Effect of SiC Abrasive Blasting Parameters on the Quality of the Ceramic and Ni-Cr Dental Alloy Joint

Abstract

:1. Introduction

2. Materials and Methods

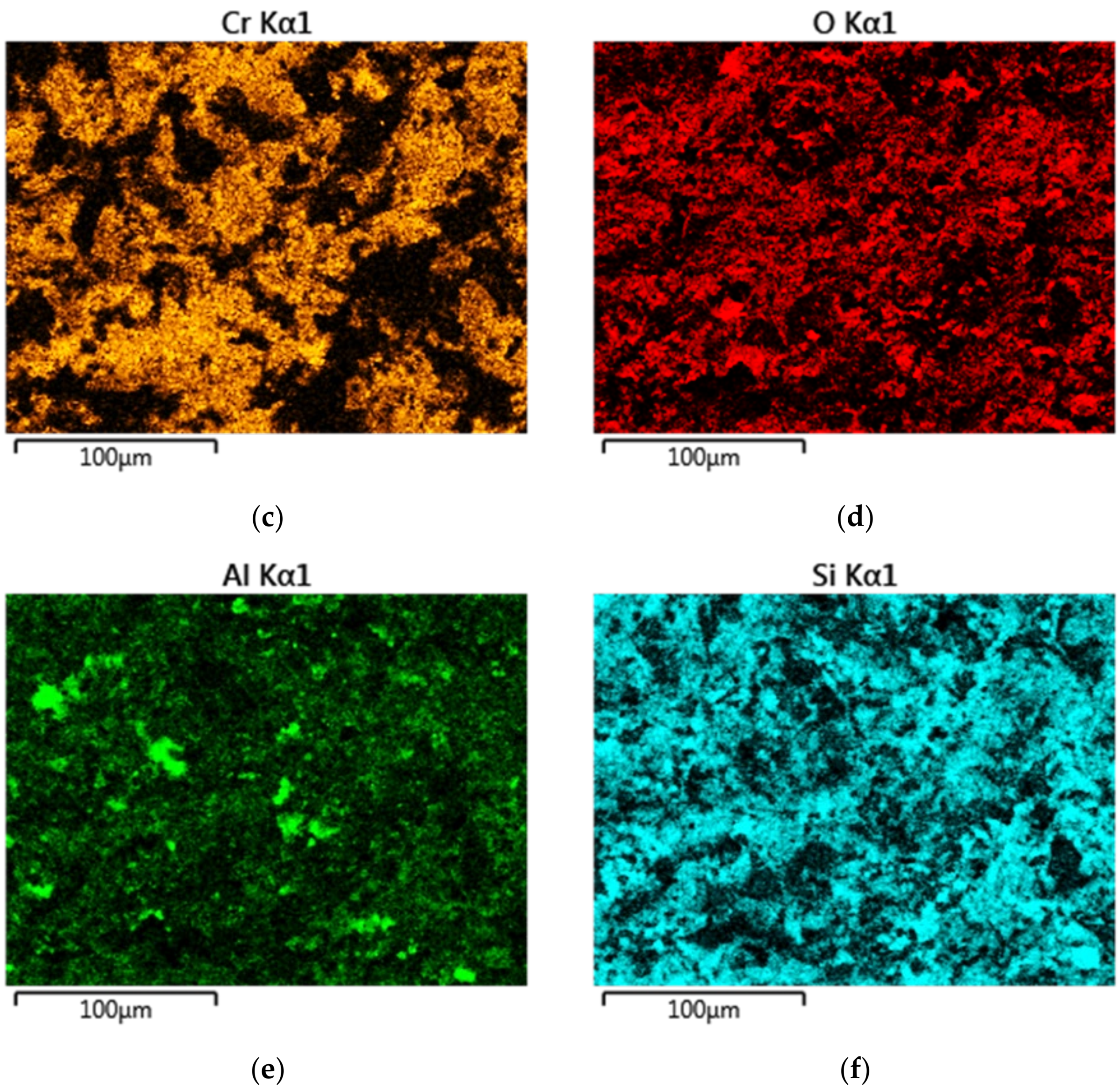

3. Results

4. Discussion

4.1. Pressure and Grit Size

4.2. Thermal Loads

4.3. Strength of the Metal—Dental Ceramic Bond

4.4. Mechanism of the Metal—Dental Ceramic Bond Deterioration

5. Conclusions

- 1.

- Preparation of a metal-ceramic dental joint by blasting with SiC abrasives using a small grit size (50 µm) under pressure of 400 kPa results in optimal strength parameters of the joint (p < 0.05);

- 2.

- Thermal loads (thermal shocks) occurring during the use of the joint significantly reduce the strength of the joint (p < 0.05).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Czepułkowska, W.; Wołowiec-Korecka, E.; Klimek, L. The Role of Mechanical, Chemical and Physical Bonds in Metal-Ceramic Bond Strength. Arch. Mater. Sci. Eng. 2018, 92, 5–14. [Google Scholar] [CrossRef] [Green Version]

- Schweitzer, D.M.; Goldstein, G.R.; Ricci, J.L.; Silva, N.R.F.A.; Hittelman, E.L. Comparison of Bond Strength of a Pressed Ceramic Fused to Metal versus Feldspathic Porcelain Fused to Metal. J. Prosthodont. 2005, 14, 239–247. [Google Scholar] [CrossRef] [PubMed]

- Külünk, T.; Kurt, M.; Ural, Ç.; Külünk, Ş.; Baba, S. Effect of Different Air-Abrasion Particles on Metal-Ceramic Bond Strength. J. Dent. Sci. 2011, 6, 140–146. [Google Scholar] [CrossRef] [Green Version]

- Pietnicki, K.; Wołowiec, E.; Klimek, L. The Effect of Abrasive Blasting on the Strength of a Joint between Dental Porcelain and Metal Base. Acta Bioeng. Biomech. 2014, 16, 63–68. [Google Scholar]

- Gołębiowski, M.; Wołowiec, E.; Klimek, L. Airborne-Particle Abrasion Parameters on the Quality of Titanium-Ceramic Bonds. J. Prosthet. Dent. 2015, 113, 453–459. [Google Scholar] [CrossRef] [Green Version]

- Tarib, N.A.; Anuar, N.; Ahmad, M. Shear Bond Strength of Veneering Ceramic to Coping Materials with Different Pre-Surface Treatments. J. Adv. Prosthodont. 2016, 8, 339. [Google Scholar] [CrossRef] [Green Version]

- Taga, Y.; Kawai, K.; Nokubi, T. New Method for Divesting Cobalt-Chromium Alloy Castings: Sandblasting with a Mixed Abrasive Powder. J. Prosthet. Dent. 2001, 85, 357–362. [Google Scholar] [CrossRef]

- İnan, Ö.; Acar, A.; Halkacı, S. Effects of Sandblasting and Electrical Discharge Machining on Porcelain Adherence to Cast and Machined Commercially Pure Titanium. J. Biomed. Mater. Res. Part B Appl. Biomater. 2006, 78, 393–400. [Google Scholar] [CrossRef]

- Czepułkowska, W.; Wołowiec-Korecka, E.; Klimek, L. The Condition of Ni-Cr Alloy Surface after Abrasive Blasting with Various Parameters. J. Mater. Eng. Perform. 2019, 29, 1439–1444. [Google Scholar] [CrossRef] [Green Version]

- Czepułkowska-Pawlak, W.; Wołowiec-Korecka, E.; Klimek, L. The Surface Condition of Ni-Cr after SiC Abrasive Blasting for Applications in Ceramic Restorations. Materials 2020, 13, 5824. [Google Scholar] [CrossRef]

- Lee, J.-J.; Song, K.-Y.; Ahn, S.-G.; Choi, J.-Y.; Seo, J.-M.; Park, J.-M. Evaluation of Effect of Galvanic Corrosion between Nickel-Chromium Metal and Titanium on Ion Release and Cell Toxicity. J. Adv. Prosthodont. 2015, 7, 172–177. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Milheiro, B.; Nozaki, K.; Kleverlaan, C.; Muris, J.; Miura, H.; Feilzer, A. In Vitro Cytotoxicity of Metallic Ions Released from Dental Alloys. Odontology 2016, 104, 136–142. [Google Scholar] [CrossRef] [PubMed]

- Kula, Z.; Semenov, M.; Klimek, L. Carbon Coatings Deposited on Prosthodontic Ni-Cr Alloy. Appl. Sci. 2021, 11, 4551. [Google Scholar] [CrossRef]

- Nematia, A.; Saghafia, M.; Khamseh, S.; Alibakhshic, E.; Zarrintajd, P.; Saebe, M. Magnetron-Sputtered TixNy Thin Films Applied on Titanium-Based Alloys for Biomedical Applications: Composition-Microstructure-Property Relationships. Surf. Coat. Technol. 2018, 349, 251–259. [Google Scholar] [CrossRef]

- Jachowicz, E.; Kaczmarek, Ł.; Rylski, A.; Przybylski, K.; Danielewski, M.; Wendler, B. New Type AlMo-, AlTi- or Si-Based Magnetron Sputtered Protective Coatings on Metallic Substrates. J. Mater. Processing Technol. 2006, 175, 427–432. [Google Scholar]

- Kaczmarek, Ł.; Wendler, B.; Siniarski, D.; Rylski, A.; Bieliński, D.; Dobrowolski, O.; Lipiński, D. Oxidation Resistance of Refractory γ-TiAlW Coatings. Surf. Coat. Technol. 2007, 201, 6167–6170. [Google Scholar] [CrossRef]

- Grabarczyk, J.; Batory, D.; Louda, P.; Couvrat, P.; Kotela, I.; Bąkowicz-Mitura, K. Carbon Coatings for Medical Implants. J. Achiev. Mater. Manuf. Eng. 2007, 20, 107–110. [Google Scholar]

- Banaszek, K.; Wiktorowska-Owczarek, A.; Kowalczyk, E.; Klimek, L. Possibilities of Applying Ti (C, N) Coatings on Prosthetic Elements-Research with the Use of Human Endothelial Cells. Acta Bioeng. Biomech. 2016, 18, 119–126. [Google Scholar]

- Banaszek, K.; Klimek, L.; Zgorzyńska, E.; Swarzyńska, A.; Walczewska, A. Cytotoxicity of Titanium Carbonitride Coatings for Prostodontic Alloys with Different Amounts of Carbon and Nitro Gen. Biomed. Mater. 2018, 13, 045003. [Google Scholar] [CrossRef]

- Banaszek, K.; Klimek, L. Ti(C, N) as Barrier Coatings. Coatings 2019, 9, 432. [Google Scholar] [CrossRef] [Green Version]

- Banaszek, K.; Klimek, L.; Dąbrowski, J.R.; Jastrzębski, W. Fretting Wear in Orthodontic and Prosthetic Alloys with Ti(C, N) Coatings. Processes 2019, 7, 874. [Google Scholar] [CrossRef] [Green Version]

- Banaszek, K.; Szymanski, W.; Pietrzyk, B.; Klimek, L. Adhesion of E. Coli Bacteria Cells to Prosthodontic Alloys Surfaces Modified by TiO2 Sol-Gel Coatings. Advances in Materials Science and Engineering 2013, 2013, 179241. [Google Scholar] [CrossRef] [Green Version]

- Liu, C.; Zhao, Q.; Liu, Y.; Wang, S.; Abel, E. Reduction of Bacterial Adhesion on Modified DLC Coatings. Colloids Surf. B Biointerfaces 2018, 61, 182–187. [Google Scholar] [CrossRef] [PubMed]

- Parchańska-Kowalik, M.; Wołowiec-Korecka, E.; Klimek, L. Effect of Chemical Surface Treatment of Titanium on Its Bond with Dental Ceramics. J. Prosthet. Dent. 2018, 120, 470–475. [Google Scholar] [CrossRef]

- Tróia, M.G.; Henriques, G.E.P.; Nóbilo, M.A.A.; Mesquita, M.F. The Effect of Thermal Cycling on the Bond Strength of Low-Fusing Porcelain to Commercially Pure Titanium and Titanium–Aluminium–Vanadium Alloy. Dent. Mater. 2003, 19, 790–796. [Google Scholar] [CrossRef]

- Oyafuso, D.K.; Özcan, M.; Bottino, M.A.; Itinoche, M.K. Influence of Thermal and Mechanical Cycling on the Flexural Strength of Ceramics with Titanium or Gold Alloy Frameworks. Dent. Mater. 2008, 24, 351–356. [Google Scholar] [CrossRef]

- Vásquez, V.; Özcan, M.; Nishioka, R.; Souza, R.; Mesquita, A.; Pavanelli, C. Mechanical and Thermal Cycling Effects on the Flexural Strength of Glass Ceramics Fused to Titanium. Dent. Mater. J. 2008, 27, 7–15. [Google Scholar] [CrossRef] [Green Version]

- Antanasova, M.; Kocjan, A.; Kovač, J.; Žužek, B.; Jevnikar, P. Influence of Thermo-Mechanical Cycling on Porcelain Bonding to Cobalt–Chromium and Titanium Dental Alloys Fabricated by Casting, Milling, and Selective Laser Melting. J. Prosthodont. Res. 2018, 62, 184–194. [Google Scholar] [CrossRef]

- De Vasconcellos, L.G.O.; Silva, L.H.; de Vasconcellos, L.M.R.; Balducci, I.; Takahashi, F.E.; Bottino, M.A. Effect of Airborne-Particle Abrasion and Mechanico-Thermal Cycling on the Flexural Strength of Glass Ceramic Fused to Gold or Cobalt–Chromium Alloy. J. Prosthodont. 2011, 20, 553–560. [Google Scholar] [CrossRef]

- Fischer, J.; Zbären, C.; Stawarczyk, B.; Hämmerle, C.H.F. The Effect of Thermal Cycling on Metal-Ceramic Bond Strength. J. Dent. 2009, 37, 549–553. [Google Scholar] [CrossRef]

- Shimoe, S.; Tanoue, N.; Yanagida, H.; Atsuta, M.; Koizumi, H.; Matsumura, H. Comparative Strength of Metal-Ceramic and Metal-Composite Bonds after Extended Thermocycling. J. Oral Rehabil. 2004, 31, 689–694. [Google Scholar] [CrossRef] [PubMed]

- De Vasconcellos, L.G.O.; Buso, L.; Lombardo, G.H.L.; Souza, R.O.A.; Nogueira Júnior, L.; Bottino, M.A.; Özcan, M. Opaque Layer Firing Temperature and Aging Effect on the Flexural Strength of Ceramic Fused to Cobalt-Chromium Alloy. J. Prosthodont. 2010, 19, 471–477. [Google Scholar] [CrossRef] [PubMed]

- ISO 9693-1:2020; Dentistry—Compability Testing—Part 1: Metal-Ceramic Systems 2020. PKN: Warsaw, Poland, 2020.

| Ni | Cr | Mo | Fe | Mn | Ta | Si | Co | Nb |

|---|---|---|---|---|---|---|---|---|

| residue | 24.63 | 9.21 | 1.53 | 0.42 | 0.19 | 1.54 | 0.15 | 0.48 |

| SiC Abrasive Particle Size [µm] | Processing Pressure [kPa] | |

|---|---|---|

| 400 | 600 | |

| 50 | S45 | S65 |

| 110 | S41 | S61 |

| 250 | S42 | S62 |

| Layer No | Temp. (Max) [°C] | Resting Temp. [°C] | Drying Time [min] | Rise Temp. [°C] | Time [min] | V1 Temp. [°C] | V2 Temp. [°C] |

|---|---|---|---|---|---|---|---|

| Opaque | |||||||

| I | 980 | 403 | 6 | 80 | 1 | 550 | 979 |

| II | 970 | 403 | 6 | 80 | 1 | 550 | 969 |

| Dentine | |||||||

| I | 920 | 403 | 4 | 60 | 1 | 580 | 919 |

| II | 910 | 403 | 4 | 60 | 1 | 580 | 909 |

| Pressure [kPa] | SiC Particle Size [µm] | Bond Strength [MPa] (Mean ± SD) | ||

|---|---|---|---|---|

| Without Thermocycles | After Thermocycles | Total (Pressure × Particle Size) | ||

| 400 | 50 | 20.97 ± 4.12 | 18.28 ± 2.85 | 19.62 ± 3.73 |

| 400 | 110 | 17.57 ± 3.48 | 15.87 ± 3.95 | 16.72 ± 3.74 |

| 400 | 250 | 16.17 ± 3.64 | 16.04 ± 2.52 | 16.10 ± 3.06 (*) |

| 600 | 50 | 15.96 ± 3.66 | 13.83 ± 1.21 | 14.90 ± 2.88 (*) |

| 600 | 110 | 18.18 ± 2.93 | 16.61 ± 2.19 | 17.40 ± 2.65 |

| 600 | 250 | 19.03 ± 4.56 | 16.57 ± 2.62 | 17.80 ± 3.85 |

| Total (Thermocycles) | 17.98 ± 4.02 (A) | 16.20 ± 2.91 (B) | ||

| 3-factor ANOVA | ||||

| Factor | F | p | Partial eta2 | Power |

| Pressure | 2.07 | 0.152 | 0.015 | 0.298 |

| Particle size | 0.11 | 0.895 | 0.002 | 0.067 |

| Thermocycles | 10.66 | 0.001 | 0.075 | 0.900 |

| Pressure × Particle size | 13.34 | 0.000 | 0.168 | 0.997 |

| Pressure × Thermocycles | 0.25 | 0.615 | 0.002 | 0.079 |

| Particle size × Thermocycles | 0.37 | 0.693 | 0.006 | 0.108 |

| Pressure × Particle size × Thermocycles | 0.68 | 0.507 | 0.010 | 0.163 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wołowiec-Korecka, E.; Czepułkowska-Pawlak, W.; Kula, Z.; Klimek, L. Effect of SiC Abrasive Blasting Parameters on the Quality of the Ceramic and Ni-Cr Dental Alloy Joint. Materials 2022, 15, 964. https://doi.org/10.3390/ma15030964

Wołowiec-Korecka E, Czepułkowska-Pawlak W, Kula Z, Klimek L. Effect of SiC Abrasive Blasting Parameters on the Quality of the Ceramic and Ni-Cr Dental Alloy Joint. Materials. 2022; 15(3):964. https://doi.org/10.3390/ma15030964

Chicago/Turabian StyleWołowiec-Korecka, Emilia, Weronika Czepułkowska-Pawlak, Zofia Kula, and Leszek Klimek. 2022. "Effect of SiC Abrasive Blasting Parameters on the Quality of the Ceramic and Ni-Cr Dental Alloy Joint" Materials 15, no. 3: 964. https://doi.org/10.3390/ma15030964