of 300M Steel

Abstract

1. Introduction

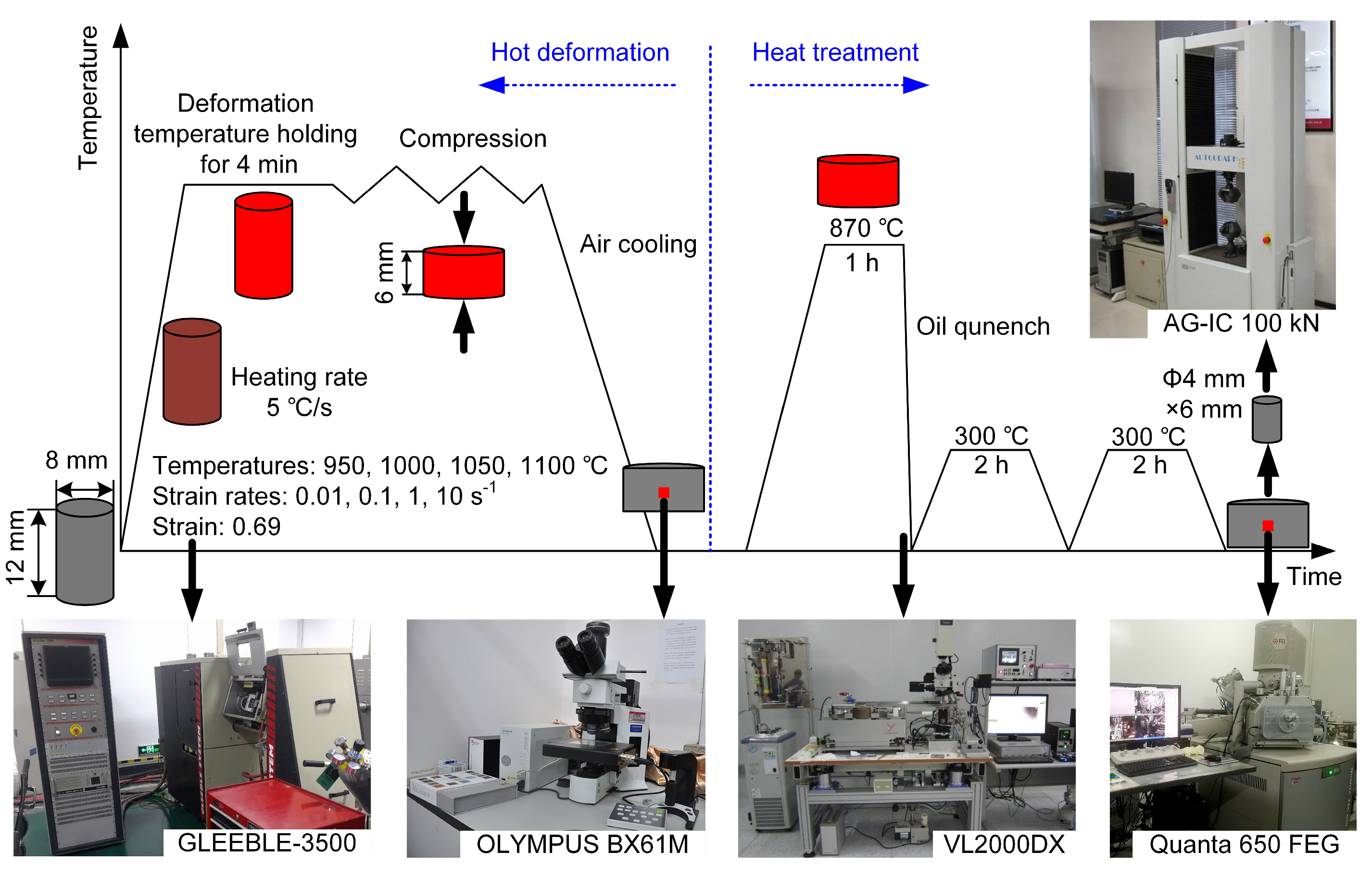

2. Materials and Methods

3. Results and Discussion

3.1. Microstructure

3.2. Mechanism of Microstructure Evolution

3.3. Mechanical Properties

4. Conclusions

- (1)

- Dynamic recrystallization occurred after hot deformation, and the microstructure after heat treatment was mainly martensite. With the increase of the Z parameter, the recrystallization grain size and the martensite unit size decreased. In addition, the decreasing tendency of the martensite block width and the martensite packet size also increased.

- (2)

- With the increase of the Z parameter, annealing twins were formed during the heat treatment. The twin boundaries hinder the growth of martensite, making the decreasing tendency of the martensite unit size increase.

- (3)

- The yield strength was mainly affected by the martensite unit size and increased with the increase of the Z parameter. When ln Z > 36, annealing twins were formed and the increasing tendency of yield strength increased.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bag, A.; Lévesque, M.; Brochu, M. Effect of shot peening on short crack propagation in 300M steel. Int. J. Fatigue 2019, 131, 105346. [Google Scholar] [CrossRef]

- Sadeghifar, M.; Sedaghati, R.; Jomaa, W.; Songmene, V. Finite element analysis and response surface method for robust multi-performance optimization of radial turning of hard 300M steel. Int. J. Adv. Manuf. Technol. 2018, 94, 2457–2474. [Google Scholar] [CrossRef]

- Graça, M.; Hoo, C.; Silva, O.; Lourenço, N. Failure analysis of a 300M steel pressure vessel. Eng. Fail. Anal. 2009, 16, 182–186. [Google Scholar] [CrossRef]

- Skubisz, P.; Sinczak, J. Properties of direct-quenched aircraft forged component made of ultrahigh-strength steel 300M. Aircr. Eng. Aerosp. Technol. 2018, 90, 713–719. [Google Scholar] [CrossRef]

- Chen, X.-M.; Lin, Y.; Wu, F. EBSD study of grain growth behavior and annealing twin evolution after full recrystallization in a nickel-based superalloy. J. Alloys Compd. 2017, 724, 198–207. [Google Scholar] [CrossRef]

- Chen, G.; Li, H.; Wang, G.; Guo, Z.; Zhang, S.; Dai, Q.; Wang, X.; Zhang, G.; Shi, Q. Effects of pin thread on the in-process material flow behavior during friction stir welding: A computational fluid dynamics study. Int. J. Mach. Tools Manuf. 2018, 124, 12–21. [Google Scholar] [CrossRef]

- Skubisz, P.; Łukaszek-Sołek, A. Effect of Processing Conditions on Forgeability and Properties of Hot and Warm-Forged Steel 300M. Arch. Met. Mater. 2017, 62, 2247–2254. [Google Scholar] [CrossRef][Green Version]

- Qi, R.-S.; Guo, B.-F.; Liu, X.-G.; Jin, M. Flow Stress Behaviors and Microstructure Evolution of 300M High Strength Steel Under Isothermal Compression. J. Iron Steel Res. Int. 2014, 21, 1116–1123. [Google Scholar] [CrossRef]

- Luo, J.; Li, M.; Liu, Y.; Sun, H. The deformation behavior in isothermal compression of 300M ultrahigh-strength steel. Mater. Sci. Eng. A 2011, 534, 314–322. [Google Scholar] [CrossRef]

- Liu, Y.; Li, M.; Luo, J. The modelling of dynamic recrystallization in the isothermal compression of 300M steel. Mater. Sci. Eng. A 2013, 574, 1–8. [Google Scholar] [CrossRef]

- Guo, P.; Deng, L.; Wang, X.; Li, J. Modelling of dynamic recrystallization kinetics of 300M steel at high strain rates during hot deformation. Sci. China Technol. Sci. 2019, 62, 1534–1544. [Google Scholar] [CrossRef]

- Liu, Y.; Li, M. Characteristics of martensite transformed from deformed austenite with various states of ultrahigh strength 300M steel. Mater. Charact. 2018, 144, 490–497. [Google Scholar] [CrossRef]

- Kasana, S.S.; Sharma, S.; Pandey, O.P. Influence of heat treatment (routes) on the microstructure and mechanical properties of 300M ultra high strength steel. Arch. Civ. Mech. Eng. 2022, 22, 1–15. [Google Scholar] [CrossRef]

- Chentouf, S.M.; Jahazi, M.; Fortin, R. Influence of the Quench Process on Microstructure Evolution in a Landing Gear Steel. Am. Soc. Mech. Eng. 2014, 46569, V08BT10A068. [Google Scholar]

- Prawoto, Y.; Jasmawati, N.; Sumeru, K. Effect of Prior Austenite Grain Size on the Morphology and Mechanical Properties of Martensite in Medium Carbon Steel. J. Mater. Sci. Technol. 2012, 28, 461–466. [Google Scholar] [CrossRef]

- Morito, S.; Yoshida, H.; Maki, T.; Huang, X. Effect of block size on the strength of lath martensite in low carbon steels. Mater. Sci. Eng. A 2006, 438-440, 237–240. [Google Scholar] [CrossRef]

- Morito, S.; Saito, H.; Ogawa, T.; Furuhara, T.; Maki, T. Effect of Austenite Grain Size on the Morphology and Crystallography of Lath Martensite in Low Carbon Steels. ISIJ Int. 2005, 45, 91–94. [Google Scholar] [CrossRef]

- Santosh, S.; Sampath, V.; Mouliswar, R. Hot deformation characteristics of NiTiV shape memory alloy and modeling using constitutive equations and artificial neural networks. J. Alloys Compd. 2022, 901, 163451. [Google Scholar] [CrossRef]

- Santosh, S.; Praveen, R.; Sampath, V. Influence of Cobalt on the Hot Deformation Characteristics of an NiTi Shape Memory Alloy. Trans. Indian Inst. Met. 2019, 72, 1465–1468. [Google Scholar] [CrossRef]

- Bernier, N.; Bracke, L.; Malet, L.; Godet, S. An alternative to the crystallographic reconstruction of austenite in steels. Mater. Charact. 2014, 89, 23–32. [Google Scholar] [CrossRef]

- Kong, H.; Chao, Q.; Cai, M.; Pavlina, E.; Rolfe, B.; Hodgson, P.; Beladi, H. One-step quenching and partitioning treatment of a commercial low silicon boron steel. Mater. Sci. Eng. A 2017, 707, 538–547. [Google Scholar] [CrossRef]

- Sang, D.-L.; Fu, R.-D.; Li, Y.-J.; Wang, Y.-P.; Kang, J. Interactions between twins and dislocations during dynamic microstructure evolution for hot shear-compression deformation of Fe-38Mn austenitic steel. J. Alloys Compd. 2018, 735, 2395–2400. [Google Scholar] [CrossRef]

- Safyari, M.; Moshtaghi, M.; Hojo, T.; Akiyama, E. Mechanisms of hydrogen embrittlement in high-strength aluminum alloys containing coherent or incoherent dispersoids. Corros. Sci. 2022, 194, 109895. [Google Scholar] [CrossRef]

- Chen, R.; Zheng, Z.; Li, N.; Li, J.; Feng, F. In-situ investigation of phase transformation behaviors of 300M steel in continuous cooling process. Mater. Charact. 2018, 144, 400–410. [Google Scholar] [CrossRef]

- Krauss, G. Martensite in steel: Strength and structure. Mater. Sci. Eng. A 1999, 273-275, 40–57. [Google Scholar] [CrossRef]

| C | Mn | Si | Ni | Cr | V | Mo | Fe |

|---|---|---|---|---|---|---|---|

| 0.38 | 0.74 | 1.64 | 1.87 | 0.84 | 0.08 | 0.40 | Balance |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, F.; Zhou, P.; Guo, P.; Li, C.; Deng, L.; Wang, X.; Jin, J. Effect of Hot Deformation Parameters on Heat-Treated Microstructures and Mechanical Properties of 300M Steel. Materials 2022, 15, 8927. https://doi.org/10.3390/ma15248927

Du F, Zhou P, Guo P, Li C, Deng L, Wang X, Jin J. Effect of Hot Deformation Parameters on Heat-Treated Microstructures and Mechanical Properties of 300M Steel. Materials. 2022; 15(24):8927. https://doi.org/10.3390/ma15248927

Chicago/Turabian StyleDu, Fei, Peng Zhou, Peng Guo, Cheng Li, Lei Deng, Xinyun Wang, and Junsong Jin. 2022. "Effect of Hot Deformation Parameters on Heat-Treated Microstructures and Mechanical Properties of 300M Steel" Materials 15, no. 24: 8927. https://doi.org/10.3390/ma15248927

APA StyleDu, F., Zhou, P., Guo, P., Li, C., Deng, L., Wang, X., & Jin, J. (2022). Effect of Hot Deformation Parameters on Heat-Treated Microstructures and Mechanical Properties of 300M Steel. Materials, 15(24), 8927. https://doi.org/10.3390/ma15248927