Gravity and Electrostatic Separation for Recovering Metals from Obsolete Printed Circuit Board

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

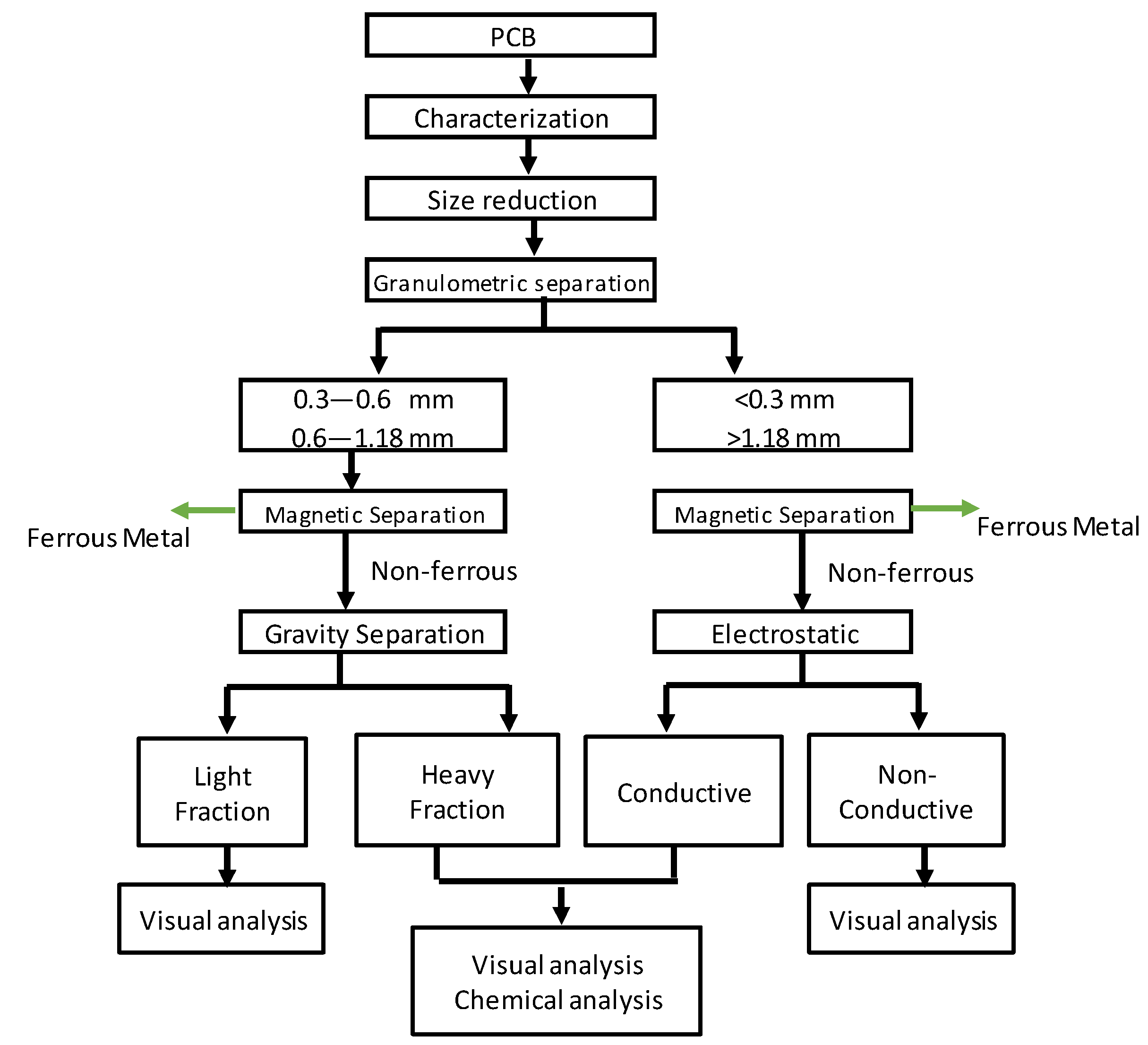

2.2. Methods

- Disassembly and size reduction

- Granulometric classification

- Magnetic separation

- Gravity separation

- Electrostatic separation

- Visual characterization

- Chemical characterization

3. Results and Discussion

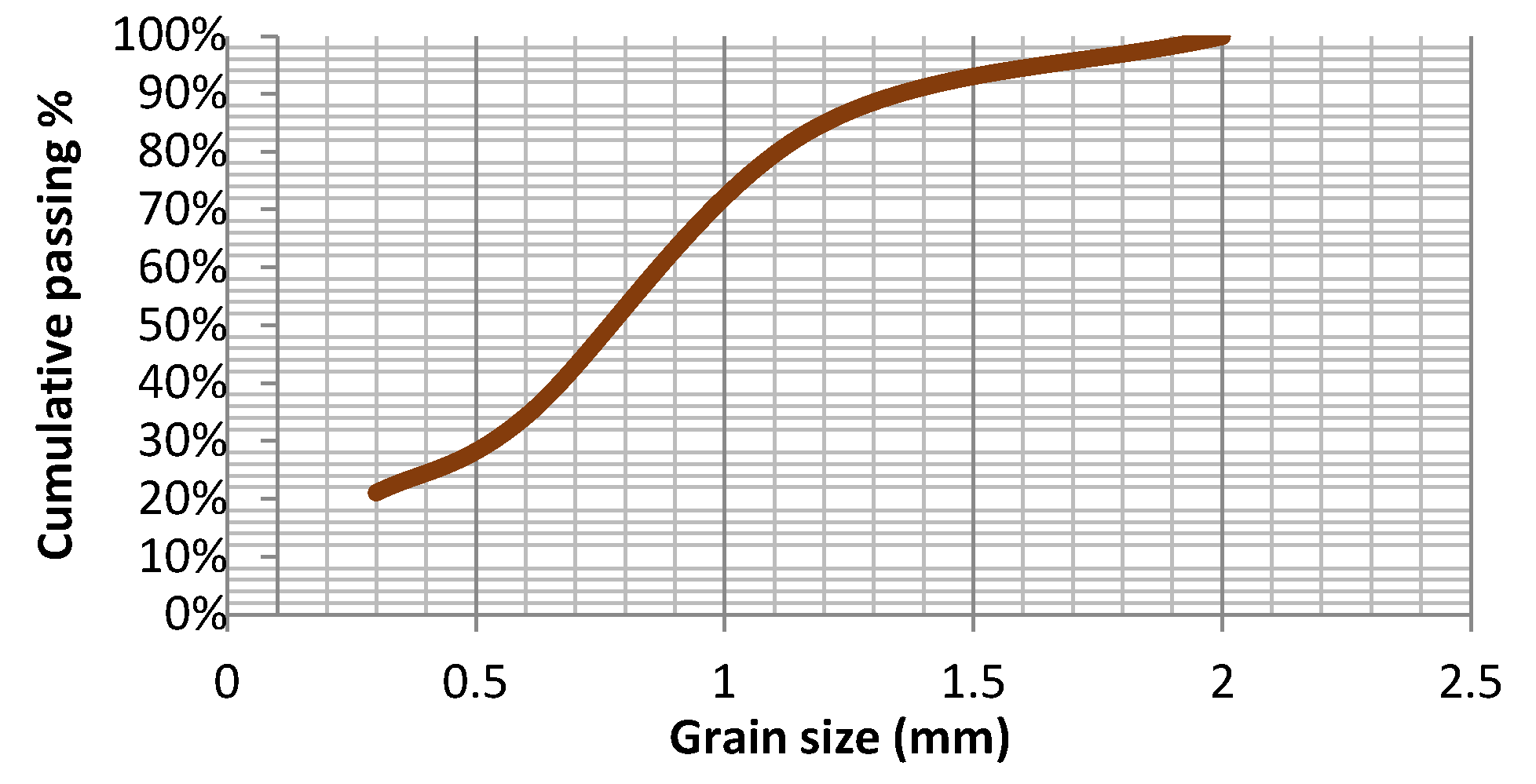

3.1. Size Reduction and Classification

3.2. Magnetic Separation

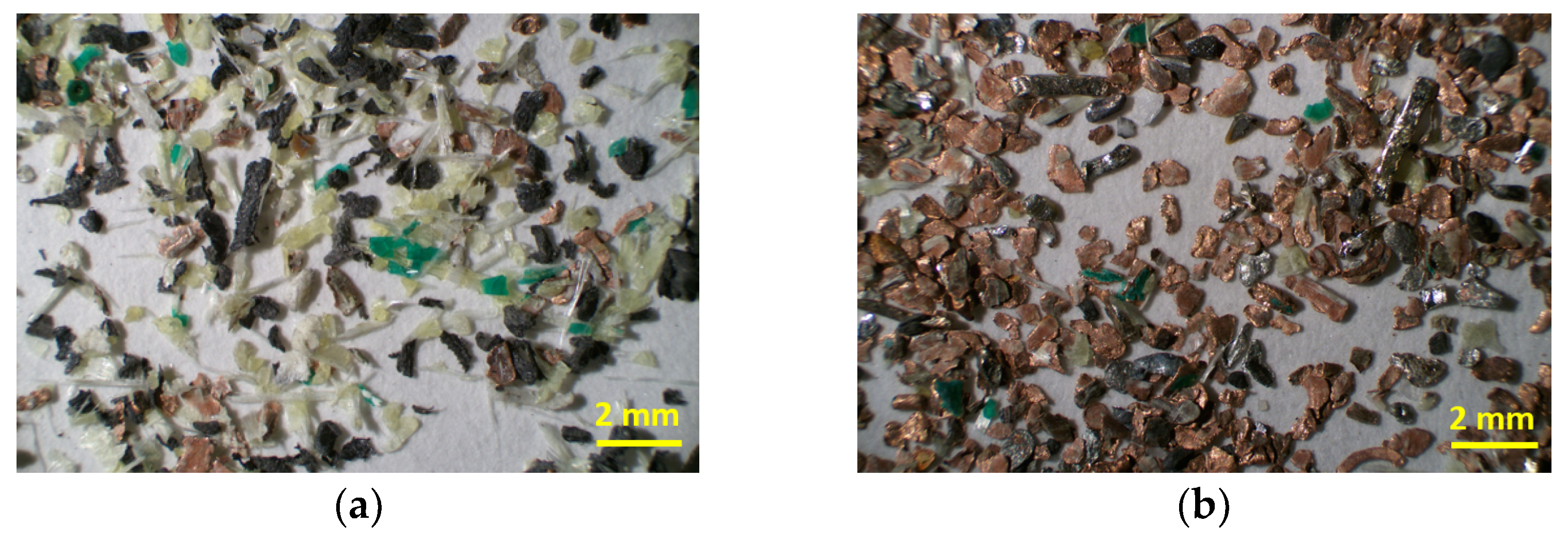

3.3. Gravity Separation

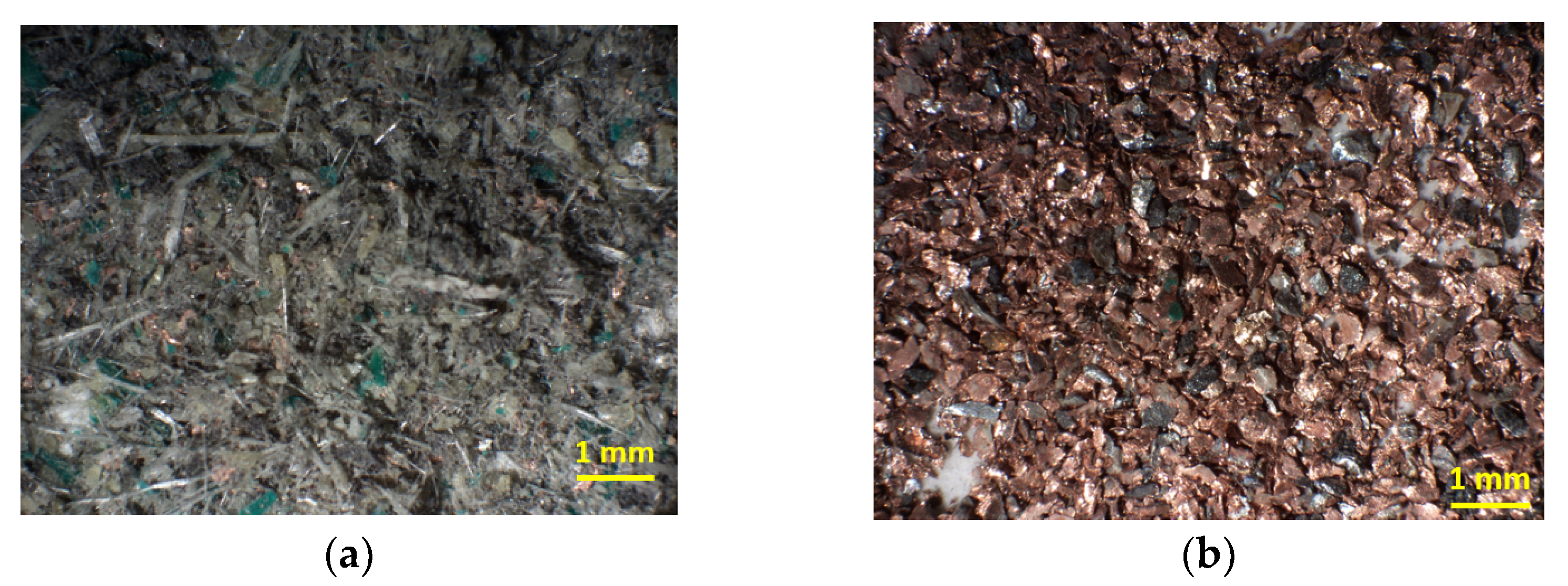

3.4. Electrostatic Separation

3.5. Visual Characterization

3.6. Chemical Characterization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Vermeșan, H.; Tiuc, A.-E.; Purcar, M. Advanced Recovery Techniques for Waste Materials from IT and Telecommunication Equipment Printed Circuit Boards. Sustainability 2019, 12, 74. [Google Scholar] [CrossRef] [Green Version]

- Arya, S.; Patel, A.; Kumar, S.; Pau-Loke, S. Urban mining of obsolete computers by manual dismantling and waste printed circuit boards by chemical leaching and toxicity assessment of its waste residues. Environ. Pollut. 2021, 283, 117033. [Google Scholar] [CrossRef] [PubMed]

- Forti, V.; Baldé, C.; Kuehr, R.; Bel, G. The Global E-Waste Monitor 2020. Quantities, Flows, and the Circular Economy Potential; United Nations University (UNU)/United Nations Institute for Training and Research (UNITAR)—Co-Hosted SCYCLE Programme; International Telecommunication Union (ITU): Geneva, Switzerland; International Solid Waste Association (ISWA): Vienna, Austria, 2020. [Google Scholar]

- Bilesan, M.R.; Makarova, I.; Wickman, B.; Repo, E. Efficient separation of precious metals from computer waste printed circuit boards by hydrocyclone and dilution-gravity methods. J. Clean. Prod. 2020, 286, 125505. [Google Scholar] [CrossRef]

- He, Y.; Xu, Z. The status and development of treatment techniques of typical waste electrical and electronic equipment in China: A review. Waste Manag. Res. J. Sustain. Circ. Econ. 2014, 32, 254–269. [Google Scholar] [CrossRef]

- Vats, M.; Singh, S. E-Waste characteristic and its disposal. Int. J. Ecol. Sci. Environ. Eng. 2014, 1, 49–61. [Google Scholar]

- Kang, K.D.; Ilankoon, I.M.S.K.; Dushyantha, N.; Chong, M.N. Assessment of Pre-Treatment Techniques for Coarse Printed Circuit Boards (PCBs). Recycl. Miner. 2021, 11, 1134. [Google Scholar] [CrossRef]

- Hao, J.; Wang, Y.; Wu, Y.; Guo, F. Metal recovery from waste printed circuit boards: A review for current status and perspectives. Resour. Conserv. Recycl. 2020, 157, 104787. [Google Scholar] [CrossRef]

- Copani, G.; Colledani, M.; Brusaferri, A.; Pievatolo, A.; Amendola, E.; Avella, M.; Fabrizio, M. Integrated Technological Solutions for Zero Waste Recycling of Printed Circuit Boards (PCBs). In Factories of the Future; Springer: Cham, Switzerland, 2019; pp. 149–169. [Google Scholar] [CrossRef] [Green Version]

- Chen, W.; Shu, Y.; Li, Y.; Chen, Y.; Wei, J. Co-pyrolysis of waste printed circuit boards with iron compounds for Br-fixing and material recovery. Environ. Sci. Pollut. Res. 2021, 28, 64642–64651. [Google Scholar] [CrossRef]

- Gande, V.V.; Vats, S.; Bhatt, N.; Pushpavanam, S. Sequential recovery of metals from waste printed circuit boards using a zero-discharge hydrometallurgical process. Clean. Eng. Technol. 2021, 4, 100143. [Google Scholar] [CrossRef]

- Kaur, P.; Sharma, S.; Albarakaty, F.M.; Kalia, A.; Hassan, M.M.; Abd-Elsalam, K.A. Biosorption and Bioleaching of Heavy Metals from Electronic Waste Varied with Microbial Genera. Sustainability 2022, 14, 935. [Google Scholar] [CrossRef]

- Kaya, M. Recovery of metals and nonmetals from electronic waste by physical and chemical recycling processes. Waste Manag. 2016, 57, 64–90. [Google Scholar] [CrossRef]

- Wang, X.; Gaustad, G. Prioritizing material recovery for end-of-life printed circuit boards. Waste Manag. 2012, 32, 1903–1913. [Google Scholar] [CrossRef]

- Shuey, S.A.; Vildal, E.E.; Taylor, P.R. Pyrometallurgical Processing of Electronic Waste. In Proceedings of the SME Annual Meeting, St. Louis, MO, USA, 27–29 March 2006. [Google Scholar]

- Oguchi, M.; Murakami, S.; Sakanakura, H.; Kida, A.; Kameya, T. A preliminary categorization of end-of-life electrical and electronic equipment as secondary metal resources. Waste Manag. 2011, 31, 2150–2160. [Google Scholar] [CrossRef]

- Goosey, M.; Kellner, R. Recycling technologies for the treatment of end of life printed circuit boards (PCBs). Circuit World 2003, 29, 33–37. [Google Scholar] [CrossRef]

- Veit, H.M.; De Pereira, C.C.; Bernardes, A.M. Using mechanical processing in recycling printed wiring boards. JOM 2002, 54, 45–47. [Google Scholar] [CrossRef]

- Bizzo, W.A.; Figueiredo, R.A.; De Andrade, V.F. Characterization of Printed Circuit Boards for Metal and Energy Recovery after Milling and Mechanical Separation. Materials 2014, 7, 4555–4566. [Google Scholar] [CrossRef]

- Zhao, Y.; Wen, X.; Li, B.; Tao, D. Recovery of copper from waste printed circuit boards. Mining Metall. Explor. 2004, 21, 99–102. [Google Scholar] [CrossRef]

- Das, A.; Vidyadhar, A.; Mehrotra, S. A novel flowsheet for the recovery of metal values from waste printed circuit boards. Resour. Conserv. Recycl. 2009, 53, 464–469. [Google Scholar] [CrossRef]

- Guo, C.; Wang, H.; Liang, W.; Fu, J.; Yi, X. Liberation characteristic and physical separation of printed circuit board (PCB). Waste Manag. 2011, 31, 2161–2166. [Google Scholar] [CrossRef]

- Veit, H.; Diehl, T.; Salami, A.; Rodrigues, J.; Bernardes, A.M.; Ten’orio, J. Utilization of magnetic and electrostatic separation in the recycling of printed circuit boards scrap. Waste Manag. 2005, 25, 67–74. [Google Scholar] [CrossRef]

- Wen, X.; Zhao, Y.; Duan, C.; Zhou, X.; Jiao, H.; Song, S. Study on Metals Recovery from Discarded Printed Circuit Boards by Physical Methods. In Proceedings of the 2005 IEEE International Symposium on Electronics and the Environment, New Orleans, LA, USA, 16–19 May 2005. [Google Scholar] [CrossRef]

- Kim, B.-S.; Lee, J.-C.; Seo, S.-P.; Park, Y.-K.; Sohn, H.Y. A process for extracting precious metals from spent printed circuit boards and automobile catalysts. JOM 2004, 56, 55–58. [Google Scholar] [CrossRef]

- Yokoyama, S.; Iji, M. Recycling of Printed Wiring Boards with Mounted Electronic Parts. In Proceedings of the 1997 IEEE International Symposium on Electronics and the Environment, San Francisco, CA, USA, 5–7 May 1997; pp. 109–114. [Google Scholar] [CrossRef]

- Yoo, J.-M.; Jeong, J.; Yoo, K.; Lee, J.-C.; Kim, W. Enrichment of the metallic components from waste printed circuit boards by a mechanical separation process using a stamp mill. Waste Manag. 2009, 29, 1132–1137. [Google Scholar] [CrossRef]

- Vasile, C.; Brebu, M.A.; Totolin, M.; Yanik, J.; Karayildirim, T.; Darie, H. Feedstock Recycling from the Printed Circuit Boards of Used Computers. Energy Fuels 2008, 22, 1658–1665. [Google Scholar] [CrossRef]

- Castro, J.; Edenir, R.P.-F. Chemical exploratory analysis of printed circuit board (PCB) using inductively coupled plasma optical emission spectrometry (ICP OES): Data treatment and elements correlation. Detritus 2020, 13, 131–139. [Google Scholar] [CrossRef]

- Santaolalla, A.; Lens, P.N.L.; Barona, A.; Rojo, N.; Ocio, A.; Gallastegui, G. Metal Extraction and Recovery from Mobile Phone PCBs by a Combination of Bioleaching and Precipitation Processes. Minerals 2021, 11, 1004. [Google Scholar] [CrossRef]

- LME (London Metal Exchange). LME. 2021. Available online: https://www.lme.com/en/Metals/ (accessed on 2 November 2021).

- Passive Electronic Components: Global Market Update, August 2021. Available online: https://passive-components.eu/passive-electronic-components-global-market-update-august-2021/ (accessed on 2 November 2021).

- Suponik, T.; Franke, D.; Nuckowski, P. Electrostatic and magnetic separations for the recovery of metals from electronic waste. IOP Conf. Ser. Mater. Sci. Eng. 2019, 641, 012017. [Google Scholar] [CrossRef]

- Tuncuk, A.; Atazi, V.; Akcil, A.; Yazici, E.Y.; Deveci, H. Aqueous metal recoverytechniques from e-scrap: Hydrometallurgy in recycling. Miner. Eng. 2012, 25, 28–37. [Google Scholar] [CrossRef]

| Metal | Weight Average (%) | Stdev (%) | Price (US$/kg) |

|---|---|---|---|

| Al | 3.02 | 1.70 | 2.68 |

| Cu | 21.44 | 9.14 | 9.65 |

| Fe | 3.28 | 2.79 | 0.0994 |

| Sn | 3.14 | 1.65 | 36.79 |

| Au | 0.04 | 0.04 | 57,598.06 |

| Pd | 0.05 | 0.11 | 65,040.96 |

| Ag | 0.13 | 0.15 | 767.28 |

| Ni | 1.03 | 1.29 | 19.824 |

| Pb | 1.86 | 0.94 | 2.40 |

| Zn | 0.73 | 0.76 | 3.34 |

| Ta | 0.01 | 0.01 | 220 * |

| Total | 34.7% |

| Class Size | Products | % Class | Yield |

|---|---|---|---|

| >1.18 mm | Magnetic fraction | 5% | 0.9% |

| Nonmagnetic fraction | 95% | 16% | |

| 0.6–1.18 mm | Magnetic fraction | 2% | 1.0% |

| Nonmagnetic fraction | 98% | 49% | |

| 0.3–0.6 mm | Magnetic fraction | 2.4% | 0.3% |

| Nonmagnetic fraction | 97.6% | 14% | |

| <0.3 mm | Magnetic fraction | 0.3% | 0.1% |

| Nonmagnetic fraction | 99.7% | 19% |

| Class Size | Products | %Class | Yield |

|---|---|---|---|

| 0.6–1.18 mm | Heavy fraction | 59% | 29% |

| Light fraction | 41% | 20% | |

| 0.3–0.6 mm | Heavy fraction | 34% | 5% |

| Light fraction | 66% | 9% |

| Class Size | Products | Class | Yield |

|---|---|---|---|

| >1.18 mm | Conductive | 64% | 10% |

| Nonconductive | 36% | 6% | |

| <0.3 mm | Conductive | 16% | 3% |

| Nonconductive | 84% | 16% |

| Class Size (mm) | Operation (Product) | Yield * | Concentration (%) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Cu | Pb | Ta | Au | Sn | Al | Ni | Others | |||

| >1.18 | Electrostatic (Conductive) | 10% | 56.1 ± 4.3 | 0.001 ± 0.001 | n.i. | 0.01 ± 0.005 | 3.1 ± 2.6 | 3.1 ± 0.6 | 0.3 ± 0.1 | 37.3 ± 7.6 |

| 0.6–1.18 | Gravity (Heavy Fraction) | 29% | 64.5 ± 0.4 | n.i. | 0.15 ± 0.15 | 0.05 ± 0.04 | 8.8 ± 0.7 | 1.6 ± 0.1 | 0.42 ± 0.02 | 24.4 ± 1.3 |

| 0.3–0.6 | Gravity (Heavy Fraction) | 5% | 75.3 ± 1.25 | 0.03 ± 0.02 | 0.6 ± 0.22 | 0.17 ± 0.06 | 11.10 ± 0.92 | 1.58 ± 0.05 | 0.68 ± 0.2 | 10.5± 2.7 |

| <0.3 | Electrostatic (Conductive) | 3% | 80.5 ± 0.42 | 0.06 ± 0.005 | 0.6 ± 0.07 | 0.17 ± 0.02 | 4.55 ± 0.7 | 2.12 ± 0.08 | 0.65 ± 0.05 | 11.4 ± 1.32 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

de Oliveira, C.M.; Bellopede, R.; Tori, A.; Zanetti, G.; Marini, P. Gravity and Electrostatic Separation for Recovering Metals from Obsolete Printed Circuit Board. Materials 2022, 15, 1874. https://doi.org/10.3390/ma15051874

de Oliveira CM, Bellopede R, Tori A, Zanetti G, Marini P. Gravity and Electrostatic Separation for Recovering Metals from Obsolete Printed Circuit Board. Materials. 2022; 15(5):1874. https://doi.org/10.3390/ma15051874

Chicago/Turabian Stylede Oliveira, Camila Mori, Rossana Bellopede, Alice Tori, Giovanna Zanetti, and Paola Marini. 2022. "Gravity and Electrostatic Separation for Recovering Metals from Obsolete Printed Circuit Board" Materials 15, no. 5: 1874. https://doi.org/10.3390/ma15051874

APA Stylede Oliveira, C. M., Bellopede, R., Tori, A., Zanetti, G., & Marini, P. (2022). Gravity and Electrostatic Separation for Recovering Metals from Obsolete Printed Circuit Board. Materials, 15(5), 1874. https://doi.org/10.3390/ma15051874