Degradation Mechanism and Numerical Simulation of Pervious Concrete under Salt Freezing-Thawing Cycle

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation and Maintenance of Samples

2.3. Test Methods

2.3.1. Effective Porosity

2.3.2. Ultrasonic Velocity

2.3.3. Compressive Strength

2.3.4. Freeze-Thaw Cycle Test

2.3.5. Mercury Intrusion Porosimetry (MIP) Test

2.3.6. Scanning Electron Microscope (SEM) Test

2.3.7. Discrete Element Method

3. Results and Discussion

3.1. Experimental Results

3.1.1. Macroscopic Performance Deterioration Test Results

Surface Morphologic

Compressive Strength

Dynamic Elastic Modulus

Effective Porosity

3.1.2. Evaluation of Freeze-Thaw Damage

Establishment of a Freeze-Thaw Damage Model

Prediction and Evaluation of Freeze-Thaw Durability

3.2. Microscopic Property Test Results

3.2.1. Mercury Intrusion Porosimetry (MIP) Results

3.2.2. Scanning Electron Microscope (SEM) Results

3.3. Establishment of Freeze-Thaw Damage in DEM

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hwang, S.; Yeon, J.H. Fly Ash-Added, Seawater-Mixed Pervious Concrete: Compressive Strength, Permeability, and Phosphorus Removal. Materials 2022, 15, 1407. [Google Scholar] [CrossRef] [PubMed]

- Baneviciene, V.; Malaiskiene, J.; Boris, R.; Zach, J. The Effect of Active Additives and Coarse Aggregate Granulometric Composition on the Properties and Durability of Pervious Concrete. Materials 2022, 15, 1035. [Google Scholar] [CrossRef] [PubMed]

- Zhu, H.; Wen, C.; Wang, Z.; Li, L. Study on the Permeability of Recycled Aggregate Pervious Concrete with Fibers. Materials 2020, 13, 321. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tsang, C.; Shehata, M.H.; Lotfy, A. Optimizing a Test Method to Evaluate Resistance of Pervious Concrete to Cycles of Freezing and Thawing in the Presence of Different Deicing Salts. Materials 2016, 9, 878. [Google Scholar] [CrossRef] [Green Version]

- Barišić, I.; Netinger Grubeša, I.; Dokšanović, T.; Zvonarić, M. Influence of Clogging and Unbound Base Layer Properties on Pervious Concrete Drainage Characteristics. Materials 2020, 13, 2455. [Google Scholar] [CrossRef]

- John, T.; Vernon, R. Mixture properties considerations for improved freeze-thaw durability of pervious concrete. Plan. Sustain. Cold Reg. Proc. 2013, 2013, 471–481. [Google Scholar]

- Liu, X.Y. Influence Factors of Frost Resistance on Pervious Concrete; Harbin Institute of Technology: Harbin, China, 2012. (In Chinese) [Google Scholar]

- Liu, H.; Luo, G.; Wei, H.; Yu, H. Strength, permeability, and freeze-thaw durability of pervious concrete with different aggregate sizes, porosities, and water-binder ratios. Appl. Sci. 2018, 8, 1217. [Google Scholar] [CrossRef] [Green Version]

- Shi, X.; Akin, M.; Pan, T.; Fay, L.; Liu, Y.; Yang, Z. Deicer impacts on pavement materials: Introduction and recent developments. Open Civ. Eng. J. 2009, 3, 16–27. [Google Scholar] [CrossRef] [Green Version]

- Xie, N.; Shi, X.; Zhang, Y. Impacts of potassium acetate and sodium-chloride deicers on concrete. J. Mater. Civ. Eng. 2017, 29, 04016229. [Google Scholar] [CrossRef]

- Haselbach, L.; Almeida, N.; Ross, M. Performance of Pervious Concrete Exposed to Magnesium Chloride Deicers. J. Mater. Civ. Eng. 2020, 32, 04020109. [Google Scholar] [CrossRef]

- Lian, C.; Zhuge, Y.; Beecham, S. The relationship between porosity and strength for porous concrete. Constr. Build. Mater. 2011, 25, 4294–4298. [Google Scholar] [CrossRef]

- Li, L.G.; Feng, J.J.; Zhu, J.; Chu, S.H.; Kwan, A.K.H. Pervious concrete: Effects of porosity on permeability and strength. Mag. Concr. Res. 2021, 73, 69–79. [Google Scholar] [CrossRef]

- David Darwin, J.B.; Gong, L.; Sean, R. Hughes, Effects of Deicers on Concrete Deterioration. ACI Mater. J. 2008, 105, 622–627. [Google Scholar]

- Cutler, H.E.; Wang, K.; Schaefer, V.R.; Kevern, J.T. Resistance of Portland Cement Pervious Concrete to Deicing Chemicals. Transp. Res. Rec. J. Transp. Res. Board 2010, 2164, 98–104. [Google Scholar] [CrossRef]

- Anderson, I.A.; Suozzo, M.; Dewoolkar, M.M. Laboratory and Field Evaluations of Pervious Concrete Laboratory and Field Evaluations of Pervious Concrete; Deicing Chemicals; University of Vermont: Burlington, VT, USA, 2013. [Google Scholar]

- Bilal, H.; Chen, T.; Ren, M.; Gao, X.; Su, A. Influence of silica fume, metakaolin & SBR latex on strength and durability performance of pervious concrete. Constr. Build. Mater. 2021, 275, 122124. [Google Scholar]

- Gesoğlu, M.; Güneyisi, E.; Khoshnaw, G.; İpek, S. Abrasion and freezing–thawing resistance of pervious concretes containing waste rubbers. Constr. Build. Mater. 2014, 73, 19–24. [Google Scholar] [CrossRef]

- Tarangini, D.; Sravana, P.; Srinivasa Rao, P. Effect of nano silica on frost resistance of pervious concrete. Mater. Today Proc. 2021, 51, 2185–2189. [Google Scholar] [CrossRef]

- Li, A.; Qiao, H.; Li, Q.; Hakuzweyezu, T.; Chen, B. Study on the performance of pervious concrete mixed with waste glass powder. Constr. Build. Mater. 2021, 300, 123997. [Google Scholar] [CrossRef]

- Taheri, B.M.; Ramezanianpour, A.M.; Sabokpa, S.; Gapele, M. Experimental evaluation of freeze-thaw durability of pervious concrete. J. Build. Eng. 2021, 33, 101617. [Google Scholar] [CrossRef]

- Zhong, R.; Wille, K. Influence of matrix and pore system characteristics on the durability of pervious concrete. Constr. Build. Mater. 2018, 162, 132–141. [Google Scholar] [CrossRef]

- Wu, H.; Liu, Z.; Sun, B.; Yin, J. Experimental investigation on freeze-thaw durability of Portland cement pervious concrete (PCPC). Constr. Build. Mater. 2016, 117, 63–71. [Google Scholar] [CrossRef]

- Almeida, N.; Haselbach, L. Accelerating carbonation in pervious concrete for improved deicer resistance. In Proceedings of the International Conference on Transportation and Development 2020, Seattle, WA, USA, 26–29 May 2020; American Society of Civil Engineers: Reston, VA, USA, 2020. [Google Scholar]

- Yang, Z. Freezing-and-Thawing Durability of Pervious Concrete under Simulated Field Conditions. ACI Mater. J. 2011, 108, 187–195. [Google Scholar]

- Richardson, A.; Coventry, K.; Edmondson, V.; Dias, E. Crumb rubber used in concrete to provide freeze-thaw protection (optimal particle size). J. Clean. Prod. 2016, 112, 599–606. [Google Scholar] [CrossRef]

- Gonzalez, M.; Tighe, S.L.; Hui, K.; Rahman, S.; de Oliveira Lima, A. Evaluation of freeze/thaw and scaling response of nanoconcrete for Portland Cement Concrete (PCC) pavements. Constr. Build. Mater. 2016, 120, 465–472. [Google Scholar] [CrossRef]

- Al-Akhras, M.N. Performance of glass concrete subjected to freeze-thaw cycling. Open Constr. Build. Technol. J. 2012, 6, 392–397. [Google Scholar] [CrossRef] [Green Version]

- Nam, J.; Kim, G.; Lee, B.; Hasegawa, R.; Hama, Y. Frost resistance of polyvinyl alcohol fiber and polypropylene fiber reinforced cementitious composites under freeze thaw cycling. Compos. Part B Eng. 2016, 90, 241–250. [Google Scholar] [CrossRef]

- Tanesi, J.; Meininger, R. Freeze-Thaw resistance of concrete with marginal air content. Transp. Res. Rec. 2007, 2020, 61–66. [Google Scholar] [CrossRef] [Green Version]

- Liang, G.; Zhu, H.; Li, H.; Liu, T.; Guo, H. Comparative study on the effects of rice husk ash and silica fume on the freezing resistance of metakaolin-based geopolymer. Constr. Build. Mater. 2021, 293, 123486. [Google Scholar] [CrossRef]

- Yuan, J.; Chen, X.; Guo, S. Experimental study on cyclic tensile behaviour of air-entrained concrete after frost damage. Sadhana-Acad. P Eng. S 2019, 44, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Rhardane, A.; Sleiman, S.A.H.; Alam, S.Y.; Grondin, F. A quantitative assessment of the parameters involved in the freeze-thaw damage of cement-based materials through numerical modelling. Constr. Build. Mater. 2021, 272, 121838. [Google Scholar] [CrossRef]

- Li, B.; Mao, J.; Shen, W.; Liu, H.; Liu, X.; Xu, G. Mesoscopic cracking model of cement-based materials subjected to freeze-thaw cycles. Constr. Build. Mater. 2019, 211, 1050–1064. [Google Scholar] [CrossRef]

- Zou, D.; Wang, Z.; Shen, M.; Liu, T.; Zhou, A. Improvement in freeze-thaw durability of recycled aggregate permeable concrete with silane modification. Constr. Build. Mater. 2021, 268, 121097. [Google Scholar] [CrossRef]

- Powers, T.C.; Helmuth, R.A. Theory of volume changes in hardened Portland cement paste during freezing. Highway Res. Board Proc. 1953, 32, 285–297. [Google Scholar]

- Vancura, M.; MacDonald, K.; Khazanovich, L. Microscopic analysis of paste and aggregate distresses in pervious concrete in a wet, hard freeze climate. Cem. Concr. Compos. 2011, 33, 1080–1085. [Google Scholar] [CrossRef]

- Duan, A.; Chen, J.; Jin, W. Numerical simulation of the freezing process of concrete. J. Mater. Civ. Eng. 2013, 25, 1317–1325. [Google Scholar] [CrossRef]

- Qiu, W.L.; Teng, F.; Pan, S.S. Damage constitutive model of concrete under repeated load after seawater freeze-thaw cycles. Constr. Build. Mater. 2020, 236, 117560. [Google Scholar] [CrossRef]

- Zhu, X.; Chen, X.; Zhang, N.; Wang, X.; Diao, H. Experimental and numerical research on triaxial mechanical behavior of self-compacting concrete subjected to freeze-thaw damage. Constr. Build. Mater. 2021, 288, 123110. [Google Scholar] [CrossRef]

- Zhu, X.; Chen, X.; Bai, Y.; Ning, Y.; Zhang, W. Evaluation of fracture behavior of high-strength hydraulic concrete damaged by freeze-thaw cycle test. Constr. Build. Mater. 2022, 321, 126346. [Google Scholar] [CrossRef]

- Li, W.; Gao, H.; Zhang, X.; Liu, J.; Ma, Y. Numerical and experimental investigation on the effects of mesostructures on the mechanical behavior and failure pattern in concrete. Constr. Build. Mater. 2022, 327, 127005. [Google Scholar] [CrossRef]

- Ning, Z.; Liu, Y.; Wang, W.; Meng, X.; Dong, J. A damage bond model to investigate the damage and crack propagation for cemented materials and parametric analysis. Mater. Struct. 2021, 54, 1–15. [Google Scholar] [CrossRef]

- Lian, C.; Zhuge, Y.; Beecham, S. Numerical simulation of the mechanical behaviour of porous concrete. Int. J. Comput. Aided Eng. Softw. 2011, 28, 984–1002. [Google Scholar] [CrossRef]

- Lian, C.; Zhuge, Y.; Beechan, S. Modelling pervious concrete under compression loading—A discrete element approach. Adv. Mater. Res. 2011, 168–170, 1590–1600. [Google Scholar]

- CJJ/T135-2009; Technical Specifications for Pervious Concrete Pavement. Ministry of Housing and Urban-Rural Construction of the People’s Republic of China: Beijing, China, 2009. (In Chinese)

- Ni, T.; Ma, W.; Yang, Y.; Yu, J.; Liu, J.; Jiang, C.; Gu, C. Interface reinforcement and a new characterization method for pore structure of pervious concrete. Constr. Build. Mater. 2021, 267, 121052. [Google Scholar] [CrossRef]

- Akkaya, A.; Çağatay, İ.H. Investigation of the density, porosity, and permeability properties of pervious concrete with different methods. Constr. Build. Mater. 2021, 294, 123539. [Google Scholar] [CrossRef]

- Malhotra, V.M.; Carino, N.J. Handbook on Nondestructive Testing of Concrete; CRC Press: Boca Raton, FL, USA, 2003. [Google Scholar]

- Mohammed, T.U.; Mahmood, A.H. Effects of maximum aggregate size on UPV of brick aggregate concrete. Ultrasonics 2016, 69, 129–136. [Google Scholar] [CrossRef] [PubMed]

- GB/T50081-2002; Standard for Test Method of Mechanical Properties on Ordinary Concrete. China Architecture & Building Press: Beijing, China, 2002. (In Chinese)

- GB/T 50082-2009; The Test Method of Long-Term and Durability on Ordinary Concrete. National Standard People’s Republic of China: Beijing, China; China Architecture & Building Press: Beijing, China, 2009. (In Chinese)

- Xu, W.; Chen, B.; Chen, X.; Chen, C. Influence of aggregate size and notch depth ratio on fracture performance of steel slag pervious concrete. Constr. Build. Mater. 2021, 273, 122036. [Google Scholar] [CrossRef]

- Ansari, A.; Mukund, M.M. Performance based simulation of pervious concrete using discrete element method. Građevinar 2020, 72, 693–701. [Google Scholar]

- Itasca Consulting Group, Inc. PFC 5.0 Documentation, User’s Guide; Itasca Consulting Group, Inc.: Minneapolis, MN, USA, 2018. [Google Scholar]

- Zhao, M. Dimensional analysis of the effects of microcosmic parameters on macrocosmic parameters for clump parallel bond-model. Chin. J. Rock Mech. Eng. 2014, 33, 327–338. [Google Scholar]

- Lyu, Z.; Shen, A.; Wang, W.; Lin, S.; Guo, Y.; Meng, W. Salt frost resistance and micro characteristics of polynary blended concrete using in frost areas. Cold Reg. Sci. Technol. 2021, 191, 103374. [Google Scholar] [CrossRef]

- Chen, Z.F.; Liu, G.F.; Peng, G.J.; Li, S.C. Mechanical Properties and Microstructure Characteristics of Manufactured-Sand Concrete under Coupled Effect of Salt Erosion and Freeze-Thaw Cycles. Sci. Adv. Mater. 2019, 11, 555–562. [Google Scholar] [CrossRef]

- Yang, Q.B. Mechanisms of deicer-frost scaling of concrete (I): Capillary-uptake degree of saturation and ice-formation pressure. J. Build. Mater. 2007, 10, 522–527. [Google Scholar]

- Farnam, Y.; Dick, S.; Wiese, A.; Davis, J.; Bentz, D.; Weiss, J. The Influence of Calcium Chloride Deicing Salt on Phase Changes and Damage Development in Cementitious Materials. Cem. Concr. Compos. 2015, 64, 1–15. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yang, Q.B. One of mechanisms on the deicer-frost scaling of concrete (II): Degree of saturationand ice-formation pressure during freezing-thawing cycles. J. Build. Mater. 2012, 15, 741–746. [Google Scholar]

- Xiao, Q.H. Durability of Concrete Structures under the Coupling Effect of Multiple Factors in Freezing-Thawing Environment; Xi’an University of Architecture and Technology: Xi’an, China, 2010. [Google Scholar]

- Zhao, T.J.; Zhu, J.Q. Characterization parameters in concrete pore analysis. In Proceedings of the Symposium on Sixty Years of Academician Wu Zhongwei’s Scientific and Educational Work; China Building Materials Industry Press: Suzhou, China, 1999. [Google Scholar]

- Feng, X.X.; Sun, X.H.; Wang, X.Y.; Wei, Q.M. Effect of late hydration of cement on long-term strength of Low water-cement ratio Mortar. In Proceedings of the International Conference on Pumping and Ultra-High Performance Concrete; South China University of Technology: Guangzhou, China, 2010. [Google Scholar]

- Tao, B. Effect of Concrete Pore Structure on Chloride Ion Diffusion; Wuhan University of Technology: Wuhan, China, 2009. [Google Scholar]

- Cwirzen, A.; Penttala, V. Aggregate–Cement paste transition zone properties affecting the salt–frost damage of high-performance concretes. Cem. Concr. Res. 2005, 35, 671–679. [Google Scholar] [CrossRef]

- Bourdette, B.; Ringot, E.; Ollivier, J.P. Modelling of the transition zone porosity. Cem. Concr. Res. 1995, 25, 741–751. [Google Scholar] [CrossRef]

- Han, Y. Experimental Study on Properties of Pervious Concrete with Recycled Aggregate and the Relationship between Ultrasonic Pulse Velocity and Properties of Pervious Concrete; Jilin University: Jilin, China, 2019. (In Chinese) [Google Scholar]

- Nguyen, T.T.; Bui, H.H.; Ngo, T.D.; Nguyen, G.D. Experimental and numerical investigation of influence of air-voids on the compressive behaviour of foamed concrete. Mater. Des. 2017, 130, 103–119. [Google Scholar] [CrossRef]

- Lu, J.F.; Zhang, C.W.; Jian, P. Meso-Structure parameters of discrete element method of sand pebble surrounding rock particles in different dense degrees. In Proceedings of the International Conference on Discrete Element Methods, Dalian, China, 1–4 August 2016; Springer: Singapore, 2016. [Google Scholar]

- Zhang, S.; Chen, L.; Lu, P.; Liu, W. Discussion on failure mechanism and strength criterion of sandstone based on particle discrete element method. KSCE J. Civil. Eng. 2021, 25, 2314–2333. [Google Scholar] [CrossRef]

- Cao, D.F. Study on compressive constitutive characteristics of concrete under freeze-thaw Cycles. J. Build. Mater. 2013, 16, 17–23. [Google Scholar]

- Pieralisi, R.; Cavalaro, S.H.; Aguado, A. Discrete element modelling of mechanical behaviour of pervious concrete. Cem. Concr. Compos. 2021, 119, 104005. [Google Scholar] [CrossRef]

| Solid Content/% | Moisture Content/% | Fineness/% | Total Alkalinity/% | NaSO4/% | CaO/% | SiO2/% | Bulk Density/g/cm3 |

|---|---|---|---|---|---|---|---|

| 96 | 3.17 | 16.87 | 6.46 | 4.83 | 0.92 | 64.6 | 0.678 |

| Cement kg/m3 | Aggregate kg/m3 | Water kg/m3 | Reinforcer kg/m3 |

|---|---|---|---|

| 417.28 | 1600 | 129.35 | 16.69 |

| Energy Spectrum Analysis Region | Element (wt%) | ||||||

|---|---|---|---|---|---|---|---|

| O | Ca | C | Si | Al | Fe | Other | |

| Aggregate | 25.64 | 68.13 | 6.23 | - | - | - | - |

| Cement paste | 45.83 | 28.73 | 15.42 | 5.68 | 1.91 | 0.75 | 1.68 |

| Number of Freeze-thaw Cycles (N) | 0 | 25 | 50 | 75 | 100 |

|---|---|---|---|---|---|

| Peak stress (MPa) | 23.13 | 21.67 | 20.18 | 18.66 | 17.12 |

| Peak strain (×10−3) | 2.78 | 4.38 | 6.03 | 7.65 | 9.28 |

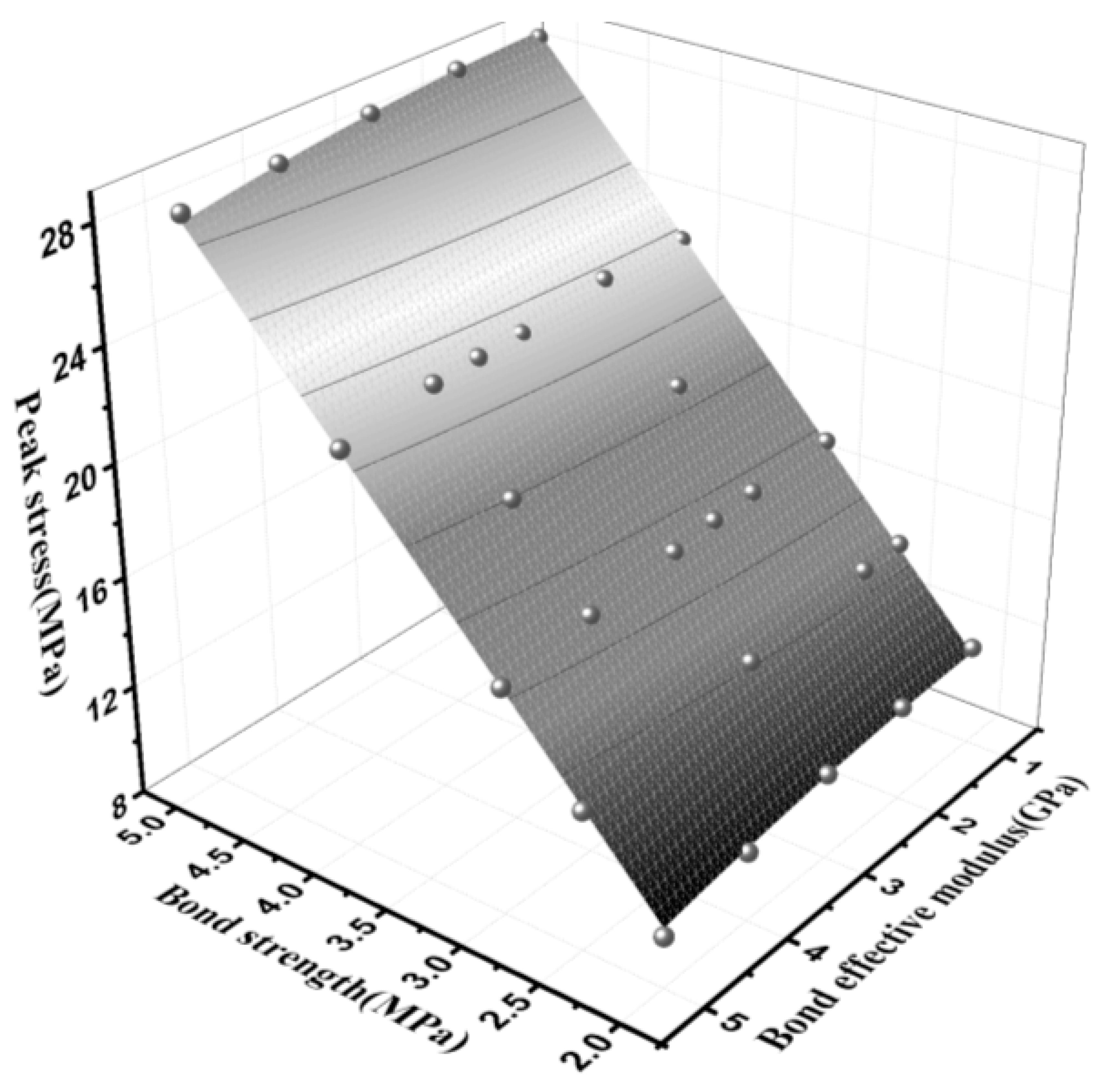

| Number of Freeze-thaw Cycles | Bond Effective Modulus (Gpa) | Cohesion (MPa) | Bond Normal-to-Shear Stiffness Ratio | Friction Angle (°) | Fric |

|---|---|---|---|---|---|

| 0 | 3.22 | 4.120 | 1.5 | 40 | 0.5 |

| 25 | 1.776 | 3.754 | 1.5 | 40 | 0.5 |

| 50 | 1.136 | 3.485 | 1.5 | 40 | 0.5 |

| 75 | 0.795 | 3.221 | 1.5 | 40 | 0.5 |

| 100 | 0.585 | 2.958 | 1.5 | 40 | 0.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiang, J.; Liu, H.; Lu, H.; Gui, F. Degradation Mechanism and Numerical Simulation of Pervious Concrete under Salt Freezing-Thawing Cycle. Materials 2022, 15, 3054. https://doi.org/10.3390/ma15093054

Xiang J, Liu H, Lu H, Gui F. Degradation Mechanism and Numerical Simulation of Pervious Concrete under Salt Freezing-Thawing Cycle. Materials. 2022; 15(9):3054. https://doi.org/10.3390/ma15093054

Chicago/Turabian StyleXiang, Junzheng, Hengrui Liu, Hao Lu, and Faliang Gui. 2022. "Degradation Mechanism and Numerical Simulation of Pervious Concrete under Salt Freezing-Thawing Cycle" Materials 15, no. 9: 3054. https://doi.org/10.3390/ma15093054