Positron Annihilation Spectroscopy Study of Metallic Materials after High-Speed Cutting

Abstract

1. Introduction

2. Materials and Methods

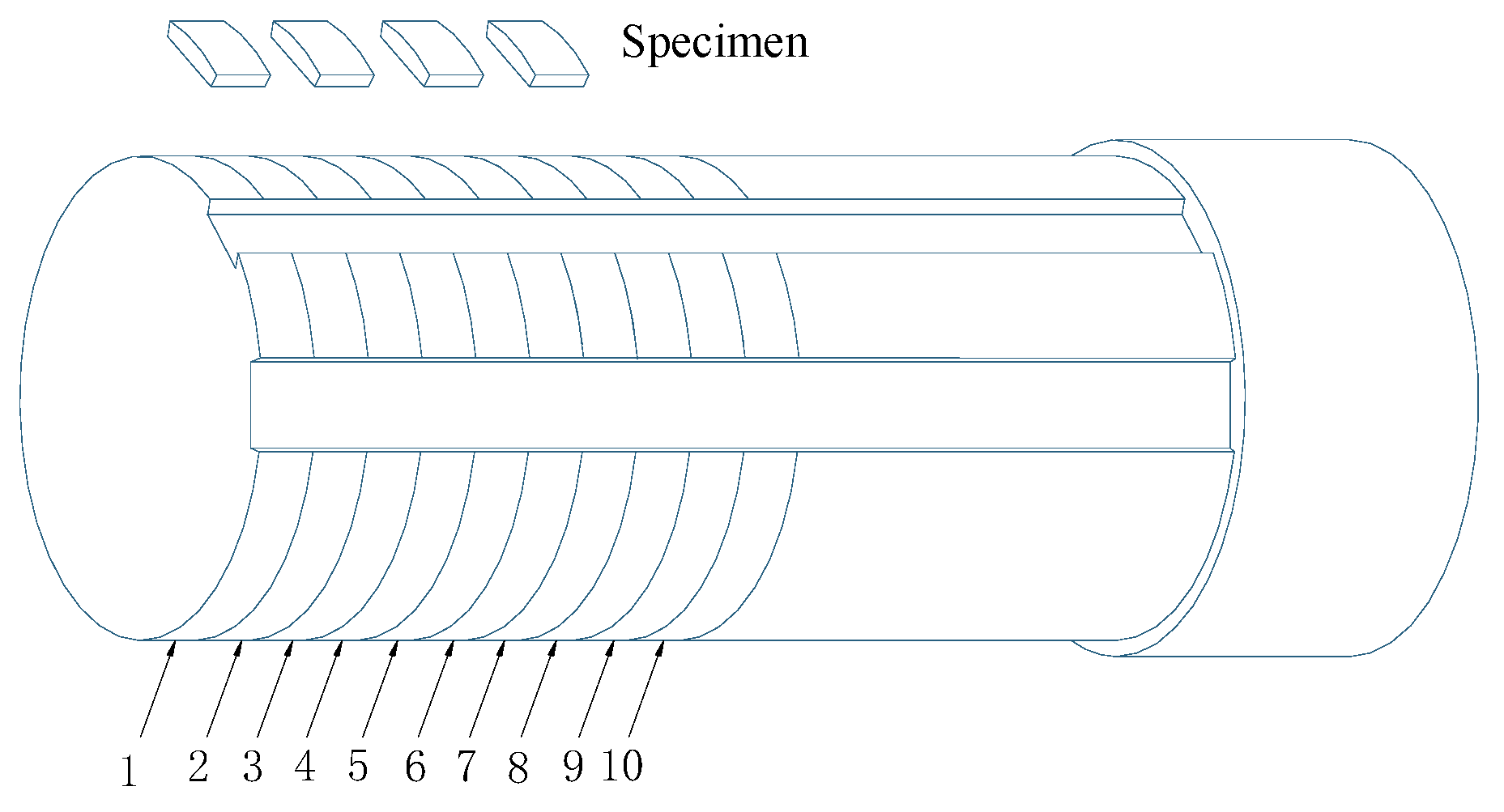

2.1. Cutting Test

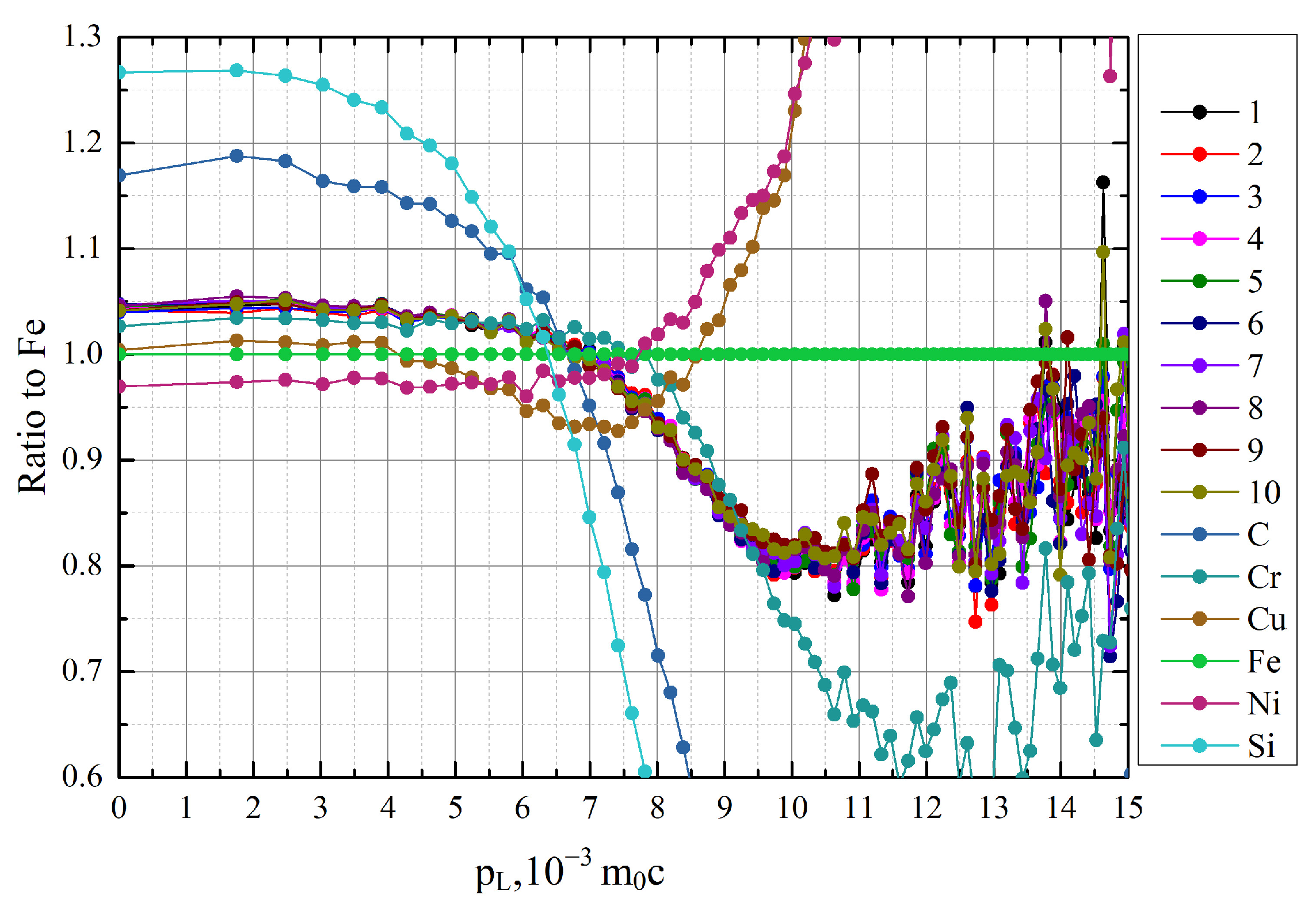

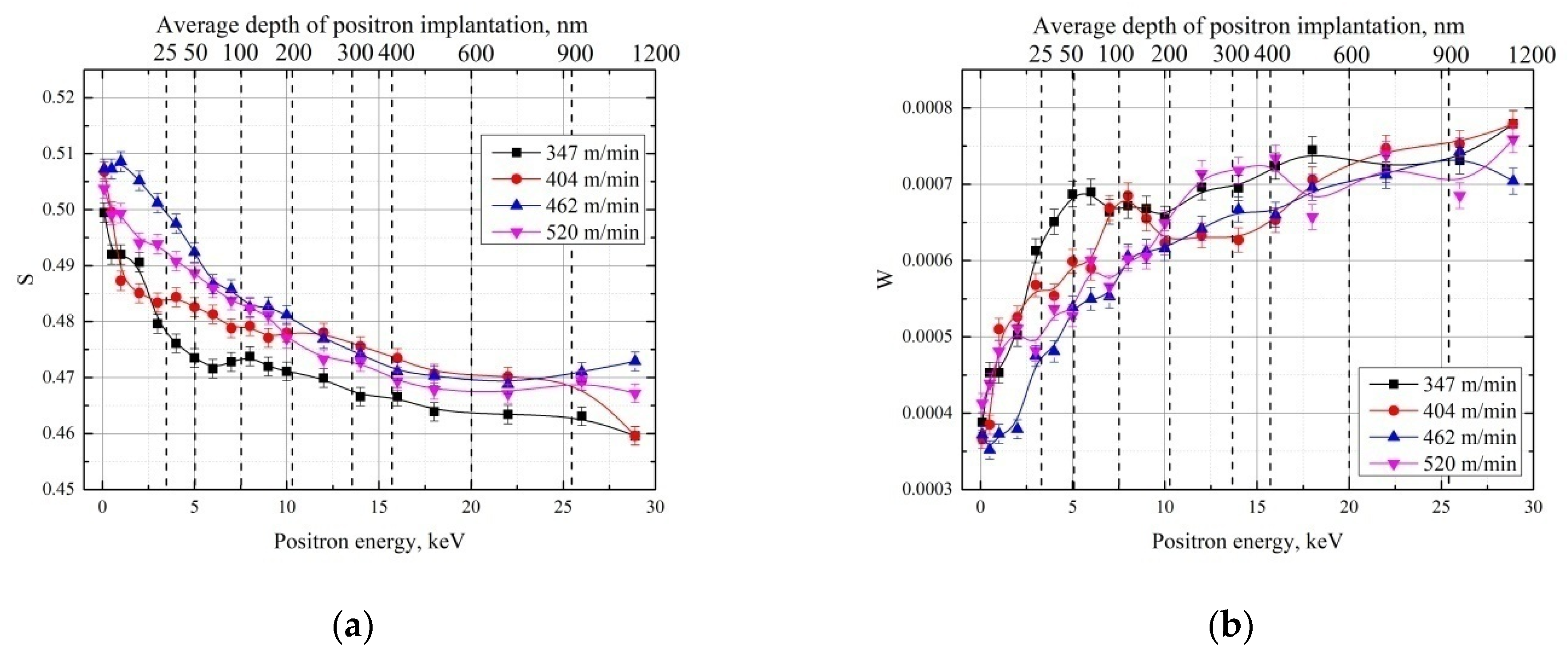

2.2. Positron Annihilation Experiment

3. Results and Discussion

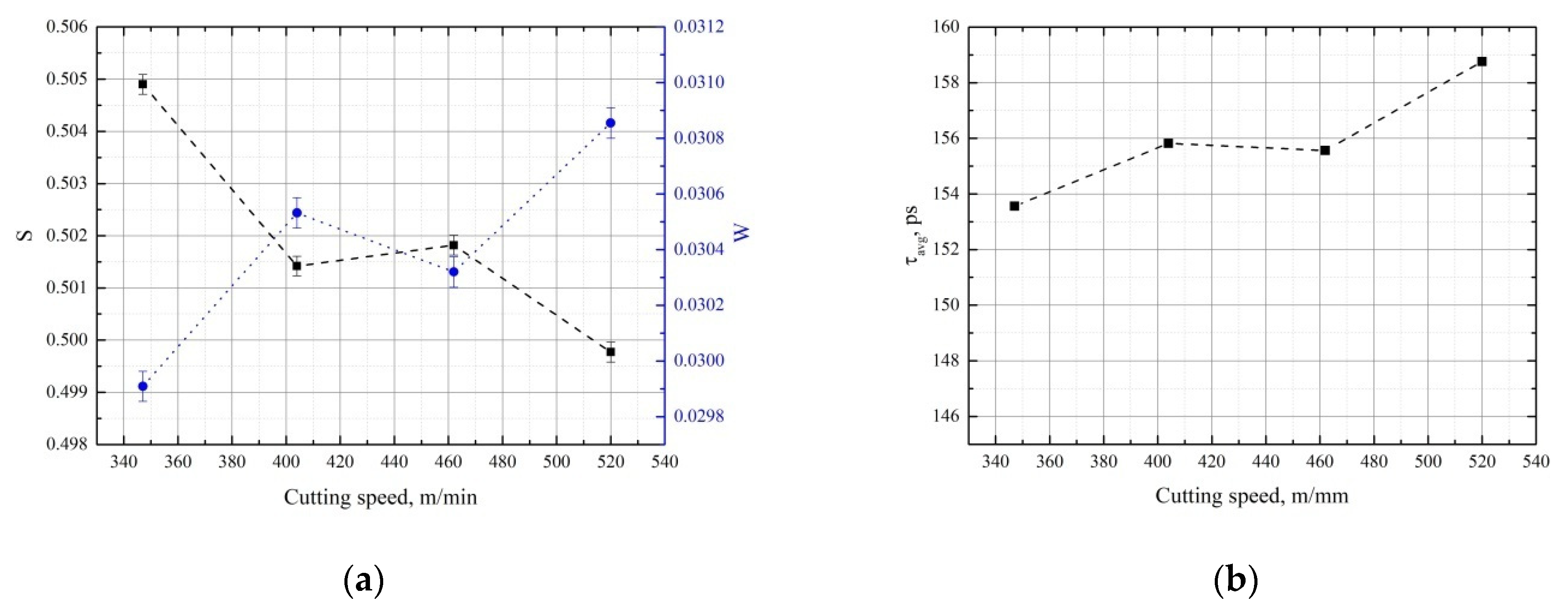

3.1. Influence of the Cutting Speed

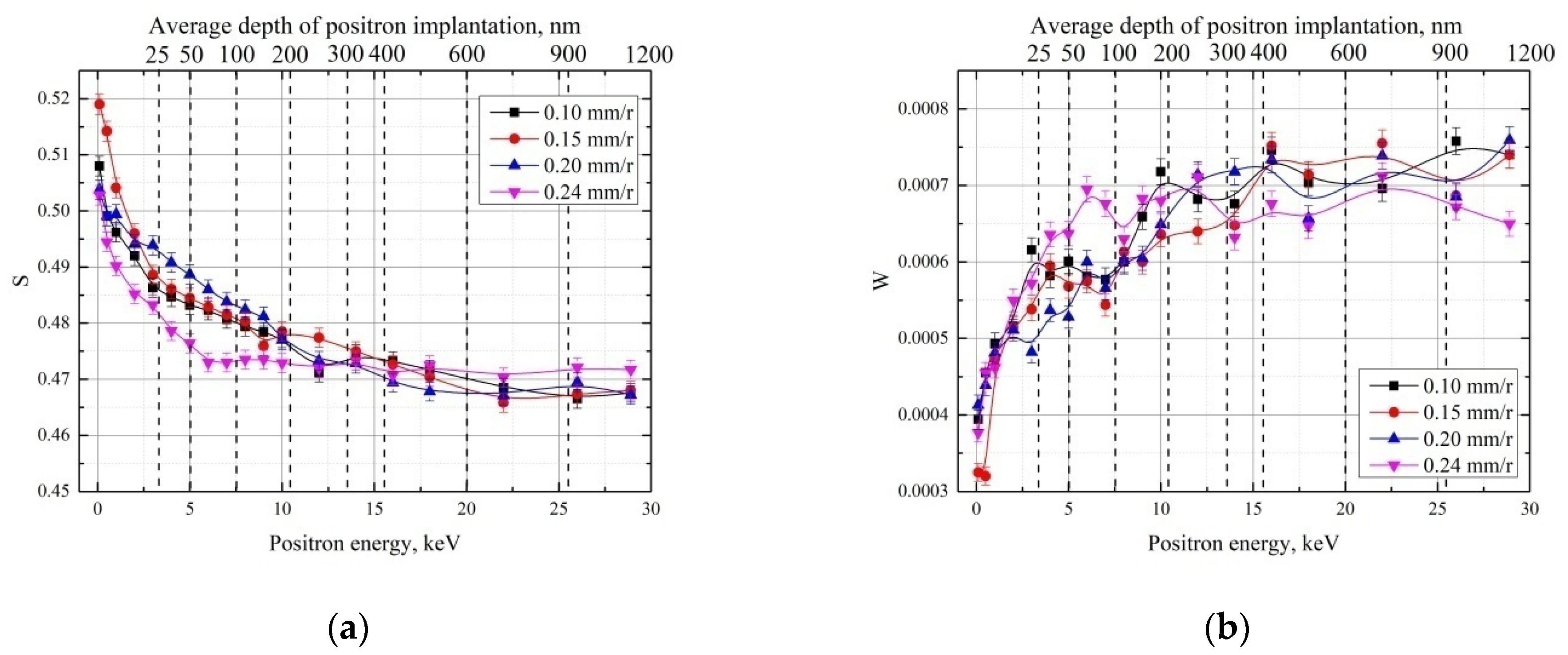

3.2. Influence of the Feed Rate

3.3. Influence of the Cutting Depth

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Poulachon, G.; Albert, A.; Schluraff, M.; Jawahir, I.S. An experimental investigation of work material microstructure effects on white layer formation in PCBN hard turning. Int. J. Mach. Tools Manuf. 2005, 45, 211–218. [Google Scholar] [CrossRef]

- Duan, C.; Zhang, F.; Kong, W. Modeling and prediction of white layer thickness in dry and hard machining of hardened steel. J. Mech. Eng. 2015, 51, 194–202. [Google Scholar] [CrossRef]

- Zhang, F.Y.; Duan, C.Z.; Wang, M.J. Research status of the machined surface metamorphic layer. Mach. Des. Manuf. 2014, 10, 265–268. [Google Scholar]

- König, W.; Komanduri, R.; Toenshoff, H.K.; Ackershott, G. Machining of hard materials. CIRP Ann. 1984, 33, 417–427. [Google Scholar] [CrossRef]

- Chou, Y.K.; Evans, C.J. White layers and thermal modeling of hard turned surfaces. Int. J. Mach. Tools Manuf. 1999, 39, 1863–1881. [Google Scholar] [CrossRef]

- Han, S.; Melkote, S.N.; Haluska, M.S.; Watkins, T.R. White layer formation due to phase transformation in orthogonal machining of AISI 1045 annealed steel. Mater. Sci. Eng. A 2008, 488, 195–204. [Google Scholar] [CrossRef]

- Bulpett, R.; Eyre, T.S.; Ralph, B. The characterization of white layers formed on digger teeth. Wear 1993, 162, 1059–1065. [Google Scholar] [CrossRef]

- Barry, J.; Byrne, G. TEM study on the surface white layer in two turned hardened steels. Mater. Sci. Eng. A 2002, 325, 356–364. [Google Scholar] [CrossRef]

- Umbrello, D. Analysis of the white layers formed during machining of hardened AISI 52100 steel under dry and cryogenic cooling conditions. Int. J. Adv. Manuf. Technol. 2013, 64, 633–642. [Google Scholar] [CrossRef]

- Chen, T.; Liu, X.; Li, S.; Li, K.; Liu, T. Mechanism of White Layer Formation on Machined Surface of High-speed Hard Machining. J. Mech. Eng. 2015, 51, 23. [Google Scholar] [CrossRef]

- Zhanqiang, L. Thermo-mechanical Coupling Mechanisms for White Layer Formation on Machined Surface of Powder Metallurgical Nickel-based Superalloy. J. Mech. Eng. 2014, 50, 186. (In Chinese) [Google Scholar]

- Weng, H.; Zhou, X.; Ye, B.; Han, R. Others Films, interfaces and near surface studies using variable energy positron beam. Wuli 2000, 29, 308–312. [Google Scholar]

- Hu, Y.-C.; Cao, X.; Li, Y.-X.; Zhang, P.; Jin, S.; Lu, E.; Yu, R.S.; Wei, L.; Wang, B. Applications and progress of slow positron beam technique in the study of metal/alloy microdefects. Acta Phys. Sin. 2015, 64, 247804. [Google Scholar]

- Cheng, G.; Cao, X.; Wu, J.; Wu, H.; Yang, J.; Jiang, X.; Yu, R.; Wang, B. Advances in Investigating Micro-defects in Fe-Cu Alloys Using Positron Annihilation Techniques. Mater. Rev. 2013, 3, 133–136. [Google Scholar]

- Xiaoyong, W.; Tao, P.A.N.; Hua, W.; Hang, S.U.; Xiangyang, L.I.; Xingzhong, C.A.O. Investigation of the toughness of low carbon tempered martensite in the surface of Ni-Cr-Mo-B ultra-heavy plate steel. Acta Met. Sin. 2012, 48, 401–406. [Google Scholar]

- Wu, Y.; Zhang, X. Applications of positron annihilation technology for metals and alloys. Wuli 2000, 29, 401–405. [Google Scholar]

- Padma, N.; Maheshwari, P.; Bhattacharya, D.; Tokas, R.B.; Sen, S.; Honda, Y.; Basu, S.; Pujari, P.K.; Rao, T.V.C. Investigations on substrate temperature-induced growth modes of organic semiconductors at dielectric/semiconductor interface and their correlation with threshold voltage stability in organic field-effect transistors. ACS Appl. Mater. Interfaces 2016, 8, 3376–3385. [Google Scholar] [CrossRef]

- Zhang, L.; Cheng, B.; Zhang, J.; Zhang, L.; Guo, W.; Liu, J.; Zhang, L.; Ye, B. Microstructure of functional materials probed by positron annihilation spectroscopy. Sci. Sin. Phys. Mech. Astron. 2012, 42, 1217–1225. [Google Scholar]

- Cao, X.; Song, L.-G.; Jin, S.; Zhang, R.-G.; Wang, B.; Wei, L. Advances in applications of positron annihilation spectroscopy to investigating semiconductor microstructures. Acta Phys. Sin. 2017, 66, 027801. [Google Scholar]

- Arutyunov, N.Y.; Elsayed, M.; Krause-Rehberg, R.; Emtsev, V.V.; Oganesyan, G.A.; Kozlovski, V.V. Positron annihilation on defects in silicon irradiated with 15 MeV protons. J. Phys. Condens. Matter 2012, 25, 35801. [Google Scholar] [CrossRef]

- Sedivy, L.; Cizek, J.; Belas, E.; Grill, R.; Melikhova, O. Positron annihilation spectroscopy of vacancy-related defects in CdTe: CI and CdZnTe: Ge at different stoichiometry deviations. Sci. Rep. 2016, 6, 20641. [Google Scholar] [CrossRef] [PubMed]

- Cizek, J. Characterization of lattice defects in metallic materials by positron annihilation spectroscopy: A review. J. Mater. Sci. Technol. 2018, 34, 577–598. [Google Scholar] [CrossRef]

- Selim, F.A. Positron annihilation spectroscopy of defects in nuclear and irradiated materials-a review. Mater. Charact. 2021, 174, 110952. [Google Scholar] [CrossRef]

- Krsjak, V.; Degmova, J.; Noga, P.; Petriska, M.; Sojak, S.; Saro, M.; Neuhold, I.; Slugen, V. Application of Positron Annihilation Spectroscopy in Accelerator-Based Irradiation Experiments. Materials 2021, 14, 6238. [Google Scholar] [CrossRef]

- Horodek, P.; Kobets, A.G.; Meshkov, I.N.; Sidorin, A.A.; Orlov, O.S. Slow positron beam at the JINR, Dubna. Nukleonika 2015, 60, 725–728. [Google Scholar] [CrossRef]

- Horodek, P.; Bugdol, M.; Kobets, A.G.; Meshkov, I.N.; Orlov, O.S.; Rudakov, A.Y.; Sidorin, A.A.; Yakovenko, S.L. Development of positron annihilation spectroscopy at LEPTA facility. Phys. Part. Nucl. Lett. 2014, 11, 708–712. [Google Scholar] [CrossRef][Green Version]

- Kuznetsov, P.V.; Mironov, Y.P.; Tolmachev, A.I.; Bordulev, Y.S.; Laptev, R.S.; Lider, A.M.; Korznikov, A.V. Positron spectroscopy of defects in submicrocrystalline nickel after low-temperature annealing. Phys. Solid State 2015, 57, 219–228. [Google Scholar] [CrossRef]

- Stepanova, E.; Bordulev, Y.; Kudiiarov, V.; Laptev, R.; Lider, A.; Xinming, J. Effect of hydrogen on the structural and phase state and defect structure of titanium alloy. In AIP Conference Proceedings; AIP Publishing LLC: Melville, NY, USA, 2016; Volume 1772, p. 30016. [Google Scholar]

- Giebel, D.; Kansy, J. A new version of LT program for positron lifetime spectra analysis. Mater. Sci. Forum 2011, 666, 138–141. [Google Scholar] [CrossRef]

- Giebel, D.; Kansy, J. LT10 program for solving basic problems connected with defect detection. Phys. Procedia 2012, 35, 122–127. [Google Scholar] [CrossRef]

- Krause-Rehberg, R.; Leipner, H.S. Positron Annihilation in Semiconductors: Defect Studies; Springer: Berlin, Germany, 1999. [Google Scholar]

- Petriska, M.; Sabelová, V.; Slugevn, V. CDBTools-evaluate positron annihilation coincidence Doppler broadening spectrum. Defect Diffus. Forum 2016, 373, 71–74. [Google Scholar] [CrossRef]

- Mizuno, M.; Araki, H.; Shirai, Y. Theoretical calculation of positron lifetimes for defects in solids. Adv. Quant. Chem. 2003, 42, 109–126. [Google Scholar]

- Hosseini, S.B.; Klement, U.; Kaminski, J. Microstructure Characterization of White Layer Formed by Hard Turning and Wire Electric Discharge Machining in High Carbon Steel (AISI 52100). Adv. Mater. Res. 2011, 409, 684–689. [Google Scholar] [CrossRef]

- Kamimura, Y.; Tsutsumi, T.; Kuramoto, E. Calculations of positron lifetimes in a jog and vacancies on an edge-dislocation line in Fe. Phys. Rev. B 1995, 52, 879. [Google Scholar] [CrossRef] [PubMed]

- Kamimura, Y.; Tsutsumi, T.; Kuramoto, E. Influence of dislocations on positron lifetime in iron. J. Phys. Soc. Jpn. 1997, 66, 3090–3096. [Google Scholar] [CrossRef]

- Hidalgo, C.; González-Doncel, G.; Linderoth, S.; San Juan, J. Structure of dislocations in Al and Fe as studied by positron-annihilation spectroscopy. Phys. Rev. B 1992, 45, 7017. [Google Scholar] [CrossRef]

- Chen, Y.Z.; Csiszár, G.; Cizek, J.; Borchers, C.; Ungár, T.; Goto, S.; Kirchheim, R. On the formation of vacancies in α-ferrite of a heavily cold-drawn pearlitic steel wire. Scr. Mater. 2011, 64, 390–393. [Google Scholar] [CrossRef]

- Dominguez-Reyes, R.; Auger, M.A.; Monge, M.A.; Pareja, R. Positron annihilation study of the vacancy clusters in ODS Fe--14Cr alloys. Philos. Mag. 2017, 97, 833–850. [Google Scholar] [CrossRef]

- Chen, Y.Z.; Csiszár, G.; Cizek, J.; Westerkamp, S.; Borchers, C.; Ungár, T.; Goto, S.; Liu, F.; Kirchheim, R. Defects in carbon-rich ferrite of cold-drawn pearlitic steel wires. Metall. Mater. Trans. A 2013, 44, 3882–3889. [Google Scholar] [CrossRef]

- Rementeria, R.; Dominguez-Reyes, R.; Capdevila, C.; Garcia-Mateo, C.; Caballero, F.G. Positron Annihilation Spectroscopy Study of carbon-Vacancy interaction in Low-temperature Bainite. Sci. Rep. 2020, 10, 487. [Google Scholar] [CrossRef]

- Dryzek, E.; Sarnek, M.; Wrobel, M. Reverse transformation of deformation-induced martensite in austenitic stainless steel studied by positron annihilation. J. Mater. Sci. 2014, 49, 8449–8458. [Google Scholar] [CrossRef]

- Campillo Robles, J.; Ogando, E.; Plazaola, F. Positron Lifetime Calculation of the Elements of the Periodic Table. J. Phys. Condens. Matter 2007, 19, 176222. [Google Scholar] [CrossRef] [PubMed]

- Hidalgo, C.; de Diego, N. Positron trapping in the alloy Fe-1.25 wt.% C. Phys. Status Solidi. A Appl. Res. 1983, 80, K145–K148. [Google Scholar] [CrossRef]

- Uhlmann, K.; Britton, D.T.; Heger, S. Investigations of Goethite, Haematite and Magnetite. Mater. Sci. Forum 1994, 175–178, 225–228. [Google Scholar] [CrossRef]

- Gläser, U.H.; Dlubek, G.; Krause, R. Vacancies and precipitates in Al-1.9 at.% Cu studied by positrons. Phys. Status Solidi B-Basic Solid State Phys. 1991, 163, 337–343. [Google Scholar] [CrossRef]

- Resch, L.; Gigl, T.; Klinser, G.; Hugenschmidt, C.; Sprengel, W.; Würschum, R. In situ monitoring of artificial aging and solution heat treatment of a commercial Al--Mg--Si alloy with a high intensity positron beam. J. Phys. Condens. Matter 2019, 32, 85705. [Google Scholar] [CrossRef]

- Horodek, P.; Dryzek, J.; Wrobel, M. Positron Annihilation Study of Defects Induced by Various Cutting Methods in Stainless Steel Grade 304. Tribol. Lett. 2012, 45, 341. [Google Scholar] [CrossRef]

- Zhang, F.-y.; Duan, C.-z.; Xu, X.-x.; Wang, W.-j. Influence of cutting condition on white layer induced by high speed machining of hardened steel. Int. J. Adv. Manuf. Technol. 2018, 98, 77–84. [Google Scholar] [CrossRef]

| Material | C | Si | Mn | P, S | Cr | Ni | Mo |

|---|---|---|---|---|---|---|---|

| GCr15 | 0.95–1.05 | 0.15–0.35 | 0.25–0.45 | 0.025 | 0.40–1.65 | Max 0.3 | Max 0.10 |

| Numbered List | Cutting Speed (V) (m/min) | Feed Rate (f) (mm/r) | Cutting Depth (ap) (mm) |

|---|---|---|---|

| 1 | 520 | 0.20 | 0.25 |

| 2 | 520 | 0.20 | 0.20 |

| 3 | 462 | 0.20 | 0.20 |

| 4 | 404 | 0.20 | 0.20 |

| 5 | 347 | 0.20 | 0.20 |

| 6 | 520 | 0.10 | 0.20 |

| 7 | 520 | 0.15 | 0.20 |

| 8 | 520 | 0.24 | 0.20 |

| 9 | 520 | 0.20 | 0.15 |

| 10 | 520 | 0.20 | 0.10 |

| Cutting Speed, m/min | χ2 | τA, ±2 ps | τB, ±4 ps | τF, ±6 ps | kA, ns−1 | kB, ns−1 | IA, % | IB, % | τavg, ps |

|---|---|---|---|---|---|---|---|---|---|

| 347 | 1.16 | 147 | 240 | 106 | 19.1 ± 0.4 | 0.04 ± 0.08 | 86.7 | 0.2 | 149 |

| 404 | 1.09 | 15.4 ± 0.1 | 0.21 ± 0.03 | 83.4 | 1.0 | 146 | |||

| 462 | 1.12 | 21.0 ± 0.2 | 0.96 ± 0.04 | 84.0 | 3.5 | 159 | |||

| 520 | 1.17 | 22.2 ± 0.5 | 0.61 ± 0.05 | 84.9 | 2.3 | 155 |

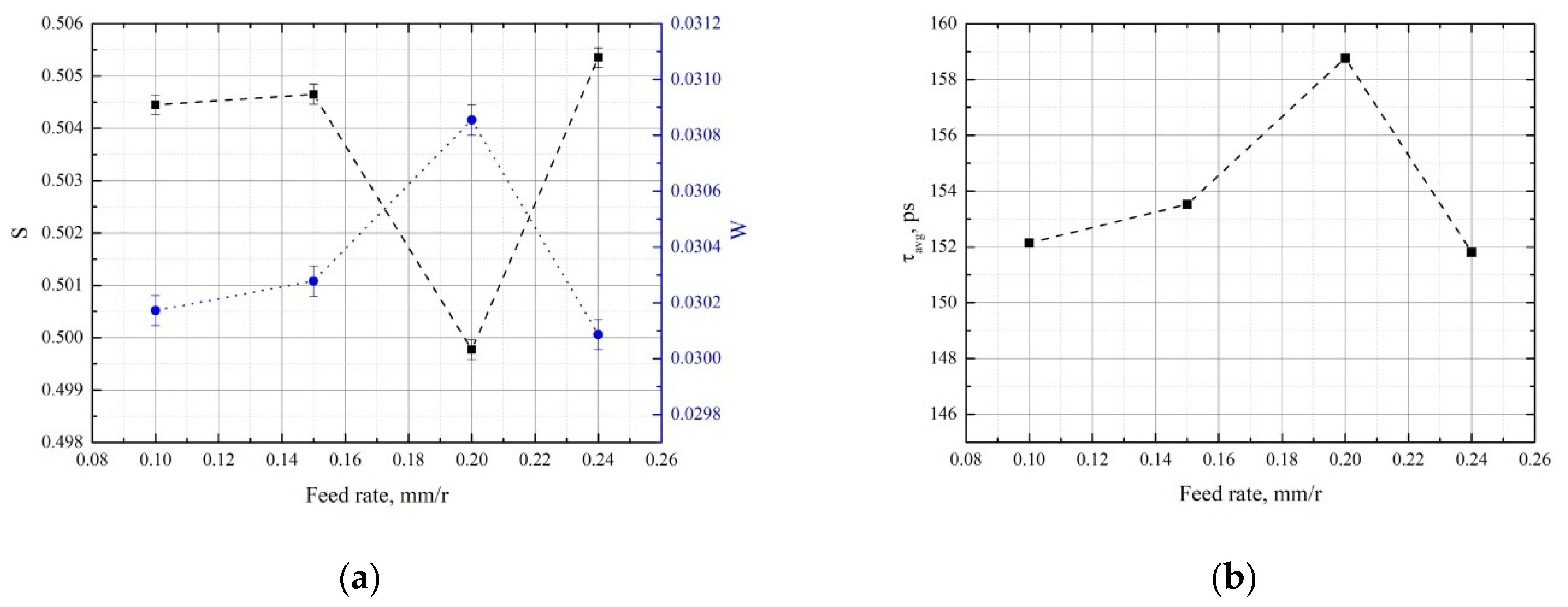

| Feed Rate, (mm/r) | χ2 | τA, ±1 ps | τB, ±4 ps | τF, ±6 ps | kA, ns−1 | kB, ns−1 | IA, % | IB,% | τavg, ps |

|---|---|---|---|---|---|---|---|---|---|

| 0.10 | 1.18 | 147 | 240 | 106 | 17.4 ± 0.1 | 0.47 ± 0.05 | 83.6 | 2.0 | 152 |

| 0.15 | 1.26 | 21.1 ± 0.1 | 0.39 ± 0.01 | 86.2 | 1.4 | 154 | |||

| 0.20 | 1.12 | 21.0 ± 0.2 | 0.96 ± 0.04 | 84.0 | 3.5 | 159 | |||

| 0.24 | 1.13 | 15.5 ± 0.2 | 0.55 ± 0.02 | 81.8 | 2.5 | 152 |

| Cutting Depth, (mm) | χ2 | τA, ±1 ps | τB, ±4 ps | τF, ±6 ps | kA, ns−1 | kB, ns−1 | IA, % | IB,% | τavg, ps |

|---|---|---|---|---|---|---|---|---|---|

| 0.10 | 1.16 | 147 | 240 | 106 | 19.1 ± 0.4 | 0.04 ± 0.08 | 86.7 | 0.2 | 149 |

| 0.15 | 1.09 | 15.4 ± 0.1 | 0.21 ± 0.03 | 83.4 | 1.0 | 146 | |||

| 0.20 | 1.12 | 21.0 ± 0.2 | 0.96 ± 0.04 | 84.0 | 3.5 | 159 | |||

| 0.25 | 1.17 | 20.2 ± 0.5 | 0.61 ± 0.05 | 84.9 | 2.3 | 155 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Laptev, R.; Bordulev, I.; Siemek, K.; Horodek, P.; Shen, H.; Lomygin, A.; Cui, J. Positron Annihilation Spectroscopy Study of Metallic Materials after High-Speed Cutting. Materials 2022, 15, 1017. https://doi.org/10.3390/ma15031017

Li J, Laptev R, Bordulev I, Siemek K, Horodek P, Shen H, Lomygin A, Cui J. Positron Annihilation Spectroscopy Study of Metallic Materials after High-Speed Cutting. Materials. 2022; 15(3):1017. https://doi.org/10.3390/ma15031017

Chicago/Turabian StyleLi, Jinquan, Roman Laptev, Iurii Bordulev, Krzysztof Siemek, Pawel Horodek, Haolun Shen, Anton Lomygin, and Jian Cui. 2022. "Positron Annihilation Spectroscopy Study of Metallic Materials after High-Speed Cutting" Materials 15, no. 3: 1017. https://doi.org/10.3390/ma15031017

APA StyleLi, J., Laptev, R., Bordulev, I., Siemek, K., Horodek, P., Shen, H., Lomygin, A., & Cui, J. (2022). Positron Annihilation Spectroscopy Study of Metallic Materials after High-Speed Cutting. Materials, 15(3), 1017. https://doi.org/10.3390/ma15031017