Exploration of the Magnetic Flux Density on the Surface of Seamless Knitted Fabrics Manufactured with Magnetic Polypropylene Fibers

Abstract

:1. Introduction

2. Establishment of Sample Schemes for Seamless Knitted Fabrics

2.1. Determination of Yarn Selection Schemes

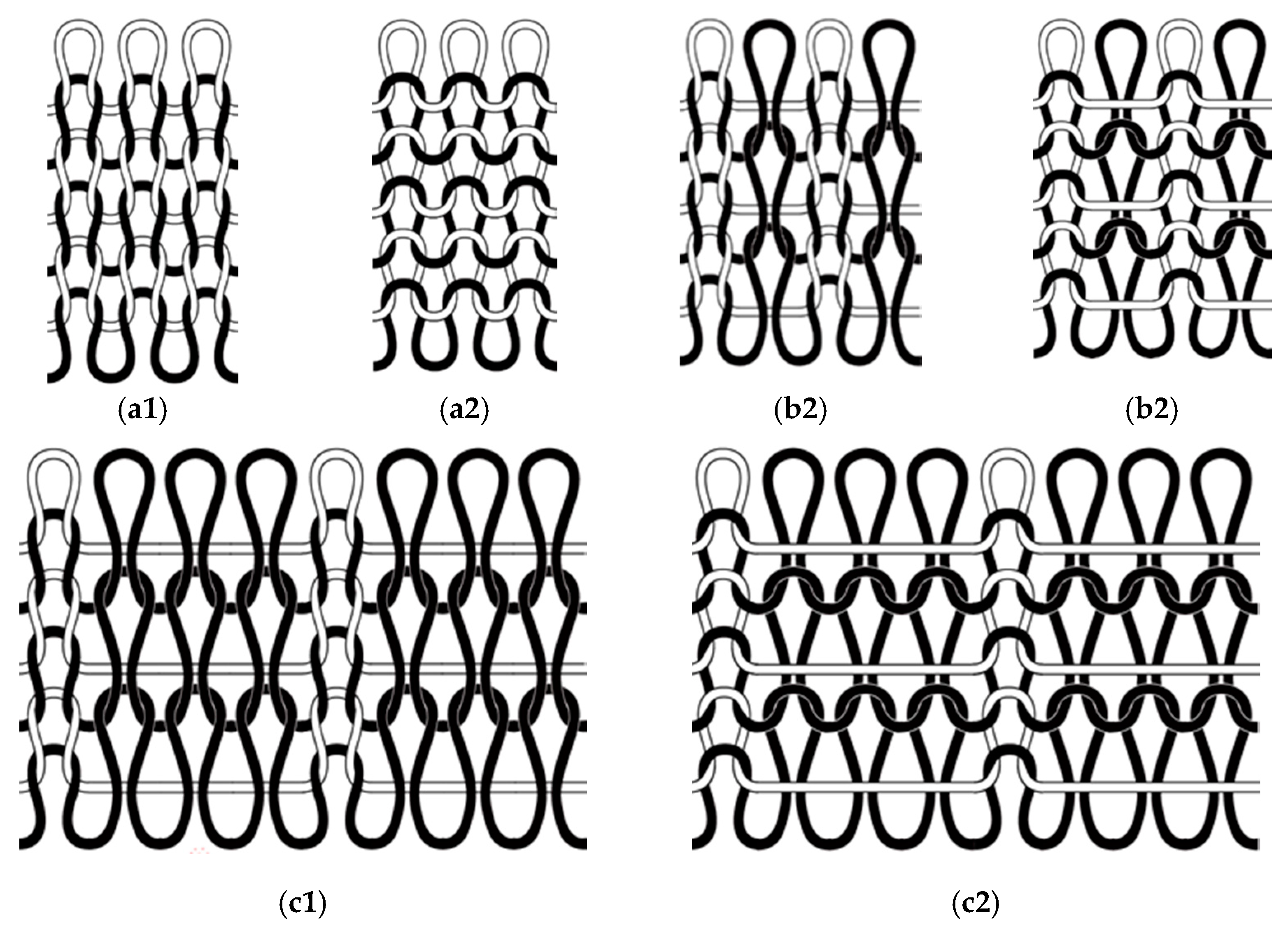

2.2. Determination of Stitches

- (1)

- Weft Plain Stitch

- (2)

- 1 + 1 and 1 + 3 Mock Rib Stitches

2.3. Determination of the Yarn Feed Ratio of Outer Fabrics

2.4. Determination of the Yarn Feed Ratio of Outer Fabrics

3. Exploration of the Magnetic Flux Density on the Surface of Fabrics

3.1. Test Principle of Magnetic Flux Density on the Surface of Fabrics

- (1)

- Test Instrument and Test Principle

- (2)

- Test Environment

3.2. Test of Magnetic Flux Density on the Surface of Fabrics

3.3. Test Result Analysis of Magnetic Flux Density on the Surface of Fabrics

3.4. Washing Fastness Test on the Magnetic Flux Density of Fabrics

3.5. Result Analysis of Washing Fastness Test on the Magnetic Flux Density of Fabrics

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, Y.Y. Study on the Status Quo of College Students’ Sub-health and Its Intervention. Int. J. Soc. Sci. Educ. Res. 2021, 4, 144. [Google Scholar]

- Xu, J.; Xue, Y.L.; Liu, G.H.; Feng, Y.F.; Xu, M.Y.; Xie, J.; Wang, X.H.; Chen, X.M.; Jiang, L.J. Establishment of the norms of Sub-Health Measurement Scale Version 1.0 for Chinese urban residents. J. South. Med. Univ. 2019, 39, 271–278. [Google Scholar]

- Zhang, X. Effects of static magnetic fields on blood flow, bone and pain. Physics 2020, 49, 373–380. [Google Scholar]

- Guo, L.W. Five Elements Magnetic Needle Magnetic Therapy Acupuncture; Traditional Chinese Medicine Ancient Books Publishing House: Beijing, China, 1997; pp. 17–24. [Google Scholar]

- Eccles, N.K. A critical review of randomized controlled trials of static magnets for pain relief. J. Altern. Complementary Med. 2005, 11, 495–509. [Google Scholar] [CrossRef] [PubMed]

- Eccles, N.K. A randomized, double-blinded, placebo-controlled pilot study to investigate the effectiveness of a static magnet to relieve dysmenorrhea. J. Altern. Complementary Med. 2005, 11, 681–687. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Alfano, A.P.; Taylor, A.G.; Foresman, P.A.; Dunkl, P.R.; McConnell, G.G.; Conaway, M.R.; Gillies, G.T. Static Magnetic Fields for Treatment of Fibromyalgia: A Randomized Controlled Trial. J. Altern. Complementary Med. 2001, 7, 53–64. [Google Scholar] [CrossRef] [PubMed]

- Collacott, E.A.; Zimmerman, J.T.; White, D.W.; Rindone, J.P. Bipolar permanent magnets for the treatment of chronic low back pain: A pilot study. JAMA 2000, 283, 1322–1325. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- WU, F.F. Magnetic Field Distribution and Design Practice of Magnetic Health-Care Clothing; Soochow University: Suzhou, China, 2014; pp. 8–9. [Google Scholar]

- Li, T.T. Preparation and Magnetic Properties of Strontium Ferrite and Its Composites; Anhui University of Technology: Anhui, China, 2016; pp. 6–7. [Google Scholar]

- Ye, J.Z.; Qi, L. Exploration on Magnetizing Conditions of Polypropylene Magnetic Fibers. Petrochem. Technol. Appl. 2003, 1, 12–14. [Google Scholar]

- Zhao, H.C.; Yao, J.B.; Gan, Y.W.; Yu, K. A qualitative and quantitative analysis method of organic magnetic fiber. Knitt. Ind. 2014, 67–69. Available online: http://en.cnki.com.cn/Article_en/CJFDTotal-ZNGU201408027.htm (accessed on 14 December 2021).

- Repon, M.R.; Shiddique, M.N.A.; Al Mamun, R. Effect of 1×1, 2×1, 2×2, 3×1 and 3×3 Knit Structure on Different Properties of Rib Knitted Fabric. Univers. J. Eng. Sci. 2019, 7, 57–63. [Google Scholar] [CrossRef] [Green Version]

- Liu, R.; Zhang, Y.; Wen, C.; Jian, T. Study on the design and analysis methods of orthogonal experiment. Exp. Technol. Manag. 2010, 27, 52–55. [Google Scholar]

- Fu, J.L.; Li, H.T.; Chen, T. Additional Method Based on Quasi-Level Design and Analysis of Weapons Experiment. J. Nav. Aeronaut. Astronaut. Univ. 2011, 26, 319–322. [Google Scholar]

- Li, C.L. Functional Study of Polyamide-Based Magnetic Textiles; Jiangnan University: Wuxi, China, 2020; pp. 1–3. [Google Scholar]

- Yu, G.J. Evaluation and Measurement of Magnetic Fabric Performance; Soochow University: Suzhou, China, 2013; pp. 33–34. [Google Scholar]

- Wang, X.J. Application and analysis of orthogonal experimental design. J. Lanzhou Univ. Arts Sci. 2016, 30, 17–22. [Google Scholar]

| No. | Raw Materials for Outer Fabric Yarn | Raw Materials for Lining Yarn |

|---|---|---|

| 1 | 122.2dtex(110D) MPF-0 | 22.2dtex(20D) polyamide fiber/77.8dtex(40D) polyurethane fiber wrap yarn |

| 2 | 122.2dtex(110D) MPF-10 | |

| 3 | 122.2dtex(110D) MPF-50 | |

| 4 | 106dtex(50s) graphene viscose yarn |

| Factor Level | A Yarn Feed Ratio of Outer Fabrics (Polypropylene Yarn with Different Magnetic Powder Contents: Graphene Viscose Yarn) | B Polypropylene Yarn with Different Magnetic Powder Contents in Outer Fabrics | C Fabric Stitch |

|---|---|---|---|

| 1 | 100:0 | MPF-0 | Weft plain stitch |

| 2 | 75:25 | MPF-10 | 1 + 1 mock rib |

| 3 | 50:50 | MPF-50 | 1 + 3 mock rib |

| 4 | 25:75 | - | - |

| Fabric No. | A Yarn Feed Ratio of Outer Fabrics | B Polypropylene Yarn with Different Magnetic Powder Contents in Outer Fabrics | C Fabric Stitch |

|---|---|---|---|

| #1 | 100:0 | MPF-0 | Weft plain stitch |

| #2 | 100:0 | MPF-10 | 1 + 1 mock rib |

| #3 | 100:0 | MPF-50 | 1 + 3 mock rib |

| #4 | 75:25 | MPF-0 | 1 + 1 mock rib |

| #5 | 75:25 | MPF-10 | 1 + 3 mock rib |

| #6 | 75:25 | MPF-50 | Weft plain stitch |

| #7 | 50:50 | MPF-0 | 1 + 3 mock rib |

| #8 | 50:50 | MPF-10 | Weft plain stitch |

| #9 | 50:50 | MPF-50 | 1 + 1 mock rib |

| #10 | 25:75 | MPF-0 | Weft plain stitch |

| #11 | 25:75 | MPF-10 | 1 + 1 mock rib |

| #12 | 25:75 | MPF-50 | 1 + 3 mock rib |

| Test Surface | Front Surface | Back Surface | Total Average Value of the Magnetic Flux Density (mT) | |||||

|---|---|---|---|---|---|---|---|---|

| Sample | Average Value (mT) | Maximum Value of N Pole (mT) | Maximum Value of S Pole (mT) | Average Value (mT) | Maximum Value of N Pole (mT) | Maximum Value of S Pole (mT) | ||

| #1 | 0.0036 | 0.0133 | −0.0092 | 0.0025 | 0.0063 | −0.0108 | 0.0031 | |

| #2 | 0.0568 | 0.1043 | −0.1255 | 0.0557 | 0.0994 | −0.1274 | 0.0562 | |

| #3 | 0.5614 | 2.1781 | −2.2112 | 0.5528 | 2.2064 | −1.2310 | 0.5571 | |

| #4 | 0.0052 | 0.0195 | −0.0056 | 0.0030 | 0.0117 | −0.0097 | 0.0041 | |

| #5 | 0.0590 | 0.1044 | −0.1231 | 0.0589 | 0.1194 | −0.1279 | 0.0590 | |

| #6 | 0.4169 | 1.3410 | −1.7747 | 0.4135 | 1.3372 | −1.8742 | 0.4152 | |

| #7 | 0.0071 | 0.0001 | −0.0172 | 0.0054 | 0.0092 | −0.0162 | 0.0063 | |

| #8 | 0.0470 | 0.0841 | −0.0905 | 0.0480 | 0.0890 | −0.0884 | 0.0475 | |

| #9 | 0.3598 | 1.6067 | −1.0729 | 0.3307 | 1.7193 | −0.8158 | 0.3453 | |

| #10 | 0.0074 | 0.0178 | −0.0186 | 0.0072 | 0.0171 | −0.0132 | 0.0073 | |

| #11 | 0.0413 | 0.0587 | −0.0725 | 0.0412 | 0.0542 | −0.0882 | 0.0412 | |

| #12 | 0.2716 | 0.9128 | −0.7364 | 0.2432 | 0.9928 | −0.8514 | 0.2574 | |

| Sample No. | Factor | Surface Magnetic Flux Density (mT) | ||

|---|---|---|---|---|

| A | B | C | ||

| #1 | 1 | 1 | 1 | 0.0031 |

| #2 | 1 | 2 | 2 | 0.0562 |

| #3 | 1 | 3 | 3 | 0.5571 |

| #4 | 2 | 1 | 2 | 0.0041 |

| #5 | 2 | 2 | 3 | 0.0590 |

| #6 | 2 | 3 | 1 | 0.4152 |

| #7 | 3 | 1 | 3 | 0.0063 |

| #8 | 3 | 2 | 1 | 0.0475 |

| #9 | 3 | 3 | 2 | 0.3453 |

| #10 | 4 | 1 | 1 | 0.0073 |

| #11 | 4 | 2 | 2 | 0.0412 |

| #12 | 4 | 3 | 3 | 0.2574 |

| Average Value K1j | 0.2055 | 0.0052 | 0.1560 | - |

| Average Value K2j | 0.1594 | 0.0517 | 0.1327 | - |

| Average Value K3j | 0.1330 | 0.3892 | 0.1575 | - |

| Average Value K4j | 0.1020 | - | - | - |

| Range R | 0.1035 | 0.3841 | 0.0248 | - |

| Optimal Level | A1 | B3 | C3 | - |

| Washing Times | Magnetic Flux Density (mT) | Sample | |||

|---|---|---|---|---|---|

| #3 | #6 | #9 | #12 | ||

| 0 | Average value | 0.5614 | 0.4169 | 0.3598 | 0.2716 |

| Maximum value of N pole | 2.1781 | 1.3410 | 1.6067 | 0.9128 | |

| Maximum value of S pole | −2.2112 | −1.7747 | −1.0729 | −0.7364 | |

| 5 | Average value | 0.5378 | 0.4033 | 0.3441 | 0.2633 |

| Maximum value of N pole | 2.4340 | 1.0769 | 0.9781 | 0.8343 | |

| Maximum value of S pole | −1.3266 | −1.6129 | −1.2187 | −0.7068 | |

| 10 | Average value | 0.5324 | 0.3920 | 0.3437 | 0.2604 |

| Maximum value of N pole | 2.6576 | 1.2342 | 1.3602 | 0.9080 | |

| Maximum value of S pole | −1.1857 | −1.9018 | −1.4524 | −1.0514 | |

| 15 | Average value | 0.5300 | 0.3845 | 0.3339 | 0.2490 |

| Maximum value of N pole | 1.9414 | 1.2578 | 1.1014 | 0.7270 | |

| Maximum value of S pole | −2.4779 | −1.1470 | −1.1090 | −0.7630 | |

| 20 | Average value | 0.5226 | 0.3806 | 0.3326 | 0.2452 |

| Maximum value of N pole | 2.8603 | 1.4825 | 0.9391 | 0.6599 | |

| Maximum value of S pole | −1.6647 | −1.5848 | −1.1512 | −0.3864 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiang, Y.; Su, M.; Jin, Z.; Chen, K.; Tao, J.; Shi, Z. Exploration of the Magnetic Flux Density on the Surface of Seamless Knitted Fabrics Manufactured with Magnetic Polypropylene Fibers. Materials 2022, 15, 880. https://doi.org/10.3390/ma15030880

Xiang Y, Su M, Jin Z, Chen K, Tao J, Shi Z. Exploration of the Magnetic Flux Density on the Surface of Seamless Knitted Fabrics Manufactured with Magnetic Polypropylene Fibers. Materials. 2022; 15(3):880. https://doi.org/10.3390/ma15030880

Chicago/Turabian StyleXiang, Yimin, Miao Su, Zimin Jin, Kunying Chen, Jianwei Tao, and Zhansong Shi. 2022. "Exploration of the Magnetic Flux Density on the Surface of Seamless Knitted Fabrics Manufactured with Magnetic Polypropylene Fibers" Materials 15, no. 3: 880. https://doi.org/10.3390/ma15030880