Suitability of Different Analytical Derivations of Electrically Induced Stress States in Planar and Cylindrical Dielectric Elastomer Actuators

Abstract

:1. Introduction

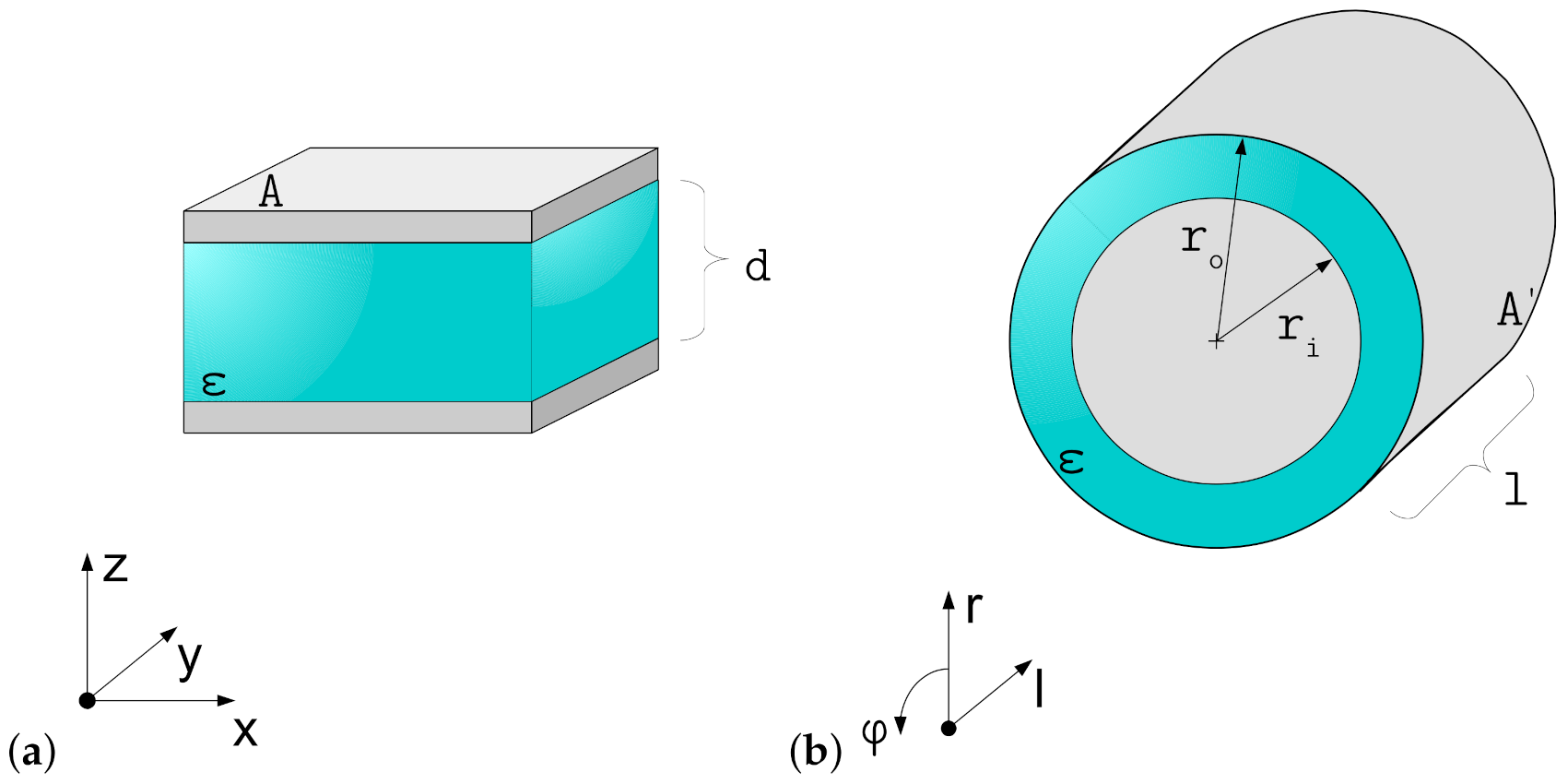

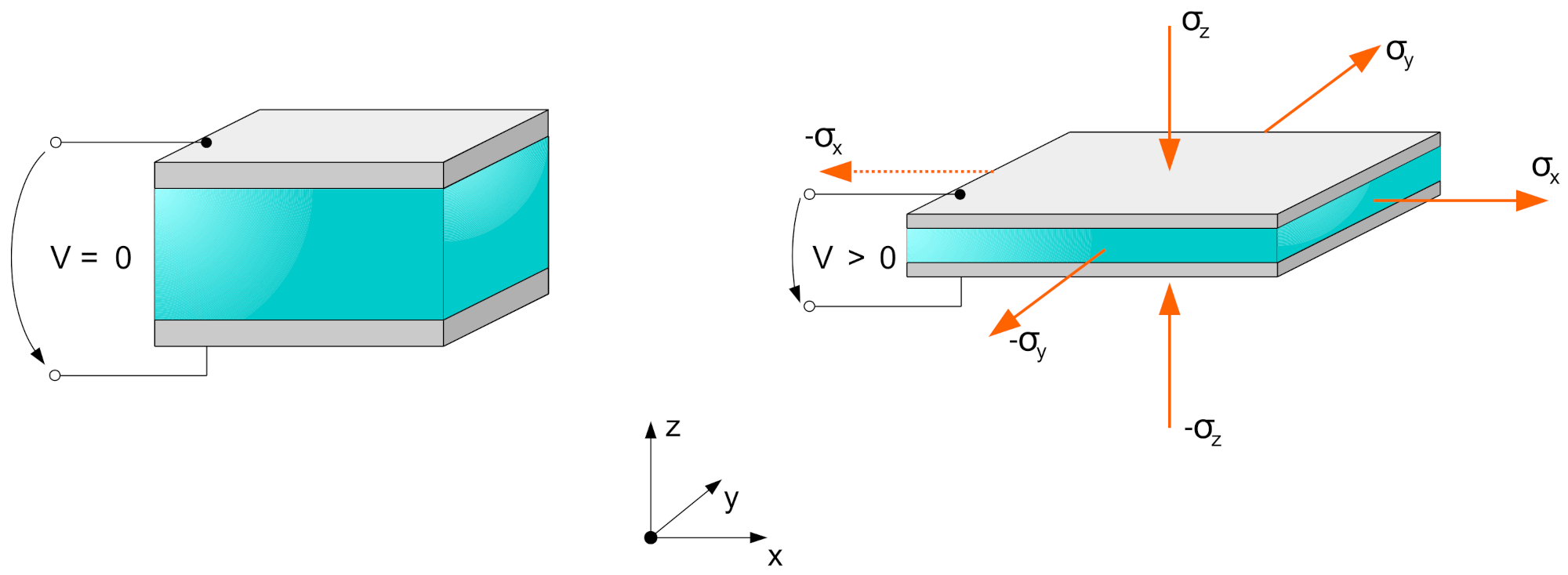

- The electrostatic pressure acting on planar DEA electrodes follows certain boundary conditions that are not directly applicable for more complex geometries.

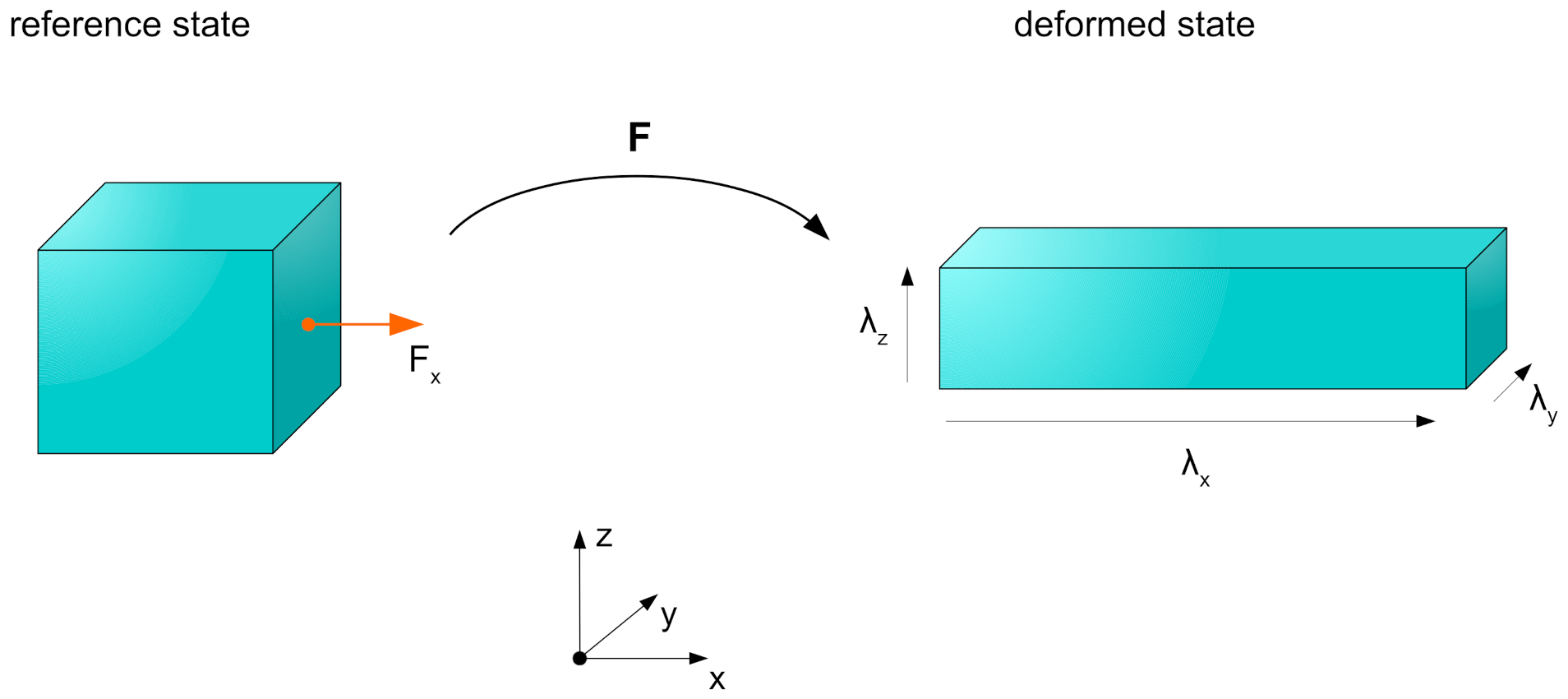

- In planar actuator geometries, the material can be modeled to be uniformly deformed under an applied electric field in thickness direction. The resulting deformation takes place in all free planar directions.

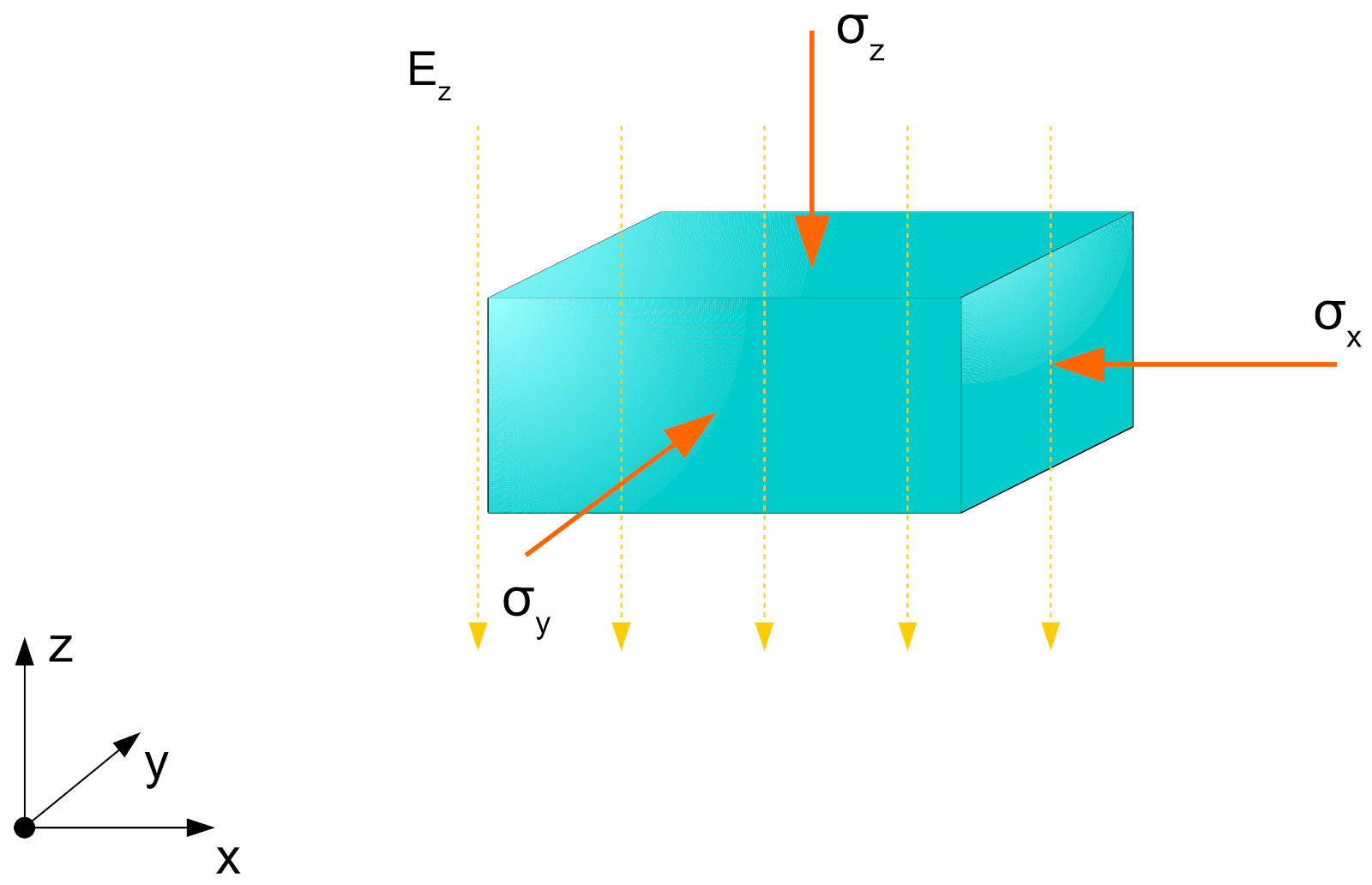

- The underlying stress state in the dielectric material can be described based on the approaches considered in this work. For planar actuator geometries these stress states can be described as dependent on only one geometrical variable. The resulting stress state is valid for the whole geometry.

- Cylindrical actuator geometries show field properties, that not only make the approaches based on the descriptions for planar DEAs more complex. Some of the approaches even can not be used to analytically describe the behavior of the macroscopic geometry.

2. Model Approaches

- The electrodes needed to apply an electric field are fully compliant and perfectly conductive. Therefore they are neglected in concern of mechanical and electrical influences.

- The applied charges are assumed to be homogeneous distributed over the electrodes.

- The resulting electric field between the electrodes is assumed to consist only of components normal to the electrode area. No side effects at the edges of the electrodes are assumed to be existent.

- The electrodes are assumed to be connected perfectly to the dielectric material without any effects of an interface layer.

- The dielectric material is considered as incompressible, isotropic and hyperelastic.

- The separated charges on the electrodes are of the same value with inverted polarizations and .

- Furthermore, we make use of the convention to shortly write for the mathematical expression with the vacuum permittivity and the relative dielectric permittivity of the material .

2.1. Stored Energy Approach

2.2. Energy Balance Approach

2.3. Maxwell Stress Tensor Approach

2.4. Resulting Deformations and Equivalent Stress States

3. Planar Actuator Geometries

4. Cylindrical Actuator Geometries

- The inner radius is fixed.

- The electrical activation leads to a reduction of the outer radius and a thinning of the dielectric layer.

- The resulting deformation exclusively takes place in length direction and radial direction.

- → radial direction

- → angular direction

- → length direction

5. Validity Comparison for Cylindrical Geometries

6. Comparison of Approaches and Conclusions

- For cylindrical geometries the approach of using the differential of the stored electrostatic energy to describe a stress state for the whole geometry is not possible as in the planar case. The differential describes only the stress acting on the outer surface of the actuator setup at , not for the whole geometry.

- The electric field distribution inside a cylindrical actuator is non-homogeneous. A deformation due to a previously derived stress state out of the electrostatic energy approach leads to changed geometrical conditions that also change the value of the electric field strength, making the stress description invalid. The approach becomes only applicable for a numerical problem solving.

- The cylindrical setup has one more degree of freedom in its electrical properties. Due to an assumed reduction of the outer radius the field strength inside the dielectric material is increased. To date, this is the same as in a planar setup. The applied voltage between the electrodes in contrast is also affected since it is derived from the electric field description which is again connected to the radius r.

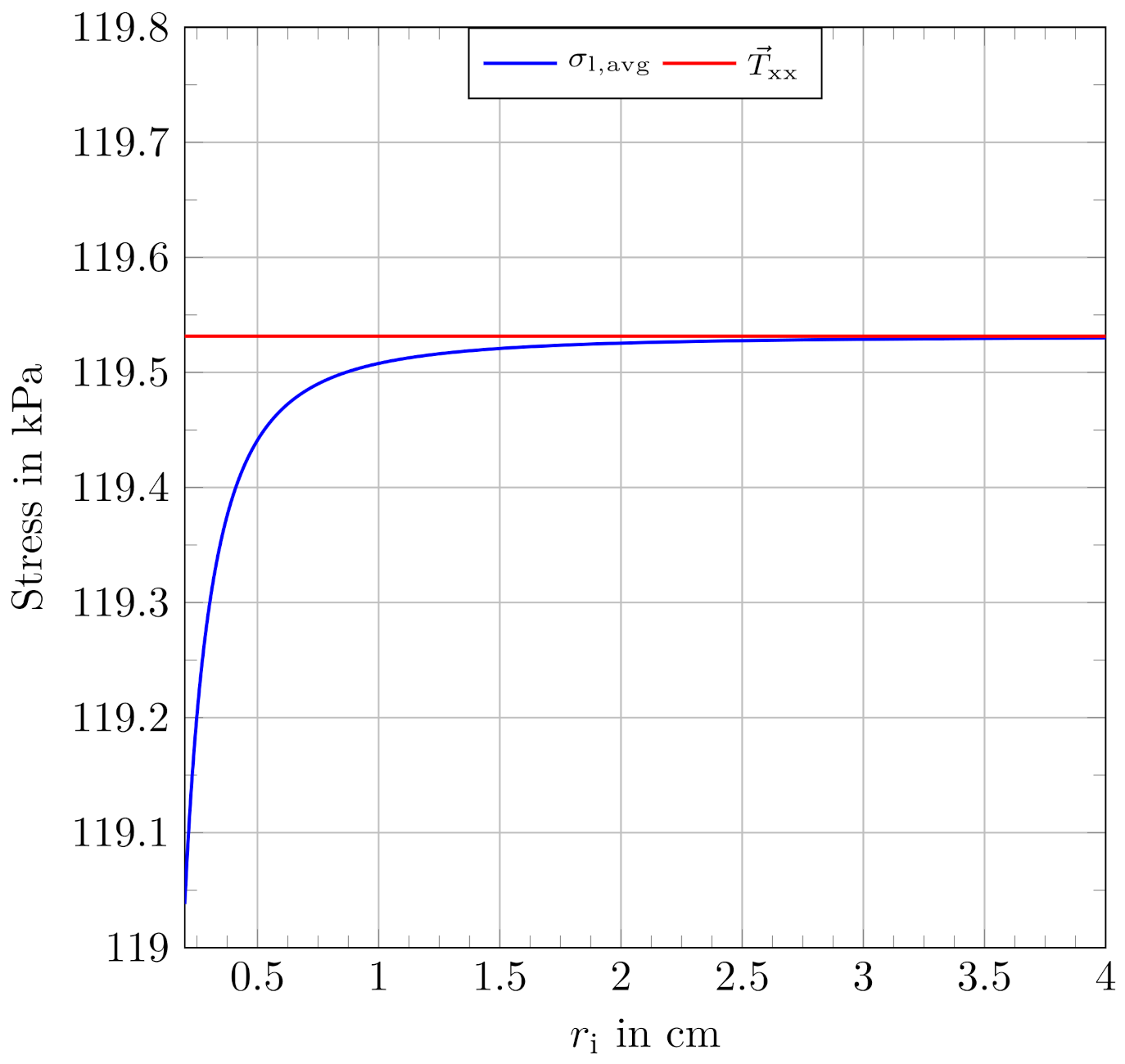

- In contrast to the electrostatic energy approaches, the Maxwell stress tensor approach delivers a component-wise expression for the stress states in the dielectric material. For cylindrical geometries these results also depend on r but the integration over a differential area element gives a force value that describes the acting force analytically. Dividing that by the geometrical area of the setup gives an average stress state that is valid for the whole geometry and can be used for engineering approaches.

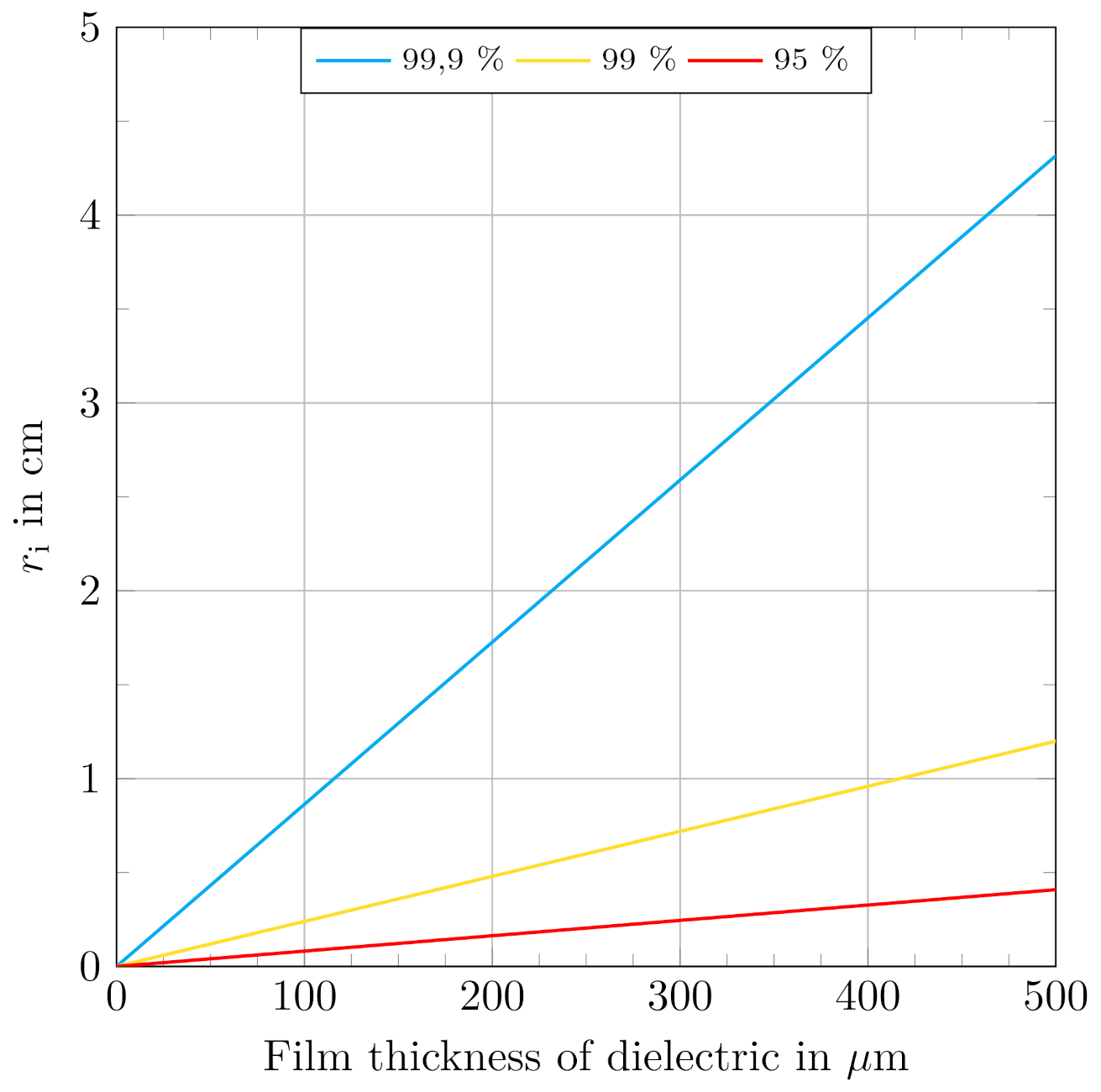

- Especially for scaled cylindrical actuator geometries with low diameters and film thicknesses, the use of the presented approaches based on the Maxwell stress tensor is strongly indicated. Especially for small actuator geometries, the resulting stress shows a highly non-linear behavior.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| DE | Dielectric elastomer |

| EAP | Electroactive polymer |

| DEA | Dielectric elastomer actuator |

References

- Goulbourne, N.C.; Mockensturm, E.M.; Frecker, M.I. Electro-elastomers: Large deformation analysis of silicone membranes. Int. J. Solids Struct. 2007, 44, 2609–2626. [Google Scholar] [CrossRef] [Green Version]

- Toupin, R. The elastic dielectric. J. Ration. Mech. Anal. 1956, 5, 850–915. [Google Scholar] [CrossRef]

- Kunze, J.; Prechtl, J.; Bruch, D.; Fasolt, B.; Nalbach, S.; Motzki, P.; Seelecke, S.; Rizzello, G. Design, Manufacturing, and Characterization of Thin, Core-Free, Rolled Dielectric Elastomer Actuators. Actuators Multidiscip. Digit. Publ. Inst. 2021, 10, 69. [Google Scholar] [CrossRef]

- Zhao, H.; Hussain, A.M.; Duduta, M.; Vogt, D.M.; Wood, R.J.; Clarke, D.R. Compact dielectric elastomer linear actuators. Adv. Funct. Mater. 2018, 28, 1804328. [Google Scholar] [CrossRef]

- Rajamani, A.; Grissom, M.D.; Rahn, C.D.; Zhang, Q. Wound roll dielectric elastomer actuators: Fabrication, analysis, and experiments. IEEE/ASME Trans. Mechatron. 2008, 13, 117–124. [Google Scholar] [CrossRef]

- Shimizu, K.; Nagai, T.; Shintake, J. Dielectric Elastomer Fiber Actuators with Aqueous Electrode. Polymers 2021, 13, 4310. [Google Scholar] [CrossRef] [PubMed]

- Arora, S.; Ghosh, T.; Muth, J. Dielectric elastomer based prototype fiber actuators. Sens. Actuators A Phys. 2007, 136, 321–328. [Google Scholar] [CrossRef]

- Zhou, J.; Jiang, L.; Khayat, R.E. Electromechanical response and failure modes of a dielectric elastomer tube actuator with boundary constraints. Smart Mater. Struct. 2014, 23, 045028. [Google Scholar] [CrossRef]

- Carpi, F.; De Rossi, D. Dielectric elastomer cylindrical actuators: Electromechanical modelling and experimental evaluation. Mater. Sci. Eng. C 2004, 24, 555–562. [Google Scholar] [CrossRef]

- Zhu, J.; Stoyanov, H.; Kofod, G.; Suo, Z. Large deformation and electromechanical instability of a dielectric elastomer tube actuator. J. Appl. Phys. 2010, 108, 074113. [Google Scholar] [CrossRef] [Green Version]

- Cameron, C.G.; Szabo, J.P.; Johnstone, S.; Massey, J.; Leidner, J. Linear actuation in coextruded dielectric elastomer tubes. Sens. Actuators A Phys. 2008, 147, 286–291. [Google Scholar] [CrossRef]

- Pelrine, R.E.; Kornbluh, R.D.; Joseph, J.P. Electrostriction of polymer dielectrics with compliant electrodes as a means of actuation. Sens. Actuators A Phys. 1998, 64, 77–85. [Google Scholar] [CrossRef]

- Sahdev, S.K. Basic Electrical Engineering; Pearson: Delhi, India, 2015. [Google Scholar]

- Wissler, M.; Mazza, E. Electromechanical coupling in dielectric elastomer actuators. Sens. Actuators A Phys. 2007, 138, 384–393. [Google Scholar] [CrossRef]

- Henke, H. Elektromagnetische Felder: Theorie und Anwendung; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Griffiths, D.J. Introduction to Electrodynamics; Pearson: Boston, MA, USA, 2013. [Google Scholar]

- Schwinger, J. Classical Electrodynamics; Perseus Books: New York, NY, USA, 1998. [Google Scholar]

- Suo, Z. Theory of dielectric elastomers. Acta Mech. Solida Sin. 2010, 23, 549–578. [Google Scholar] [CrossRef]

| Stored Energy Approach | Energy Balance Approach | Maxwell Stress Tensor Approach | |

|---|---|---|---|

| Assumptions |

|

|

|

| Boundary conditions |

|

|

|

| Applicability |

|

|

|

| Advantages |

|

|

|

| Disadvantages |

|

|

|

| Stored Energy Approach | Energy Balance Approach | Maxwell Stress Tensor Approach | |

|---|---|---|---|

| 0 | 0 | ||

| 0 | 0 | ||

| Component | Maxwell Stress | Maxwell Force | Averaged Maxwell Stress |

|---|---|---|---|

| radial component | |||

| angular component | |||

| length component |

| Accuracy | 95% Boundary | 99% Boundary | 99.9% Boundary |

|---|---|---|---|

| R | 0.450 | 0.706 | 0.896 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pfeil, S.; Gerlach, G. Suitability of Different Analytical Derivations of Electrically Induced Stress States in Planar and Cylindrical Dielectric Elastomer Actuators. Materials 2022, 15, 1321. https://doi.org/10.3390/ma15041321

Pfeil S, Gerlach G. Suitability of Different Analytical Derivations of Electrically Induced Stress States in Planar and Cylindrical Dielectric Elastomer Actuators. Materials. 2022; 15(4):1321. https://doi.org/10.3390/ma15041321

Chicago/Turabian StylePfeil, Sascha, and Gerald Gerlach. 2022. "Suitability of Different Analytical Derivations of Electrically Induced Stress States in Planar and Cylindrical Dielectric Elastomer Actuators" Materials 15, no. 4: 1321. https://doi.org/10.3390/ma15041321

APA StylePfeil, S., & Gerlach, G. (2022). Suitability of Different Analytical Derivations of Electrically Induced Stress States in Planar and Cylindrical Dielectric Elastomer Actuators. Materials, 15(4), 1321. https://doi.org/10.3390/ma15041321