Corrosion and Microstructural Investigation on Additively Manufactured 316L Stainless Steel: Experimental and Statistical Approach

Abstract

:1. Introduction

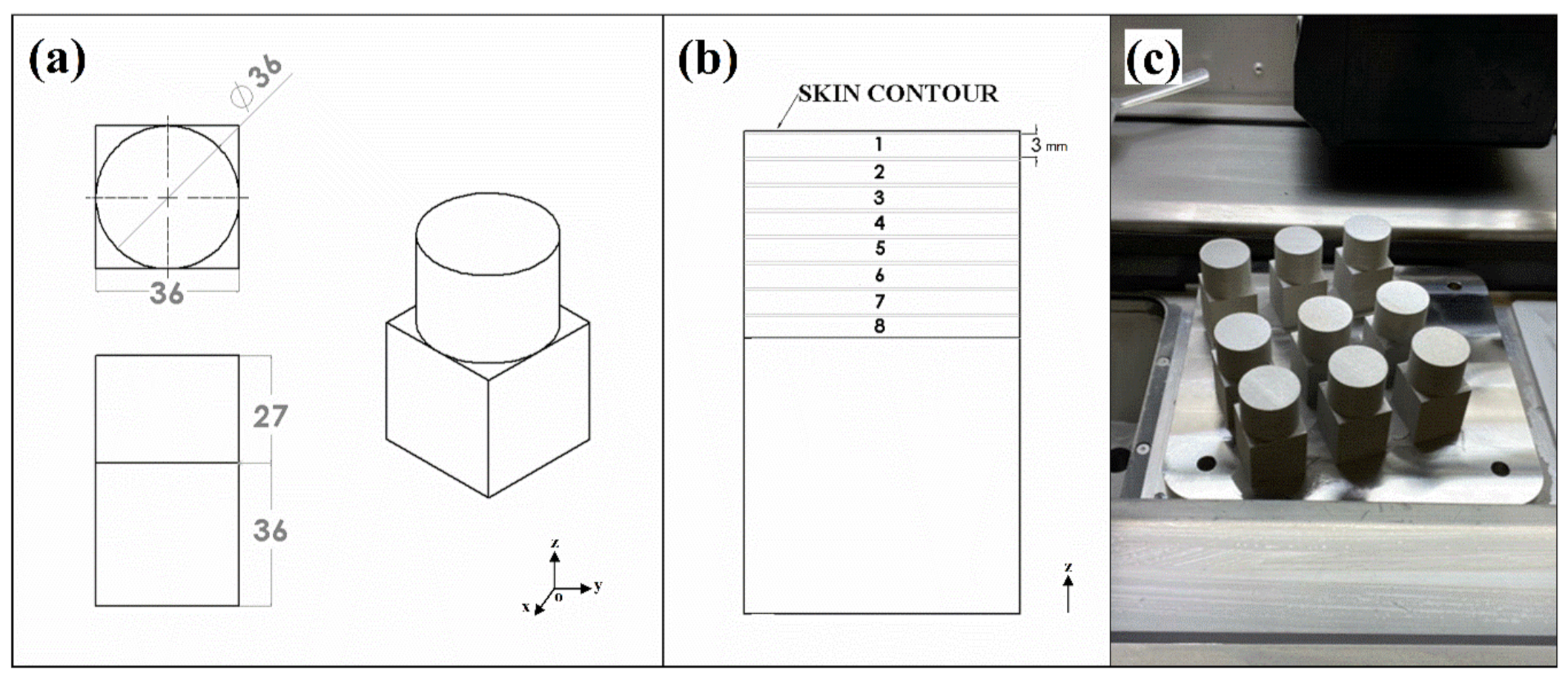

2. Materials and Methods

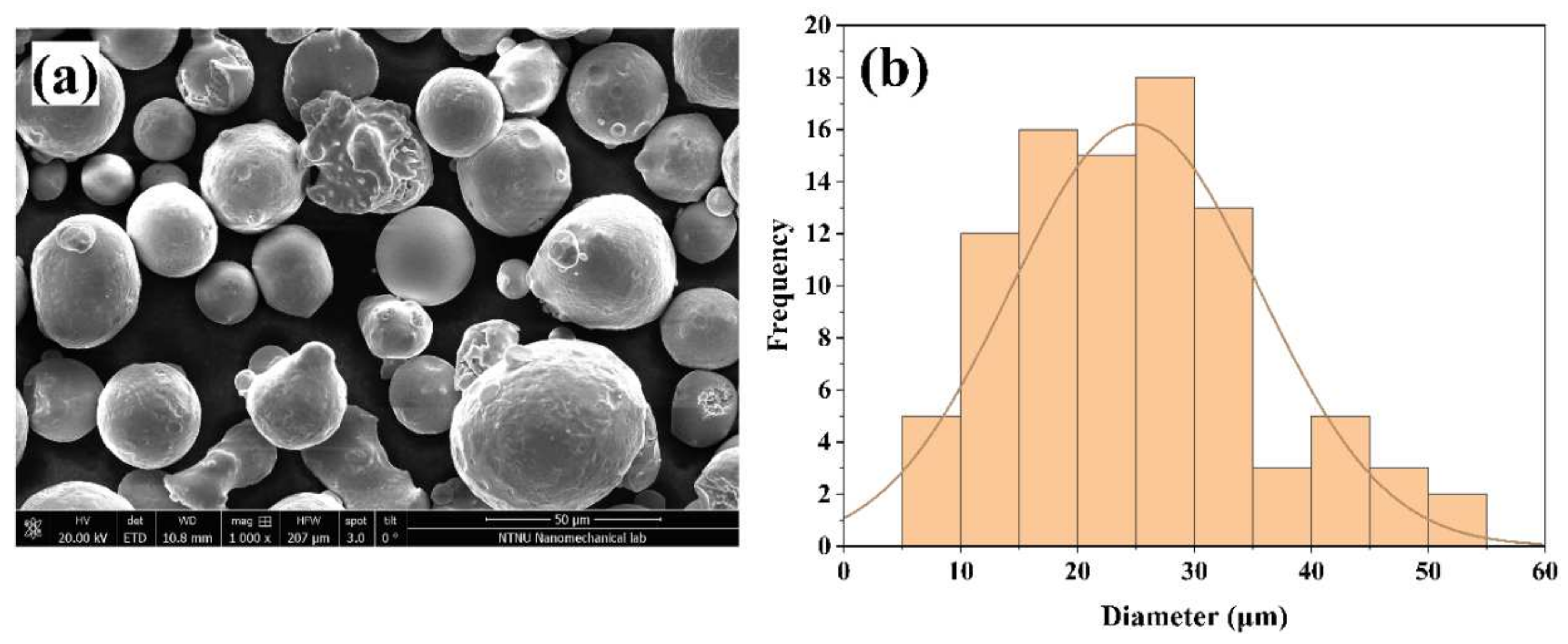

2.1. Materials

2.2. Microstructural Studies

2.2.1. Porosity/Pore Measurement

2.2.2. Roughness (Ra)

2.2.3. Hardness

2.2.4. Grain Size

2.3. Corrosion Evaluation

2.4. Statistical Analysis

3. Results

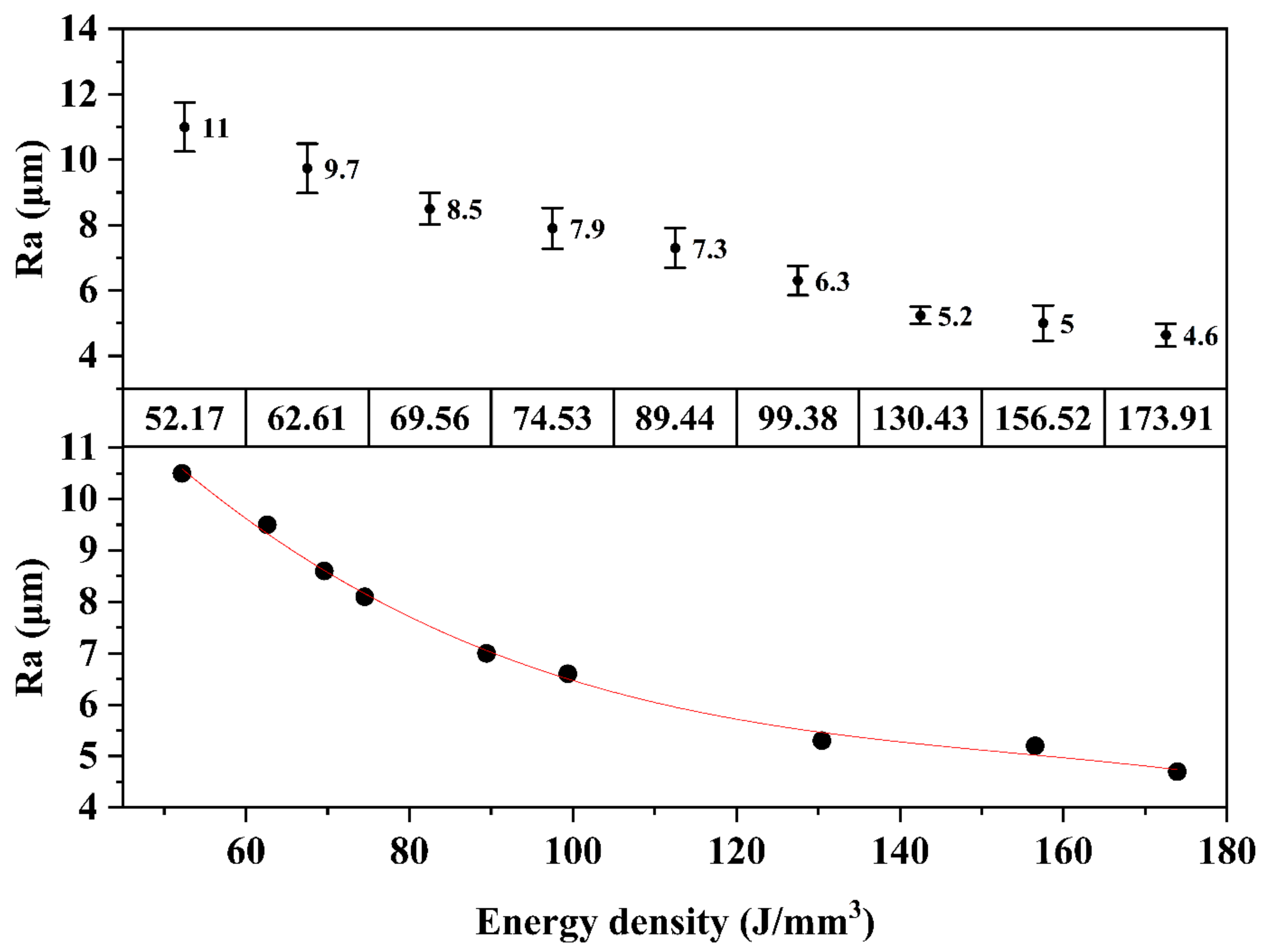

3.1. Roughness Measurements

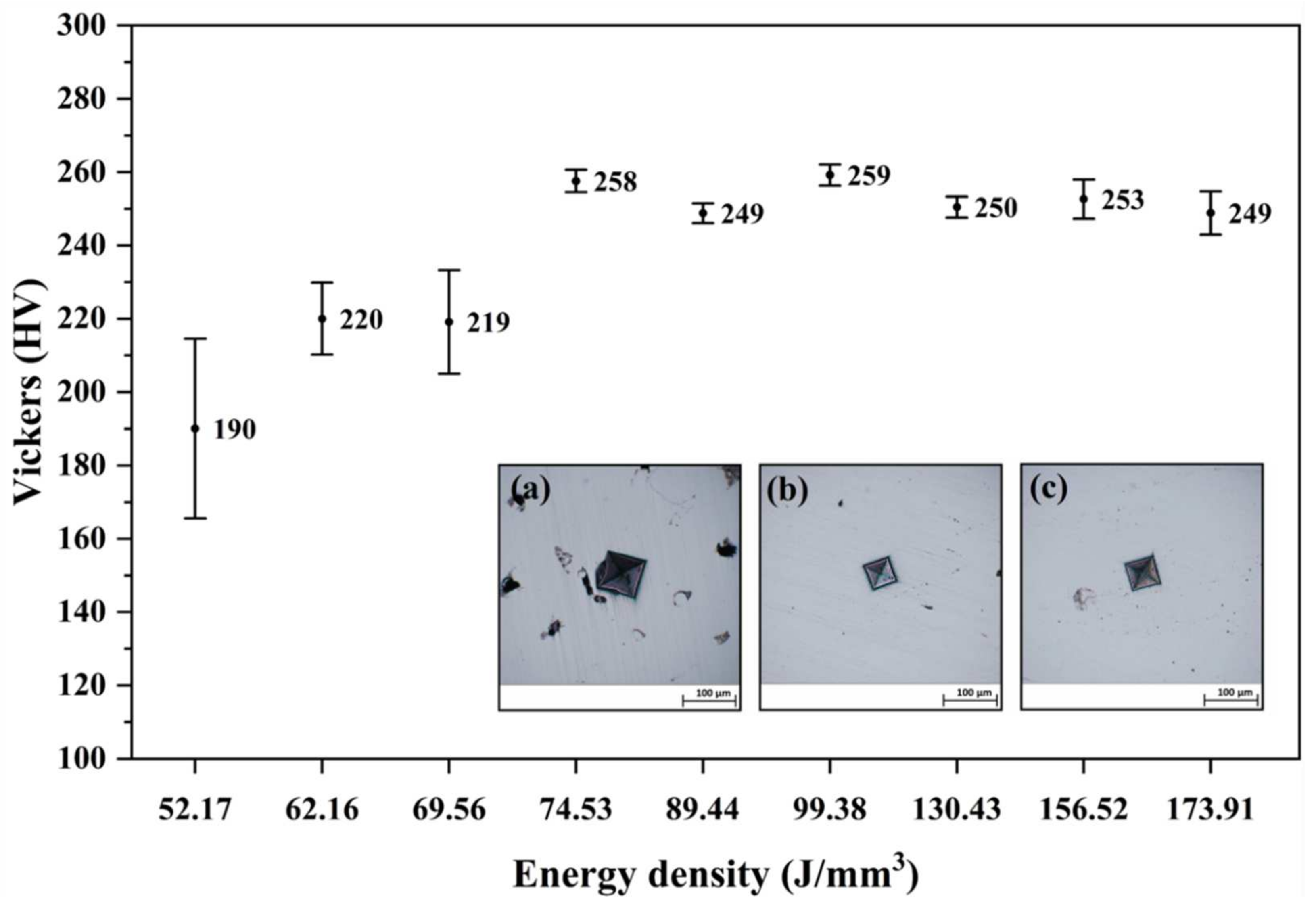

3.2. Hardness Measurements

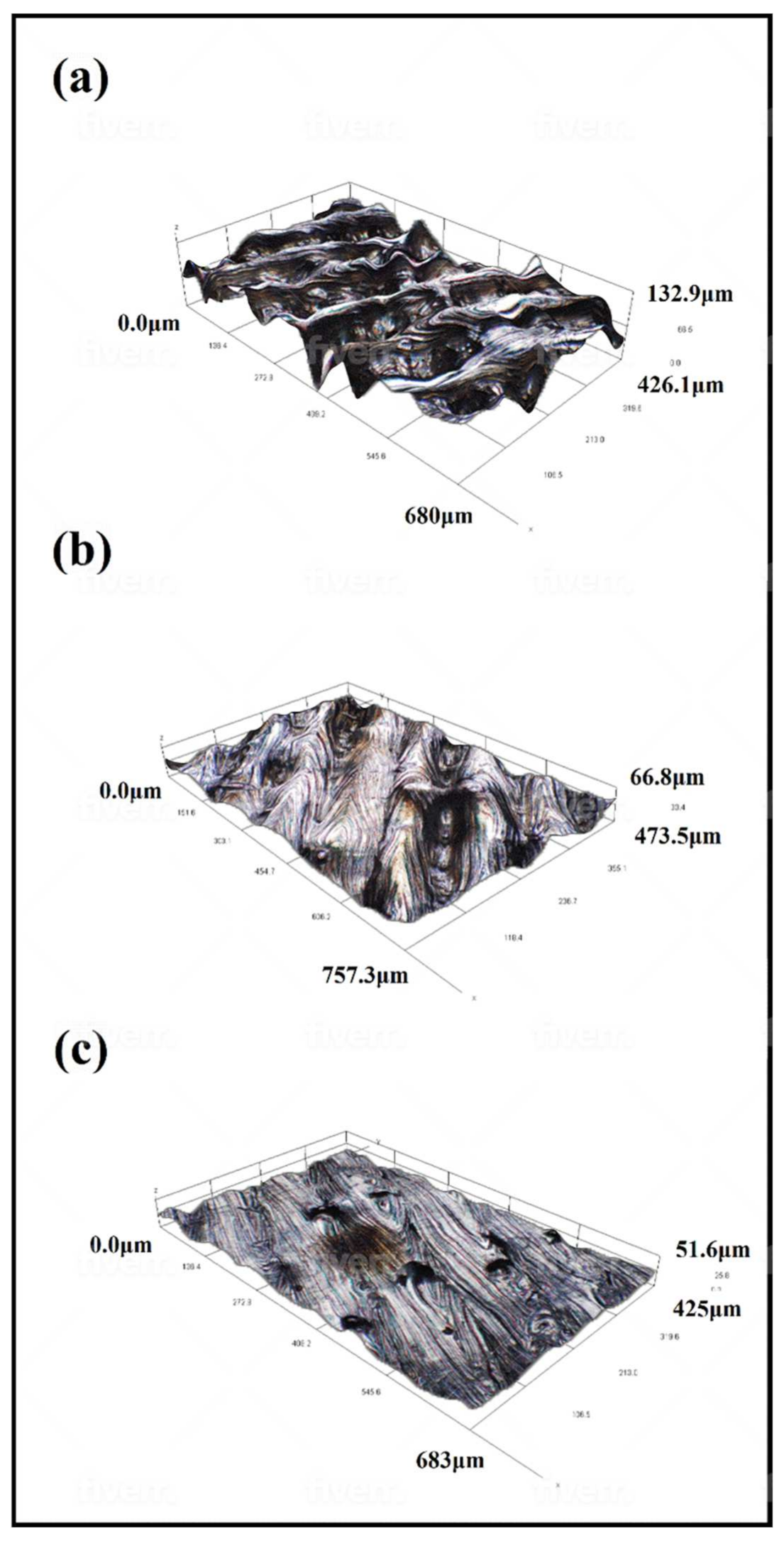

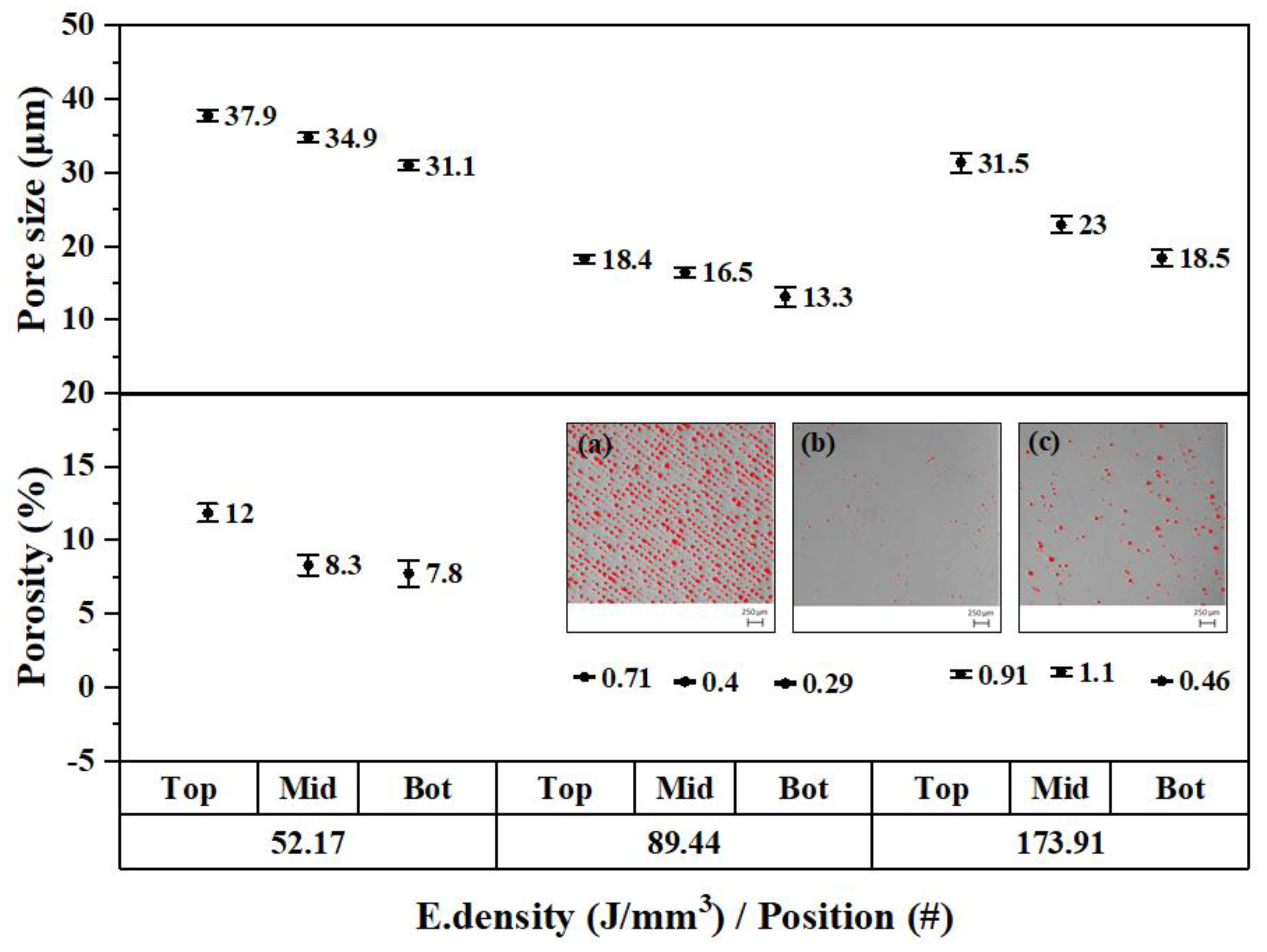

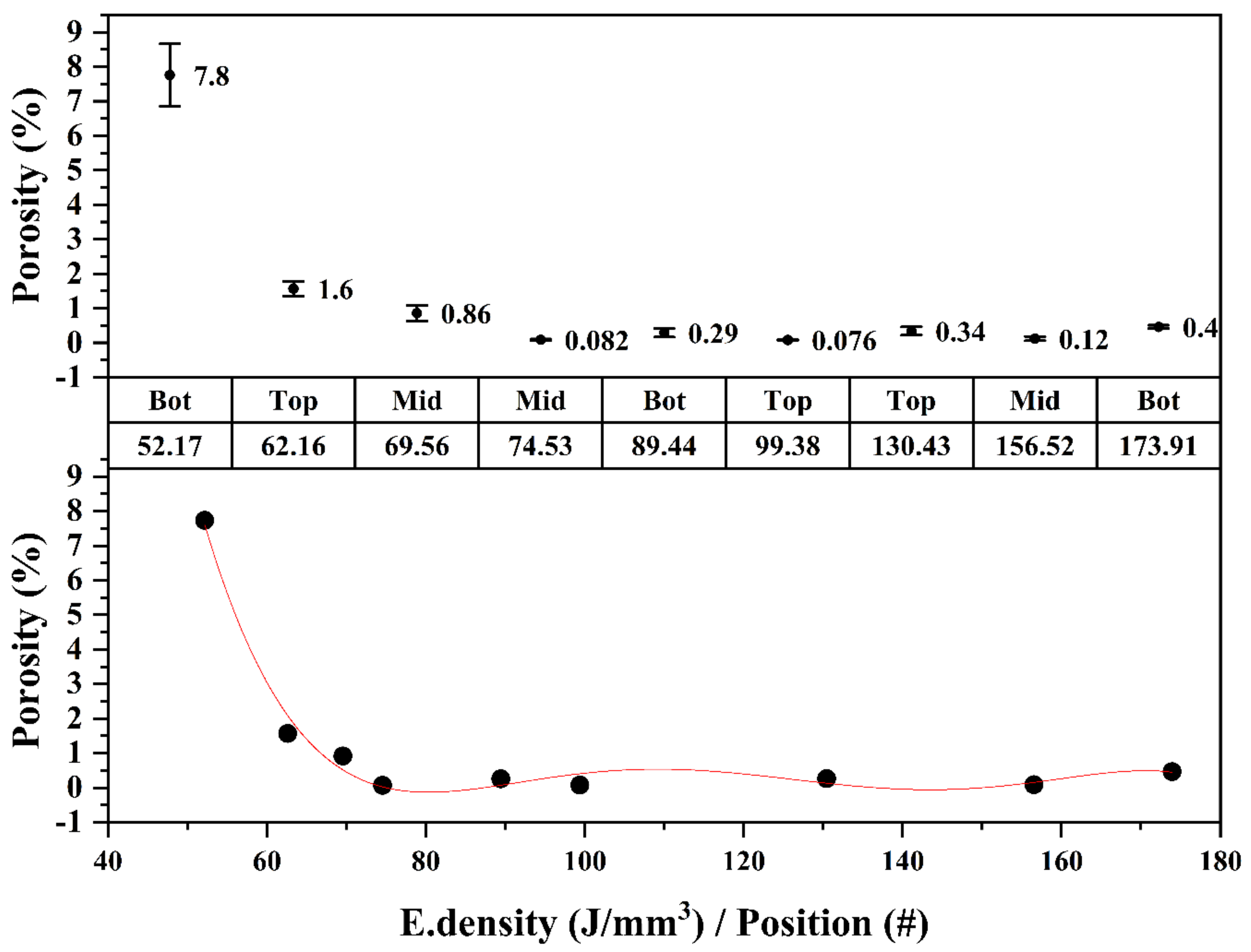

3.3. The Effect of Energy Density and Building Positions on Porosity

3.4. Grain Size and Internal Stress

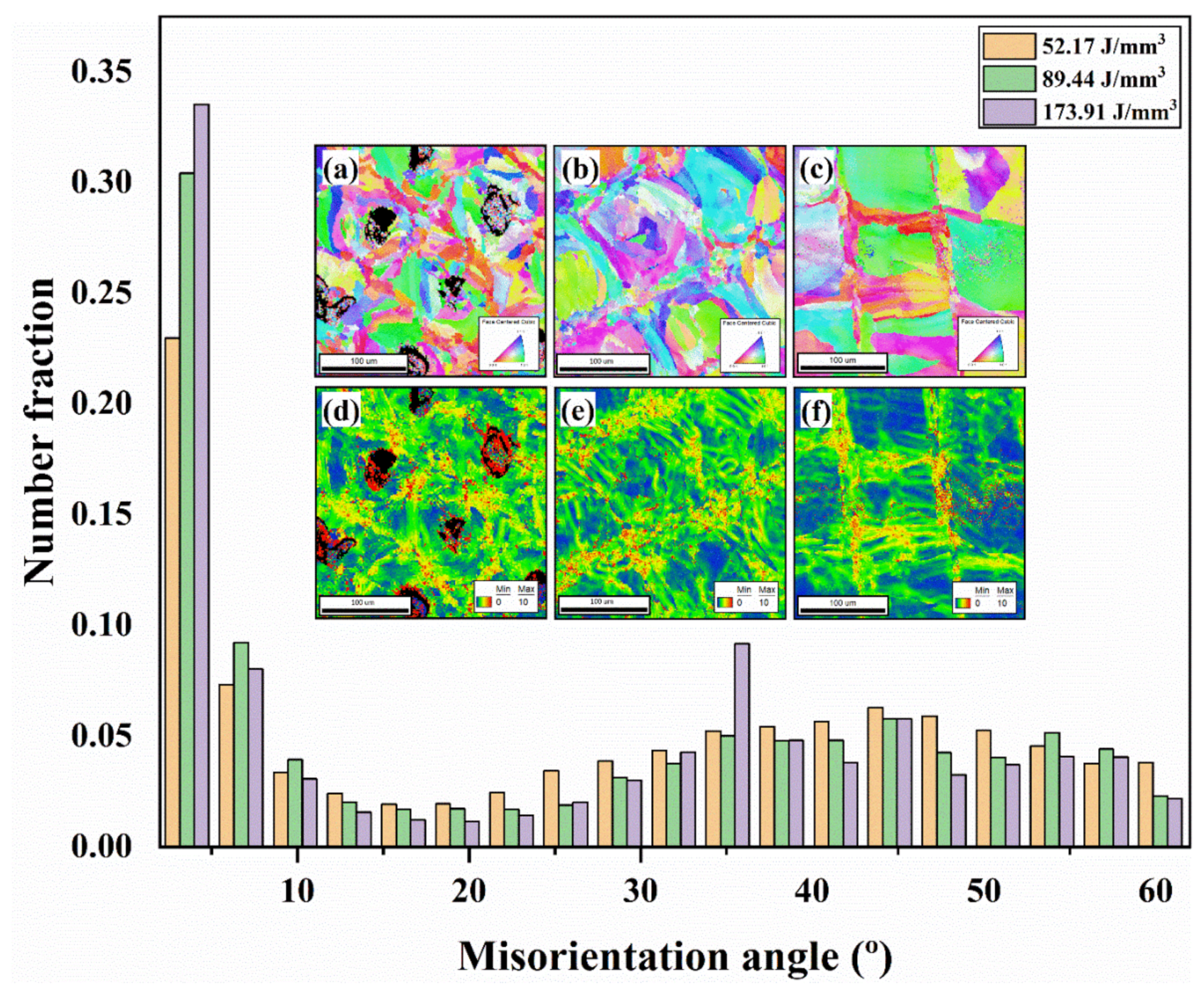

3.5. Corrosion Results

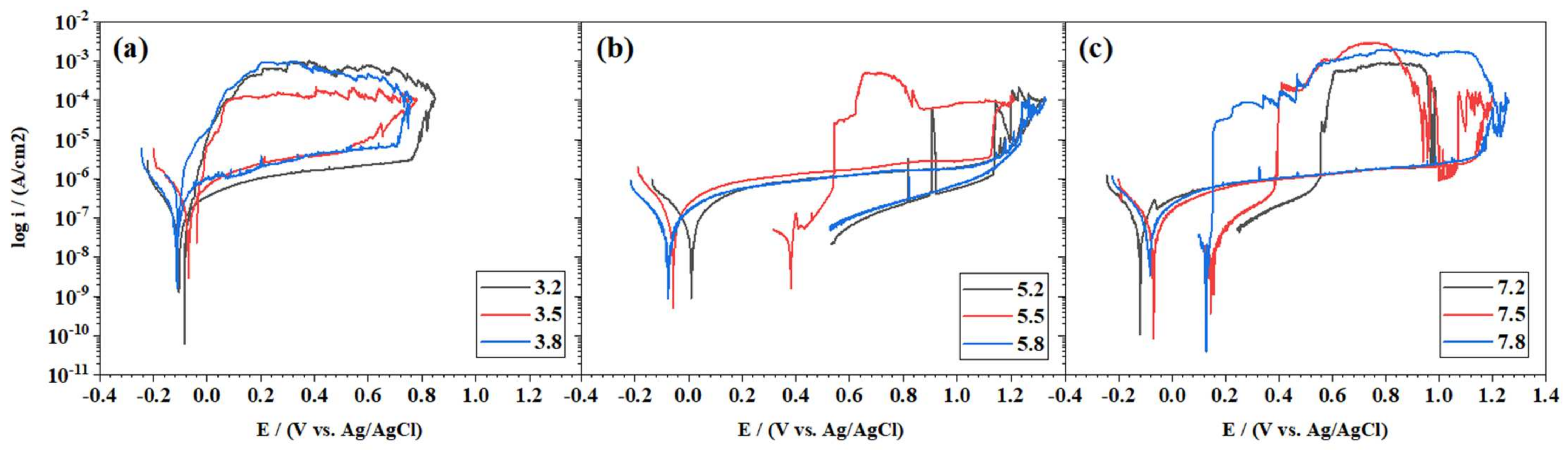

3.5.1. Effect of Building Position on Corrosion

3.5.2. Effect of Energy Density on Corrosion

3.6. Statistical Modelling

3.6.1. Factor Interactions (Taguchi)

3.6.2. Confirmation Test for the Suggested Combination

3.6.3. Analysis of Variance (ANOVA)

3.6.4. Modelling (Regression Equation)

4. Discussion

4.1. The Role of Building Position on the Microstructure and Corrosion Performance

4.2. The Energy Density Influence on the Microstructure and Corrosion Performance

5. Conclusions

- The position along the building in the Z-direction influences the amount of porosity and pore size on a printed component, both increasing for higher positions on the Z axis.

- The highest porosity was found in the samples produced with low energy densities (52.17 J/mm3). When increasing that value to 89.44 J/mm3, the porosity decreased. However, it increased again for higher energy densities (173.91 J/mm3). The Taguchi model suggested 99.38 J/mm3 as the optimal energy density to produce samples with low levels of porosity (0.05%).

- The ANOVA confirmed the scanning speed as the most influential factor in reducing the porosity percentage (74.9% reduction), followed by the position along the Z axis (22.8%), and finally, the laser energy (2.3%).

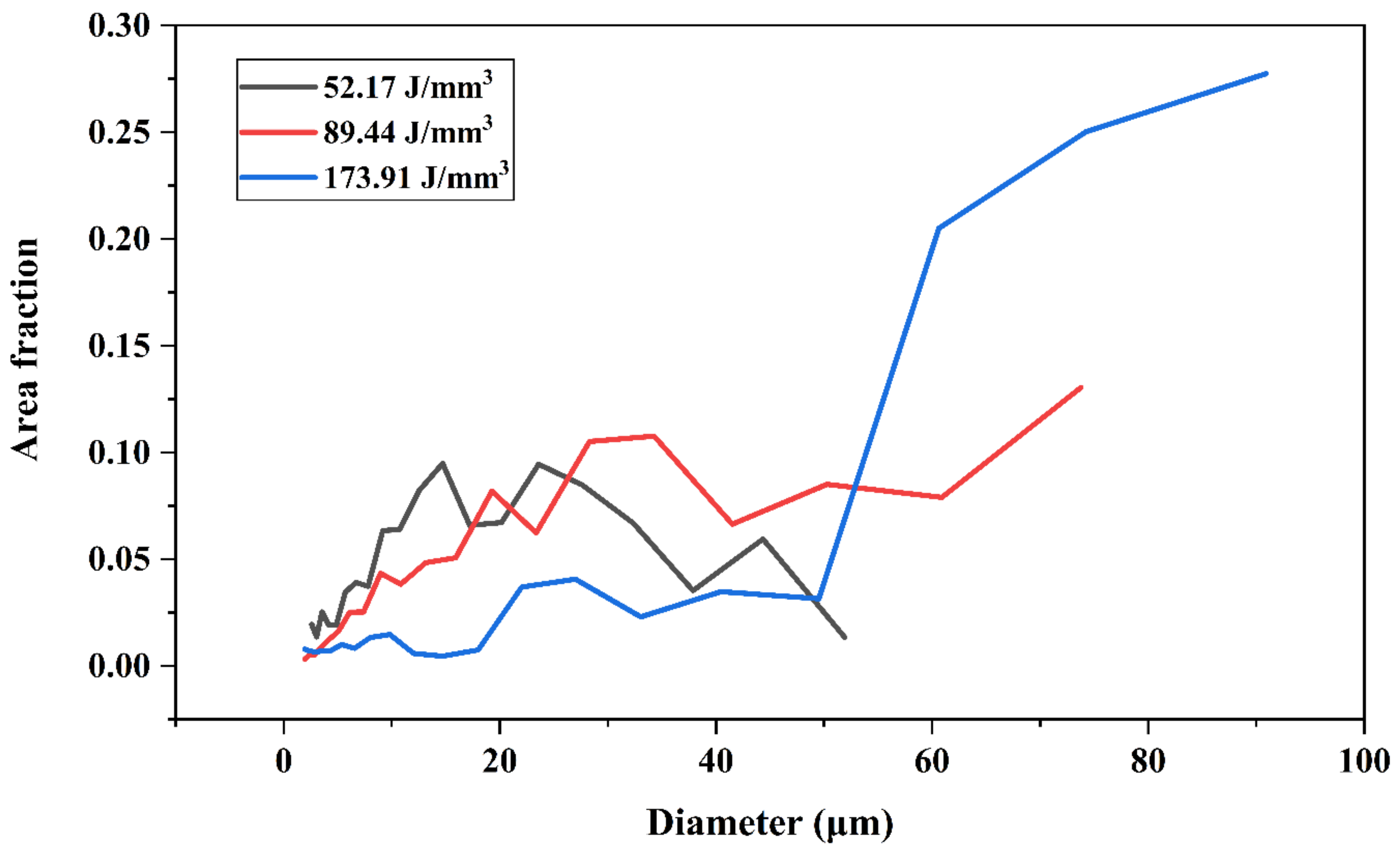

- The average surface roughness (Ra) of the AM samples decreased linearly from 11 to 4.6 µm, with increasing energy densities. The hardness (HV) increased drastically between the lowest energy densities, and stabilized around ~253 HV for energy densities >74.53 J/mm3. The area fraction of large grains increased with increasing energy densities as well as the low-angle grain boundaries.

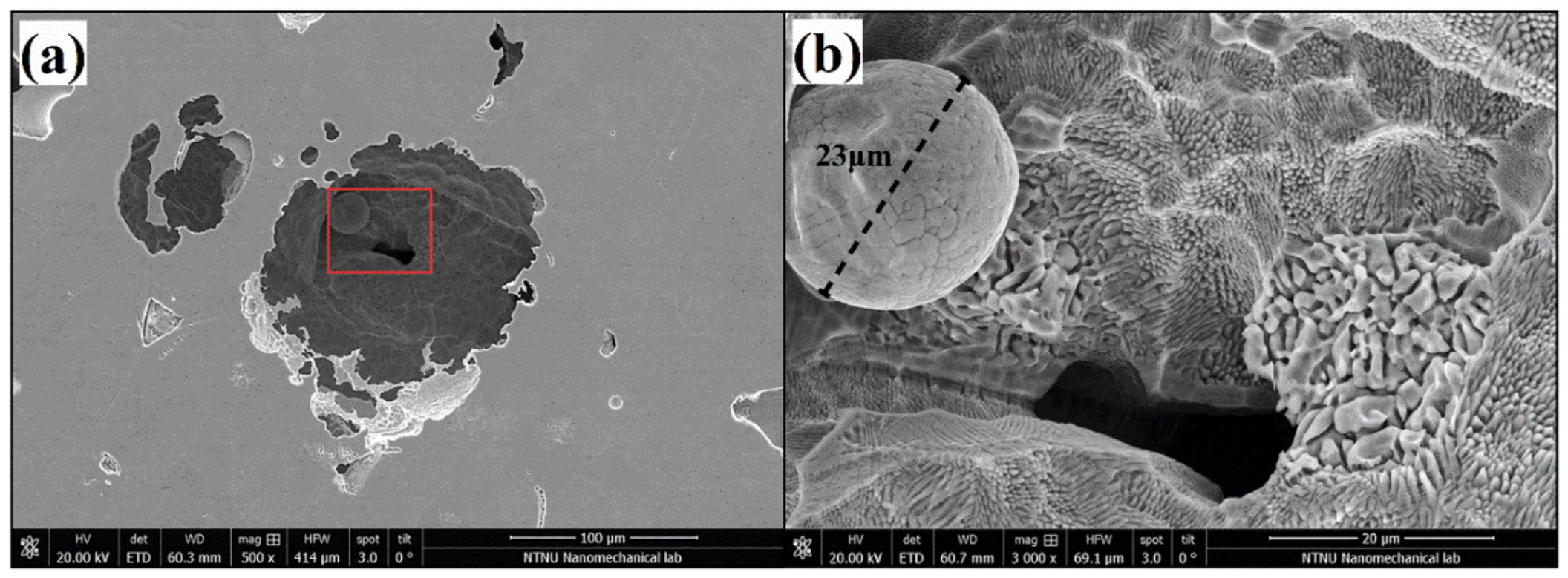

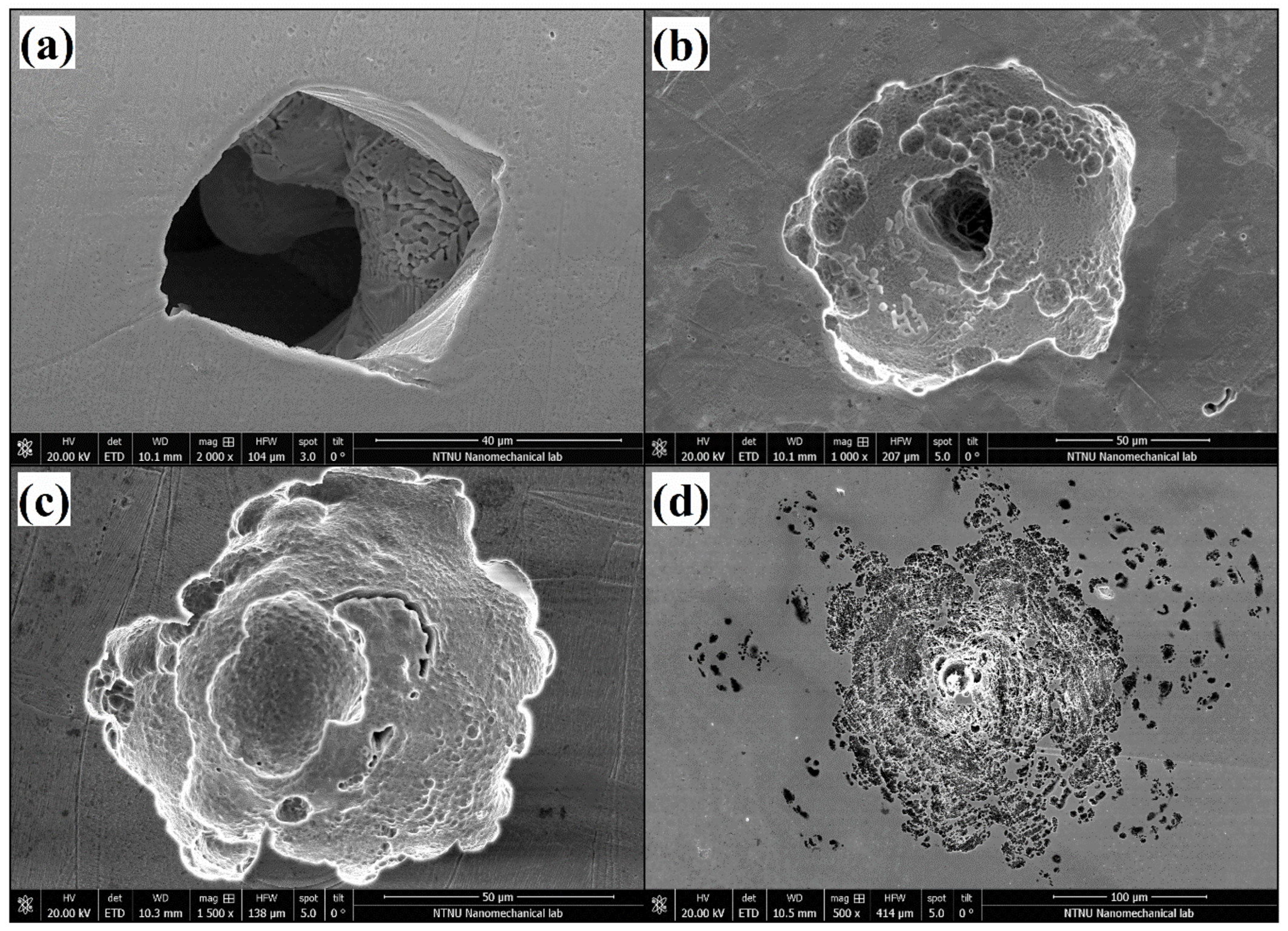

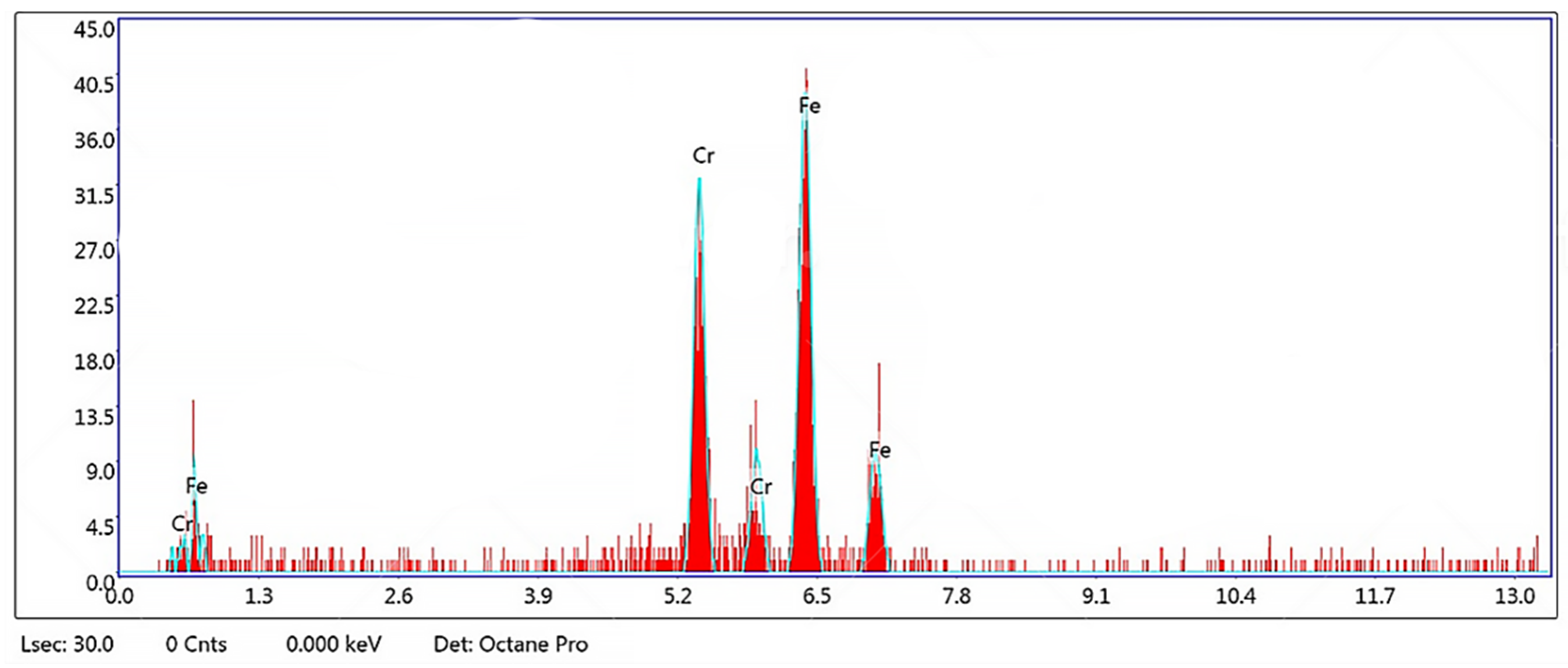

- The cyclic potentiodynamic polarization curves confirmed the higher corrosion resistance of the AM samples compared to wrought samples. More positive breakdown potentials and repassivation potentials were found in the AM samples with porosity levels <1%. The pores were found to be preferred pit initiation sites, as revealed by the SEM images. In samples with high porosity, most pits originated within the pores, spreading the corrosion attack towards the vicinity via a network of interconnected porosities. No inclusions, such as MnS or other elements that could be detrimental to the corrosion resistance of the AM samples, were found in the EDS analysis.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tepylo, N.; Huang, X.; Patnaik, P.C. Laser-Based Additive Manufacturing Technologies for Aerospace Applications. Adv. Eng. Mater. 2019, 21, 2019–2020. [Google Scholar] [CrossRef]

- Ziółkowski, M.; Dyl, T. Possible applications of additive manufacturing technologies in shipbuilding: A review. Machines 2020, 8, 84. [Google Scholar] [CrossRef]

- Sgarbossa, F.; Peron, M.; Lolli, F.; Balugani, E. Conventional or additive manufacturing for spare parts management: An extensive comparison for Poisson demand. Int. J. Prod. Econ. 2021, 233, 107993. [Google Scholar] [CrossRef]

- Fox, J.C.; Moylan, S.P.; Lane, B.M. Effect of process parameters on the surface roughness of overhanging structures in laser powder bed fusion additive manufacturing. Procedia CIRP 2016, 45, 131–134. [Google Scholar] [CrossRef] [Green Version]

- Sander, G.; Tan, J.; Balan, P.; Gharbi, O.; Feenstra, D.R.; Singer, L.; Thomas, S.; Kelly, R.G.; Scully, J.R.; Birbilis, N. Corrosion of additively manufactured alloys: A review. Corrosion 2018, 74, 1318–1350. [Google Scholar] [CrossRef] [Green Version]

- Kruth, J.P.; Badrossamay, M.; Yasa, E.; Deckers, J.; Thijs, L.; Van Humbeeck, J. Part and material properties in selective laser melting of metals. In Proceedings of the 16th International Symposium on Electromachining (ISEM XVI), Shanghai, China, 19–23 April 2010; pp. 3–14. [Google Scholar]

- Vanmeensel, K.; Lietaert, K.; Vrancken, B.; Dadbakhsh, S.; Li, X.; Kruth, J.P.; Krakhmalev, P.; Yadroitsev, I.; Van Humbeeck, J. Additively manufactured metals for medical applications. In Additive Manufacturing: Materials, Processes, Quantifications and Applications; Elsevier: Amsterdam, The Netherlands, 2018; pp. 261–309. ISBN 9780128121559. [Google Scholar] [CrossRef]

- Branner, G.; Zaeh, M.F.; Groth, C. Coupled-field simulation in additive layer manufacturing. In Proceedings of the 3rd International Conference on Polymers and Moulds Innovations, Ghent, Belgium, 17–19 September 2008; pp. 184–193. [Google Scholar]

- Liu, J.; Song, Y.; Chen, C.; Wang, X.; Li, H.; Zhou, C.; Wang, J.; Guo, K.; Sun, J. Effect of scanning speed on the microstructure and mechanical behavior of 316L stainless steel fabricated by selective laser melting. Mater. Des. 2020, 186, 108355. [Google Scholar] [CrossRef]

- Shang, Y.; Yuan, Y.; Li, D.; Li, Y.; Chen, J. Effects of scanning speed on in vitro biocompatibility of 316L stainless steel parts elaborated by selective laser melting. Int. J. Adv. Manuf. Technol. 2017, 92, 4379–4385. [Google Scholar] [CrossRef]

- Cherry, J.A.; Davies, H.M.; Mehmood, S.; Lavery, N.P.; Brown, S.G.R.; Sienz, J. Investigation into the effect of process parameters on microstructural and physical properties of 316L stainless steel parts by selective laser melting. Int. J. Adv. Manuf. Technol. 2014, 76, 869–879. [Google Scholar] [CrossRef] [Green Version]

- Yasa, E.; Kruth, J. Application of Laser Re-Melting on Selective Laser Melting Parts. Adv. Prod. Eng. Manag. 2011, 6, 259–270. [Google Scholar]

- Mugwagwa, L.; Dimitrov, D.; Matope, S.; Yadroitsev, I. Influence of process parameters on residual stress related distortions in selective laser melting. Procedia Manuf. 2018, 21, 92–99. [Google Scholar] [CrossRef]

- Campanelli, S.L.; Contuzzi, N.; Angelastro, A.; Ludovico, A.D. Capabilities and Performances of the Selective Laser Melting Process. New Trends Technol. Dev. Comp. Commun. Ind. Syst. 2010, 1, 233–252. [Google Scholar]

- Liu, Y.; Yang, Y.; Wang, D. A study on the residual stress during selective laser melting (SLM) of metallic powder. Int. J. Adv. Manuf. Technol. 2016, 87, 647–656. [Google Scholar] [CrossRef]

- Wang, D.; Wu, S.; Yang, Y.; Dou, W.; Deng, S.; Wang, Z.; Li, S. The effect of a scanning strategy on the residual stress of 316L steel parts fabricated by selective laser melting (SLM). Materials 2018, 11, 1821. [Google Scholar] [CrossRef] [Green Version]

- Sander, G.; Thomas, S.; Cruz, V.; Jurg, M.; Birbilis, N.; Gao, X.; Brameld, M.; Hutchinson, C.R. On The Corrosion and Metastable Pitting Characteristics of 316L Stainless Steel Produced by Selective Laser Melting. J. Electrochem. Soc. 2017, 164, C250–C257. [Google Scholar] [CrossRef]

- Sun, Y.; Moroz, A.; Alrbaey, K. Sliding wear characteristics and corrosion behaviour of selective laser melted 316L stainless steel. J. Mater. Eng. Perform. 2014, 23, 518–526. [Google Scholar] [CrossRef]

- Suryawanshi, J.; Baskaran, T.; Prakash, O.; Arya, S.B.; Ramamurty, U. On the corrosion resistance of some selective laser melted alloys. Materialia 2018, 3, 153–161. [Google Scholar] [CrossRef]

- Woźniak, A.; Adamiak, M.; Chladek, G.; Kasperski, J. The influence of the process parameters on the microstructure and properties SLM processed 316 L stainless steel. Arch. Metall. Mater. 2020, 65, 17–80. [Google Scholar] [CrossRef]

- Jones, D.A. Principles and Prevention of Corrosion; Macmillan: New York, NY, USA, 1992; ISBN 0023612150. [Google Scholar]

- Alhazaa, A.; Haneklaus, N. Diffusion bonding and transient liquid phase (TLP) bonding of type 304 and 316 austenitic stainless steel—A review of similar and dissimilar material joints. Metals 2020, 10, 613. [Google Scholar] [CrossRef]

- Nasar, S.; Baruch, L.J.; Vijay, S.J.; Srinivas, C.K.; Jose, J.; Popov, V.V. Comparative Study on H20 Steel Billets: Additive Manufacturing vs. Powder Metallurgy. Phys. Met. Metallogr. 2021, 122, 515–526. [Google Scholar] [CrossRef]

- Kale, A.; Kim, B.; Kim, D.; Castle, E.; Reece, M.; Choi, S.-H. An Investigation of the Corrosion Behavior of 316L Stainless Steel Fabricated by SLM and SPS Techniques; Elsevier: Amsterdam, The Netherlands, 2020. [Google Scholar]

- Gor, M.; Soni, H.; Wankhede, V.; Sahlot, P.; Grzelak, K.; Szachgluchowicz, I.; Kluczyński, J. A critical review on effect of process parameters on mechanical and microstructural properties of powder-bed fusion additive manufacturing of ss316l. Materials 2021, 14, 6527. [Google Scholar] [CrossRef]

- Liverani, E.; Toschi, S.; Ceschini, L.; Fortunato, A. Effect of selective laser melting (SLM) process parameters on microstructure and mechanical properties of 316L austenitic stainless steel. J. Mater. Process. Technol. 2017, 249, 255–263. [Google Scholar] [CrossRef]

- Hanzl, P.; Zetek, M.; Bakša, T.; Kroupa, T. The influence of processing parameters on the mechanical properties of SLM parts. Procedia Eng. 2015, 100, 1405–1413. [Google Scholar] [CrossRef] [Green Version]

- Li, R.; Liu, J.; Shi, Y.; Du, M.; Xie, Z. 316L stainless steel with gradient porosity fabricated by selective laser melting. J. Mater. Eng. Perform. 2010, 19, 666–671. [Google Scholar] [CrossRef]

- Montgomery, D.C. Design and Analysis of Experiments, 9th ed.; Wiley: Hoboken, NJ, USA, 2017; ISBN 9781119113478. Available online: https://lccn.loc.gov/2017002355 (accessed on 15 February 2021).

- Yang, K.; El-Haik, B. Taguchi’s Orthogonal Array Experiment. In Design for Six Sigma: A Roadmap for Product Development; McGraw-Hill: New York, NY, USA, 2008; pp. 469–497. ISBN 9780071547673. [Google Scholar]

- Wang, Y.M.; Voisin, T.; McKeown, J.T.; Ye, J.; Calta, N.P.; Li, Z.; Zeng, Z.; Zhang, Y.; Chen, W.; Roehling, T.T.; et al. Additively manufactured hierarchical stainless steels with high strength and ductility. Nat. Mater. 2018, 17, 63–70. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Example of Analyze Taguchi Design (Static)-Minitab. Available online: https://support.minitab.com/en-us/minitab/18/help-and-how-to/modeling-statistics/doe/how-to/taguchi/analyze-taguchi-design/before-you-start/example-of-analyzing-a-static-design/ (accessed on 7 February 2021).

- Sivaiah, P.; Chakradhar, D. Modeling and optimization of sustainable manufacturing process in machining of 17-4 PH stainless steel. Meas. J. Int. Meas. Confed. 2019, 134, 142–152. [Google Scholar] [CrossRef]

- Methods and Formulas for Analyze Taguchi Design-Minitab. Available online: https://support.minitab.com/en-us/minitab/18/help-and-how-to/modeling-statistics/doe/how-to/taguchi/analyze-taguchi-design/methods-and-formulas/methods-and-formulas/ (accessed on 7 February 2021).

- Dzukey, G.A.; Yang, K. Process Parameter Optimization for Selective Laser Melting of 316L Stainless Steel Material using Taguchi’s Statistical Design of Experiment Procedure. Int. J. Eng. Technol. 2019, 11, 6–13. [Google Scholar] [CrossRef] [Green Version]

- Gu, D.; Shen, Y. Balling phenomena in direct laser sintering of stainless steel powder: Metallurgical mechanisms and control methods. Mater. Des. 2009, 30, 2903–2910. [Google Scholar] [CrossRef]

- Tolosa, I.; Garciandía, F.; Zubiri, F. Study of mechanical properties of AISI 316 stainless steel processed by “selective laser melting”, following different manufacturing strategies. Int. J. Adv. Manuf. Technol. 2010, 639–647. [Google Scholar] [CrossRef]

- Sistiaga, M.L.M.; Nardone, S.; Hautfenne, C.; van Humbeeck, J. Effect of heat treatment of 316L stainless steel produced by selective laser melting (SLM). In Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 8–10 July 2016; pp. 558–565. [Google Scholar]

- Chao, Q.; Cruz, V.; Thomas, S.; Birbilis, N.; Collins, P.; Taylor, A.; Hodgson, P.D.; Fabijanic, D. On the enhanced corrosion resistance of a selective laser melted austenitic stainless steel. Scr. Mater. 2017, 141, 94–98. [Google Scholar] [CrossRef]

- Frankel, G.S.; Li, T.; Scully, J.R. Perspective—Localized Corrosion: Passive Film Breakdown vs Pit Growth Stability. J. Electrochem. Soc. 2017, 164, C180–C181. [Google Scholar] [CrossRef]

- Kong, D.; Dong, C.; Ni, X.; Li, X. Corrosion of metallic materials fabricated by selective laser melting. npj Mater. Degrad. 2019, 3, 24. [Google Scholar] [CrossRef]

- Trelewicz, J.R.; Halada, G.P.; Donaldson, O.K.; Manogharan, G. Microstructure and Corrosion Resistance of Laser Additively Manufactured 316L Stainless Steel. JOM 2016, 68, 850–859. [Google Scholar] [CrossRef]

- Kong, D.; Dong, C.; Ni, X.; Zhang, L.; Luo, H.; Li, R.; Wang, L.; Man, C.; Li, X. The passivity of selective laser melted 316L stainless steel. Appl. Surf. Sci. 2020, 504, 144495. [Google Scholar] [CrossRef]

| Element | C | Cr | Ni | Mo | Si | Mn | S | Fe |

|---|---|---|---|---|---|---|---|---|

| Mass fraction (%) | 0.03 | 16.5–18 | 10–13 | 2–2.5 | 0–1 | 0–2 | 0–0.03 | Balance |

| Laser Energy (W) | Hatch Spacing (mm) | Layer Thickness (mm) | Scanning Speed (mm/s) | Energy Density (J/mm3) | No. Runs |

|---|---|---|---|---|---|

| 150 | 0.115 | 0.025 | 400 | 130.43 | 1 |

| 700 | 74.53 | 2 | |||

| 1000 | 52.17 | 3 | |||

| 180 | 0.115 | 0.025 | 400 | 156.52 | 4 |

| 700 | 89.44 | 5 | |||

| 1000 | 62.61 | 6 | |||

| 200 | 0.115 | 0.025 | 400 | 173.91 | 7 |

| 700 | 99.38 | 8 | |||

| 1000 | 69.56 | 9 |

| Factors | Units | Levels | ||

|---|---|---|---|---|

| 1 | 2 | 3 | ||

| Laser energy | W | 150 | 180 | 200 |

| Scanning speed | mm/s | 400 | 700 | 1000 |

| Position (XOZ) | # | 2 | 5 | 8 |

| Sample | Ecorr | Epit | Erep | ipass | Porosity (%) |

|---|---|---|---|---|---|

| 3.2 | −0.1054 | 0.7637 | −0.0634 | 1.63 × 10−6 | 12.01 |

| 3.5 | −0.0694 | 0.5154 | −0.0339 | 3.91 × 10−6 | 8.16 |

| 3.8 | −0.1127 | 0.7050 | −0.1107 | 4.18 × 10−6 | 7.74 |

| 5.2 | 0.0085 | 1.0807 | * | 0.92 × 10−6 | 0.72 |

| 5.5 | −0.0566 | 1.1325 | 0.5410 | 1.31 × 10−6 | 0.43 |

| 5.8 | −0.0772 | 1.1440 | * | 0.86 × 10−6 | 0.26 |

| 7.2 | −0.1193 | 0.9814 | 0.5573 | 1.00 × 10−6 | 1.10 |

| 7.5 | −0.0682 | 1.1187 | 0.3968 | 0.75 × 10−6 | 0.84 |

| 7.8 | −0.0825 | 1.1447 | 0.1573 | 1.04 × 10−6 | 0.47 |

| CM | 0.0085 | 0.3831 | 0.1690 | 4.71 × 10−6 | 0.00 |

| Exp. Runs | Factors | Experimental Results | S/N Ratios of Results | ||

|---|---|---|---|---|---|

| # (XOZ) | Porosity (%) | Porosity (dB) | |||

| 1 | 150 | 400 | 2 | 0.27 | 11.3727 |

| 2 | 150 | 700 | 5 | 0.07 | 23.098 |

| 3 | 150 | 1000 | 8 | 7.74 | −17.7748 |

| 4 | 180 | 400 | 5 | 0.09 | 20.9151 |

| 5 | 180 | 700 | 8 | 0.26 | 11.7005 |

| 6 | 180 | 1000 | 2 | 1.57 | −3.918 |

| 7 | 200 | 400 | 8 | 0.47 | 6.558 |

| 8 | 200 | 700 | 2 | 0.08 | 21.9382 |

| 9 | 200 | 1000 | 5 | 0.92 | 0.7242 |

| Symbol | Process Parameters | Mean S/N Ratio | ||||

|---|---|---|---|---|---|---|

| Level 1 | Level 2 | Level 3 | Max–Min | Rank | ||

| Laser energy (W) | 5.565 | 9.565 | 9.74 | 4.175 | 3 | |

| Scanning speed(mm/s) | 12.948 | 18.912 | −6.989 | 25.901 | 1 | |

| # | Position (XOZ) | 9.797 | 14.912 | 0.161 | 14.751 | 2 |

| Optimal Process Parameters | Optimal Process Parameters | |

|---|---|---|

| (Supplier) | (Taguchi) | |

| Level | ||

| Porosity (%) | 0.43 | 0.05 |

| Percentage reduction of porosity | 88.37% |

| Factors | Degree of Freedom | Sum of Squares | Mean Squares | %Contribution |

|---|---|---|---|---|

| Laser energy Scanning speed Position Total | 2 2 2 8 | 33.46 1104.00 336.62 1474.73 | 16.732 551.999 168.310 | 2.268% 74.861% 22.825% |

| Run | Experimental | Predicted | Residuals |

|---|---|---|---|

| Porosity (%) | Porosity (%) | Porosity (%) | |

| 1 | 7.75 | 7.62 | 0.13 |

| 4 | 0.08 | 0.01 | 0.07 |

| 7 | 0.34 | 0.13 | 0.21 |

| 9 | 0.45 | 0.43 | 0.02 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maicas-Esteve, H.; Taji, I.; Wilms, M.; Gonzalez-Garcia, Y.; Johnsen, R. Corrosion and Microstructural Investigation on Additively Manufactured 316L Stainless Steel: Experimental and Statistical Approach. Materials 2022, 15, 1605. https://doi.org/10.3390/ma15041605

Maicas-Esteve H, Taji I, Wilms M, Gonzalez-Garcia Y, Johnsen R. Corrosion and Microstructural Investigation on Additively Manufactured 316L Stainless Steel: Experimental and Statistical Approach. Materials. 2022; 15(4):1605. https://doi.org/10.3390/ma15041605

Chicago/Turabian StyleMaicas-Esteve, Héctor, Iman Taji, Marc Wilms, Yaiza Gonzalez-Garcia, and Roy Johnsen. 2022. "Corrosion and Microstructural Investigation on Additively Manufactured 316L Stainless Steel: Experimental and Statistical Approach" Materials 15, no. 4: 1605. https://doi.org/10.3390/ma15041605

APA StyleMaicas-Esteve, H., Taji, I., Wilms, M., Gonzalez-Garcia, Y., & Johnsen, R. (2022). Corrosion and Microstructural Investigation on Additively Manufactured 316L Stainless Steel: Experimental and Statistical Approach. Materials, 15(4), 1605. https://doi.org/10.3390/ma15041605