Many-Scale Investigations of Deformation Behavior of Polycrystalline Composites: II—Micro-Macro Simultaneous FE and Discrete Dislocation Dynamics Simulation

Abstract

:1. Introduction

2. Materials and Experiments

2.1. Materials

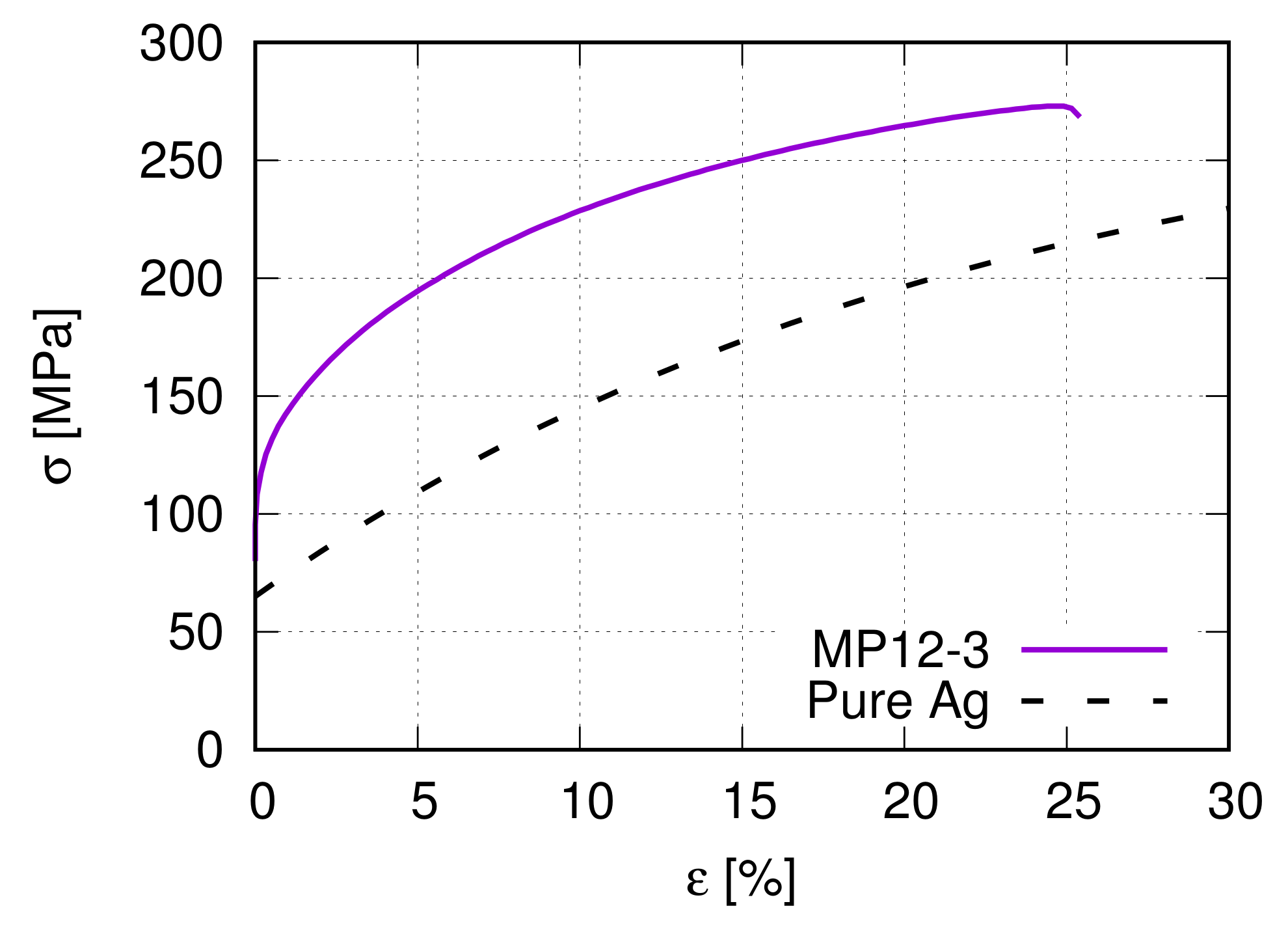

2.2. Selected Material Data and Tensile Flow Curves

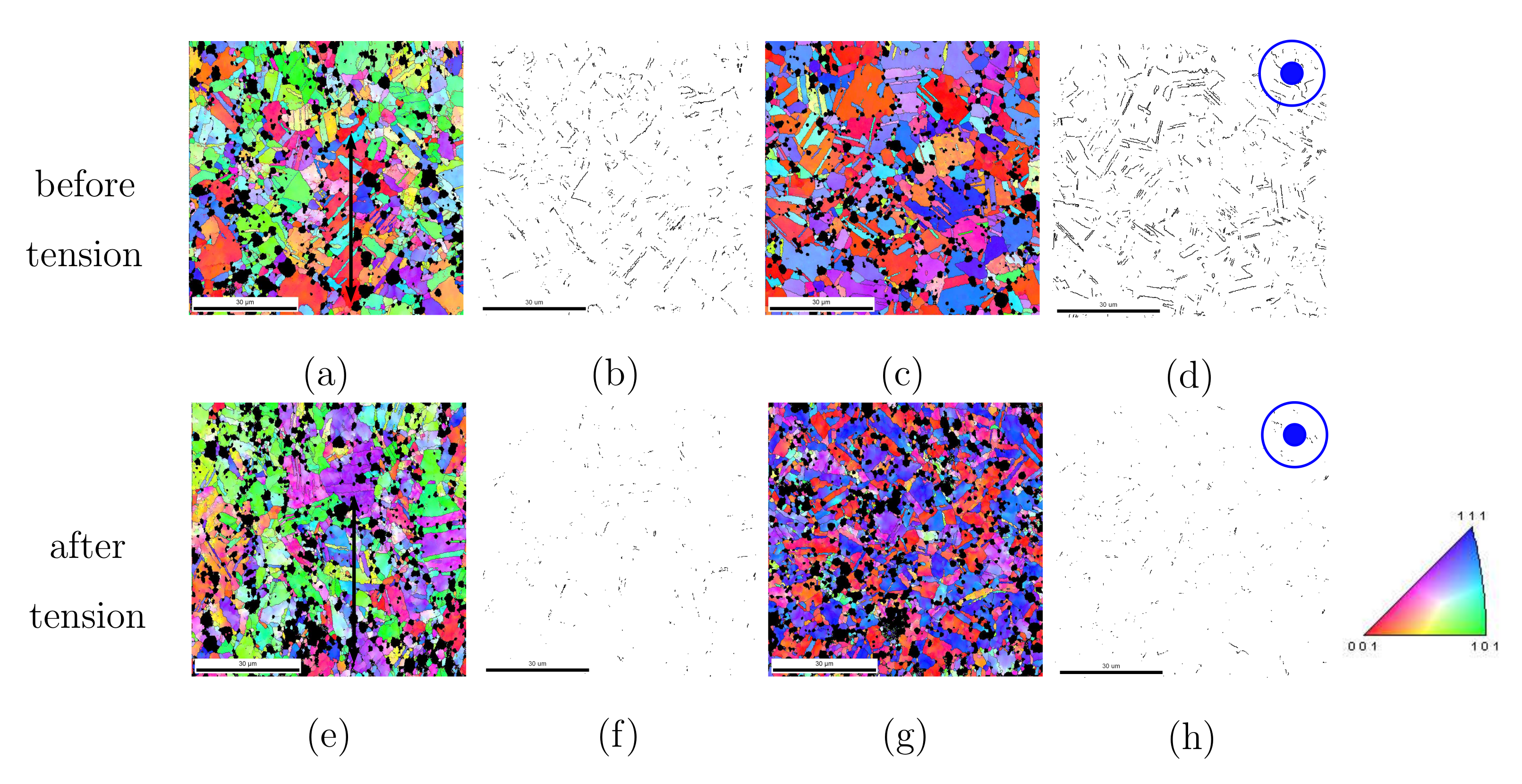

2.3. Measured 3-Twins and Texture

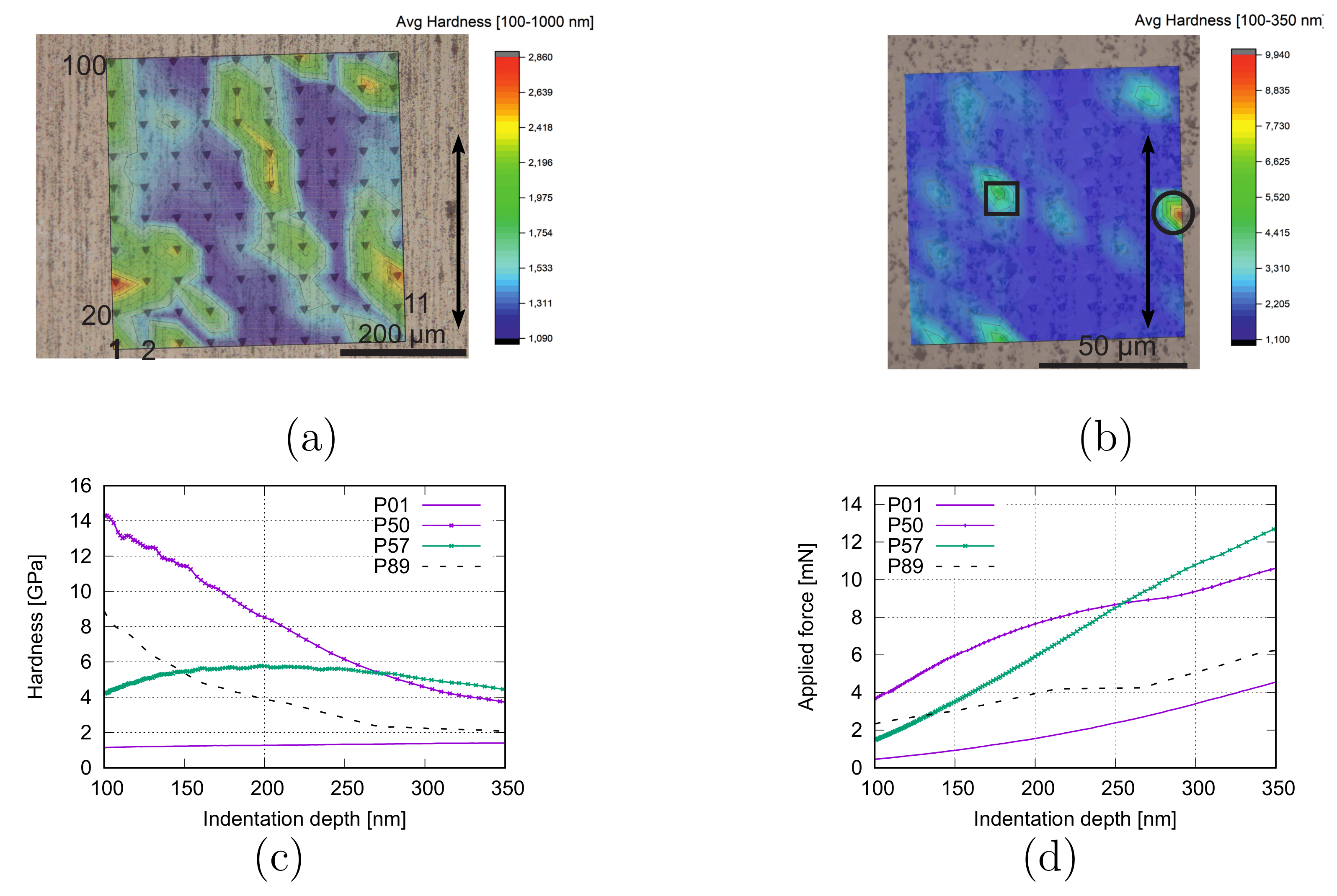

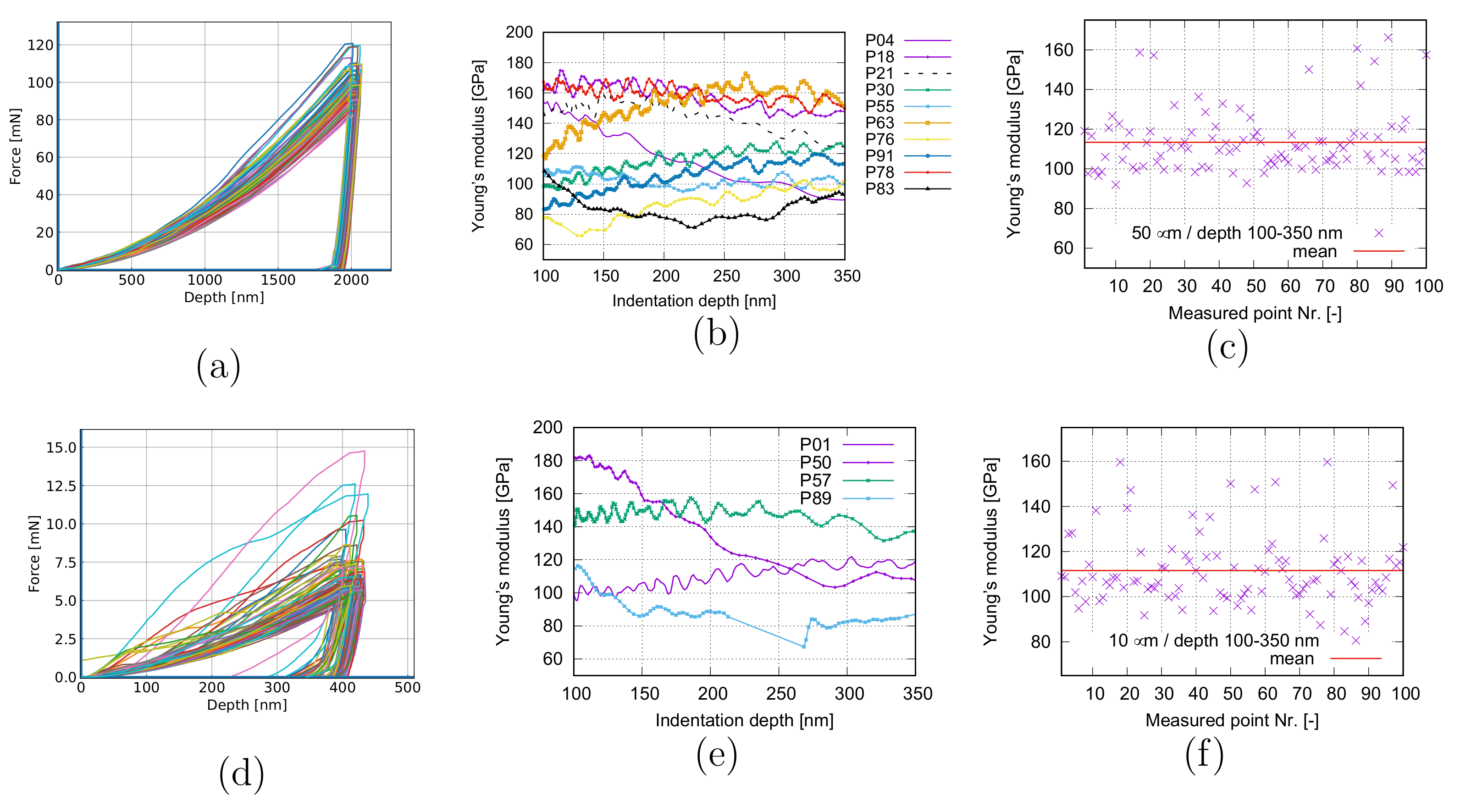

2.4. Indentation Tests

3. Finite Element Simulation

3.1. Material Law

3.1.1. Crystal Plasticity: Elasto-Viscoplasticity

Elastic Law

Flow Rule

Hardening Rule

Homogenization

3.1.2. Applied Structure, Meshing, and Boundary Conditions

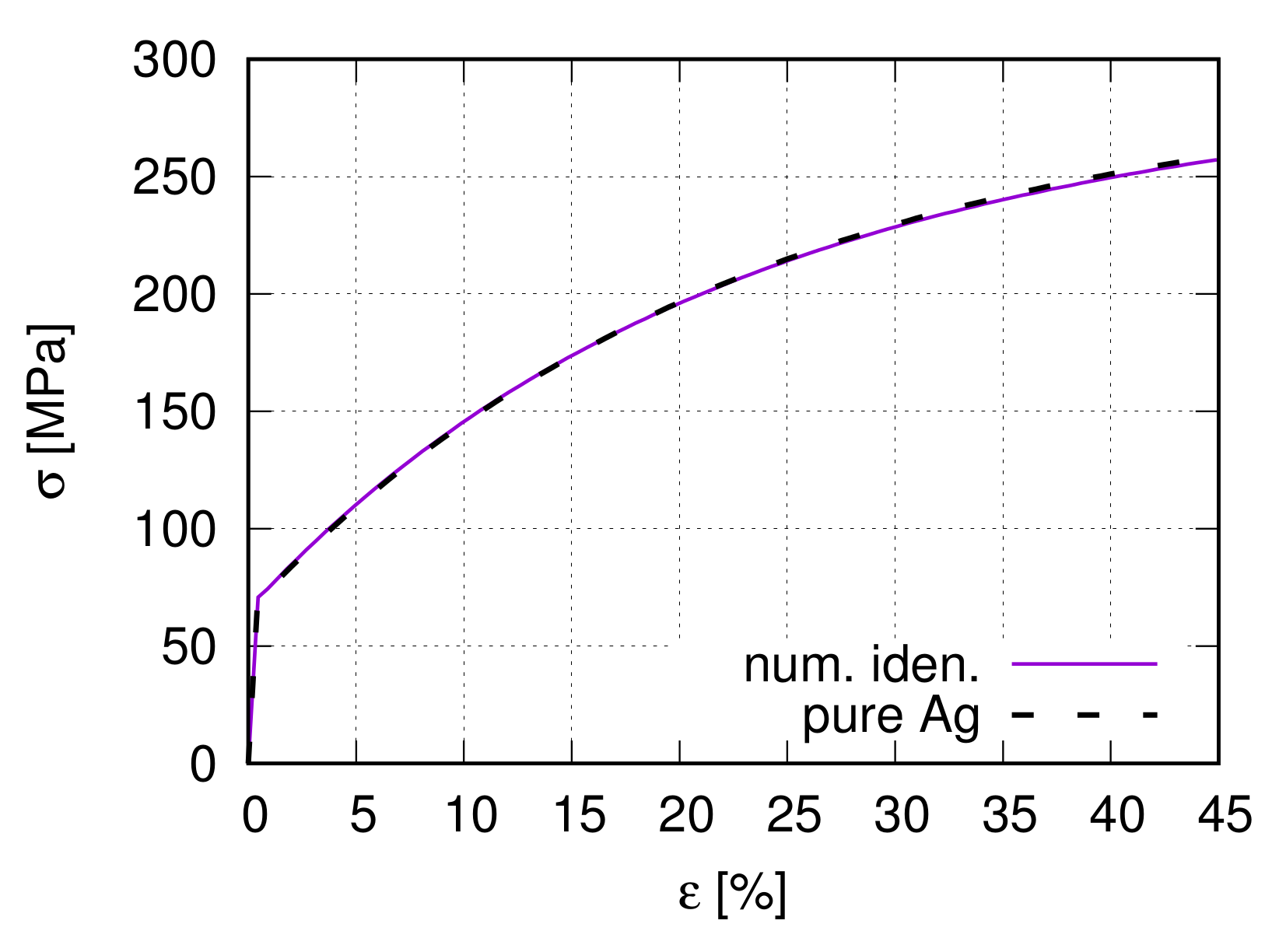

3.1.3. Parameter Identification

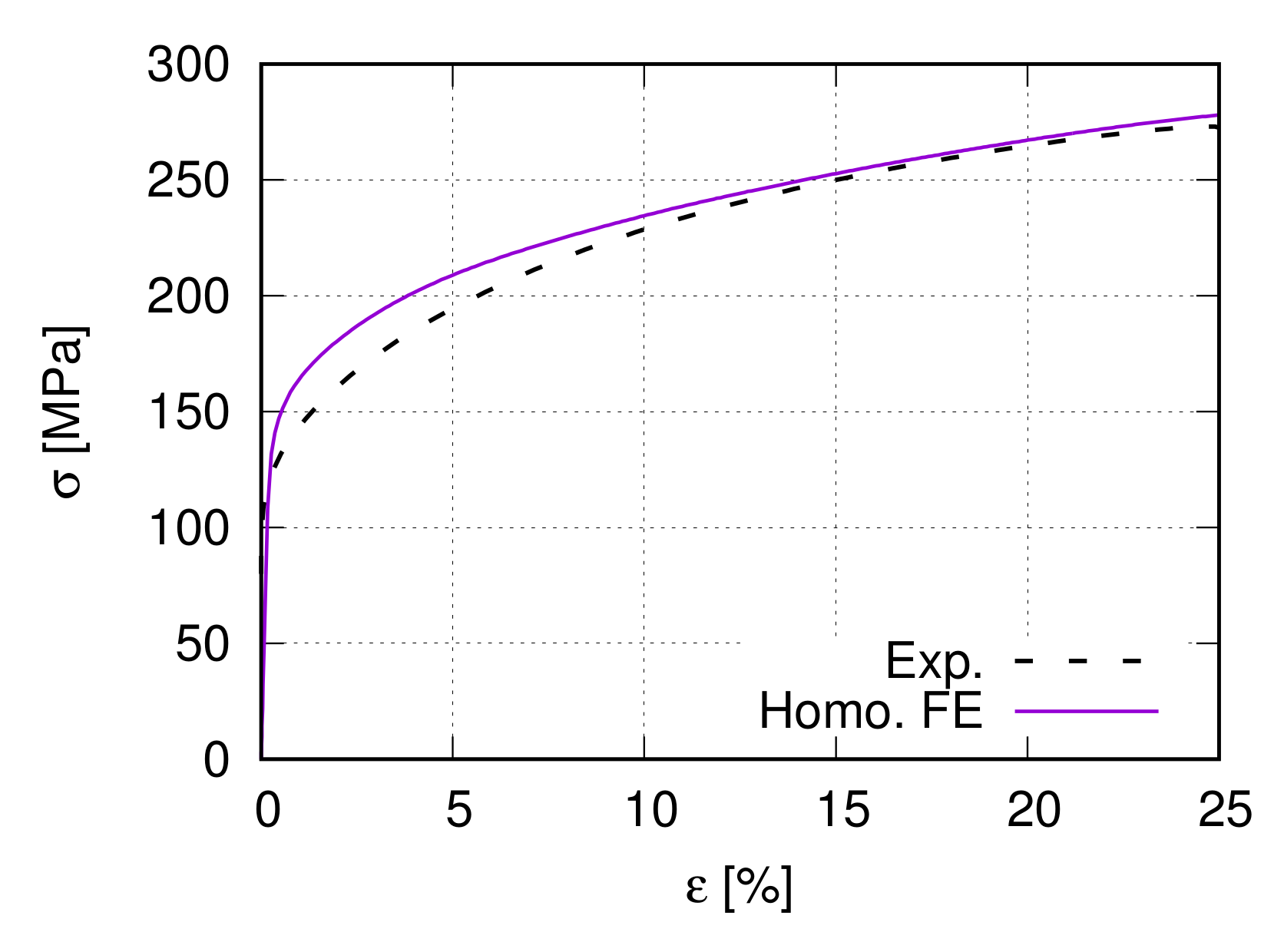

3.2. Numerical and Experimental Result Comparison and Discussion

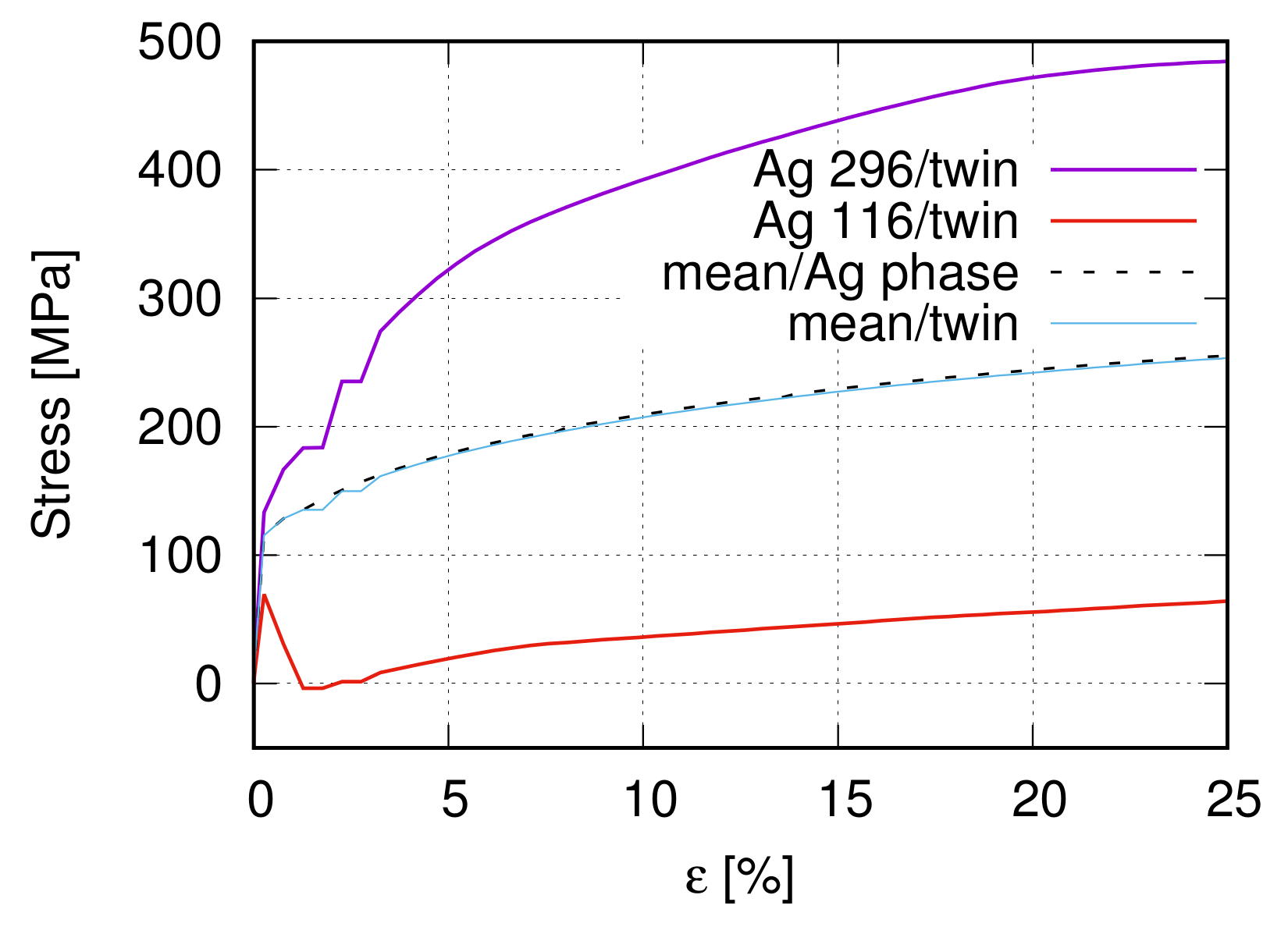

3.2.1. Global and Local Stress-Strain Behavior

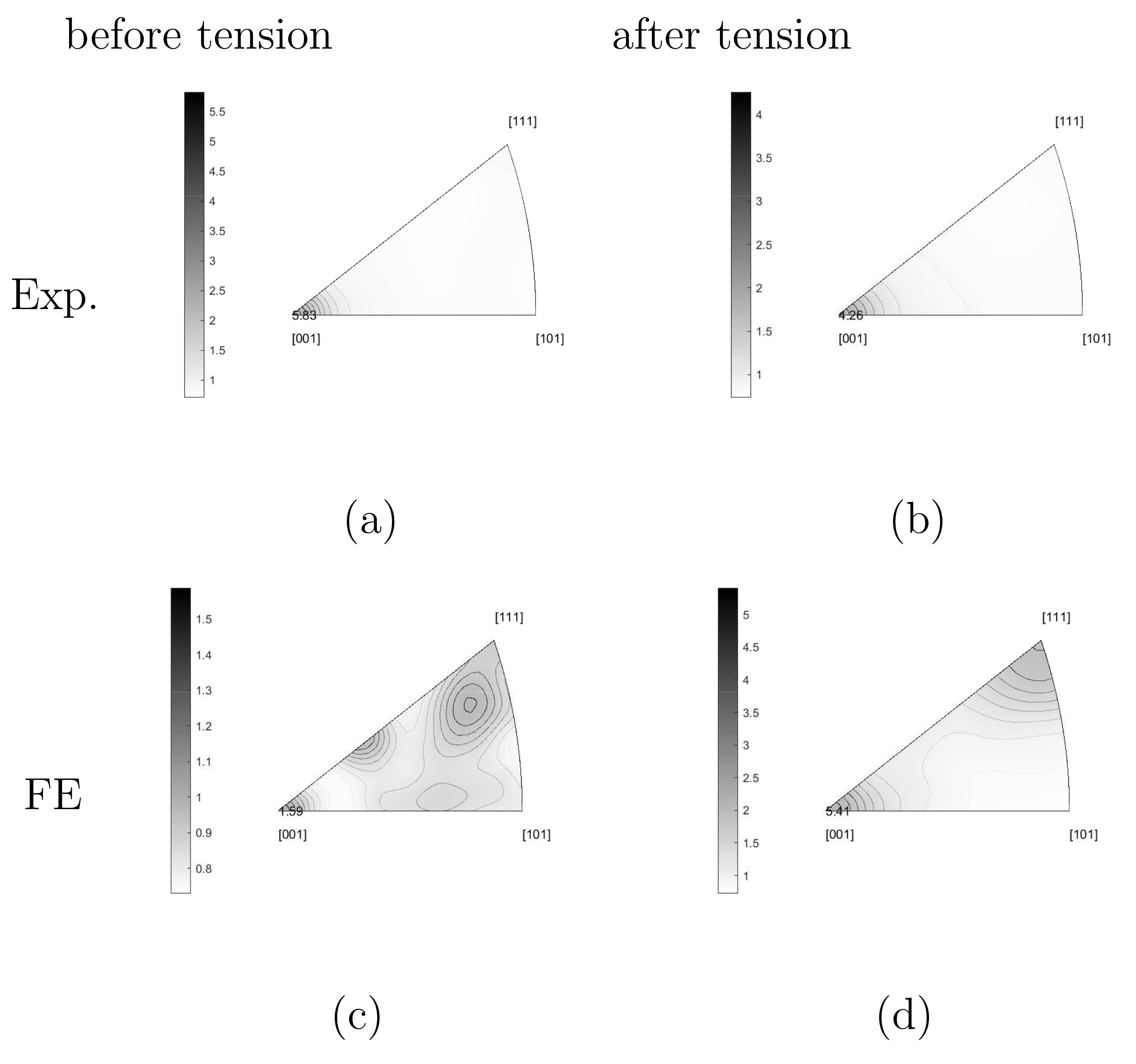

3.2.2. Texture Evolution

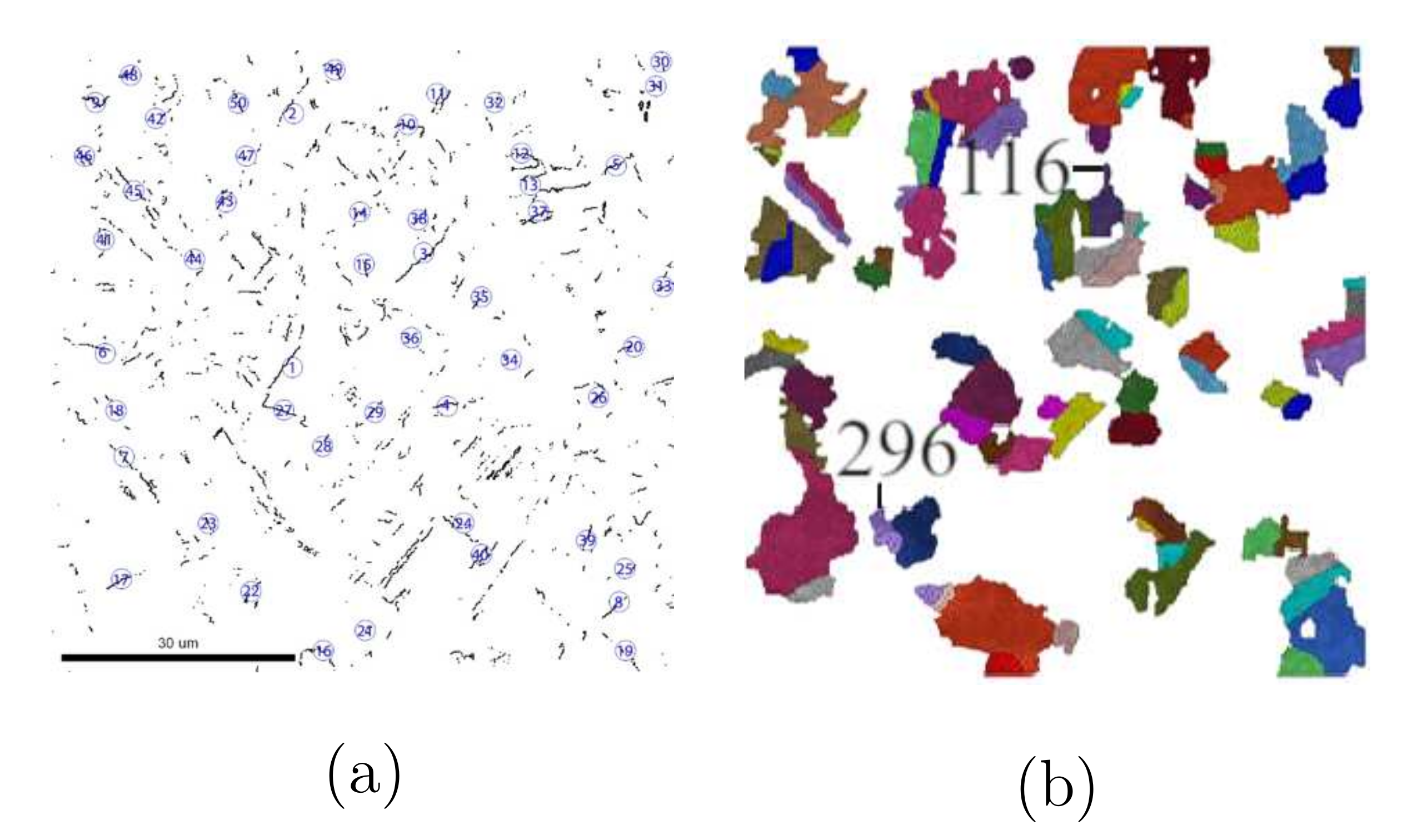

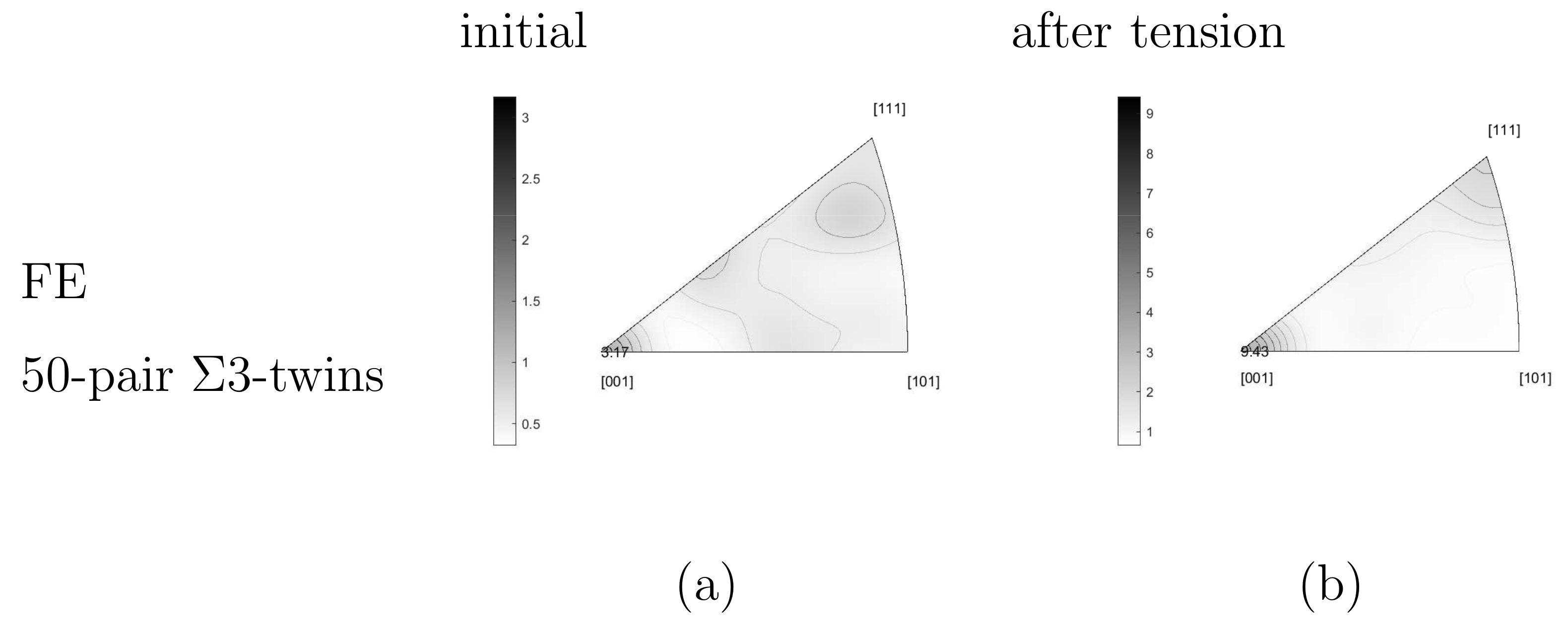

3.2.3. 3-Twins Effect on Deformation Behaviors

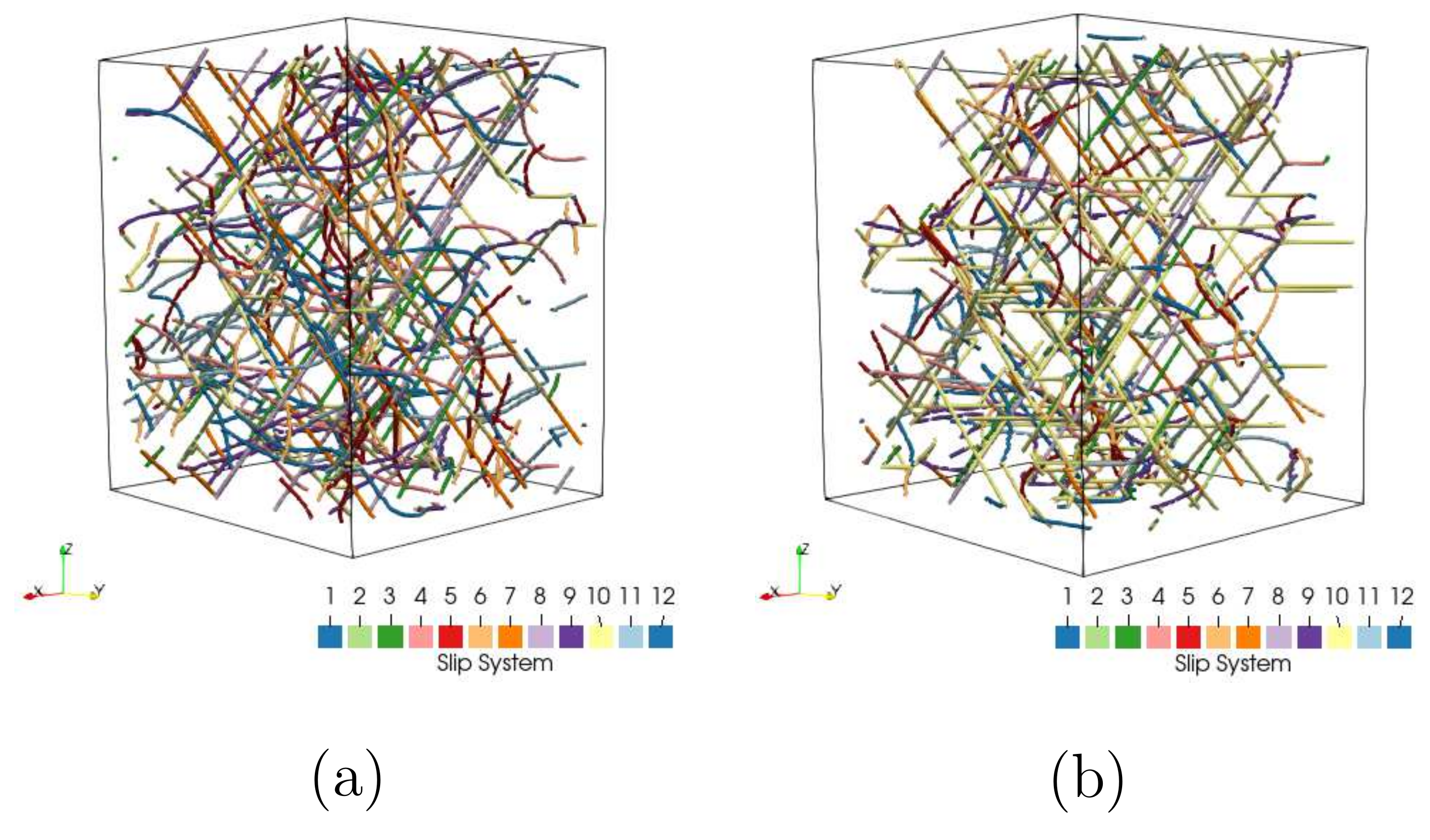

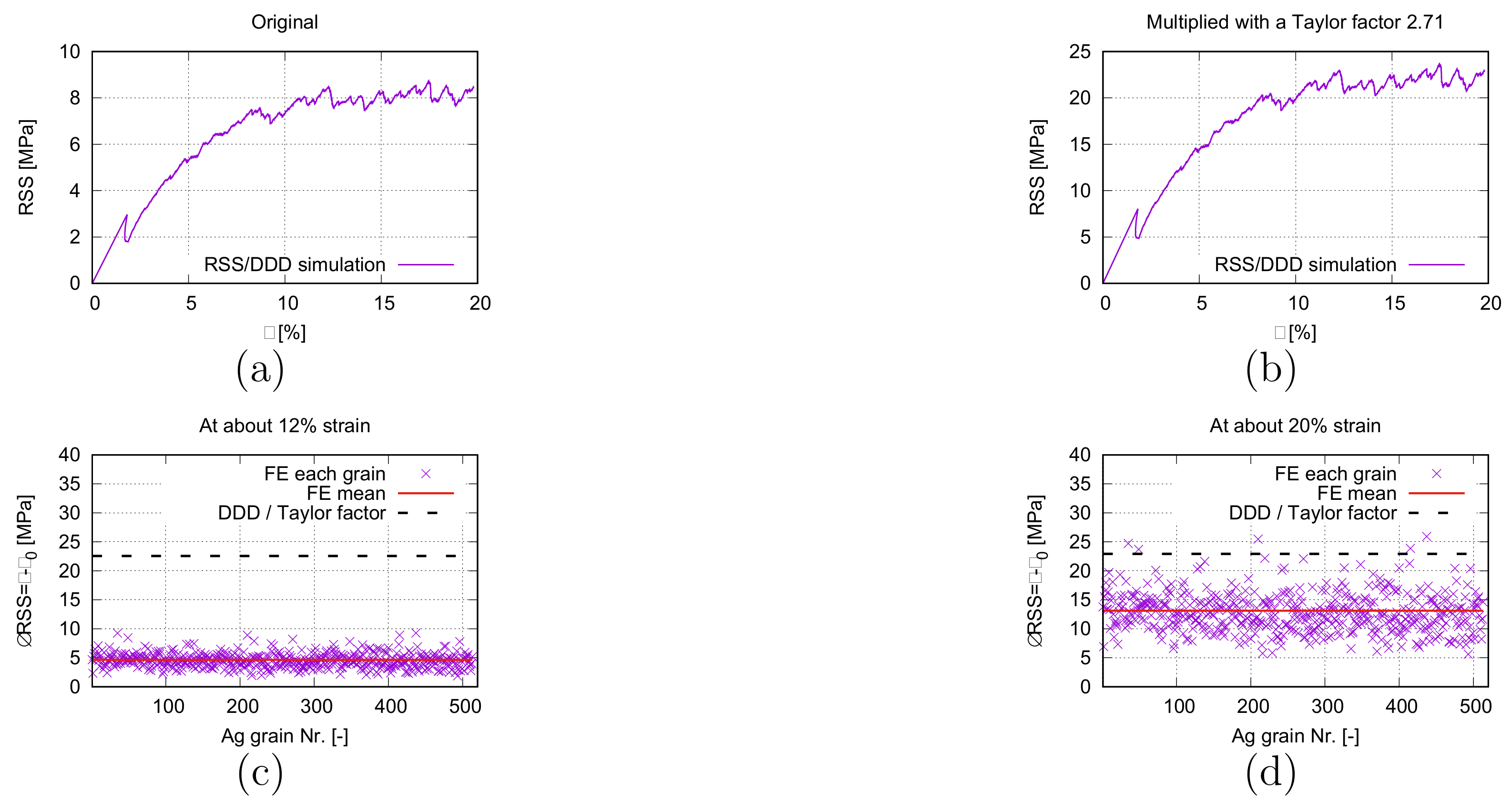

4. Discrete Dislocation Dynamics Simulation and Result Comparison

5. Further Work

6. Conclusions

- The homogenized stress–strain flow behavior of the micromechanical FE simulation matches the measured global one very well;

- The FE prediction can capture the measured tensile texture volution characteristics: high [001] and [111] fiber intensity. The selected 50 pairs of 3-twins present a higher fiber intensity increment than the Ag phase. It means some 3-twins vanished after the tensile loading, which corresponds to the measured result (vol.% reduction of 3-twins);

- The 3-twins show a slightly softer hardening behavior compared to the Ag phase in the FE simulation;

- Based on the FE results, it let be deduced that 3-twins prefer to rotate to [001] and [111] fiber direction (twins disappear), and this preference caused other grains to rotate away from [001] and [111]. As a result, the overall [001] and [111] fiber intensity was deduced compared to the initial state (observation from the experiment);

- DDD-predicted local yielding strains (elastic moduli) strongly depend on the initial grain orientations and dislocation density. The dislocation morphology evolution indicates that only the slip systems with the highest values of the Schmidt factor are activated by the external loading, whereas dislocations in systems perpendicular to the loading direction remain static.

- At about 12% tensile strain, on the microscale, the RSS values () among 513 considered Ag grains cover a range of ≈[2, 10] MPa and its mean value ≈4.6 MPa. A large discrepancy of the RSS existed between the FE and DDD ( 22.5 MPa in DDD) simulations. However, at 20% loading strain, some FE predicted values of individual grains are comparable with the RSS in DDD;

- From machine learning results for autonomous EBSD image segmentation, one performable method came to light to realize a multiscale simulation with the usage of experimental data: all considered hundreds of Ag grains are parsed into a few grain-groups due to the very sharp initial texture; for each grain-group, the resulting orientation and mean grain size (as input data for DDD simulation) can be calculated; the CRSS values () predicted by DDD simulations can be used as initial local yielding stresses for grains in the FE simulation (will be performed in the further work).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lu, X.; Zhang, X.; Shi, M.; Roters, F.; Kang, G.; Raabe, D. Dislocation mechanism based size-dependent crystal plasticity modeling and simulation of gradient nano-grained copper. Int. J. Plast. 2019, 113, 52–73. [Google Scholar] [CrossRef]

- Konijnenberg, P.; Zaefferer, S.; Raabe, D. Assessment of geometrically necessary dislocation levels derived by 3D EBSD. Acta Mater. 2015, 99, 402–414. [Google Scholar] [CrossRef]

- Zaafarani, N.; Raabe, D.; Singh, R.; Roters, F.; Zaefferer, S. Three-dimensional investigation of the texture and microstructure below a nanoindent in a Cu single crystal using 3D EBSD and crystal plasticity finite element simulations. Acta Mater. 2006, 54, 1862–1876. [Google Scholar] [CrossRef]

- Loeb, A.; Ferry, M.; Bassman, L. Segmentation of 3D EBSD data for subgrain boundary identification and feature characterization. Ultramicroscopy 2016, 161, 83–89. [Google Scholar] [CrossRef] [Green Version]

- Okabe, A.; Boots, B.; Sugihara, K. Spatial Tessellations: Concepts and Applications of Voronoi Diagrams; John Wiley: Chichester, UK, 1992. [Google Scholar] [CrossRef]

- Stoyan, D.; Kendall, W.S.; Mecke, J. Stochastic Geometry and Its Applications, 2nd ed.; John Wiley & Sons: Chichester, UK, 1995. [Google Scholar]

- Schneider, Y.; Weber, U.; Wasserbäch, W.; Zielke, R.; Schmauder, S.; Tillmann, W. A numerical method for the generation of hierarchical Poisson Voronoi microstructures applied in micromechanical finite element simulations part I: Method. Comp. Mech. 2020, 66, 651–667. [Google Scholar] [CrossRef]

- Zeng, Z.; Li, X.; Xu, D.; Lu, L.; Gao, H.; Zhu, T. Gradient plasticity in gradient nano-grained metals. Extreme Mech. Lett. 2016, 8, 213–219. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.; Yang, F. Grain rotations during uniaxial deformation of gradient nano-grained metals using crystal plasticity finite element simulations. Extreme Mech. Lett. 2017, 16, 41–48. [Google Scholar] [CrossRef]

- Lyu, H.; Hamid, M.; Ruimi, A.; Zbib, H.M. Stress/strain gradient plasticity model for size effects in heterogeneous nano-microstructures. Int. J. Plas. 2017, 97, 46–63. [Google Scholar] [CrossRef]

- Devincre, B.; Madec, R.; Monnet, G.; Queyreau, S.; Gatti, R.; Kubin, L. Modeling crystal plasticity with dislocation dynamics simulations: The “micromegas“ code. In Mechanics of Nano-Objects; Thomas, O., Ponchet, A., Forest, S., Eds.; Presse des Mines: Paris, France, 2011. [Google Scholar]

- Schwarz, K.W. Modelling dislocation behavior at the continuum level. In Multiscale Materials Modelling: Fundamentals and Applications; Elsevier: Amsterdam, The Netherlands, 2007; Volume 7, pp. 25–61. [Google Scholar]

- Wasserbäch, W.; Skrotzki, W. Microstructure and texture development in oxide-dispersion strengthened silver rods processed by hot-extrusion. Materialia 2019, 5, 100175. [Google Scholar] [CrossRef]

- Wasserbäch, W.; Skrotzki, W.; Chekhonin, P. Strengthening of ODS silver wires. Materialia 2020, 12, 100818. [Google Scholar] [CrossRef]

- Lutz, O.; Behrens, V.; Wasserbäch, W.; Franz, S.; Honig, T.; Späth, D.; Heinrich, J. Improved silver/tin oxide contact materials for automotive applications. In Proceedings of the 24th International Conference on Electrical Contacts (ICEC), Saint Malo, France, 9–12 June 2008; pp. 89–93. [Google Scholar]

- ASM International. Powder metal technologies and applications, powder metallurgy electrical contact materials. In ASM Handbook; ASM International: Almere, The Netherlands, 2002; Volume 7, pp. 1021–1030. [Google Scholar]

- Huang, J.; Strunk, H.P.; Wasserbäch, W.; Franz, S. Internally oxidized silver contact materials—A case for the elastoplasticity of an inhomogeneous body. Cryst. Res. Technol. 2009, 44, 1147–1155. [Google Scholar] [CrossRef]

- Özer, T.; Cabuk, S. Investigation of structural and mechanical properties of rutile SnO2. Mater. Res. Express 2019, 6, 085069. [Google Scholar] [CrossRef]

- Ouni, B.; Boukhachem, A.; Dabbous, S.; Amlouk, A.; Boubaker, K.; Amlouk, M. Some Transparent Semiconductor Metal Oxides: Comparative Investigations in Terms of Wemple-Didomenico Parameters, Mechanical Performance and Amlouk—Boubaker Opto-Thermal Expansivity. Mater. Res. Express 2010, 13, 281–287. [Google Scholar] [CrossRef]

- El-Bahay, M.M.; Mossalamy, E.E.E.; Mahdy, M.; Bahgat, A.A. Some mechanical properties of Sn—3.5 Ag eutectic alloy at different temperatures. J. Mater. Sci. Mater. Electron. 2004, 15, 519–526. [Google Scholar] [CrossRef]

- Edalati, K.; Horita, Z. Universal plot for hardness variation in pure metals processed by high-pressure torsion. Mater. Trans. 2010, 51, 1051–1054. [Google Scholar] [CrossRef] [Green Version]

- Pavlina, E.; Tyne, C.J.V. Correlation of yield strength and tensiles trength with hardness for steels. J. Mater. Eng. Perform. 2008, 17, 888–893. [Google Scholar] [CrossRef]

- Böhlke, T.; Haus, U.; Schulze, V. Crystallographic texture approximation by quadratic programming. Acta Mater. 2006, 54, 1359–1368. [Google Scholar] [CrossRef] [Green Version]

- Böhlke, T.; Risy, G.; Bertram, A. A micro-mechanically based quadratic yield condition for textured polycrystals. ZAMM 2008, 88, 379–387. [Google Scholar] [CrossRef] [Green Version]

- Schneider, Y.; Bertram, A.; Böhlke, T. Three-dimensional simulation of local and global behaviour of αFe-Cu composites under large plastic deformation. Tech. Mech. 2013, 33, 34–51. [Google Scholar]

- Schneider, Y.; Bertram, A.; Böhlke, T.; Hartig, C. Plastic deformation behaviour of Fe-Cu composites predicted by 3D finite element simulation. Comp. Mat. Sci. 2010, 48, 456–465. [Google Scholar] [CrossRef]

- Wulfinghoff, S.; Böhlke, T. Gradient crystal plasticity including dislocation-based work-hardening and dislocation transport. Int. J. Plast. 2015, 69, 152–169. [Google Scholar] [CrossRef]

- Bayerschen, E.; McBride, A.; Reddy, B.D.; Böhlke, T. Review on slip transmission criteria in experiments and crystal plasticity models. J. Mater. Sci. 2016, 51, 2243–2258. [Google Scholar] [CrossRef] [Green Version]

- Albiez, J.; Sprenger, I.; Seemüller, C.; Weygand, D.; Heilmaier, M.; Böhlke, T. Physically motivated model for creep of directionally solidified eutectics evaluated for the intermetallic NiAl-9Mo. Acta Mater. 2016, 110, 377–385. [Google Scholar] [CrossRef]

- Erdle, H.; Böhlke, T. A gradient crystal plasticity theory for large deformations with a discontinuous accumulated plastic slip. Comp. Mech. 2017, 60, 923–942. [Google Scholar] [CrossRef]

- Albiez, J.; Erdle, H.; Weygand, D.; Böhlke, T. A gradient plasticity creep model accounting for slip transfer/activation at interfaces evaluated for the intermetallic NiAl-9Mo. Int. J. Plast. 2019, 113, 291–311. [Google Scholar] [CrossRef]

- Yuan, Z.; Fish, J. Toward realization of computational homogenization in practice. Int. J. Numer. Meth. Engng. 2008, 73, 361–380. [Google Scholar] [CrossRef]

- Miehe, C.; Koch, A. Computational micro-to-macro transitions of discretized microstructures undergoing small strains. Arch. Appl. Mech. 2002, 72, 300–317. [Google Scholar] [CrossRef]

- Bertram, A. An alternative approach to finite plasticity based on material isomorphisms. Int. J. Plast. 1999, 15, 353–374. [Google Scholar] [CrossRef]

- Bertram, A. Elasticity and Plasticity of Large Deformations—An Introduction, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Lee, E. Elastic-plastic deformation at finite strains. J. Appl. Mech. 1969, 36, 1–6. [Google Scholar] [CrossRef]

- Hutchinson, J.W. Bounds and self-consistent estimates for creep of polycrystalline materials. Proc. R. Soc. Lon. A 1976, 348, 101–127. [Google Scholar] [CrossRef]

- Kocks, U.F.; Mecking, H. Physics and phenomenology of strain hardening: The FCC case. Progr. Mat. Sci. 2003, 48, 171–273. [Google Scholar] [CrossRef]

- Böhlke, T. Crystallographic Texture Evolution and Elastic Anisotropy: Simulation, Modeling, and Applications; Shaker Verlag: Aachen, Germany, 2001. [Google Scholar]

- Hartig, C.; Mecking, H. Finite element modelling of two-phase Fe-Cu polycrystals. Comp. Mat. Sci. 2005, 32, 370–377. [Google Scholar] [CrossRef]

- Kocks, U.F. Laws for work-hardening and low-temperature creep. J. Eng. Mater. Techn. 1976, 98, 76–85. [Google Scholar] [CrossRef]

- Glüge, R.; Böhlke, T.; Bertram, A. Texture evolution and swift effect in NaAl. Proc. Appl. Math. Mech. 2006, 6, 477–478. [Google Scholar] [CrossRef] [Green Version]

- Hill, R. Elastic properties of reinforced solids: Some theoretical principles. J. Mech. Phys. Solids 1963, 11, 357–372. [Google Scholar] [CrossRef]

- Simpleware ScanIP, Version 2018.12-SP2; Synopsys: San José, CA, USA, 2017.

- Schneider, Y.; Wasserbäch, W.; Schmauder, S.; Zhou, Z.; Zielke, R.; Tillmann, W. A numerical method to improve the representativeness of real microstructure cut-outs applied in finite element simulations. Crystals 2021, 11, 382. [Google Scholar] [CrossRef]

- Liebermann, R. Elastic properties of polycrystalline SnO2 and GeO2: Comparison with stishovite and rutile data. Phys. Earth Planet. Inter. 1973, 7, 461–465. [Google Scholar] [CrossRef]

- Chang, E.; Graham, E.K. The elastic constants of Cassiterite SnO2 and their pressure and temperature dependence. J. Geophys. Res. 1975, 80, 2595–2599. [Google Scholar] [CrossRef]

- Smith, D.R.; Fickett, F.R. Low-temperatur properties of silver. J. Res. Natl. Inst. Stand. Technol. 1995, 100, 119–171. [Google Scholar] [CrossRef]

- Schneider, Y. Simulation of the Deformation Behaviour of Two-Phase Composites. Ph.D. Thesis, Fakultät für Maschinenbau, Otto-von-Guericke-Universität Magdeburg, Magdeburg, Germany, 2007. [Google Scholar]

- Liesner, C.; Wassermann, G. Verformungsverhalten und mechanische Eigenschaften von Verbundwerkstoffen aus Kupfer mit α-Korund. Int. J. Mater. Res. 1969, 60, 827–835. [Google Scholar] [CrossRef]

- Wassermann, G. Deformation mechanism and properties of two phase composite wires. Int. J. Mater. Res. 1973, 64, 844–848. [Google Scholar] [CrossRef]

- Bergmann, H. Mechanische Eigenschaften und Verformungsverhalten einer metallischen Matrix mit nichtmetallischen anorganischen Zusätzen. J. Mater. Technol. 1976, 7, 129–135. [Google Scholar] [CrossRef]

- Bergmann, H.; Wassermann, G. Einfluss von unverformbaren Teilchen auf die Strangpresstexturen von Verbundwerkstoffen. J. Mater. Technol. 1981, 12, 88–90. [Google Scholar] [CrossRef]

- Grewen, J.; Huber, J. Das Entfestigungsverhalten von stranggepressten und nachgezogenen AlMgSi1-Stangen. Z. Met. 1977, 68, 647–653. [Google Scholar]

- Brimhall, J.; Huggins, R. Electron-microscopic observations of deformed internally oxidized alloys. Trans. AIME 1965, 233, 1076–1084. [Google Scholar]

- Poudens, A.; Bacroix, B.; Bretheau, T. Influence of microstructures and particle concentrations on the development of extrusion textures in metal matrix composites. Mat. Sci. Eng. A 1995, 196, 219–228. [Google Scholar] [CrossRef]

- Konovalova, E.; Perevalova, O.; Koneva, N.; Kozlov, E. Σ3 twin boundaries and texture in fcc solid solutions and alloys with L12 superstructure. Bull. Russ. Acad. Sci. Phys. 2016, 80, 402–414. [Google Scholar] [CrossRef]

- Lepinoux, J.; Kubin, L.P. The dynamic organization of dislocation structures: A simulation. Scripta Metall. 1987, 21, 833–838. [Google Scholar] [CrossRef]

- Kubin, L.P.; Canova, G.; Condat, M.; Devincre, B.; Pontikis, V.; Bréchet, Y. Dislocation microstructures and plastic flow: A 3D simulation. Solid State Phenom. 1992, 23–24, 455–472. [Google Scholar] [CrossRef]

- Molnar, D.; Weber, U.; Binkele, P.; Rapp, D.; Schmauder, S. Prediction of macroscopic damage behaviour of precipitation strengthened steels via multiscale simulations. GAMM-Mitt 2015, 38, 228–247. [Google Scholar] [CrossRef]

- Po, G.; Mohamed, M.S.; Crosby, T.; Erel, C.; El-Azab, A.; Ghoniem, N. Recent progress in discrete dislocation dynamics and its applications to micro plasticity. Met. Mater. Soc. 2014, 66, 2108–2120. [Google Scholar] [CrossRef]

| Material | SnO vol.% | Ag D [m] | SnO d [m] | [MPa] | 3 [%] LS | 3 [%] CS |

|---|---|---|---|---|---|---|

| PM12-2 | 17 | 3.60 | 0.56 ± 0.16 | 118 ± 5 | 13.2 | 5.6 |

| PM12-3 | 17 | 4.36 | 0.93 ± 0.20 | 106 ± 3 | 13.0 | 23.4 |

| Ag 99.97 | - | ≈5 | - | 65 | - | - |

| | | m | n | ||||

|---|---|---|---|---|---|---|

| 123.99 | 93.67 | 46.12 | 0.001 | 80 | 1.0 | 46.3 |

| 210 | 215 | 35 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schneider, Y.; Rapp, D.-M.; Yang, Y.; Wasserbäch, W.; Schmauder, S. Many-Scale Investigations of Deformation Behavior of Polycrystalline Composites: II—Micro-Macro Simultaneous FE and Discrete Dislocation Dynamics Simulation. Materials 2022, 15, 2852. https://doi.org/10.3390/ma15082852

Schneider Y, Rapp D-M, Yang Y, Wasserbäch W, Schmauder S. Many-Scale Investigations of Deformation Behavior of Polycrystalline Composites: II—Micro-Macro Simultaneous FE and Discrete Dislocation Dynamics Simulation. Materials. 2022; 15(8):2852. https://doi.org/10.3390/ma15082852

Chicago/Turabian StyleSchneider, Yanling, Dennis-Michael Rapp, Yifang Yang, Werner Wasserbäch, and Siegfried Schmauder. 2022. "Many-Scale Investigations of Deformation Behavior of Polycrystalline Composites: II—Micro-Macro Simultaneous FE and Discrete Dislocation Dynamics Simulation" Materials 15, no. 8: 2852. https://doi.org/10.3390/ma15082852

APA StyleSchneider, Y., Rapp, D.-M., Yang, Y., Wasserbäch, W., & Schmauder, S. (2022). Many-Scale Investigations of Deformation Behavior of Polycrystalline Composites: II—Micro-Macro Simultaneous FE and Discrete Dislocation Dynamics Simulation. Materials, 15(8), 2852. https://doi.org/10.3390/ma15082852