Iron-Based Shape Memory Alloys in Construction: Research, Applications and Opportunities

Abstract

:1. Introduction

2. Basic Properties

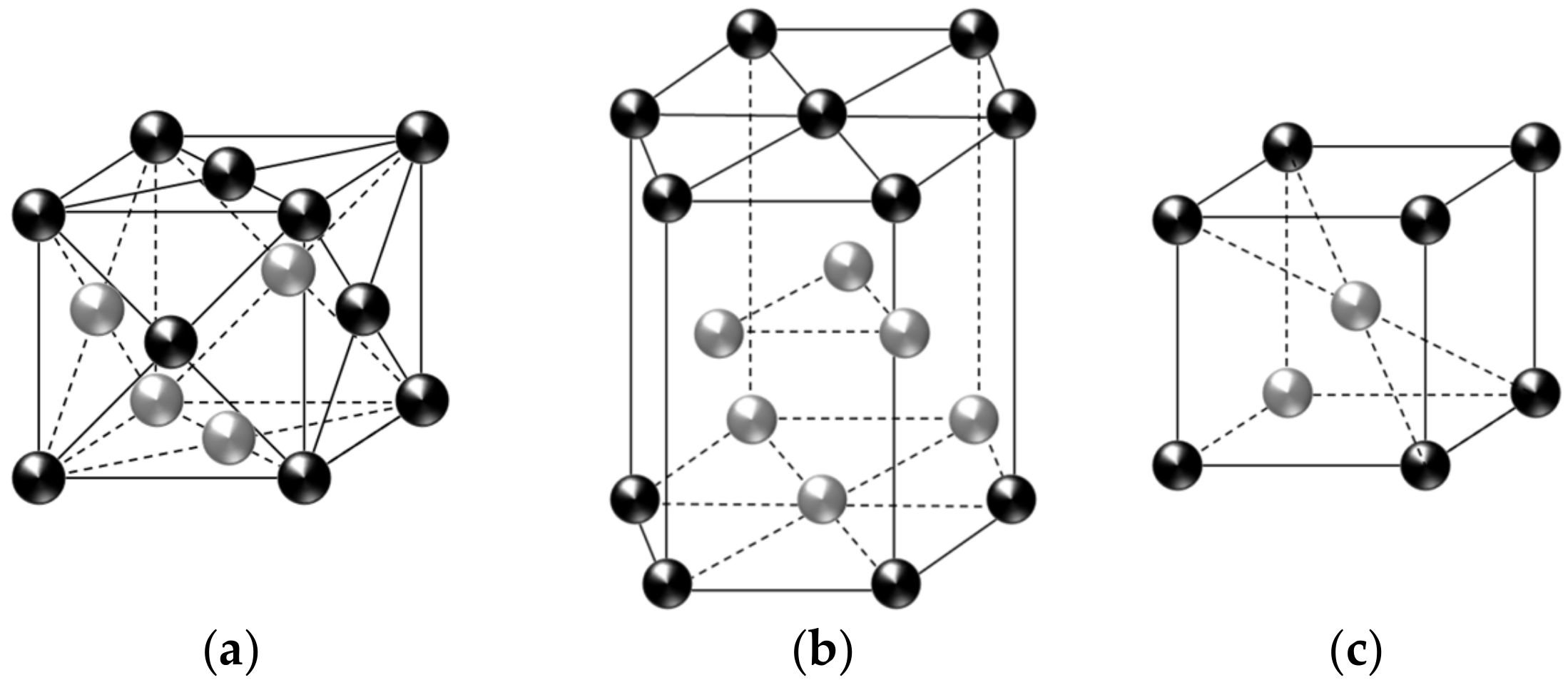

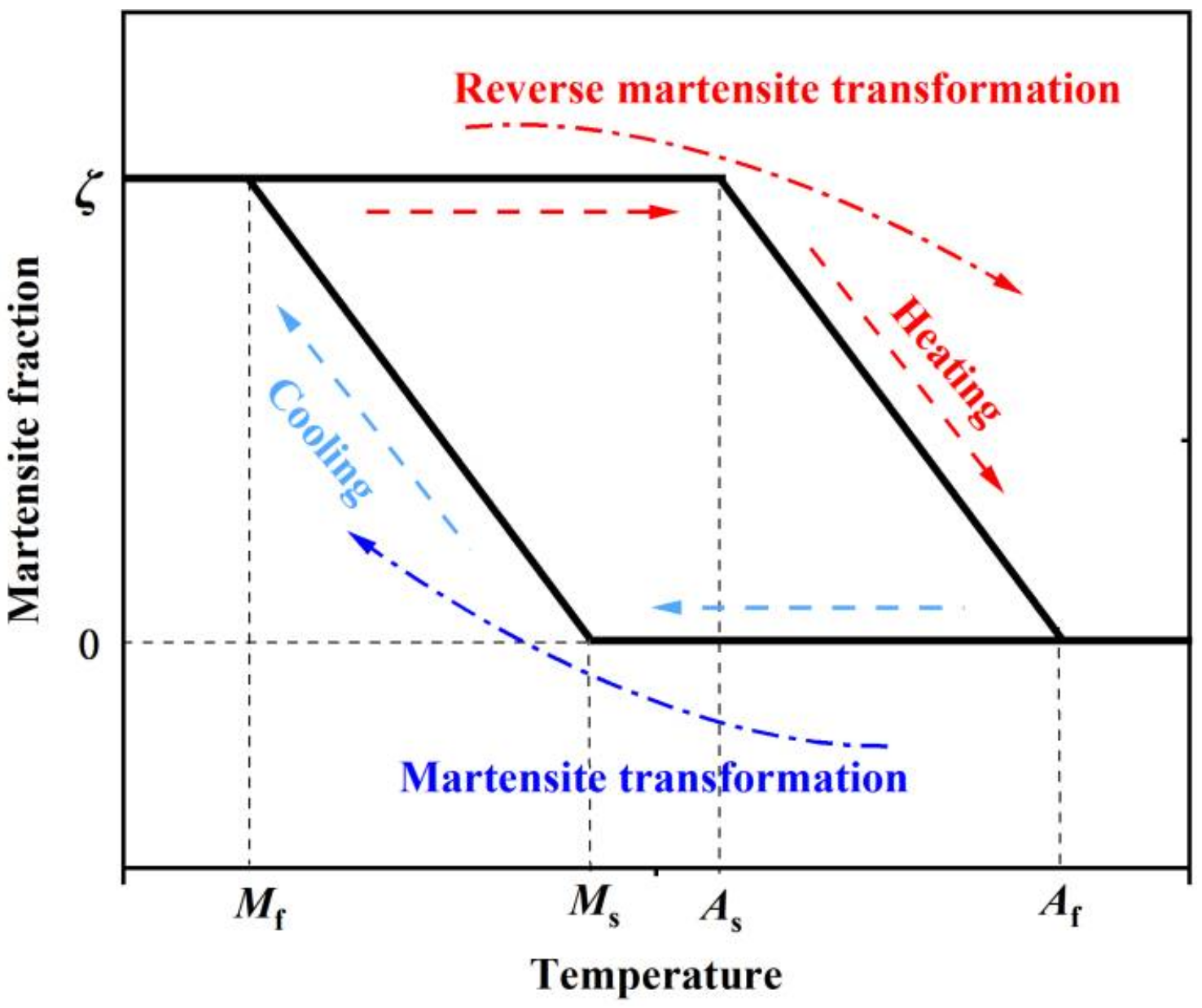

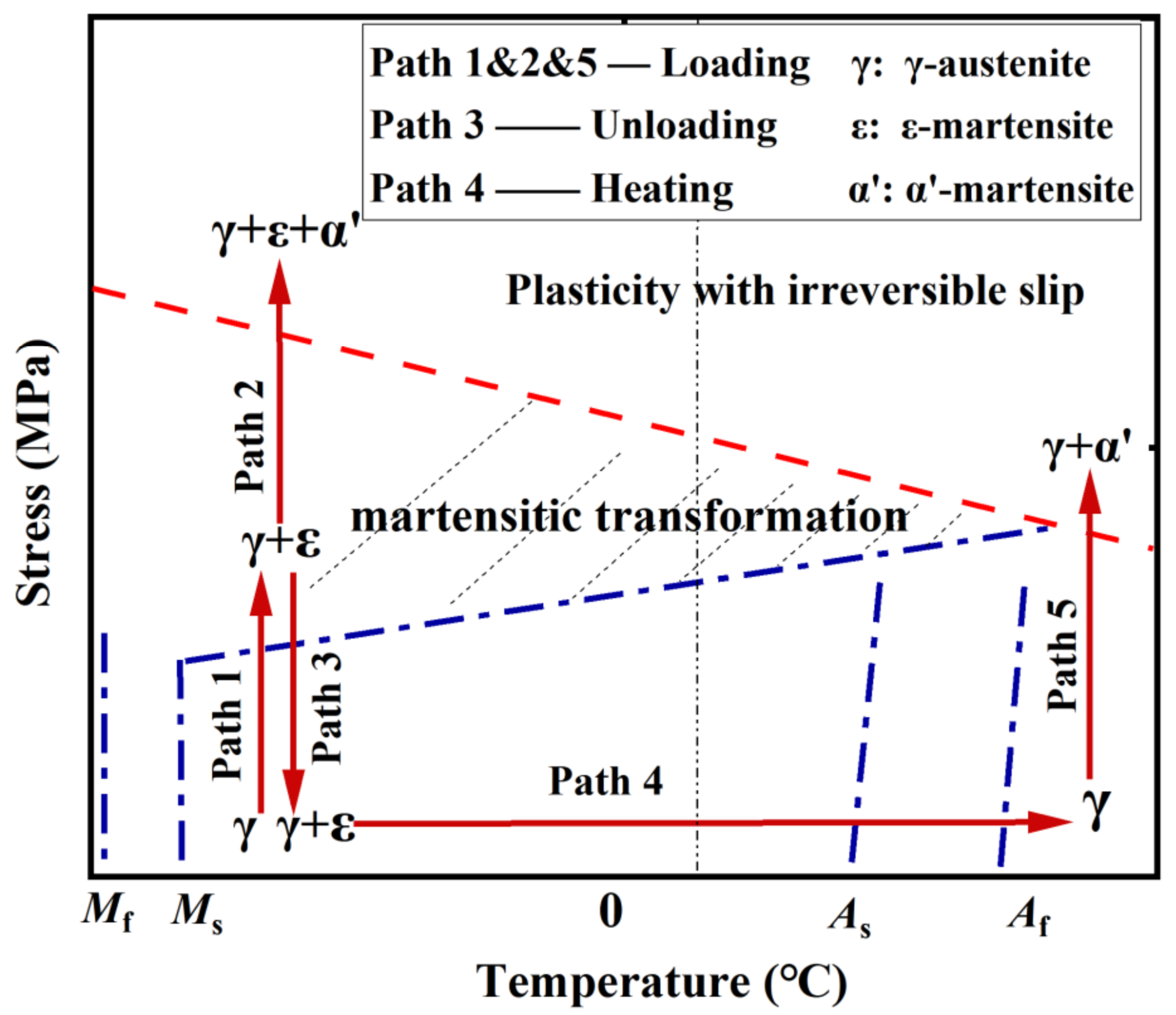

2.1. Metallographic Transformation in Fe-SMA

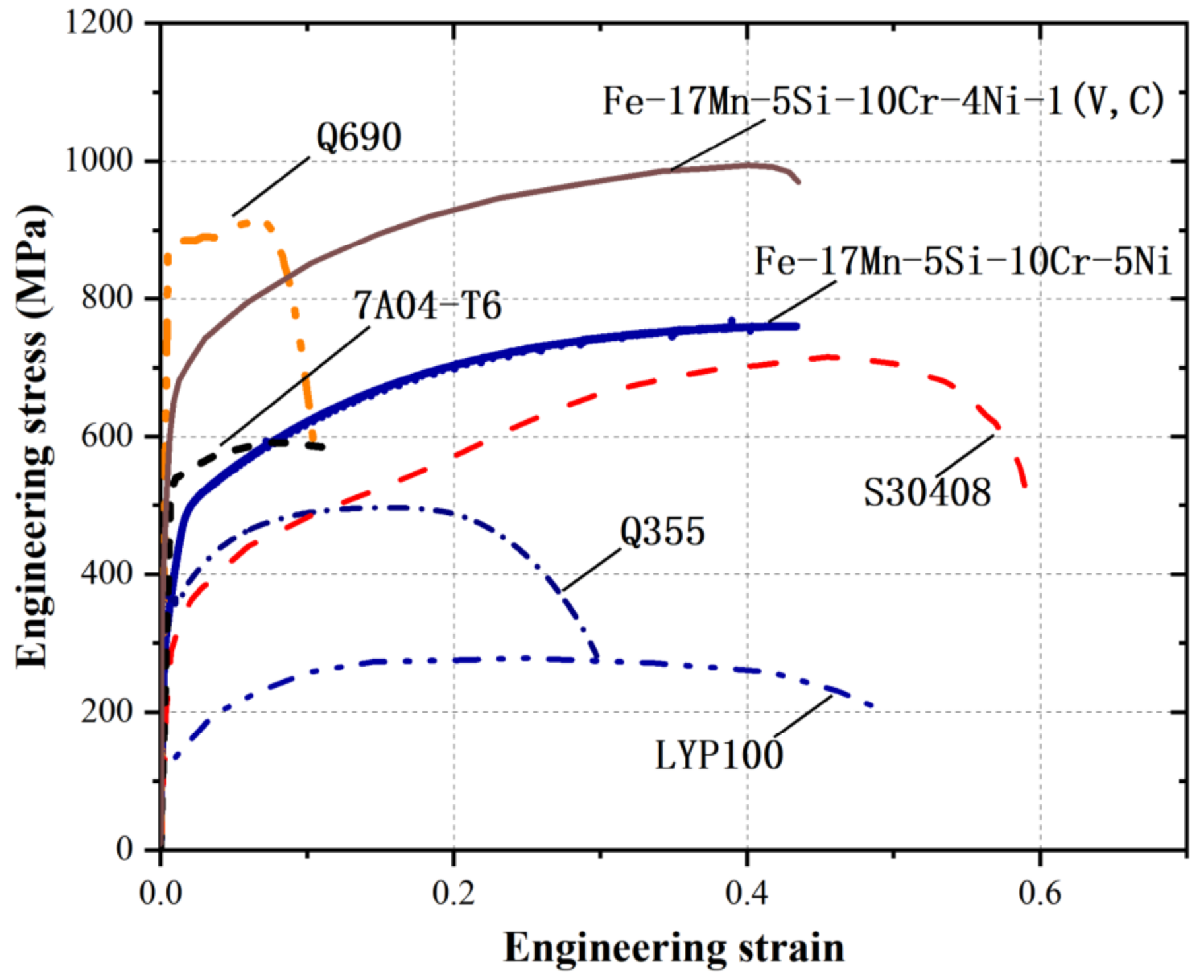

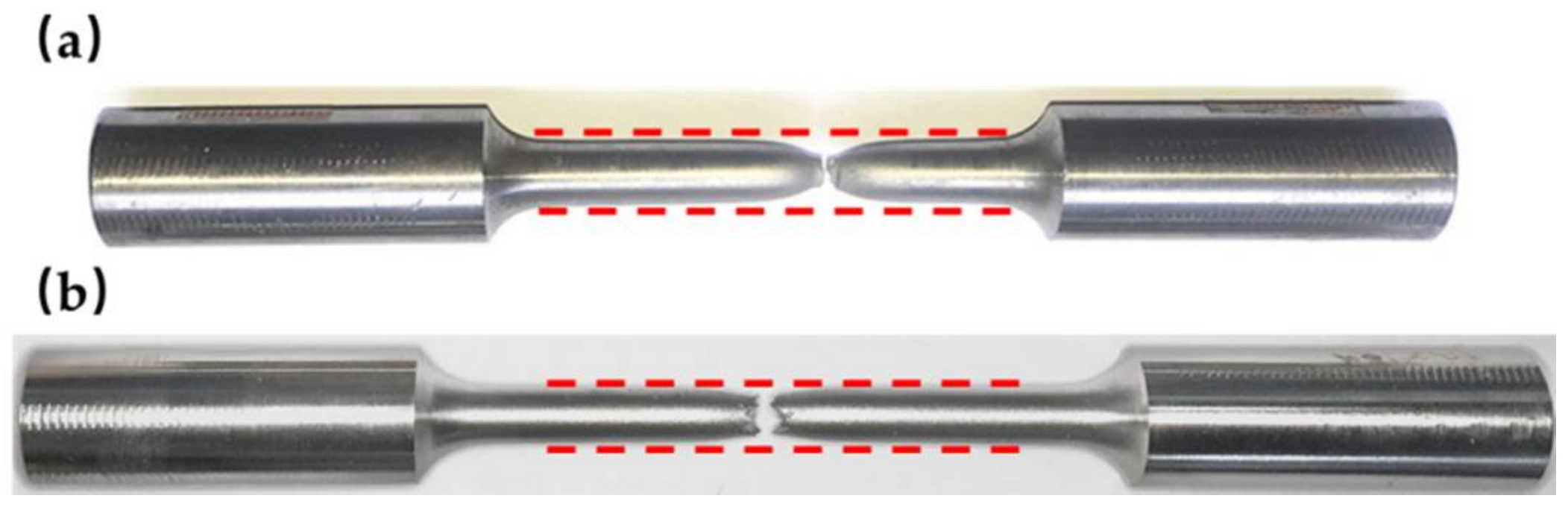

2.2. Monotonic Loading Property

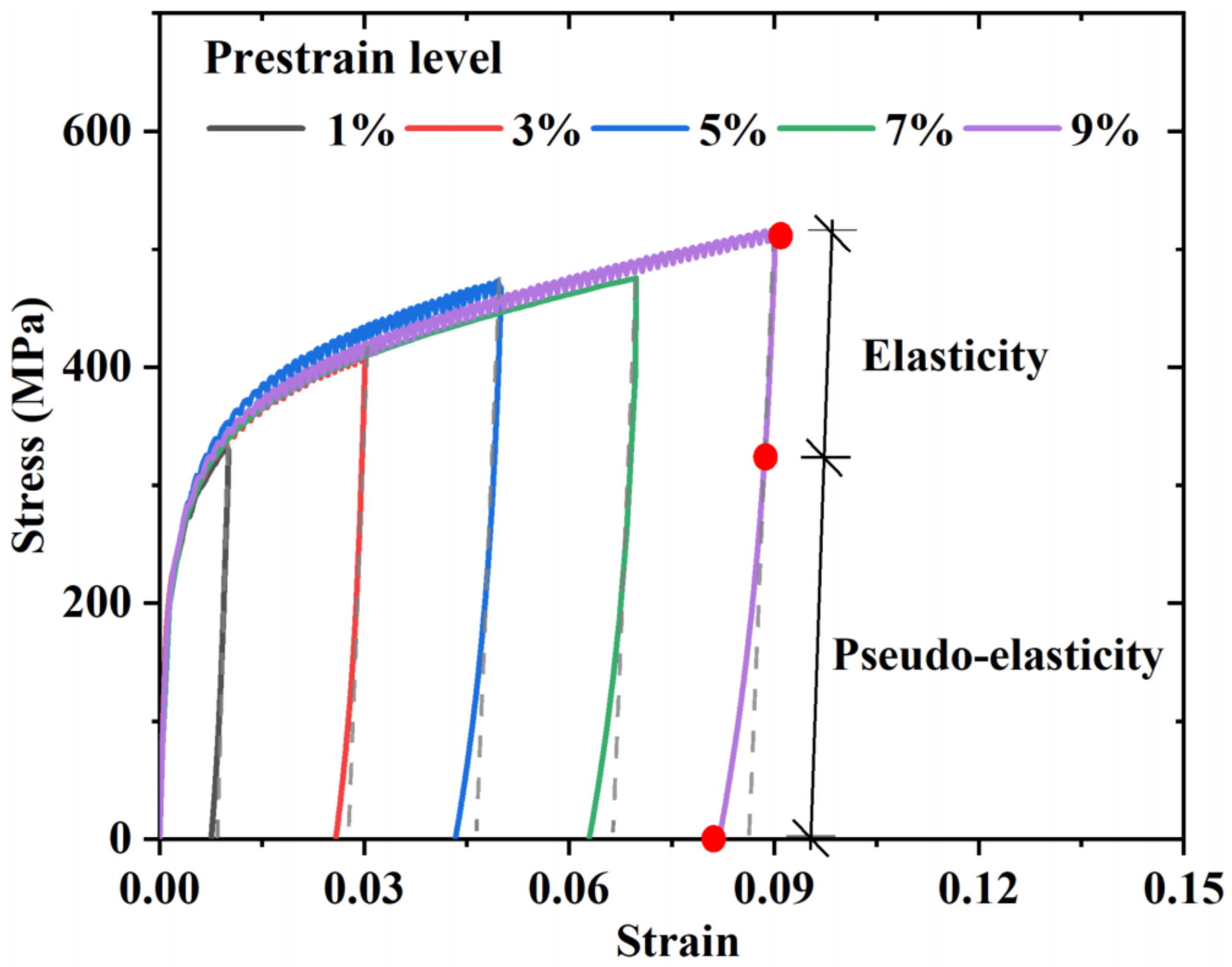

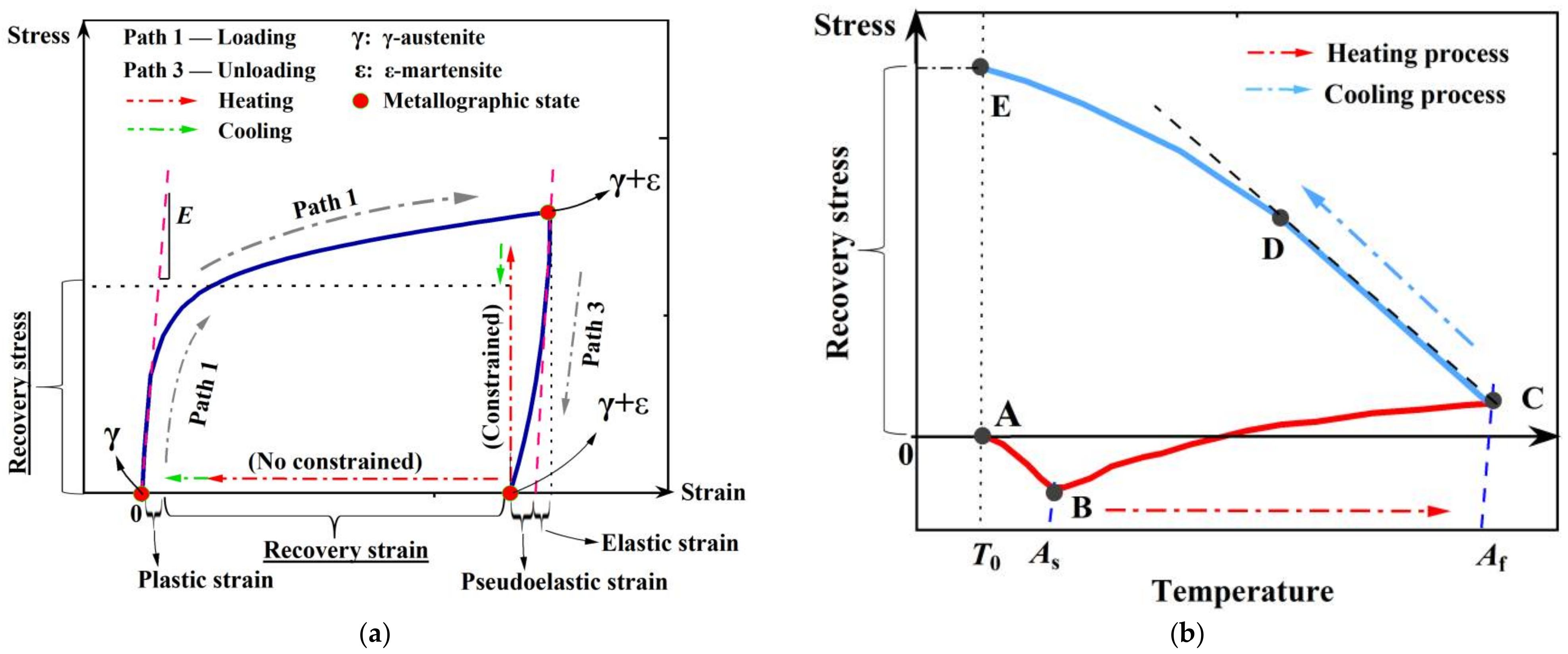

2.3. Pseudo-Elasticity and Shape Recovery Property

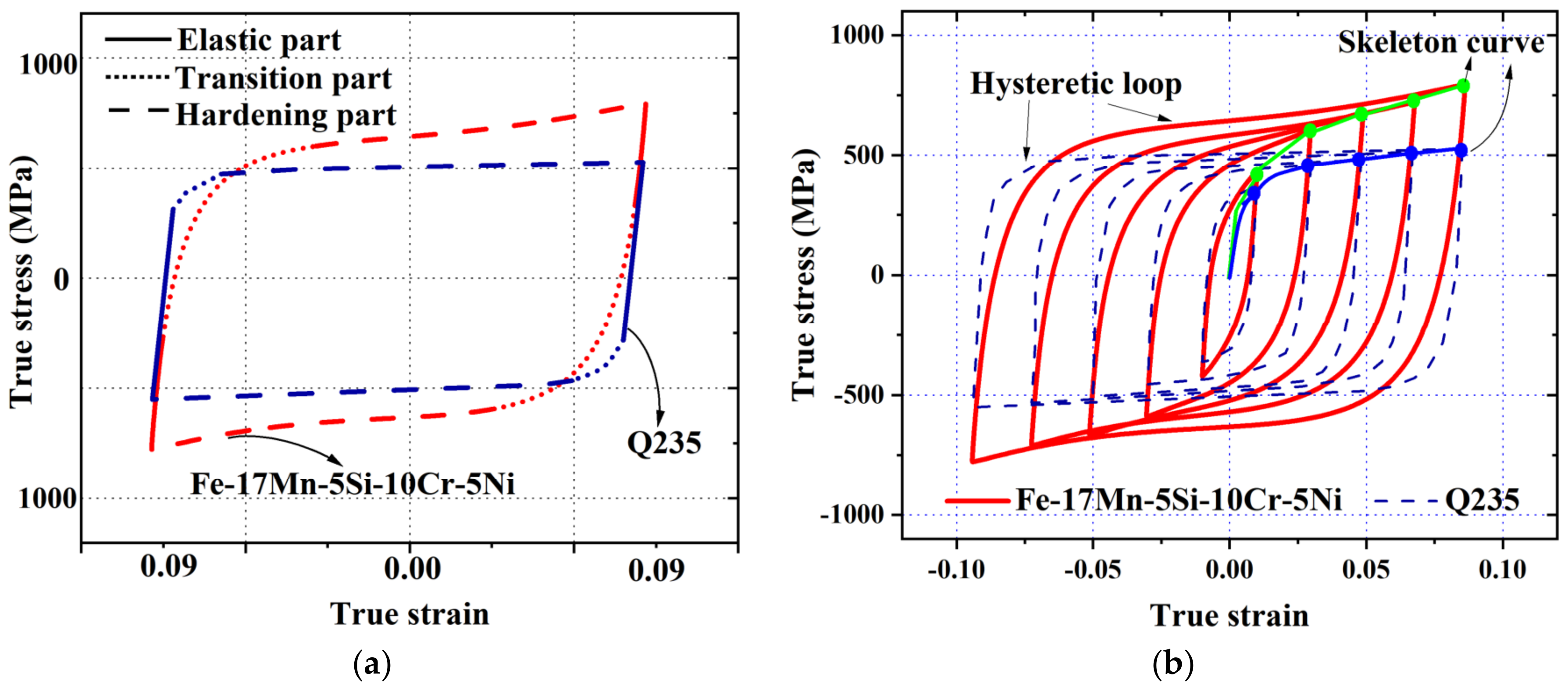

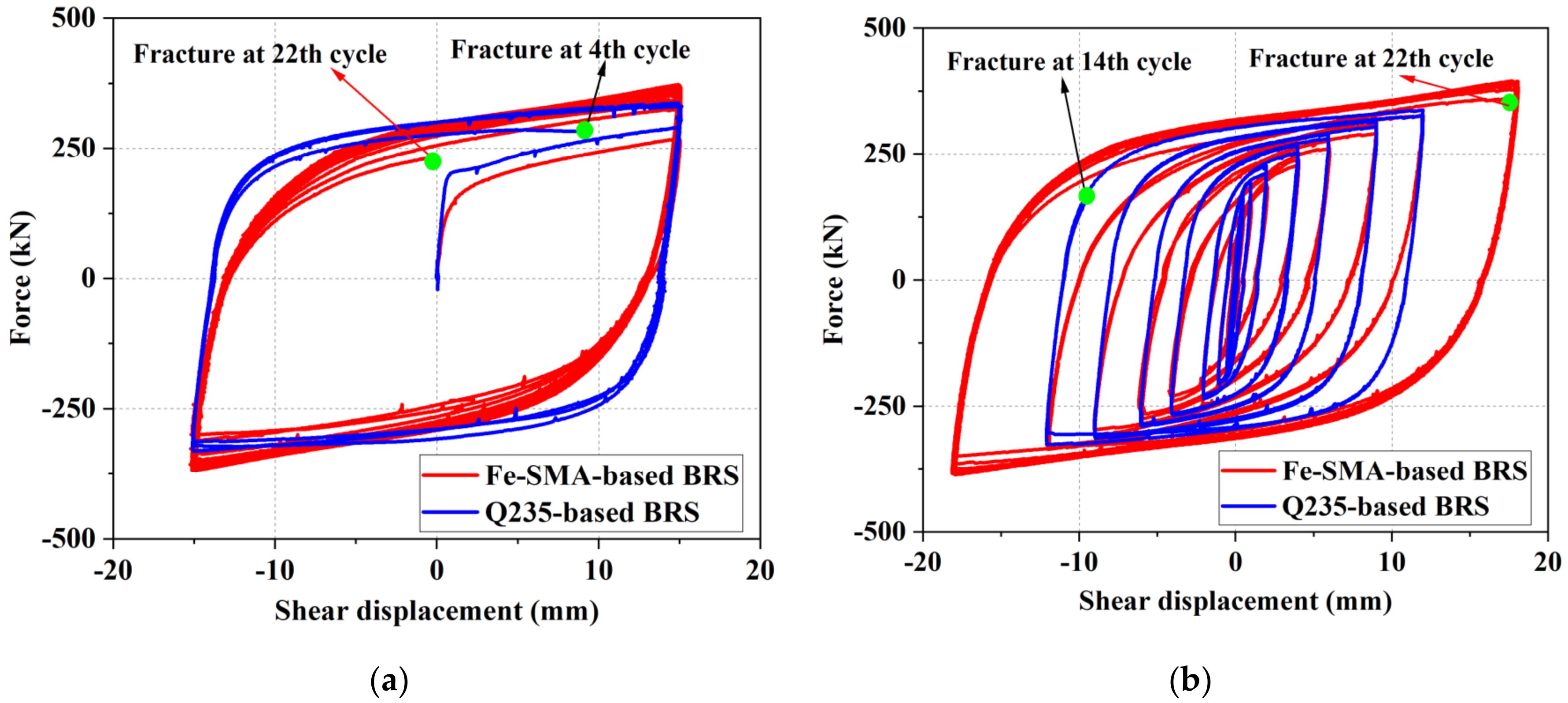

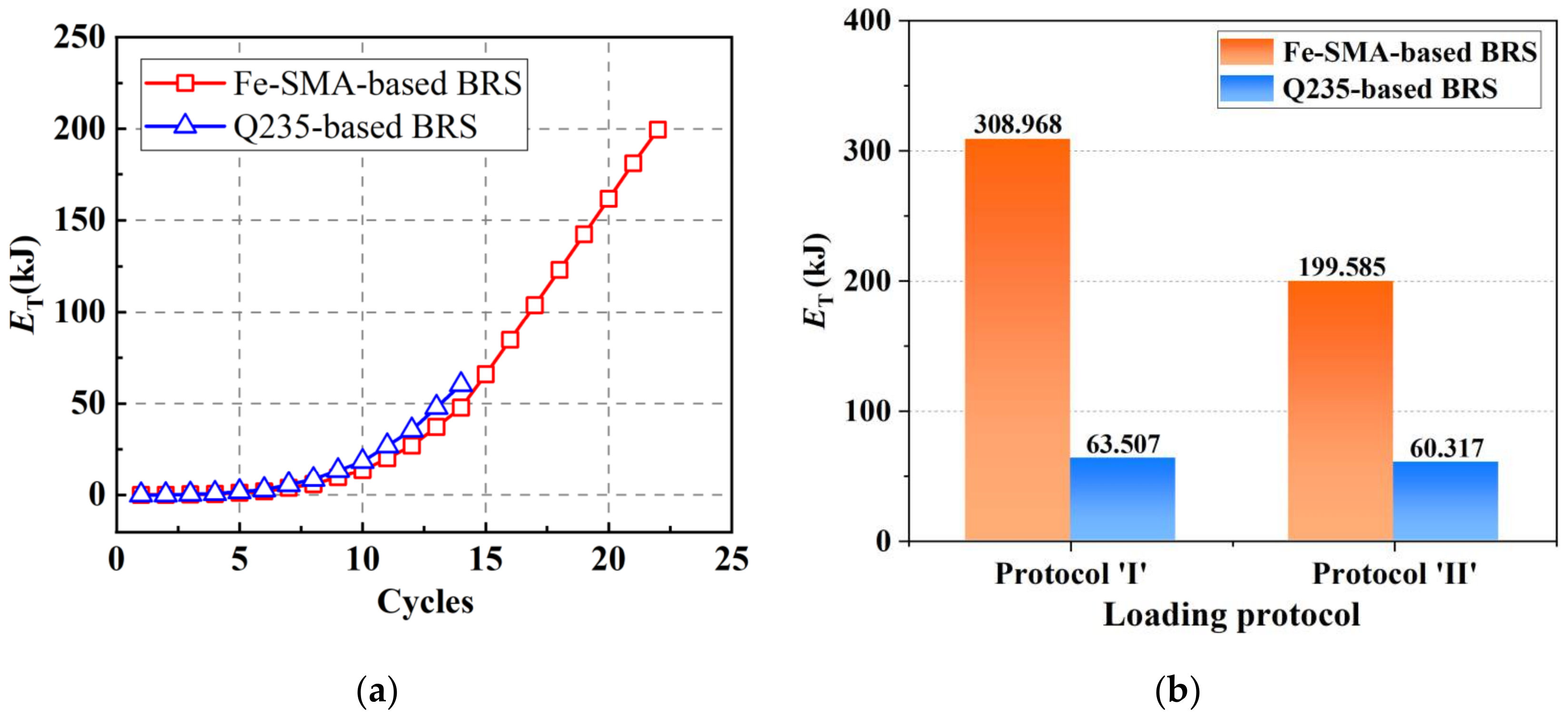

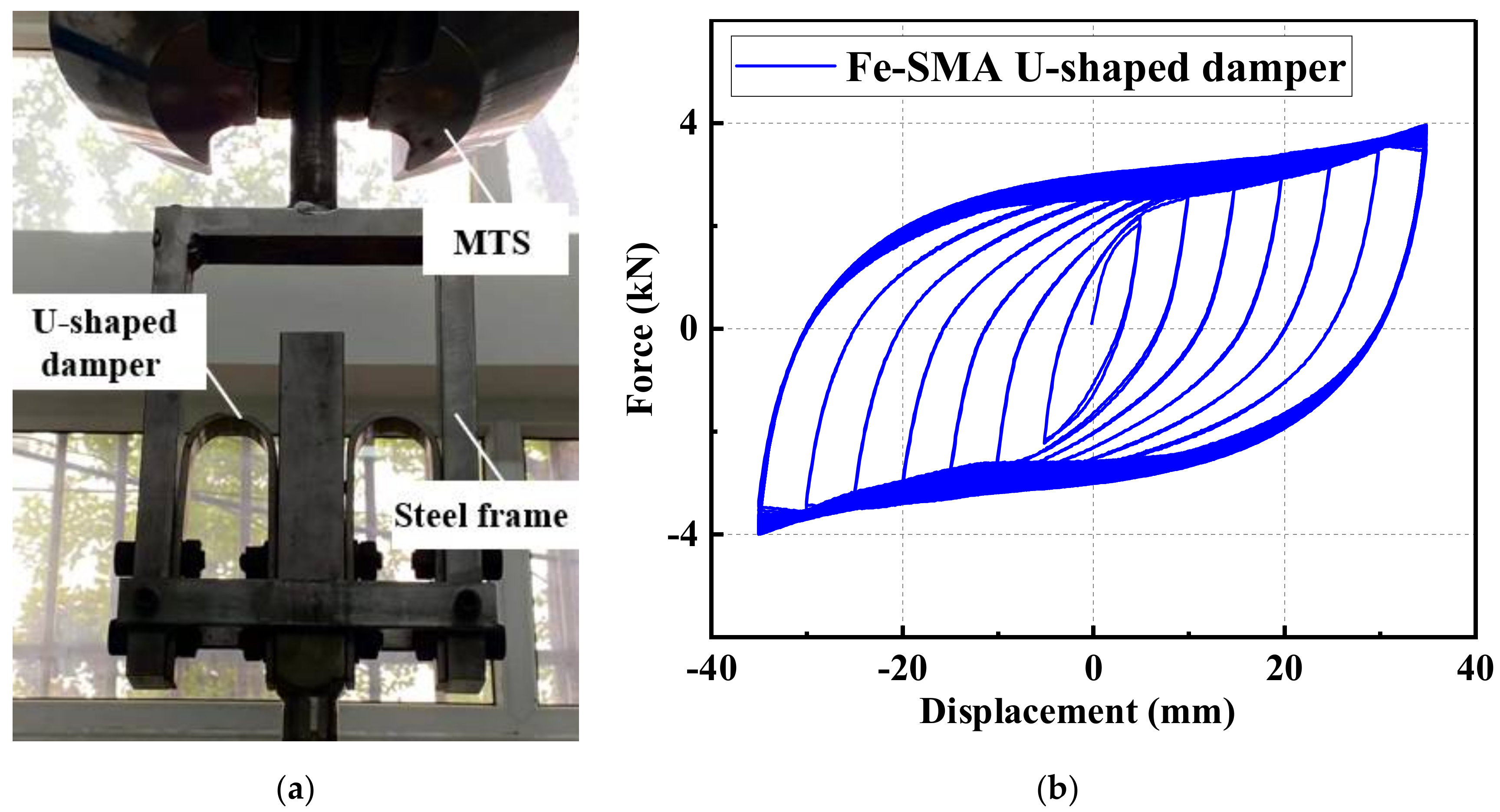

2.4. Cyclic Behavior, Low Cycle Fatigue and Energy Dissipation Capacity

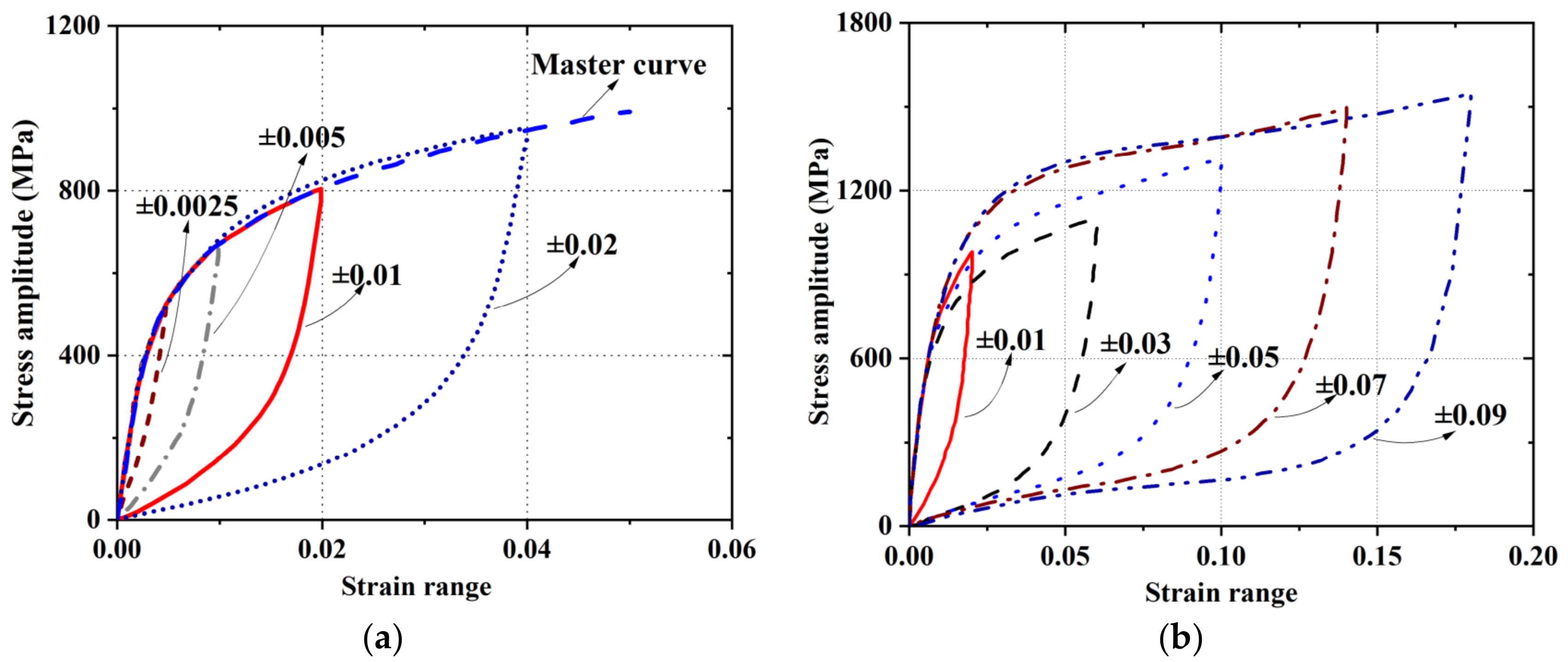

2.4.1. Hysteretic Behavior

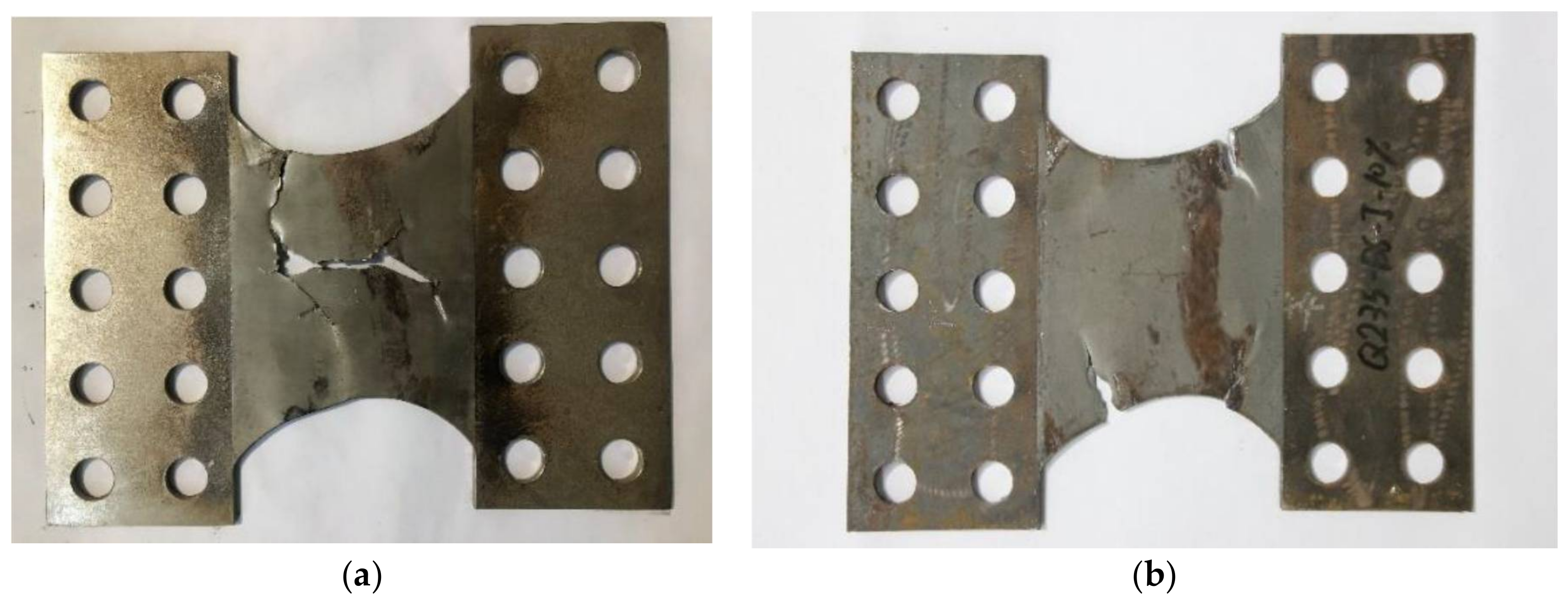

2.4.2. Low Cycle Fatigue (LCF) Behavior

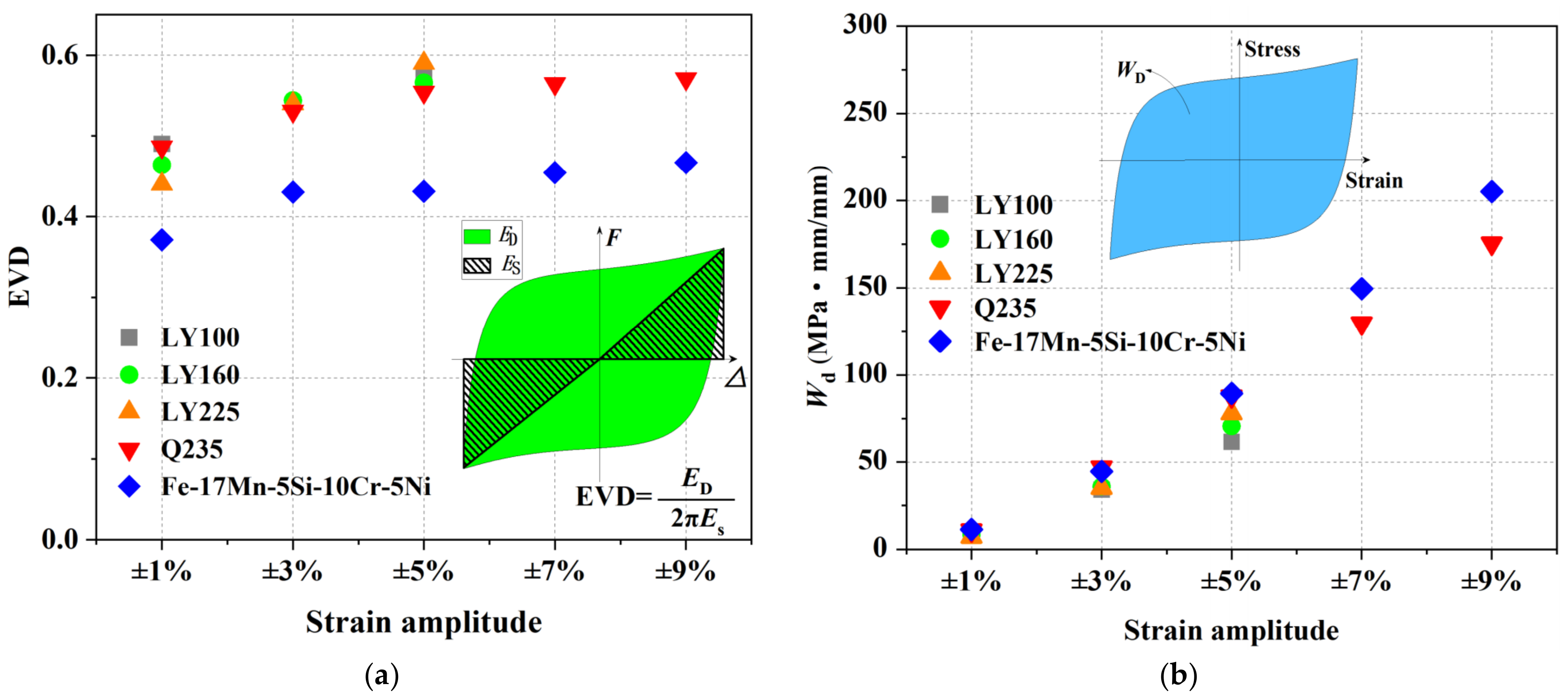

2.4.3. Energy Dissipation

3. Research and Potential Engineering Applications

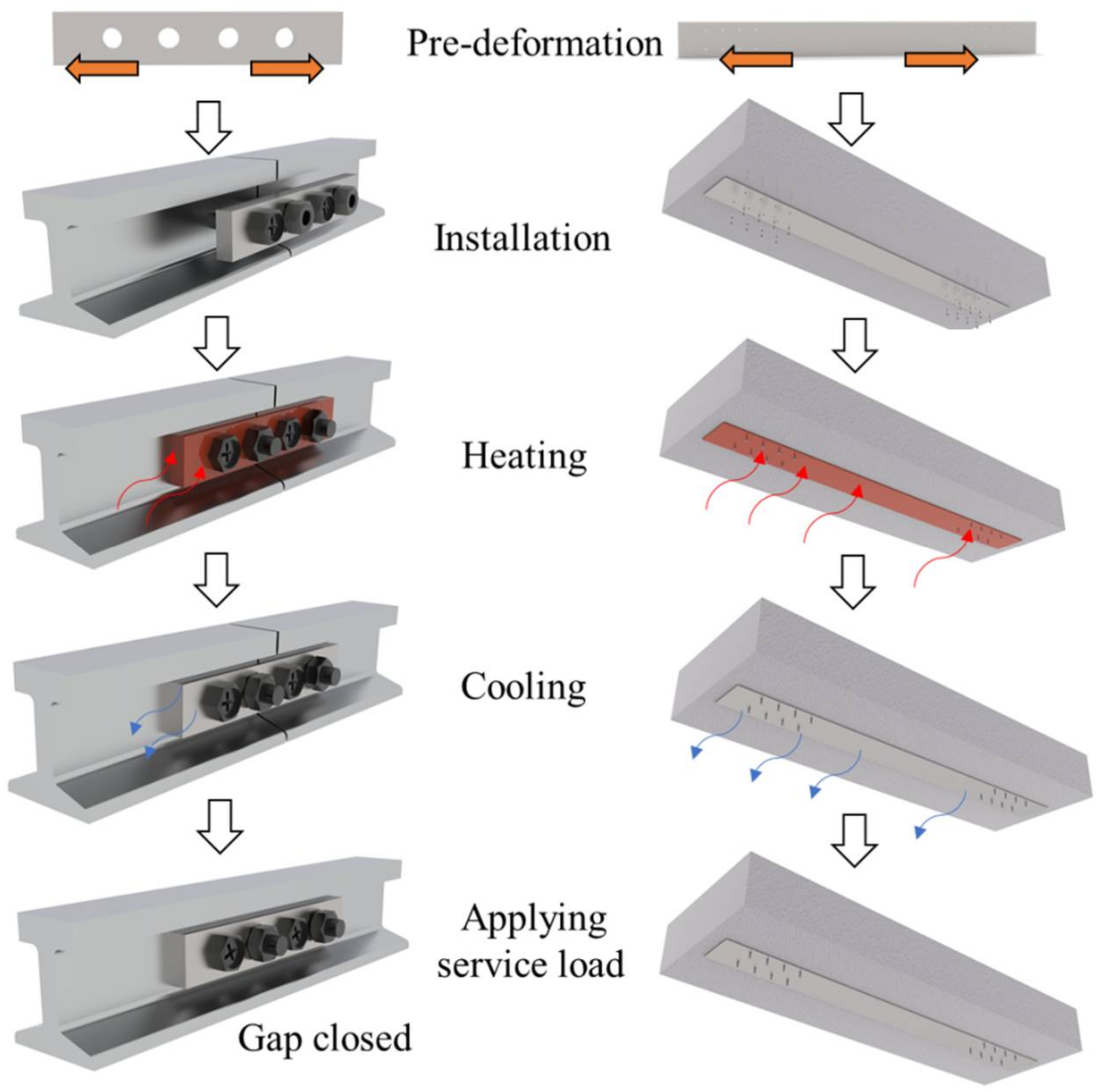

3.1. Novel Strengthening Solution Based on SME of Fe-SMA

- (1)

- Pre-deform (for most cases, pre-tension) the Fe-SMA elements to a preset strain value or the expected shape;

- (2)

- Connect the pre-deformed Fe-SMA elements to the base components (i.e., those ready for strengthening or connecting);

- (3)

- Apply electric heating (or infrared heating) to the pre-deformed Fe-SMA elements to a preset temperature and keep it for a short period of time to guarantee fully activated SME;

- (4)

- Wait until the Fe-SMA elements cool down to room temperature, and recovery stress is generated;

- (5)

- The structures then return to normal service state.

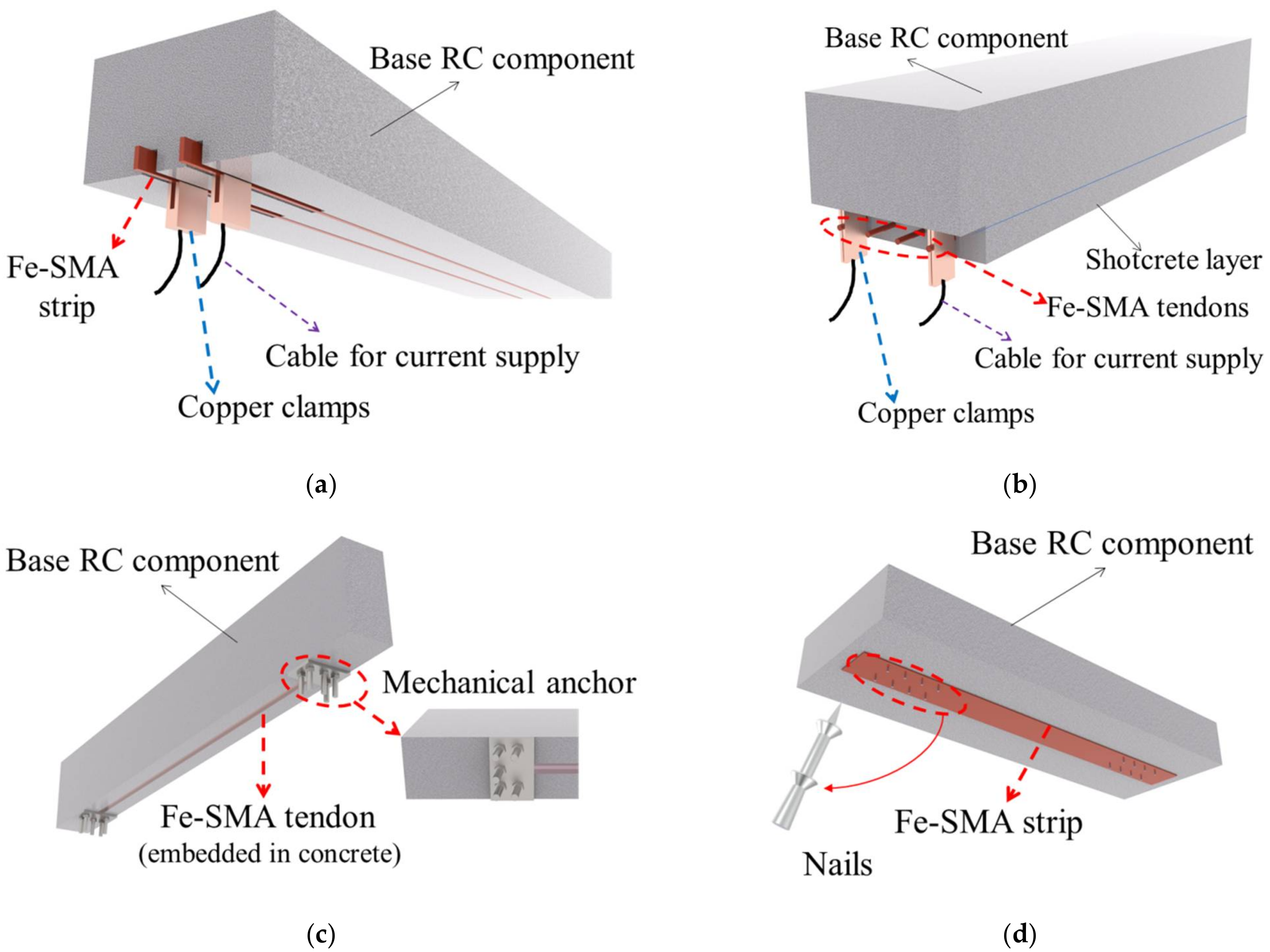

3.1.1. Strengthening for Reinforced Concrete (RC) Structures

3.1.2. Strengthening for Steel Structures

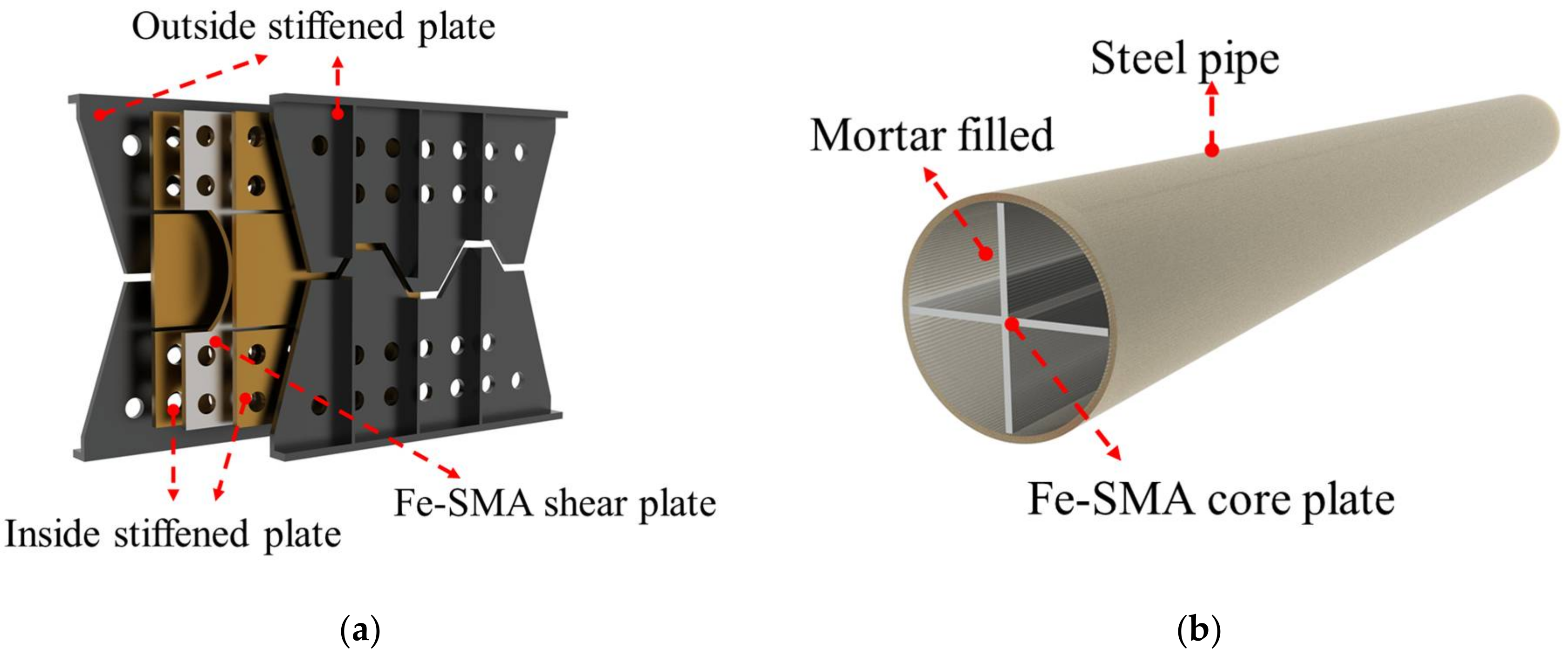

3.2. Seismic Dampers

3.3. Advantages Compared with Alternative Solutions

4. Further Research Needs

5. Concluding Remarks

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sato, A.; Chishima, E.; Soma, K.; Mori, T. Shape memory effect in gamma-ebsel transformation in Fe-30Mn-1Si alloy single crystals. Acta Metall. 1982, 30, 1177–1183. [Google Scholar] [CrossRef]

- Sato, A.; Mori, T. Development of a shape memory alloy Fe-Mn-Si. Mater. Sci. Eng. A 1991, 146, 197–204. [Google Scholar] [CrossRef]

- Sawaguchi, T.; Kikuchi, T.; Ogawa, K.; Yin, F.X.; Kajiwara, S.; Kushibe, A.; Ogawa, T. Internal Friction of Fe-Mn-Si-Based Shape Memory Alloys Containing Nb and C and Their Application as a Seismic Damping Material. Key Eng. Mater. 2006, 319, 53–58. [Google Scholar] [CrossRef]

- Lee, W.J.; Weber, B.; Leinenbach, C. Recovery stress formation in a restrained Fe–Mn–Si-based shape memory alloy used for prestressing or mechanical joining. Constr. Build. Mater. 2015, 95, 600–610. [Google Scholar] [CrossRef]

- Cladera, A.; Weber, B.; Leinenbach, C.; Czaderski, C.; Shahverdi, M.; Motavalli, M. Iron-based shape memory alloys for civil engineering structures: An overview. Constr. Build. Mater. 2014, 63, 281–293. [Google Scholar] [CrossRef]

- Fang, C.; Yam, M.C.H.; Ma, H.; Chung, K.F. Tests on superelastic Ni–Ti SMA bars under cyclic tension and direct-shear: Towards practical recentring connections. Mater. Struct. 2013, 48, 1013–1030. [Google Scholar] [CrossRef]

- Fang, C.; Zhou, X.; Osofero, A.; Shu, Z.; Corradi, M. Superelastic SMA Belleville washers for seismic resisting applications: Experimental study and modelling strategy. Smart Mater. Struct. 2016, 25, 105013. [Google Scholar] [CrossRef] [Green Version]

- Wang, W.; Fang, C.; Liu, J. Large size superelastic SMA bars: Heat treatment strategy, mechanical property and seismic application. Smart Mater. Struct. 2016, 25, 075001. [Google Scholar] [CrossRef]

- Sawaguchi, T.; Maruyama, T.; Otsuka, H.; Kushibe, A.; Inoue, Y.; Tsuzaki, K. Design Concept and Applications of Fe–Mn–Si-Based Alloys—from Shape-Memory to Seismic Response Control. Mater. Trans. 2016, 57, 283–293. [Google Scholar] [CrossRef] [Green Version]

- Janke, L. Applications of shape memory alloys in civil engineering structures—Overview, limits and new ideas. Mater. Struct. 2005, 38, 578–592. [Google Scholar]

- Lu, M. Handbook of Practical Mechanical Engineering Materials; Liaoning Science and Technology Press: Shenyang, China, 2004. [Google Scholar]

- General Administration of Quality Supervision Inspection and Quarantine of the People’s Republic of China. General Administration of Quality Supervision Inspection and Quarantine of the People’s Republic of China, Stainless and Heat-Resisting Steels-Designation and Chemical Composition: GB/T 20878-2007; Standards Press of China: Beijing, China, 2007. [Google Scholar]

- Mohd Jani, J.; Leary, M.; Subic, A.; Gibson, M.A. A review of shape memory alloy research, applications and opportunities. Mater. Des. 2014, 56, 1078–1113. [Google Scholar] [CrossRef]

- Dong, Z.; Klotz, U.E.; Leinenbach, C.; Bergamini, A.; Czaderski, C.; Motavalli, M. A Novel Fe-Mn-Si Shape Memory Alloy with Improved Shape Recovery Properties by VC Precipitation. Adv. Eng. Mater. 2009, 11, 40–44. [Google Scholar] [CrossRef]

- Lee, W.J.; Weber, B.; Feltrin, G.; Czaderski, C.; Motavalli, M.; Leinenbach, C. Phase transformation behavior under uniaxial deformation of an Fe–Mn–Si–Cr–Ni–VC shape memory alloy. Mater. Sci. Eng. A 2013, 581, 1–7. [Google Scholar] [CrossRef]

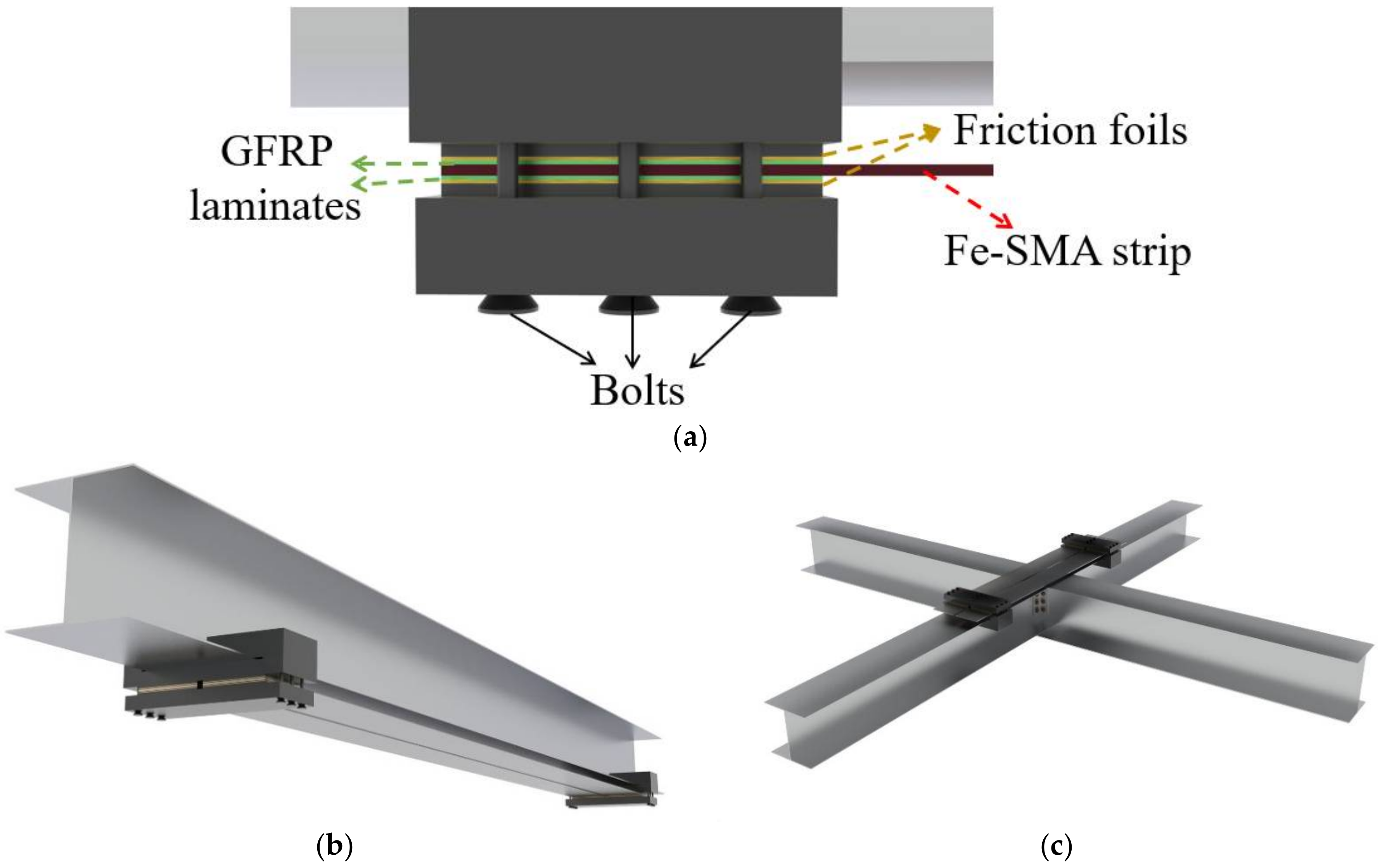

- Chen, J.; Wang, W.; Fang, C. Manufacturing, testing and simulation of novel SMA-based variable friction dampers with enhanced deformability. J. Build. Eng. 2021, 45, 103513. [Google Scholar] [CrossRef]

- Maruyama, T.; Kubo, H. Ferrous (Fe-based) shape memory alloys (SMAs): Properties, processing and applications. In Shape Memory and Superelastic Alloys; Elsevier: Amsterdam, The Netherlands, 2011; pp. 141–159. [Google Scholar]

- Ghafoori, E.; Hosseini, E.; Leinenbach, C.; Michels, J.; Motavalli, M. Fatigue behavior of a Fe-Mn-Si shape memory alloy used for prestressed strengthening. Mater. Des. 2017, 133, 349–362. [Google Scholar] [CrossRef]

- Zirakian, T.; Zhang, J. Structural performance of unstiffened low yield point steel plate shear walls. J. Constr. Steel Res. 2015, 112, 40–53. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Z. Experimental Investigation and FE Analysis on Constitutive Relationship of High Strength Aluminum Alloy under Cyclic Loading. Adv. Mater. Sci. Eng. 2016, 2016, 2941874. [Google Scholar] [CrossRef] [Green Version]

- Shahverdi, M.; Michels, J.; Czaderski, C.; Motavalli, M. Iron-based shape memory alloy strips for strengthening RC members: Material behavior and characterization. Constr. Build. Mater. 2018, 173, 586–599. [Google Scholar] [CrossRef]

- Yin, F.; Yang, L.; Wang, M.; Zong, L.; Chang, X. Study on ultra-low cycle fatigue behavior of austenitic stainless steel. Thin-Walled Struct. 2019, 143, 106205. [Google Scholar] [CrossRef]

- Fang, C.; Wang, W.; Ji, Y.; Yam, M.C. Superior low-cycle fatigue performance of iron-based SMA for seismic damping application. J. Constr. Steel Res. 2021, 184, 106817. [Google Scholar] [CrossRef]

- Gu, T.; Jia, L.-J.; Chen, B.; Xia, M.; Guo, H.; He, M.-C. Unified full-range plasticity till fracture of meta steel and structural steels. Eng. Fract. Mech. 2021, 253, 107869. [Google Scholar] [CrossRef]

- Shi, G.; Gao, Y.; Wang, X.; Cui, Y. Energy-based low cycle fatigue analysis of low yield point steels. J. Constr. Steel Res. 2018, 150, 346–353. [Google Scholar] [CrossRef]

- Rosa, D.I.H.; Hartloper, A.; Sousa, A.D.C.E.; Lignos, D.G.; Motavalli, M.; Ghafoori, E. Experimental behavior of iron-based shape memory alloys under cyclic loading histories. Constr. Build. Mater. 2021, 272, 121712. [Google Scholar] [CrossRef]

- Koster, M.; Lee, W.J.; Schwarzenberger, M.; Leinenbach, C. Cyclic deformation and structural fatigue behavior of an FE–Mn–Si shape memory alloy. Mater. Sci. Eng. A 2015, 637, 29–39. [Google Scholar] [CrossRef]

- Inoue, Y.; Kushibe, A.; Umemura, K.; Mizushima, Y.; Sawaguchi, T.; Nakamura, T.; Otsuka, H.; Chiba, Y. Fatigue-resistant Fe-Mn-Si-based alloy seismic dampers to counteract long-period ground motion. Jpn. Archit. Rev. 2020, 4, 76–87. [Google Scholar] [CrossRef]

- Koyama, M.; Sawaguchi, T.; Ogawa, K.; Kikuchi, T.; Murakami, M. Continuous Transition of Deformation Modes in Fe-30Mn-5Si-1Al Alloy. Mater. Trans. 2010, 51, 1194–1199. [Google Scholar] [CrossRef] [Green Version]

- Bouaziz, O.; Allain, S.; Scott, C.P.; Cugy, P.; Barbier, D. High manganese austenitic twinning induced plasticity steels: A review of the microstructure properties relationships. Curr. Opin. Solid State Mater. Sci. 2011, 15, 141–168. [Google Scholar] [CrossRef]

- Lu, F.; Yang, P.; Meng, L.; Cui, F.; Ding, H. Influences of Thermal Martensites and Grain Orientations on Strain-induced Martensites in High Manganese TRIP/TWIP Steels. J. Mater. Sci. Technol. 2011, 27, 257–265. [Google Scholar] [CrossRef]

- Khalil, W.; Saint-Sulpice, L.; Chirani, S.A.; Bouby, C.; Mikolajczak, A.; Ben Zineb, T. Experimental analysis of Fe-based shape memory alloy behavior under thermomechanical cyclic loading. Mech. Mater. 2013, 63, 1–11. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, W.-N.; Liu, Z.-Y.; Wang, G.-D. Microstructural evolution and deformation mechanism of a Fe-15Mn alloy investigated by electron back-scattered diffraction and transmission electron microscopy. Mater. Sci. Eng. A 2017, 698, 198–205. [Google Scholar] [CrossRef]

- Tasaki, W.; Sawaguchi, T.; Tsuchiya, K. EBSD analysis of dual γ/ε phase microstructures in tensile-deformed Fe-Mn-Si shape memory alloy. J. Alloys Compd. 2019, 797, 529–536. [Google Scholar] [CrossRef]

- Yang, Y.; Breveglieri, M.; Shahverdi, M. Effect of Phase Changes on the Axial Modulus of an FeMnSi-Shape Memory Alloy. Materials 2021, 14, 4815. [Google Scholar] [CrossRef] [PubMed]

- Matsumura, O.; Sumi, T.; Tamura, N.; Sakao, K.; Furukawa, T.; Otsuka, H. Pseudoelasticity in an Fe–28Mn–6Si–5Cr shape memory alloy. Mater. Sci. Eng. A 2000, 279, 201–206. [Google Scholar] [CrossRef]

- Sawaguchi, T.; Kikuchi, T.; Kajiwara, S. The pseudoelastic behavior of Fe–Mn–Si-based shape memory alloys containing Nb and C. Smart Mater. Struct. 2005, 14, S317–S322. [Google Scholar] [CrossRef]

- Baruj, A.; Bertolino, G.; Troiani, H.E. Temperature dependence of critical stress and pseudoelasticity in a Fe–Mn–Si–Cr pre-rolled alloy. J. Alloys Compd. 2010, 502, 54–58. [Google Scholar] [CrossRef]

- Lin, H.C.; Wu, S.K.; Peng, Y.T.; Cheng, T.C.; Lin, K.M. Pseudoelasticity of thermo-mechanically treated Fe–Mn–Si–Cr–Ta alloys. J. Alloys Compd. 2013, 577, S338–S343. [Google Scholar] [CrossRef]

- Vollmer, M.; Segel, C.; Krooß, P.; Günther, J.; Tseng, L.W.; Karaman, I.; Weidner, A.; Biermann, H.; Niendorf, T. On the effect of gamma phase formation on the pseudoelastic performance of polycrystalline Fe–Mn–Al–Ni shape memory alloys. Scr. Mater. 2015, 108, 23–26. [Google Scholar] [CrossRef]

- Arabi-Hashemi, A.; Lee, W.; Leinenbach, C. Recovery stress formation in FeMnSi based shape memory alloys: Impact of precipitates, texture and grain size. Mater. Des. 2018, 139, 258–268. [Google Scholar] [CrossRef]

- Megdiche, M.; Sallami, A.; Thiébaud, F.; Bouraoui, T.; Ben Zineb, T.; Chirani, S.A. Experimental analysis of the pseudoelastic damping capacity of the Fe-30Mn-6Si-5Cr Shape Memory Alloy. Smart Mater. Struct. 2020, 29, 084002. [Google Scholar] [CrossRef]

- Fang, C.; Zheng, Y.; Chen, J.; Yam, M.C.; Wang, W. Superelastic NiTi SMA cables: Thermal-mechanical behavior, hysteretic modelling and seismic application. Eng. Struct. 2019, 183, 533–549. [Google Scholar] [CrossRef]

- Liang, D.; Zheng, Y.; Fang, C.; Yam, M.C.H.; Zhang, C. Shape memory alloy (SMA)-cable-controlled sliding bearings: Development, testing, and system behavior. Smart Mater. Struct. 2020, 29, 085006. [Google Scholar] [CrossRef]

- Sato, A.; Chishima, E.; Yamaji, Y.; Mori, T. Orientation and composition dependencies of shape memory effect IN Fe-Mn-Si alloys. Acta Metall. 1984, 32, 539–547. [Google Scholar] [CrossRef]

- Yang, J.H.; Chen, H.; Wayman, C.M. Development of Fe-Based Shape Memory Alloys Associated with Face-Centered Cubic-Hexagonal Close-Packed Martensitic Transformations Part I. Shape Memory Behavior. Metall. Trans. A 1992, 23, 1431–1437. [Google Scholar] [CrossRef]

- Ohtsuka, H.; Kajiwara, S.; Kikuchi, T.; Ishihara, T.; Nagai, K. Growth Process and Microstructure of ε Martensite in an Fe-Mn-Si-Cr-Ni Shape Memory Alloy. J. Phys. Colloq. 1995, 5, C8-451–C8-455. [Google Scholar] [CrossRef]

- Kikuchi, T.; Kajiwara, S.; Yomota, Y. Microscopic Studies on Stress-induced Martensite Transformation and Its Reversion in an Fe–Mn–Si–Cr–Ni Shape Memory Alloy. Mater. Trans. 1995, 36, 719–728. [Google Scholar] [CrossRef] [Green Version]

- Baruj, A.; Kikuchi, T.; Kajiwara, S.; Shinya, N. Effect of Pre-Deformation of Austenite on Shape Memory Properties in Fe-Mn-Si-based Alloys Containing Nb and C. Mater. Trans. 2002, 43, 585–588. [Google Scholar] [CrossRef] [Green Version]

- Baruj, A.; Kikuchi, T.; Kajiwara, S.; Shinya, N. Improvement of shape memory properties of NbC containing Fe–Mn–Si based shape memory alloys by simple thermomechanical treatments. Mater. Sci. Eng. A 2004, 378, 333–336. [Google Scholar] [CrossRef]

- Wen, Y.H.; Li, N.; Xiong, L.R. Composition design principles for Fe–Mn–Si–Cr–Ni based alloys with better shape memory effect and higher recovery stress. Mater. Sci. Eng. A 2005, 407, 31–35. [Google Scholar] [CrossRef]

- Koyama, M.; Murakami, M.; Ogawa, K.; Kikuchi, T.; Sawaguchi, T. Influence of Al on Shape Memory Effect and Twinning Induced Plasticity of Fe-Mn-Si-Al System Alloy. Mater. Trans. 2007, 48, 2729–2734. [Google Scholar] [CrossRef] [Green Version]

- Koyama, M.; Sawaguchi, T.; Tsuzaki, K. Si content dependence on shape memory and tensile properties in Fe–Mn–Si–C alloys. Mater. Sci. Eng. A 2011, 528, 2882–2888. [Google Scholar] [CrossRef]

- Koyama, M.; Sawaguchi, T.; Tsuzaki, K. Microstructure characteristic and its effect on mechanical and shape memory properties in a Fe–17Mn–8Si–0.3C alloy. J. Alloy Compd. 2013, 573, 15–19. [Google Scholar] [CrossRef]

- Omori, T.; Okano, M.; Kainuma, R. Effect of grain size on superelasticity in Fe-Mn-Al-Ni shape memory alloy wire. APL Mater. 2013, 1, 032103. [Google Scholar] [CrossRef]

- Pricop, B.; Mihalache, E.; Nicoleta-Monica, L.; Istrate, B.; Mocanu, M.; Özkal, B.; Bujoreanu, L.-G. Powder metallurgy and mechanical alloying effects on the formation of thermally induced martensite in an FeMnSiCrNi SMA. MATEC Web Conf. 2015, 33, 04004. [Google Scholar] [CrossRef] [Green Version]

- Xiong, R.; Peng, H.; Wang, S.; Si, H.; Wen, Y. Effect of stacking fault energy on work hardening behaviors in Fe–Mn–Si–C high manganese steels by varying silicon and carbon contents. Mater. Des. 2015, 85, 707–714. [Google Scholar] [CrossRef]

- Xu, Z.; Hodgson, M.A.; Cao, P. A comparative study of powder metallurgical (PM) and wrought Fe–Mn–Si alloys. Mater. Sci. Eng. A 2015, 630, 116–124. [Google Scholar] [CrossRef]

- Mihalache, E.; Pricop, B.; Suru, M.-G.; Lohan, N.M.; Comăneci, R.I.; Istrate, B.; Ozkal, B.; Bujoreanu, L. Factors influencing martensite transitions in Fe-based shape memory alloys. MATEC Web Conf. 2015, 33, 04002. [Google Scholar] [CrossRef] [Green Version]

- La Roca, P.; Baruj, A.; Sade, M. Shape-Memory Effect and Pseudoelasticity in Fe–Mn-Based Alloys. Shape Mem. Superelast. 2017, 3, 37–48. [Google Scholar] [CrossRef]

- Tasaki, W.; Tsuchiya, K.; Sawaguchi, T.; Takamori, S. Comparison of Reverse Transformation Behaviors of Thermally- and Deformation-Induced ε-Martensite in Fe-28Mn-6Si-5Cr Shape Memory Alloy. Mater. Trans. 2016, 57, 1707–1713. [Google Scholar] [CrossRef] [Green Version]

- Xu, Z.; Hodgson, M.A.; Cao, P. Effects of Mechanical Milling and Sintering Temperature on the Densification, Microstructure and Tensile Properties of the Fe–Mn–Si Powder Compacts. J. Mater. Sci. Technol. 2016, 32, 1161–1170. [Google Scholar] [CrossRef]

- Watanabe, Y.; Yamamura, A.; Sato, H. Fabrication of Fe-Mn-Si-Cr Shape Memory Alloy Fiber/Aluminum Matrix Smart Composite by Casting. Mater. Trans. 2016, 57, 590–599. [Google Scholar] [CrossRef] [Green Version]

- Suru, M.-G.; Lohan, N.-M.; Mihalache, E.; Pricop, B.; Mocanu, M.; Bujoreanu, L. AFM Evaluation of Pre-Straining Degree Effects on the Dimensions of Stress Induced Martensite Plates in Fe-Mn-Si Based SMAs. J. Test. Eval. 2016, 45, 419–427. [Google Scholar] [CrossRef]

- Xu, Z.; Hodgson, M.A.; Chang, K.; Chen, G.; Yuan, X.; Cao, P. Effect of Sintering Time on the Densification, Microstructure, Weight Loss and Tensile Properties of a Powder Metallurgical Fe-Mn-Si Alloy. Metals 2017, 7, 81. [Google Scholar] [CrossRef] [Green Version]

- Leinenbach, C.; Arabi-Hashemi, A.; Lee, W.J.; Lis, A.; Sadegh-Ahmadi, M.; Van Petegem, S.; Panzner, T.; Van Swygenhoven, H. Characterization of the deformation and phase transformation behavior of VC-free and VC-containing FeMnSi-based shape memory alloys by in situ neutron diffraction. Mater. Sci. Eng. A 2017, 703, 314–323. [Google Scholar] [CrossRef]

- Lai, M.; Li, Y.; Lillpopp, L.; Ponge, D.; Will, S.; Raabe, D. On the origin of the improvement of shape memory effect by precipitating VC in Fe–Mn–Si-based shape memory alloys. Acta Mater. 2018, 155, 222–235. [Google Scholar] [CrossRef]

- Pricop, B.; Söyler, A.U.; Özkal, B.; Bujoreanu, L. Powder Metallurgy: An Alternative for FeMnSiCrNi Shape Memory Alloys Processing. Front. Mater. 2020, 7, 247. [Google Scholar] [CrossRef]

- Popa, M.; Mihalache, E.; Cojocaru, V.D.; Gurău, C.; Gurău, G.; Cimpoeşu, N.; Pricop, B.; Comăneci, R.-I.; Vollmer, M.; Krooß, P.; et al. Effects of Thermomechanical Processing on the Microstructure and Mechanical Properties of Fe-Based Alloys. J. Mater. Eng. Perform. 2020, 29, 2274–2282. [Google Scholar] [CrossRef]

- Nikulin, I.; Sawaguchi, T.; Yoshinaka, F.; Takamori, S. Influence of cold rolling deformation mechanisms on the grain refinement of Fe–15Mn–10Cr–8Ni–4Si austenitic alloy. Mater. Charact. 2020, 162, 110191. [Google Scholar] [CrossRef]

- Yoshinaka, F.; Sawaguchi, T. Characterization of crystallographic fracture surfaces in Fe–33Mn–6Si alloy. Int. J. Fatigue 2020, 130, 105271. [Google Scholar] [CrossRef]

- Lee, W.J.; Weber, B.; Feltrin, G.; Czaderski, C.; Motavalli, M.; Leinenbach, C. Stress recovery behaviour of an Fe–Mn–Si–Cr–Ni–VC shape memory alloy used for prestressing. Smart Mater. Struct. 2013, 22, 125037. [Google Scholar] [CrossRef]

- Gu, X.-L.; Chen, Z.-Y.; Yu, Q.-Q.; Ghafoori, E. Stress recovery behavior of an Fe-Mn-Si shape memory alloy. Eng. Struct. 2021, 243, 112710. [Google Scholar] [CrossRef]

- Wang, W.-Y.; Liu, B.; Kodur, V. Effect of Temperature on Strength and Elastic Modulus of High-Strength Steel. J. Mater. Civ. Eng. 2013, 25, 174–182. [Google Scholar] [CrossRef]

- Wang, B.; Zhu, S. Cyclic behavior of iron-based shape memory alloy bars for high-performance seismic devices. Eng. Struct. 2021, 252, 113588. [Google Scholar] [CrossRef]

- Leinenbach, C.; Kramer, H.; Bernhard, C.; Eifler, D. Thermo-Mechanical Properties of an Fe-Mn-Si-Cr-Ni-VC Shape Memory Alloy with Low Transformation Temperature. Adv. Eng. Mater. 2012, 14, 62–67. [Google Scholar] [CrossRef]

- Sawaguchi, T.; Sahu, P.; Kikuchi, T.; Ogawa, K.; Kajiwara, S.; Kushibe, A.; Higashino, M.; Ogawa, T. Vibration mitigation by the reversible fcc/hcp martensitic transformation during cyclic tension–compression loading of an Fe–Mn–Si-based shape memory alloy. Scr. Mater. 2006, 54, 1885–1890. [Google Scholar] [CrossRef]

- Sawaguchi, T.; Bujoreanu, L.G.; Kikuchi, T.; Ogawa, K.; Koyama, M.; Murakami, M. Mechanism of reversible transformation-induced plasticity of Fe–Mn–Si shape memory alloys. Scr. Mater. 2008, 59, 826–829. [Google Scholar] [CrossRef]

- Watanabe, Y.; Sato, H.; Nishino, Y.; Kim, I.S. Training Effects on Damping Capacity in Fe-Mn and Fe-Mn-Cr Alloys. Mater. Sci. Forum 2010, 638–642, 2201–2206. [Google Scholar] [CrossRef]

- Nikulin, I.; Sawaguchi, T.; Tsuzaki, K. Effect of alloying composition on low-cycle fatigue properties and microstructure of Fe–30Mn–(6−x)Si–xAl TRIP/TWIP alloys. Mater. Sci. Eng. A 2013, 587, 192–200. [Google Scholar] [CrossRef]

- Nikulin, I.; Sawaguchi, T.; Ogawa, K.; Tsuzaki, K. Microstructure Evolution Associated with a Superior Low-Cycle Fatigue Resistance of the Fe-30Mn-4Si-2Al Alloy. Met. Mater. Trans. A 2015, 46, 5103–5113. [Google Scholar] [CrossRef]

- Sawaguchi, T.; Nikulin, I.; Ogawa, K.; Sekido, K.; Takamori, S.; Maruyama, T.; Chiba, Y.; Kushibe, A.; Inoue, Y.; Tsuzaki, K. Designing Fe–Mn–Si alloys with improved low-cycle fatigue lives. Scr. Mater. 2015, 99, 49–52. [Google Scholar] [CrossRef]

- Nagashima, N.; Sawaguchi, T.; Ogawa, K. Low Cycle Fatigue Properties of Fe-28Mn-6Si-5Cr-0.5NbC Alloy. Tetsu-to-Hagane 2016, 102, 517–524. [Google Scholar] [CrossRef] [Green Version]

- Nikulin, I.; Sawaguchi, T.; Kushibe, A.; Inoue, Y.; Otsuka, H.; Tsuzaki, K. Effect of strain amplitude on the low-cycle fatigue behavior of a new Fe–15Mn–10Cr–8Ni–4Si seismic damping alloy. Int. J. Fatigue 2016, 88, 132–141. [Google Scholar] [CrossRef]

- Nikulin, I.; Sawaguchi, T.; Ogawa, K.; Tsuzaki, K. Effect of γ to ε martensitic transformation on low-cycle fatigue behaviour and fatigue microstructure of Fe–15Mn–10Cr–8Ni–xSi austenitic alloys. Acta Mater. 2016, 105, 207–218. [Google Scholar] [CrossRef]

- Shao, C.; Zhang, P.; Liu, R.; Zhang, Z.; Pang, J. Low-cycle and extremely-low-cycle fatigue behaviors of high-Mn austenitic TRIP/TWIP alloys: Property evaluation, damage mechanisms and life prediction. Acta Mater. 2016, 103, 781–795. [Google Scholar] [CrossRef]

- Tasaki, W.; Sawaguchi, T.; Nikulin, I.; Sekido, K.; Tsuchiya, K. Effect of Deformation Temperature on Low-Cycle Fatigue Properties of Fe-28Mn-6Si-5Cr Shape Memory Alloy. Mater. Trans. 2016, 57, 639–646. [Google Scholar] [CrossRef] [Green Version]

- Ju, Y.-B.; Koyama, M.; Sawaguchi, T.; Tsuzaki, K.; Noguchi, H. Effects of ε-martensitic transformation on crack tip deformation, plastic damage accumulation, and slip plane cracking associated with low-cycle fatigue crack growth. Int. J. Fatigue 2017, 103, 533–545. [Google Scholar] [CrossRef]

- Nagashima, N.; Sawaguchi, T. Influence of Transformation Pseudoelasticity and Accumulated Plastic Strain on Low Cycle Fatigue Characteristics of Fe-30Mn-4Si-2Al Alloy. Tetsu-to-Hagane 2018, 104, 393–399. [Google Scholar] [CrossRef] [Green Version]

- Nikulin, I.; Nagashima, N.; Yoshinaka, F.; Sawaguchi, T. Superior fatigue life of Fe-15Mn-10Cr-8Ni-4Si seismic damping alloy subjected to extremely high strain amplitudes. Mater. Lett. 2018, 230, 257–260. [Google Scholar] [CrossRef]

- Nikulin, I.; Yoshinaka, F.; Sawaguchi, T. Superior fatigue life of Fe-15Mn-10Cr-8Ni-4Si seismic damping alloy under asymmetric cyclic loading with tensile mean strain. Mater. Sci. Eng. A 2019, 748, 371–378. [Google Scholar] [CrossRef]

- Nikulin, I.; Yoshinaka, F.; Takamori, S.; Sawaguchi, T. Effect of carbon on the low-cycle fatigue resistance and microstructure of the Fe–15Mn–10Cr–8Ni–4Si seismic damping alloy. Mater. Sci. Eng. A 2019, 766, 138321. [Google Scholar] [CrossRef]

- Yoshinaka, F.; Sawaguchi, T.; Ilya, N.; Takamori, S.; Nagashima, N. Improved fatigue life of the newly developed Fe-15Mn-10Cr-8Ni-4Si seismic damping alloy. Procedia Struct. Integr. 2019, 19, 214–223. [Google Scholar] [CrossRef]

- Yoshinaka, F.; Sawaguchi, T.; Nikulin, I.; Takamori, S. Fatigue properties and plastically deformed microstructure of Fe-15Mn-10Cr-8Ni-4Si alloy in high-cycle-fatigue regime. Int. J. Fatigue 2019, 129, 105224. [Google Scholar] [CrossRef]

- Fang, C.; Ping, Y.; Chen, Y. Loading protocols for experimental seismic qualification of members in conventional and emerging steel frames. Earthq. Eng. Struct. Dyn. 2019, 49, 155–174. [Google Scholar] [CrossRef]

- Guo, Y.; Fang, C.; Zheng, Y. Post-fire hysteretic and low-cycle fatigue behaviors of Q345 carbon steel. J. Constr. Steel Res. 2021, 187, 106991. [Google Scholar] [CrossRef]

- Fang, C.; Liang, D.; Zheng, Y.; Lu, S. Seismic performance of bridges with novel SMA cable-restrained high damping rubber bearings against near-fault ground motions. Earthq. Eng. Struct. Dyn. 2021, 51, 44–65. [Google Scholar] [CrossRef]

- Fang, C.; Wang, W.; Feng, W. Experimental and numerical studies on self-centring beam-to-column connections free from frame expansion. Eng. Struct. 2019, 198, 198. [Google Scholar] [CrossRef]

- Wang, W.; Fang, C.; Zhao, Y.; Sause, R.; Hu, S.; Ricles, J. Self-centering friction spring dampers for seismic resilience. Earthq. Eng. Struct. Dyn. 2019, 48, 1045–1065. [Google Scholar] [CrossRef]

- Fang, C.; Wang, W.; Zhang, A.; Sause, R.; Ricles, J.; Chen, Y. Behavior and Design of Self-Centering Energy Dissipative Devices Equipped with Superelastic SMA Ring Springs. J. Struct. Eng. 2019, 145, 04019109. [Google Scholar] [CrossRef]

- Fang, C.; Zhong, Q.; Wang, W.; Hu, S.; Qiu, C. Peak and residual responses of steel moment-resisting and braced frames under pulse-like near-fault earthquakes. Eng. Struct. 2018, 177, 579–597. [Google Scholar] [CrossRef]

- Fang, C.; Ping, Y.; Chen, Y.; Yam, M.C.H.; Chen, J.; Wang, W. Seismic Performance of Self-centering Steel Frames with SMA-viscoelastic Hybrid Braces. J. Earthq. Eng. 2020, 1–28. [Google Scholar] [CrossRef]

- Lamarche, C.-P.; Tremblay, R. Seismically induced cyclic buckling of steel columns including residual-stress and strain-rate effects. J. Constr. Steel Res. 2011, 67, 1401–1410. [Google Scholar] [CrossRef]

- Fang, C.; Yam, M.C.H.; Lam, C.C.; Xie, L. Cyclic performance of extended end-plate connections equipped with shape memory alloy bolts. J. Constr. Steel Res. 2014, 94, 122–136. [Google Scholar] [CrossRef]

- Wang, W.; Fang, C.; Liu, J. Self-Centering Beam-to-Column Connections with Combined Superelastic SMA Bolts and Steel Angles. J. Struct. Eng. 2017, 143, 04016175. [Google Scholar] [CrossRef]

- Fang, C.; Yam, M.C.; Chan, T.M.; Wang, W.; Yang, X.; Lin, X. A study of hybrid self-centring connections equipped with shape memory alloy washers and bolts. Eng. Struct. 2018, 164, 155–168. [Google Scholar] [CrossRef]

- Qiu, C.; Fang, C.; Liang, D.; Du, X.; Yam, M.C. Behavior and application of self-centering dampers equipped with buckling-restrained SMA bars. Smart Mater. Struct. 2020, 29, 035009. [Google Scholar] [CrossRef]

- Dusicka, P.; Itani, A.M.; Buckle, I.G. Cyclic response of plate steels under large inelastic strains. J. Constr. Steel Res. 2007, 63, 156–164. [Google Scholar] [CrossRef]

- Nip, K.; Gardner, L.; Davies, C.; Elghazouli, A. Extremely low cycle fatigue tests on structural carbon steel and stainless steel. J. Constr. Steel Res. 2010, 66, 96–110. [Google Scholar] [CrossRef]

- Lu, B.; Silva, P.F. Estimating equivalent viscous damping ratio for RC members under seismic and blast loadings. Mech. Res. Commun. 2006, 33, 787–795. [Google Scholar] [CrossRef]

- Maruyama, T.; Kurita, T.; Kozaki, S.; Andou, K.; Farjami, S.; Kubo, H. Innovation in producing crane rail fishplate using Fe–Mn–Si–Cr based shape memory alloy. Mater. Sci. Technol. 2013, 24, 908–912. [Google Scholar] [CrossRef]

- Hosseini, A.; Ghafoori, E.; Motavalli, M.; Nussbaumer, A.C.; Zhao, X.-L. Mode I fatigue crack arrest in tensile steel members using prestressed CFRP plates. Compos. Struct. 2017, 178, 119–134. [Google Scholar] [CrossRef]

- Hong, K.; Lee, S.; Han, S.; Yeon, Y. Evaluation of Fe-Based Shape Memory Alloy (Fe-SMA) as Strengthening Material for Reinforced Concrete Structures. Appl. Sci. 2018, 8, 730. [Google Scholar] [CrossRef] [Green Version]

- Hong, K.; Lee, S.; Yeon, Y.; Jung, K. Flexural Response of Reinforced Concrete Beams Strengthened with Near-Surface-Mounted Fe-Based Shape-Memory Alloy Strips. Int. J. Concr. Struct. Mater. 2018, 12, 45. [Google Scholar] [CrossRef]

- Michels, J.; Shahverdi, M.; Czaderski, C. Flexural strengthening of structural concrete with iron-based shape memory alloy strips. Struct. Concr. 2018, 19, 876–891. [Google Scholar] [CrossRef]

- Rojob, H.; El-Hacha, R. Fatigue performance of RC beams strengthened with self-prestressed iron-based shape memory alloys. Eng. Struct. 2018, 168, 35–43. [Google Scholar] [CrossRef]

- Rojob, H.; El-Hacha, R. Performance of RC beams strengthened with self-prestressed Fe-SMA bars exposed to freeze-thaw cycles and sustained load. Eng. Struct. 2018, 169, 107–118. [Google Scholar] [CrossRef]

- Strieder, E.; Aigner, C.; Petautschnig, G.; Horn, S.; Marcon, M.; Schwenn, M.; Zeman, O.; Castillo, P.; Wan-Wendner, R.; Bergmeister, K. Strengthening of Reinforced Concrete Beams with Externally Mounted Sequentially Activated Iron-Based Shape Memory Alloys. Materials 2019, 12, 345. [Google Scholar] [CrossRef] [Green Version]

- Dolatabadi, N.; Shahverdi, M.; Ghassemieh, M.; Motavalli, M. RC Structures Strengthened by an Iron-Based Shape Memory Alloy Embedded in a Shotcrete Layer—Nonlinear Finite Element Modeling. Materials 2020, 13, 5504. [Google Scholar] [CrossRef]

- Soroushian, P.; Ostowari, K.; Nossoni, A.; Chowdhury, H. Repair and Strengthening of Concrete Structures Through Application of Corrective Posttensioning Forces with Shape Memory Alloys. Transp. Res. Rec. J. Transp. Res. Board 2001, 1770, 20–26. [Google Scholar] [CrossRef]

- El-Hacha, R.; Soudki, K. Prestressed near-surface mounted fibre reinforced polymer reinforcement for concrete structures—A review. Can. J. Civ. Eng. 2013, 40, 1127–1139. [Google Scholar] [CrossRef]

- Czaderski, C.; Shahverdi, M.; Brönnimann, R.; Leinenbach, C.; Motavalli, M. Feasibility of iron-based shape memory alloy strips for prestressed strengthening of concrete structures. Constr. Build. Mater. 2014, 56, 94–105. [Google Scholar] [CrossRef]

- Abouali, S.; Shahverdi, M.; Ghassemieh, M.; Motavalli, M. Nonlinear simulation of reinforced concrete beams retrofitted by near-surface mounted iron-based shape memory alloys. Eng. Struct. 2019, 187, 133–148. [Google Scholar] [CrossRef]

- Schranz, B.; Czaderski, C.; Vogel, T.; Shahverdi, M. Bond behaviour of ribbed near-surface-mounted iron-based shape memory alloy bars with short bond lengths. Mater. Des. 2020, 191, 108647. [Google Scholar] [CrossRef]

- Schranz, B.; Czaderski, C.; Vogel, T.; Shahverdi, M. Bond investigations of prestressed, near-surface-mounted, ribbed memory-steel bars with full bond length. Mater. Des. 2020, 196, 109145. [Google Scholar] [CrossRef]

- Shahverdi, M.; Czaderski, C.; Annen, P.; Motavalli, M. Strengthening of RC beams by iron-based shape memory alloy bars embedded in a shotcrete layer. Eng. Struct. 2016, 117, 263–273. [Google Scholar] [CrossRef]

- Czaderski, C.; Shahverdi, M.; Michels, J. Iron based shape memory alloys as shear reinforcement for bridge girders. Constr. Build. Mater. 2021, 274, 121793. [Google Scholar] [CrossRef]

- Shahverdi, M.; Czaderski, C.; Motavalli, M. Iron-based shape memory alloys for prestressed near-surface mounted strengthening of reinforced concrete beams. Constr. Build. Mater. 2016, 112, 28–38. [Google Scholar] [CrossRef]

- Rojob, H.; El-Hacha, R. Ductility behavior of RC beams strengthened in flexure with NSM Iron-based Shape Memory Alloy bars. In Proceedings of the Third Conference on Smart Monitoring, Assessment and Rehabilitation of Civil Structures, Antalya, Turkey, 7–9 September 2015. [Google Scholar]

- Rojob, H.; El-Hacha, R. Self-Prestressing Using Fe-SMA for Flexural Strengthening of Reinforced Concrete Beams. ACI Struct. J. 2017, 114, 523–532. [Google Scholar] [CrossRef]

- Cladera, A.; Montoya-Coronado, L.A.; Ruiz-Pinilla, J.G.; Ribas, C. Shear strengthening of slender reinforced concrete T-shaped beams using iron-based shape memory alloy strips. Eng. Struct. 2020, 221, 111018. [Google Scholar] [CrossRef]

- Rojob, H.; El-Hacha, R. Strengthening of concrete structures with iron-based shape memory alloy elements: Case studies. In Proceedings of the SMAR 2019—Fifth Conference on Smart Monitoring, Assessment and Rehabilitation of Civil Structures, Potsdam, Germany, 27–29 August 2019. [Google Scholar]

- Izadi, M.; Ghafoori, E.; Shahverdi, M.; Motavalli, M.; Maalek, S. Development of an iron-based shape memory alloy (Fe-SMA) strengthening system for steel plates. Eng. Struct. 2018, 174, 433–446. [Google Scholar] [CrossRef]

- Izadi, M.; Ghafoori, E.; Motavalli, M.; Maalek, S. Iron-based shape memory alloy for the fatigue strengthening of cracked steel plates: Effects of re-activations and loading frequencies. Eng. Struct. 2018, 176, 953–967. [Google Scholar] [CrossRef]

- Izadi, M.; Hosseini, A.; Michels, J.; Motavalli, M.; Ghafoori, E. Thermally activated iron-based shape memory alloy for strengthening metallic girders. Thin-Walled Struct. 2019, 141, 389–401. [Google Scholar] [CrossRef]

- Hosseini, A.; Ghafoori, E.; Motavalli, M.; Nussbaumer, A.; Zhao, X.-L.; Al-Mahaidi, R. Flat prestressed unbonded retrofit system for strengthening of existing metallic I-Girders. Compos. Part B Eng. 2018, 155, 156–172. [Google Scholar] [CrossRef]

- Izadi, M.; Motavalli, M.; Ghafoori, E. Iron-based shape memory alloy (Fe-SMA) for fatigue strengthening of cracked steel bridge connections. Constr. Build. Mater. 2019, 227, 116800. [Google Scholar] [CrossRef]

- Wang, W.; Hosseini, A.; Ghafoori, E. Experimental study on Fe-SMA-to-steel adhesively bonded interfaces using DIC. Eng. Fract. Mech. 2021, 244, 107553. [Google Scholar] [CrossRef]

- Wang, W.; Li, L.; Hosseini, A.; Ghafoori, E. Novel fatigue strengthening solution for metallic structures using adhesively bonded Fe-SMA strips: A proof of concept study. Int. J. Fatigue 2021, 148, 106237. [Google Scholar] [CrossRef]

- Hou, H.; Qu, B. Duraion effect of spectrally matched fround motions on seismic demands of elasric perfectly plastic SDOFS. Eng. Struct. 2015, 90, 48–60. [Google Scholar] [CrossRef]

- Hosseini, A.; Michels, J.; Izadi, M.; Ghafoori, E. A comparative study between Fe-SMA and CFRP reinforcements for prestressed strengthening of metallic structures. Constr. Build. Mater. 2019, 226, 976–992. [Google Scholar] [CrossRef]

- Ghafoori, E.; Neuenschwander, M.; Shahverdi, M.; Czaderski, C.; Fontana, M. Elevated temperature behavior of an iron-based shape memory alloy used for prestressed strengthening of civil structures. Constr. Build. Mater. 2019, 211, 437–452. [Google Scholar] [CrossRef]

- Bu, D.; Peng, H.; Wen, Y.; Li, N. Influence of ageing on wear resistance of an Fe–Mn–Si–Cr–Ni–Ti–C shape memory alloy. Mater. Des. 2011, 32, 2969–2973. [Google Scholar] [CrossRef]

- Della Rovere, C.; Alano, J.; Otubo, J.; Kuri, S. Corrosion behavior of shape memory stainless steel in acid media. J. Alloys Compd. 2011, 509, 5376–5380. [Google Scholar] [CrossRef]

- Della Rovere, C.; Alano, J.; Silva, R.; Nascente, P.; Otubo, J.; Kuri, S. Influence of alloying elements on the corrosion properties of shape memory stainless steels. Mater. Chem. Phys. 2012, 133, 668–673. [Google Scholar] [CrossRef]

- Ma, R.; Peng, H.; Wen, Y.; Zhang, L.; Zhao, K. Oxidation behavior of an austenitic stainless FeMnSiCrNi shape memory alloy. Corros. Sci. 2013, 66, 269–277. [Google Scholar] [CrossRef]

- Leinenbach, C.; Lee, W.J.; Lis, A.; Arabi-Hashemi, A.; Cayron, C.; Weber, B. Creep and stress relaxation of a FeMnSi-based shape memory alloy at low temperatures. Mater. Sci. Eng. A 2016, 677, 106–115. [Google Scholar] [CrossRef] [Green Version]

- Lee, W.J.; Partovi-Nia, R.; Suter, T.; Leinenbach, C. Electrochemical characterization and corrosion behavior of an Fe-Mn-Si shape memory alloy in simulated concrete pore solutions. Mater. Corros. 2016, 67, 839–846. [Google Scholar] [CrossRef]

- Silva, R.; Arana, C.; Malafaia, A.D.S.; Filho, A.M.; Pascal, C.; Otubo, J.; Sordi, V.; Rovere, C. Microstructure and surface oxidation behavior of an austenitic Fe-Mn-Si-Cr-Ni-Co shape memory stainless steel at 800 °C in air. Corros. Sci. 2019, 158, 158. [Google Scholar] [CrossRef]

- Silva, R.; Vacchi, G.; Santos, Í.; Malafaia, A.; Kugelmeier, C.; Filho, A.M.; Pascal, C.; Sordi, V.; Rovere, C. Insights into high-temperature oxidation of Fe-Mn-Si-Cr-Ni shape memory stainless steels and its relationship to alloy chemical composition. Corros. Sci. 2020, 163, 163. [Google Scholar] [CrossRef]

- Hosseini, E.; Ghafoori, E.; Leinenbach, C.; Motavalli, M.; Holdsworth, S.R. Stress recovery and cyclic behaviour of an Fe–Mn–Si shape memory alloy after multiple thermal activation. Smart Mater. Struct. 2018, 27, 025009. [Google Scholar] [CrossRef] [Green Version]

- Baddoo, N.R. Stainless steel in construction: A review of research, applications, challenges and opportunities. J. Constr. Steel Res. 2008, 64, 1199–1206. [Google Scholar] [CrossRef]

- Fang, C.; Ping, Y.; Zheng, Y.; Chen, Y. Probabilistic economic seismic loss estimation of steel braced frames incorporating emerging self-centering technologies. Eng. Struct. 2021, 241, 112486. [Google Scholar] [CrossRef]

- Zheng, Y.; Fang, C.; Liang, D.; Sun, R. An innovative seismic-resilient bridge with shape memory alloy-washer-based footing rocking RC piers. J. Intell. Mater. Syst. Struct. 2021, 32, 549–567. [Google Scholar] [CrossRef]

- Chen, J.; Fang, C.; Wang, W.; Liu, Y. Variable-friction self-centering energy-dissipation braces (VF-SCEDBs) with NiTi SMA cables for seismic resilience. J. Constr. Steel Res. 2020, 175, 106318. [Google Scholar] [CrossRef]

- Wang, W.; Fang, C.; Zhang, A.; Liu, X. Manufacturing and performance of a novel self-centring damper with shape memory alloy ring springs for seismic resilience. Struct. Control Health Monit. 2019, 26, e2337. [Google Scholar] [CrossRef]

- Fang, C.; Yam, M.C.H.; Lam, A.C.C.; Zhang, Y. Feasibility study of shape memory alloy ring spring systems for self-centring seismic resisting devices. Smart Mater. Struct. 2015, 24, 75024. [Google Scholar] [CrossRef]

- Lin, H.C.; Lin, K.M.; Chuang, Y.C.; Chou, T.S. The welding characteristics of Fe–30Mn–6Si and Fe–30Mn–6Si–5Cr shape memory alloys. J. Alloys Compd. 2000, 306, 189–192. [Google Scholar] [CrossRef]

- Dong, Z.Z.; Sawaguchi, T.; Kajiwara, S.; Kikuchi, T.; Kim, S.H.; Lee, G.C. Microstructure change and shape memory characteristics in welded Fe–28Mn–6Si–5Cr–0.53Nb–0.06C alloy. Mater. Sci. Eng. A 2006, 438–440, 800–803. [Google Scholar] [CrossRef]

- Qiao, Z.; Li, L.; Wang, D.; Li, Z. Microstructure and shape recovery characteristics in a TIG-welded Fe-Mn-Si-Cr-Ni shape memory alloy. In Proceedings of the Third International Conference on Smart Materials and Nanotechnology in Engineering, Harbin, China, 1–4 July 2007. [Google Scholar]

- Zhou, C.; Lin, C.; Liu, L. Study on CO2 laser weldability of Fe-Mn-Si shape memory alloy. In Proceedings of the Third International Conference on Smart Materials and Nanotechnology in Engineering, Shenzhen, China, 11–13 November 2011. [Google Scholar]

- Druker, A.V.; Perotti, A.; Esquivel, I.; Malarría, J. A manufacturing process for shaft and pipe couplings of Fe–Mn–Si–Ni–Cr shape memory alloys. Mater. Des. (1980–2015) 2014, 56, 878–888. [Google Scholar] [CrossRef]

- Yam, M.C.H.; Fang, C.; Lam, C.C.; Zhang, Y. Numerical study and practical design of beam-to-column connections with shape memory alloys. J. Constr. Steel Res. 2015, 104, 177–192. [Google Scholar] [CrossRef]

- Fang, C.; Wang, W.; He, C.; Chen, Y. Self-centring behaviour of steel and steel-concrete composite connections equipped with NiTi SMA bolts. Eng. Struct. 2017, 150, 390–408. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, H.; Qiu, C.; Zhao, X. Seismic Behavior of Superelastic Shape Memory Alloy Spring in Base Isolation System of Multi-Story Steel Frame. Materials 2019, 12, 997. [Google Scholar] [CrossRef] [Green Version]

- Fang, C.; Liang, D.; Zheng, Y.; Yam, M.C.; Sun, R. Rocking bridge piers equipped with shape memory alloy (SMA) washer springs. Eng. Struct. 2020, 214, 110651. [Google Scholar] [CrossRef]

- Qiu, C.; Zhao, X.; Zhu, S. Seismic upgrading of multistory steel moment-resisting frames by installing shape memory alloy braces: Design method and performance evaluation. Struct. Control. Health Monit. 2020, 27, e2596. [Google Scholar] [CrossRef]

- Nahar, M.; Islam, K.; Billah, A.M. Seismic collapse safety assessment of concrete beam-column joints reinforced with different types of shape memory alloy rebars. J. Build. Eng. 2020, 29, 101106. [Google Scholar] [CrossRef]

| Property | Units | Value | ||||

|---|---|---|---|---|---|---|

| Fe-SMA | NiTinol | Q235 | SUS304 | |||

| (Martensite) | (Austenite) | |||||

| Density | g/cm3 | 7.2–7.5 | 6.45–6.5 | 7.86 | 7.93 | |

| Young’s modulus | GPa | 170 | 28–41 | 83 | 201 | 193 |

| Electrical resistivity | μΩ·cm | 100–130 | 76–80 | 82–100 | 29.3 | 73 |

| Specific Heat Capacity | J/kg·°C | 540 | 836.8 | 836.8 | 745 | 500 |

| Thermal conductivity | W/(m·°C) | 8.4 | 8.6–10 | 18 | 61.1 | 16.3 |

| Thermal expansion coefficient | (×10−6) °C−1 | 16.5 | 6.6 | 11 | 12.6 | 17.2 |

| Melting point | °C | 1320–1350 | 1240–1310 | 1468 | 1398–1454 | |

| Strain recovery limit | % | 2 | 10 | - | - | |

| Poisson’s ratio | - | 0.359 | 0.33 | 0.294 | 0.25 | |

| Material | Mf (°C) | Ms (°C) | As (°C) | Af (°C) | Ref. |

|---|---|---|---|---|---|

| Fe-SMA | −90 | −75 | 85 | 110 | [14] |

| Fe-SMA | −64 | −60 | 103 | 162 | [15] |

| NiTinol | −70–55 | 15–21 | −22–2 | 17–30 | [16] |

| Material | E0/GPa | fy/MPa | fu/MPa | fy//fu | εu | fu2/MPa | εu2 | EL(%) | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| S30408 | 249 | 273 | 710 | 0.38 | 0.48 | 520 | 0.59 | - | [22] |

| 7A04-T6 | 72 | 537 | 594 | 0.91 | 0.08 | 590 | 0.10 | - | [20] |

| LYP100 | 200 | 100 | 279 | 0.36 | 0.25 | 205 | 0.50 | - | [19] |

| LY100 | 199 | 128 | 252 | 0.51 | 0.27 | - | - | 47.3 | [25] |

| LY160 | 194 | 186 | 294 | 0.63 | 0.24 | - | - | 44.5 | [25] |

| LY225 | 202 | 191 | 295 | 0.65 | 0.23 | - | - | 44.0 | [25] |

| Q235 | 208 | 282 | 467 | 0.60 | 0.25 | 354 | 0.38 | - | [24] |

| Q355 | 206 | 385 | 533 | 0.72 | 0.25 | 390 | 0.36 | - | [24] |

| Q690 | 218 | 876 | 909 | 0.96 | 0.07 | 809 | 0.20 | - | [24] |

| Fe-SMA | 184 | 450 | 950 | 0.47 | - | - | 0.54 | - | [26] |

| Fe-SMA | 200 | 310 | 993 | 0.31 | - | - | - | - | [27] |

| Fe-SMA | 160 | 534 | 992 | 0.54 | 0.40 | 969 | 0.44 | - | [21] |

| Fe-17Mn-5Si-10Cr-5Ni | 172 | 297 | 774 | 0.38 | 0.45 | 698 | 0.48 | - | [23] |

| Fe-28Mn-6Si-5Cr | 170 | 250 | 800 | 0.31 | 0.40 | - | - | - | [17] |

| Fe-15Mn-4Si-10Cr-8Ni | 184 | 260 | 676 | 0.38 | - | - | - | 74.0 | [28] |

| Ref. | Manufacturing Details | Specimen 1 | Pre-Strain 2 | Pre-Load | Activation Temperature | fR/MPa 3 |

|---|---|---|---|---|---|---|

| [41] | Hot rolled at 1040 °C | SP-15 × 150 | 4% | 50 MPa | 160 °C | 444 |

| Hot rolled at 1000 °C | SP-15 × 150 | 4% | 50 MPa | 160 °C | 448 | |

| [14] | Hot rolled, solution treated at 1100 °C for 5 h, aging at 850 °C for 2 h | SP-0.7 × 1 | 4% | 50 MPa | 160 °C | 330 |

| SP-0.7 × 1 | 4% | 50 MPa | 225 °C | 380 | ||

| [76] | Hot press at 1100 °C and cold rolled, solution treated at 1100 °C for 5 h and water quenched, aging at 850 °C for 2 h followed by air cooling | SP-0.7 × 1 | 4% | 50 MPa | 160 °C | 565 |

| [72] | Hot press at 1100 °C and cold rolled, solution treated at 1100 °C for 5 h and water quenched, aging at 850 °C for 2 h followed by air cooling | SP-0.8 × 2 | 2% | - | 100 °C | 290 |

| SP-0.8 × 2 | 4% | - | 100 °C | 303 | ||

| SP-0.8 × 2 | 2% | - | 140 °C | 317 | ||

| SP-0.8 × 2 | 4% | - | 140 °C | 355 | ||

| [21] | Hot pressed and cold rolled | SP-1.5 × 15 | 0.5% | 50 MPa | 160 °C | 293 |

| SP-1.5 × 15 | 2% | 50 MPa | 160 °C | 346 | ||

| SP-1.5 × 15 | 2% | 50 MPa | 195 °C | 388 | ||

| SP-1.5 × 15 | 4% | 50 MPa | 160 °C | 334 | ||

| SP-0.5 × 15 | 4% | 50 MPa | 160 °C | 331 | ||

| SP-1.5 × 15 | 6% | 70 MPa | 160 °C | 298 | ||

| SP-1.5 × 15 | 8% | 83 MPa | 160 °C | 334 | ||

| [73] | Hot rolled at 1150 °C and cold rolled, solution treated at 1100 °C in H2N2-atmosphere for 5 h, aging at 850 °C for 2 h | SP-1.6 × 6 | 1% | 50 MPa | 200 °C | 330 |

| SP-1.6 × 6 | 2% | 50 MPa | 200 °C | 344 | ||

| SP-1.6 × 6 | 4% | 50 MPa | 200 °C | 342 | ||

| SP-1.6 × 6 | 6% | 50 MPa | 200 °C | 332 | ||

| SP-1.6 × 6 | 8% | 50 MPa | 200 °C | 337 | ||

| SP-1.6 × 6 | 2% | 50 MPa | 349 °C | 364 | ||

| SP-1.6 × 6 | 4% | 50 MPa | 350 °C | 421 | ||

| SP-1.6 × 6 | 6% | 50 MPa | 350 °C | 428 | ||

| SP-1.6 × 6 | 8% | 50 MPa | 350 °C | 445 |

| Research Group | Material | Strain Amplitude | Ref. | ||||

|---|---|---|---|---|---|---|---|

| ±1% | ±3% | ±5% | ±7% | ±9% | |||

| Tongji University | Fe-17Mn-5Si-10Cr-5Ni | 4007 | 880 | 210 | 102 | 83 | [23] |

| Portland State University | GR345 | 536 | 69 | 27 | 16 | - | [108] |

| HPS485 | 400 | 51 | 21 | 13 | - | [108] | |

| HS440 | 720 | 69 | 31 | 15 | - | [108] | |

| LYP225 | - | 38 | - | 9 | - | [108] | |

| LYP100 | 720 | 50 | 32 | 11 | - | [108] | |

| Imperial College | S355 | 495–732 | 53–107 | 22–24 | 9–15 | - | [109] |

| S235 | 439–521 | 16–21 | 8–20 | 3 | - | [109] | |

| EN1.4301 | 266–335 | 27–78 | 7–61 | 2–4 | - | [109] | |

| Tsinghua University | LY100 | 512–694 | 82–103 | - | - | - | [25] |

| LY160 | 1008 | 121 | 40 | - | - | [25] | |

| LY225 | 1220 | 101 | 46 | - | - | [25] | |

| Japanese National Institute for Materials Science | Fe-15Mn-(0-6)Si-10Cr-8Ni | 2860–8500 | - | - | - | - | [85] |

| Fe-30Mn-(6-x)Si-xAl | 2024–8070 | - | - | - | - | [80] | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.-X.; Zhang, J.; Wu, H.; Ji, Y.; Kumar, D.D. Iron-Based Shape Memory Alloys in Construction: Research, Applications and Opportunities. Materials 2022, 15, 1723. https://doi.org/10.3390/ma15051723

Zhang Z-X, Zhang J, Wu H, Ji Y, Kumar DD. Iron-Based Shape Memory Alloys in Construction: Research, Applications and Opportunities. Materials. 2022; 15(5):1723. https://doi.org/10.3390/ma15051723

Chicago/Turabian StyleZhang, Zhe-Xi, Jie Zhang, Honglei Wu, Yuezhen Ji, and Dheeraj D. Kumar. 2022. "Iron-Based Shape Memory Alloys in Construction: Research, Applications and Opportunities" Materials 15, no. 5: 1723. https://doi.org/10.3390/ma15051723

APA StyleZhang, Z.-X., Zhang, J., Wu, H., Ji, Y., & Kumar, D. D. (2022). Iron-Based Shape Memory Alloys in Construction: Research, Applications and Opportunities. Materials, 15(5), 1723. https://doi.org/10.3390/ma15051723