3D PEEK Objects Fabricated by Fused Filament Fabrication (FFF)

Abstract

:1. Introduction

2. Materials and Methods

2.1. FFF Method to Print PEEK

2.2. Surface Roughness Measurement

3. Results and Discussion

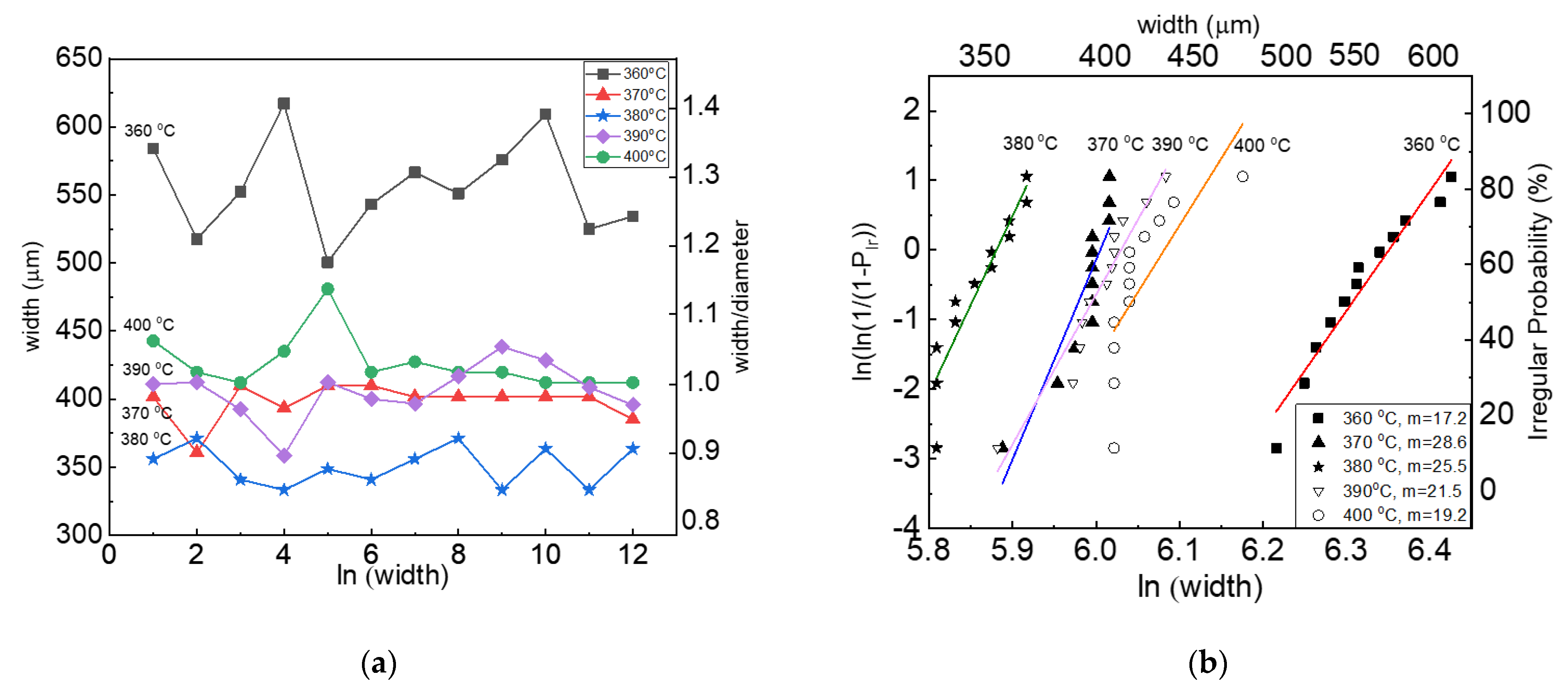

3.1. Dimensional Deformation of 3D Printed PEEK Filaments

3.2. Surface Roughness of 3D Printed PEEK Objects

3.3. Reliability of 3D Printed PEEK Lines

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Verma, S.; Sharma, N.; Kango, S.; Sharma, S. Developments of PEEK (Polyetheretherketone) as a biomedical material: A focused review. Eur. Polym. J. 2021, 147. [Google Scholar] [CrossRef]

- McDowell, J.C. The Low Earth Orbit Satellite Population and Impacts of the SpaceX Starlink Constellation. Astrophys. J. 2020, 892. [Google Scholar] [CrossRef] [Green Version]

- Chahat, N.; Decrossas, E.; Gonzalez-Ovejero, D.; Yurduseven, O.; Radway, M.J.; Hodges, R.E.; Estabrook, P.; Baker, J.D.; Bell, D.J.; Cwik, T.A.; et al. Advanced CubeSat Antennas for Deep Space and Earth Science Missions: A review. IEEE Antennas Propag. Mag. 2019, 61, 37–46. [Google Scholar] [CrossRef] [Green Version]

- Dimitriadis, A.I.; Debogovic, T.; Favre, M.; Billod, M.; Barloggio, L.; Ansermet, J.-P.; de Rijk, E. Polymer-Based Additive Manufacturing of High-Performance Waveguide and Antenna Components. Proc. IEEE 2017, 105, 668–676. [Google Scholar] [CrossRef]

- Timbie, P.T.; Grade, J.; Weide, D.v.d.; Maffei, B.; Pisano, G. Stereolithographed MM-wave corrugated horn antennas. In Proceedings of the 2011 International Conference on Infrared, Millimeter, and Terahertz Waves, Houston, TX, USA, 2–7 October 2011; pp. 1–3. [Google Scholar]

- D’Auria, M.; Otter, W.J.; Hazell, J.; Gillatt, B.T.W.; Long-Collins, C.; Ridler, N.M.; Lucyszyn, S. 3-D Printed Metal-Pipe Rectangular Waveguides. IEEE Trans. Compon. Packag. Manuf. Technol. 2015, 5, 1339–1349. [Google Scholar] [CrossRef] [Green Version]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- ISO/ASTM 52900:2021; Standard Terminology for Additive Manufacturing—General Principles—Terminology. ASTM International: West Conshohocken, PA, USA, 2021.

- The Tool Hub, Understanding Shrink Rates. Available online: https://thetoolhub.com/part-design/shrink/ (accessed on 4 December 2021).

- Kim, N.; Yi, T. Investigation of Temperature-Dependent Microscopic Morphological Variation of PEEK Powder for a 3D Printer using Dissipative Particle and Molecular Dynamics Simulations. Korean Soc. Manuf. Process Eng. 2018, 17, 117–122. [Google Scholar] [CrossRef]

- Deng, D.; Chen, Y.; Zhou, C. Investigation on PEEK Fabrication Using Mask-image-projection-based Stereolithography. In Proceedings of the Annual International Solid Freeform Fabrication Symposium, University of Texas at Austin, Austin, TX, USA, 6–8 August 2012. [Google Scholar]

- Oladapo, B.I.; Zahedi, S.A.; Ismail, S.O.; Omigbodun, F.T.; Bowoto, O.K.; Olawumi, M.A.; Muhammad, M.A. 3D printing of PEEK–cHAp scaffold for medical bone implant. Bio-Des. Manuf. 2020, 4, 44–59. [Google Scholar] [CrossRef]

- Hu, B.; Duan, X.; Xing, Z.; Xu, Z.; Du, C.; Zhou, H.; Chen, R.; Shan, B. Improved design of fused deposition modeling equipment for 3D printing of high-performance PEEK parts. Mech. Mater. 2019, 137. [Google Scholar] [CrossRef]

- Rinaldi, M.; Cecchini, F.; Pigliaru, L.; Ghidini, T.; Lumaca, F.; Nanni, F. Additive Manufacturing of Polyether Ether Ketone (PEEK) for Space Applications: A Nanosat Polymeric Structure. Polymers 2020, 13, 11. [Google Scholar] [CrossRef] [PubMed]

- Hoskins, T.J.; Dearn, K.D.; Kukureka, S.N. Mechanical performance of PEEK produced by additive manufacturing. Polym. Test. 2018, 70, 511–519. [Google Scholar] [CrossRef]

- ISO 21920-2:2021; Geometrical Product Specifications (GPS)—Surface texture: Profile—Part 2: Terms, Definitions and Surface Texture Parameters. International Organization for Standardization: Geneva, Switzerland, 2021.

- VICTREX. PEEK: Materials Properties Guide; VICTREX: Lancashire, UK, 2002; pp. 5–6. [Google Scholar]

- Yang, C.; Tian, X.; Li, D.; Cao, Y.; Zhao, F.; Shi, C. Influence of thermal processing conditions in 3D printing on the crystallinity and mechanical properties of PEEK material. J. Mater. Process. Technol. 2017, 248, 1–7. [Google Scholar] [CrossRef]

- Wu, W.Z.; Geng, P.; Zhao, J.; Zhang, Y.; Rosen, D.W.; Zhang, H.B. Manufacture and thermal deformation analysis of semicrystalline polymer polyether ether ketone by 3D printing. Mater. Res. Innov. 2014, 18, S5-12–S5-16. [Google Scholar] [CrossRef]

- Wang, P.; Zou, B.; Ding, S. Modeling of surface roughness based on heat transfer considering diffusion among deposition filaments for FDM 3D printing heat-resistant resin. Appl. Therm. Eng. 2019, 161. [Google Scholar] [CrossRef]

- Wang, P.; Zou, B.; Xiao, H.; Ding, S.; Huang, C. Effects of printing parameters of fused deposition modeling on mechanical properties, surface quality, and microstructure of PEEK. J. Mater. Process. Technol. 2019, 271, 62–74. [Google Scholar] [CrossRef]

- Ding, S.; Zou, B.; Wang, P.; Ding, H. Effects of nozzle temperature and building orientation on mechanical properties and microstructure of PEEK and PEI printed by 3D-FDM. Polym. Test. 2019, 78. [Google Scholar] [CrossRef]

| TN | Width (μm) | Deviation |

|---|---|---|

| 360 °C | 556.47 | 35.73 |

| 370 °C | 398.23 | 13.75 |

| 380 °C | 351.04 | 14.56 |

| 390 °C | 406.01 | 20.14 |

| 400 °C | 426.22 | 19.76 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baek, I.; Kwon, O.; Lim, C.-M.; Park, K.Y.; Bae, C.-J. 3D PEEK Objects Fabricated by Fused Filament Fabrication (FFF). Materials 2022, 15, 898. https://doi.org/10.3390/ma15030898

Baek I, Kwon O, Lim C-M, Park KY, Bae C-J. 3D PEEK Objects Fabricated by Fused Filament Fabrication (FFF). Materials. 2022; 15(3):898. https://doi.org/10.3390/ma15030898

Chicago/Turabian StyleBaek, Inwoo, Oeun Kwon, Chul-Min Lim, Kyoung Youl Park, and Chang-Jun Bae. 2022. "3D PEEK Objects Fabricated by Fused Filament Fabrication (FFF)" Materials 15, no. 3: 898. https://doi.org/10.3390/ma15030898

APA StyleBaek, I., Kwon, O., Lim, C.-M., Park, K. Y., & Bae, C.-J. (2022). 3D PEEK Objects Fabricated by Fused Filament Fabrication (FFF). Materials, 15(3), 898. https://doi.org/10.3390/ma15030898