Evaluation of Mechanical and Microstructural Properties and Global Warming Potential of Green Concrete with Wheat Straw Ash and Silica Fume

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Burning and Grinding of Wheat Straw Ash

2.1.2. Concrete Mixture Proportions

2.2. Methods

2.2.1. Concrete Mixing and Preparation of Concrete Specimens

2.2.2. Compressive and Splitting Tensile Strength Tests

2.2.3. Water Absorption

2.2.4. Casting and Curing of Paste Samples for Microstructure and Pore Structure Analysis

Scanning Electron Microscopy/Energy-Dispersive X-ray Spectroscopy (SEM–EDS) Analysis

Nitrogen Adsorption Isotherm Technique

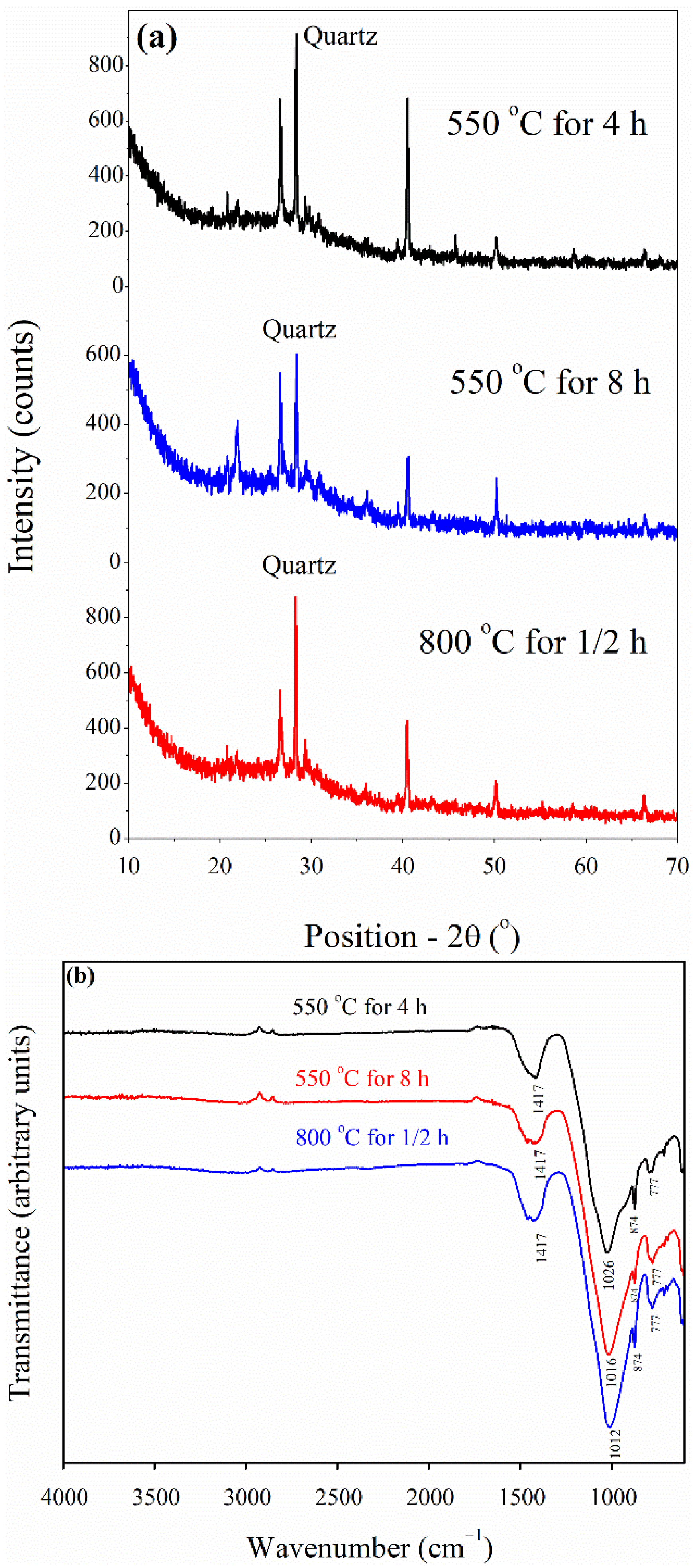

Fourier Transform Infrared (FTIR) Analysis

Thermogravimetric Analysis (TGA) of Cement Pastes

2.2.5. Methodology to Calculate Global Warming Potential (kg CO2-eq) of Concrete Mixes

3. Results and Discussion

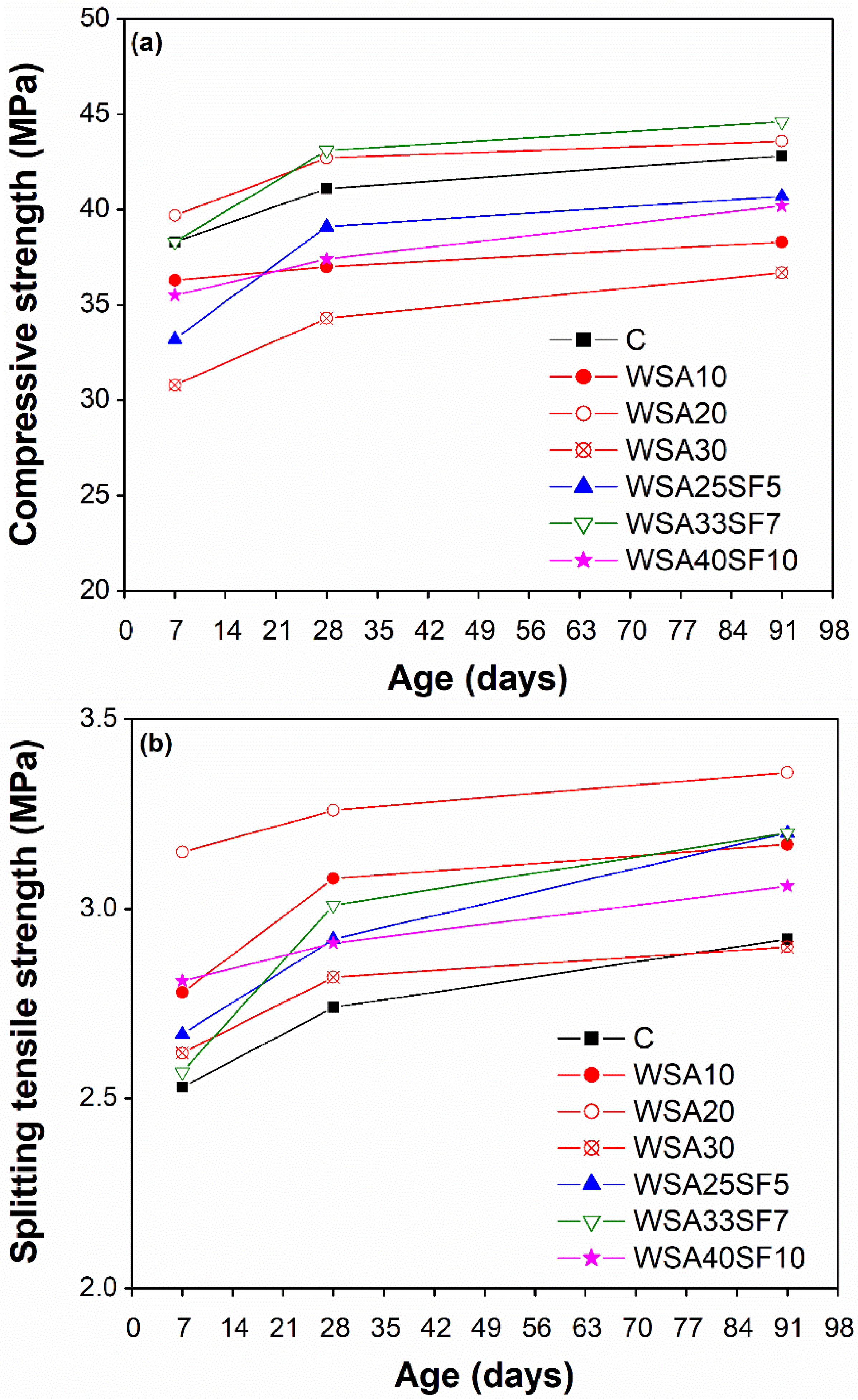

3.1. Compressive and Tensile Strength Evolution of Binary (C/WSA) and Ternary (C/WSA/SF) Concretes

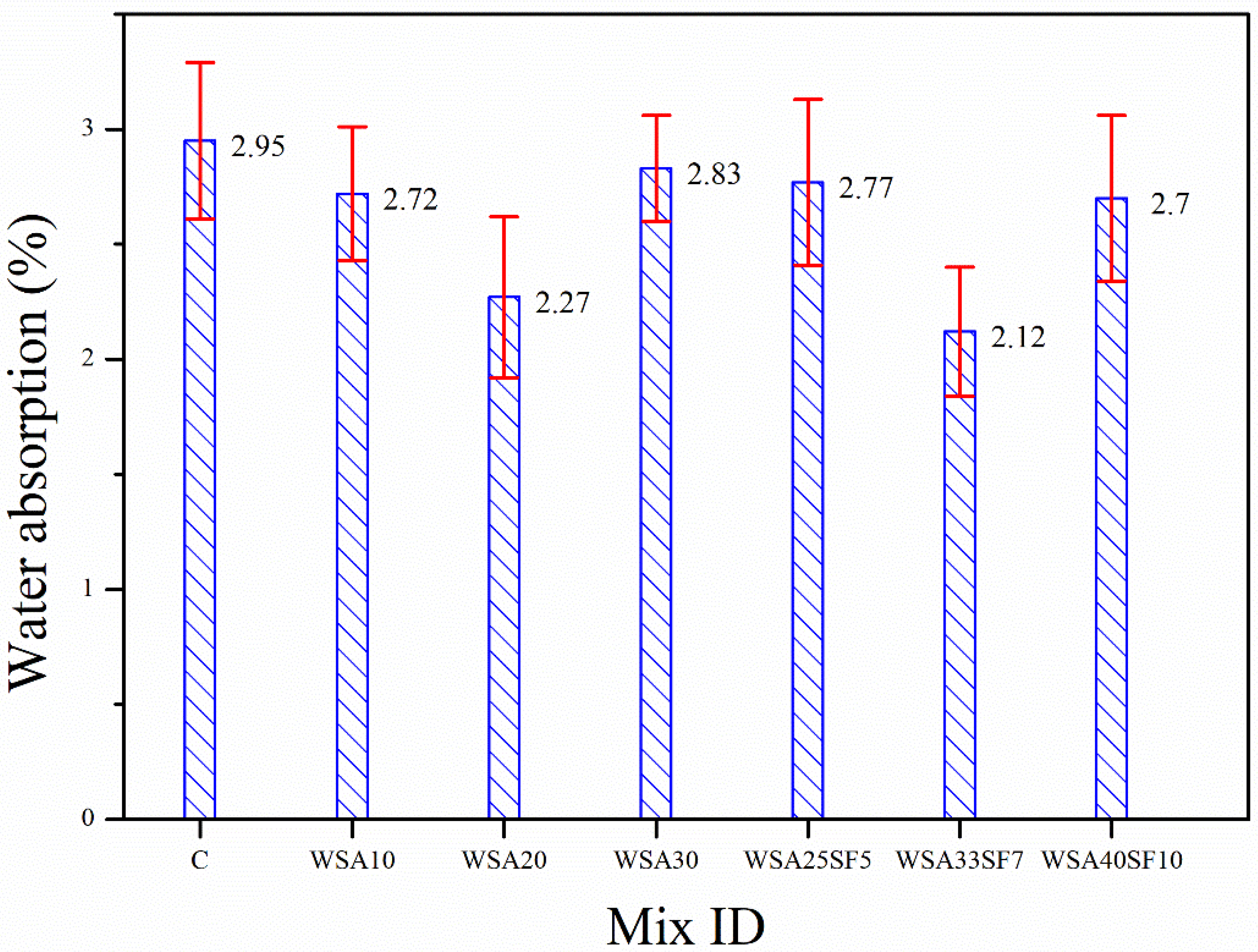

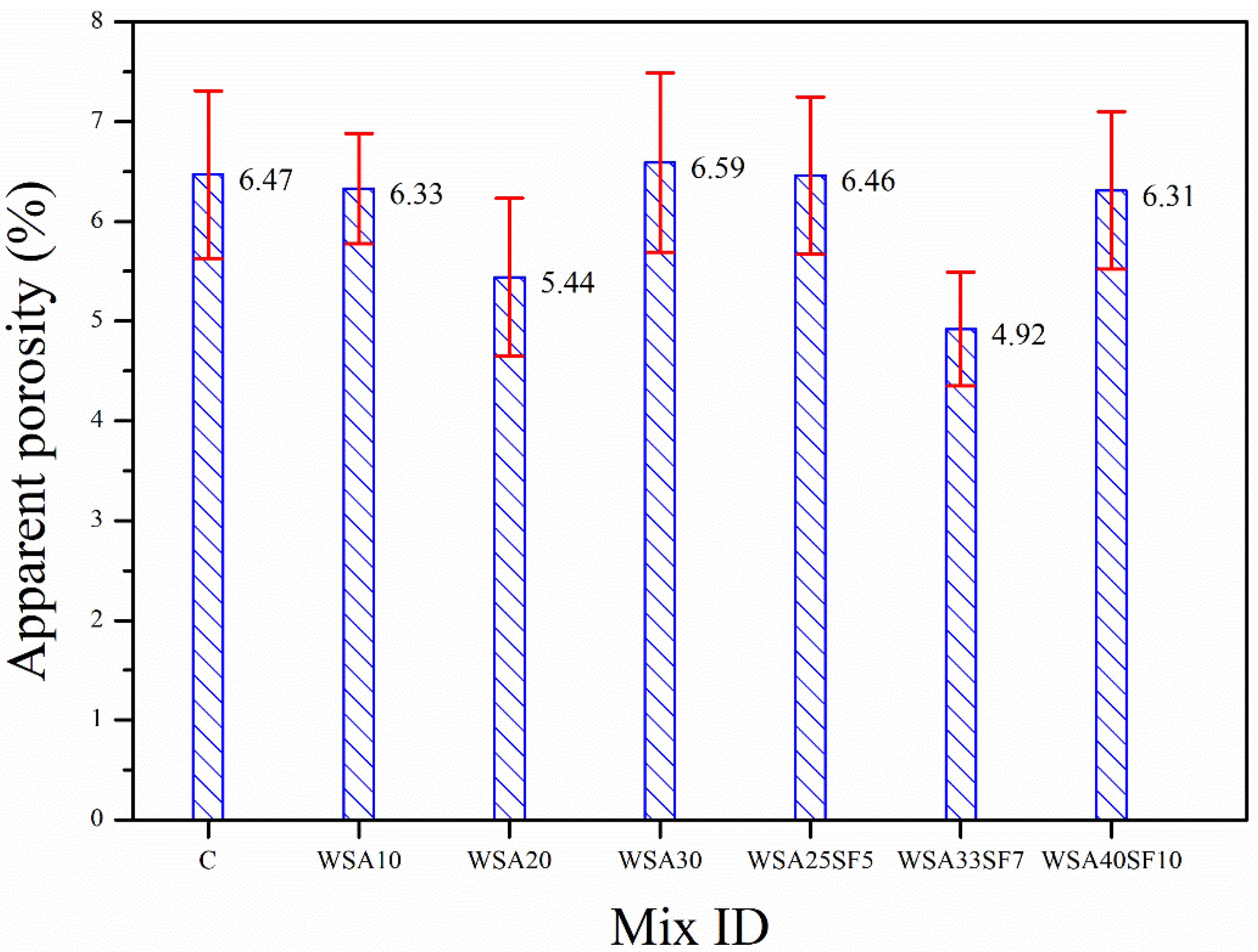

3.2. Comparison of the Water Absorption and Apparent Porosity of Control Concrete and Binary and Ternary Concrete Mixtures

3.3. Evaluation of Compressive and Tensile Strength Correlation of Concrete by Prediction Models

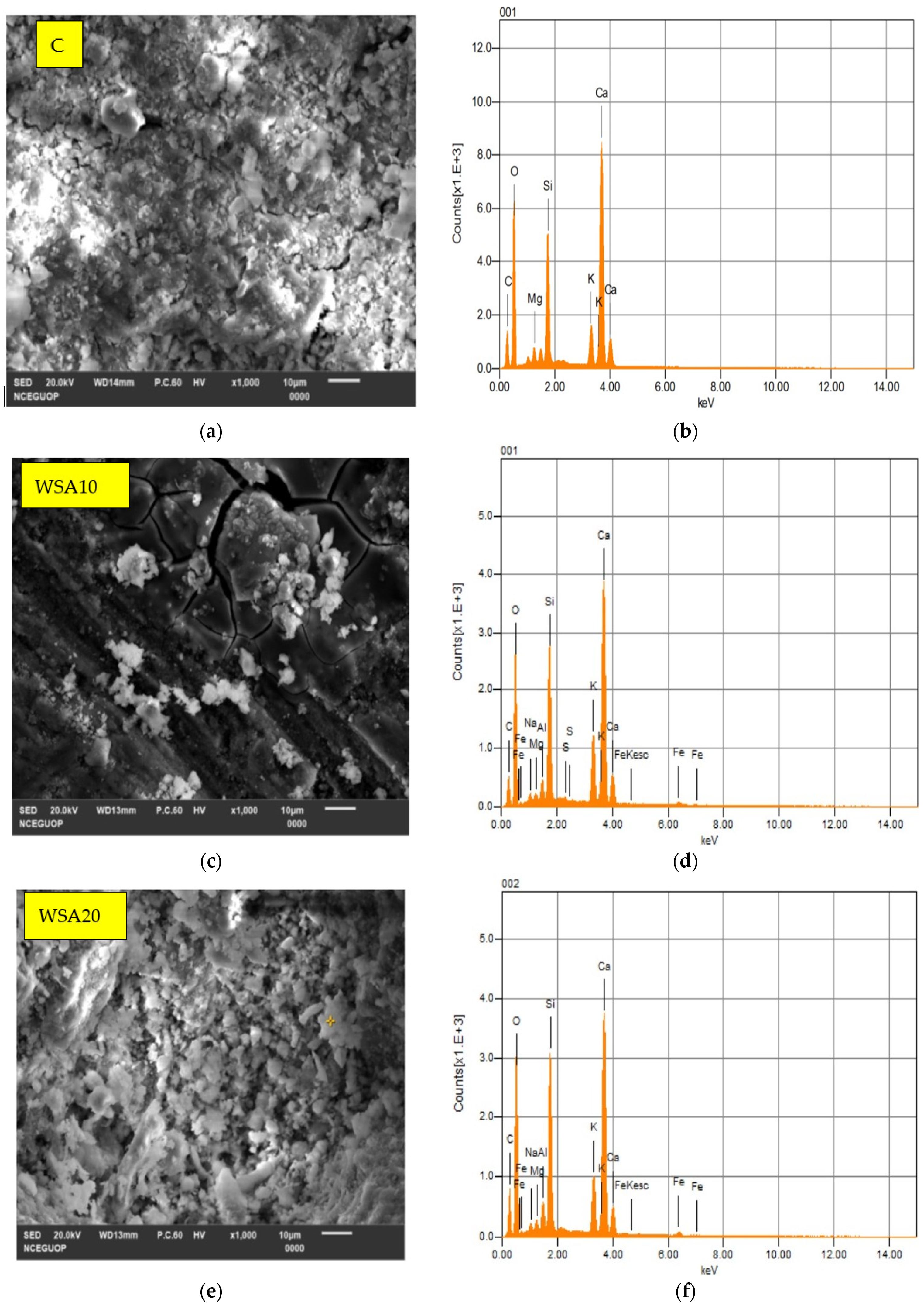

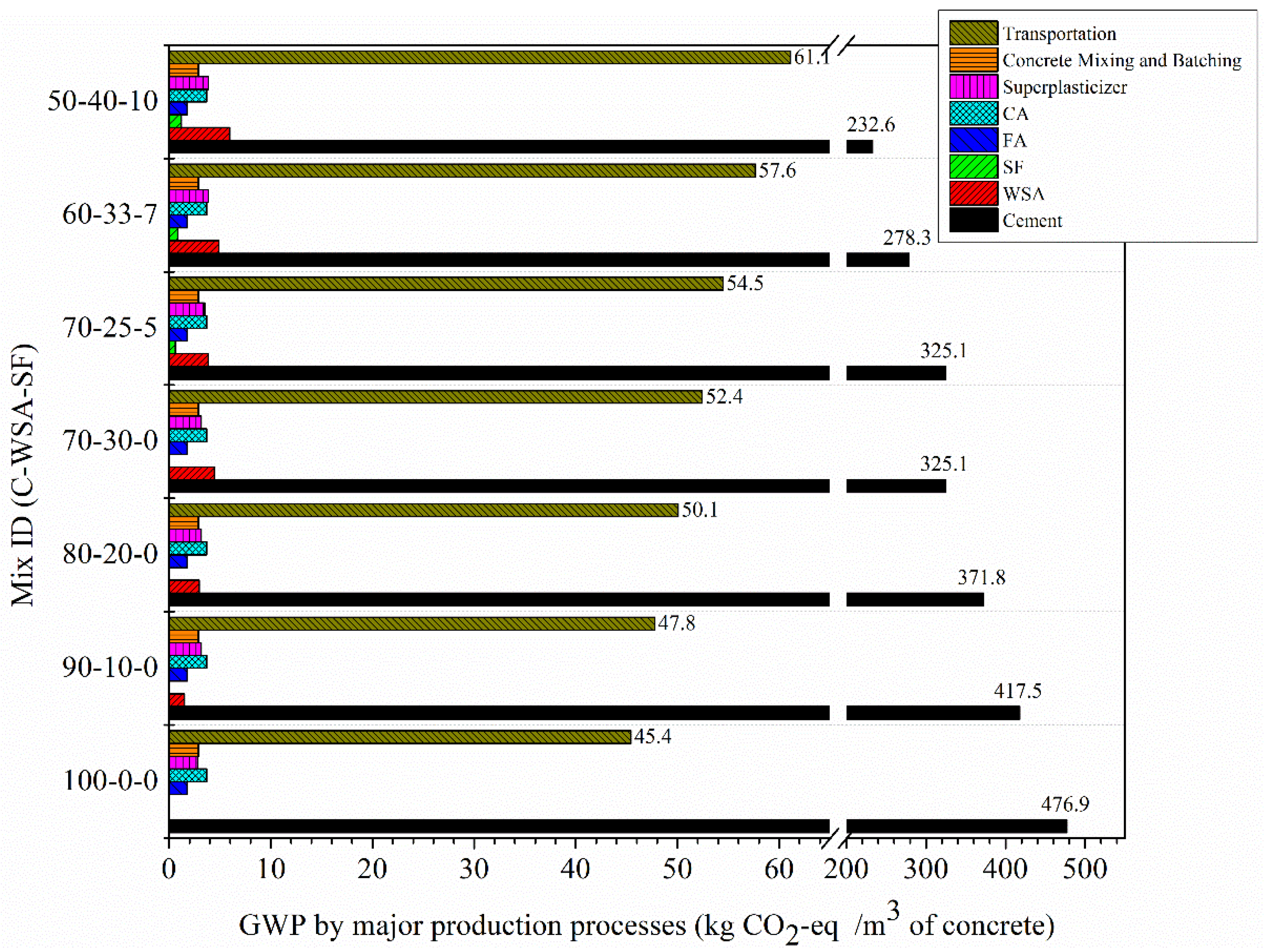

3.4. SEM–EDS Analysis of Control (C), Binary (C/WSA), and Ternary (C/WSA/SF) Cementitious Pastes

3.5. Fourier Transform Infrared (FTIR) Analysis of Cement Pastes

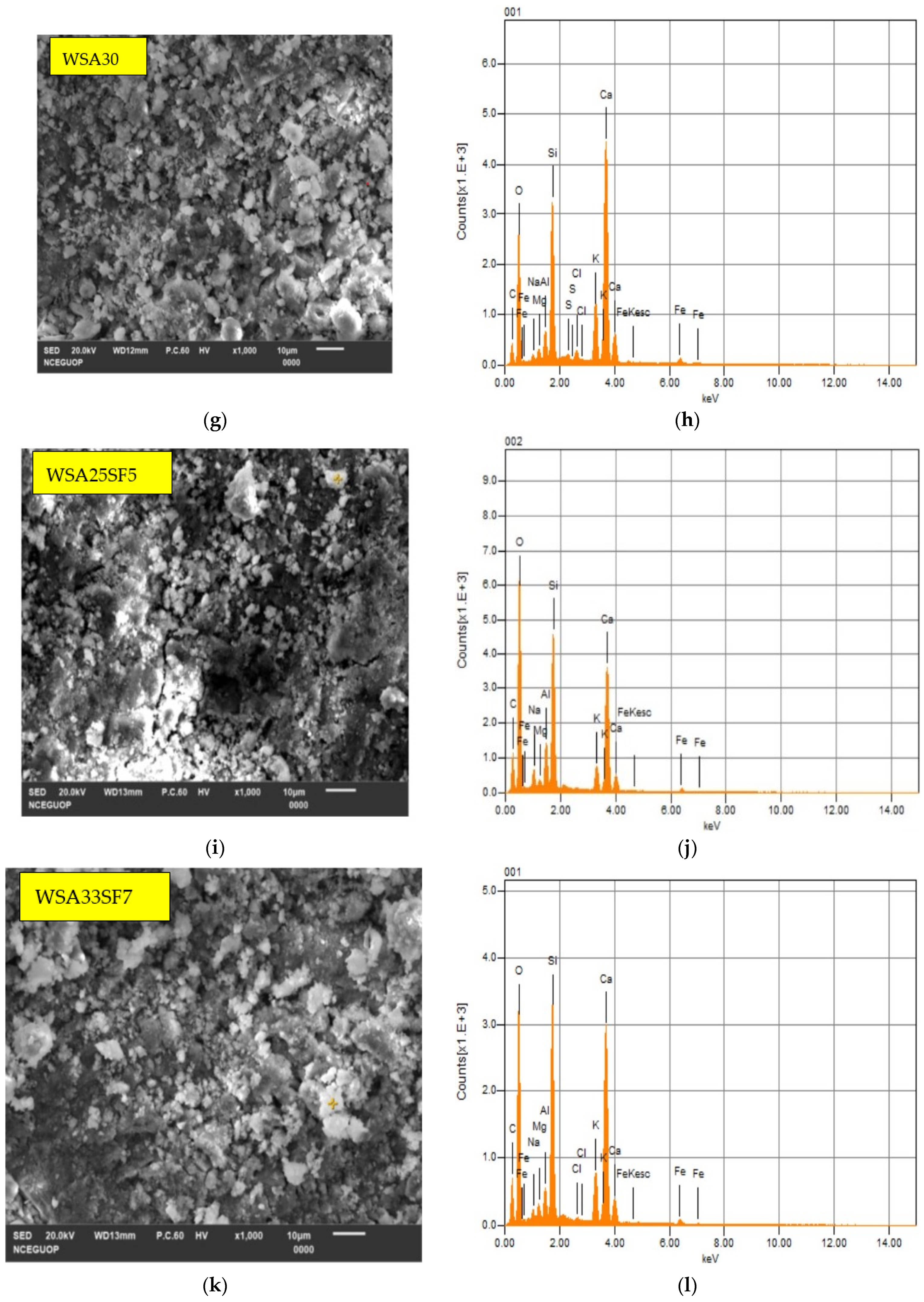

3.6. Nitrogen Adsorption Results (Surface Area and Pore Structure of Cement Pastes)

3.7. Thermogravimetric Analysis (TGA) of Cement Pastes

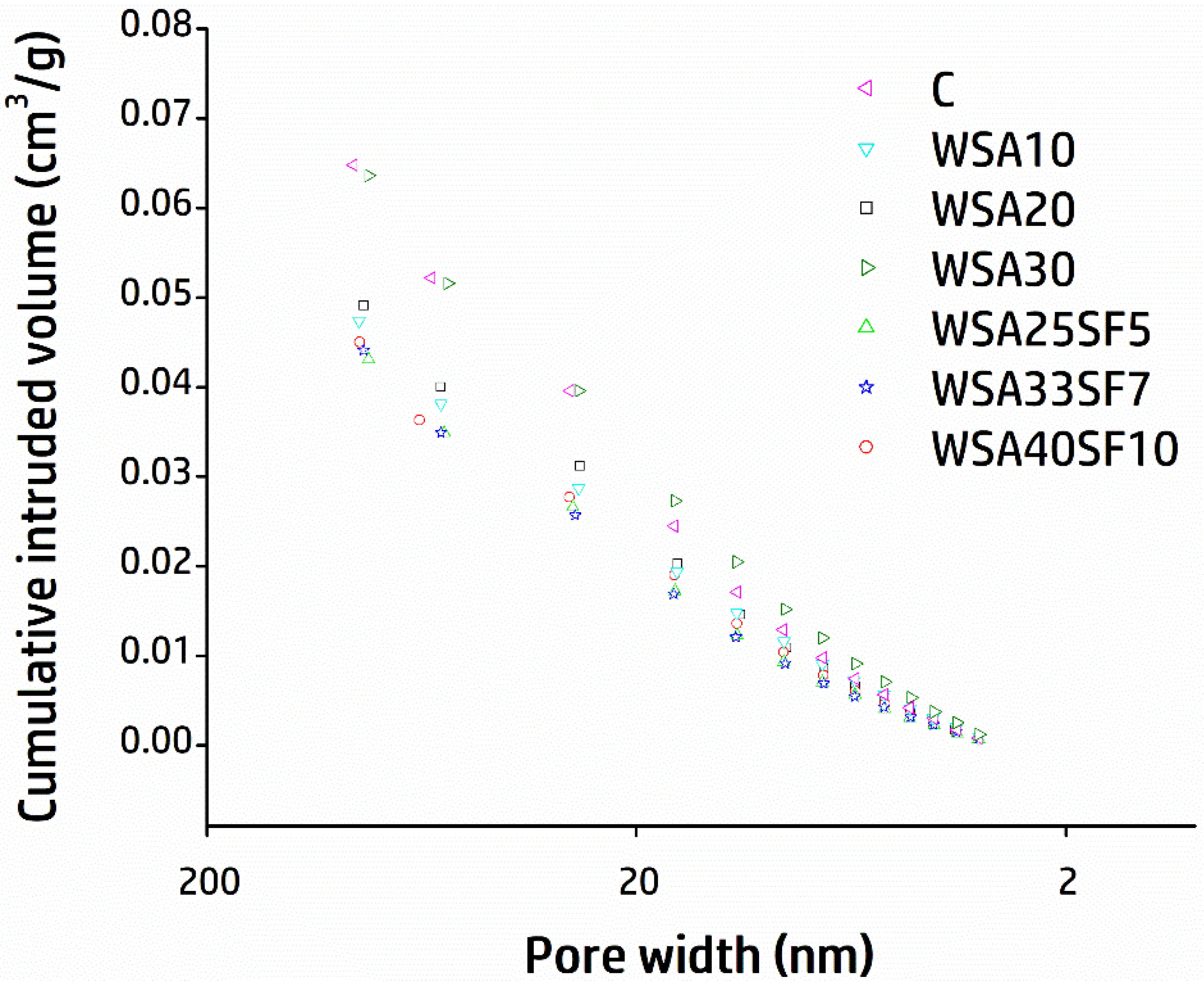

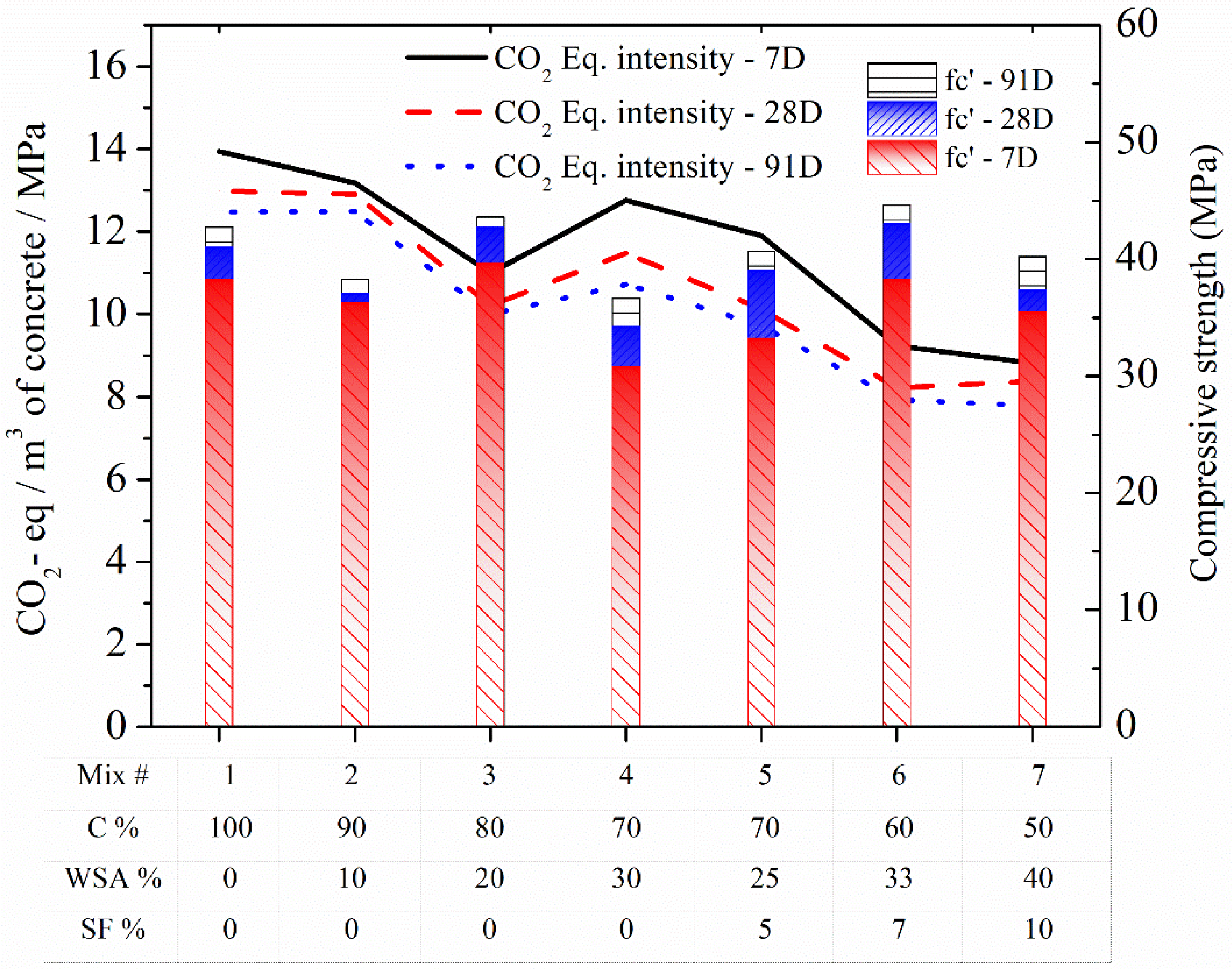

3.8. Global Warming Potential

3.8.1. Comparison of CO2-eq for Unit Concrete Production among Control, Binary, and Ternary Concrete Mixes

3.8.2. Comparison of Normalized CO2-eq for Unit Concrete Production per Unit Strength (MPa) among Control, Binary, and Ternary Concrete Mixes

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zareei, S.A.; Ameri, F.; Bahrami, N.; Shoaei, P.; Moosaei, H.R.; Salemi, N. Performance of sustainable high strength concrete with basic oxygen steel-making (BOS) slag and nano-silica. J. Build. Eng. 2019, 25, 100791. [Google Scholar] [CrossRef]

- Koushkbaghi, M.; Kazemi, M.J.; Mosavi, H.; Mohseni, E. Acid resistance and durability properties of steel fiber-reinforced concrete incorporating rice husk ash and recycled aggregate. Constr. Build. Mater. 2019, 202, 266–275. [Google Scholar] [CrossRef]

- Rashad, A.M. A preliminary study on the effect of fine aggregate replacement with metakaolin on strength and abrasion resistance of concrete. Constr. Build. Mater. 2013, 44, 487–495. [Google Scholar] [CrossRef]

- Luhar, S.; Cheng, T.-W.; Luhar, I. Incorporation of natural waste from agricultural and aquacultural farming as supplementary materials with green concrete: A review. Compos. Part B Eng. 2019, 175, 107076. [Google Scholar] [CrossRef]

- Khan, K.; Amin, M.N.; Saleem, M.U.; Qureshi, H.J.; AlFaiad, M.; Qadir, M.G. Effect of Fineness of Basaltic Volcanic Ash on Pozzolanic Reactivity, ASR Expansion and Drying Shrinkage of Blended Cement Mortars. Materials 2019, 12, 2603. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Celik, K.; Hay, R.; Hargis, C.W.; Moon, J. Effect of volcanic ash pozzolan or limestone replacement on hydration of Portland cement. Constr. Build. Mater. 2018, 197, 803–812. [Google Scholar] [CrossRef]

- Mohan, A.; Mini, K.M. Strength and durability studies of SCC incorporating silica fume and ultra fine GGBS. Constr. Build. Mater. 2018, 171, 919–928. [Google Scholar] [CrossRef]

- Jeong, Y.; Kang, S.-H.; Kim, M.O.; Moon, J. Acceleration of cement hydration from supplementary cementitious materials: Performance comparison between silica fume and hydrophobic silica. Cem. Concr. Compos. 2020, 112, 103688. [Google Scholar] [CrossRef]

- Booya, E.; Gorospe, K.; Das, S.; Loh, P. The influence of utilizing slag in lieu of fly ash on the performance of engineered cementitious composites. Constr. Build. Mater. 2020, 256, 119412. [Google Scholar] [CrossRef]

- Mahmud, S.; Manzur, T.; Samrose, S.; Torsha, T. Significance of properly proportioned fly ash based blended cement for sustainable concrete structures of tannery industry. Structures 2021, 29, 1898–1910. [Google Scholar] [CrossRef]

- Amin, M.N.; Khan, K.; Saleem, M.U.; Khurram, N.; Niazi, M.U.K. Influence of Mechanically Activated Electric Arc Furnace Slag on Compressive Strength of Mortars Incorporating Curing Moisture and Temperature Effects. Sustainability 2017, 9, 1178. [Google Scholar] [CrossRef] [Green Version]

- Yoon, H.; Seo, J.; Kim, S.; Lee, H.; Park, S. Hydration of calcium sulfoaluminate cement blended with blast-furnace slag. Constr. Build. Mater. 2020, 268, 121214. [Google Scholar] [CrossRef]

- Thakare, A.A.; Siddique, S.; Sarode, S.N.; Deewan, R.; Gupta, V.; Gupta, S.; Chaudhary, S. A study on rheological properties of rubber fiber dosed self-compacting mortar. Constr. Build. Mater. 2020, 262, 120745. [Google Scholar] [CrossRef]

- Tian, L.; Qiu, L.-C.; Liu, Y. Fabrication of integrally hydrophobic self-compacting rubberized mortar with excellent waterproof ability, corrosion resistance and stable mechanical properties. Constr. Build. Mater. 2021, 304, 124684. [Google Scholar] [CrossRef]

- Wang, D.; Wang, Q.; Huang, Z. Reuse of copper slag as a supplementary cementitious material: Reactivity and safety. Resour. Conserv. Recycl. 2020, 162, 105037. [Google Scholar] [CrossRef]

- Gopalakrishnan, R.; Nithiyanantham, S. Microstructural, mechanical, and electrical properties of copper slag admixtured cement mortar. J. Build. Eng. 2020, 31, 101375. [Google Scholar] [CrossRef]

- Zhang, P.; Liao, W.; Kumar, A.; Zhang, Q.; Ma, H. Characterization of sugarcane bagasse ash as a potential supplementary cementitious material: Comparison with coal combustion fly ash. J. Clean. Prod. 2020, 277, 123834. [Google Scholar] [CrossRef]

- Yadav, A.L.; Sairam, V.; Muruganandam, L.; Srinivasan, K. An overview of the influences of mechanical and chemical processing on sugarcane bagasse ash characterisation as a supplementary cementitious material. J. Clean. Prod. 2020, 245, 8854. [Google Scholar] [CrossRef]

- Rumman, R.; Bari, M.; Manzur, T.; Kamal, M.; Noor, M. A Durable Concrete Mix Design Approach using Combined Aggregate Gradation Bands and Rice Husk Ash Based Blended Cement. J. Build. Eng. 2020, 30, 101303. [Google Scholar] [CrossRef]

- Khan, K.; Ullah, M.F.; Shahzada, K.; Amin, M.N.; Bibi, T.; Wahab, N.; Aljaafari, A. Effective use of micro-silica extracted from rice husk ash for the production of high-performance and sustainable cement mortar. Constr. Build. Mater. 2020, 258, 119589. [Google Scholar] [CrossRef]

- Tamanna, K.; Raman, S.N.; Jamil, M.; Hamid, R. Utilization of wood waste ash in construction technology: A review. Constr. Build. Mater. 2019, 237, 117654. [Google Scholar] [CrossRef]

- Caldas, L.R.; Da Gloria, M.Y.R.; Pittau, F.; Andreola, V.M.; Habert, G.; Filho, R.D.T. Environmental impact assessment of wood bio-concretes: Evaluation of the influence of different supplementary cementitious materials. Constr. Build. Mater. 2020, 268, 121146. [Google Scholar] [CrossRef]

- Šupić, S.; Malešev, M.; Radonjanin, V.; Bulatović, V.; Milović, T. Reactivity and Pozzolanic Properties of Biomass Ashes Generated by Wheat and Soybean Straw Combustion. Materials 2021, 14, 1004. [Google Scholar] [CrossRef]

- Thomas, B.S.; Yang, J.; Mo, K.H.; Abdalla, J.A.; Hawileh, R.A.; Ariyachandra, E. Biomass ashes from agricultural wastes as supplementary cementitious materials or aggregate replacement in cement/geopolymer concrete: A comprehensive review. J. Build. Eng. 2021, 40, 102332. [Google Scholar] [CrossRef]

- Charitha, V.; Athira, V.; Jittin, V.; Bahurudeen, A.; Nanthagopalan, P. Use of different agro-waste ashes in concrete for effective upcycling of locally available resources. Constr. Build. Mater. 2021, 285, 122851. [Google Scholar] [CrossRef]

- Bheel, N.; Ali, M.O.A.; Kirgiz, M.S.; Galdino, A.G.D.S.; Kumar, A. Fresh and mechanical properties of concrete made of binary substitution of millet husk ash and wheat straw ash for cement and fine aggregate. J. Mater. Res. Technol. 2021, 13, 872–893. [Google Scholar] [CrossRef]

- Rattanachu, P.; Toolkasikorn, P.; Tangchirapat, W.; Chindaprasirt, P.; Jaturapitakkul, C. Performance of recycled aggregate concrete with rice husk ash as cement binder. Cem. Concr. Compos. 2020, 108, 103533. [Google Scholar] [CrossRef]

- Memon, S.; Javed, U.; Haris, M.; Khushnood, R.; Kim, J. Incorporation of Wheat Straw Ash as Partial Sand Replacement for Production of Eco-Friendly Concrete. Materials 2021, 14, 2078. [Google Scholar] [CrossRef] [PubMed]

- Amin, M.N.; Murtaza, T.; Shahzada, K.; Khan, K.; Adil, M. Pozzolanic Potential and Mechanical Performance of Wheat Straw Ash Incorporated Sustainable Concrete. Sustainability 2019, 11, 519. [Google Scholar] [CrossRef] [Green Version]

- Sadik, M.W.; El Shaer, H.M.; Yakot, H.M. Recycling of Agriculture and Animal Farm Wastes into Compost Using Compost Activator in Saudi Arabia. J. Environ. Sci. Int. 2010, 5, 397–403. [Google Scholar]

- Pan, X.; Sano, Y. Fractionation of wheat straw by atmospheric acetic acid process. Bioresour. Technol. 2005, 96, 1256–1263. [Google Scholar] [CrossRef]

- Ahmad, J.; Tufail, R.; Aslam, F.; Mosavi, A.; Alyousef, R.; Javed, M.F.; Zaid, O.; Niazi, M.K. A Step towards Sustainable Self-Compacting Concrete by Using Partial Substitution of Wheat Straw Ash and Bentonite Clay Instead of Cement. Sustainability 2021, 13, 824. [Google Scholar] [CrossRef]

- Biricik, H.; Aköz, F.; Berktay, I.; Tulgar, A.N. Study of pozzolanic properties of wheat straw ash. Cem. Concr. Res. 1999, 29, 637–643. [Google Scholar] [CrossRef]

- Memon, S.A.; Wahid, I.; Khan, M.K.; Tanoli, M.A.; Bimaganbetova, M. Environmentally Friendly Utilization of Wheat Straw Ash in Cement-Based Composites. Sustainability 2018, 10, 1322. [Google Scholar] [CrossRef] [Green Version]

- Al-Akhras, N.M.; Abu-Alfoul, B.A. Effect of wheat straw ash on mechanical properties of autoclaved mortar. Cem. Concr. Res. 2002, 32, 859–863. [Google Scholar] [CrossRef]

- Qudoos, A.; Kim, H.G.; Atta-Ur-Rehman, A.-U.; Ryou, J.-S. Effect of mechanical processing on the pozzolanic efficiency and the microstructure development of wheat straw ash blended cement composites. Constr. Build. Mater. 2018, 193, 481–490. [Google Scholar] [CrossRef]

- Al-Akhras, N.M. Durability of wheat straw ash concrete exposed to freeze–thaw damage. Proc. Inst. Civ. Eng.-Constr. Mater. 2011, 164, 79–86. [Google Scholar] [CrossRef]

- Khushnood, R.A.; Rizwan, S.A.; Memon, S.A.; Tulliani, J.-M.; Ferro, G.A. Experimental Investigation on Use of Wheat Straw Ash and Bentonite in Self-Compacting Cementitious System. Adv. Mater. Sci. Eng. 2014, 2014, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Bheel, N.; Ibrahim, M.H.W.; Adesina, A.; Kennedy, C.; Shar, I.A. Mechanical performance of concrete incorporating wheat straw ash as partial replacement of cement. J. Build. Pathol. Rehabil. 2020, 6, 1–7. [Google Scholar] [CrossRef]

- Mehta, A.; Kar, D.; Ashish, K. Silica fume and waste glass in cement concrete production: A review. J. Build. Eng. 2019, 15, 100888. [Google Scholar] [CrossRef]

- Sinyoung, S.; Kunchariyakun, K.; Asavapisit, S.; MacKenzie, K. Synthesis of belite cement from nano-silica extracted from two rice husk ashes. J. Environ. Manag. 2017, 190, 53–60. [Google Scholar] [CrossRef] [PubMed]

- Diamond, S.; Sahu, S.; Thaulow, N. Reaction products of densified silica fume agglomerates in concrete. Cem. Concr. Res. 2004, 34, 1625–1632. [Google Scholar] [CrossRef]

- Rodriguez, E.D.; Bernal, S.A.; Provis, J.L.; Payá, J.; Monzó, J.M.; Borrachero, M.V. Structure of Portland Cement Pastes Blended with Sonicated Silica Fume. J. Mater. Civ. Eng. 2012, 24, 1295–1304. [Google Scholar] [CrossRef]

- Holland, T.C. Federal Highway Administration Report FHWA-IF-05-016. In Silica Fume User’s Manual; Federal Highway Administration: Washington, DC, USA, 2005; p. 193. [Google Scholar]

- Murthi, P.; Poongodi, K.; Awoyera, P.O.; Gobinath, R.; Saravanan, R. Enhancing the Strength Properties of High-Performance Concrete Using Ternary Blended Cement: OPC, Nano-Silica, Bagasse Ash. Silicon 2019, 12, 1949–1956. [Google Scholar] [CrossRef]

- Sadrmomtazi, A.; Sobhani, J.; Mirgozar, M.A.; Najimi, M. Properties of multi-strength grade EPS concrete containing silica fume and rice husk ash. Constr. Build. Mater. 2012, 35, 211–219. [Google Scholar] [CrossRef]

- Xu, W.T.; Lo, T.Y.; Wang, W.L.; Ouyang, D.; Wang, P.G.; Xing, F. Pozzolanic Reactivity of Silica Fume and Ground Rice Husk Ash as Reactive Silica in a Cementitious System: A Comparative Study. Materials 2016, 9, 146. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jamil, M.; Khan, M.; Karim, M.; Kaish, A.B.M.A.; Zain, M. Physical and chemical contributions of Rice Husk Ash on the properties of mortar. Constr. Build. Mater. 2016, 128, 185–198. [Google Scholar] [CrossRef]

- Gursel, A.P. Life-Cycle Assessment of Concrete: Decision-Support Tool and Case Study Application, University of California, Berkeley. 2014. Available online: https://escholarship.org/uc/item/5q24d64s (accessed on 1 December 2021).

- Azam, A.; Rafiq, M.; Shafique, M.; Ateeq, M.; Yuan, J. Causality Relationship Between Electricity Supply and Economic Growth: Evidence from Pakistan. Energies 2020, 13, 837. [Google Scholar] [CrossRef] [Green Version]

- ACI 318-08: Building Code Requirements for Structural Concrete and Commentary; American Concrete Institute: Farmington Hills, MI, USA, 2008.

- ACI Committee 363. State of the Art Report on High-Strength Concrete; American Concrete Institute: Farmington Hills, MI, USA, 1992. [Google Scholar]

- Telford, T. CEB-FIP MODEL CODE 1990, DESIGN CODE; Comité Euro-International du Béton: Laussane, Switzerland, 1993. [Google Scholar]

- Zain, M.; Mahmud, H.; Ilham, A.; Faizal, M. Prediction of splitting tensile strength of high-performance concrete. Cem. Concr. Res. 2002, 32, 1251–1258. [Google Scholar] [CrossRef]

- Iravani, S. Mechanical properties of high-performance concrete. ACI Mater. J. 1996, 93, 416–426. [Google Scholar]

- Shah, S.P.; Ahmad, S.H. Structural Properties of High Strength Concrete and its Implications for Precast Prestressed Concrete. PCI J. 1985, 30, 92–119. [Google Scholar] [CrossRef]

- Kim, J.-K.; Han, S.H.; Song, Y.C. Effect of temperature and aging on the mechanical properties of concrete: Part I. Experimental results. Cem. Concr. Res. 2002, 32, 1087–1094. [Google Scholar] [CrossRef]

- Tomosawa, F.; Noguchi, T.; Tamura, M. The Way Concrete Recycling Should Be. J. Adv. Concr. Technol. 2005, 3, 3–16. [Google Scholar] [CrossRef] [Green Version]

- Design, L. Standard Specifications for Concrete Structures; Japan Society for Civil Engineers: Tokyo, Japan, 2013; pp. 34–35. (In Japanese) [Google Scholar]

- De Larrard, F.; Malier, Y. Engineering Properties of Very High Performance Concretes. Mater. Struct. 2018, 20, 85–114. [Google Scholar] [CrossRef]

- Gmira, A.; Pellenq, R.-M.; Rannou, I.; Duclaux, L.; Clinard, C.; Cacciaguerra, T.; Lequeux, N.; Van Damme, H. A Structural Study of Dehydration/Rehydration of Tobermorite, a Model Cement Compound. Stud. Surf. Sci. Catal. 2002, 144, 601–608. [Google Scholar] [CrossRef]

- Li, J.; Yu, Q.; Huang, H.; Yin, S. Effects of Ca/Si Ratio, Aluminum and Magnesium on the Carbonation Behavior of Calcium Silicate Hydrate. Materials 2019, 12, 1268. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kunther, W.; Lothenbach, B.; Skibsted, J. Influence of the Ca/Si ratio of the C–S–H phase on the interaction with sulfate ions and its impact on the ettringite crystallization pressure. Cem. Concr. Res. 2015, 69, 37–49. [Google Scholar] [CrossRef]

- Yu, P.; Kirkpatrick, R.J.; Poe, B.; McMillan, P.F.; Cong, X. Structure of Calcium Silicate Hydrate (C-S-H): Near-, Mid-, and Far-Infrared Spectroscopy. J. Am. Ceram. Soc. 2004, 82, 742–748. [Google Scholar] [CrossRef]

- Fernández-Carrasco, L.; Torrens-Martín, D.; Morales, L.; Martínez-Ramírez, L.M.A.S. Infrared Spectroscopy in the Analysis of Building and Construction Materials. Eng. Technol. 2012, 1, 369–382. [Google Scholar] [CrossRef] [Green Version]

- Hughes, T.L.; Methven, C.M.; Jones, T.G.; Pelham, S.E.; Fletcher, P.; Hall, C. Determining cement composition by Fourier transform infrared spectroscopy. Adv. Cem. Based Mater. 1995, 2, 91–104. [Google Scholar] [CrossRef]

- Kupwade-Patil, K.; Chin, S.H.; Johnston, M.L.; Maragh, J.; Masic, A.; Büyüköztürk, O. Particle Size Effect of Volcanic Ash towards Developing Engineered Portland Cements. J. Mater. Civ. Eng. 2018, 30, 04018190. [Google Scholar] [CrossRef]

- Bose, B.; Davis, C.R.; Erk, K.A. Microstructural refinement of cement paste internally cured by polyacrylamide composite hydrogel particles containing silica fume and nanosilica. Cem. Concr. Res. 2021, 143, 106400. [Google Scholar] [CrossRef]

- Bodor, E.; Skalny, J.; Brunauer, S.; Hagymassy, J.; Yudenfreund, M. Pore structures of hydrated calcium silicates and portland cements by nitrogen adsorption. J. Colloid Interface Sci. 1970, 34, 560–570. [Google Scholar] [CrossRef]

- Kupwade-Patil, K.; Al-Aibani, A.F.; Abdulsalam, M.F.; Mao, C.; Bumajdad, A.; Palkovic, S.D.; Büyüköztürk, O. Microstructure of cement paste with natural pozzolanic volcanic ash and Portland cement at different stages of curing. Constr. Build. Mater. 2016, 113, 423–441. [Google Scholar] [CrossRef] [Green Version]

- Helmi, M.; Hall, M.; Stevens, L.; Rigby, S. Effects of high-pressure/temperature curing on reactive powder concrete microstructure formation. Constr. Build. Mater. 2016, 105, 554–562. [Google Scholar] [CrossRef]

- Scrivener, K.; Snellings, R.; Lothenbach, B. A Practical Guide to Microstructural Analysis of Cementitious Materials; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Loser, R.; Münch, B.; Lura, P. A volumetric technique for measuring the coefficient of thermal expansion of hardening cement paste and mortar. Cem. Concr. Res. 2010, 40, 1138–1147. [Google Scholar] [CrossRef]

| OPC | WSA | SF | |

|---|---|---|---|

| Physical properties | |||

| Specific gravity (kg/m3) | 3.20 | 2.21 | 2.23 |

| Blain fineness (m2/g) | 0.344 | - | 21.5 |

| Chemical properties (oxides, % by weight) | |||

| SiO2 | 21.3 | 65.1 | 93.3 |

| Al2O3 | 5.56 | 9.10 | - |

| Fe2O3 | 3.24 | 2.67 | 0.58 |

| SiO2 + Al2O3 + Fe2O3 * | - | 76.87 | - |

| CaO | 63.4 | 5.90 | 1.82 |

| MgO | 0.93 | 1.11 | 0.28 |

| Na2O | 0.13 | 0.40 | 0.19 |

| K2O | 0.62 | 10.5 | 0.88 |

| SO3 | 2.25 | 1.13 | - |

| LOI ** | 2.41 | 4.03 | 2.25 |

| Mineral composition (%) *** | |||

| C2S C3S C3A C4AF | 47.9 24.7 8.76 9.86 | - - - - | - - - - |

| Sieve # | Sieve Size (mm) | Weight Retained (%) | Cumulative Passing (%) | Cumulative Retained (%) |

|---|---|---|---|---|

| Coarse aggregate (CA) | ||||

| 1 inch | 25 | 0 | 100 | 0 |

| 3/4 inch | 19 | 0 | 100 | 0 |

| 1/2 inch | 12.5 | 50.5 | 50 | 50 |

| 3/8 inch | 9.5 | 26.1 | 23 | 77 |

| No. 4 | 4.75 | 23.4 | 0 | 100 |

| Fine aggregate (FA) | ||||

| 3/8 inch | 9.5 | 0 | 100 | 0 |

| No. 4 | 4.75 | 0 | 100 | 0 |

| No. 8 | 2.36 | 4.54 | 95.46 | 4.54 |

| No. 16 | 1.18 | 16.1 | 79.33 | 20.67 |

| No. 30 | 0.600 | 30.9 | 48.40 | 51.60 |

| No. 50 | 0.300 | 26.4 | 22.02 | 77.98 |

| No. 100 | 0.150 | 21.3 | 0.67 | 99.33 |

| Pan | - | 0.67 | - | - |

| Fineness Modulus of FA (FM) = (0 + 4.54 + 20.67 + 51.6 + 77.98 + 99.33)/100 = 2.54 | ||||

| Mix ID (Total # of Specimens for Each = 18 and Cured for 7, 28, 91 Days) | W (kg/m3) | Binder, b (kg/m3) | Aggregates, a (kg/m3) | Superplasticizer (% of b) | Slump (mm) | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| C | WSA | SF | FA (S) | CA 10 mm | CA 20 mm | |||||

| Control concrete (CC) | 160 | 457 | - | - | 617 | 462 | 462 | 1 | 120 ± 30 | |

| Concrete containing 10% WSA (WSA10) | 411 | 46 | - | 1 | ||||||

| Concrete containing 20% WSA (WSA20) | 366 | 91 | - | 1 | ||||||

| Concrete containing 30% WSA (WSA30) | 320 | 137 | - | 1.1 | ||||||

| Concrete containing 25% WSA and 5% SF (WSA25SF5) | 320 | 114 | 23 | 1.2 | ||||||

| Concrete containing 33% WSA and 7% SF (WSA33SF7) | 274 | 151 | 32 | 1.3 | ||||||

| Concrete containing 40% WSA and 10% SF (WSA40SF10) | 229 | 182 | 46 | 1.4 | ||||||

| User Input Data: | Type of Material | |

|---|---|---|

| Ordinary Portland cement (OPC) | ASTM Type I | |

| SCMs | Silica fume (SF), Wheat straw ash (WSA) | |

| Admixture | Superplasticizer | |

| Electricity grid mix for: | Location | |

| Cement supplier | Cherat, Pak | |

| Fine aggregates supplier | Larunspur, Pak | |

| Coarse aggregates supplier | Taxila, Pak | |

| Gypsum supplier | Dera Ismael Khan, Pak | |

| SF supplier | Karachi, Pak | |

| Wheat straw ash collection | Punjab, Pak | |

| Transportation details for: | Mode | Distance (km) |

| Cement raw materials to cement plant | Truck Class 8b | 5 |

| Gypsum to cement plant | Truck Class 8b | 300 |

| Cement to concrete plant | Truck Class 8b | 200 |

| Fine aggregates to concrete plant | Truck Class 8b | 200 |

| Coarse aggregates to concrete plant | Truck Class 8b | 100 |

| Admixture to concrete plant | Truck Class 2 | 1000 |

| WSA to concrete plant | Truck Class 8b | 200 |

| SF to concrete plant | Truck Class 8b | 1200 |

| Technology options for: | Type of technology selected | |

| Cement raw materials prehomogenization | Dry, raw storing, preblending | |

| Cement raw materials grinding | Dry, raw grinding, tube mill | |

| Cement raw meal blending/homogenization | Dry, raw meal blending, storage | |

| Clinker pyroprocessing | Preheater/precalciner kiln with US average kiln fuel mix | |

| Clinker cooling | Reciprocating grate cooler (modern) | |

| Cement finish milling/grinding/blending | Tube mill | |

| Cement PM control technology | ESP | |

| Conveying within the cement plant | Screw pump | 20 m between process stations |

| Concrete batching plant loading/mixing | Mixer loading (central mix) | |

| Concrete batching plant PM control | Fabric filter | |

| User Input Data: | National Grid (%) |

|---|---|

| Coal | 12 |

| Natural gas | 29 |

| Fuel oil | 20 |

| Pet coke | - |

| Nuclear | 2.5 |

| Hydropower | 34 |

| Biomass | 0.5 |

| Geothermal | - |

| Solar | 1 |

| Wind | 1 |

| Mix ID | Ca/Si Atomic Ratio | |

|---|---|---|

| C-S-H Phase | C-H Phase | |

| CC | 1.93 | 3.3 |

| WSA10 | 1.63 | 3.1 |

| WSA20 | 1.42 | 2.65 |

| WSA30 | 1.6 | 2.94 |

| WSA25SF5 | 1.05 | 2.16 |

| WSA33SF7 | 0.91 | 2.1 |

| WSA40SF10 | 1.24 | 2.3 |

| Mix ID | C-H (%) | C-H/OPC (%) |

|---|---|---|

| CC | 18.5 | 18.5 |

| WSA10 | 13.87 | 15.4 |

| WSA20 | 11.28 | 14.1 |

| WSA30 | 8.85 | 12.6 |

| WSA25SF5 | 7.47 | 10.7 |

| WSA33SF7 | 7.26 | 12.1 |

| WSA40SF10 | 6.44 | 12.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, K.; Ishfaq, M.; Amin, M.N.; Shahzada, K.; Wahab, N.; Faraz, M.I. Evaluation of Mechanical and Microstructural Properties and Global Warming Potential of Green Concrete with Wheat Straw Ash and Silica Fume. Materials 2022, 15, 3177. https://doi.org/10.3390/ma15093177

Khan K, Ishfaq M, Amin MN, Shahzada K, Wahab N, Faraz MI. Evaluation of Mechanical and Microstructural Properties and Global Warming Potential of Green Concrete with Wheat Straw Ash and Silica Fume. Materials. 2022; 15(9):3177. https://doi.org/10.3390/ma15093177

Chicago/Turabian StyleKhan, Kaffayatullah, Muhammad Ishfaq, Muhammad Nasir Amin, Khan Shahzada, Nauman Wahab, and Muhammad Iftikhar Faraz. 2022. "Evaluation of Mechanical and Microstructural Properties and Global Warming Potential of Green Concrete with Wheat Straw Ash and Silica Fume" Materials 15, no. 9: 3177. https://doi.org/10.3390/ma15093177