Accurate Estimation of Yield Strength and Ultimate Tensile Strength through Instrumented Indentation Testing and Chemical Composition Testing

Abstract

:1. Introduction

2. Materials and Methods

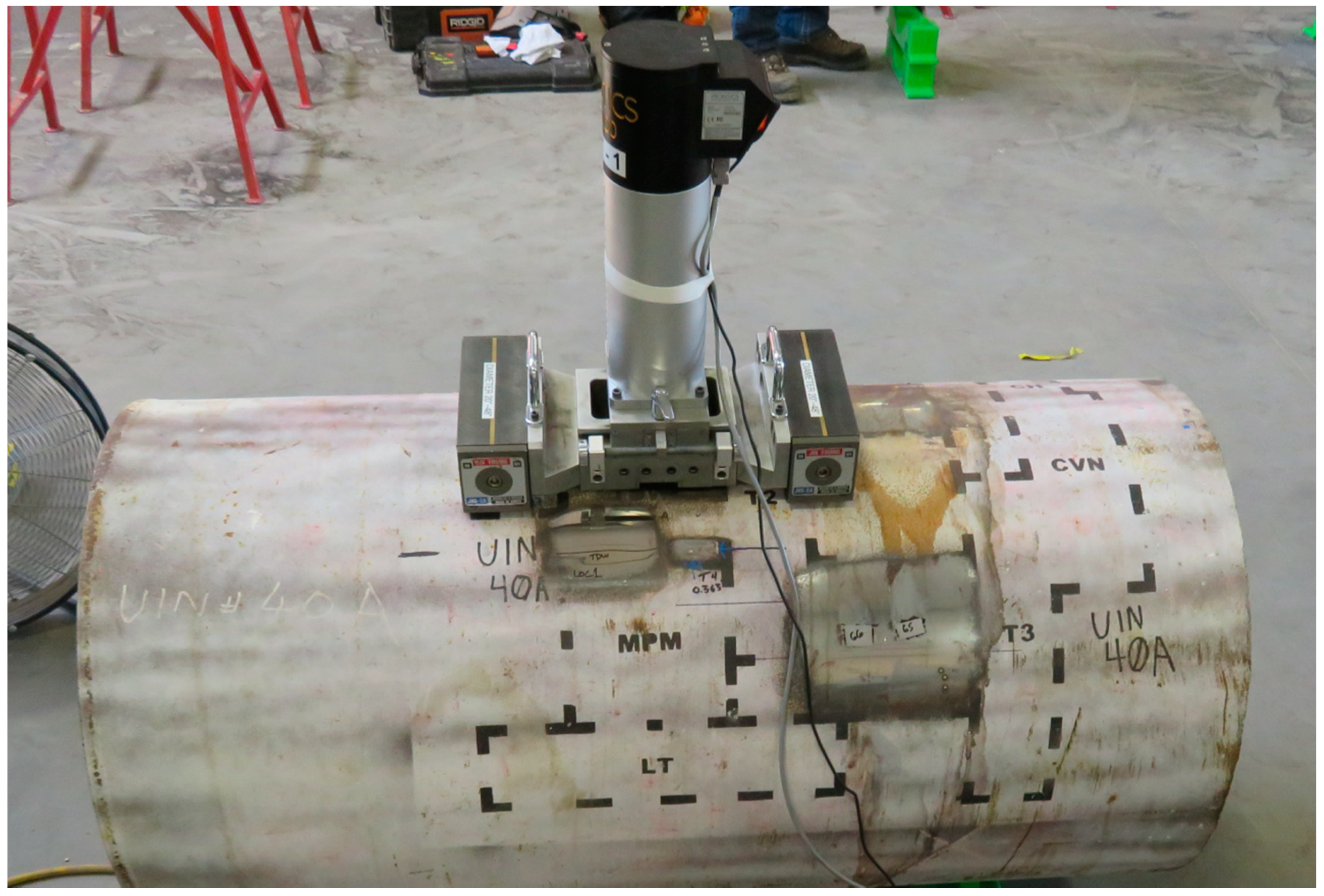

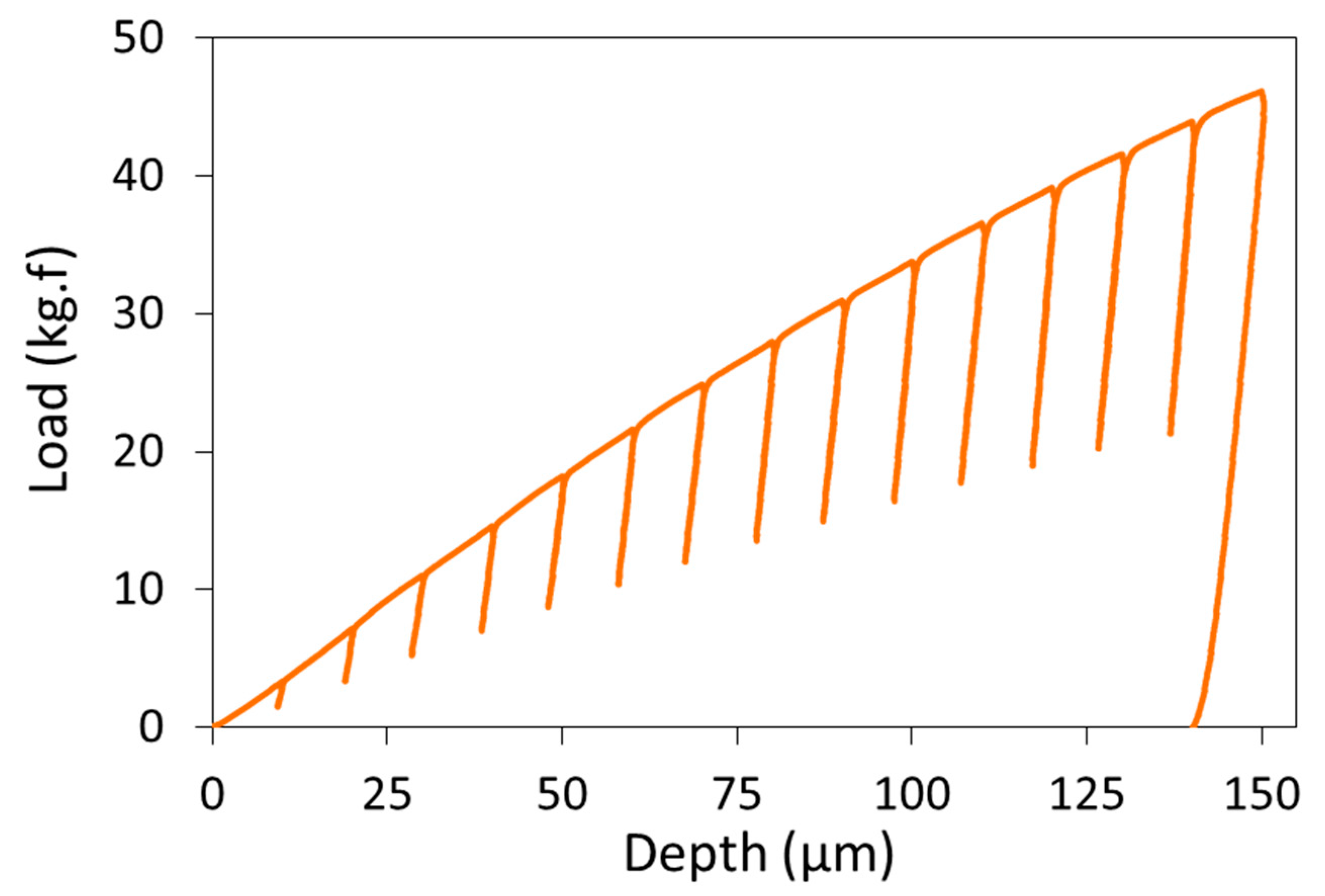

2.1. Instrumented Indentation Testing

2.2. Tensile Testing

2.3. Chemical Composition Testing

2.4. Materials

3. Results

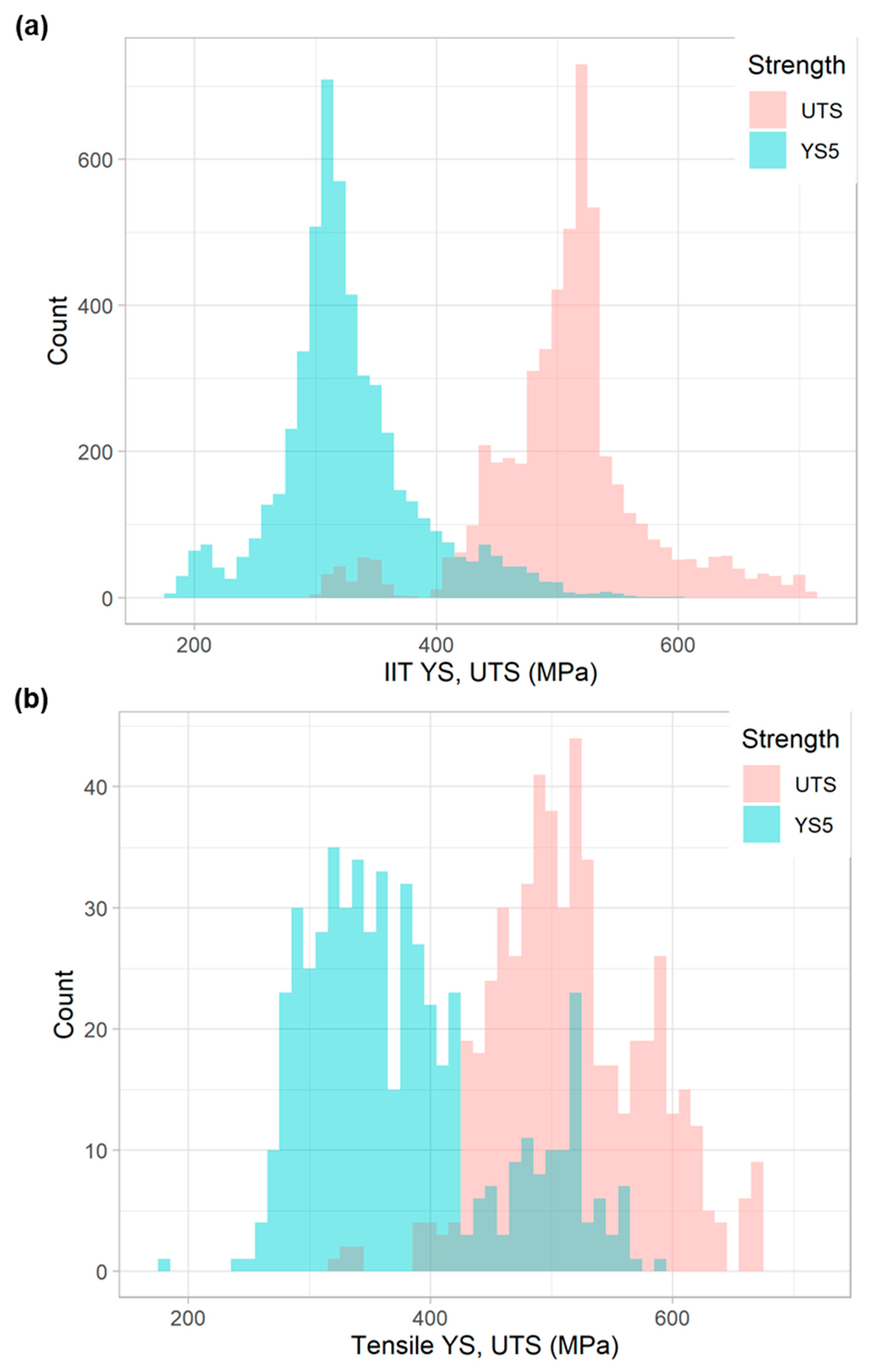

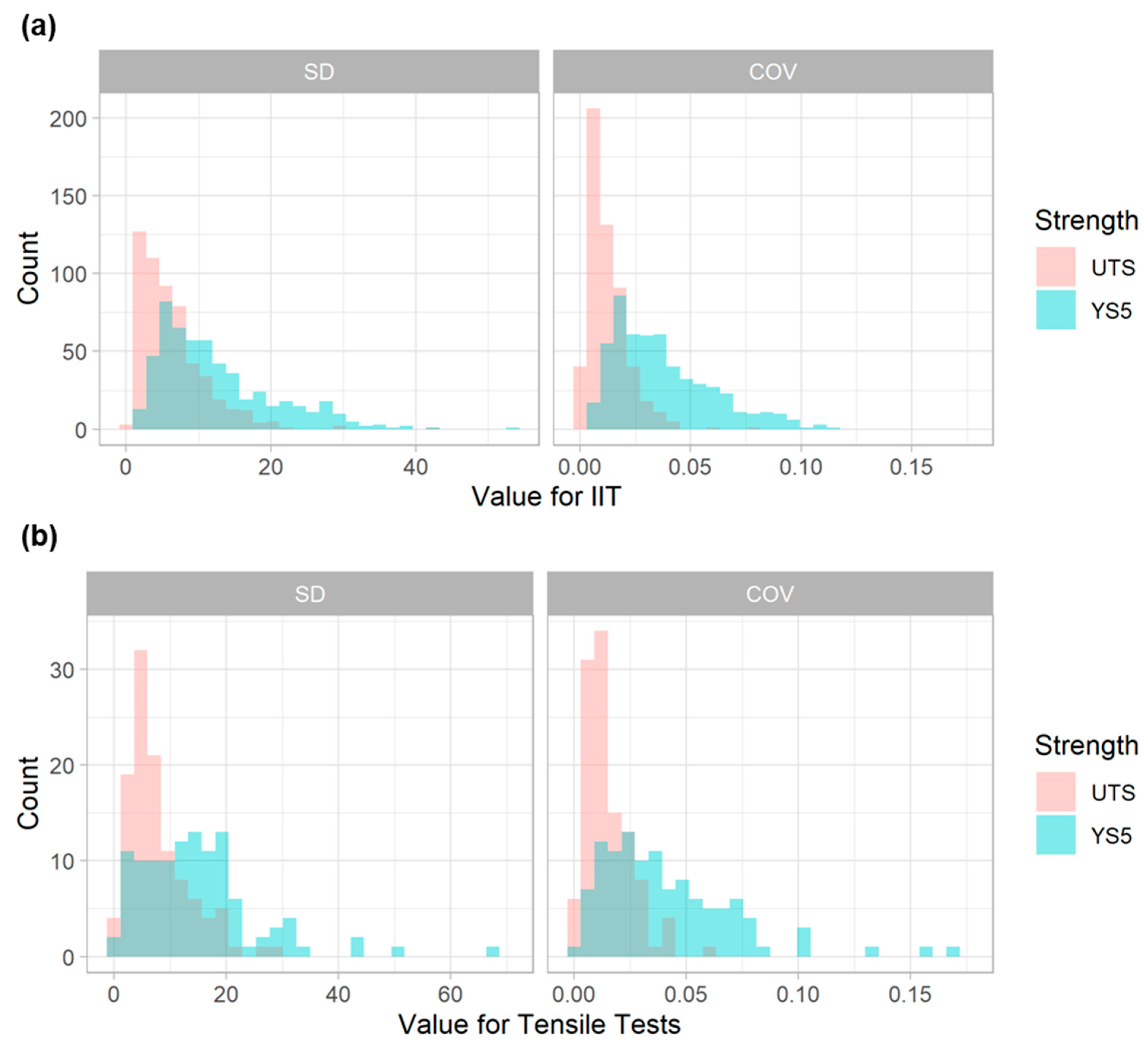

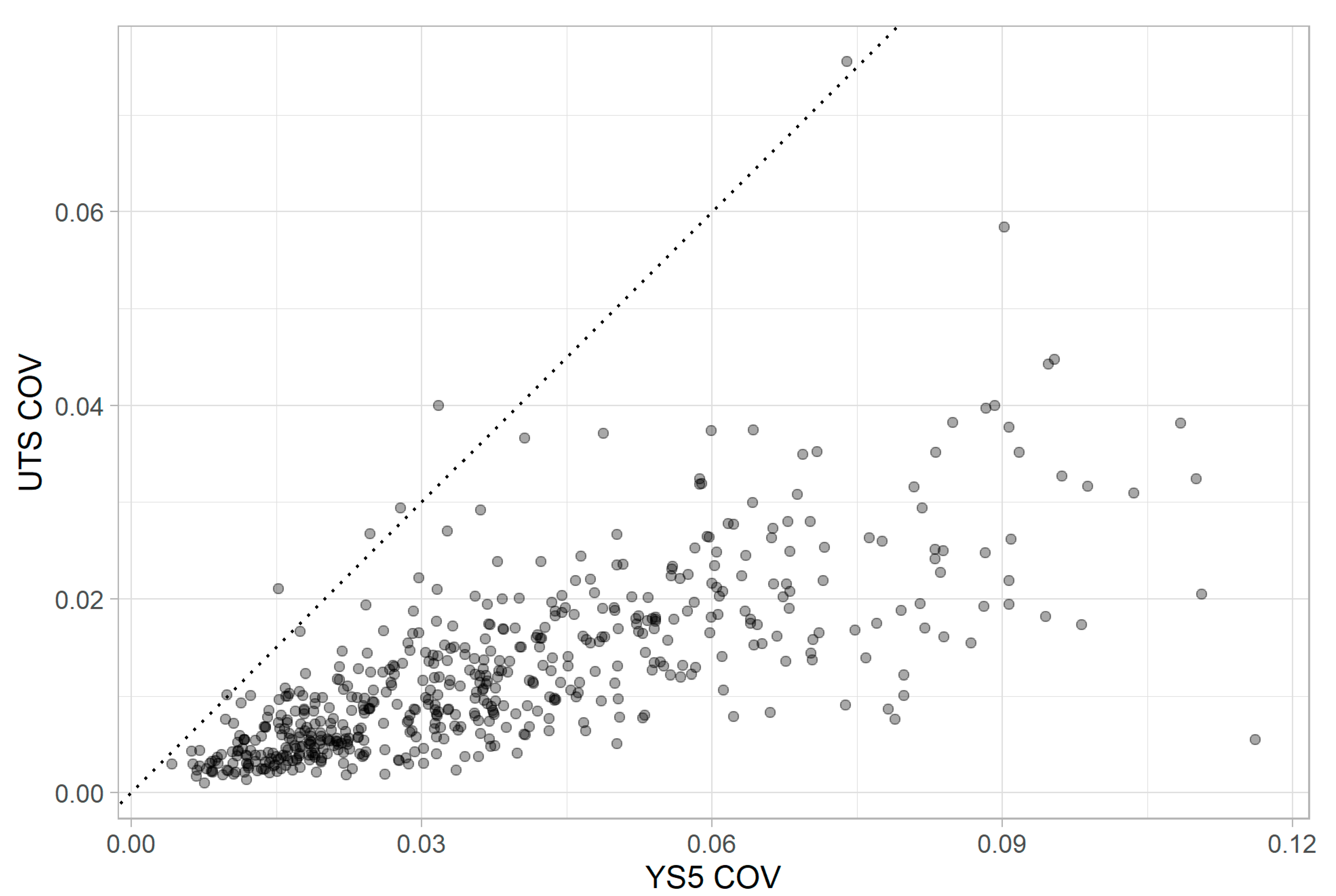

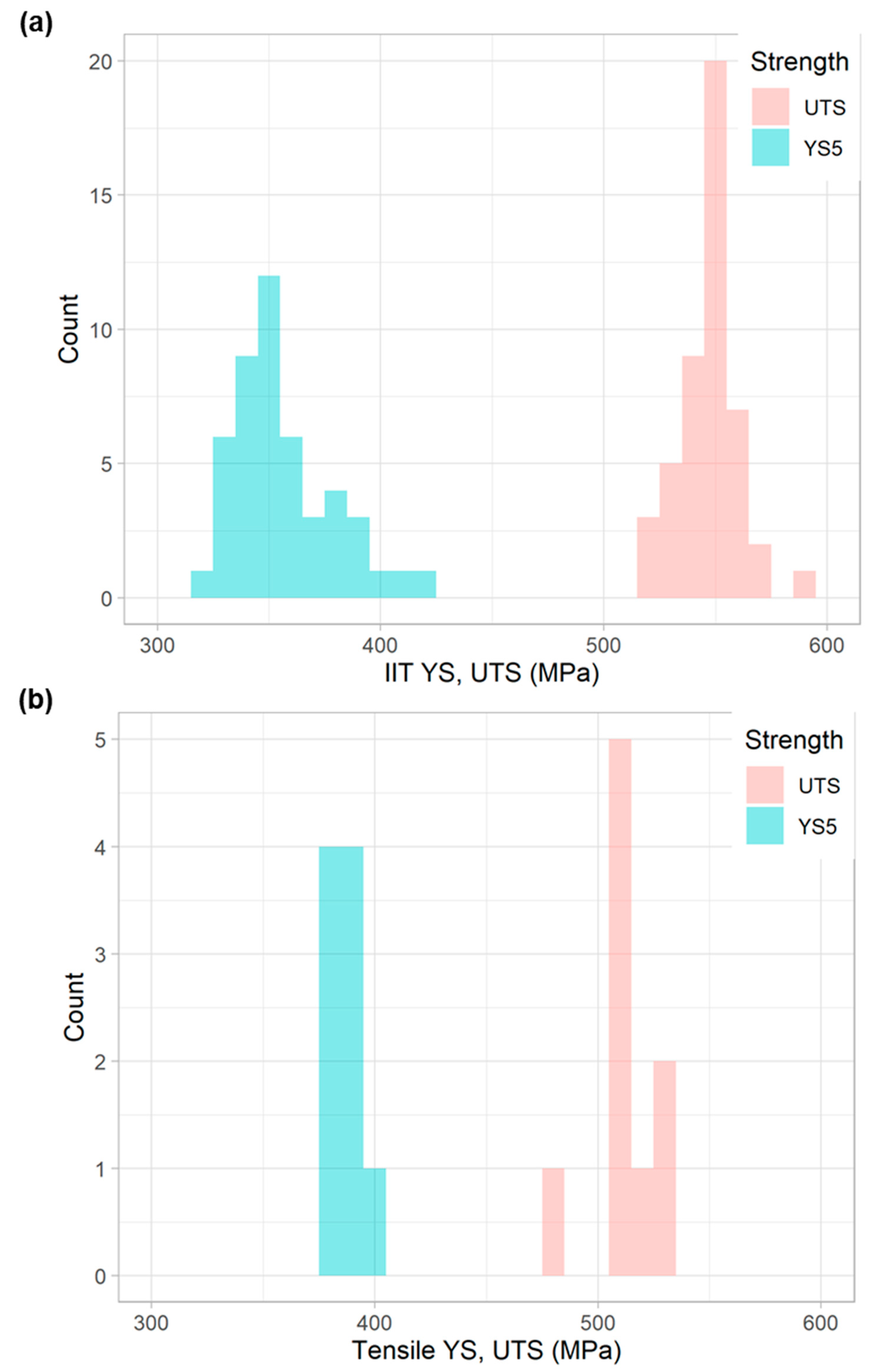

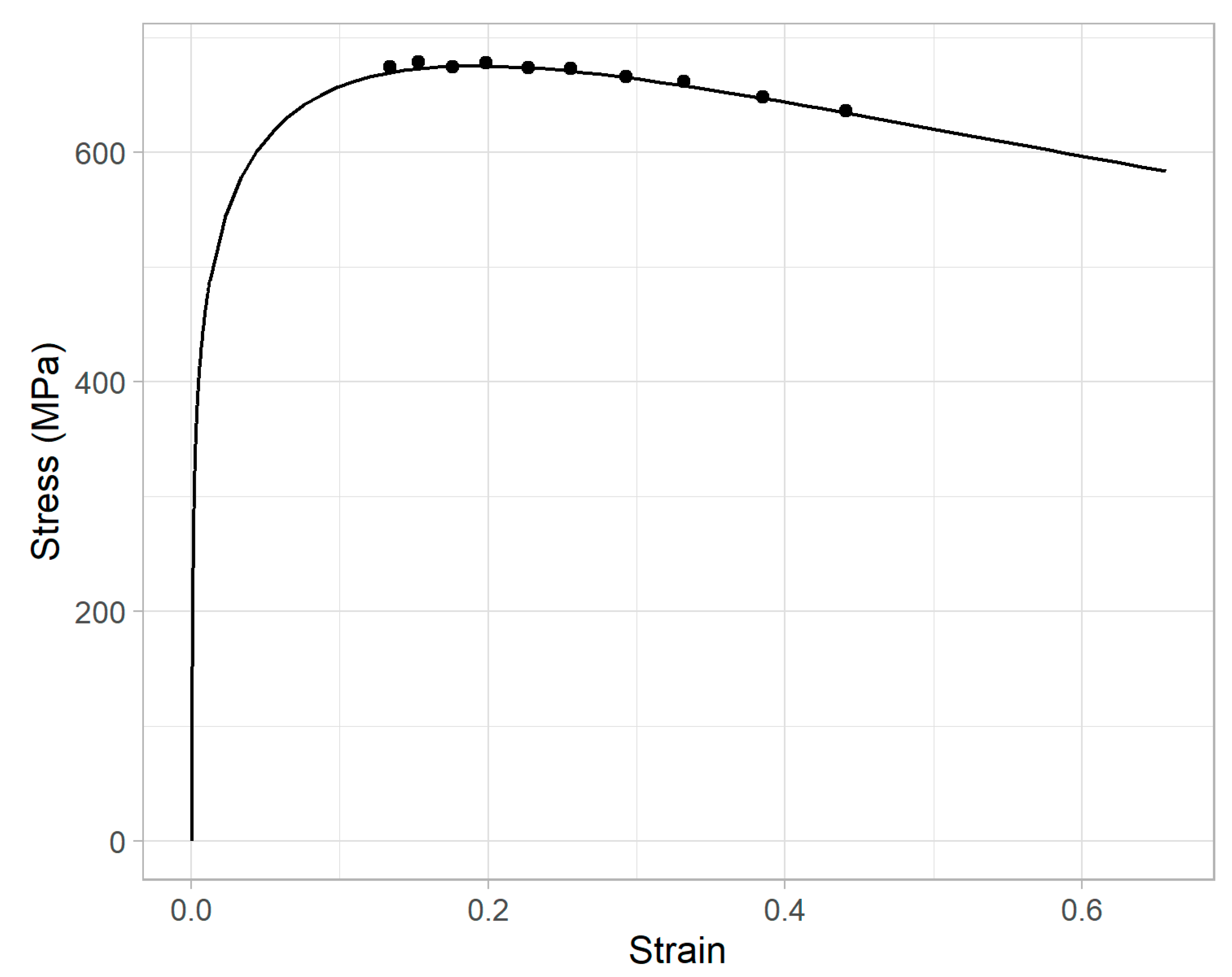

3.1. IIT Measurements and Analysis

3.2. Comparison to Destructive Data

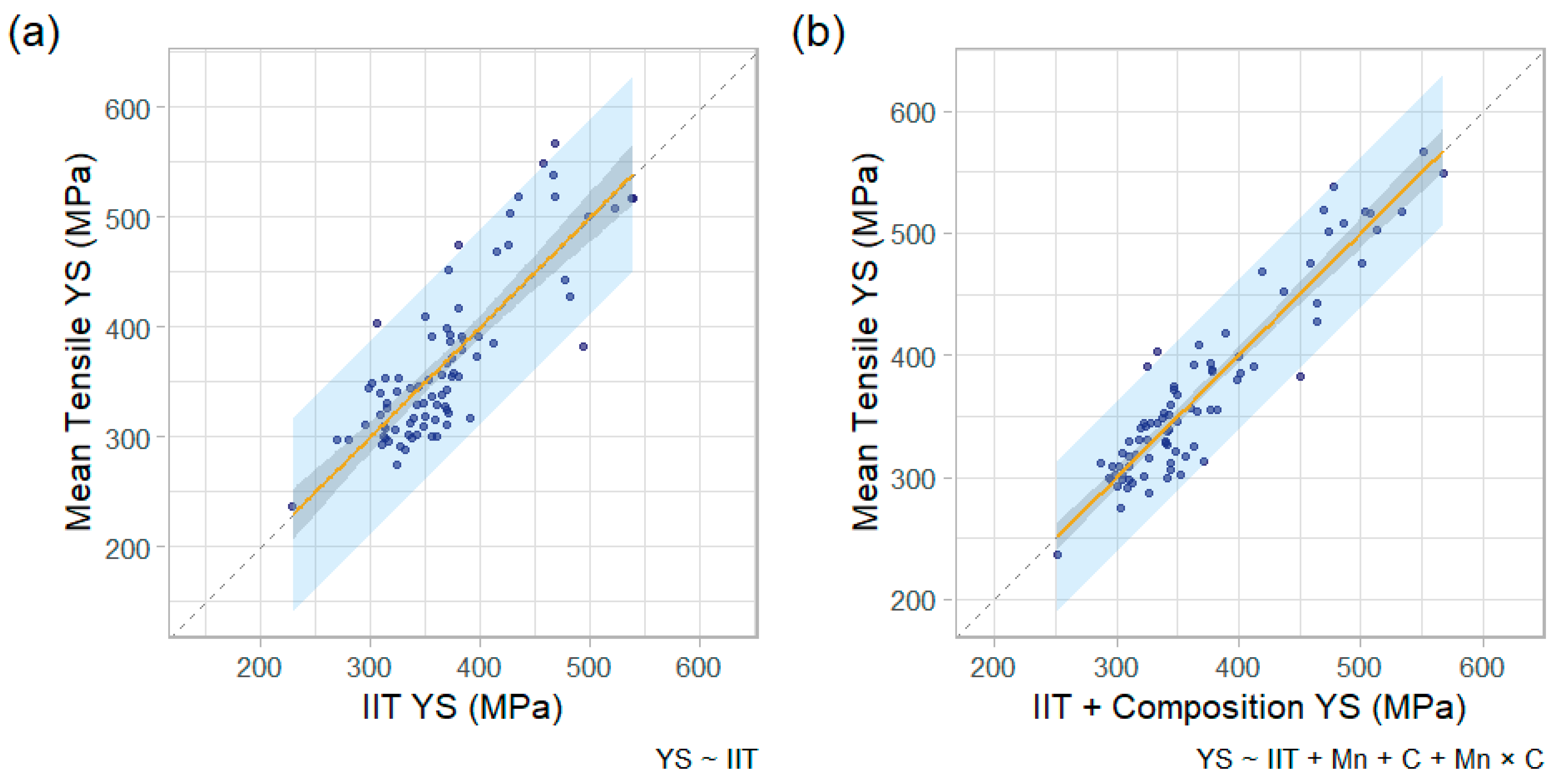

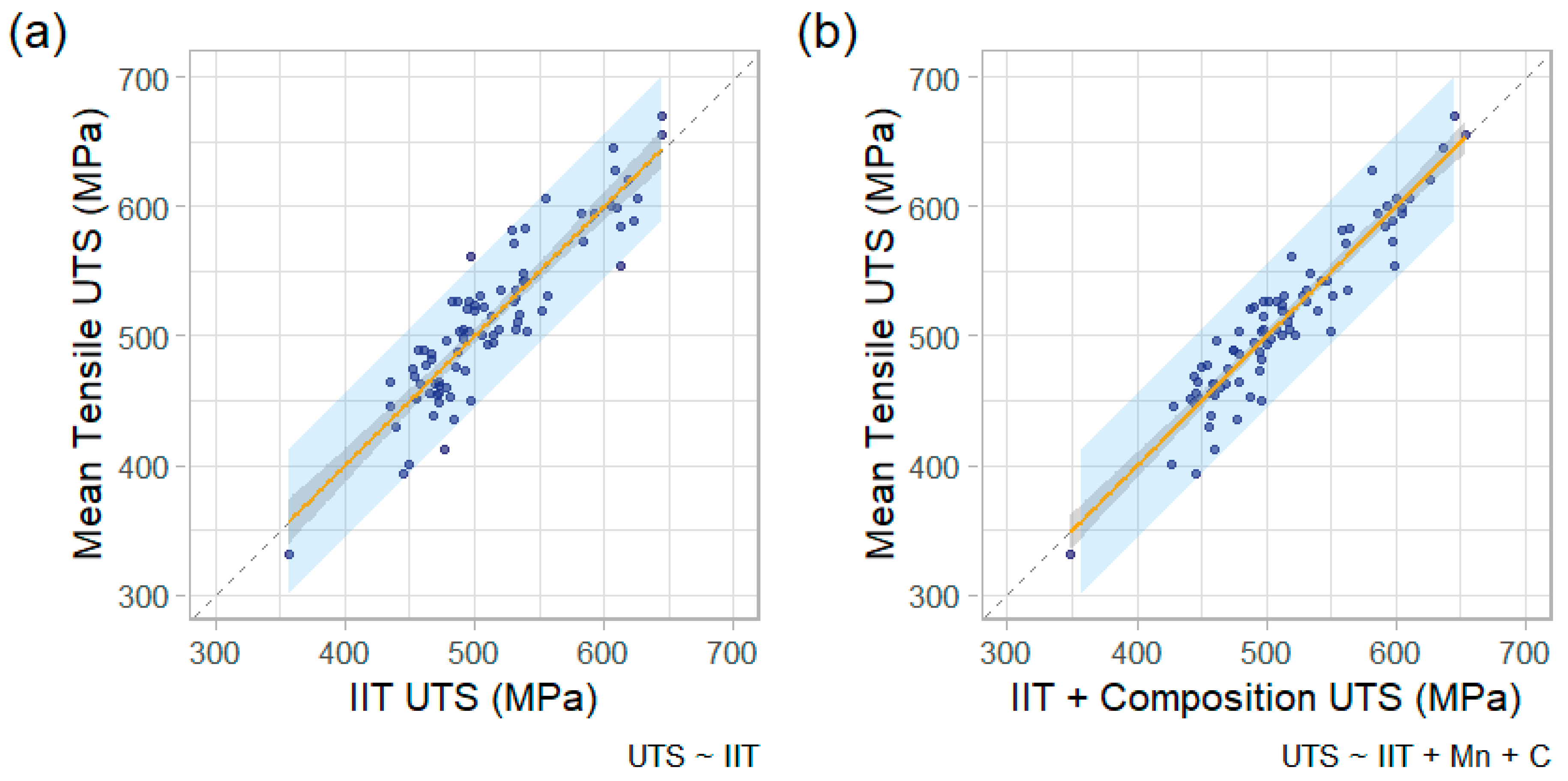

3.3. IIT + Composition Machine Learning Model

3.4. An Example Measurement

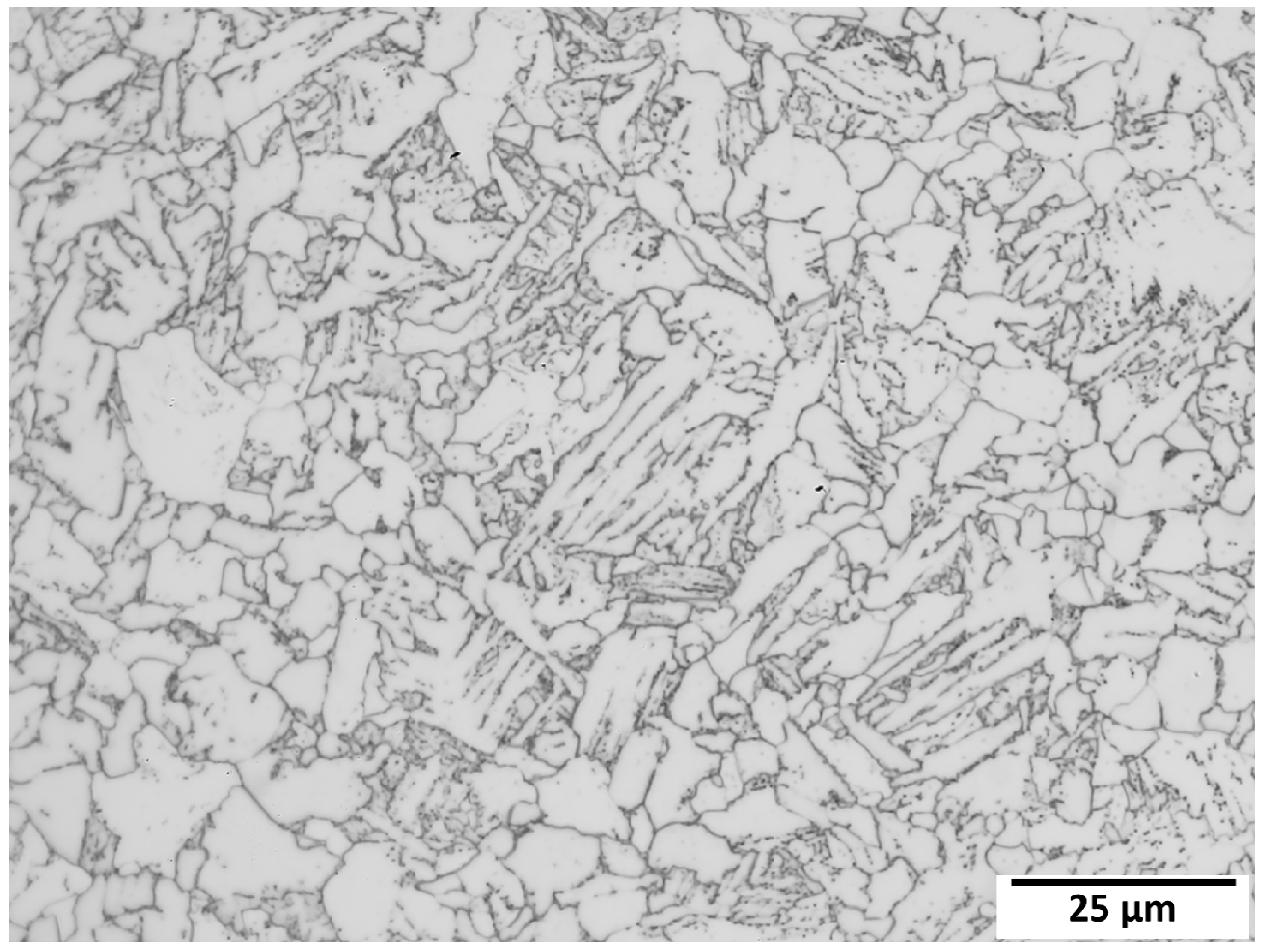

4. Discussion

4.1. Experimental Factors

4.2. Mechanical Factors

4.3. Metallurgical Factors

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pipeline and Hazardous Materials Safety Administration. Verification of Pipeline Material Properties and Attributes: Onshore Steel Transmission Pipelines; 49 Fed. Reg §192.607; The National Archives and Records Administration: College Park, MD, USA, 2019.

- API Specification 5L. In Specification for Line Pipe; American Petroleum Institute: Washington, DC, USA, 2018; Volume 46.

- Bolzon, G.; Molinas, B.; Talassi, M. Mechanical Characterisation of Metals by Indentation Tests: An Experimental Verification Study for On-site Applications. Strain 2012, 48, 517–527. [Google Scholar] [CrossRef]

- Bolzon, G.; Gabetta, G.; Molinas, B.J. Integrity Assessment of Pipeline Systems by an Enhanced Indentation Technique. J. Pipeline Syst. Eng. Pract. 2015, 6, 04014010. [Google Scholar] [CrossRef]

- Bolzon, G.; Rivolta, B.; Nykyforchyn, H.; Zvirko, O. Micro and macro mechanical analysis of gas pipeline steels. In Proceedings of the 2nd International Conference on Structural Integrity, ICSI 2017, Funchal, Madeira, Portugal, 4–7 September 2017. [Google Scholar]

- Midawi, A.; Simha, C.; Gesing, M.; Gerlich, A. Elastic-plastic property evaluation using a nearly flat instrumented indenter. Int. J. Solids Struct. 2017, 104–105, 81–91. [Google Scholar] [CrossRef]

- Midawi, A.; Simha, C.; Gerlich, A. Assessment of yield strength mismatch in X80 pipeline steel welds using instrumented indentation. Int. J. Press. Vessel. Pip. 2018, 168, 258–268. [Google Scholar] [CrossRef]

- Montanari, R.; Varone, A. Flat-Top Cylinder Indenter for Mechanical Characterization: A Report of Industrial Applications. Materials 2021, 14, 1742. [Google Scholar] [CrossRef] [PubMed]

- Moharrami, R.; Sanayei, M. Developing a method in measuring residual stress on steel alloys by instrumented indentation technique. Measurement 2020, 158, 107718. [Google Scholar] [CrossRef]

- Rosenfeld, M.J.; Ma, J. Probabilistic Determination of Pipe Grade. In Proceedings of the 29th Pipeline Pigging & Integrity Management (PPIM) Conference, Houston, TX, USA, 27 February–2 March 2017. [Google Scholar]

- Rosenfeld, M.J.; Ma, J.; Rovella, T.; Veloo, P. Going from In-situ Nondestructive Testing to a Probabilistic MAOP. In Proceedings of the 30th Pipeline Pigging & Integrity Management (PPIM) Conference, Houston, TX, USA, 29 January–1 February 2018. [Google Scholar]

- Kornuta, J.A.; Ames, N.M.; Louie, M.W.; Veloo, P.; Rovella, T. Uncertainty quantification of nondestructive techniques to verify pipeline material strength. In ASME International Pipeline Conference. Volume 1: Pipeline and Facilities Integrity; American Society of Mechanical Engineers: New York, NY, USA, 2018. [Google Scholar] [CrossRef]

- Ma, J.; Rosenfeld, M.; Veloo, P.; Rovella, T.; Martin, P. An Approach to Engineering Critical Assessment of Assets That Cannot Be Inline Inspected. In ASME International Pipeline Conference, Volume 1: Pipeline and Facilities Integrity; American Society of Mechanical Engineers: New York, NY, USA, 2018. [Google Scholar] [CrossRef]

- Rovella, T.; Veloo, P.S.; Rosenfeld, M.; Ma, J. MAOP Verification for Station Piping using Alternative Technology. In Proceedings of the American Gas Association (AGA) Operations Conference, Washington, DC, USA, 25–26 June 2018. [Google Scholar]

- Pavlina, E.J.; Van Tyne, C.J. Correlation of Yield Strength and Tensile Strength with Hardness for Steels. J. Mater. Eng. Perform. 2008, 17, 888–893. [Google Scholar] [CrossRef]

- Halfa, H. Recent Trends in Producing Ultrafine Grained Steels. J. Miner. Mater. Charact. Eng. 2014, 2, 428–469. [Google Scholar] [CrossRef]

- Switzner, N.; Liong, M.; Veloo, P.; Gould, M.; Rovella, T. Nondestructive Testing of Pipeline Materials: Further Evaluation of Portable OES, XRF, LIBS, and Filings to Estimate Chemical Composition. In Proceedings of the 32nd Pipeline Pigging & Integrity Management (PPIM) Conference, Paper #67, Houston, TX, USA, 19–21 February 2020. [Google Scholar]

- Louie, M.; Switzner, N.; Veloo, P.; Amend, B.; Liong, M.; Gould, M.; Rovella, T.; Martin, P. Nondestructive Testing of Pipeline Materials: Analysis of Chemical Composition from Metal Filings. In Proceedings of the 31st Pipeline Pigging & Integrity Management (PPIM) Conference, Paper #50, Houston, TX, USA, 20–22 February 2019. [Google Scholar]

- Pickering, F.B. Physical Metallurgy and the Design of Steels; Applied Science Publishers, LTD: London, UK, 1978; pp. 39–40, 49–50, 62. [Google Scholar]

- Bain, E. Functions of the Alloying Elements in Steel; ASM: Cleveland, OH, USA, 1939; p. 66. [Google Scholar]

- Pickering, F. The Effect of Composition and Microstructure on Ductility and Toughness. In Toward Improved Ductility and Toughness; Climax Molybdenum Development Co.: Tokyo, Japan, 1971; pp. 9–31. [Google Scholar]

- Pickering, F. Structure-Property Relationships in Steels, Constitution and Properties of Steels; Pickering, F., Ed.; Materials Science and Technology; VCH: Weinheim, Germany, 1992; pp. 41–94. [Google Scholar]

- Switzner, N.; Veloo, P.; Rosenfeld, M.; Rovella, T.; Gibbs, J. An approach to establishing manufacturing process and vintage of line pipe using in-situ nondestructive examination and historical manufacturing data. In Proceedings of the International Pipeline Conference (IPC 2020), Calgary, AB, Canada, 28 September–2 October 2020. Proceedings from American Society of Mechanical Engineers (ASME). [Google Scholar]

- Elkin, C.; Bathla, R.; Poplawski, T.; Agashe, S.; Devbhaktuni, V. Improved Prediction of Steel Hardness Through Neural Network Regression. AIST Digit. Trans. Iron Steel Technol. Nov. 2021, 40–44. [Google Scholar] [CrossRef]

- Hosseinzadeh, A.; Mahmoudi, A.-H. Determination of mechanical properties using sharp macro-indentation method and genetic algorithm. Mech. Mater. 2017, 114, 57–68. [Google Scholar] [CrossRef]

- Diao, Y.; Yan, L.; Gao, K. A strategy assisted machine learning to process multi-objective optimization for improving mechanical properties of carbon steels. J. Mater. Sci. Technol. 2021, 109, 86–93. [Google Scholar] [CrossRef]

- ISO-14577-1:2015. Metallic Materials—Instrumented Indentation Test for Hardness and Materials Parameters. Part 1—Test Method. (ISO/DIS Standard No. 14577-1); International Organization for Standardization (ISO): Geneva, Switzerland, 2015. [Google Scholar]

- Ahn, J.-H.; Kwon, D. Derivation of plastic stress–strain relationship from ball indentations: Examination of strain definition and pileup effect. J. Mater. Res. 2001, 16, 3170–3178. [Google Scholar] [CrossRef]

- Kim, S.H.; Lee, B.W.; Choi, Y.; Kwon, D. Quantitative determination of contact depth during spherical indentation of metallic materials—A FEM study. Mater. Sci. Eng. A 2006, 415, 59–65. [Google Scholar] [CrossRef]

- Jeon, E.-C.; Kim, J.-Y.; Baik, M.-K.; Kim, S.-H.; Park, J.-S.; Kwon, D. Optimum definition of true strain beneath a spherical indenter for deriving indentation flow curves. Mater. Sci. Eng. A 2006, 419, 196–201. [Google Scholar] [CrossRef]

- Kim, J.Y.; Lee, K.W.; Lee, J.S.; Kwon, D. Determination of tensile properties by instrumented indentation technique: Repre-sentative stress and strain approach. Surf. Coat. Technol. 2006, 201, 4278–4283. [Google Scholar] [CrossRef]

- Tabor, D. A simple theory of static and dynamic hardness. Proc. R. Soc. A 1948, 192, 247–274. [Google Scholar]

- Kornuta, J.; Thorsson, S.; Gibbs, J.; Veloo, P.; Rovella, T. Automated Error Identification During Nondestructive Testing of Pipelines for Strength. In Proceedings of the International Pipeline Conference (IPC 2020), Calgary, AB, Canada, 28 September–2 October 2020. Proceedings from American Society of Mechanical Engineers (ASME). [Google Scholar]

- Kuhn, M.; Wickham, H. Tidymodels: A Collection of Packages for Modeling and Machine Learning using Tidyverse Principles. 2020. Available online: https://www.tidymodels.org (accessed on 15 October 2021).

- Yen, H.-W.; Chiang, M.-H.; Lin, Y.-C.; Chen, D.; Huang, C.-Y.; Lin, H.-C. High-Temperature Tempered Martensite Embrittlement in Quenched-and-Tempered Offshore Steels. Metals 2017, 7, 253. [Google Scholar] [CrossRef] [Green Version]

- Gray, J.M.; Siciliano, F. High Strength Microalloyed Linepipe: Half a Century of Evolution; Microalloyed Steel Institute: Houston, TX, USA, 2009. [Google Scholar]

| a | b1 | b2 | c1 | c2 | |

|---|---|---|---|---|---|

| 0.75 | 0.131 | −3.423 | 0.079 | 6.258 | −8.072 |

| Model | Adjusted R2 | RMSE (MPa) |

|---|---|---|

| IIT Only | 0.67 | 42.7 |

| IIT + Composition | 0.87 | 27.2 |

| Estimate | p-Value | Conf. Int. (Lower Lim.) | Conf. Int. (Upper Lim.) | |

|---|---|---|---|---|

| (Intercept) | 364 | <1 × 10−16 | 357 | 370 |

| YS (IIT) | 0.455 | 8.45 × 10−9 | 0.315 | 0.595 |

| Manganese | 105 | 3.73 × 10−11 | 77.6 | 132 |

| Carbon | −215 | 1.76 × 10−4 | −324 | −106 |

| Mn × C | −451 | 1.84 × 10−3 | −730 | −173 |

| Model | Adj. R2 | RMSE (MPa) |

|---|---|---|

| IIT Only | 0.81 | 26.9 |

| IIT + Composition | 0.88 | 21.4 |

| Estimate | p-Value | Conf. Int. (Lower Lim.) | Conf. Int. (Upper Lim.) | |

|---|---|---|---|---|

| (Intercept) | 512 | <1 × 10−16 | 507 | 516 |

| UTS (IIT) | 0.611 | 1.76 × 10−15 | 0.488 | 0.734 |

| Manganese | 87.6 | 2.64 × 10−9 | 61.6 | 114 |

| Carbon | 119 | 4.39 × 10−3 | 38.3 | 200 |

| YS (MPa) | YS Uncertainty * (MPa) | UTS (MPa) | UTS Uncertainty * (MPa) | |

|---|---|---|---|---|

| Mean Tensile Measurement | 387 | 8.3 | 511 | 13.6 |

| Mean IIT Measurement | 357 | 22.6 | 547 | 13.5 |

| IIT-Only Trained Estimate | 373 | 288–459 | 532 | 479–586 |

| IIT+Composition Trained Estimate | 378 | 323–434 | 516 | 473–559 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Scales, M.; Anderson, J.; Kornuta, J.A.; Switzner, N.; Gonzalez, R.; Veloo, P. Accurate Estimation of Yield Strength and Ultimate Tensile Strength through Instrumented Indentation Testing and Chemical Composition Testing. Materials 2022, 15, 832. https://doi.org/10.3390/ma15030832

Scales M, Anderson J, Kornuta JA, Switzner N, Gonzalez R, Veloo P. Accurate Estimation of Yield Strength and Ultimate Tensile Strength through Instrumented Indentation Testing and Chemical Composition Testing. Materials. 2022; 15(3):832. https://doi.org/10.3390/ma15030832

Chicago/Turabian StyleScales, Martin, Joel Anderson, Jeffrey A. Kornuta, Nathan Switzner, Ramon Gonzalez, and Peter Veloo. 2022. "Accurate Estimation of Yield Strength and Ultimate Tensile Strength through Instrumented Indentation Testing and Chemical Composition Testing" Materials 15, no. 3: 832. https://doi.org/10.3390/ma15030832

APA StyleScales, M., Anderson, J., Kornuta, J. A., Switzner, N., Gonzalez, R., & Veloo, P. (2022). Accurate Estimation of Yield Strength and Ultimate Tensile Strength through Instrumented Indentation Testing and Chemical Composition Testing. Materials, 15(3), 832. https://doi.org/10.3390/ma15030832