The Possibility to Use Pine Timber Pieces with Small Size in the Production of Glulam Beams

Abstract

:1. Introduction

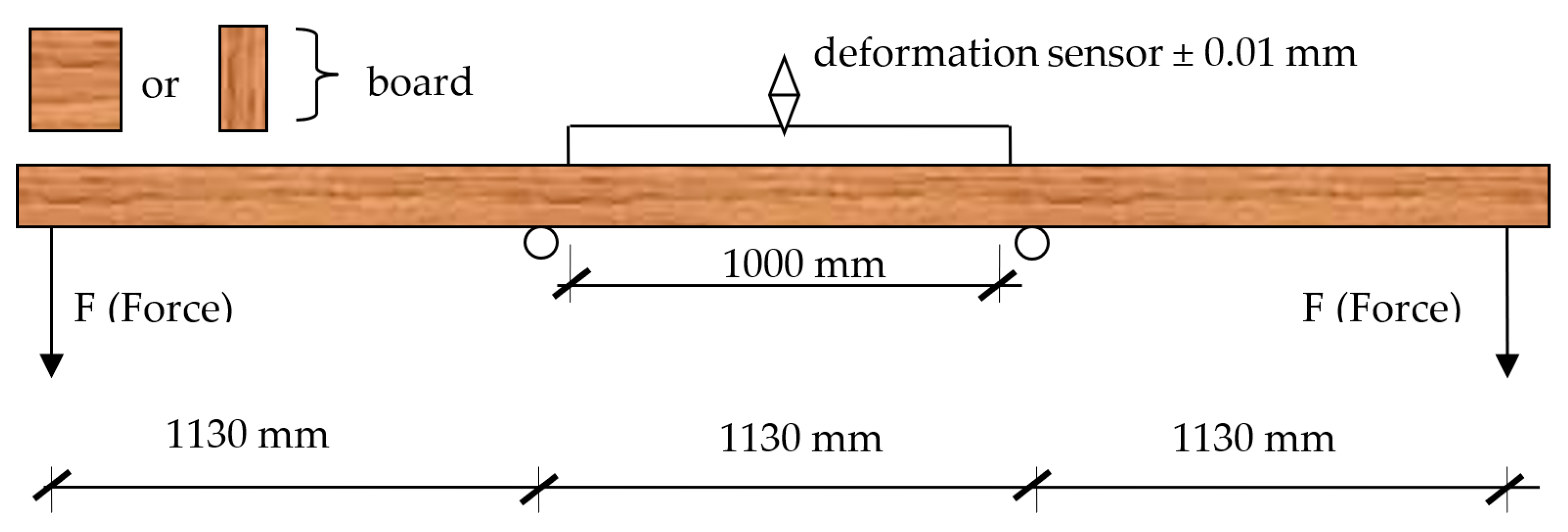

2. Materials and Methods

- (A)

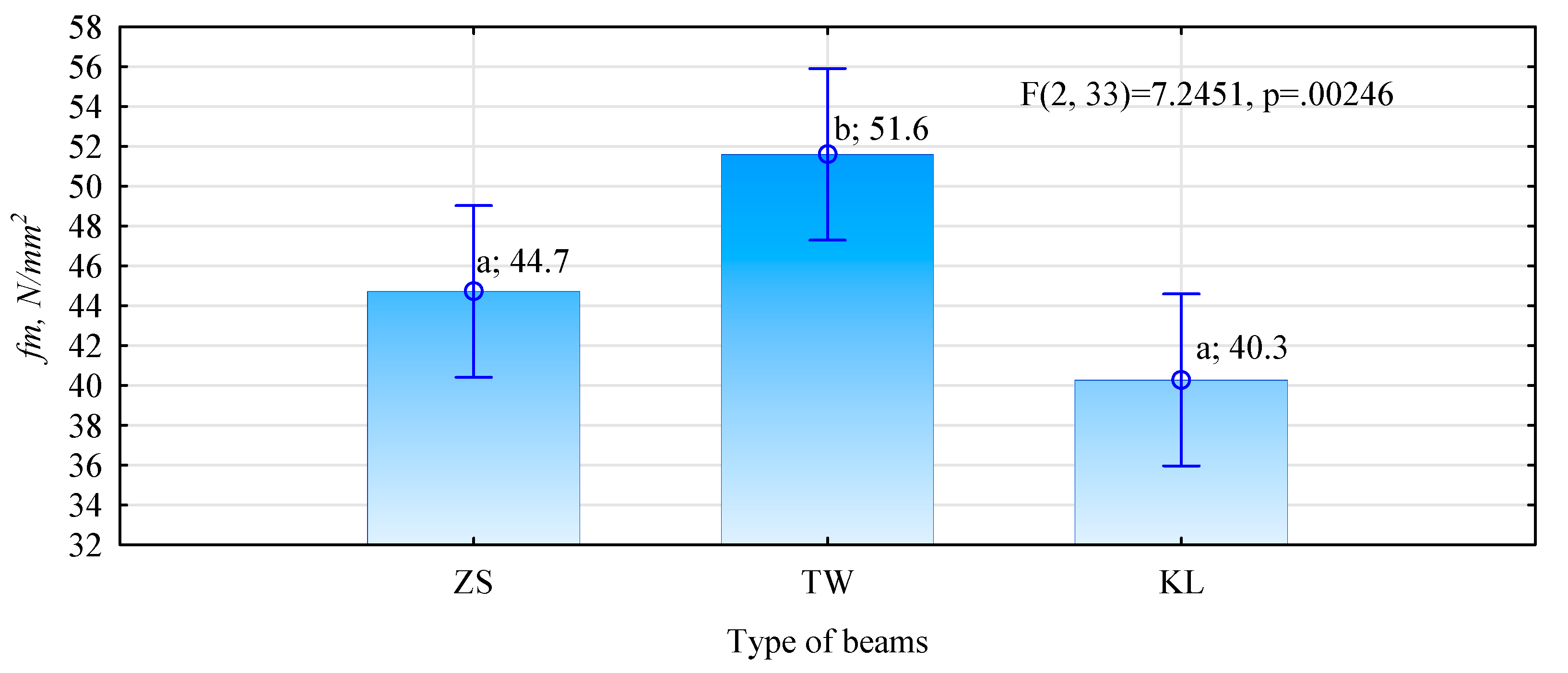

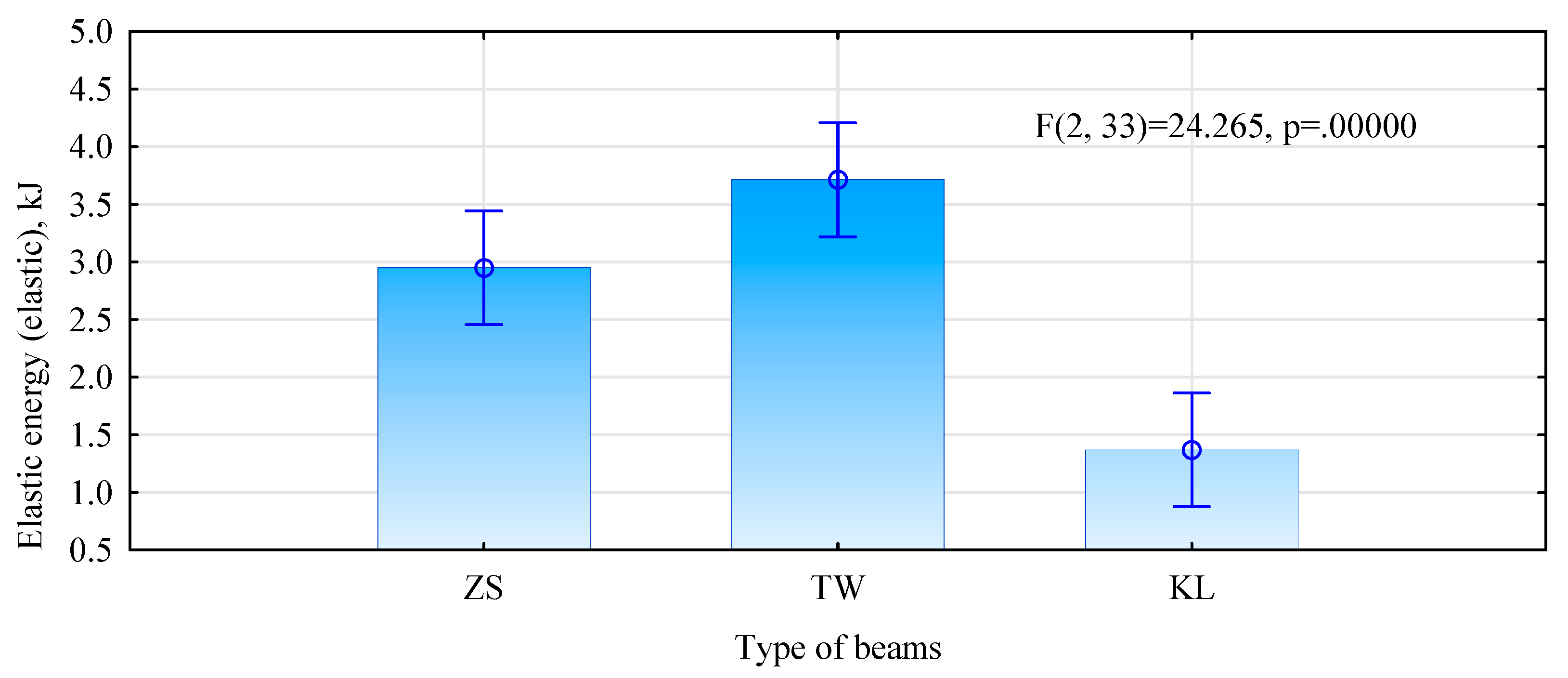

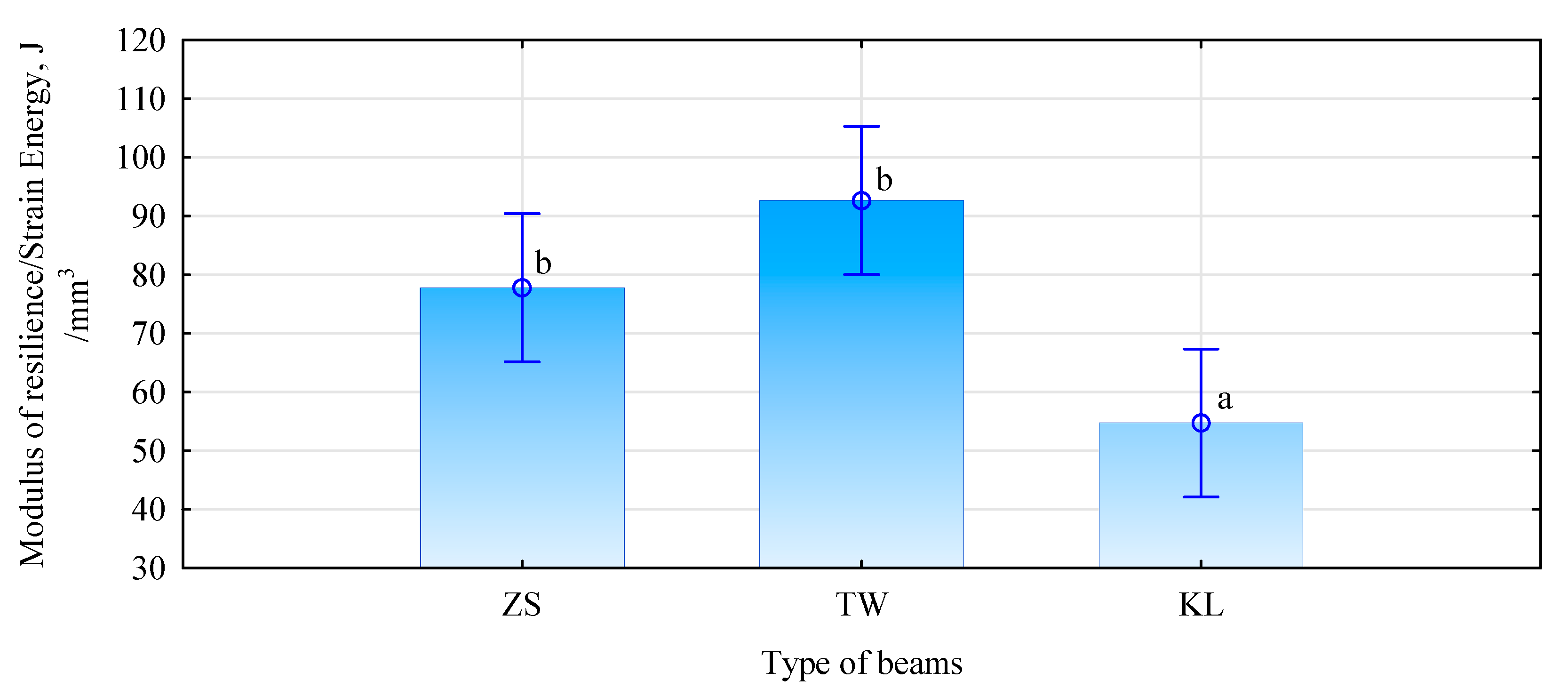

- An eight-layer combined glulam beam (160 mm × 80 mm), manufactured from side boards of 20 mm in thickness and 80 mm in width (the TW variant, Figure 1). The timber was visually graded following the assumptions of PN-D-93021:2013-10 [26] and, on this basis, it was classified to four grades, i.e., KW (premium), KS (medium grade), KD (low grade), and out-of-grade. The beam was formed, so that the face layers were made from KW timber, the second and seventh layers from KS timber, and the core (four layers) consisted of KD timber.

- (B)

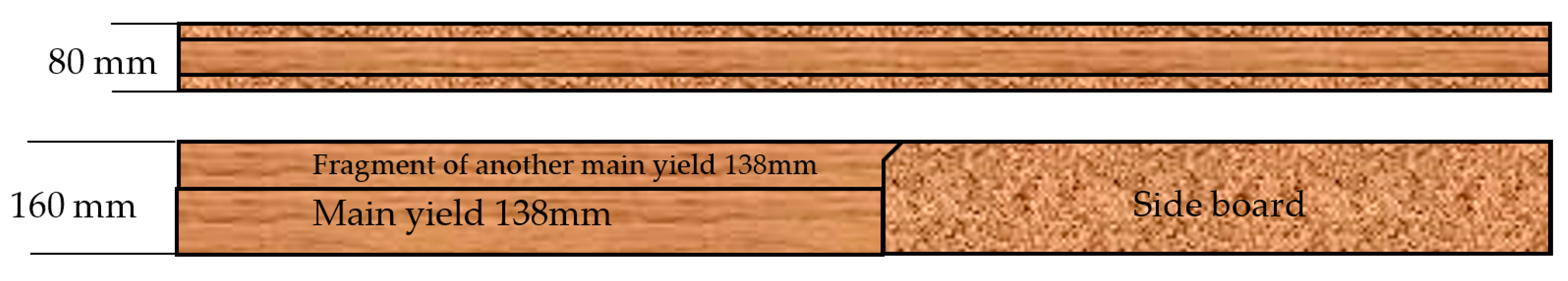

- A three-layer beam (160 × 80), manufactured from two side boards of 21 mm in thickness and 160 mm in width and main yield boards of 40 mm in thickness and 138 mm in width (the ZS variant, Figure 2). Main yield was first bonded into boards approximately 97 cm in width, from which, lamellas of 160 mm in width and 40 mm in thickness were manufactured. The lamellas prepared in this way were then planed. Ultimately, their thickness was 38 mm.

- (C)

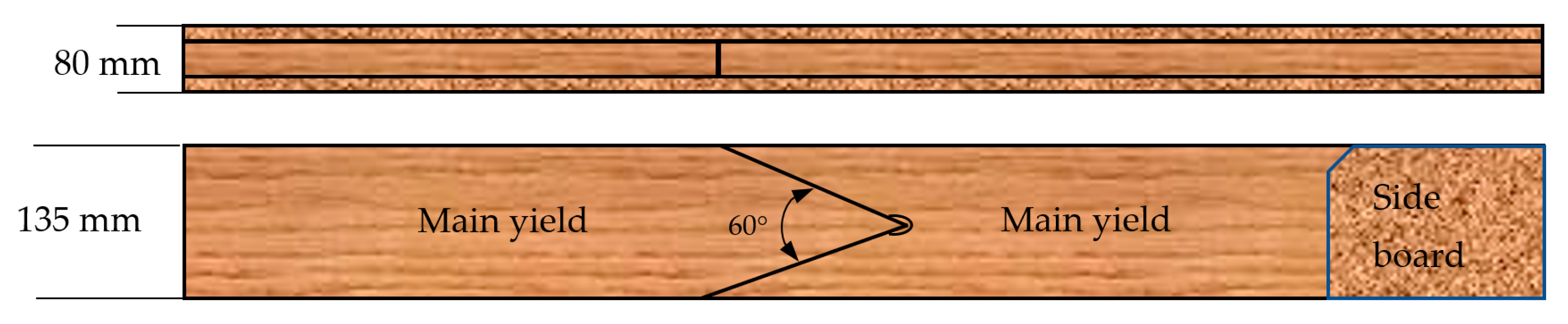

- A three-layer beam (135 × 80), manufactured from two side boards of 21 mm in thickness and 135 mm in width and main yield boards of 38 mm in thickness and 135 mm in width (variant KL, Figure 3). Main yield boards were composed of two elements, wedge-jointed at a 60°angle, with the same MUF adhesive mixture applied for gluing the boards. In the timber section containing the wedge, prior to wedge cutting, a hole, 10 mm in diameter, was drilled at the recess tip.

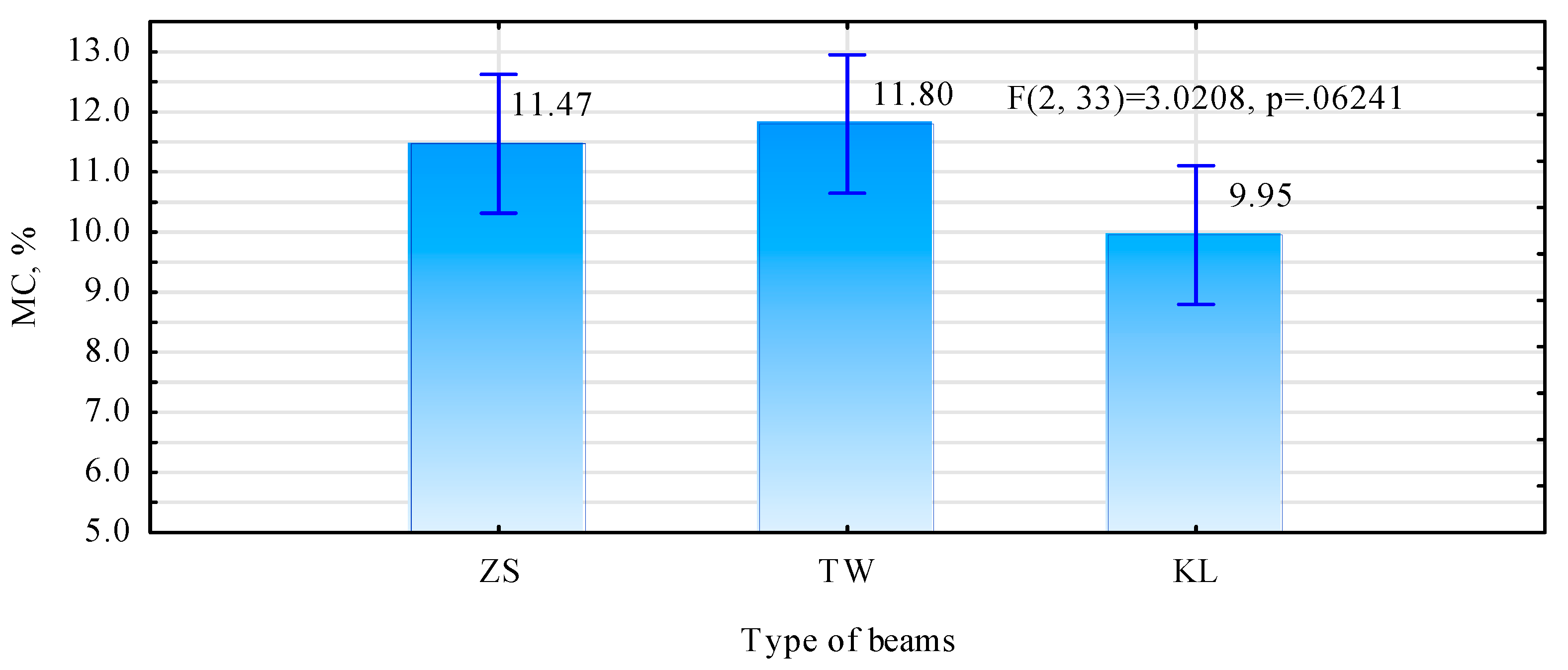

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Thelandersson, S.; Larsen, H.J. Timber Engineering; John Wiley & Sons: Hoboken, NJ, USA, 2003; ISBN 0-470-84469-8. [Google Scholar]

- Thorhallsson, E.R.; Hinriksson, G.I.; Snæbjörnsson, J.T. Strength and Stiffness of Glulam Beams Reinforced with Glass and Basalt Fibres. Compos. Part B Eng. 2017, 115, 300–307. [Google Scholar] [CrossRef]

- Kandler, G.; Lukacevic, M.; Füssl, J. Experimental Study on Glued Laminated Timber Beams with Well-Known Knot Morphology. Eur. J. Wood Wood Prod. 2018, 76, 1435–1452. [Google Scholar] [CrossRef] [Green Version]

- Meyers, M.A.; McKittrick, J.; Chen, P.-Y. Structural Biological Materials: Critical Mechanics-Materials Connections. Science 2013, 339, 773–779. [Google Scholar] [CrossRef] [Green Version]

- Song, J.; Chen, C.; Zhu, S.; Zhu, M.; Dai, J.; Ray, U.; Li, Y.; Kuang, Y.; Li, Y.; Quispe, N. Processing Bulk Natural Wood into a High-Performance Structural Material. Nature 2018, 554, 224–228. [Google Scholar] [CrossRef]

- Mirski, R.; Dziurka, D.; Kuliński, M.; Trociński, A.; Kawalerczyk, J.; Antonowicz, R. Strength Properties of Structural Glulam Manufactured from Pine (Pinus Sylvestris L.) Side Boards. Materials 2021, 14, 7312. [Google Scholar] [CrossRef] [PubMed]

- Kawalerczyk, J.; Kuliński, M.; Dziurka, D.; Mirski, R. The Possibility to Use a Side-Timber in Glulam Beams Manufacturing for Structural Applications. Ann. WULS SGGW For. Wood Technol. 2021, 113, 65–73. [Google Scholar] [CrossRef]

- Mirski, R.; Dziurka, D.; Chuda-Kowalska, M.; Wieruszewski, M.; Kawalerczyk, J.; Trociński, A. The Usefulness of Pine Timber (Pinus Sylvestris L.) for the Production of Structural Elements. Part I: Evaluation of the Quality of the Pine Timber in the Bending Test. Materials 2020, 13, 3957. [Google Scholar] [CrossRef] [PubMed]

- Nadir, Y.; Nagarajan, P. The Behavior of Horizontally Glued Laminated Beams Using Rubber Wood. Constr. Build. Mater. 2014, 55, 398–405. [Google Scholar] [CrossRef]

- Martins, C.; Monteiro, S.; Knapic, S.; Dias, A. Assessment of Bending Properties of Sawn and Glulam Blackwood in Portugal. Forests 2020, 11, 418. [Google Scholar] [CrossRef] [Green Version]

- Fujimoto, K.; Hiramatsu, Y.; Miyatake, A.; Shindo, K.; Karube, M.; Harada, M.; Ukyo, S. Strength Properties of Glued Laminated Timber Made from Edge-Glued Laminae I: Strength Properties of Edge-Glued Karamatsu (Larix Kaempferi) Laminae. J. Wood Sci. 2010, 56, 444–451. [Google Scholar] [CrossRef]

- Hiramatsu, Y.; Fujimoto, K.; Miyatake, A.; Shindo, K.; Nagao, H.; Kato, H.; Ido, H. Strength Properties of Glued Laminated Timber Made from Edge-Glued Laminae II: Bending, Tensile, and Compressive Strength of Glued Laminated Timber. J. Wood Sci. 2011, 57, 66–70. [Google Scholar] [CrossRef]

- Connolly, T.; Loss, C.; Iqbal, A.; Tannert, T. Feasibility Study of Mass-Timber Cores for the UBC Tall Wood Building. Buildings 2018, 8, 98. [Google Scholar] [CrossRef] [Green Version]

- Phillips, G.E. Flow-Grain Analogy. Wood Fiber Sci. 1981, 14, 55–64. [Google Scholar]

- Chiorescu, S.; Gronlund, A. The Visual Grading System for Scots Pine Logs in Relation to the Quality of Sideboards Produced. For. Prod. J. 2003, 53, 53. [Google Scholar]

- Mirski, R.; Wieruszewski, M.; Trociński, A.; Kawalerczyk, J.; Łabęda, K. Elastic Moduli of Butt-End Logs and the Variable Knots Distribution in Scots Pine from Western Poland. BioResources 2021, 16, 1842. [Google Scholar] [CrossRef]

- Mirski, R.; Dziurka, D.; Chuda-Kowalska, M.; Kawalerczyk, J.; Kuliński, M.; Łabęda, K. The Usefulness of Pine Timber (Pinus Sylvestris L.) for the Production of Structural Elements. Part II: Strength Properties of Glued Laminated Timber. Materials 2020, 13, 4029. [Google Scholar] [CrossRef]

- As, N.; Goker, Y.; Dundar, T. Effect of Knots on the Physical and Mechanical Properties of Scots Pine. Wood Res. Slovak. 2006, 51, 51–58. [Google Scholar]

- Desch, H.E.; Dinwoodie, J.M. Timber: Structure, Properties, Conversion and Use; Macmillan International Higher Education: London, UK, 2016; ISBN 1-349-13427-9. [Google Scholar]

- Rapp, P. The Numerical Modeling of Adhesive Joints in Reinforcement of Wooden Elements, Subjected to Bending and Shearing. Drew. Pr. Nauk. Doniesienia Komun. 2017, 60, 22–36. [Google Scholar] [CrossRef]

- Rapp, P.; Fiszer, S. Approximate Numerical Model for Adhesive Scarf Joints in Wooden Beams. Drew. Pr. Nauk. Doniesienia Komun. 2015, 58, 5–21. [Google Scholar] [CrossRef]

- Özçifçi, A.; Yapıcı, F. Structural Performance of the Finger-Jointed Strength of Some Wood Species with Different Joint Configurations. Constr. Build. Mater. 2008, 22, 1543–1550. [Google Scholar] [CrossRef]

- Meghlat, E.M.; Oudjene, M.; Ait-Aider, H.; Batoz, J.L. A New Approach to Model Nailed and Screwed Timber Joints Using the Finite Element Method. Constr. Build. Mater. 2013, 41, 263–269. [Google Scholar] [CrossRef]

- Komariah, R.N.; Hadi, Y.S.; Massijaya, M.Y.; Suryana, J. Physical-Mechanical Properties of Glued Laminated Timber Made from Tropical Small-Diameter Logs Grown in Indonesia. J. Korean Wood Sci. Technol. 2015, 43, 156–167. [Google Scholar] [CrossRef] [Green Version]

- Mirski, R.; Kuliński, M.; Dziurka, D.; Thomas, M.; Antonowicz, R. Strength Properties of Structural Glulam Elements from Pine (Pinus Sylvestris L.) Timber Reinforced in the Tensile Zone with Steel and Basalt Rods. Materials 2021, 14, 2574. [Google Scholar] [CrossRef]

- PN-D-93021:2013-10; Tarcica Konstrukcyjna Iglasta Sortowana Metodami Wytrzymałościowymi (Construction Timber Graded by Strength Methods). Polish Committee for Standardization: Warsaw, Poland, 2013.

- EN 408:2013; Timber Structures—Structural Timber and Glued Laminated Timber—Determination of Some Physical and Mechanical Properties. European Committee for Standardization: Brussels, Belgium, 2012.

- San Ha, N.; Lu, G. A review of recent research on bio-inspired structures and materials for energy absorption applications. Compos. Part B Eng. 2020, 181, 107496. [Google Scholar] [CrossRef]

- Zhang, G.; Wang, B.; Ma, L.; Yiong, J.; Wu, L. Response of sandwich structures with pyramidal truss cores under the compression and impact loading. Compos. Struct. 2013, 100, 451–463. [Google Scholar] [CrossRef]

- Yang, L.; Harrysson, O.; West, H.; Cormier, D. A Comparison of Bending Properties for Cellular Core Sandwich Panels. Mater. Sci. Appl. 2013, 4, 471–477. [Google Scholar] [CrossRef] [Green Version]

- Tao, Y.; Li, W.; Wei, K.; Duan, S.; Wen, W.; Chen, L.; Pei, Y.; Fang, D. Mechanical properties and energy absorption of 3D printed square hierarchical honeycombs under in-plane axial compression. Compos. Part B Eng. 2019, 176, 107219. [Google Scholar] [CrossRef]

- Schneider, C.; Zenkert, D.; Deshpande, V.S.; Kazemahvazi, S. Bending energy absorption of self-reinforced poly(ethylene terephthalate) composite sandwich beams. Compos. Struct. 2016, 140, 582–589. [Google Scholar] [CrossRef] [Green Version]

- Krzysik, F. Wood Science; Państwowe Wydawnictwo Naukowe: Warszawa, Poland, 1974. (In Polish) [Google Scholar]

- PN-B-03150:2000; Konstrukcje Drewniane—Obliczenia Statyczne i Projektowanie (Timber Structures—Calculation and Design Rules). Polish Committee for Standardization: Warsaw, Poland, 2000.

- EN 14080:2013; Timber Structures—Glued Laminated Timber and Glued Solid Timber—Requirements. European Committee for Standardization: Brussels, Belgium, 2013.

- Bodig, J.; Jayne, B.A. Mechanics of Wood and Wood Composites; Van Nostrand Reinhold: Hoboken, NJ, USA, 1982; p. 376. [Google Scholar]

| Produced Cross-Section Variants | Available Lengths | ||||||

|---|---|---|---|---|---|---|---|

| Dimensions (mm × mm) | Mean (%) | Min. (%) | Max. (%) | Dimensions (m) | Mean (%) | Min. (%) | Max. (%) |

| 80 × 180 | 25 | 20 | 30 | 6.5–7 | 60 | 50 | 70 |

| 80 × 200 | 8 | 5 | 10 | Up to 6 | 35 | 30 | 45 |

| 140 × 140 | 15 | 10 | 20 | Up to 9 | 50 | 40 | 60 |

| 160 × 240 | 7 | 5 | 10 | Up to 12 | 7 | 5 | 10 |

| Others | 52 | 35 | 60 | Others | 8 | 0 | 25 |

| Beam Type | Layer | ||

|---|---|---|---|

| Face | Core | Face | |

| Mean Modulus of Elasticity, kN/mm2 | |||

| KL | 16.9 | 16.7 | 16.8 |

| ZS | 13.3 | 13.0 | 13.3 |

| TW | Assumed modulus of elasticity for individual grades | ||

| KW | KS | KD | |

| Modulus of elasticity, kN/mm2 | |||

| 11.5–12 | 10–11 | 9 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dziurka, D.; Kawalerczyk, J.; Walkiewicz, J.; Derkowski, A.; Mirski, R. The Possibility to Use Pine Timber Pieces with Small Size in the Production of Glulam Beams. Materials 2022, 15, 3154. https://doi.org/10.3390/ma15093154

Dziurka D, Kawalerczyk J, Walkiewicz J, Derkowski A, Mirski R. The Possibility to Use Pine Timber Pieces with Small Size in the Production of Glulam Beams. Materials. 2022; 15(9):3154. https://doi.org/10.3390/ma15093154

Chicago/Turabian StyleDziurka, Dorota, Jakub Kawalerczyk, Joanna Walkiewicz, Adam Derkowski, and Radosław Mirski. 2022. "The Possibility to Use Pine Timber Pieces with Small Size in the Production of Glulam Beams" Materials 15, no. 9: 3154. https://doi.org/10.3390/ma15093154

APA StyleDziurka, D., Kawalerczyk, J., Walkiewicz, J., Derkowski, A., & Mirski, R. (2022). The Possibility to Use Pine Timber Pieces with Small Size in the Production of Glulam Beams. Materials, 15(9), 3154. https://doi.org/10.3390/ma15093154