Quantitative Analysis of the Calcium Hydroxide Content of EVA-Modified Cement Paste Based on TG-DSC in a Dual Atmosphere

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.3. Methods

3. Results and Discussion

3.1. XRD Pattern

3.2. FT-IR Spectrum

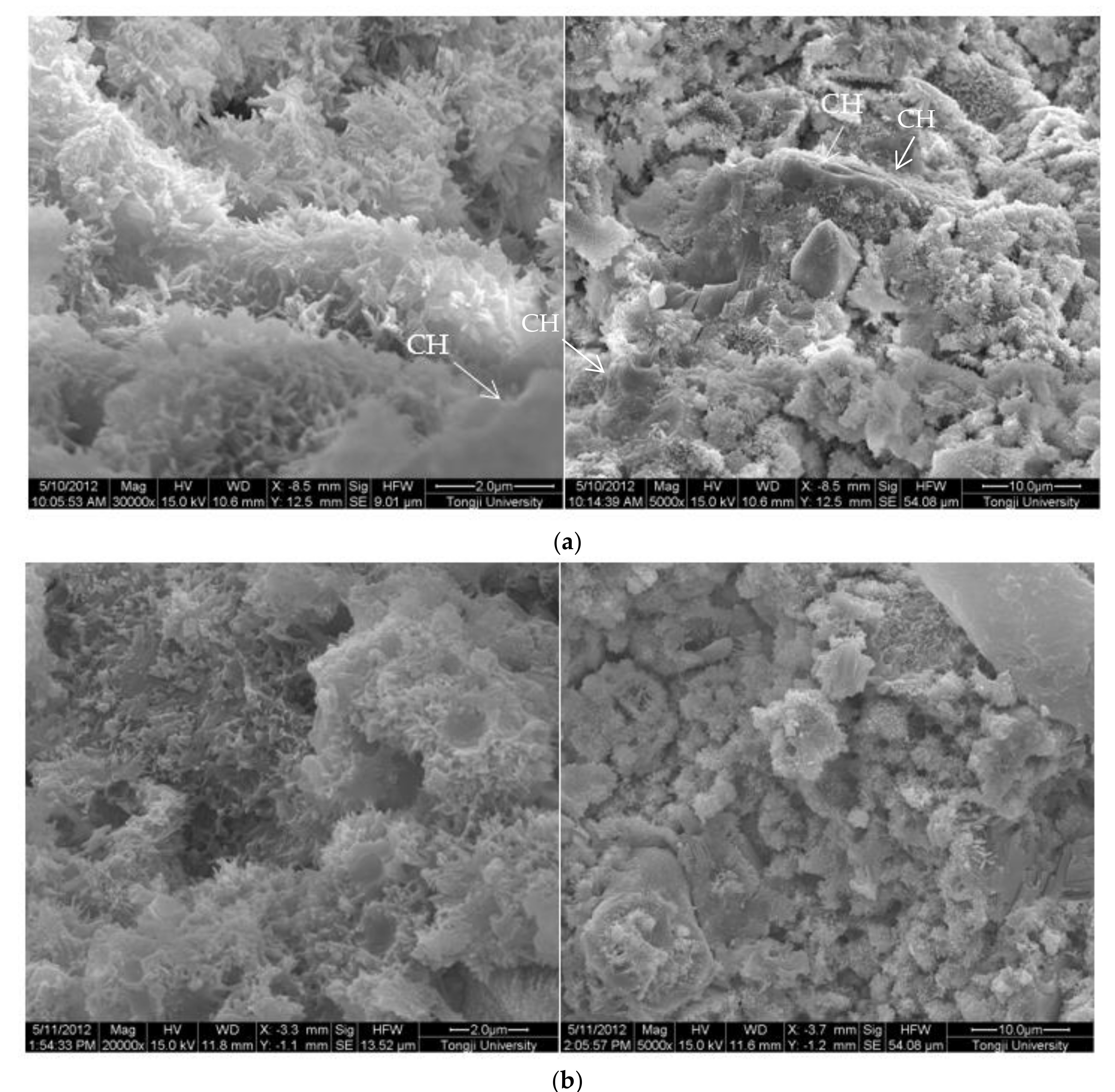

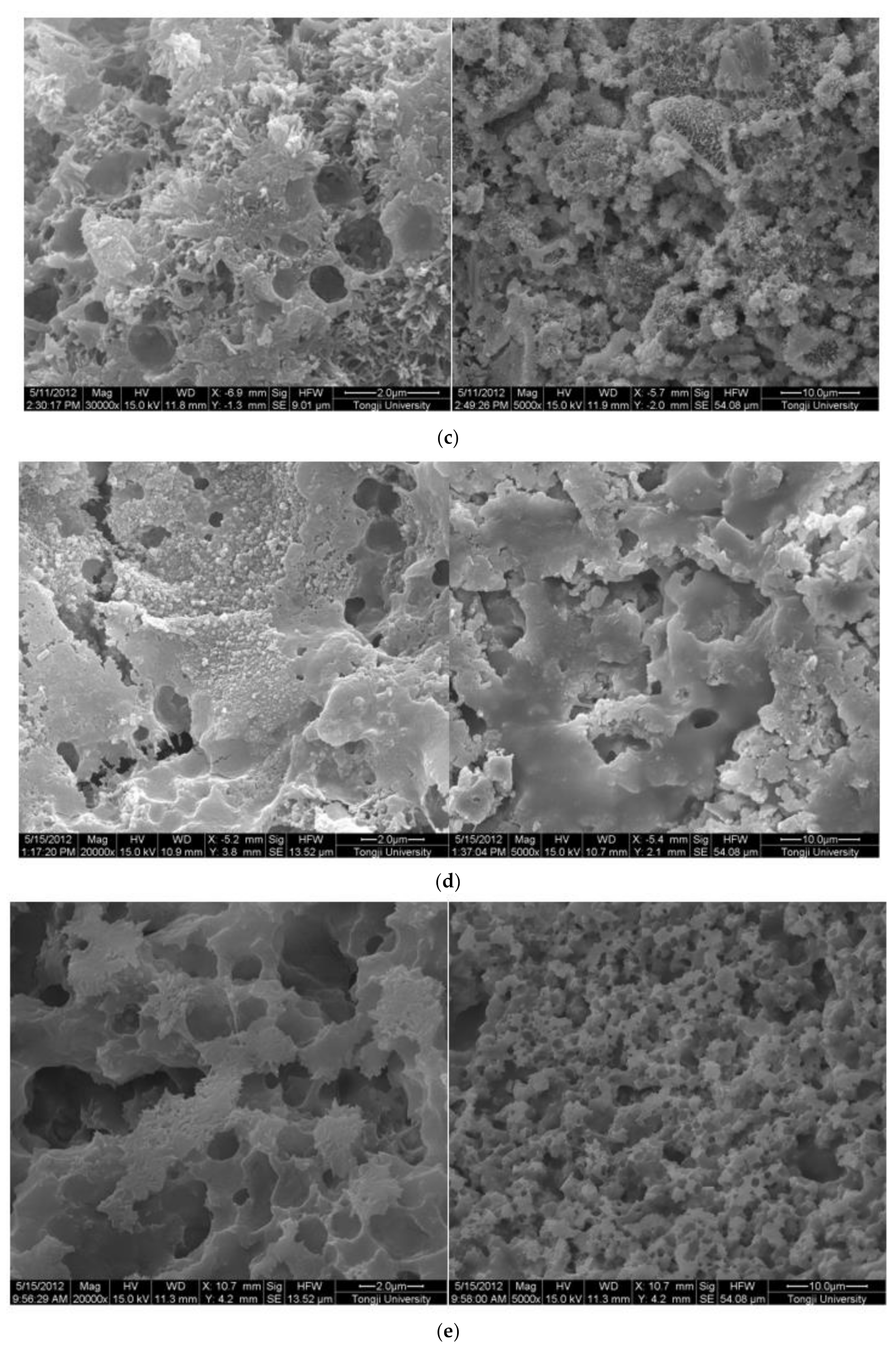

3.3. SEM Observation

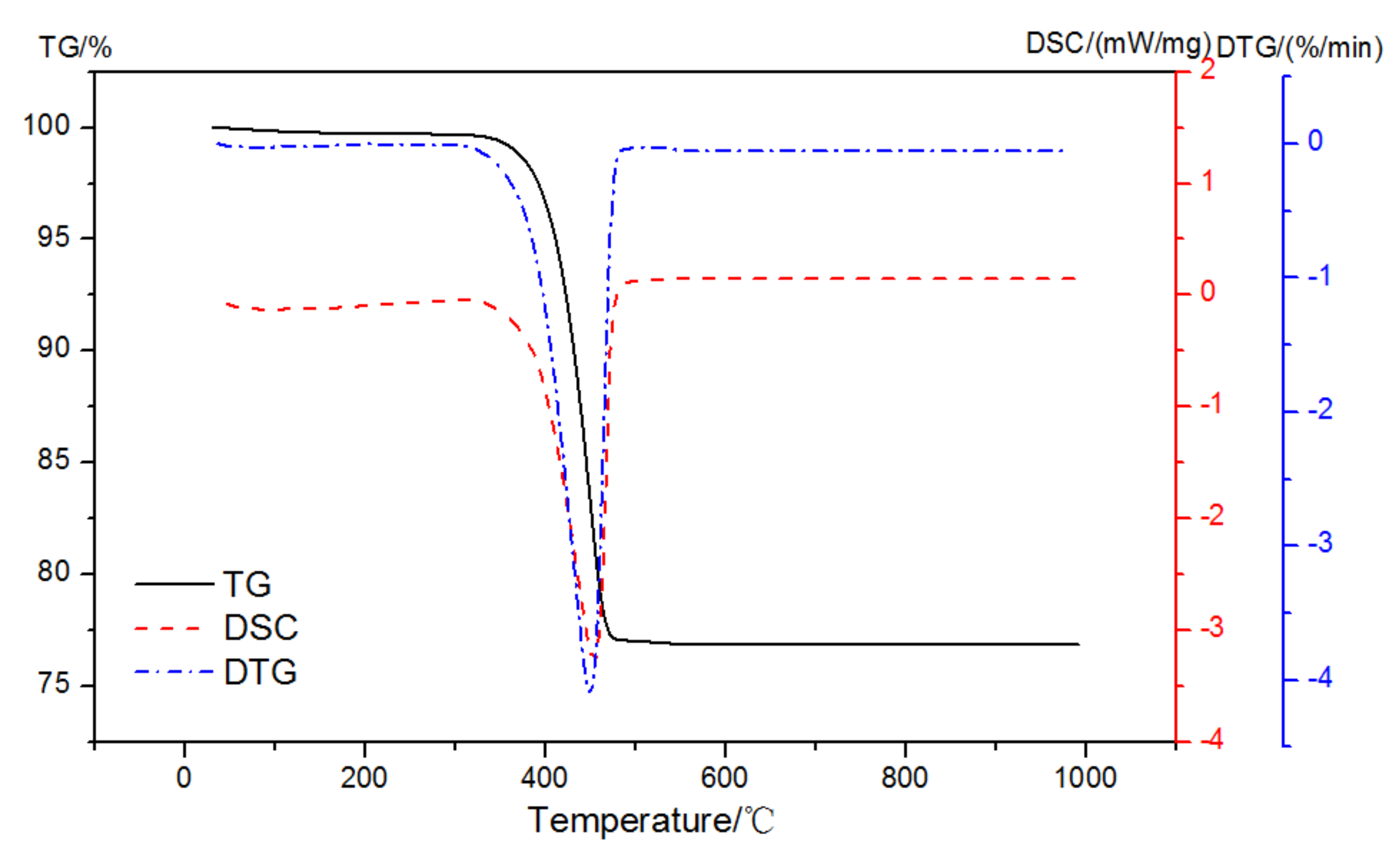

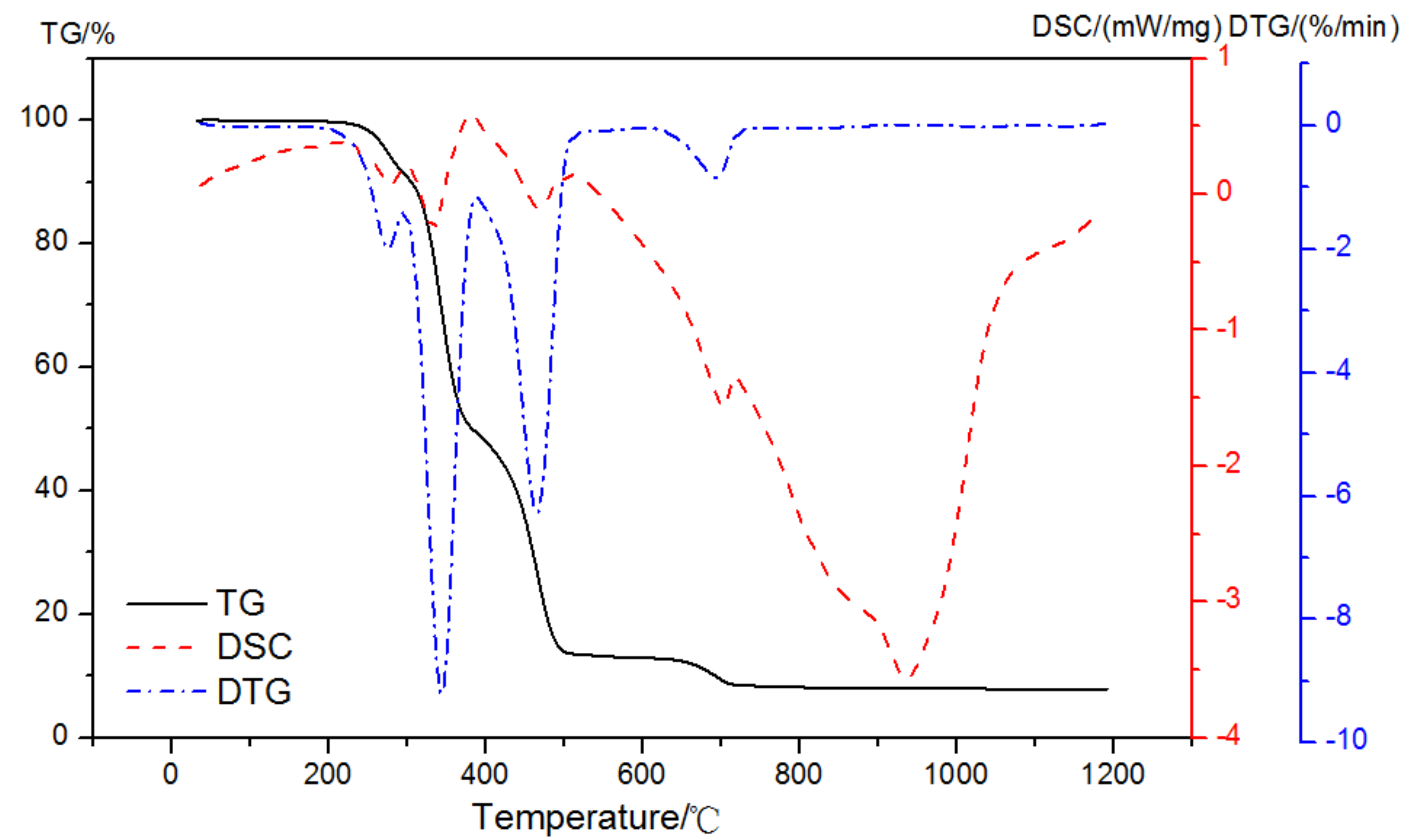

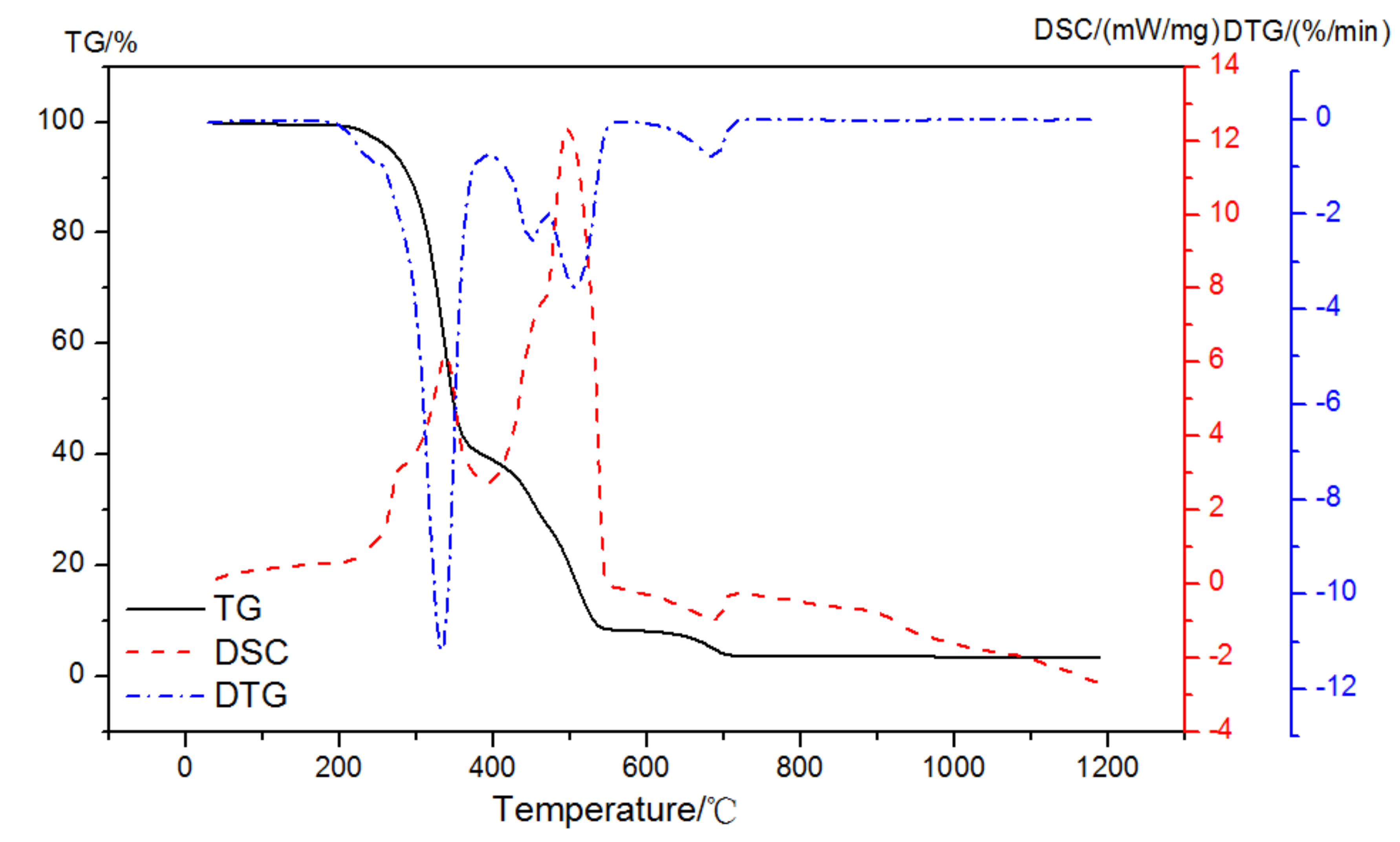

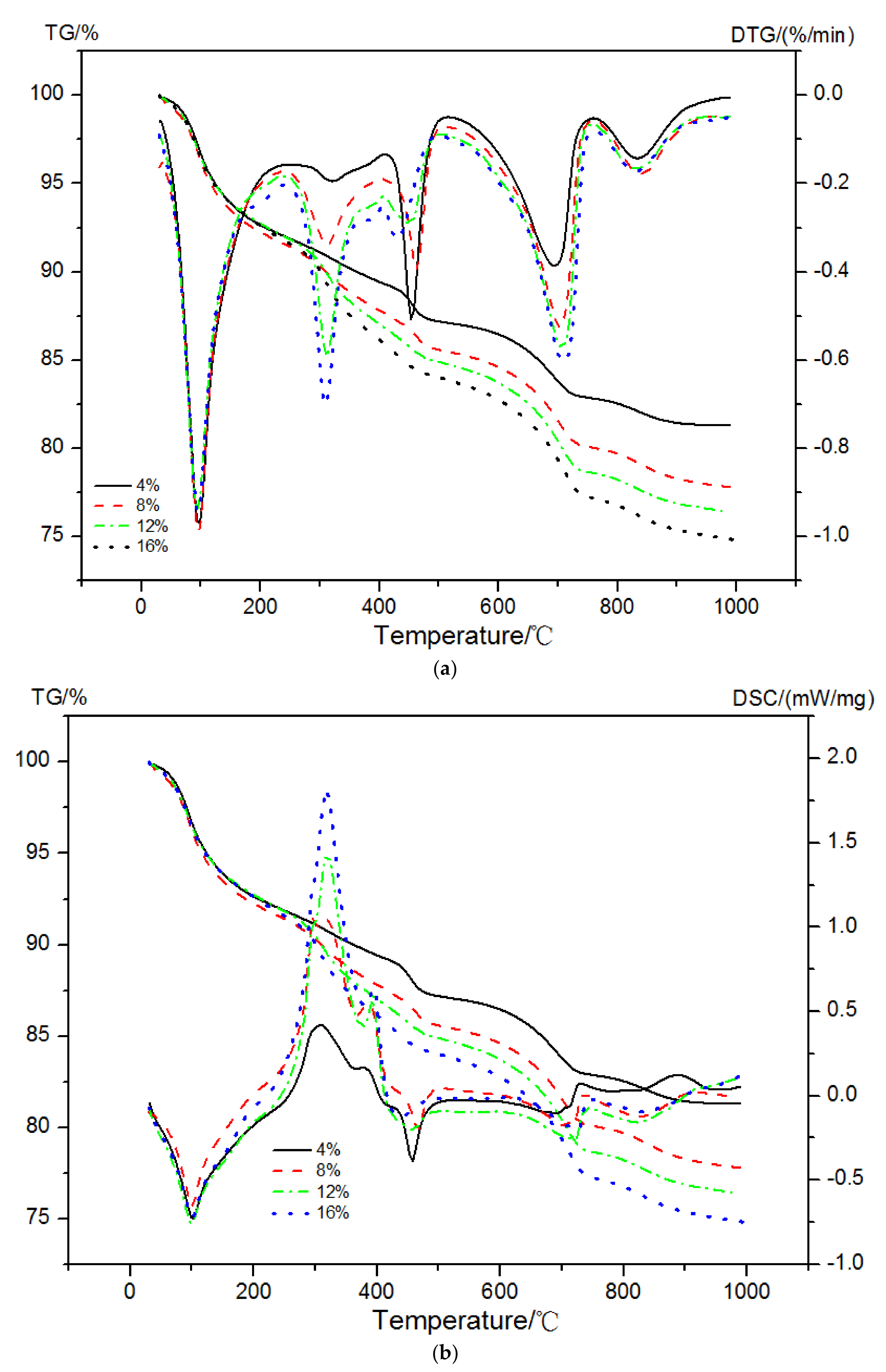

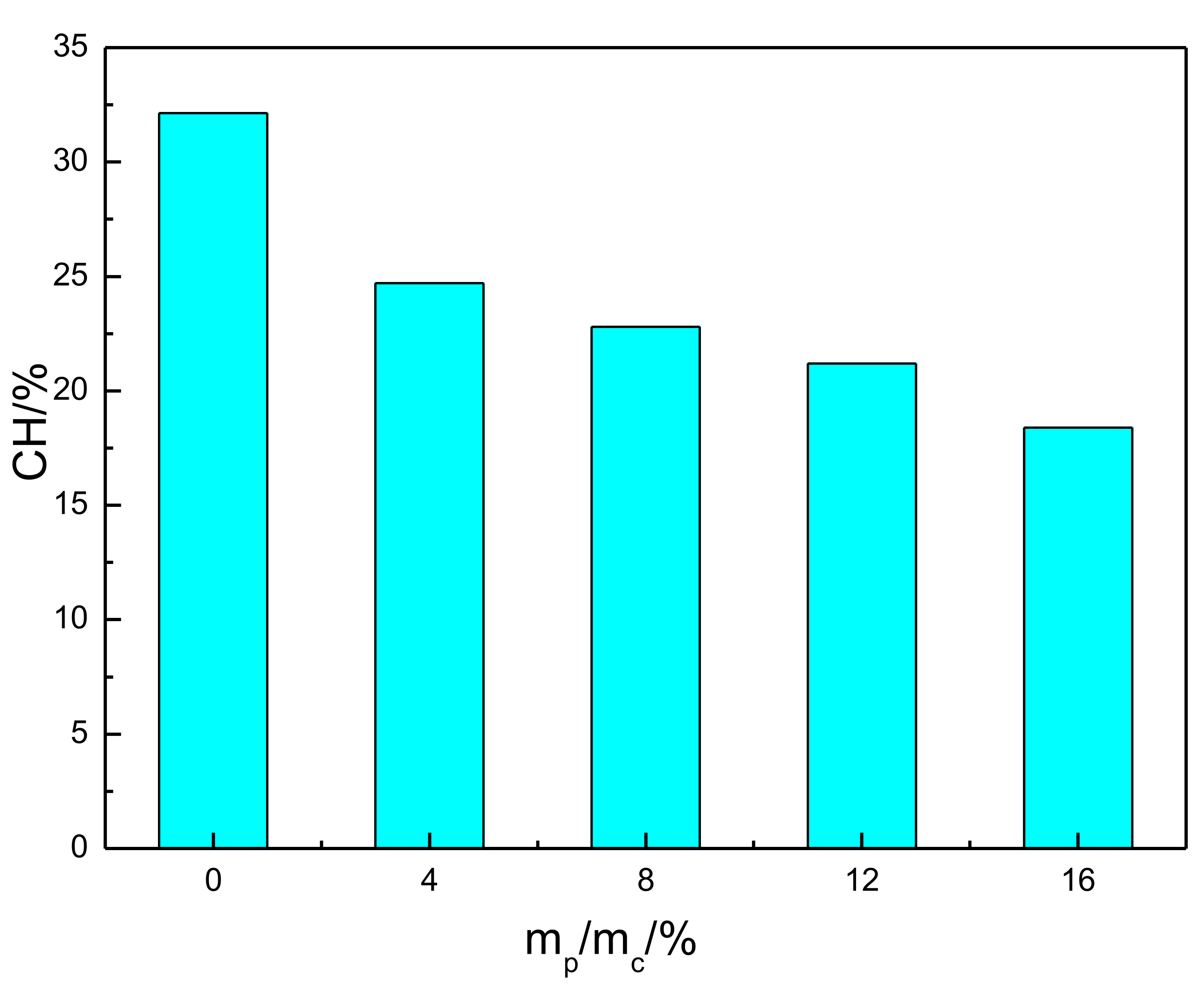

3.4. Calcium Hydroxide Content from TG-DSC

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Han, S.; Yan, P.Y.; Liu, R.G. Study on the hydration product of cement in early age using TEM. Sci. China-Technol. Sci. 2012, 55, 2284–2290. [Google Scholar] [CrossRef]

- Sheng, G.H.; Li, Q.; Zhai, J.P. Investigation on the hydration of CFBC fly ash. Fuel 2012, 98, 61–66. [Google Scholar] [CrossRef]

- Zhang, G.F.; Wang, Y.W.; Wang, P.M.; Xu, L. Calorimetric study on the influence of redispersible E/VC/VL terpolymer on the early hydration of Portland cement. J. Therm. Anal. Calorim. 2016, 124, 1229–1241. [Google Scholar] [CrossRef]

- Chen, D.; Deng, M.; Lan, X.H.; Mo, L. In-situ investigation of cement hydration at early age by laser scanning confocal microscopy. J. Chin. Ceram. Soc. 2014, 42, 590–595. [Google Scholar]

- Ma, B.; Ou, Z.; Jian, S.; Xu, R. Influence of cellulose ethers on hydration products of portland cement. J. Wuhan Univ. Technol.-Mater. Sci. Ed. 2011, 26, 588–593. [Google Scholar] [CrossRef]

- Li, X.; Yan, P.Y.; Aruhan, B. Assessment method of hydration degree of cement in complex binder based on the calcium hydroxied content. J. Chin. Silic. Soc. 2009, 37, 1597–1601. [Google Scholar]

- Hu, S.G.; He, Y.G.; Liu, L.N. Semi-quantitative assessment of C-S-H gel in a blended cement paste based on Ca(OH)2 decoupling method. J. Mater. Sci. Eng. 2006, 24, 666–669. [Google Scholar]

- Wang, P.M.; Peng, Y.; Liu, X.P. Comparison of methods for determination of hydration degree of polymer modified cement paste. J. Chin. Ceram. Soc. 2013, 41, 1116–1123. [Google Scholar]

- Li, X.; Yang, H.Q.; Li, M.X. Assessment of hydration degree of cement in the fly ash-cement pastes based on the calcium hydroxide content. Mater. Res. Appl. 2014, 875–877, 177–182. [Google Scholar] [CrossRef]

- Wang, P.M.; Pang, M.; Liu, X.P. Correlation between initial calcium oxide content of slag blended cement and mortar leaching mass loss. J. Chin. Ceram. Soc. 2016, 44, 634–639. [Google Scholar]

- Feng, S.X.; Wang, P.M. Chemical reaction of fly ash in portland cement paste. J. Build. Mater. 2017, 20, 321–325. [Google Scholar]

- Jiang, Z.W.; Xu, H.Y.; Wang, P.M.; Long, G.; Xie, Y. Hydration process of compound cementitious materials under steam curing condition. J. Chin. Silic. Soc. 2010, 38, 1702–1706. [Google Scholar]

- Yan, P.Y.; Jia, Y.D.; Aruhan, B. Alteration of Ca(OH)2 content during hydration process of composite binders. J. Build. Mater. 2010, 13, 563–567. [Google Scholar]

- Sisomphon, K.; Franke, L. Evaluation of calcium hydroxide contents in pozzolanic cement pastes by a chemical extraction method. Constr. Build. Mater. 2011, 25, 190–194. [Google Scholar] [CrossRef]

- Bentz, D.P.; Jensen, O.M.; Coats, A.M. Influence of silica fume on diffusivity in cement-based materials I. Experimental and computer modeling studies on cement pastes. Cem. Concr. Res. 2000, 30, 953–962. [Google Scholar] [CrossRef]

- Ramachandran, V.S. Differential thermal method of estimating calcium hydroxide in calcium silicate and cement pastes. Cem. Concr. Res. 1979, 9, 677–684. [Google Scholar] [CrossRef] [Green Version]

- Williams, P.J.; Biernacki, J.J.; Bai, J.M. Assessment of a synchrotron X-ray method for quantitative analysis of calcium hydroxide. Cem. Concr. Res. 2003, 33, 1553–1559. [Google Scholar] [CrossRef]

- Li, H.; Sun, W.; Liu, J.P. Quantitative analysis of phases for cement—Based materials by XRD- Rietveld method. Concrete 2013, 357–360, 1362–1369. [Google Scholar]

- Zhang, T.L. Determination of CaCO3 and Ca(OH)2 in carbonized hardened cement pastes by DSC-TG. Chin. J. Spectrosc. Lab. 2013, 30, 2160–2164. [Google Scholar]

- Silva, D.A.; Monteiro, P.J.M. ESEM analysis of polymeric film in EVA-modified cement paste. Cem. Concr. Res. 2005, 35, 2047–2050. [Google Scholar] [CrossRef]

- Tarannum, N.; Pooja, K.M.; Khan, R. Preparation and applications of hydrophobic multicomponent based redispersible polymer powder: A review. Constr. Build. Mater. 2020, 247, 118579. [Google Scholar] [CrossRef]

- Ding, S.P.; Wang, J.T.; Liu, Y.P. Effects of curing conditions on hydration behavior and pore structure of EVA emulsion modified cement paste. Bull. Chinses Ceram. Soc. 2021, 40, 2145–2151. [Google Scholar]

- Liu, S.F.; Wan, T.T.; Wang, P.M. Shrinkage stress-strain evolution of mortars modified by EVA polymer at early age. J. Build. Mater. 2016, 19, 791–796. [Google Scholar]

- Yang, N.R.; Yue, W.H. Handbook of a Collection of Illustrative Plates of Inorganic Nonmetal Materials; Wuhan University of Technology Publishing Company: Wuhan, China, 2000. [Google Scholar]

- Ou, Z.H.; Ma, B.G.; Jian, S.W. Comparison of FT-IR, thermal analysis and XRD for determination of products of cement hydration. Adv. Mater. Res. 2011, 168–170, 518–522. [Google Scholar] [CrossRef]

- Silva, D.A.; Roman, H.R.; Gleize, P.J.P. Evidences of chemical interaction between EVA and hydrating Portland cement. Cem. Concr. Res. 2002, 32, 1383–1390. [Google Scholar] [CrossRef]

- Li, H.; Xue, Z.; Liang, G.; Wu, K.; Dong, B.; Wang, W. Effect of C-S-Hs-PCE and sodium sulfate on the hydration kinetics and mechanical properties of cement paste. Constr. Build. Mater. 2021, 266, 121096. [Google Scholar] [CrossRef]

- Lu, Z.; Kong, X.; Jansen, D.; Zhang, C.; Wang, J.; Pang, X.; Yin, J. Towards a further understanding of cement hydration in the presence of triethanolamine. Cem. Concr. Res. 2020, 132, 106041. [Google Scholar] [CrossRef]

- Tan, H.; Nie, K.; He, X.; Deng, X.; Zhang, X.; Su, Y.; Yang, J. Compressive strength and hydration of high-volume wet-grinded coal fly ash cementitious materials. Constr. Build. Mater. 2019, 206, 248–260. [Google Scholar] [CrossRef]

- Ahn, T.H.; Wreden, C.P. Influence of lead and chromium ions as toxic heavy metals between AFt and AFm phases based on C3A and C4A3S. J. Ceram. Processing Res. 2014, 15, 539–544. [Google Scholar]

- Liang, G.W.; Ni, D.Y.; Li, H.X. Synergistic effect of EVA, TEA and C-S-Hs-PCE on the hydration process and mechanical properties of Portland cement paste at early age. Constr. Build. Mater. 2021, 272, 121891. [Google Scholar] [CrossRef]

| Oxides | SiO2 | CaO | Al2O3 | Fe2O3 | MgO | SO3 | f-CaO | Na2O | Cl− | Loss |

|---|---|---|---|---|---|---|---|---|---|---|

| Content/% | 22.01 | 62.1 | 4.00 | 3.47 | 2.57 | 2.71 | 0.87 | 0.53 | 0.01 | 1.73 |

| Mineral Compositions | C3S | C2S | C3A | C4AF |

|---|---|---|---|---|

| Content/% | 57.34 | 18.90 | 6.47 | 11.25 |

| Solid | Ash Content/% | Glass Transition Temp./°C | Min. Film Building Temp./°C | Granule Size/μm |

|---|---|---|---|---|

| 98~100 | 8–12 | −6 | 0 | 1–7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Du, J.; Shi, M. Quantitative Analysis of the Calcium Hydroxide Content of EVA-Modified Cement Paste Based on TG-DSC in a Dual Atmosphere. Materials 2022, 15, 2660. https://doi.org/10.3390/ma15072660

Zhang Z, Du J, Shi M. Quantitative Analysis of the Calcium Hydroxide Content of EVA-Modified Cement Paste Based on TG-DSC in a Dual Atmosphere. Materials. 2022; 15(7):2660. https://doi.org/10.3390/ma15072660

Chicago/Turabian StyleZhang, Zhenlei, Jiang Du, and Meilun Shi. 2022. "Quantitative Analysis of the Calcium Hydroxide Content of EVA-Modified Cement Paste Based on TG-DSC in a Dual Atmosphere" Materials 15, no. 7: 2660. https://doi.org/10.3390/ma15072660

APA StyleZhang, Z., Du, J., & Shi, M. (2022). Quantitative Analysis of the Calcium Hydroxide Content of EVA-Modified Cement Paste Based on TG-DSC in a Dual Atmosphere. Materials, 15(7), 2660. https://doi.org/10.3390/ma15072660