Effect of Hot Working Parameters on Microstructure and Texture Evolution of Hot-Deformed Zr-45Ti-5Al-3V Alloy

Abstract

:1. Introduction

2. Experimental

3. Results and Discussion

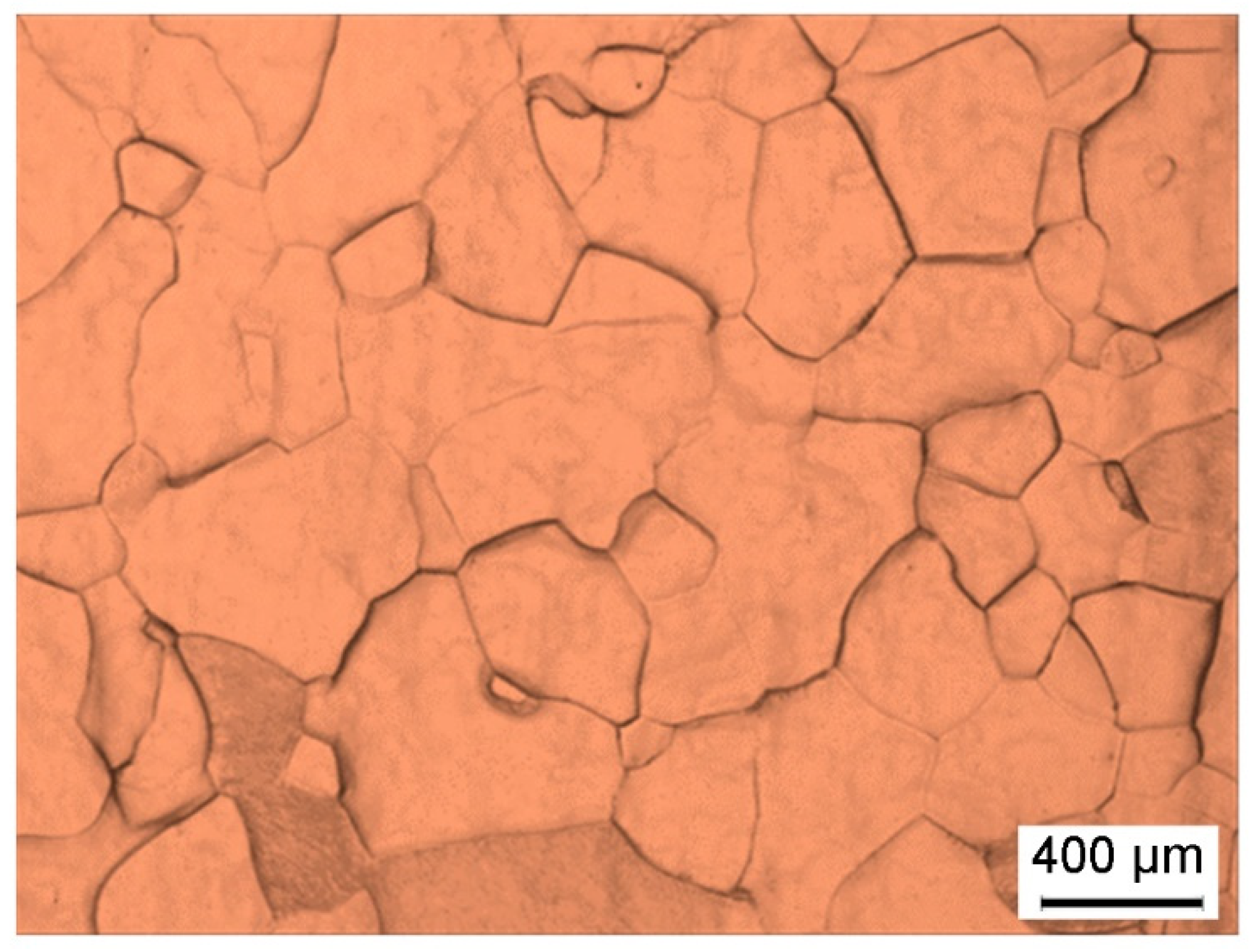

3.1. Microstructure Evolution of Hot-Deformed Zr-45Ti-5Al-3V Alloy

3.2. Dynamic Recrystallization Mechanism of Hot-Deformed Samples

3.3. Texture Evolution of Hot-Deformed Zr-45Ti-5Al-3V Alloy

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Boyer, R.; Welsch, G.; Collings, E.W. Materials Handbook: Titanium Alloys; ASM International, Materials Park, OH: Almere, The Netherlands, 1994. [Google Scholar]

- Seagle, S.R. The state of the USA titanium industry in 1995. Mater. Sci. Eng. A 1996, 213, 1–7. [Google Scholar] [CrossRef]

- Boyer, R.R. An overview on the use of titanium in the aerospace industry. Mater. Sci. Eng. A 1996, 213, 103–114. [Google Scholar] [CrossRef]

- Akahori, T.; Niinomi, M.; Fukunaga, K.-I. An investigation of the effect of fatigue deformation on the residual mechanical properties of Ti-6Al-4V ELI. Metall. Mater. Trans. A 2000, 31, 1937–1948. [Google Scholar] [CrossRef]

- Borgioli, F.; Galvanetto, E.; Iozzelli, F.; Pradelli, G. Improvement of wear resistance of Ti-6Al-4V alloy by means of thermal oxidation. Mater. Lett. 2005, 59, 2159–2162. [Google Scholar] [CrossRef]

- Liang, S.X.; Ma, M.Z.; Jing, R.; Zhang, X.Y.; Liu, R.P. Microstructure and mechanical properties of hot-rolled ZrTiAlV alloys. Mater. Sci. Eng. A 2012, 532, 1–5. [Google Scholar] [CrossRef]

- Liang, S.X.; Ma, M.Z.; Jing, R.; Zhou, Y.K.; Jing, Q.; Liu, R.P. Preparation of the ZrTiAlV alloy with ultra-high strength and good ductility. Mater. Sci. Eng. A 2012, 539, 42–47. [Google Scholar] [CrossRef]

- Lin, Y.C.; Wen, D.X.; Deng, J.; Liu, G.; Chen, J. Constitutive models for high-temperature flow behaviors of a Ni-based superalloy. Mater. Des. 2014, 59, 115–123. [Google Scholar] [CrossRef]

- Yang, J.L.; Wang, G.F.; Jiao, X.Y.; Li, X.; Yang, C. Hot deformation behavior and microstructural evolution of Ti22Al25Nb1.0B alloy prepared by elemental powder metallurgy. J. Alloy. Compd. 2017, 695, 1038–1044. [Google Scholar] [CrossRef]

- Wu, Y.; Kou, H.C.; Wu, Z.H.; Tang, B.; Li, J.S. Dynamic recrystallization and texture evolution of Ti-22Al-25Nb alloy during plane-strain compression. J. Alloy. Compd. 2018, 749, 844–852. [Google Scholar] [CrossRef]

- Lin, Y.C.; Pang, G.D.; Jiang, Y.Q.; Liu, X.G.; Zhang, X.Y.; Chen, C.; Zhou, K.C. Hot compressive deformation behavior and microstructure evolution of a Ti-55511 alloy with basket-weave microstructures. Vacuum 2019, 169, 108878. [Google Scholar] [CrossRef]

- Li, J.S.; Dong, R.F.; Kou, H.C.; Fan, J.K.; Zhu, B.; Tang, B. Texture evolution and the recrystallization behavior in a near β titanium alloy Ti-7333 during the hot-rolling process. Mater. Charact. 2020, 159, 109999. [Google Scholar] [CrossRef]

- Dong, R.F.; Li, J.S.; Kou, H.C.; Fan, J.K.; Tang, B. Dependence of mechanical properties on the microstructure characteristics of a near β titanium alloy Ti-7333. J. Mater. Sci. Technol. 2019, 35, 48–54. [Google Scholar] [CrossRef]

- Tan, Y.B.; Yang, L.H.; Tian, C.; Liu, W.C.; Liu, R.P.; Zhang, X.Y. Processing maps for hot working of 47Zr-45Ti-5Al-3V alloy. Mater. Sci. Eng. A 2014, 597, 171–177. [Google Scholar] [CrossRef]

- Tan, Y.B.; Yang, L.H.; Duan, J.L.; Liu, W.C.; Zhang, J.W.; Liu, R.P. Effect of initial grain size on the hot deformation behavior of 47Zr-45Ti-5Al-3V alloy. J. Nucl. Mater. 2014, 454, 413–420. [Google Scholar] [CrossRef]

- Zhang, W.W.; Yang, Q.Y.; Tan, Y.B.; Yang, Y.; Xiang, S.; Zhao, F. Study on the dynamic recrystallization behavior of 47Zr-45Ti-5Al-3V alloy by CA-FE simulation. Materials 2021, 14, 2562. [Google Scholar] [CrossRef]

- Liang, S.X.; Ma, M.Z.; Jing, R.; Tan, C.L.; Liu, R.P. Structural evolution and mechanical properties of Zr-45Ti-5Al-3V alloy by heat treatments. Mater. Sci. Eng. A 2012, 541, 67–72. [Google Scholar] [CrossRef]

- Tan, Y.B.; Yang, L.H.; Duan, J.L.; Ji, L.Y.; Liu, W.C. Studies on the kinetics of β→α phase transformation in 47Zr-45Ti-5Al-3V alloy under isothermal conditions by X-ray diffraction. Mater. Charact. 2016, 112, 98–104. [Google Scholar] [CrossRef]

- Li, H.W.; Sun, X.X.; Yang, H. A three-dimensional cellular automata-crystal plasticity finite element model for predicting the multiscale interaction among heterogeneous deformation, DRX microstructural evolution and mechanical responses in titanium alloys. Int. J. Plast. 2016, 87, 154–180. [Google Scholar] [CrossRef]

- Cao, Z.H.; Sun, Y.; Zhou, C.; Wan, Z.P.; Yang, W.H.; Ren, L.L.; Hu, L.X. Cellular Automaton Simulation of Dynamic Recrystallization Behavior in V-10Cr-5Ti Alloy under Hot Deformation Conditions. Trans. Nonferrous Met. Soc. China 2019, 29, 98–111. [Google Scholar] [CrossRef]

- Chen, F.; Cui, Z.; Liu, J.; Chen, W.; Chen, S. Mesoscale Simulation of the Hightemperature Austenitizing and Dynamic Recrystallization by Coupling a Cellular Automaton with a Topology Deformation Technique. Mater. Sci. Eng. A 2010, 527, 5539–5549. [Google Scholar] [CrossRef]

- Zhao, Q.Y.; Yang, F.; Torrens, R.; Bolzoni, L. Comparison of hot deformation behaviour and microstructural evolution for Ti-5Al-5V-5Mo-3Cr alloys prepared by powder metallurgy and ingot metallurgy approaches. Mater. Des. 2019, 169, 107682. [Google Scholar] [CrossRef]

- Jandaghi, M.R.; Pouraliakbar, H. Study on the effect of post-annealing on the microstructural evolutions and mechanical properties of rolled CGPed Aluminum-Manganese-Silicon alloy. Mater. Sci. Eng. A 2017, 679, 493–503. [Google Scholar] [CrossRef]

- Fan, X.G.; Zhang, Y.; Gao, P.F.; Lei, Z.N.; Zhan, M. Deformation behavior and microstructure evolution during hot working of a coarse-grained Ti-5Al-5Mo-5V-3Cr-1Zr titanium alloy in beta phase field. Mater. Sci. Eng. A 2017, 694, 24–32. [Google Scholar] [CrossRef]

- Lin, Y.C.; Wu, X.Y.; Chen, X.M.; Chen, J.; Wen, D.X.; Zhang, J.L.; Li, L.T. EBSD study of a hot deformed nickel-based superalloy. J. Alloy. Compd. 2015, 640, 101–113. [Google Scholar] [CrossRef]

- Zhang, J.J.; Yi, Y.P.; He, H.L.; Huang, S.Q.; Mao, X.C.; Guo, W.F.; You, W.; Guo, Y.L.; Dong, F.; Tang, J.G. Kinetic model for describing continuous and discontinuous dynamic recrystallization behaviors of 2195 aluminum alloy during hot deformation. Mater. Charact. 2021, 181, 111492. [Google Scholar] [CrossRef]

- Lin, Y.C.; He, D.G.; Chen, M.S.; Chen, X.M.; Zhao, C.Y.; Ma, X.; Long, Z.L. EBSD analysis of evolution of dynamic recrystallization grains and δ phase in a nickel-based superalloy during hot compressive deformation. Mater. Des. 2016, 97, 13–24. [Google Scholar] [CrossRef]

- Sakai, T.; Belyakov, A.; Kaibyshev, R.; Miura, H.; Jonas, J.J. Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions. Prog. Mater. Sci. 2014, 60, 130–207. [Google Scholar] [CrossRef] [Green Version]

- Humphreys, J.; Rohrer, S.G.; Rollett, A. Recrystallization and Related Annealing Phenomena; Elsevier: Amsterdam, The Netherlands, 2017; pp. 469–508. [Google Scholar] [CrossRef]

- Sander, B.; Raabe, D. Texture inhomogeneity in a Ti-Nb-based β-titanium alloy after warm rolling and recrystallization. Mater. Sci. Eng. A 2008, 479, 236–247. [Google Scholar] [CrossRef]

- Lan, C.B.; Wu, Y.; Guo, L.L.; Chen, F. Effects of cold rolling on microstructure, texture evolution and mechanical properties of Ti-32.5Nb-6.8Zr-2.7Sn-0.3O alloy for biomedical applications. Mater. Sci. Eng. A 2017, 690, 170–176. [Google Scholar] [CrossRef]

- Xu, Y.F.; Yi, D.Q.; Liu, H.Q.; Wu, X.Y.; Wang, B.; Yang, F.L. Effects of cold deformation on microstructure, texture evolution and mechanical properties of Ti-Nb-Ta-Zr-Fe alloy for biomedical applications. Mater. Sci. Eng. A 2012, 547, 64–71. [Google Scholar] [CrossRef]

- Shen, F.H.; Sun, Z.Z.; Li, W.F.; Zhou, Z.R.; Zhong, S.Y.; Huang, H.Y.; Guo, J.W.; Xie, C.X.; Wang, Y.L.; Yi, D.Q. Texture evolution in hot-rolled Al-Cu-Mg sheets using orientation streamline approach and texture index. J. Alloys Compd. 2020, 816, 152415. [Google Scholar] [CrossRef]

- Fu, J.W.; Li, F.; Sun, J.J.; Wu, Y.C. Texture, orientation, and mechanical properties of Ti-stabilized Fe-17Cr ferritic stainless steel. Mater. Sci. Eng. A 2018, 738, 335–343. [Google Scholar] [CrossRef]

- Gupta, A.; Khatirkar, R.K.; Kumar, A.; Thool, K.; Bibhanshu, N.; Suwas, S. Microstructure and texture development in Ti-15V-3Cr-3Sn-3Al alloy—Possible role of strain path. Mater. Charact. 2019, 156, 109884. [Google Scholar] [CrossRef]

- Hölscher, M.; Raabe, D.; Lücke, K. Relationship between rolling textures and shear textures in f.c.c. and b.c.c. metals. Acta Metall. Mater. 1994, 42, 879–886. [Google Scholar] [CrossRef]

- Chen, Y.; Li, J.; Tang, B.; Kou, H.; Xue, X.; Cui, Y. Texture evolution and dynamic recrystallization in a beta titanium alloy during hot-rolling process. J. Alloy. Compd. 2015, 618, 146–152. [Google Scholar] [CrossRef]

- Yang, Q.Y.; Ma, M.; Tan, Y.B.; Xiang, S.; Zhao, F.; Liang, Y.L. Microstructure and texture evolution of TB8 titanium alloys during hot compression. Rare Met. 2021, 40, 2917–2926. [Google Scholar] [CrossRef]

- Yan, H.L.; Zhao, X.; Jia, N.; Zheng, Y.R.; He, T. Influence of shear banding on the formation of brass-type textures in polycrystalline fcc metals with low stacking fault energy. J. Mater. Sci. Technol. 2014, 30, 408–416. [Google Scholar] [CrossRef]

- Wen, W.; M’Guil, S.; Ahzi, S.; Gracio, J.J. Coupled effects of the lattice rotation definition, twinning and interaction strength on the FCC rolling texture evolution using the viscoplastic Φ-model. Int. J. Plast. 2013, 46, 23–36. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lei, Y.; Yang, Y.; Tan, Y.; Zhang, W.; Wu, S.; Ma, M. Effect of Hot Working Parameters on Microstructure and Texture Evolution of Hot-Deformed Zr-45Ti-5Al-3V Alloy. Materials 2022, 15, 1382. https://doi.org/10.3390/ma15041382

Lei Y, Yang Y, Tan Y, Zhang W, Wu S, Ma M. Effect of Hot Working Parameters on Microstructure and Texture Evolution of Hot-Deformed Zr-45Ti-5Al-3V Alloy. Materials. 2022; 15(4):1382. https://doi.org/10.3390/ma15041382

Chicago/Turabian StyleLei, Yuanyuan, Ya Yang, Yuanbiao Tan, Wenwei Zhang, Shanshan Wu, and Min Ma. 2022. "Effect of Hot Working Parameters on Microstructure and Texture Evolution of Hot-Deformed Zr-45Ti-5Al-3V Alloy" Materials 15, no. 4: 1382. https://doi.org/10.3390/ma15041382