3D Printing of Concrete-Geopolymer Hybrids

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Production of Geopolymer

2.3. Production of Concrete

2.4. Production of Hybrid Materials

2.5. Methods

3. Results

3.1. Mineralogical Composition

3.2. Leaching Tests

3.3. Flexural Strength

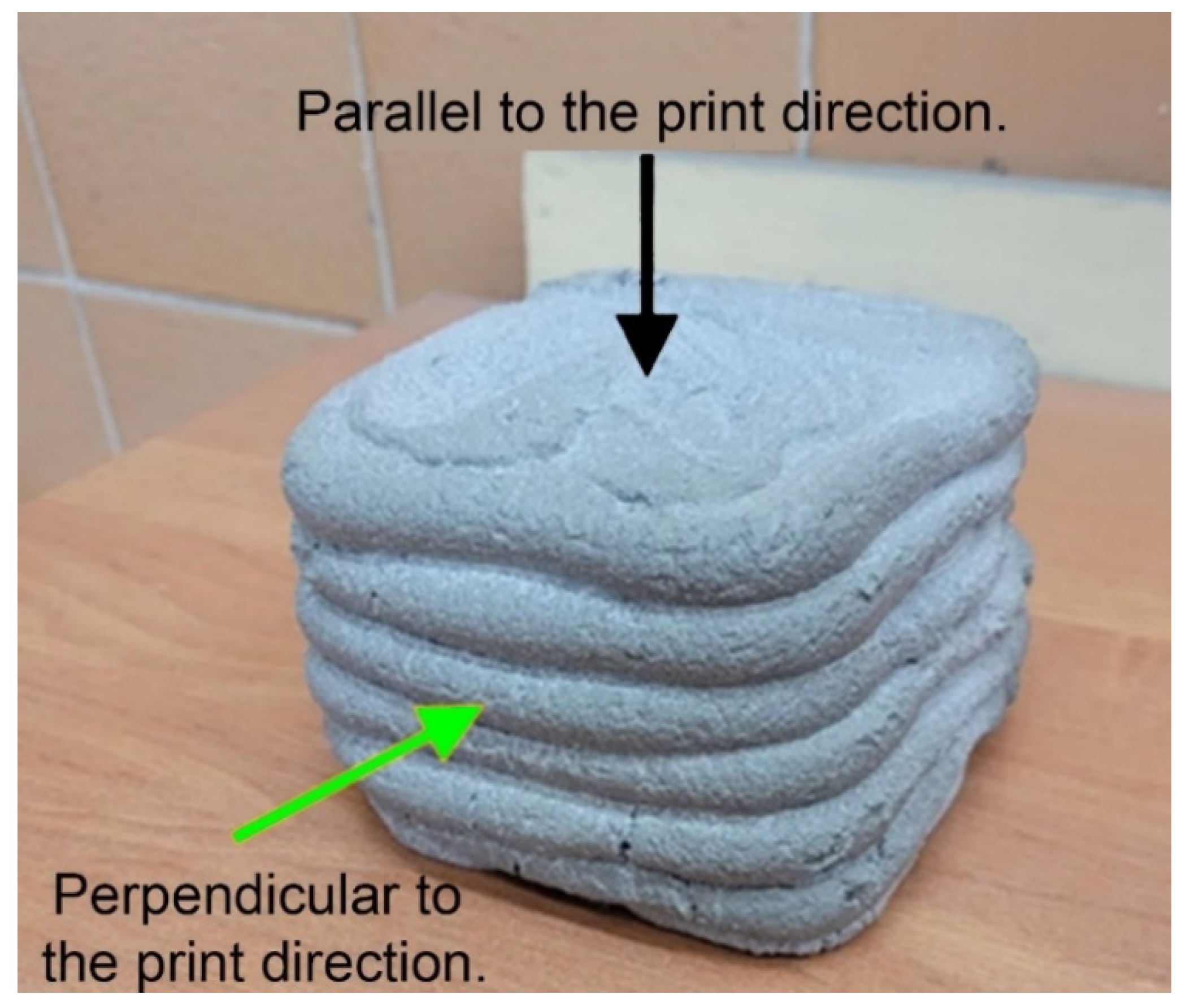

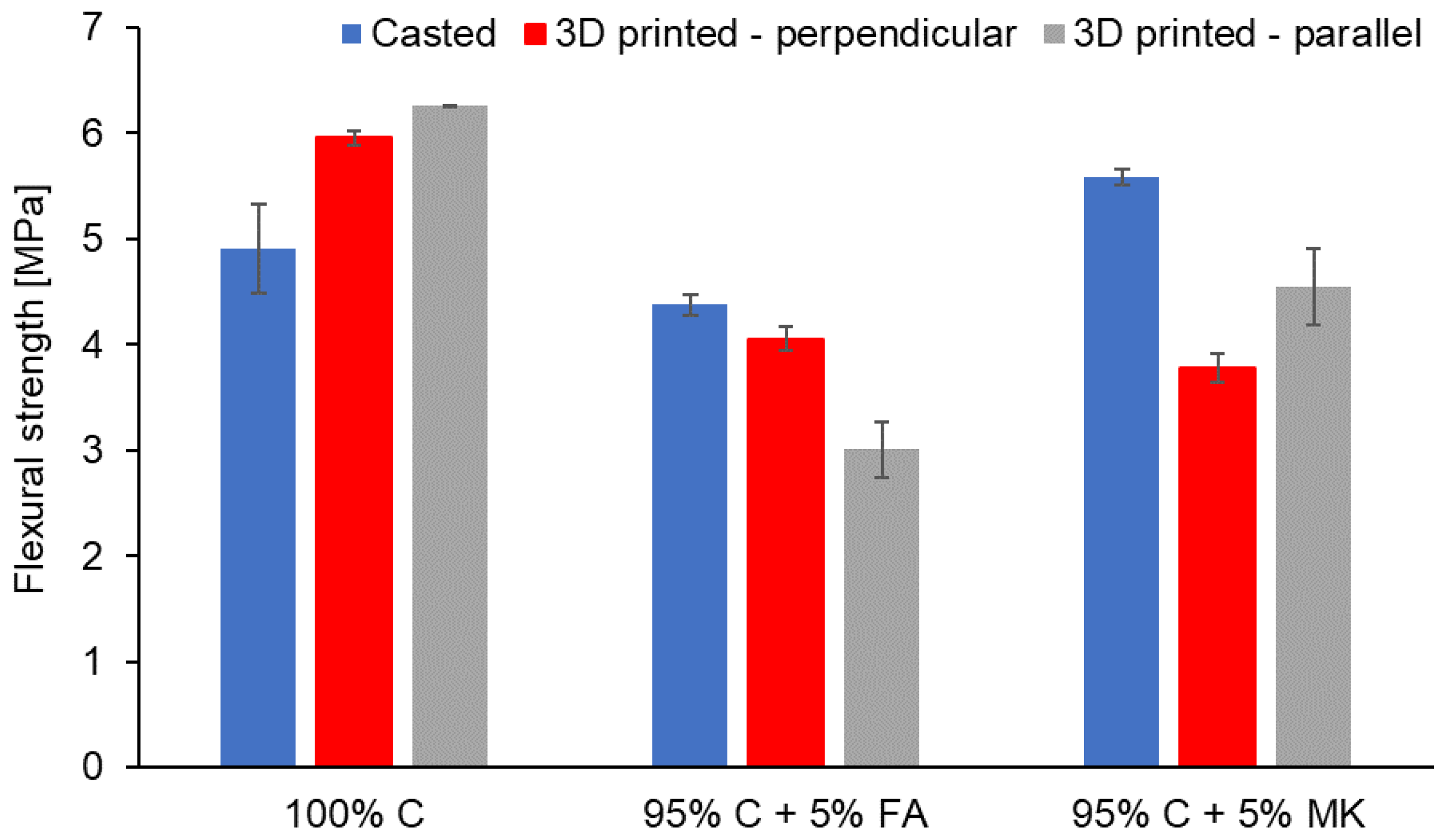

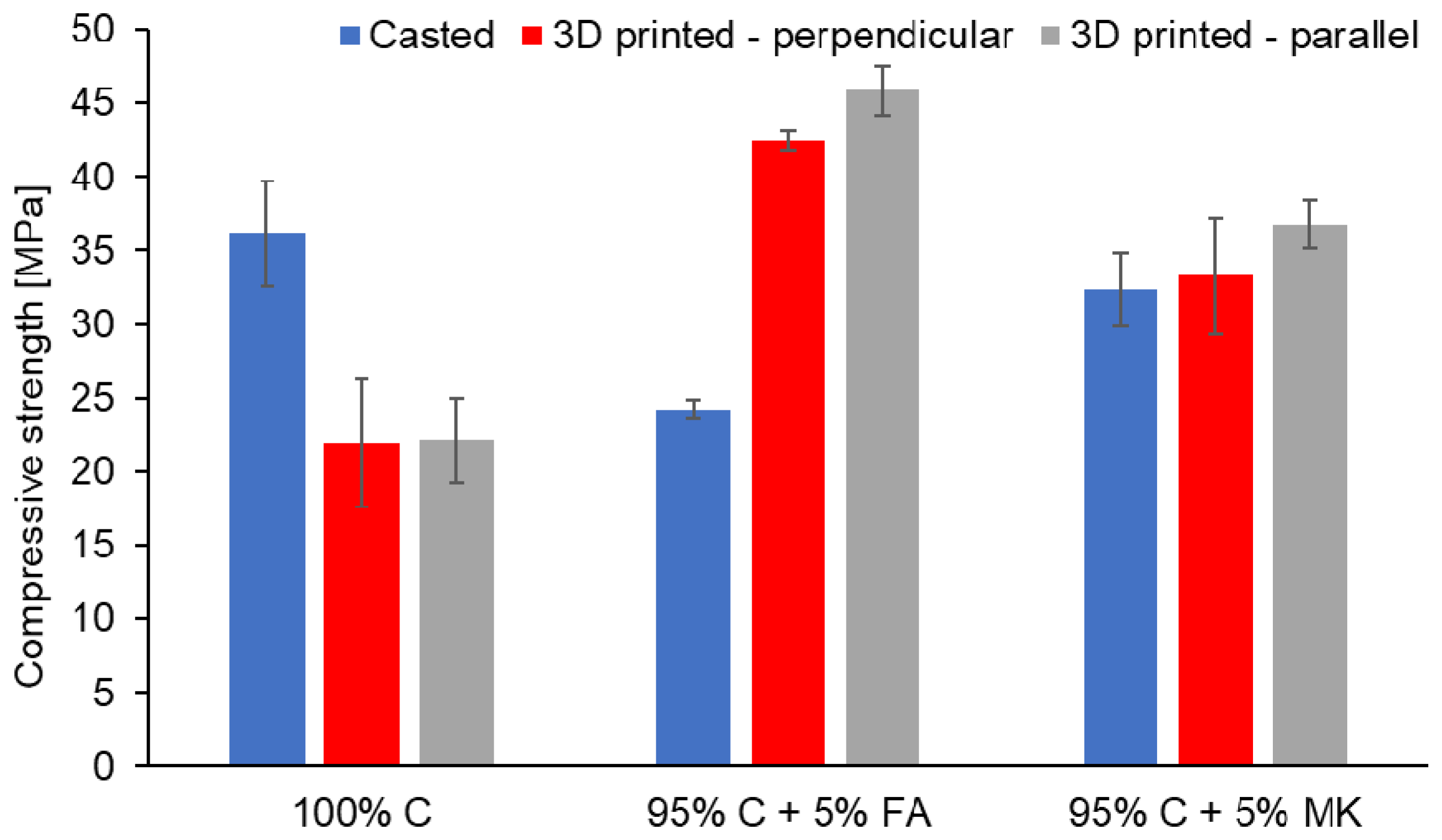

3.4. Compressive Strength

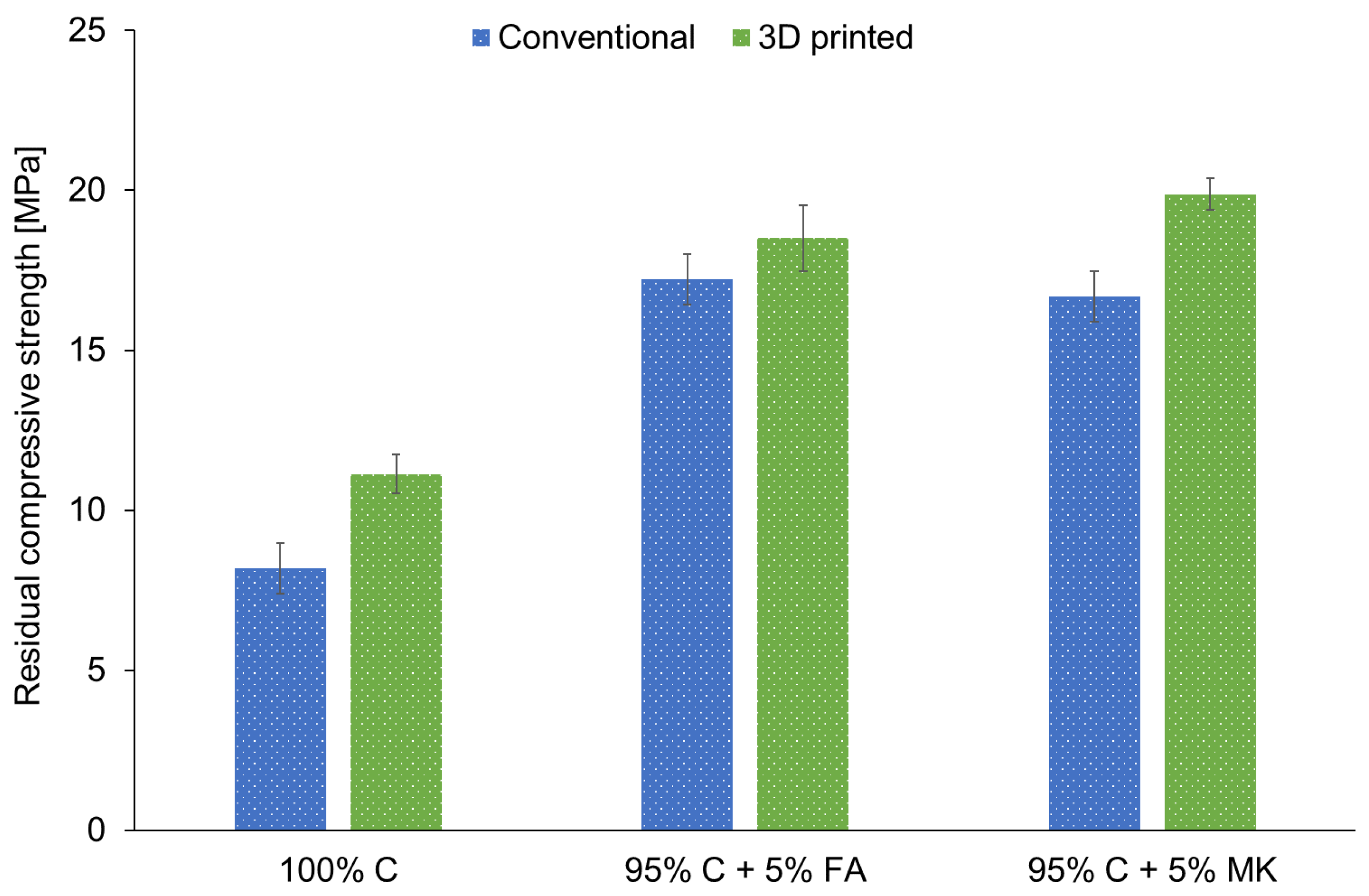

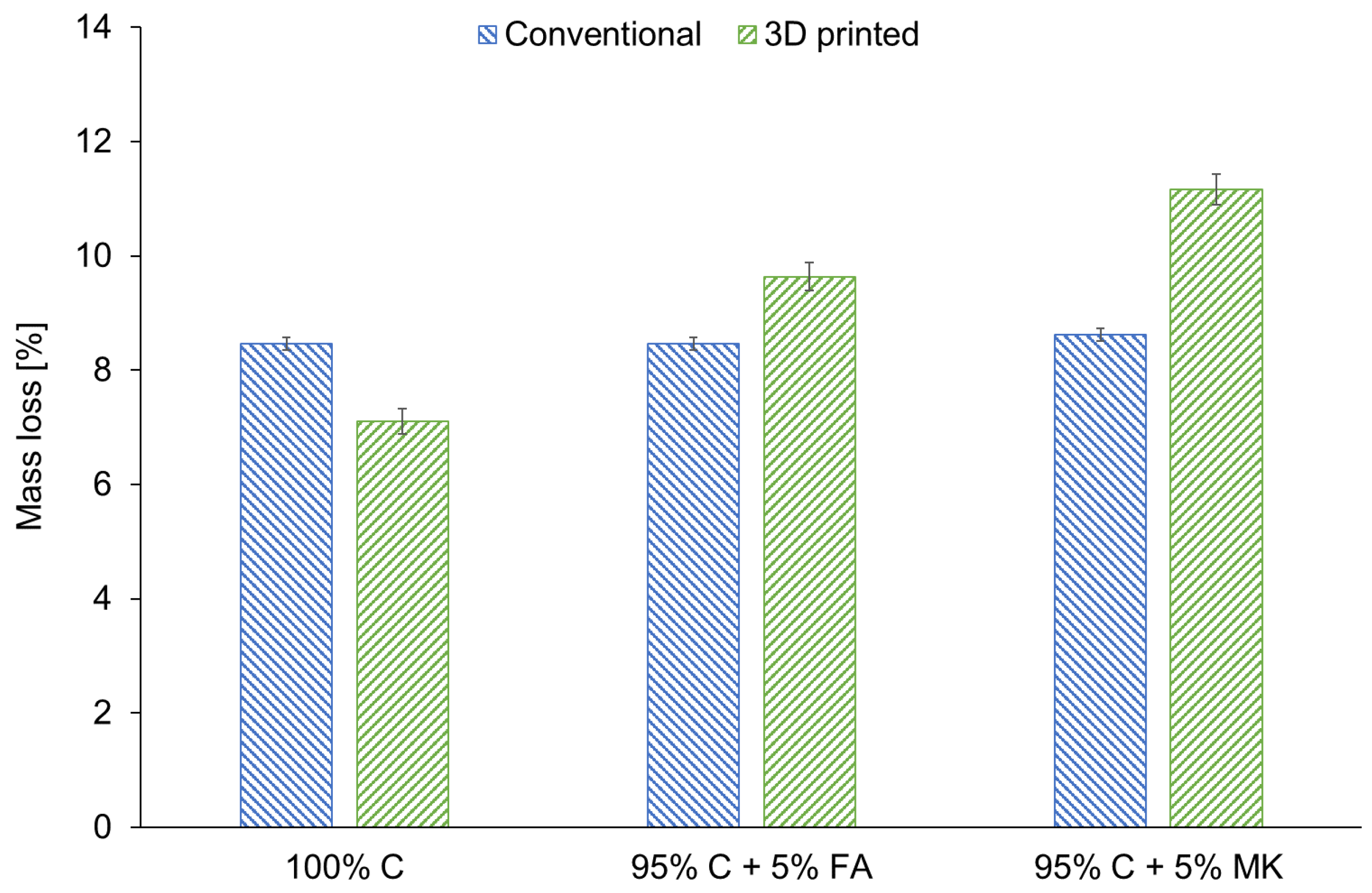

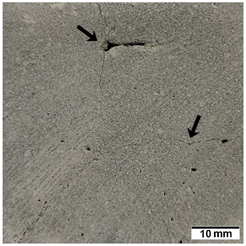

3.5. Fire Resistance

4. Conclusions

- The chemical analysis of concrete and hybrid leachates showed that the concentration of toxic metals was below the limit values; therefore, the materials can be classified as environmentally neutral. The concentration of toxic metals in the tested samples did not exceed 5% of the permissible values that are indicated in Council Decision 2003/33/EC. In general, the leachate of concrete-geopolymer hybrids had a lower content of hazardous compounds compared to concrete samples. Thus, the addition of geopolymer makes the obtained composites more environmentally friendly than concrete.

- The compressive strength of concrete was approximately 40% higher for cast samples than for 3D printed ones. However, for hybrids, this trend was reversed. The addition of fly ash to concrete resulted in a 20% higher compressive strength compared to analogous hybrid mixtures containing the addition of metakaolin. Furthermore, the compressive strength of the samples tested in the parallel direction was 7–10% higher compared to the specimens analyzed in the perpendicular direction to the Z-axis of the printout.

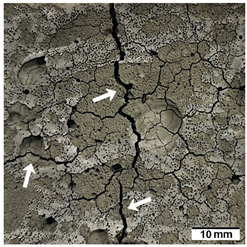

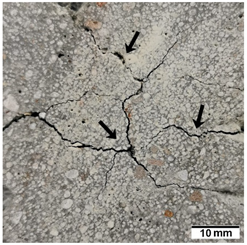

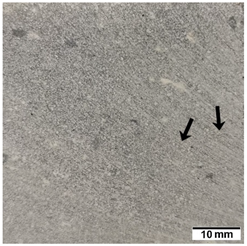

- The sample compressive strength of 24–43 MPa decreased to 8–19 MPa after fire resistance tests. This resulted from moisture evaporation, weight loss, thermal deformation, and crack development. The residual compressive strengths of all the investigated hybrid samples were 1.5- to 2-fold higher than for the concrete samples. Therefore, it can be stated that the addition of geopolymer to the concrete improved the fire resistance of the samples. The 95% C + 5% FA hybrids had a 4% higher residual compressive strength than the 95% C + 5% MK samples. It was also observed that the samples produced by the 3D printing process showed smaller cracks after fire resistance tests compared to the cast samples. On the basis of the obtained results, it was concluded that all the tested materials can be classified as class A1fl.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gagg, C.R. Cement and Concrete as an Engineering Material: An Historic Appraisal and Case Study Analysis. Eng. Fail. Anal. 2014, 40, 114–140. [Google Scholar] [CrossRef]

- Deepa Raj, S.; Ramachandran, A. Performance of Hybrid Fibre Reinforced Geopolymer Concrete Beams. SN Appl. Sci. 2019, 1, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Xie, N. Mechanical and Environmental Resistance of Nanoparticle-Reinforced Pavement Materials. In Innovative Developments of Advanced Multifunctional Nanocomposites in Civil and Structural Engineering; Woodhead Publishing: Sawston, UK, 2016; pp. 217–246. [Google Scholar] [CrossRef]

- Rogelja, I. Concrete and Coal: China’s Infrastructural Assemblages in the Balkans. Political Geogr. 2020, 81, 102220. [Google Scholar] [CrossRef]

- Ismail, M.A.; Mueller, C.T. Minimizing Embodied Energy of Reinforced Concrete Floor Systems in Developing Countries through Shape Optimization. Eng. Struct. 2021, 246, 112955. [Google Scholar] [CrossRef]

- Olofinnade, O.; Morawo, A.; Okedairo, O.; Kim, B. Solid Waste Management in Developing Countries: Reusing of Steel Slag Aggregate in Eco-Friendly Interlocking Concrete Paving Blocks Production. Case Stud. Constr. Mater. 2021, 14, e00532. [Google Scholar] [CrossRef]

- Batayneh, M.K.; Marie, I.; Asi, I. Promoting the Use of Crumb Rubber Concrete in Developing Countries. Waste Manag. 2008, 28, 2171–2176. [Google Scholar] [CrossRef] [PubMed]

- Cosgun, N.; Esin, T. A Study Regarding the Environmental Management System of Ready Mixed Concrete Production in Turkey. Build. Environ. 2006, 41, 1099–1105. [Google Scholar] [CrossRef]

- Hoang, N.H.; Ishigaki, T.; Kubota, R.; Tong, T.K.; Nguyen, T.T.; Nguyen, H.G.; Yamada, M.; Kawamoto, K. Financial and Economic Evaluation of Construction and Demolition Waste Recycling in Hanoi, Vietnam. Waste Manag. 2021, 131, 294–304. [Google Scholar] [CrossRef]

- Tale Masoule, M.S.; Bahrami, N.; Karimzadeh, M.; Mohasanati, B.; Shoaei, P.; Ameri, F.; Ozbakkaloglu, T. Lightweight Geopolymer Concrete: A Critical Review on the Feasibility, Mixture Design, Durability Properties, and Microstructure. Ceram. Int. 2022, 48, 10347–10371. [Google Scholar] [CrossRef]

- Wang, D.; Xiao, J.; Duan, Z. Strategies to Accelerate CO2 Sequestration of Cement-Based Materials and Their Application Prospects. Constr. Build. Mater. 2022, 314, 125646. [Google Scholar] [CrossRef]

- Muthukrishnan, S.; Ramakrishnan, S.; Sanjayan, J. Effect of Alkali Reactions on the Rheology of One-Part 3D Printable Geopolymer Concrete. Cem. Concr. Compos. 2021, 116, 103899. [Google Scholar] [CrossRef]

- Guo, S.Y.; Zhang, X.; Ren, J.; Chen, J.Z.; Zhao, T.J.; Li, T.W.; Zhang, L. Preparation of TiO2/Epoxy Resin Composite and Its Effect on Mechanical and Bonding Properties of OPC Mortars. Constr. Build. Mater. 2021, 272, 121960. [Google Scholar] [CrossRef]

- Sharma, A.; Basumatary, N.; Singh, P.; Kapoor, K.; Singh, S.P. Potential of Geopolymer Concrete as Substitution for Conventional Concrete: A Review—ScienceDirect. Mater. Today Proc. 2021. [Google Scholar] [CrossRef]

- Chen, S.; Ruan, S.; Zeng, Q.; Liu, Y.; Zhang, M.; Tian, Y.; Yan, D. Pore Structure of Geopolymer Materials and Its Correlations to Engineering Properties: A Review. Constr. Build. Mater. 2022, 328, 127064. [Google Scholar] [CrossRef]

- Alhawat, M.; Ashour, A.; Yıldırım, G.; Aldemir, A.; Sahmaran, M. Properties of Geopolymer Sourced from Construction and Demolition Waste: A Review. J. Build. Eng. 2022, 50, 104104. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, C.; Zhu, H.; Wu, Q. Reaction Kinetics and Mechanical Properties of a Mineral-Micropowder/Metakaolin-Based Geopolymer. Ceram. Int. 2022, 48, 14173–14181. [Google Scholar] [CrossRef]

- Lazorenko, G.; Kasprzhitskii, A.; Fini, E.H. Sustainable Construction via Novel Geopolymer Composites Incorporating Waste Plastic of Different Sizes and Shapes. Constr. Build. Mater. 2022, 324, 126697. [Google Scholar] [CrossRef]

- Sharma, A.; Singh, P.; Kapoor, K. Utilization of Recycled Fine Powder as an Activator in Fly Ash Based Geopolymer Mortar. Constr. Build. Mater. 2022, 323, 126581. [Google Scholar] [CrossRef]

- Zawrah, M.F.; Sadek, H.E.H.; Ngida, R.E.A.; Sawan, S.E.A.; El-Kheshen, A.A. Effect of Low-Rate Firing on Physico-Mechanical Properties of Unfoamed and Foamed Geopolymers Prepared from Waste Clays. Ceram. Int. 2022, 48, 11330–11337. [Google Scholar] [CrossRef]

- Liang, G.; Zhu, H.; Li, H.; Liu, T.; Guo, H. Comparative Study on the Effects of Rice Husk Ash and Silica Fume on the Freezing Resistance of Metakaolin-Based Geopolymer. Constr. Build. Mater. 2021, 293, 123486. [Google Scholar] [CrossRef]

- Grela, A.; Łach, M.; Bajda, T.; Mikuła, J.; Hebda, M. Characterization of the Products Obtained from Alkaline Conversion of Tuff and Metakaolin. J. Therm. Anal. Calorim. 2018, 133, 217–226. [Google Scholar] [CrossRef] [Green Version]

- Szechyńska-Hebda, M.; Marczyk, J.; Ziejewska, C.; Hordyńska, N.; Mikuła, J.; Hebda, M. Neutral Geopolymer Foams Reinforced with Cellulose Studied with the FT-Raman Spectroscopy. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 706, p. 012017. [Google Scholar]

- Mendes, B.C.; Pedroti, L.G.; Vieira, C.M.F.; Carvalho, J.M.F.; Ribeiro, J.C.L.; Albuini-Oliveira, N.M.; Andrade, I.K.R. Evaluation of Eco-Efficient Geopolymer Using Chamotte and Waste Glass-Based Alkaline Solutions. Case Stud. Constr. Mater. 2022, 16, e00847. [Google Scholar] [CrossRef]

- Bai, T.; Song, Z.G.; Wu, Y.G.; Hu, X.D.; Bai, H. Influence of Steel Slag on the Mechanical Properties and Curing Time of Metakaolin Geopolymer. Ceram. Int. 2018, 44, 15706–15713. [Google Scholar] [CrossRef]

- Jiao, Z.; Li, X.; Yu, Q. Effect of Curing Conditions on Freeze-Thaw Resistance of Geopolymer Mortars Containing Various Calcium Resources. Constr. Build. Mater. 2021, 313, 125507. [Google Scholar] [CrossRef]

- Nikoloutsopoulos, N.; Sotiropoulou, A.; Kakali, G.; Tsivilis, S. The Effect of Solid/Liquid Ratio on Setting Time, Workability and Compressive Strength of Fly Ash Based Geopolymers. Mater. Today Proc. 2018, 5, 27441–27445. [Google Scholar] [CrossRef]

- Eliche-Quesada, D.; Ruiz-Molina, S.; Pérez-Villarejo, L.; Castro, E.; Sánchez-Soto, P.J. Dust Filter of Secondary Aluminium Industry as Raw Material of Geopolymer Foams. J. Build. Eng. 2020, 32, 101656. [Google Scholar] [CrossRef]

- Bewa, C.N.; Tchakouté, H.K.; Banenzoué, C.; Cakanou, L.; Mbakop, T.T.; Kamseu, E.; Rüscher, C.H. Acid-Based Geopolymers Using Waste Fired Brick and Different Metakaolins as Raw Materials. Appl. Clay Sci. 2020, 198, 105813. [Google Scholar] [CrossRef]

- Gómez-Casero, M.A.; de Dios-Arana, C.; Bueno-Rodríguez, J.S.; Pérez-Villarejo, L.; Eliche-Quesada, D. Physical, Mechanical and Thermal Properties of Metakaolin-Fly Ash Geopolymers. Sustain. Chem. Pharm. 2022, 26, 100620. [Google Scholar] [CrossRef]

- Wang, R.; Wang, J.; Dong, T.; Ouyang, G. Structural and Mechanical Properties of Geopolymers Made of Aluminosilicate Powder with Different SiO2/Al2O3 Ratio: Molecular Dynamics Simulation and Microstructural Experimental Study. Constr. Build. Mater. 2020, 240, 117935. [Google Scholar] [CrossRef]

- Tian, Q.; Nakama, S.; Sasaki, K. Immobilization of Cesium in Fly Ash-Silica Fume Based Geopolymers with Different Si/Al Molar Ratios. Sci. Total Environ. 2019, 687, 1127–1137. [Google Scholar] [CrossRef]

- Yavana Rani, S.; Saleh Nusari, M.; bin Non, J.; Poddar, S.; Bhaumik, A. Durability of Geopolymer Concrete with Addition of Polypropylene Fibre. Mater. Today Proc. 2021. [Google Scholar] [CrossRef]

- Zhao, J.; Liebscher, M.; Tzounis, L.; Mechtcherine, V. Role of Sizing Agent on the Microstructure Morphology and Mechanical Properties of Mineral-Impregnated Carbon-Fiber (MCF) Reinforcement Made with Geopolymers. Appl. Surf. Sci. 2021, 567, 150740. [Google Scholar] [CrossRef]

- Muthukrishnan, S.; Ramakrishnan, S.; Sanjayan, J. Set on Demand Geopolymer Using Print Head Mixing for 3D Concrete Printing. Cem. Concr. Compos. 2022, 128, 104451. [Google Scholar] [CrossRef]

- Ma, S.; Yang, H.; Zhao, S.; He, P.; Zhang, Z.; Duan, X.; Yang, Z.; Jia, D.; Zhou, Y. 3D-Printing of Architectured Short Carbon Fiber-Geopolymer Composite. Compos. Part B Eng. 2021, 226, 109348. [Google Scholar] [CrossRef]

- van Deventer, J.S.J.; Provis, J.L.; Duxson, P.; Brice, D.G. Chemical Research and Climate Change as Drivers in the Commercial Adoption of Alkali Activated Materials. Waste Biomass Valorization 2010, 1, 145–155. [Google Scholar] [CrossRef]

- Gökçe, H.S.; Tuyan, M.; Nehdi, M.L. Alkali-Activated and Geopolymer Materials Developed Using Innovative Manufacturing Techniques: A Critical Review. Constr. Build. Mater. 2021, 303, 124483. [Google Scholar] [CrossRef]

- Criado, M.; Vicent, M.; García-Ten, F.J. Reactivation of Alkali-Activated Materials Made up of Fly Ashes from a Coal Power Plant. Clean. Mater. 2022, 3, 100043. [Google Scholar] [CrossRef]

- Adesina, A.; de Azevedo, A.R.G.; Amin, M.; Hadzima-Nyarko, M.; Agwa, I.S.; Zeyad, A.M.; Tayeh, B.A. Fresh and Mechanical Properties Overview of Alkali-Activated Materials Made with Glass Powder as Precursor. Clean. Mater. 2022, 3, 100036. [Google Scholar] [CrossRef]

- Qing, L.; Shaokang, S.; Zhen, J.; Junxiang, W.; Xianjun, L. Effect of CaO on Hydration Properties of One-Part Alkali-Activated Material Prepared from Tailings through Alkaline Hydrothermal Activation. Constr. Build. Mater. 2021, 308, 124931. [Google Scholar] [CrossRef]

- Davidovits, J.; Davidovits, R.; Davidovits, M. Geopolymeric Cement Based on Fly Ash and Harmless to Use. US8202362B2, 2012. [Google Scholar]

- Lin, C.-Y.; Chen, T.-A. Effects of Composition Type and Activator on Fly Ash-Based Alkali Activated Materials. Polymers 2021, 14, 63. [Google Scholar] [CrossRef]

- Kumar Maurya, A.; Kumar, A. Effect of Building Orientation & Heat-Treatment on Microhardness & Surface Roughness of Additive Manufactured IN718 Alloy. Mater. Today Proc. 2021. [Google Scholar] [CrossRef]

- Kim, T.G.; Shin, G.Y.; Shim, D.S. Study on the Interfacial Characteristics and Crack Propagation of 630 Stainless Steel Fabricated by Hybrid Additive Manufacturing (Additional DED Building on L-PBFed Substrate). Mater. Sci. Eng. A 2022, 835, 142657. [Google Scholar] [CrossRef]

- Attaran, M. The Rise of 3-D Printing: The Advantages of Additive Manufacturing over Traditional Manufacturing. Bus. Horiz. 2017, 60, 677–688. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Traxel, K.D.; Lang, M.; Juhasz, M.; Eliaz, N.; Bose, S. Alloy Design via Additive Manufacturing: Advantages, Challenges, Applications and Perspectives. Mater. Today 2022, 52, 207–224. [Google Scholar] [CrossRef]

- Çam, G. Prospects of Producing Aluminum Parts by Wire Arc Additive Manufacturing (WAAM). Mater. Today Proc. 2022. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; Suman, R.; Rab, S. Role of Additive Manufacturing Applications towards Environmental Sustainability. Adv. Ind. Eng. Polym. Res. 2021, 4, 312–322. [Google Scholar] [CrossRef]

- Ford, S.; Despeisse, M. Additive Manufacturing and Sustainability: An Exploratory Study of the Advantages and Challenges. J. Clean. Prod. 2016, 137, 1573–1587. [Google Scholar] [CrossRef]

- Aramian, A.; Razavi, S.M.J.; Sadeghian, Z.; Berto, F. A Review of Additive Manufacturing of Cermets. Addit. Manuf. 2020, 33, 101130. [Google Scholar] [CrossRef]

- Manikandan, K.; Jiang, X.; Singh, A.A.; Li, B.; Qin, H. Effects of Nozzle Geometries on 3D Printing of Clay Constructs: Quantifying Contour Deviation and Mechanical Properties. Procedia Manuf. 2020, 48, 678–683. [Google Scholar] [CrossRef]

- Durai Murugan, P.; Vijayananth, S.; Natarajan, M.P.; Jayabalakrishnan, D.; Arul, K.; Jayaseelan, V.; Elanchezhian, J. A Current State of Metal Additive Manufacturing Methods: A Review. Mater. Today Proc. 2021. [Google Scholar] [CrossRef]

- Liu, X.; Sun, B. The Influence of Interface on the Structural Stability in 3D Concrete Printing Processes. Addit. Manuf. 2021, 48, 102456. [Google Scholar] [CrossRef]

- Pradeep, P.V.; Paul, L. Review on Novel Biomaterials and Innovative 3D Printing Techniques in Biomedical Applications. Mater. Today Proc. 2022. [Google Scholar] [CrossRef]

- Park, S.; Shou, W.; Makatura, L.; Matusik, W.; Fu, K. 3D Printing of Polymer Composites: Materials, Processes, and Applications. Matter 2022, 5, 43–76. [Google Scholar] [CrossRef]

- Li, Z.; Ma, G.; Wang, F.; Wang, L.; Sanjayan, J. Expansive Cementitious Materials to Improve Micro-Cable Reinforcement Bond in 3D Concrete Printing. Cem. Concr. Compos. 2022, 125, 104304. [Google Scholar] [CrossRef]

- Voney, V.; Odaglia, P.; Brumaud, C.; Dillenburger, B.; Habert, G. From Casting to 3D Printing Geopolymers: A Proof of Concept. Cem. Concr. Res. 2021, 143, 106374. [Google Scholar] [CrossRef]

- Chen, Y.; He, S.; Gan, Y.; Çopuroğlu, O.; Veer, F.; Schlangen, E. A Review of Printing Strategies, Sustainable Cementitious Materials and Characterization Methods in the Context of Extrusion-Based 3D Concrete Printing. J. Build. Eng. 2022, 45, 103599. [Google Scholar] [CrossRef]

- Reinold, J.; Nerella, V.N.; Mechtcherine, V.; Meschke, G. Extrusion Process Simulation and Layer Shape Prediction during 3D-Concrete-Printing Using the Particle Finite Element Method. Autom. Constr. 2022, 136, 104173. [Google Scholar] [CrossRef]

- Hojati, M.; Li, Z.; Memari, A.M.; Park, K.; Zahabi, M.; Nazarian, S.; Duarte, J.P.; Radlińska, A. 3D-Printable Quaternary Cementitious Materials towards Sustainable Development: Mixture Design and Mechanical Properties. Results Eng. 2022, 13, 100341. [Google Scholar] [CrossRef]

- Suraneni, P.; Burris, L.; Shearer, C.R.; Hooton, R.D. ASTM C618 Fly Ash Specification: Comparison with Other Specifications, Shortcomings, and Solutions. ACI Mater. J. 2021, 118, 157–167. [Google Scholar] [CrossRef]

- Marczyk, J.; Ziejewska, C.; Gądek, S.; Korniejenko, K.; Łach, M.; Góra, M.; Kurek, I.; Doğan-Sağlamtimur, N.; Hebda, M.; Szechyńska-Hebda, M. Hybrid Materials Based on Fly Ash, Metakaolin, and Cement for 3D Printing. Materials 2021, 14, 6874. [Google Scholar] [CrossRef]

- Jain, A.; Chaudhary, S.; Gupta, R. Mechanical and Microstructural Characterization of Fly Ash Blended Self-Compacting Concrete Containing Granite Waste. Constr. Build. Mater. 2022, 314, 125480. [Google Scholar] [CrossRef]

- Burduhos Nergis, D.D.; Vizureanu, P.; Sandu, A.V.; Burduhos Nergis, D.P.; Bejinariu, C. XRD and TG-DTA Study of New Phosphate-Based Geopolymers with Coal Ash or Metakaolin as Aluminosilicate Source and Mine Tailings Addition. Materials 2022, 15, 202. [Google Scholar] [CrossRef] [PubMed]

- Liu, K.; Wang, S.; Quan, X.; Duan, W.; Nan, Z.; Wei, T.; Xu, F.; Li, B. Study on the Mechanical Properties and Microstructure of Fiber Reinforced Metakaolin-Based Recycled Aggregate Concrete. Constr. Build. Mater. 2021, 294, 123554. [Google Scholar] [CrossRef]

- Honorio, T.; Guerra, P.; Bourdot, A. Molecular Simulation of the Structure and Elastic Properties of Ettringite and Monosulfoaluminate. Cem. Concr. Res. 2020, 135, 106126. [Google Scholar] [CrossRef]

- Szechyńska-Hebda, M.; Marczyk, J.; Ziejewska, C.; Hordyńska, N.; Mikuła, J.; Hebda, M. Optimal Design of PH-Neutral Geopolymer Foams for Their Use in Ecological Plant Cultivation Systems. Materials 2019, 12, 2999. [Google Scholar] [CrossRef] [Green Version]

- Doğan-Sağlamtimur, N.; Bilgil, A.; Ertürk, S.; Bozkurt, V.; Süzgeç, E.; Akan, A.G.; Nas, P.; Çetin, H.; Szechyńska-Hebda, M.; Hebda, M. Eco-Geopolymers: Physico-Mechanical Features, Radiation Absorption Properties, and Mathematical Model. Polymers 2022, 14, 262. [Google Scholar] [CrossRef]

- Korniejenko, K.; Figiela, B.; Ziejewska, C.; Marczyk, J.; Bazan, P.; Hebda, M.; Choińska, M.; Lin, W.T. Fracture Behavior of Long Fiber Reinforced Geopolymer Composites at Different Operating Temperatures. Materials 2022, 15, 482. [Google Scholar] [CrossRef]

- Korniejenko, K.; Figiela, B.; Miernik, K.; Ziejewska, C.; Marczyk, J.; Hebda, M.; Cheng, A.; Lin, W.T. Mechanical and Fracture Properties of Long Fiber Reinforced Geopolymer Composites. Materials 2021, 14, 5183. [Google Scholar] [CrossRef]

- Łach, M.; Gado, R.A.; Marczyk, J.; Ziejewska, C.; Doğan-Sağlamtimur, N.; Mikuła, J.; Szechyńska-Hebda, M.; Hebda, M. Process Design for a Production of Sustainable Materials from Post-Production Clay. Materials 2021, 14, 953. [Google Scholar] [CrossRef]

- Doğan-Sağlamtimur, N.; Bilgil, A.; Szechyńska-Hebda, M.; Parzych, S.; Hebda, M. Eco-Friendly Fired Brick Produced from Industrial Ash and Natural Clay: A Study of Waste Reuse. Materials 2021, 14, 877. [Google Scholar] [CrossRef]

- Pantazopoulou, E.; Zouboulis, A. Chemical Toxicity and Ecotoxicity Evaluation of Tannery Sludge Stabilized with Ladle Furnace Slag. J. Environ. Manag. 2018, 216, 257–262. [Google Scholar] [CrossRef] [PubMed]

- Council of the European Union. Council Decision Establishing Criteria and Procedures for the Acceptance of Waste at Landfills Pursuant to Article 16 of and Annex II to Directive 1999/31/EC; Council of the European Union: Brussels, Belgium, 2003; pp. 27–49. [Google Scholar]

- Pang, T.; Marken, F.; Zhang, D.; Shen, J. Investigating the Role of Dissolved Inorganic and Organic Carbon in Fluoride Removal by Membrane Capacitive Deionization. Desalination 2022, 528, 115618. [Google Scholar] [CrossRef]

- Fuzail Hashmi, A.; Shariq, M.; Baqi, A. Flexural Performance of High Volume Fly Ash Reinforced Concrete Beams and Slabs. Structures 2020, 25, 868–880. [Google Scholar] [CrossRef]

- Adanagouda; Somasekharaiah, H.M.; Shobha, M.S.; Mallikarjuna, H.M. Mechanical Properties and Acid Attack Test of Hybrid Fiber Reinforced High Performance Concrete for Fly Ash Based Mineral Admixture. Mater. Today Proc. 2022, 51, 742–749. [Google Scholar] [CrossRef]

- Adanagouda; Somasekharaiah, H.M.; Shobha, M.S.; Mallikarjuna, H.M. Combined Effect of Metakaolin and Hybrid Fibers on the Strength Properties of High Performance Concrete. Mater. Today Proc. 2022, 49, 1527–1536. [Google Scholar] [CrossRef]

- Chand, G.; Happy, S.K.; Ram, S. Assessment of the Properties of Sustainable Concrete Produced from Quaternary Blend of Portland Cement, Glass Powder, Metakaolin and Silica Fume. Clean. Eng. Technol. 2021, 4, 100179. [Google Scholar] [CrossRef]

- Yu, S.; Xia, M.; Sanjayan, J.; Yang, L.; Xiao, J.; Du, H. Microstructural Characterization of 3D Printed Concrete. J. Build. Eng. 2021, 44, 102948. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, Y.; Pang, B.; Liu, Z.; Liu, G. Extrusion-Based 3D Printing Concrete with Coarse Aggregate: Printability and Direction-Dependent Mechanical Performance. Constr. Build. Mater. 2021, 296, 123624. [Google Scholar] [CrossRef]

- Wolfs, R.J.M.; Bos, F.P.; Salet, T.A.M. Hardened Properties of 3D Printed Concrete: The Influence of Process Parameters on Interlayer Adhesion. Cem. Concr. Res. 2019, 119, 132–140. [Google Scholar] [CrossRef]

- Sanjayan, J.G.; Nematollahi, B.; Xia, M.; Marchment, T. Effect of Surface Moisture on Inter-Layer Strength of 3D Printed Concrete. Constr. Build. Mater. 2018, 172, 468–475. [Google Scholar] [CrossRef]

- Ding, T.; Xiao, J.; Zou, S.; Wang, Y. Hardened Properties of Layered 3D Printed Concrete with Recycled Sand. Cem. Concr. Compos. 2020, 113, 103724. [Google Scholar] [CrossRef]

- Rahul, A.V.; Santhanam, M.; Meena, H.; Ghani, Z. Mechanical Characterization of 3D Printable Concrete. Constr. Build. Mater. 2019, 227, 116710. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Nerella, V.N.; Will, F.; Näther, M.; Otto, J.; Krause, M. Large-Scale Digital Concrete Construction—CONPrint3D Concept for on-Site, Monolithic 3D-Printing. Autom. Constr. 2019, 107, 102933. [Google Scholar] [CrossRef]

- Rehman, A.U.; Kim, J.H. 3D Concrete Printing: A Systematic Review of Rheology, Mix Designs, Mechanical, Microstructural, and Durability Characteristics. Materials 2021, 14, 3800. [Google Scholar] [CrossRef] [PubMed]

- Marchment, T.; Sanjayan, J.G.; Nematollahi, B.; Xia, M. Interlayer Strength of 3D Printed Concrete: Influencing Factors and Method of Enhancing. In 3D Concrete Printing Technology; Butterworth-Heinemann: Oxford, UK, 2019; pp. 241–264. [Google Scholar] [CrossRef]

- Lu, C.; Wang, Q.; Liu, Y.; Xue, T.; Yu, Q.; Chen, S. Influence of New Organic Alkali Activators on Microstructure and Strength of Fly Ash Geopolymer. Ceram. Int. 2022, 48, 12442–12449. [Google Scholar] [CrossRef]

- Aziz, I.H.; al Bakri Abdullah, M.M.; Yong, H.C.; Ming, L.Y.; Hussin, K.; Surleva, A.; Azimi, E.A. Manufacturing Parameters Influencing Fire Resistance of Geopolymers: A Review. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2019, 233, 721–733. [Google Scholar] [CrossRef]

- Albidah, A.; Alqarni, A.S.; Abbas, H.; Almusallam, T.; Al-Salloum, Y. Behavior of Metakaolin-Based Geopolymer Concrete at Ambient and Elevated Temperatures. Constr. Build. Mater. 2022, 317, 125910. [Google Scholar] [CrossRef]

- Razak, S.N.A.; Shafiq, N.; Guillaumat, L.; Wahab, M.M.A.; Farhan, S.A.; Husna, N.; Ismail, F.I. Fire Performance of Fly Ash-Based Geopolymer Concrete: Effect of Burning Temperature. IOP Conf. Ser. Earth Environ. Sci. 2021, 945, 012062. [Google Scholar] [CrossRef]

- Klima, K.M.; Schollbach, K.; Brouwers, H.J.H.; Yu, Q. Thermal and Fire Resistance of Class F Fly Ash Based Geopolymers—A Review. Constr. Build. Mater. 2022, 323, 126529. [Google Scholar] [CrossRef]

- Hebda, M.; Laska, M.; Szechyńska-Hebda, M. Application of a device used for observation of controlled thermal processes in a furnace: Examples of delubrication, oxidation, melting, pyrolysis, and combustion. J. Therm. Anal. Calorim. 2013, 114, 1099–1109. [Google Scholar] [CrossRef] [Green Version]

- Kong, D.L.Y.; Sanjayan, J.G.; Sagoe-Crentsil, K. Comparative Performance of Geopolymers Made with Metakaolin and Fly Ash after Exposure to Elevated Temperatures. Cem. Concr. Res. 2007, 37, 1583–1589. [Google Scholar] [CrossRef]

- Lahoti, M.; Tan, K.H.; Yang, E.H. A Critical Review of Geopolymer Properties for Structural Fire-Resistance Applications. Constr. Build. Mater. 2019, 221, 514–526. [Google Scholar] [CrossRef]

| Component | Fly Ash (%) | Metakaolin (%) |

|---|---|---|

| SiO2 | 48.220 | 52.430 |

| Al2O3 | 26.130 | 42.750 |

| Fe2O3 | 7.010 | 1.200 |

| CaO | 5.120 | 0.490 |

| K2O | 3.480 | 1.300 |

| Na2O | 1.615 | 0.000 |

| MgO | 1.720 | 0.175 |

| SO3 | 1.110 | 0.030 |

| TiO2 | 1.110 | 0.310 |

| P2O5 | 0.700 | 0.440 |

| Cl | 0.090 | 0.060 |

| Sample | C Mixture | Geopolymer Mixture | |||

|---|---|---|---|---|---|

| OPC | Sand | MK | FA | Sand | |

| C | 25 | 25 | - | - | - |

| 95% C + 5% FA | 23.75 | 23.75 | - | 1.25 | 1.25 |

| 95% C + 5% MK | 23.75 | 23.75 | 1.25 | - | 1.25 |

| Sample | ||||

|---|---|---|---|---|

| 100% C | 95% C + 5% FA | 95% C + 5% MK | ||

| Quartz | 56.5 | 56.8 | 69.4 | |

| Alite | 31.2 | 24.1 | 19.2 | |

| C-S-H | 2.7 | 7.3 | 6.8 | |

| Phase (%) | Calcite | 9.1 | 10.3 | 3.4 |

| Ettringite | 0.6 | 1.5 | 1.2 | |

| Samples | Unit | 100% C | 95% C + 5% FA | 95% C + 5% MK |

|---|---|---|---|---|

| pH of the water extract | - | 12.67 ± 0.08 | 12.64 ± 0.08 | 12.64 ± 0.08 |

| Total dissolved substances | mg/dm3 | 2032 ± 80 | 2109 ± 83 | 2098 ± 82 |

| Chlorides | 7.52 ± 0.62 | 6.97 ± 0.58 | 6.70 ± 0.56 | |

| Fluorides | 0.5 ± 0.1 | 0.4 ± 0.1 | 0.4 ± 0.1 | |

| Sulfates | 11.5 ± 0.9 | 5.14 ± 0.42 | 3.14 ± 0.26 | |

| Zn | 0.0030 ± 0.0005 | <0.001 | 0.0060 ± 0.0009 | |

| Cd | <0.001 | <0.001 | <0.001 | |

| Cu | 0.0020 ± 0.0002 | <0.001 | <0.001 | |

| Pb | 0.252 ± 0.037 | <0.001 | 0.035 ± 0.005 | |

| Ni | <0.001 | <0.001 | <0.001 | |

| Ba | 0.765 ± 0.170 | 0.805 ± 0.179 | 0.489 ± 0.109 | |

| Cr | 0.096 ± 0.022 | 0.063 ± 0.015 | 0.050 ± 0.012 | |

| Cr (VI) | 0.090 ± 0.005 | 0.061 ± 0.003 | 0.050 ± 0.012 | |

| Hg | <0.01 | <0.01 | <0.01 | |

| As | <0.01 | <0.01 | <0.01 | |

| Se | <0.02 | <0.02 | <0.02 | |

| Mo | <0.02 | <0.02 | <0.02 | |

| Sb | <0.02 | <0.02 | <0.02 | |

| Dissolved organic carbon | 6.30 ± 0.57 | 5.76 ± 0.52 | 4.76 ± 0.43 |

| Sample | Mold Casting | 3D Printing |

|---|---|---|

| 100% C |  |  |

| 95% C + 5% FA |  |  |

| 95% C + 5% MK |  |  |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ziejewska, C.; Marczyk, J.; Korniejenko, K.; Bednarz, S.; Sroczyk, P.; Łach, M.; Mikuła, J.; Figiela, B.; Szechyńska-Hebda, M.; Hebda, M. 3D Printing of Concrete-Geopolymer Hybrids. Materials 2022, 15, 2819. https://doi.org/10.3390/ma15082819

Ziejewska C, Marczyk J, Korniejenko K, Bednarz S, Sroczyk P, Łach M, Mikuła J, Figiela B, Szechyńska-Hebda M, Hebda M. 3D Printing of Concrete-Geopolymer Hybrids. Materials. 2022; 15(8):2819. https://doi.org/10.3390/ma15082819

Chicago/Turabian StyleZiejewska, Celina, Joanna Marczyk, Kinga Korniejenko, Sebastian Bednarz, Piotr Sroczyk, Michał Łach, Janusz Mikuła, Beata Figiela, Magdalena Szechyńska-Hebda, and Marek Hebda. 2022. "3D Printing of Concrete-Geopolymer Hybrids" Materials 15, no. 8: 2819. https://doi.org/10.3390/ma15082819

APA StyleZiejewska, C., Marczyk, J., Korniejenko, K., Bednarz, S., Sroczyk, P., Łach, M., Mikuła, J., Figiela, B., Szechyńska-Hebda, M., & Hebda, M. (2022). 3D Printing of Concrete-Geopolymer Hybrids. Materials, 15(8), 2819. https://doi.org/10.3390/ma15082819