Numerical Simulation and Experimental Verification of Residual Stress in the Welded Joints of Weldolet–Branch Pipe Dissimilar Steels

Abstract

1. Introduction

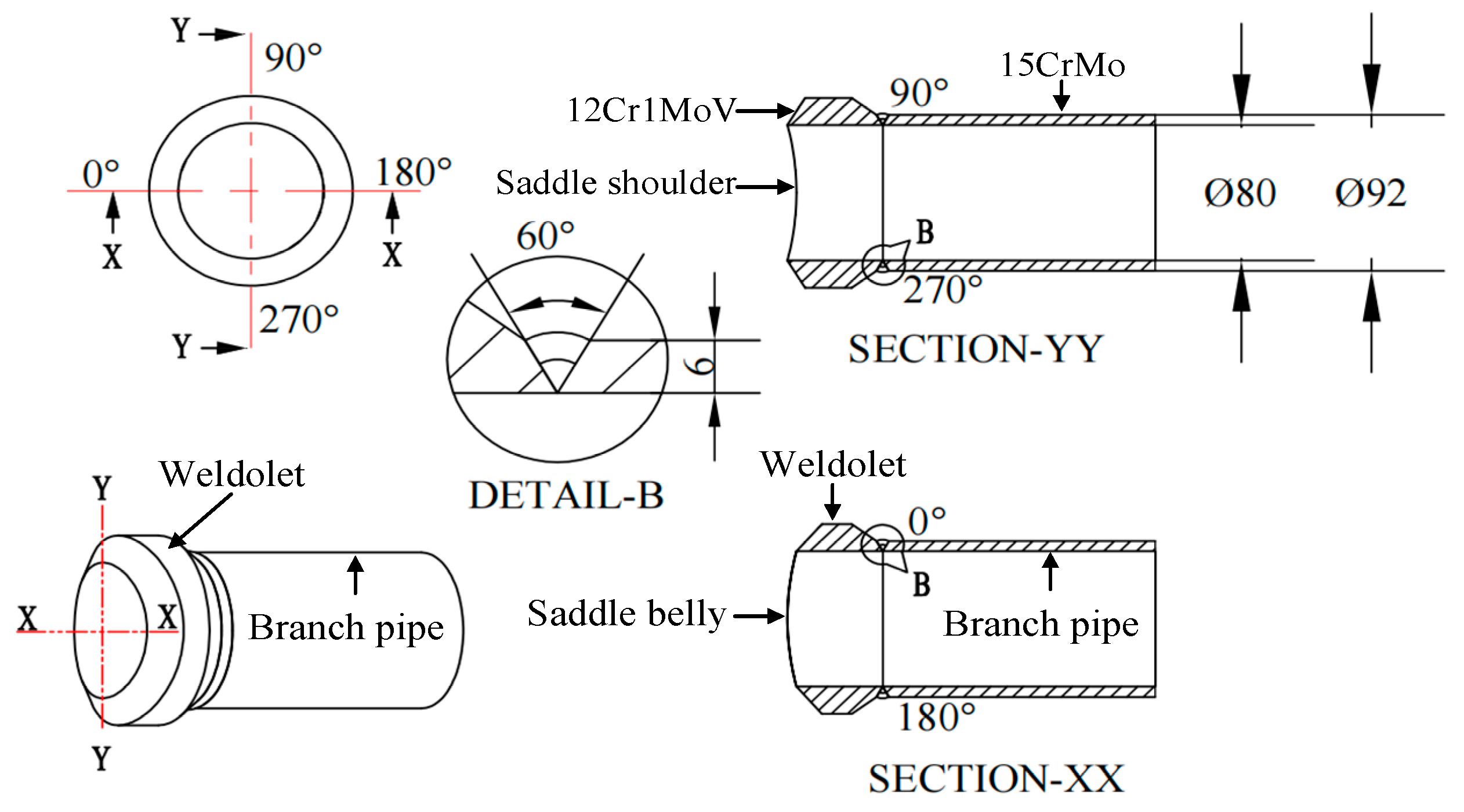

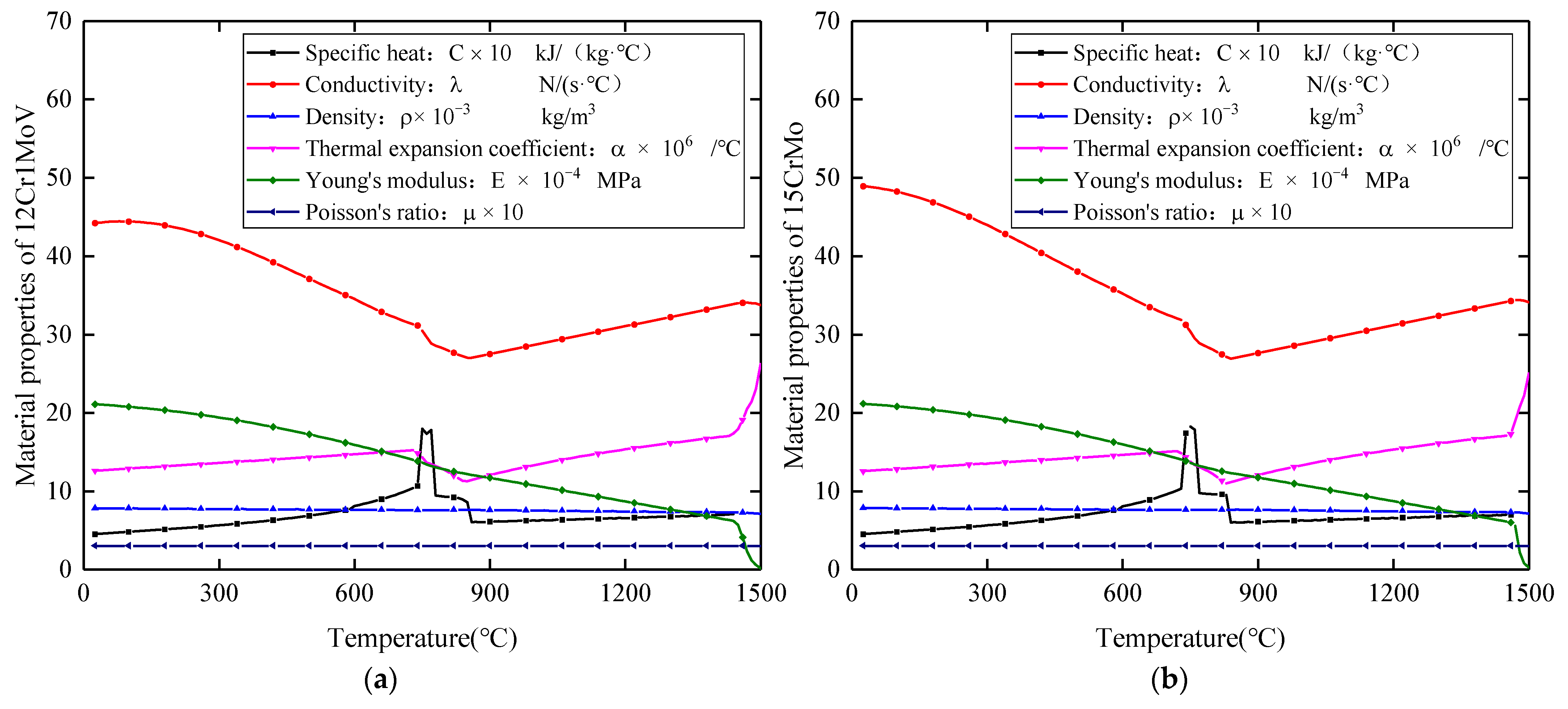

2. Experimental Procedure

3. Finite Element Analysis

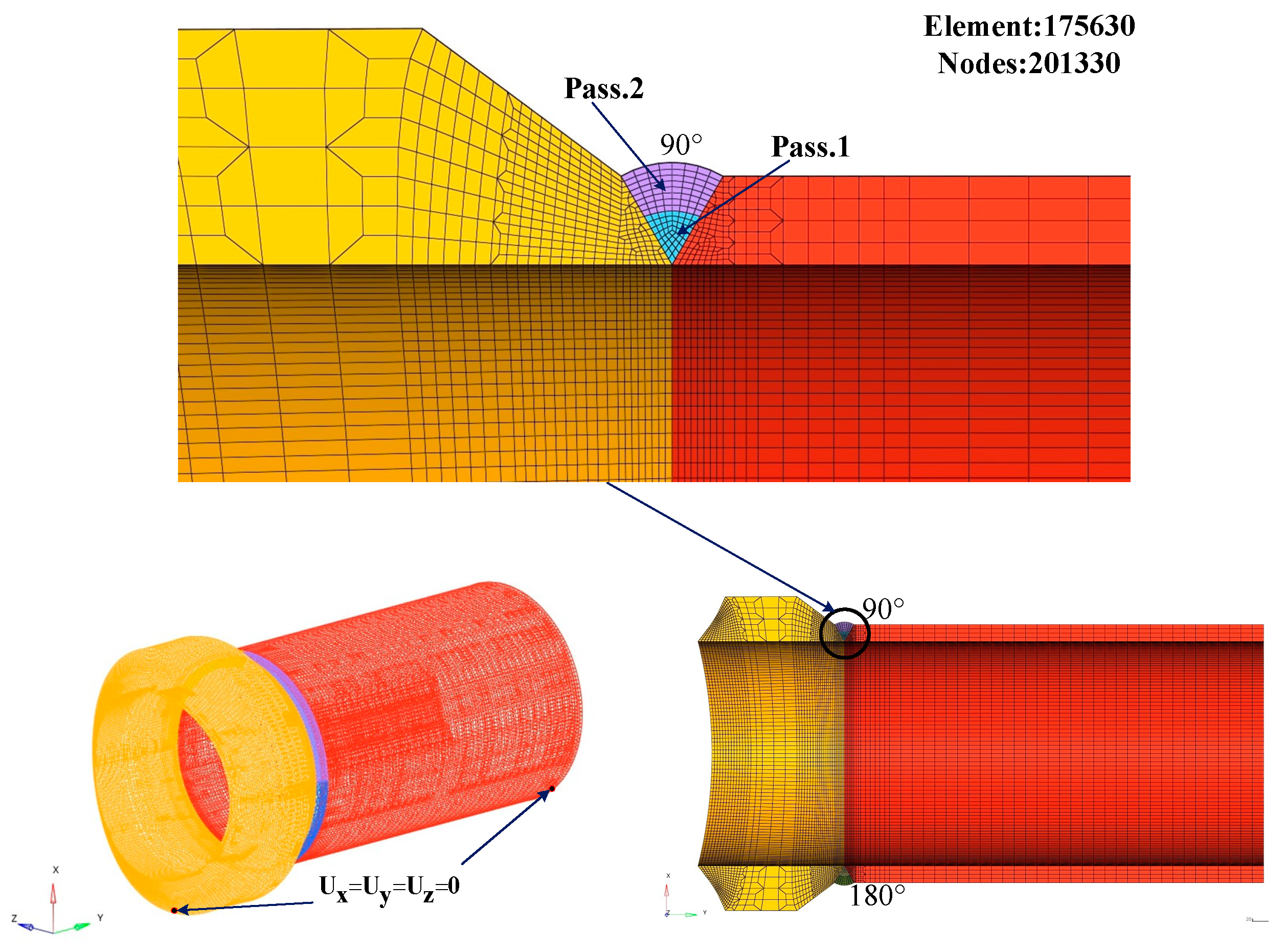

3.1. Finite Element Modeling

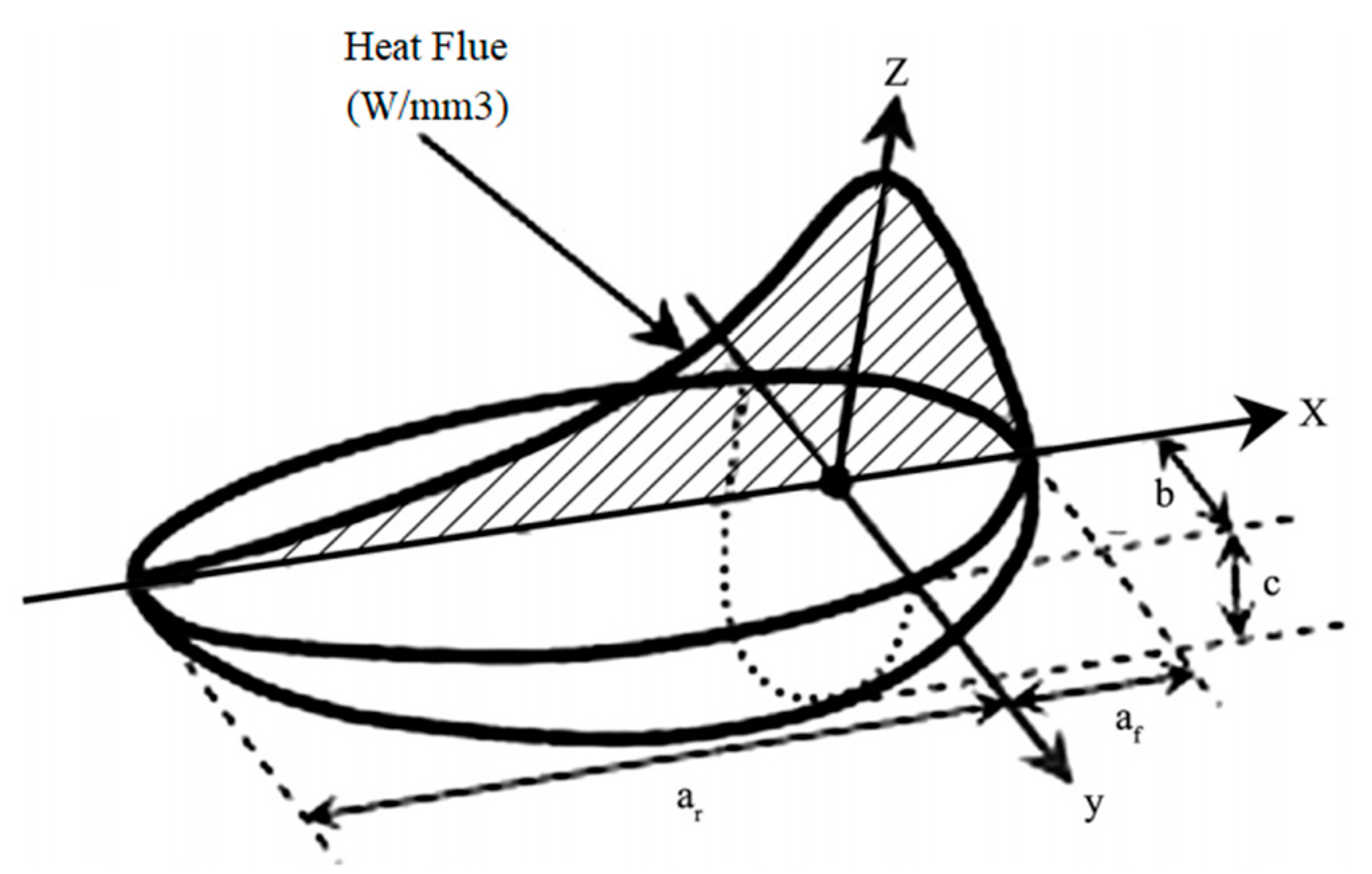

3.2. Heat Source Model and Thermal Analysis

3.3. Mechanical Analysis

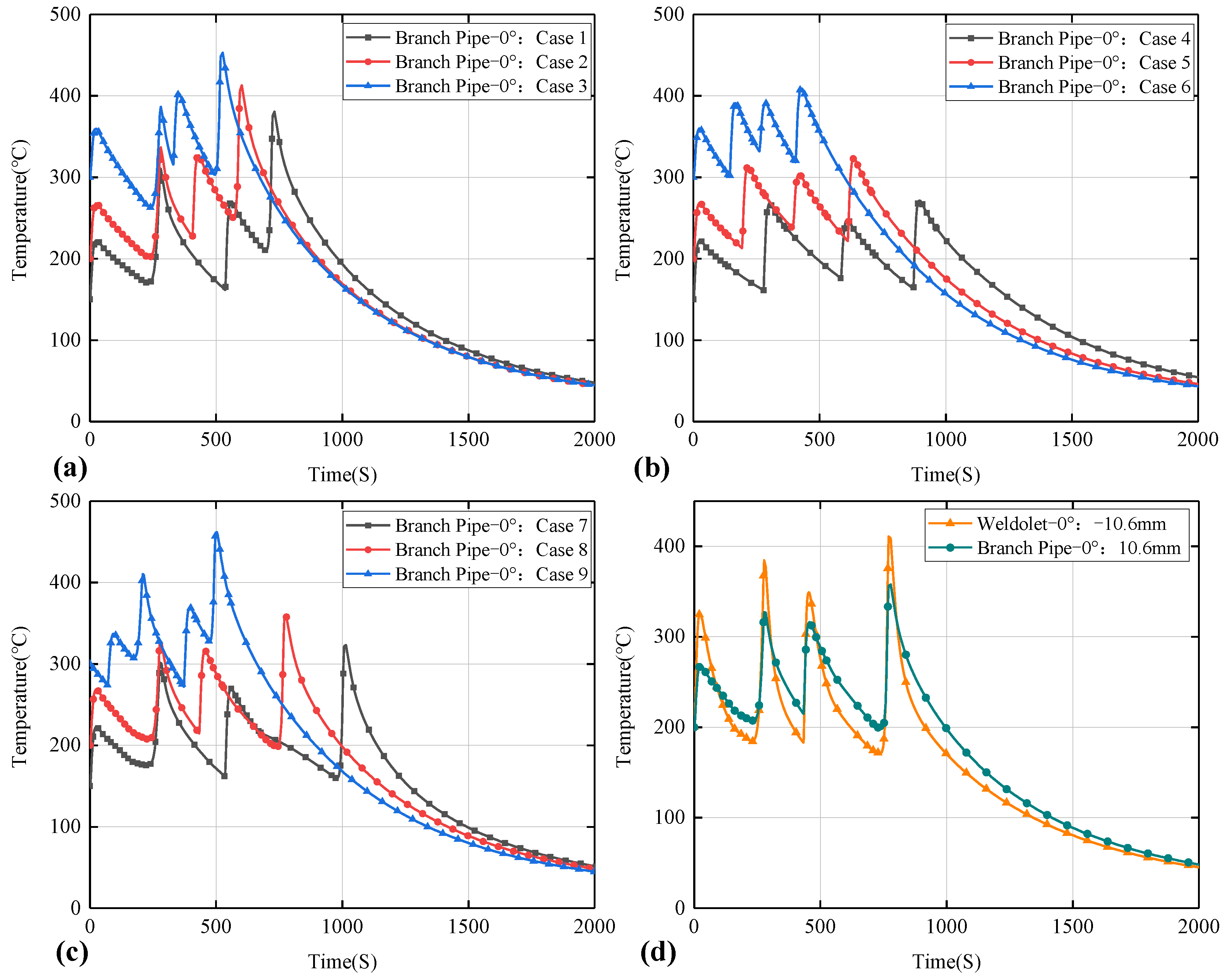

3.4. Simulation Cases

4. Results and Discussion

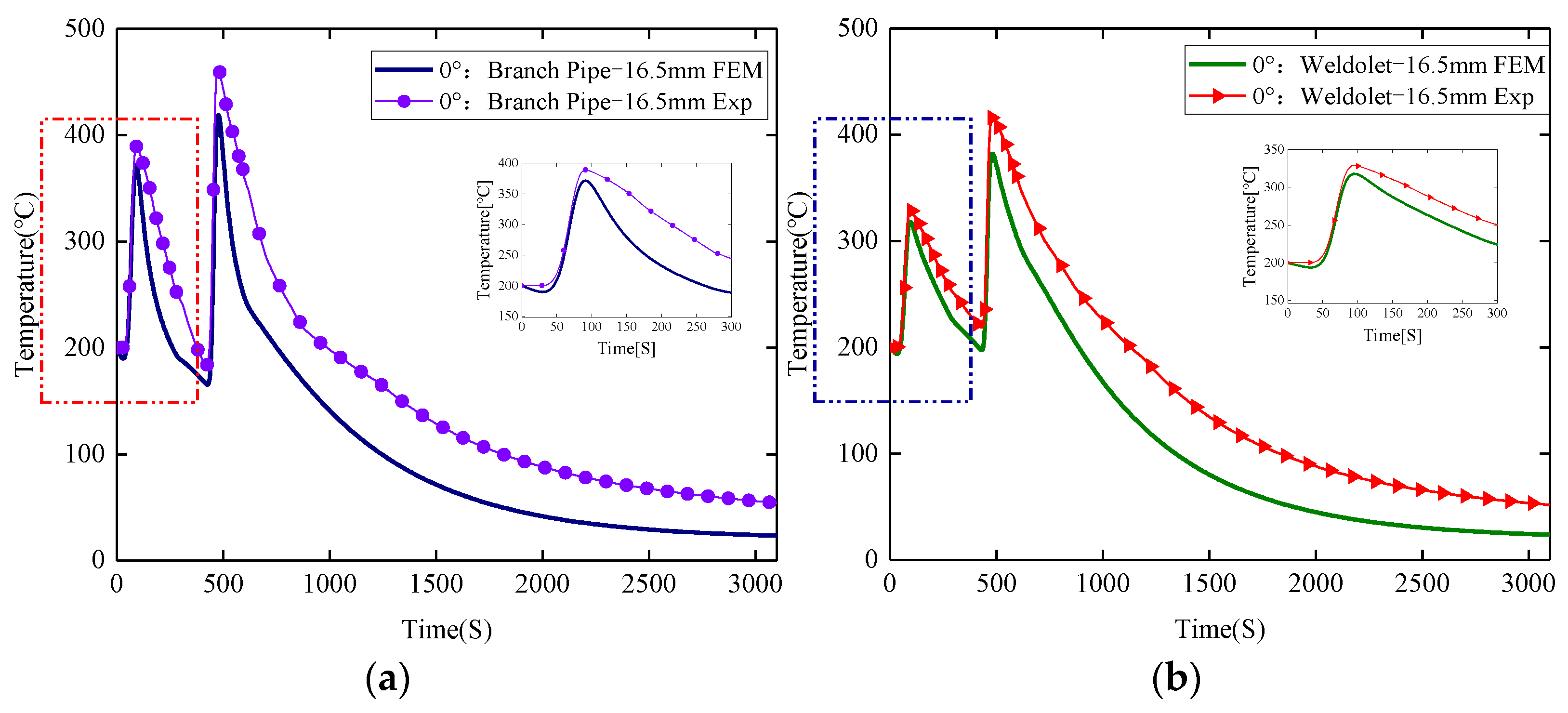

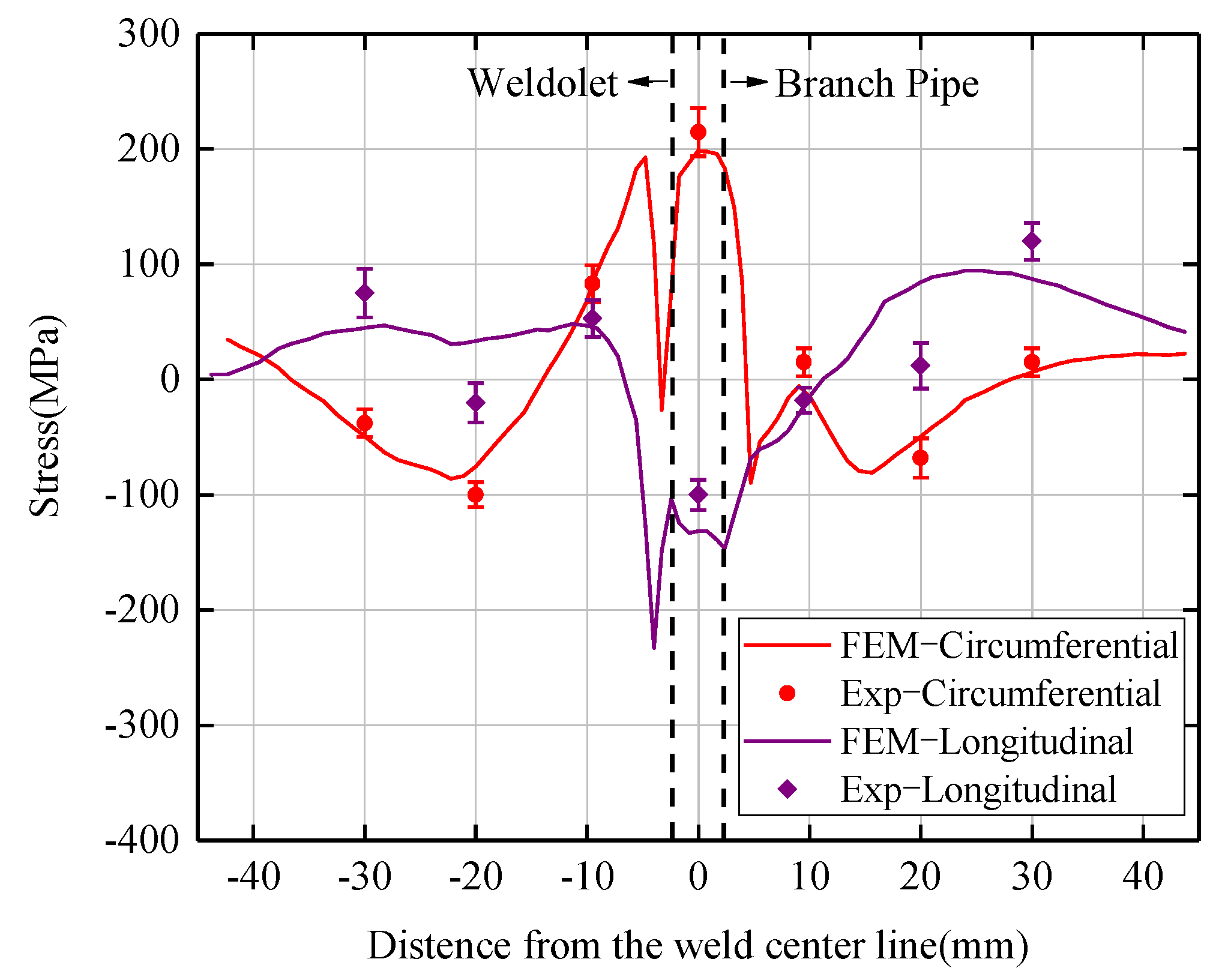

4.1. Comparison of Experimental Result and Numerical Simulations

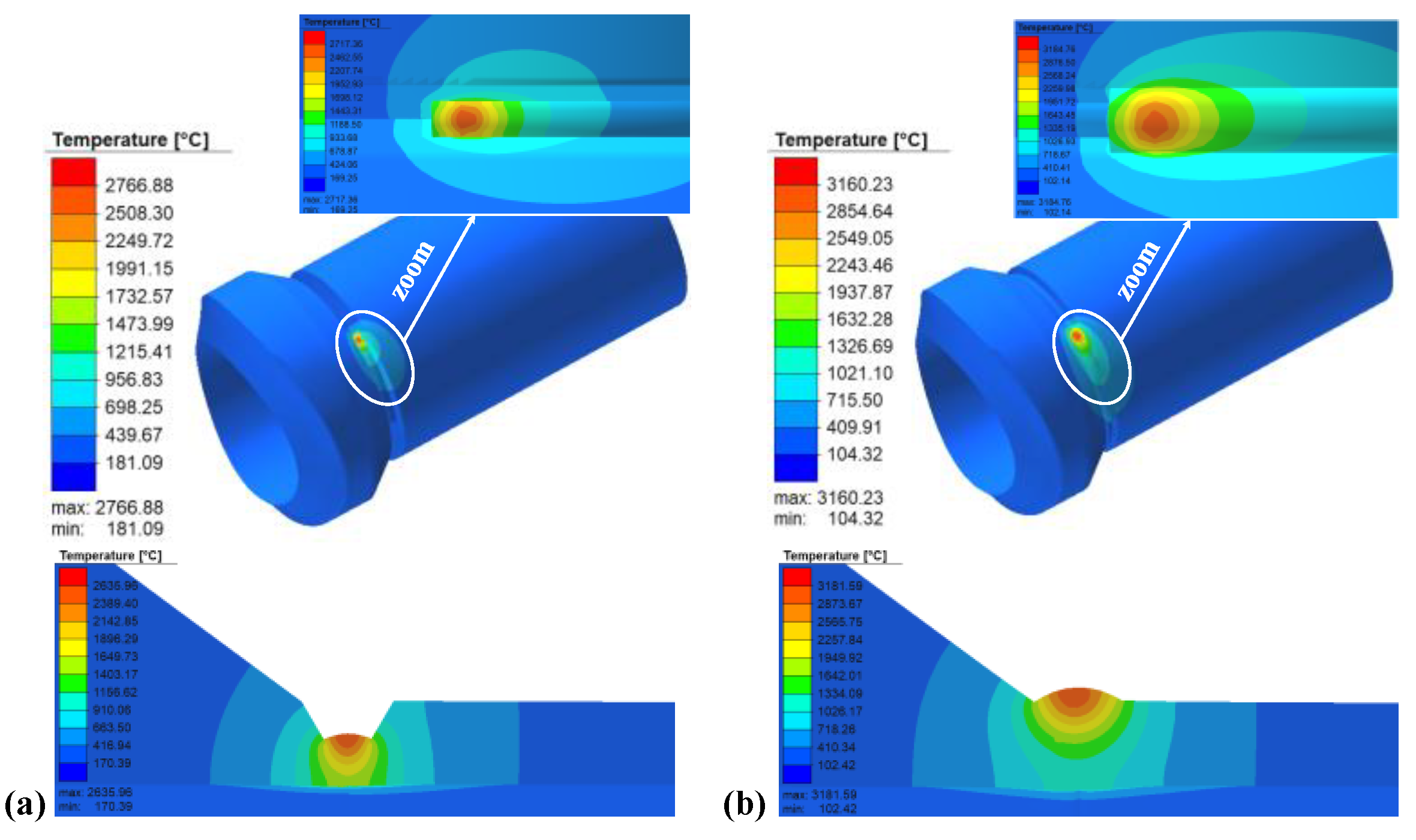

4.2. Simulation Results of Thermal Field

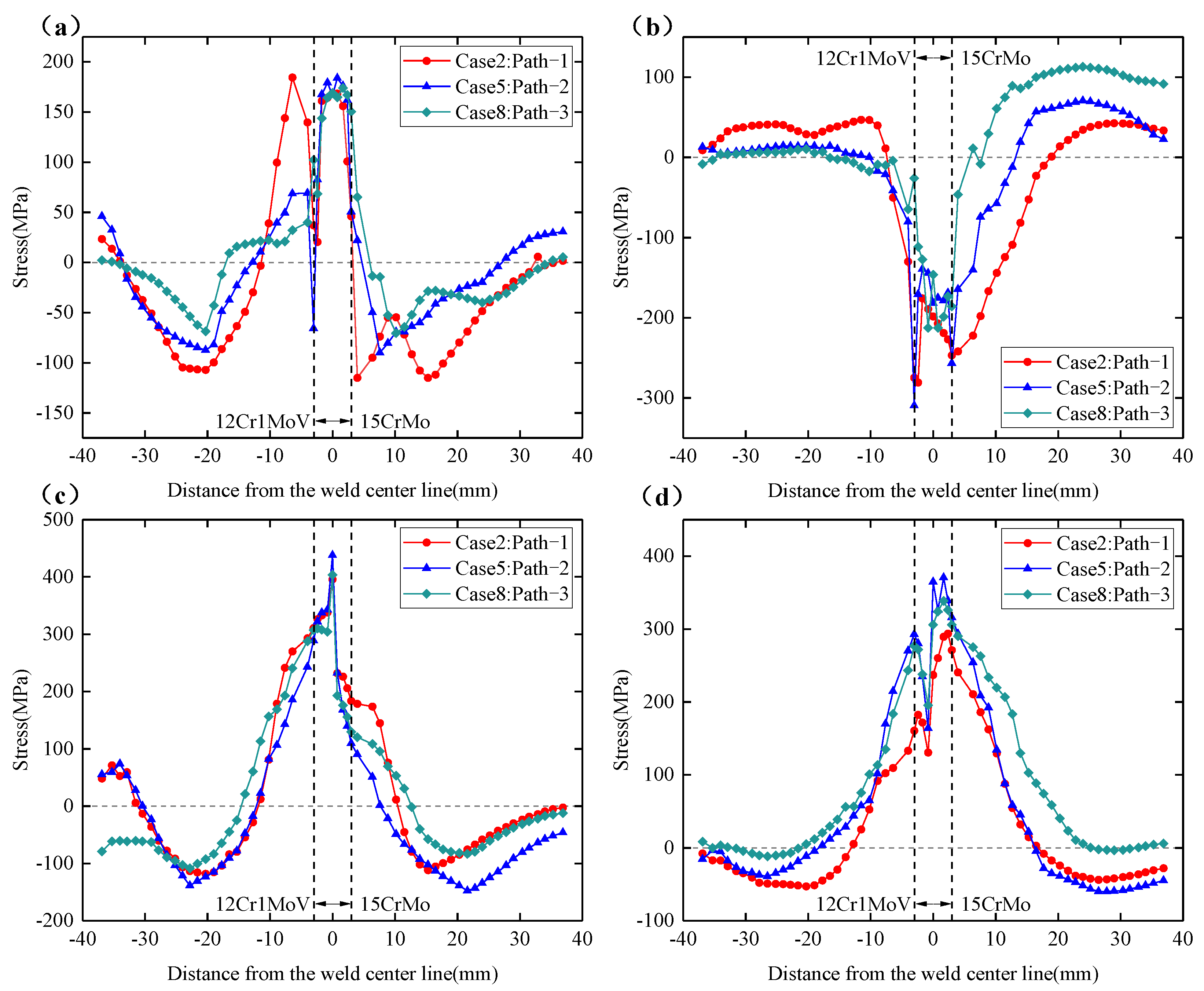

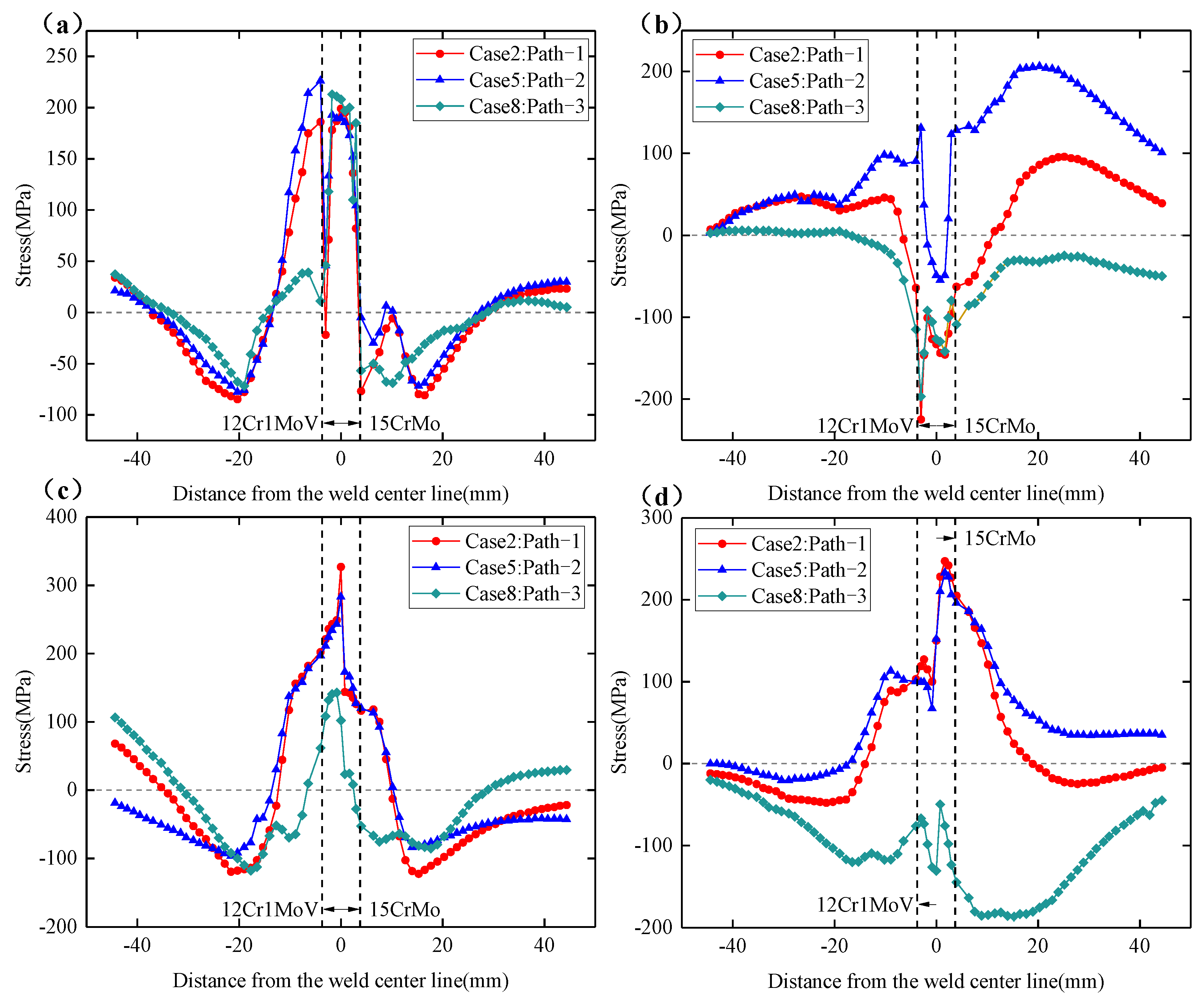

4.3. Welding Residual Stress along a Defined Path

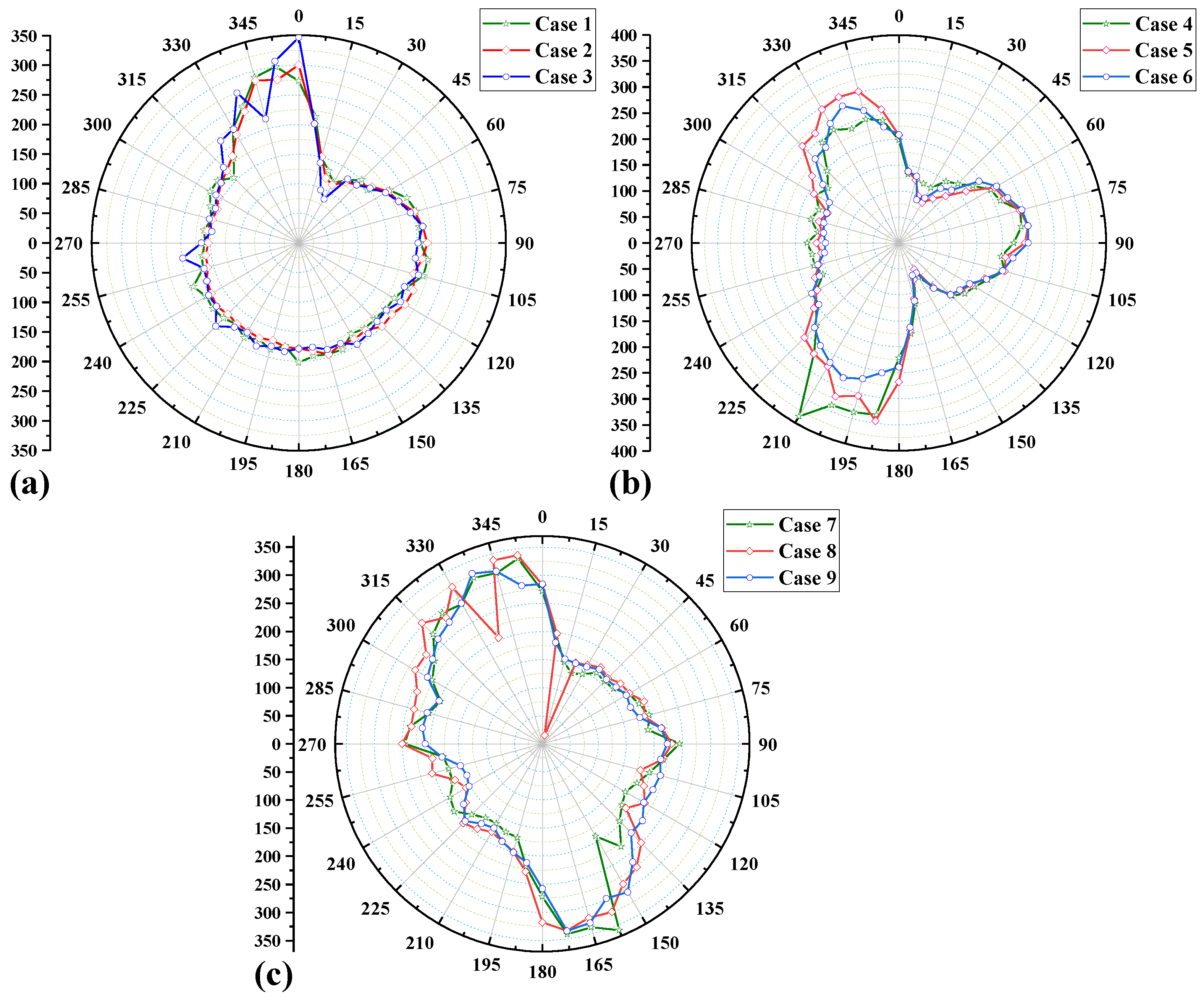

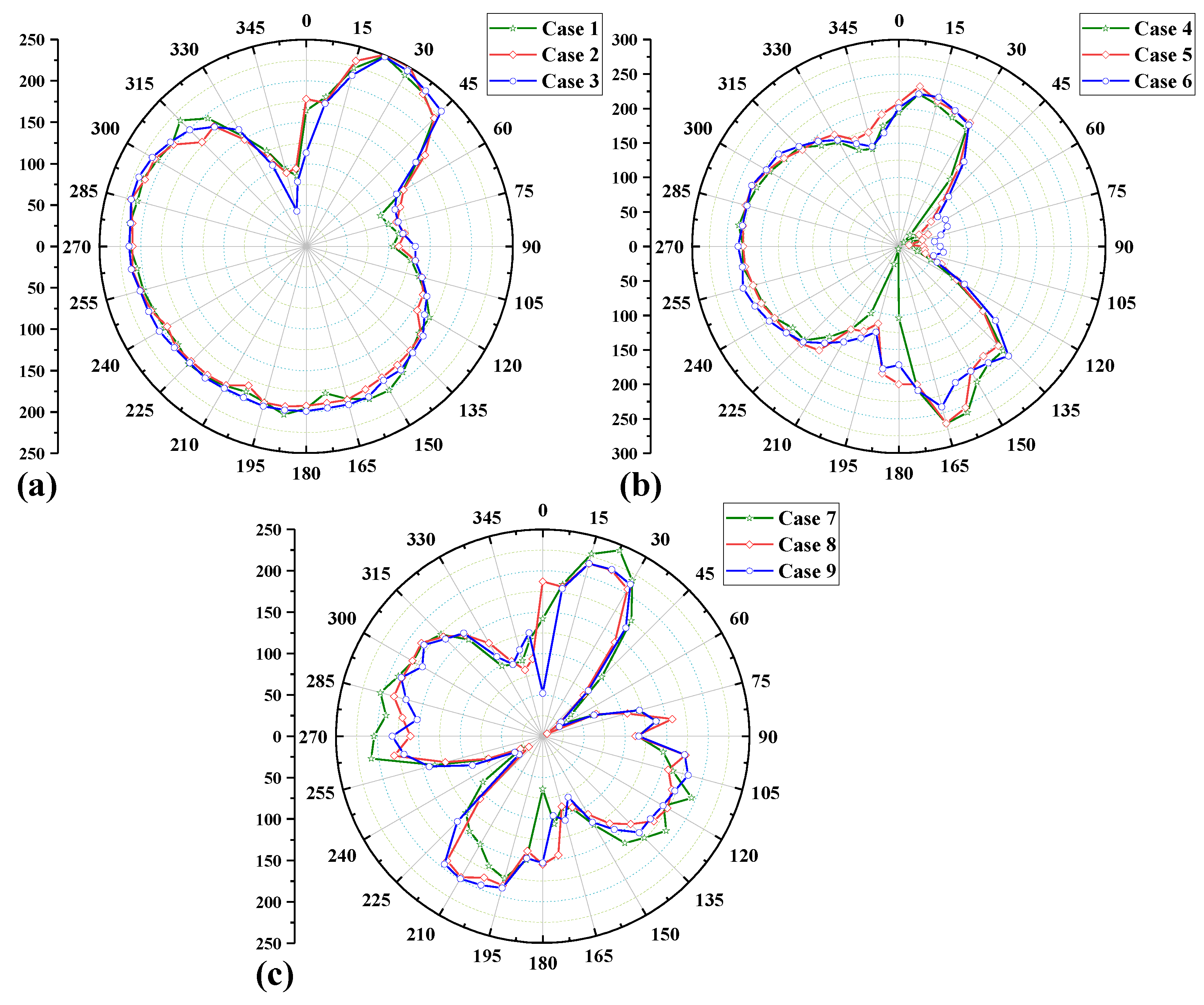

4.4. Effect of Welding Sequence on Residual Stress

5. Conclusions

- (1)

- In this study, the Case 2 (interlayer temperature of 300 °C, welding sequence path-1) model was selected to verify the residual stress and transient temperature. The simulation results are in good agreement with the experimental results, which verifies the reliability of the experimental model.

- (2)

- The transient temperature distribution results show that the differences in the thermophysical properties of the materials during welding of dissimilar steels lead to an asymmetric distribution of the transient temperature field about the center of the weld. The high temperature range of the 15CrMo steel side is larger than that of the 12Cr1MoV steel side, and the heat-affected zone is relatively wider.

- (3)

- The circumferential and axial residual stress distribution on both sides of the weldolet–branch pipe is not symmetrical, and there are always large fluctuations and stress gradients in the weld and the area near the weld. There is always a peak residual stress at the weld fusion line on both sides of the weld.

- (4)

- The interlayer temperature of the weld has little effect on the distribution pattern of the residual stresses, which mainly affect the peak residual stresses. The peak residual stress along the defined path occurs more often at interlayer temperatures of 150 °C or 300 °C.

- (5)

- The welding sequence is a decisive factor affecting the residual stress. By adjusting the welding sequence, not only can the residual stress distribution area be changed, but also the residual stress in specific areas can be reduced. The post-welded seam largely changes the residual stresses near the first weld, and the high stress areas are mostly concentrated at the post-weld.

- (6)

- The number and position distribution of the start/end point of the weld also effect the distribution of residual stress, and the distribution trend of circumferential residual stress and axial residual stress on the outer surface is opposite. The overall residual stress distribution at the 90° section is smaller than the other three sections.

- (7)

- At the 0° and 180° sections, the residual stress distribution of path-1, path-2 and path-3 are very similar, and the circumferential and axial residual stresses on the inner surface are larger than those on the outer surface. However, the residual stresses on the inner and outer surfaces of the segmental jump welding method path-3 are smaller than those of path-1 and path-2 in the 90° and 270° sections as a whole. The residual stresses reach a minimum in the 90° section. It can be concluded that path-3 is more suitable for the welding of weldolet–branch pipe dissimilar steel joints.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Vremenko, A.V.; Goncharov, N.G.; Ponomarev, P.A.; Kolesnikov, O.I. The choice of the weldolet parameters based on computer modeling. Nauka Tekhnol.-Truboprovodn. Transp. Nefti Nefteprod. 2019, 9, 151–155. [Google Scholar] [CrossRef]

- Goncharov, N.G.; Mikhailov, I.I.; Yushin, A.A. Specific aspects of the quality control for weldolet weld joints. Nauka Tekhnol.-Truboprovodn. Transp. Nefti Nefteprod. 2018, 8, 420–425. [Google Scholar] [CrossRef]

- DeAquino, C.T.; Maneschy, E. Fatigue evaluation of piping connections under thermal transients. Int. J. Press. Vessels Pip. 1995, 61, 9–12. [Google Scholar] [CrossRef][Green Version]

- Ghosh, A.; Niu, Y.; Arjunan, R. Difficulties in predicting cycles of failure using finite element analysis of acoustically induced vibration (aiv) problems in piping systems. In Pressure Vessels and Piping Conference; American Society of Mechanical Engineers: Anaheim, CA, USA, 2014; p. V003T03A004. [Google Scholar]

- Goncharov, N.G.; Kolesnikov, O.I.; Yushin, A.A. Weldolets welding technology features. Nauka Tekhnol.-Truboprovodn. Transp. Nefti Nefteprod. 2018, 8, 232–239. [Google Scholar] [CrossRef]

- Chludzinski, M.; dos Santos, R.E.; Churiaque, C.; Ortega-Iguña, M.; Sánchez-Amaya, J.M. Pulsed laser welding applied to metallic materials—A material approach. Metals 2021, 11, 640. [Google Scholar] [CrossRef]

- Moreira, R.C.S.; Kovalenko, O.; Souza, D.; Reis, R.P. Metal matrix composite material reinforced with metal wire and produced with gas metal arc welding. J. Compos. Mater. 2019, 53, 4411–4426. [Google Scholar] [CrossRef]

- Ghosh, N.; Pal, P.K.; Nandi, G. Gmaw dissimilar welding of aisi 409 ferritic stainless steel to aisi 316l austenitic stainless steel by using aisi 308 filler wire. Eng. Sci. Technol. 2017, 20, 1334–1341. [Google Scholar] [CrossRef]

- Lu, W.; Zhang, Y.; Yu, D.; Sun, D.; Li, H. Research progress on control strategy of intermetallic compounds in welding process of heterogeneous materials. Steel Res. Int. 2021, 2100427. [Google Scholar] [CrossRef]

- Zhang, Y.; Bi, Y.; Zhou, J.; Sun, D.; Li, H. Weldability and machinability of the dissimilar joints of ti alloy and stainless steel—A review. Int. J. Mater. Res. 2021, 112, 826–847. [Google Scholar] [CrossRef]

- Liu, Z.; Hu, X.; Yang, Z.; Yang, B.; Chen, J.; Luo, Y.; Song, M. Optimization study of post-weld heat treatment for 12cr1mov pipe welded joint. Metals 2021, 11, 127. [Google Scholar] [CrossRef]

- Zhao, Y.P.; Gong, J.M.; Jiang, Y.; Li, Q.N.; Wang, X.W. Effect of repair welding on the creep behavior of a 12cr1mov/gtr-2cm/p91 dissimilar joint. Procedia Eng. 2015, 130, 509–516. [Google Scholar] [CrossRef][Green Version]

- Zhu, Z.; Song, X.; Song, Y.; Zhou, P.; He, M. Corrosion behavior of 15crmo steel for water-wall tubes in thermal power plants in the presence of urea and its byproducts. Corros. Rev. 2021, 39, 43–53. [Google Scholar] [CrossRef]

- Sirohi, S.; Taraphdar, P.K.; Dak, G.; Pandey, C.; Sharma, S.K.; Goyal, A. Study on evaluation of through-thickness residual stresses and microstructure-mechanical property relation for dissimilar welded joint of modified 9cr–1mo and ss304h steel. Int. J. Press. Vessel. Pip. 2021, 194, 104557. [Google Scholar] [CrossRef]

- Huang, J.; Li, S.; Zhong, H.; Xiao, S.; Li, D. Microstructure, mechanical properties, and corrosion behavior of laser-welded dissimilar joints between dp980 and qp980 steel. Steel Res. Int. 2021, 65, 2100541. [Google Scholar] [CrossRef]

- Sahu, S.; Mypati, O.; Pal, S.K.; Shome, M.; Srirangam, P. Effect of weld parameters on joint quality in friction stir welding of mg alloy to dp steel dissimilar materials. CIRP J. Manuf. Sci. Technol. 2021, 35, 502–516. [Google Scholar] [CrossRef]

- Ramesh Kumar, S.; SreeArravind, M. Assessment of magnetically impelled arc butt welded dissimilar boiler graded steel tubes: Sae213 t11 and sae213 t91. J. Mater. Eng. Perform. 2021, 1–11. [Google Scholar] [CrossRef]

- Anca, A.; Cardona, A.; Risso, J.; Fachinotti, V.D. Finite element modeling of welding processes. Appl. Math. Model. 2011, 35, 688–707. [Google Scholar] [CrossRef]

- Trupiano, S.; Belardi, V.G.; Fanelli, P.; Gaetani, L.; Vivio, F. A novel modeling approach for multi-passes butt-welded plates. J. Therm. Stresses. 2021, 44, 829–849. [Google Scholar] [CrossRef]

- Lee, C.-H.; Chang, K.-H. Temperature fields and residual stress distributions in dissimilar steel butt welds between carbon and stainless steels. Appl. Therm. Eng. 2012, 45–46, 33–41. [Google Scholar] [CrossRef]

- Huang, B.S.; Fang, Z.Y.; Yang, J.; Zheng, J.N.; Wang, S.B. Numerical simulation of s355jr-316l dissimilar metal welding. Weld. World 2021, 1–13. [Google Scholar] [CrossRef]

- Sauraw, A.; Sharma, A.K.; Fydrych, D.; Sirohi, S.; Gupta, A.; Swierczynska, A.; Pandey, C.; Rogalski, G. Study on microstructural characterization, mechanical properties and residual stress of gtaw dissimilar joints of p91 and p22 steels. Materials 2021, 14, 6591. [Google Scholar] [CrossRef]

- Sepe, R.; Giannella, V.; Greco, A.; De Luca, A. Fem simulation and experimental tests on the smaw welding of a dissimilar t-joint. Metals 2021, 11, 1016. [Google Scholar] [CrossRef]

- Khamari, B.K.; Dash, S.S.; Karak, S.K.; Biswal, B.B. Effect of welding parameters on mechanical and microstructural properties of gmaw and smaw mild steel joints. Ironmak. Steelmak. 2019, 47, 844–851. [Google Scholar] [CrossRef]

- Karalis, D.G.; Papazoglou, V.J.; Pantelis, D.I. Mechanical response of thin smaw arc welded structures: Experimental and numerical investigation. Theor. Appl. Fract. Mech. 2009, 51, 87–94. [Google Scholar] [CrossRef]

- Taghipour, M.; Bahrami, A.; Mohammadi, H.; Esmaeili, V. Root cause analysis of a failure in a flange-pipe welded joint in a steam line in an ammonia plant: Experimental investigation and simulation assessment. Eng. Fail. Anal. 2021, 129, 105730. [Google Scholar] [CrossRef]

- Xia, J.; Jin, H. Numerical analysis for controlling residual stresses in welding design of dissimilar materials girth joints. Int. J. Precis. Eng. Manuf. 2018, 19, 57–66. [Google Scholar] [CrossRef]

- Pamnani, R.; Vasudevan, M.; Jayakumar, T.; Vasantharaja, P.; Ganesh, K.C. Numerical simulation and experimental validation of arc welding of dmr-249a steel. Def. Technol. 2016, 12, 305–315. [Google Scholar] [CrossRef]

- Li, Y.; Li, K.; Cai, Z.; Pan, J.; Liu, X.; Wang, P. Alloy design of welding filler metal for 9cr/2.25cr dissimilar welded joint and mechanical properties investigation. Weld. World 2018, 62, 1137–1151. [Google Scholar] [CrossRef]

- Li, S.; Hu, L.; Dai, P.; Bi, T.; Deng, D. Influence of the groove shape on welding residual stresses in p92/sus304 dissimilar metal butt-welded joints. J. Manuf. Process 2021, 66, 376–386. [Google Scholar] [CrossRef]

- Huang, B.; Liu, J.; Zhang, S.; Chen, Q.; Chen, L. Effect of post-weld heat treatment on the residual stress and deformation of 20/0cr18ni9 dissimilar metal welded joint by experiments and simulations. J. Mater. Res. Technol. 2020, 9, 6186–6200. [Google Scholar] [CrossRef]

- Xie, Y.; Zhuang, J.; Huang, B.; Chen, Q.; Li, G. Effect of different welding parameters on residual stress and deformation of 20/0cr18ni9 dissimilar metal arc-welding joint. J. Adhes. Sci. Technol. 2020, 34, 1628–1652. [Google Scholar] [CrossRef]

- Goldak, J.; Chakravarti, A.; Bibby, M. A new finite element model for welding heat sources. Metall. Trans. B 1984, 15, 299–305. [Google Scholar] [CrossRef]

| Welding Method | Levels | Filling Material | Welding Wire (bar) Diameter/mm | Current I/A | Voltage U/V | Welding Speed mm/s | Gas Flow |

|---|---|---|---|---|---|---|---|

| GTAW | 1 | R30 | 2.5 | 80~110 | 15~20 | 1 | 8 L/min |

| SMAW | 2 | R307 | 3.2 | 90~120 | 20~24 | 1.3 |

| Weld Metals | Melting Point/°C | Steel Plate Thickness/mm | Tensile Strength/Mpa | Yield Strength/Mpa | Elongation | Temperature/°C | Impact Energy/J |

|---|---|---|---|---|---|---|---|

| 12Cr1MoV | 1520 °C | 6~60 | 440~590 | ≥245 | ≥19 | ≥20 | ≥47 |

| 15CrMo | 1500 °C | 6~60 | 450~590 | ≥295 | ≥19 | ≥20 | ≥31 |

| Case | Welding Sequence | Preheating Temperature/°C | Interlayer Temperature/°C |

|---|---|---|---|

| Case 1 | Path-1 | 150 | 150 |

| Case 2 | Path-1 | 200 | 200 |

| Case 3 | Path-1 | 300 | 300 |

| Case 4 | Path-2 | 150 | 150 |

| Case 5 | Path-2 | 200 | 200 |

| Case 6 | Path-2 | 300 | 300 |

| Case 7 | Path-3 | 150 | 150 |

| Case 8 | Path-3 | 200 | 200 |

| Case 9 | Path-3 | 300 | 300 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mai, C.; Hu, X.; Zhang, L.; Song, B.; Zheng, X. Numerical Simulation and Experimental Verification of Residual Stress in the Welded Joints of Weldolet–Branch Pipe Dissimilar Steels. Materials 2022, 15, 1044. https://doi.org/10.3390/ma15031044

Mai C, Hu X, Zhang L, Song B, Zheng X. Numerical Simulation and Experimental Verification of Residual Stress in the Welded Joints of Weldolet–Branch Pipe Dissimilar Steels. Materials. 2022; 15(3):1044. https://doi.org/10.3390/ma15031044

Chicago/Turabian StyleMai, Chunliang, Xue Hu, Lixin Zhang, Bao Song, and Xiongfei Zheng. 2022. "Numerical Simulation and Experimental Verification of Residual Stress in the Welded Joints of Weldolet–Branch Pipe Dissimilar Steels" Materials 15, no. 3: 1044. https://doi.org/10.3390/ma15031044

APA StyleMai, C., Hu, X., Zhang, L., Song, B., & Zheng, X. (2022). Numerical Simulation and Experimental Verification of Residual Stress in the Welded Joints of Weldolet–Branch Pipe Dissimilar Steels. Materials, 15(3), 1044. https://doi.org/10.3390/ma15031044