Effect of Current Density on the Microstructure and Mechanical Properties of 3YSZ/Al2O3 Composites by Flash Sintering

Abstract

:1. Introduction

2. Experimental Section

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cologna, M.; Prette, A.L.G.; Raj, R. Flash-Sintering of cubic yttria-stabilized zirconia at 750 °C for possible use in SOFC manufacturing. J. Am. Ceram. Soc. 2011, 94, 316–319. [Google Scholar] [CrossRef]

- Todd, R.I.; Zapata-Solvas, E.; Bonilla, R.S.; Sneddon, T.; Wilshaw, P.R. Electrical characteristics of flash sintering: Thermal runaway of Joule heating. J. Eur. Ceram. Soc. 2015, 35, 1865–1877. [Google Scholar] [CrossRef]

- Spiridigliozzi, L.; Pinter, L.; Biesuz, M.; Dell’Agli, G.; Accardo, G.; Sglavo, V.M. Gd/Sm-Pr Co-doped ceria: A first report of the precipitation method effect on flash sintering. Materials 2019, 12, 1218. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mishra, T.P.; Neto, R.; Raj, R.; Guillon, O.; Bram, M. Current-rate flash sintering of gadolinium doped ceria: Microstructure and defect generation. Acta Mater. 2020, 189, 145–153. [Google Scholar] [CrossRef]

- Storion, A.G.; Ferreira, J.A.; Maestrelli, S.C.; de Jesus Agnolon Pallone, E.M. Influence of the forming method on flash sintering of ZnO ceramics. Ceram. Int. 2021, 47, 965–972. [Google Scholar] [CrossRef]

- Biesuz, M.; Sglavo, V.M. Flash sintering of alumina: Effect of different operating conditions on densification. J. Eur. Ceram. Soc. 2016, 36, 2535–2542. [Google Scholar] [CrossRef]

- Prette, A.L.G.; Cologna, M.; Sglavo, V.; Raj, R. Flash-sintering of Co2MnO4 spinet for solid oxide fuel cell applications. J. Power Sources 2011, 196, 2061–2065. [Google Scholar] [CrossRef]

- Salahi, E.; Esfahani, H.; Mobasherpour, I.; Bijarchi, M.A.; Taheri, M. Sintering behavior and mechanical properties of alumina/zirconia multilayers composite via nano-powder processing. Ceram. Int. 2014, 40, 2717–2722. [Google Scholar] [CrossRef]

- Li, Y.; Kim, H.-E.; Koh, Y.-H. Improving the surface hardness of zirconia toughened alumina (ZTA) composites by surface treatment with a boehmite sol. Ceram. Int. 2012, 38, 2889–2892. [Google Scholar] [CrossRef]

- Calambas Pulgarin, H.L.; Garrido, L.B.; Albano, M.P. Processing of different alumina-zirconia composites by slip casting. Ceram. Int. 2013, 39, 6657–6667. [Google Scholar] [CrossRef]

- Guo, X.; Waser, R. Electrical properties of the grain boundaries of oxygen ion conductors: Acceptor-doped zirconia and ceria. Progress Mater. Sci. 2006, 51, 151–210. [Google Scholar] [CrossRef]

- Kumar, B.; Thokchom, J. Space Charge-Mediated Ionic Transport in Yttria-Stabilized Zirconia–Alumina Composite Membranes. J. Am. Ceram. Soc. 2008, 91, 1175–1181. [Google Scholar] [CrossRef]

- Verkerk, M.J.; Middelhuis, B.J.; Burggraaf, A.J. Effect of grain boundaries on the conductivity of high-purity ZrO2/Y2O3 ceramics. Solid State Ion. 1982, 6, 159–170. [Google Scholar] [CrossRef] [Green Version]

- Naik, K.S.; Sglavo, V.M.; Raj, R. Field assisted sintering of ceramic constituted by alumina and yttria stabilized zirconia. J. Eur. Ceram. Soc. 2014, 34, 2435–2442. [Google Scholar] [CrossRef]

- Ojaimi, C.L.; Ferreira, J.A.; Chinelatto, A.L.; Antonio Chinelatto, A.S.; de Jesus Agnolon Pallone, E.M. Microstructural analysis of ZrO2/Al2O3 composite: Flash and conventional sintering. Ceram. Int. 2020, 46, 2473–2480. [Google Scholar] [CrossRef]

- Jia, Y.; Su, X.; Wu, Y.; Wang, Z.; Meng, L.; Xu, X.; Zhang, A. Flash sintering of 3YSZ/Al2O3-platelet composites. J. Am. Ceram. Soc. 2020, 103, 2351–2361. [Google Scholar] [CrossRef]

- Raj, R. Joule heating during flash-sintering. J. Eur. Ceram. Soc. 2012, 32, 2293–2301. [Google Scholar] [CrossRef]

- Jiang, T.; Liu, Y.; Wang, Z.; Sun, W.; Qiao, J.; Sun, K. An improved direct current sintering technique for proton conductor—BaZr0.1Ce0.7Y0.1Yb0.1O3: The effect of direct current on sintering process. J. Power Sources 2014, 248, 70–76. [Google Scholar] [CrossRef]

- Dong, Y.; Chen, I.W. Predicting the Onset of Flash Sintering. J. Am. Ceram. Soc. 2015, 98, 2333–2335. [Google Scholar] [CrossRef]

- Yoshida, H.; Sakka, Y.; Yamamoto, T.; Lebrun, J.-M.; Raj, R. Densification behaviour and microstructural development in undoped yttria prepared by flash-sintering. J. Eur. Ceram. Soc. 2014, 34, 991–1000. [Google Scholar] [CrossRef]

- Gaur, A.; Sglavo, V.M. Flash Sintering of (La, Sr)(Co, Fe)O3–Gd-Doped CeO2 Composite. J. Am. Ceram. Soc. 2015, 98, 1747–1752. [Google Scholar] [CrossRef]

- Zhang, Y.; Nie, J.; Chan, J.M.; Luo, J. Probing the densification mechanisms during flash sintering of ZnO. Acta Mater. 2017, 125, 465–475. [Google Scholar] [CrossRef] [Green Version]

- Corapcioglu, G.; Gulgun, M.A.; Kisslinger, K.; Sturm, S.; Jha, S.K.; Raj, R. Microstructure and microchemistry of flash sintered K0.5Na0.5NbO3. J. Ceram. Soc. Jpn. 2016, 124, 321–328. [Google Scholar] [CrossRef] [Green Version]

- Tarasi, F.; Medraj, M.; Dolatabadi, A.; Oberste-Berghaus, J.; Moreau, C. Amorphous and crystalline phase formation during suspension plasma spraying of the alumina-zirconia composite. J. Eur. Ceram. Soc. 2011, 31, 2903–2913. [Google Scholar] [CrossRef] [Green Version]

- Jones, G.M.; Biesuz, M.; Ji, W.; John, S.F.; Grimley, C.; Manière, C.; Dancer, C.E.J. Promoting microstructural homogeneity during flash sintering of ceramics through thermal management. MRS Bull. 2021, 46, 59–66. [Google Scholar] [CrossRef]

- Wu, G.; Yazhenskikh, E.; Hack, K.; Wosch, E.; Müller, M. Viscosity model for oxide melts relevant to fuel slags. Part 1: Pure oxides and binary systems in the system SiO2–Al2O3–CaO–MgO–Na2O–K2O. Fuel Process. Technol. 2015, 137, 93–103. [Google Scholar] [CrossRef]

- Zhang, G.; Chou, K. Correlation between viscosity and electrical conductivity of aluminosilicate melts. Metallurg. Mater. Trans. B 2012, 43, 849–855. [Google Scholar] [CrossRef]

- Shu, Y.A.; Dl, A.; Jl, B.; La, C. Ultrafast preparation of Al2O3–ZrO2 multiphase ceramics with eutectic morphology via flash sintering. Ceram. Int. 2021, 47, 31555–31560. [Google Scholar] [CrossRef]

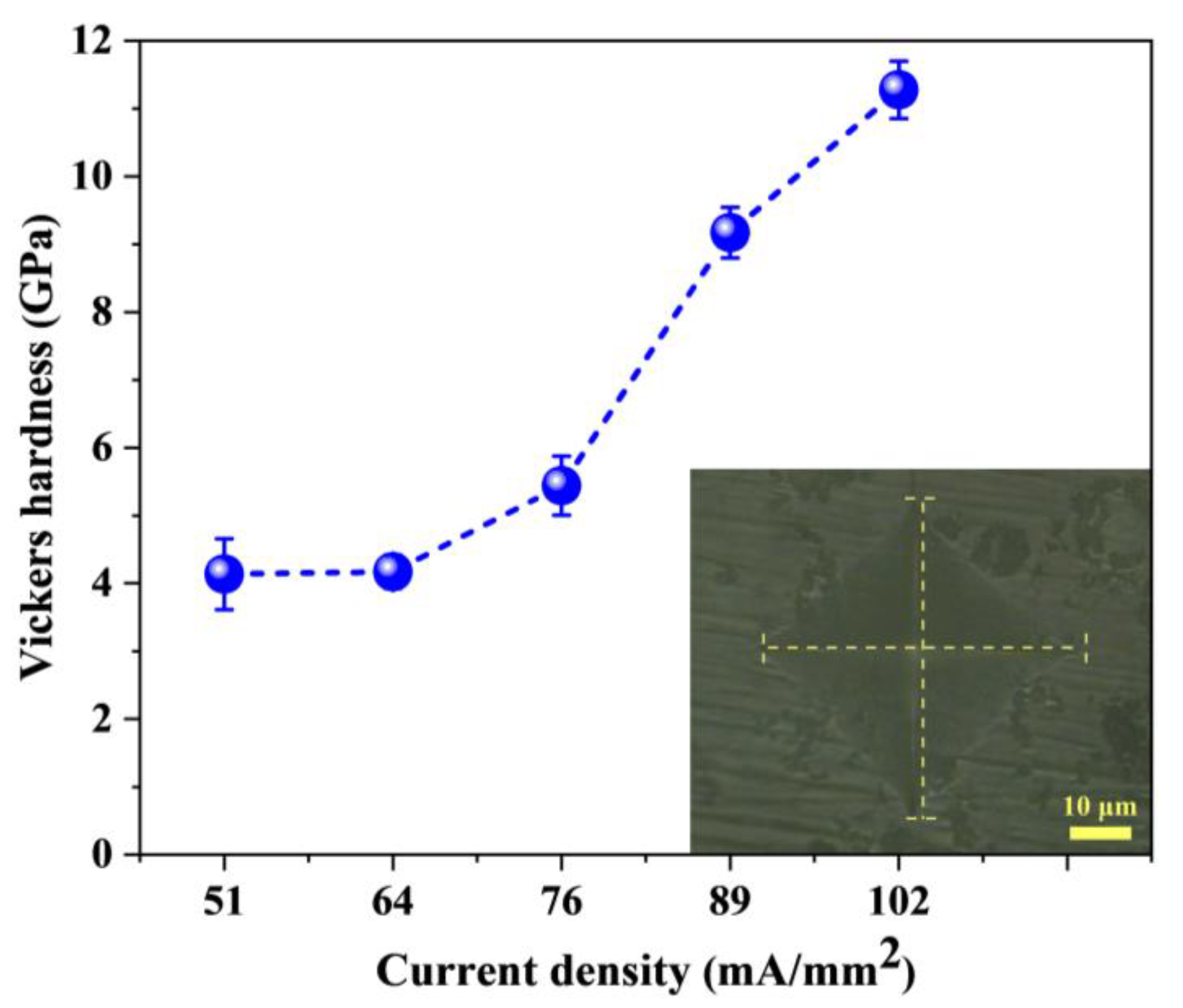

| Sample | Average Grainsize (μm) | Relative Density (%) | Sample Temperature (°C) | |

|---|---|---|---|---|

| ZrO2 | Al2O3 | |||

| FS-51 | 0.18 | 0.22 | 83.6 | 1130 |

| FS-64 | 0.23 | 0.27 | 84.1 | 1221 |

| FS-76 | 0.29 | 0.32 | 85.5 | 1297 |

| FS-89 | 0.31 | 0.41 | 92.7 | 1391 |

| FS-102 | 0.33 | 0.47 | 94.2 | 1467 |

| CS | 0.30 | 0.36 | 93.2 | 1400 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bai, Y.; Zhang, Y.; Tian, Z.; Zhang, J.; Shi, Z. Effect of Current Density on the Microstructure and Mechanical Properties of 3YSZ/Al2O3 Composites by Flash Sintering. Materials 2022, 15, 3110. https://doi.org/10.3390/ma15093110

Bai Y, Zhang Y, Tian Z, Zhang J, Shi Z. Effect of Current Density on the Microstructure and Mechanical Properties of 3YSZ/Al2O3 Composites by Flash Sintering. Materials. 2022; 15(9):3110. https://doi.org/10.3390/ma15093110

Chicago/Turabian StyleBai, Yujie, Ying Zhang, Zhifeng Tian, Junzhan Zhang, and Zongmo Shi. 2022. "Effect of Current Density on the Microstructure and Mechanical Properties of 3YSZ/Al2O3 Composites by Flash Sintering" Materials 15, no. 9: 3110. https://doi.org/10.3390/ma15093110

APA StyleBai, Y., Zhang, Y., Tian, Z., Zhang, J., & Shi, Z. (2022). Effect of Current Density on the Microstructure and Mechanical Properties of 3YSZ/Al2O3 Composites by Flash Sintering. Materials, 15(9), 3110. https://doi.org/10.3390/ma15093110