Corn Cob Ash versus Sunflower Stalk Ash, Two Sustainable Raw Materials in an Analysis of Their Effects on the Concrete Properties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

- A reference composition of micro concrete, RC, with cement, sand and river gravel aggregates up to 8 mm in diameter, with a water/cement ratio of 0.5;

- Eight concrete compositions with vegetal ash developed on the basis of RC:

- -

- With corn cob ash of A quality, as 2.5% and 5% replacement of cement volume (CCA1A, CCA2A),

- -

- With corn cob ash of B quality, as 2.5% and 5% replacement of cement volume (CCA1B, CCA2B),

- -

- With sunflower stalk ash of A quality, as 2.5% and 5% replacement of cement volume (SSA1A, SSA2A),

- -

- With sunflower stalks ash of B quality, as 2.5% and 5% replacement of cement volume (SSA1B, SSA2B).

2.2. Methods

2.2.1. Vegetal Ash Preparation

2.2.2. Sunflower Stalk Ash Analysis

2.2.3. Composite Mixes Preparation

2.2.4. Concrete Specimens Properties

Composition Analysis

Mechanical and Durability Properties Analysis

Resistance to Repeated Freeze–Thaw Cycles

Resistance to Chemical Attack of Hydrochloric Acid (HCl)

3. Results and Discussions

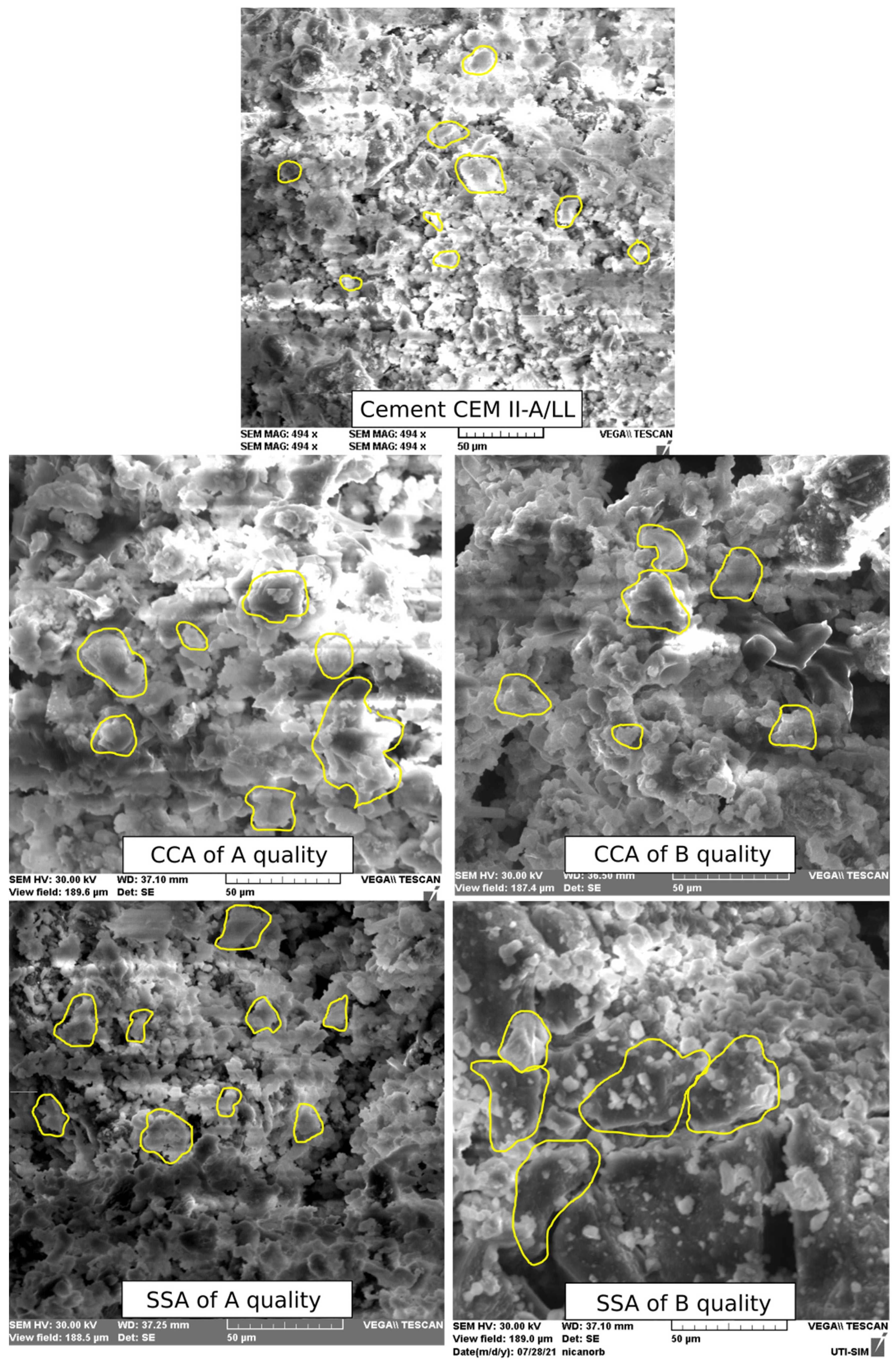

3.1. Vegetal Ashes and Cement

- Si content in CCA is quite significant compared with SSA, being 10 times higher for A quality, whereas it is lacking in SSA at B quality;

- Only CCA at B quality has a small rate of Al and Fe;

- Ca content is around six times higher in SSA than in CCA;

- K quantities are very high in all ashes, around 21–23% in CCA and around 23–25% in SSA; the B quality of SSA has the bigger K content;

- S and P are present only in CCA;

- C content is much higher in CCA than in SSA, with 1.8 times higher for A-quality ash, and with 2.5 times higher for B quality;

- Mg content is almost double in SSA than in CCA, whereas the Cl rates does not differ significantly between them.

3.2. Composite Specimens Properties

3.2.1. Chemical Composition Analysis

3.2.2. Compressive Strength

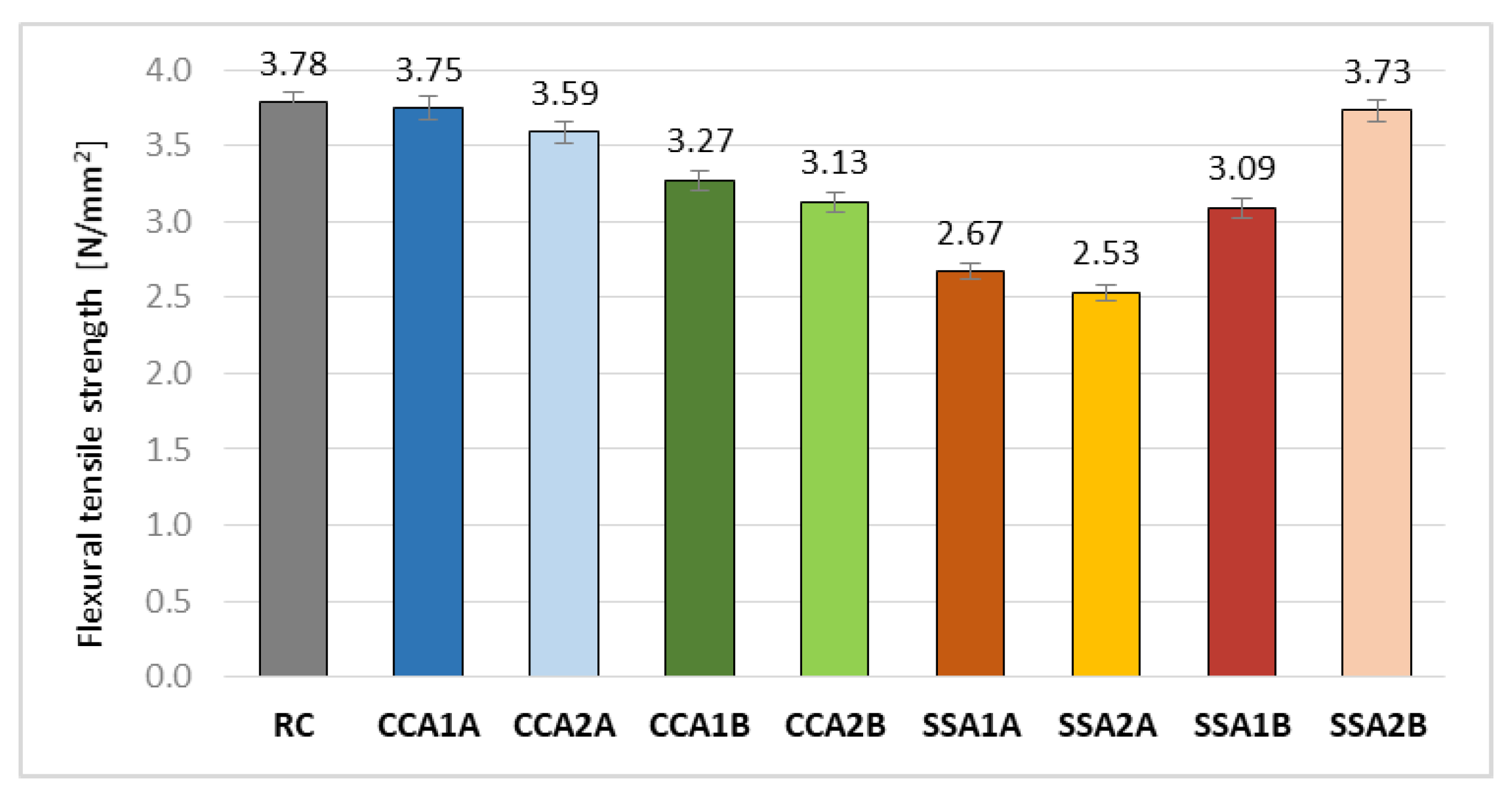

3.2.3. Flexural Tensile Strength

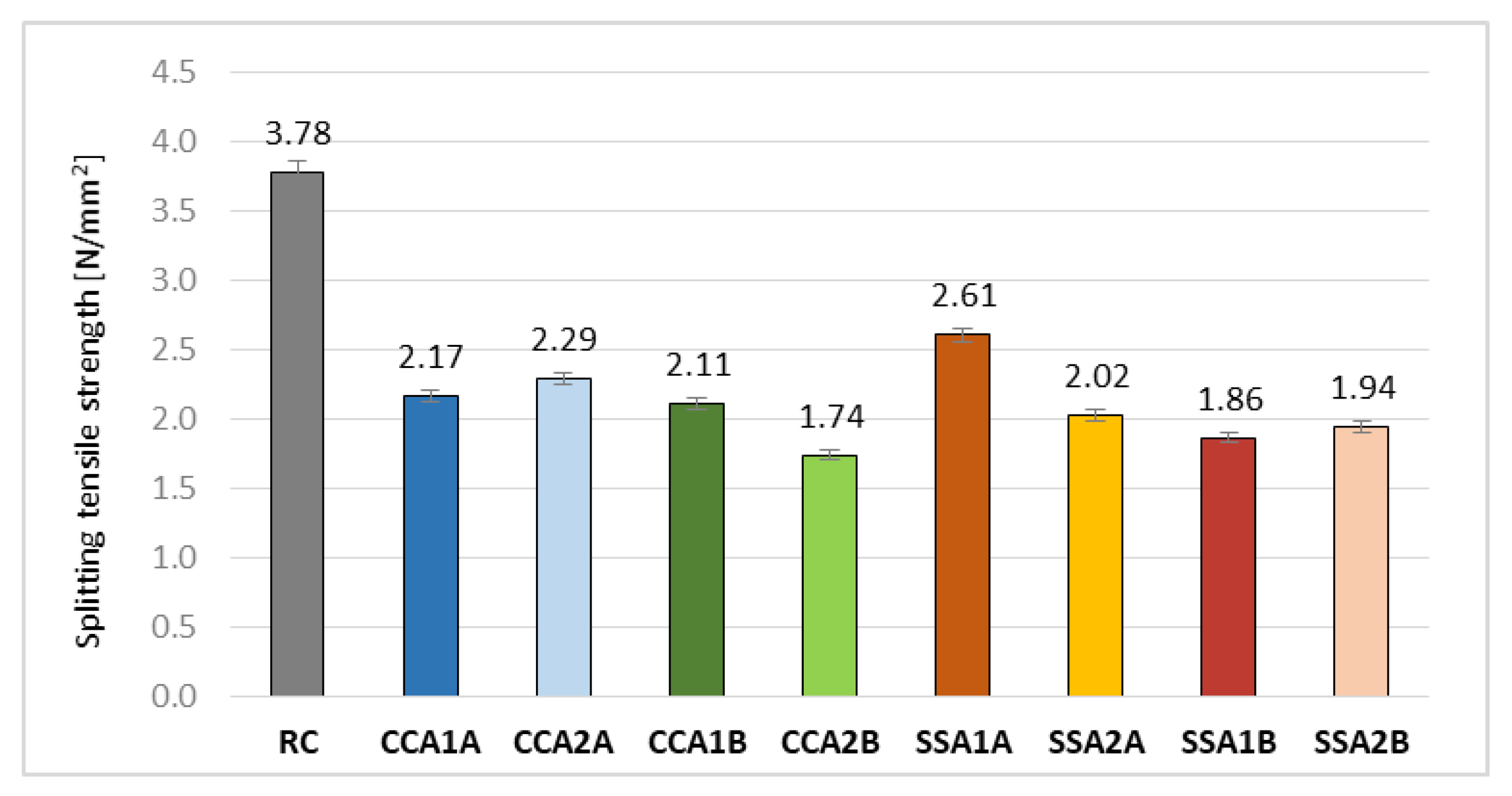

3.2.4. Splitting Tensile Strength

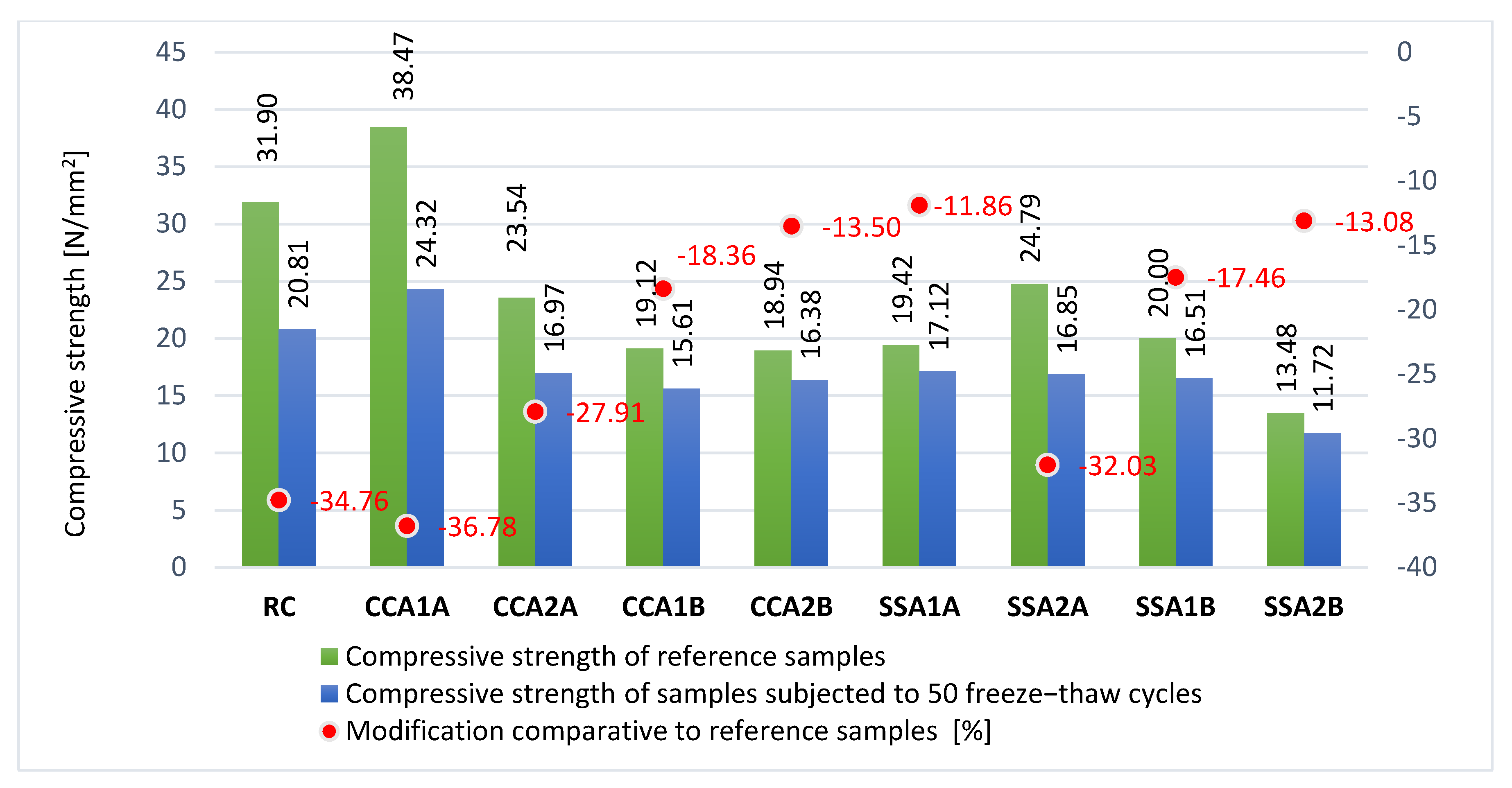

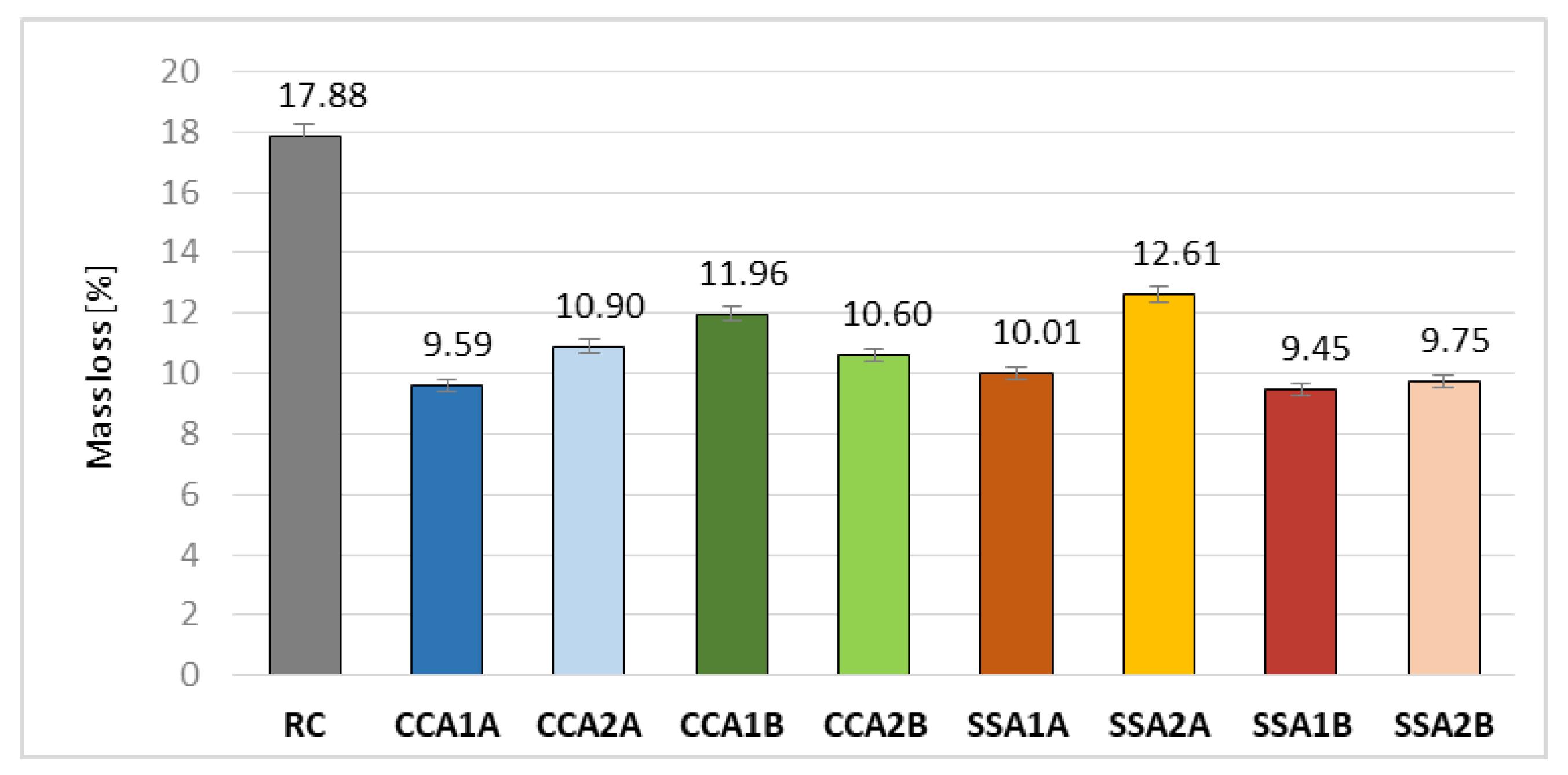

3.2.5. Resistance to Repeated Freeze–Thaw Cycles

3.2.6. Resistance to HCl Chemical Attack

4. Conclusions

- The best results for compressive strength between all mixes with vegetal ash were obtained by CCA1A, SSA1A, and CCA1B, with very close values between them. Therefore, the 2.5% of CCA, no matter its quality, and 2.5% of SSA of A quality led to similar compressive strength values. Between these three variants of mixes with vegetal ashes, only SSA1A obtained a very good gain in compressive strength during a period of 3 months, very close to that of RC.

- Regarding flexural tensile strength, CCA1A and SSA2B registered the best results, with a more insignificant decrease than RC of only about 1%.

- CCA and SSA, no matter of the quality used, determined decreases in splitting tensile strength of RC, between 31% and 54%. The smallest decreases were registered by SSA1A and CCA2A, with 31% and 39%, respectively, smaller than the reference.

- All vegetal ashes used in this study led to very significant improvement of resistance to freeze–thaw and to the chemical attack of HCl. Regarding resistance to repeated freeze–thaw cycles, the biggest improvements were obtained by SSA1A, followed very closely by SSA2B and CCA2B, with 23–23% smaller losses in compressive strength than RC. Regarding resistance to chemical attack of 18% HCl solution, all studied mixes with vegetal ash obtained improvements of this parameter, between 30% and 47% more than the reference.

- CCA1A led to the smallest decreases in compressive strength at 28 days and flexural tensile strength, and it registered one of the biggest values regarding resistance to HCl action.

- SSA1A was the optimum mix regarding compressive strength at 28 days and 3 months, splitting tensile strength and freeze–thaw resistance, and it obtained a very significant improvement of resistance to HCl, at 44%.

- SSA1B obtained the biggest improvement of the resistance from the HCl action point of view, and one of the best results from the freeze–thaw resistance point of view.

- CCA2B and SSA2B obtained very significant increases as resistance to freeze–thaw cycles and to HCl action.

- SSA2B registered the biggest compressive strength gain in time, bigger than RC, and one of the smallest decreases in flexural tensile strength.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rui Guo, R.; Wang, J.; Bing, L.; Dan Tong, D.; Ciais, P.; Davis, S.J.; Andrew, R.M.; Xi, F.; Liu, Z. Global CO2 uptake of cement in 1930–2019. Earth Syst. Sci. Data 2020, 13, 1791–1805. [Google Scholar] [CrossRef]

- Hasanbeigi, A. Global Cement Industry’s GHG Emissions. 2021. Available online: https://www.globalefficiencyintel.com/new-blog/2021/global-cement-industry-ghg-emissions (accessed on 15 October 2021).

- Garside, M. Major Countries in Worldwide Cement Production 2010–2020. 2021. Available online: https://www.statista.com/statistics/267364/world-cement-production-by-country (accessed on 15 October 2021).

- Gambhir. Concrete Technology 4e; Tata McGraw-Hill Education: New York, NY, USA, 2009. [Google Scholar]

- Kamau, J.; Ahmed, A.; Hirst, P.; Kangwa, J. Suitability of Corncob Ash as a supplementary Cementitious Material. Int. J. Mater. Sci. Eng. 2016, 4, 215–228. [Google Scholar] [CrossRef]

- Bie, R.S.; Song, X.F.; Liu, Q.Q.; Ji, X.Y.; Chen, P. Studies on effects of burning conditions and rice husk ash (RHA) blending amount on the mechanical behavior of cement. Cem. Concr. Compos. 2015, 55, 162–168. [Google Scholar] [CrossRef]

- Antiohos, S.K.; Tapali, J.G.; Zervaki, M.; Sousa-Coutinho, J.; Tsimas, S.; Papadakis, V.G. Low embodied energy cement containing untreated RHA: A strength development and durability study. Constr. Build. Mat. 2013, 49, 455–463. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Rukzon, S.; Sirivivatnanon, V. Resistance to Chloride Penetration of Blended Portland cement Mortar Containing Palm Oil Fuel Ash, Rice Husk Ash and Fly Ash. Constr. Build. Mat. 2008, 22, 932–938. [Google Scholar] [CrossRef]

- Amin, M.N.; Khan, K.; Aslam, F.; Shah, M.I.; Javed, M.F.; Musarat, M.A.; Usanova, K. Multigene Expression Programming Based Forecasting the Hardened Properties of Sustainable Bagasse Ash Concrete. Materials 2021, 14, 5659. [Google Scholar] [CrossRef]

- Bahurudeen, A.; Kanraj, D.; Gokul Dev, V.; Santhanam, M. Performance evaluation of sugarcane bagasse ash blended cement in concrete. Cem. Concr. Compos. 2015, 59, 77–88. [Google Scholar] [CrossRef]

- Bheel, N.; Adesina, A. Influence of Binary Blend of Corn Cob Ash and Glass Powder as Partial Replacement of Cement in Concrete. Silicon 2021, 13, 1647–1654. [Google Scholar] [CrossRef]

- Adesanya, D.A.; Raheem, A.A. Development of corn cob ash blended cement. Constr. Build. Mater. 2009, 23, 347–352. [Google Scholar] [CrossRef]

- Memon, S.A.; Javed, U.; Haris, M.; Khushnood, R.A.; Kim, J. Incorporation of Wheat Straw Ash as Partial Sand Replacement for Production of Eco-Friendly Concrete. Materials 2021, 14, 2078. [Google Scholar] [CrossRef] [PubMed]

- Aksoğan, O.; Binici, H.; Ortlek, E. Durability of concrete made by partial replacement of fine aggregate by colemanite and barite and cement by ashes of corn stalk, wheat straw and sunflower stalk ashes. Constr. Build. Mater. 2016, 106, 253–263. [Google Scholar] [CrossRef]

- Martirena, F.; Monzó, J. Vegetable ashes as supplementary cementitious materials. Cem. Concr. Res. 2018, 114, 57–64. [Google Scholar] [CrossRef]

- Shafigh, P.; Mahmud, H.B.; Jumaat, M.Z.; Zargar, M. Agricultural wastes as aggregate in concrete mixtures—A review. Constr. Build. Mater. 2014, 53, 110–117. [Google Scholar] [CrossRef]

- OECD (Organisation for Economic Cooperation and Development). Crop Production (Indicator). Available online: https://www.oecd-ilibrary.org/agriculture-and-food/crop-production/indicator/english_49a4e677-en (accessed on 20 September 2021).

- USDA (United States Department of Agriculture). World Agricultural Production. Circular Series WAP 10-21 2021, 38. Available online: https://apps.fas.usda.gov/psdonline/circulars/production.pdf (accessed on 20 September 2021).

- Leff, B.; Ramankutty, N.; Foley, J.A. Geographic distribution of major crops across the world. Glob. Biogeochem. Cycles 2004, 18, 33. [Google Scholar] [CrossRef]

- Adesanya, D. Evaluation of blended cement mortar, concrete and stabilized earth made from ordinary Portland cement and corn cob ash. Constr. Build. Mater. 1996, 10, 451–456. [Google Scholar] [CrossRef]

- Binici, H.; Yucegok, F.; Aksogan, O.; Kaplan, H. Effect of corncob, wheat straw, and plane leaf ashes as mineral admixtures on concrete durability. J. Mater. Civ. Eng. 2008, 20, 478–483. [Google Scholar] [CrossRef]

- Kamau, J.; Ahmed, A.; Hirst, P.; Kangwa, J. Permeability of corncob ash, anthill soils and rice husk replaced concrete. Int. J. Sci. Environ. Technol. 2017, 6, 1299–1308. [Google Scholar]

- Memon, S.A.; Khan, M.K. Ash blended cement composites: Eco-friendly and sustainable option for utilization of corncob ash. J. Clean. Prod. 2018, 175, 442–455. [Google Scholar] [CrossRef]

- Oladipupo, O.S.; Olutoge, F.A. Strength Properties of Corn Cob Ash Concrete. J. Emerg. Trends Eng. Appl. Sci. 2012, 3, 297–301. [Google Scholar]

- Mujedu, K.A.; Adebara, S.A.; Lamidi, I.O. The Use of Corn Cob Ash and Saw Dust Ash as Cement. Int. J. Eng. Sci. 2014, 3, 22–28. [Google Scholar]

- Ahangba, A.; Michael, T. Partial replacement of cement with corn cob ash. Int. J. Innov. Res. Multidiscip. Field 2016, 2, 158–169. [Google Scholar]

- Owolabi, T.A.; Oladipo, I.O.; Popoola, O.O. Effect of corncob ash as partial substitute for cement in concrete. N. Y. Sci. J. 2015, 8, 1–4. [Google Scholar]

- Shakouri, M.; Exstrom, C.L.; Ramanathan, S.; Suraneni, P. Hydration, strength, and durability of cementitious materials incorporating untreated corn cob ash. Constr. Build. Mater. 2020, 243, 118171. [Google Scholar] [CrossRef]

- Darweesh, H.H.M. Influence of sun flower stalk ash (SFSA) on the behavior of Portland cement pastes. Results Eng. 2020, 8, 100171. [Google Scholar] [CrossRef]

- EN 197-1:2011. Cement. Composition, Specifications and Conformity Criteria for Common Cements; European Committee for Standardization: Brussels, Belgium, 2011. [Google Scholar]

- NE 012/1-2007. Normativ Pentru Producerea Betonului Și Executarea Lucrarilor Din. Beton, Beton Armat Și Beton Precomprimat—Partea 1: Producerea Betonului (Regulations for the Production of Concrete and the Execution of Concrete, Reinforced Concrete and Prestressed Concrete); ASRO—Romanian Standardization Association: Bucharest, Romania, 2007. [Google Scholar]

- EN 12390-3:2019. Testing Hardened Concrete Part. 3: Compressive Strength of Test. Specimens; European Committee for Standardization: Brussels, Belgium, 2019. [Google Scholar]

- EN 12390-5:2019. Testing Hardened Concrete Part. 3: Flexural Tensile Strength of Test. Specimens; European Committee for Standardization: Brussels, Belgium, 2019. [Google Scholar]

- EN 12390-6:2010. Testing Hardened Concrete; Part. 6: Split Tensile Strength of Test. Specimens; European Committee for Standardization: Brussels, Belgium, 2010. [Google Scholar]

- SR 3518:2009. Încercări Pe Betoane. Determinarea Rezistenței La Îngheț-Dezgheț Prin Masurarea Variației Rezistenței La Compresiune¸ Si/Sau Modulului de Elasticitate Dinamic Relativ (Tests Hard-Ened Concrete. Determination of Freeze-Thaw Resistance by Measuring the Variation of the Com-Pressive Strength and/or the Relatively Dynamic Modulus of Elasticity); ASRO—Romanian Standardization Association: Bucharest, Romania, 2009. [Google Scholar]

- Neville, A.M. Properties of Concrete, 5th ed.; Trans-Atlantic Publications, Inc.: Philadelphia, PA, USA, 2012. [Google Scholar]

| Ash Type | Bulk Density (g/L) | Specific Gravity (N/m3) |

|---|---|---|

| CCA of A quality | 725 | 2.102 |

| CCA of B quality | 699 | 2.027 |

| SSA of A quality | 805 | 2.334 |

| SSA of B quality | 799 | 2.317 |

| Test | Specimens’ Type | Specimens’ Dimensions | Specimens Number Tested for Each Mix | Standard Applied |

|---|---|---|---|---|

| Compressive strength | Cylinder | 100 mm diameter 200 mm length | 3 | EN 12390-3: 2019 [32] |

| Flexural tensile strength | Prism | 100 × 100 mm2 transversal section 550 mm length | 3 | EN 12390-5: 2019 [33] |

| Splitting tensile strength | Cylinder | 100 mm diameter 200 mm length | 3 | EN 12390-6: 2010 [34] |

| Resistance to freeze–thaw | Cube | sides of 100 mm | 6 | SR 3518: 2009 [35] EN 12390-3: 2019 [32] |

| Resistance to hydrochloric acid action | Cube | sides of 50 mm | 3 | Figure 2 |

| Element | CCA | SSA | Cement | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| A | B | A | B | |||||||

| Mass Norm. (%) | Atom (%) | Mass Norm. (%) | Atom (%) | Mass Norm. (%) | Atom (%) | Mass Norm. (%) | Atom (%) | Mass Norm. (%) | Atom (%) | |

| Oxygen (O) | 47.58 | 56.28 | 39.56 | 45.81 | 50.81 | 63.76 | 52.85 | 65.29 | 47.65 | 64.17 |

| Silicon (Si) | 7.14 | 4.81 | 5.42 | 3.58 | 0.68 | 0.49 | - | - | 20.97 | 16.09 |

| Aluminum (Al) | - | - | 1.76 | 1.21 | - | - | - | - | 12.89 | 10.29 |

| Calcium (Ca) | 1.63 | 0.77 | 1.41 | 0.65 | 10.18 | 5.10 | 8.94 | 4.41 | 12.12 | 6.51 |

| Iron (Fe) | - | - | 1.14 | 0.38 | - | - | - | - | 4.25 | 1.64 |

| Potassium (K) | 21.22 | 10.27 | 22.75 | 10.78 | 22.85 | 11.73 | 25.00 | 12.64 | 1.07 | 0.59 |

| Sulfur (S) | 1.18 | 0.70 | 0.69 | 0.40 | - | - | - | - | 1.05 | 0.70 |

| Carbon (C) | 14.62 | 23.64 | 22.13 | 34.13 | 7.91 | 13.23 | 8.97 | 14.77 | - | - |

| Magnesium (Mg) | 1.83 | 1.43 | 1.13 | 0.86 | 5.41 | 4.47 | 2.06 | 1.68 | - | - |

| Chlorine (Cl) | 3.03 | 1.62 | 2.50 | 1.31 | 2.16 | 1.22 | 2.18 | 1.21 | - | - |

| Phosphorus (P) | 1.77 | 1.08 | 1.51 | 0.90 | - | - | - | - | - | - |

| SUM | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Element | RC | CCA1A | CCA2A | CCA1B | CCA2B | SSA1A | SSA2A | SSA1B | SSA2B | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mass [%] | Atom [%] | Mass [%] | Atom [%] | Mass [%] | Atom [%] | Mass [%] | Atom [%] | Mass [%] | Atom [%] | Mass [%] | Atom [%] | Mass [%] | Atom [%] | Mass [%] | Atom [%] | Mass [%] | Atom [%] | |

| Oxygen | 53.96 | 61.22 | 53.33 | 64.29 | 53.62 | 64.10 | 53.01 | 63.51 | 53.69 | 64.01 | 52.34 | 60.75 | 51.54 | 62.22 | 51.92 | 62.15 | 52.07 | 59.86 |

| Silicon | 20.69 | 13.38 | 26.63 | 18.29 | 20.80 | 14.17 | 25.79 | 17.60 | 21.24 | 14.42 | 20.94 | 13.84 | 24.86 | 17.10 | 35.58 | 24.26 | 20.15 | 13.20 |

| Carbon | 13.02 | 19.68 | 6.74 | 10.82 | 8.27 | 13.16 | 7.71 | 12.30 | 8.40 | 13.33 | 11.80 | 18.24 | 7.22 | 11.61 | 6.09 | 9.71 | 13.05 | 19.98 |

| Calcium | 10.39 | 4.71 | 10.26 | 4.94 | 13.75 | 6.56 | 10.25 | 4.90 | 13.34 | 6.35 | 12.13 | 5.62 | 7.74 | 3.73 | - | - | 11.26 | 5.17 |

| Aluminum | 1.13 | 0.76 | 1.67 | 1.20 | 1.89 | 1.34 | 1.58 | 1.12 | 1.82 | 1.29 | 1.75 | 1.20 | 4.04 | 2.89 | 4.04 | 2.87 | 1.49 | 1.02 |

| Iron | 0.81 | 0.26 | 1.37 | 0.47 | 1.03 | 0.35 | 1.66 | 0.57 | 0.91 | 0.31 | 1.04 | 0.35 | 2.02 | 0.70 | 1.01 | 0.35 | 1.13 | 0.37 |

| Sodium | - | - | - | - | - | - | - | - | - | - | - | - | 1.39 | 1.17 | - | - | - | - |

| Potassium | - | - | - | - | 0.63 | 0.31 | - | - | 0.61 | 0.30 | - | - | 1.19 | 0.59 | 1.36 | 0.67 | 0.85 | 0.40 |

| SUM | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Șerbănoiu, A.A.; Grădinaru, C.M.; Muntean, R.; Cimpoeșu, N.; Șerbănoiu, B.V. Corn Cob Ash versus Sunflower Stalk Ash, Two Sustainable Raw Materials in an Analysis of Their Effects on the Concrete Properties. Materials 2022, 15, 868. https://doi.org/10.3390/ma15030868

Șerbănoiu AA, Grădinaru CM, Muntean R, Cimpoeșu N, Șerbănoiu BV. Corn Cob Ash versus Sunflower Stalk Ash, Two Sustainable Raw Materials in an Analysis of Their Effects on the Concrete Properties. Materials. 2022; 15(3):868. https://doi.org/10.3390/ma15030868

Chicago/Turabian StyleȘerbănoiu, Adrian Alexandru, Cătălina Mihaela Grădinaru, Radu Muntean, Nicanor Cimpoeșu, and Bogdan Vasile Șerbănoiu. 2022. "Corn Cob Ash versus Sunflower Stalk Ash, Two Sustainable Raw Materials in an Analysis of Their Effects on the Concrete Properties" Materials 15, no. 3: 868. https://doi.org/10.3390/ma15030868

APA StyleȘerbănoiu, A. A., Grădinaru, C. M., Muntean, R., Cimpoeșu, N., & Șerbănoiu, B. V. (2022). Corn Cob Ash versus Sunflower Stalk Ash, Two Sustainable Raw Materials in an Analysis of Their Effects on the Concrete Properties. Materials, 15(3), 868. https://doi.org/10.3390/ma15030868