Waste Material via Geopolymerization for Heavy-Duty Application: A Review

Abstract

:1. Introduction

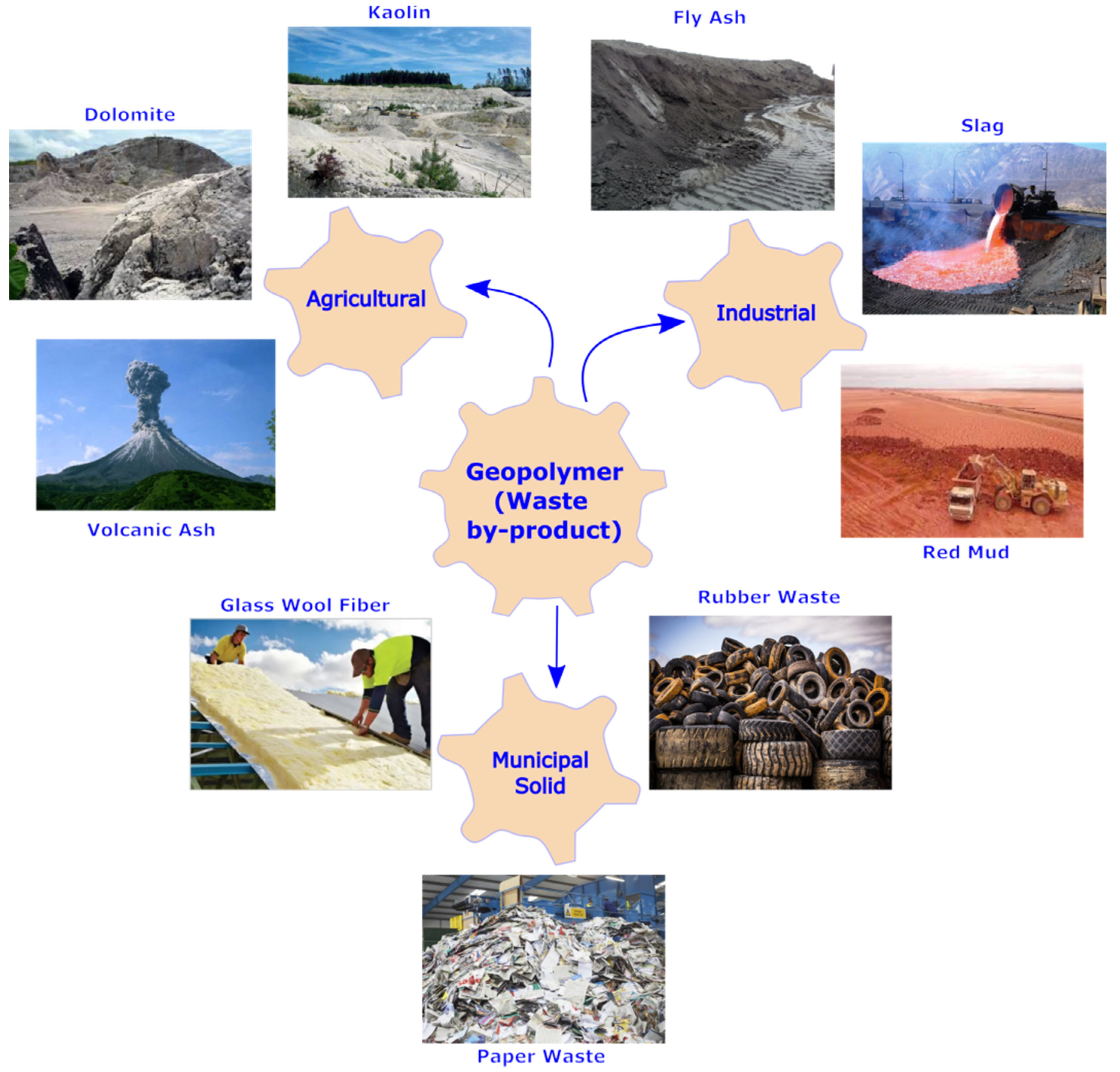

Type of Waste

2. Geopolymerization

3. Waste-By Products Based Geopolymer

| Type of Slag | Chemical Composition (wt %) | |||||||

|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | CaO | MgO | Fe2O3 | K2O | Na2O | SO3 | |

| Fly Ash [65] | 55.38 | 28.14 | 3.45 | 1.85 | 3.31 | 1.39 | 2.30 | 0.32 |

| Fly ash [66] | 56.00 | 18.10 | 7.24 | 0.93 | 5.31 | 1.36 | 1.21 | 1.65 |

| Fly ash [67] | 65.90 | 24.00 | 1.59 | 0.42 | 2.87 | 1.44 | 0.49 | N/A |

| Fly ash [68] | 47.90 | 25.70 | 4.11 | 1.36 | 14.70 | 0.67 | 0.81 | 0.19 |

| High Calcium Fly Ash [69] | 37.30 | 14.90 | 17.10 | 3.72 | 16.50 | 1.66 | 1.74 | 2.56 |

| High Calcium Fly Ash [70] | 34.00 | 13.50 | 16.50 | 3.10 | 5.00 | 5.50 | 1.50 | 2.80 |

| High Calcium Fly Ash [71] | 36.20 | 19.90 | 14.20 | 1.90 | 11.90 | 2.40 | N/A | 3.60 |

| Ground Granulated Blast Furnace Slag [72] | 35.34 | 20.69 | 31.32 | 8.11 | 0.18 | 0.29 | 1.36 | 1.79 |

| Ground Granulated Blast Furnace Slag [73] | 18.90 | 6.43 | 66.90 | 1.41 | 0.74 | 0.67 | N/A | 1.97 |

| Ground Granulated Blast Furnace Slag [74] | 28.20 | 9.73 | 52.69 | 2.90 | 0.98 | 1.22 | N/A | 1.46 |

| Ground Granulated Blast Furnace Slag [75] | 36.50 | 9.95 | 43.38 | 6.74 | 0.38 | 0.35 | N/A | N/A |

| Red Mud [76] | 14.40 | 22.20 | 2.00 | 0.17 | 40.20 | 0.11 | 12.70 | 0.28 |

| Red Mud [77] | 16.51 | 28.05 | 2.22 | 0.70 | 30.32 | 0.26 | 8.70 | N/A |

| Red Mud [78] | 27.54 | 30.59 | 25.48 | 0.49 | 4.60 | N/A | N/A | 1.42 |

| Rice Husk Ash [79] | 92.33 | 0.18 | 0.63 | 0.82 | 0.17 | 0.15 | 0.07 | N/A |

| Rice Husk Ash [80] | 93.10 | 0.30 | 1.50 | 0.49 | 0.20 | 2.30 | 0.06 | N/A |

| Silica Fume [79] | 87.60 | 0.38 | 0.57 | 3.67 | 0.66 | 2.36 | 1.26 | N/A |

| Silica Fume [81] | 90.00 | 1.20 | 1.00 | 0.60 | 2.00 | N/A | N/A | 0.50 |

| Volcanic Ash [82] | 43.32 | 14.84 | 8.80 | 7.70 | 14.19 | 1.52 | 3.04 | 0.01 |

| High Magnesium Nickel Slag [74] | 43.22 | 4.35 | 3.45 | 26.15 | 10.34 | 0.18 | 0.23 | 0.28 |

4. Heavy-Duty Applications of Geopolymers

4.1. Geopolymer in Military Application

4.2. Geopolymer in Civil-Engineering Application

4.3. Geopolymer in Road Application

5. Conclusions and Suggestions for Future Works

- Durability works using waste material in advanced application in the civil construction or aerospace fields;

- Establishing standards in order to conduct more advanced tests and research on these waste materials and, as a a result, expand the application as heavy-duty material in civil construction or the aerospace industry;

- Besides construction and airbase application, the geopolymer material can also be implemented as a defence material that consists of lightweight and higher mechanical properties such as bulletproof, Kevlar helmet, and body armour;

- The study on the landfill and waste management cost is crucial in considering the impact of the 3R implementation;

- An alternative activator to hydroxides and silicates that leads to lower environmental impact and can cut the cost of geopolymer production;

- For better understanding and experimental application, standardize dosage and quantify ingredients utilized in the manufacturing of activated alkali component.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tripathi, A.D.; Mishra, R.; Maurya, K.K.; Singh, R.B.; Wilson, D.W. Estimates for world population and global food availability for global health. In The Role of Functional Food Security in Global Health; Elsevier: Amsterdam, The Netherlands, 2019; pp. 3–24. [Google Scholar]

- Devadoss, P.M.; Agamuthu, P.; Mehran, S.; Santha, C.; Fauziah, S. Implications of municipal solid waste management on greenhouse gas emissions in Malaysia and the way forward. Waste Manag. 2021, 119, 135–144. [Google Scholar] [CrossRef] [PubMed]

- Pariatamby, A.; Fauziah, S. Sustainable 3R practice in the Asia and Pacific Regions: The challenges and issues. In Municipal Solid Waste Management in Asia and the Pacific Islands; Springer: Berlin/Heidelberg, Germany, 2014; pp. 15–40. [Google Scholar]

- Inanc, B.; Idris, A.; Terazono, A.; Sakai, S.I. Development of a database of landfills and dump sites in Asian countries. J. Mater. Cycles Waste Manag. 2004, 6, 97–103. [Google Scholar] [CrossRef]

- Ngoc, U.N.; Schnitzer, H. Sustainable solutions for solid waste management in Southeast Asian countries. Waste Manag. 2009, 29, 1982–1995. [Google Scholar] [CrossRef] [PubMed]

- Agamuthu, P. Landfilling in Developing Countries; Sage Publications Sage UK: London, UK, 2013; Volume 31, pp. 1–2. [Google Scholar]

- Palod, R.; Deo, S.; Ramtekkar, G. Utilization of waste from steel and iron industry as replacement of cement in mortars. J. Mater. Cycles Waste Manag. 2019, 21, 1361–1375. [Google Scholar] [CrossRef]

- Zanelli, C.; Conte, S.; Molinari, C.; Soldati, R.; Dondi, M. Waste recycling in ceramic tiles: A technological outlook. Resour. Conserv. Recycl. 2021, 168, 105289. [Google Scholar] [CrossRef]

- Leiva, C.; Luna-Galiano, Y.; Arenas, C.; Alonso-Fariñas, B.; Fernández-Pereira, C. A porous geopolymer based on aluminum-waste with acoustic properties. Waste Manag. 2019, 95, 504–512. [Google Scholar] [CrossRef]

- Simão, F.V.; Chambart, H.; Vandemeulebroeke, L.; Cappuyns, V. Incorporation of sulphidic mining waste material in ceramic roof tiles and blocks. J. Geochem. Explor. 2021, 225, 106741. [Google Scholar] [CrossRef]

- Priyadarshini, M.; Giri, J.P.; Patnaik, M. Variability in the compressive strength of non-conventional bricks containing agro and industrial waste. Case Stud. Constr. Mater. 2021, 14, e00506. [Google Scholar] [CrossRef]

- Ali, M.; Alabdulkarem, A.; Nuhait, A.; Al-Salem, K.; Iannace, G.; Almuzaiqer, R. Characteristics of agro waste fibers as new thermal insulation and sound absorbing materials: Hybrid of date palm tree leaves and wheat straw fibers. J. Nat. Fibers 2021, 2, 1–19. [Google Scholar] [CrossRef]

- Kazmi, S.M.S.; Munir, M.J.; Patnaikuni, I.; Wu, Y.-F.; Fawad, U. Thermal performance enhancement of eco-friendly bricks incorporating agro-wastes. Energy Build. 2018, 158, 1117–1129. [Google Scholar] [CrossRef]

- Ahmadi, P.F.; Ardeshir, A.; Ramezanianpour, A.M.; Bayat, H. Characteristics of heat insulating clay bricks made from zeolite, waste steel slag and expanded perlite. Ceram. Int. 2018, 44, 7588–7598. [Google Scholar] [CrossRef]

- Lima, M.S.; Thives, L.P. Evaluation of red mud as filler in Brazilian dense graded asphalt mixtures. Constr. Build. Mater. 2020, 260, 119894. [Google Scholar] [CrossRef]

- Ter Teo, P.; Anasyida, A.S.; Kho, C.M.; Nurulakmal, M.S. Recycling of Malaysia’s EAF steel slag waste as novel fluxing agent in green ceramic tile production: Sintering mechanism and leaching assessment. J. Clean. Prod. 2019, 241, 118144. [Google Scholar] [CrossRef]

- Hansen, S.; Sadeghian, P. Recycled gypsum powder from waste drywalls combined with fly ash for partial cement replacement in concrete. J. Clean. Prod. 2020, 274, 122785. [Google Scholar] [CrossRef]

- Hamid, N.J.A.; Kadir, A.A.; Hashar, N.N.H.; Pietrusiewicz, P.; Nabiałek, M.; Wnuk, I.; Gucwa, M.; Palutkiewicz, P.; Hashim, A.A.; Sarani, N.A. Influence of Gypsum Waste Utilization on Properties and Leachability of Fired Clay Brick. Materials 2021, 14, 2800. [Google Scholar] [CrossRef] [PubMed]

- Podolsky, Z.; Liu, J.; Dinh, H.; Doh, J.; Guerrieri, M.; Fragomeni, S. State of the art on the application of waste materials in geopolymer concrete. Case Stud. Constr. Mater. 2021, 15, e00637. [Google Scholar] [CrossRef]

- Sharma, R.; Bhardwaj, A. Effect of construction demolition and glass waste on stabilization of clayey soil. In Proceedings of the International Conference on sustainable Waste Management Through Design, Ludhiana, India, 2–3 November 2018; pp. 87–94. [Google Scholar]

- de Azevedo, A.R.; Costa, A.M.; Cecchin, D.; Pereira, C.R.; Marvila, M.T.; Adesina, A. Economic potential comparative of reusing different industrial solid wastes in cementitious composites: A case study in Brazil. Environ. Dev. Sustain. 2022, 24, 5938–5961. [Google Scholar] [CrossRef]

- Balwada, J.; Samaiya, S.; Mishra, R.P. Packaging plastic waste management for a circular economy and identifying a better waste collection system using analytical hierarchy process (ahp). Procedia CIRP 2021, 98, 270–275. [Google Scholar] [CrossRef]

- Agenda, I. The New Plastics Economy Rethinking the Future of Plastics; The World Economic Forum: Geneva, Switzerland, 2016; p. 36. [Google Scholar]

- Job, S.; Leeke, G.; Mativenga, P.; Oliveux, G.; Pickering, S.; Shuaib, N. Composites Recycling—Where Are We Now? 2016. Available online: https://compositesuk.co.uk./system/files/documents/Recycling.pdf (accessed on 26 April 2022).

- Saxena, D.; Maiti, P. Utilization of ABS from plastic waste through single-step reactive extrusion of LDPE/ABS blends of improved properties. Polymer 2021, 221, 123626. [Google Scholar] [CrossRef]

- Oladele, I.O.; Omotosho, T.F.; Adediran, A.A. Polymer-based composites: An indispensable material for present and future applications. Int. J. Polym. Sci. 2020, 2020, 8834518. [Google Scholar] [CrossRef]

- Aydın, S.; Baradan, B. Mechanical and microstructural properties of heat cured alkali-activated slag mortars. Mater. Des. 2012, 35, 374–383. [Google Scholar] [CrossRef]

- Giasuddin, H.M.; Sanjayan, J.G.; Ranjith, P. Strength of geopolymer cured in saline water in ambient conditions. Fuel 2013, 107, 34–39. [Google Scholar] [CrossRef]

- Ranjbar, N.; Mehrali, M.; Behnia, A.; Alengaram, U.J.; Jumaat, M.Z. Compressive strength and microstructural analysis of fly ash/palm oil fuel ash based geopolymer mortar. Mater. Des. 2014, 59, 532–539. [Google Scholar] [CrossRef]

- Jamil, N.H.; Abdullah, M.; Al Bakri, M.; Che Pa, F.; Hasmaliza, M.; W Ibrahim, W.M.A.; A Aziz, I.H.; Jeż, B.; Nabiałek, M. Phase Transformation of Kaolin-Ground Granulated Blast Furnace Slag from Geopolymerization to Sintering Process. Magnetochemistry 2021, 7, 32. [Google Scholar] [CrossRef]

- He, J.; Jie, Y.; Zhang, J.; Yu, Y.; Zhang, G. Synthesis and characterization of red mud and rice husk ash-based geopolymer composites. Cem. Concr. Compos. 2013, 37, 108–118. [Google Scholar] [CrossRef]

- McLellan, B.C.; Williams, R.P.; Lay, J.; Van Riessen, A.; Corder, G.D. Costs and carbon emissions for geopolymer pastes in comparison to ordinary portland cement. J. Clean. Prod. 2011, 19, 1080–1090. [Google Scholar] [CrossRef] [Green Version]

- Turner, L.K.; Collins, F.G. Carbon dioxide equivalent (CO2-e) emissions: A comparison between geopolymer and OPC cement concrete. Constr. Build. Mater. 2013, 43, 125–130. [Google Scholar] [CrossRef]

- Al Bakri, A.; Abdulkareem, O.A.; Rafiza, A.; Zarina, Y.; Norazian, M.; Kamarudin, H. Review on Processing of low calcium fly ash geopolymer concrete. Aust. J. Basic Appl. Sci. 2013, 7, 342–349. [Google Scholar]

- Duan, P.; Yan, C.; Zhou, W. Influence of partial replacement of fly ash by metakaolin on mechanical properties and microstructure of fly ash geopolymer paste exposed to sulfate attack. Ceram. Int. 2016, 42, 3504–3517. [Google Scholar] [CrossRef]

- Joseph, B.; Mathew, G. Influence of aggregate content on the behavior of fly ash based geopolymer concrete. Sci. Iran. 2012, 19, 1188–1194. [Google Scholar] [CrossRef] [Green Version]

- Vakili, M.; Rafatullah, M.; Ibrahim, M.H.; Salamatinia, B.; Gholami, Z.; Zwain, H.M. A review on composting of oil palm biomass. Environ. Dev. Sustain. 2015, 17, 691–709. [Google Scholar] [CrossRef]

- Sinulingga, K.; Agusnar, H.; Basuki Wirjosentono, Z.M. The effect of mixing rice husk ash and palm oil boiler ash on concrete strength. Am. J. Phys. Chem. 2014, 3, 9–14. [Google Scholar]

- Kamseu, E.; à Moungam, L.B.; Cannio, M.; Billong, N.; Chaysuwan, D.; Melo, U.C.; Leonelli, C. Substitution of sodium silicate with rice husk ash-NaOH solution in metakaolin based geopolymer cement concerning reduction in global warming. J. Clean. Prod. 2017, 142, 3050–3060. [Google Scholar] [CrossRef]

- Ye, N.; Chen, Y.; Yang, J.; Liang, S.; Hu, Y.; Xiao, B.; Huang, Q.; Shi, Y.; Hu, J.; Wu, X. Co-disposal of MSWI fly ash and Bayer red mud using an one-part geopolymeric system. J. Hazard. Mater. 2016, 318, 70–78. [Google Scholar] [CrossRef] [PubMed]

- Liew, Y.-M.; Heah, C.-Y.; Kamarudin, H. Structure and properties of clay-based geopolymer cements: A review. Prog. Mater. Sci. 2016, 83, 595–629. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhu, H.; Zhou, C.; Wang, H. Geopolymer from kaolin in China: An overview. Appl. Clay Sci. 2016, 119, 31–41. [Google Scholar] [CrossRef]

- Azimi, E.A.; Abdullah, M.M.A.B.; Vizureanu, P.; Salleh, M.A.A.M.; Sandu, A.V.; Chaiprapa, J.; Yoriya, S.; Hussin, K.; Aziz, I.H. Strength development and elemental distribution of dolomite/fly ash geopolymer composite under elevated temperature. Materials 2020, 13, 1015. [Google Scholar] [CrossRef] [Green Version]

- Davidovits, J. Geopolymer cement. A Review. Geopolymer Inst. Tech. Pap. 2013, 21, 1–11. [Google Scholar]

- Shobeiri, V.; Bennett, B.; Xie, T.; Visintin, P. A comprehensive assessment of the global warming potential of geopolymer concrete. J. Clean. Prod. 2021, 297, 126669. [Google Scholar] [CrossRef]

- Gunasekara, C.; Law, D.; Bhuiyan, S.; Setunge, S.; Ward, L. Chloride induced corrosion in different fly ash based geopolymer concretes. Constr. Build. Mater. 2019, 200, 502–513. [Google Scholar] [CrossRef]

- Luhar, S.; Chaudhary, S.; Luhar, I. Thermal resistance of fly ash based rubberized geopolymer concrete. J. Build. Eng. 2018, 19, 420–428. [Google Scholar] [CrossRef]

- Aziz, I.H.; Abdullah, M.M.A.B.; Salleh, M.M.; Yoriya, S.; Chaiprapa, J.; Rojviriya, C.; Li, L.Y. Microstructure and porosity evolution of alkali activated slag at various heating temperatures. J. Mater. Res. Technol. 2020, 9, 15894–15907. [Google Scholar] [CrossRef]

- Yuan, Y.; Zhao, R.; Li, R.; Wang, Y.; Cheng, Z.; Li, F.; Ma, Z.J. Frost resistance of fiber-reinforced blended slag and Class F fly ash-based geopolymer concrete under the coupling effect of freeze-thaw cycling and axial compressive loading. Constr. Build. Mater. 2020, 250, 118831. [Google Scholar] [CrossRef]

- Li, N.; Farzadnia, N.; Shi, C. Microstructural changes in alkali-activated slag mortars induced by accelerated carbonation. Cem. Concr. Res. 2017, 100, 214–226. [Google Scholar] [CrossRef]

- Ibrahim, M.; Johari, M.A.M.; Rahman, M.K.; Maslehuddin, M.; Mohamed, H.D. Enhancing the engineering properties and microstructure of room temperature cured alkali activated natural pozzolan based concrete utilizing nanosilica. Constr. Build. Mater. 2018, 189, 352–365. [Google Scholar] [CrossRef]

- Guo, X.; Shi, H.; Wei, X. Pore properties, inner chemical environment, and microstructure of nano-modified CFA-WBP (class C fly ash-waste brick powder) based geopolymers. Cem. Concr. Compos. 2017, 79, 53–61. [Google Scholar] [CrossRef]

- Temuujin, J.; Surenjav, E.; Ruescher, C.H.; Vahlbruch, J. Processing and uses of fly ash addressing radioactivity (critical review). Chemosphere 2019, 216, 866–882. [Google Scholar] [CrossRef]

- Rashad, A.M. A brief on high-volume Class F fly ash as cement replacement—A guide for Civil Engineer. Int. J. Sustain. Built Environ. 2015, 4, 278–306. [Google Scholar] [CrossRef] [Green Version]

- Wongsa, A.; Kunthawatwong, R.; Naenudon, S.; Sata, V.; Chindaprasirt, P. Natural fiber reinforced high calcium fly ash geopolymer mortar. Constr. Build. Mater. 2020, 241, 118143. [Google Scholar] [CrossRef]

- Gupta, R.; Bhardwaj, P.; Mishra, D.; Prasad, M.; Amritphale, S. Formulation of mechanochemically evolved fly ash based hybrid inorganic–organic geopolymers with multilevel characterization. J. Inorg. Organomet. Polym. Mater. 2017, 27, 385–398. [Google Scholar] [CrossRef]

- Aziz, I.H.; Abdullah, M.M.A.B.; Heah, C.-Y.; Liew, Y.-M. Behaviour changes of ground granulated blast furnace slag geopolymers at high temperature. Adv. Cem. Res. 2020, 32, 465–475. [Google Scholar] [CrossRef]

- Salvador, R.P.; Rambo, D.A.; Bueno, R.M.; Silva, K.T.; de Figueiredo, A.D. On the use of blast-furnace slag in sprayed concrete applications. Constr. Build. Mater. 2019, 218, 543–555. [Google Scholar] [CrossRef]

- Amran, Y.M.; Alyousef, R.; Alabduljabbar, H.; El-Zeadani, M. Clean production and properties of geopolymer concrete; A review. J. Clean. Prod. 2020, 251, 119679. [Google Scholar] [CrossRef]

- Aziz, I.H.; Abdullah, M.M.A.B.; Salleh, M.A.A.M.; Ming, L.Y.; Li, L.Y.; Sandu, A.V.; Vizureanu, P.; Nemes, O.; Mahdi, S.N. Recent Developments in Steelmaking Industry and Potential Alkali Activated Based Steel Waste: A Comprehensive Review. Materials 2022, 15, 1948. [Google Scholar] [CrossRef]

- Nie, Q.; Hu, W.; Huang, B.; Shu, X.; He, Q. Synergistic utilization of red mud for flue-gas desulfurization and fly ash-based geopolymer preparation. J. Hazard. Mater. 2019, 369, 503–511. [Google Scholar] [CrossRef]

- Yang, Z.; Mocadlo, R.; Zhao, M.; Sisson, R.D., Jr.; Tao, M.; Liang, J. Preparation of a geopolymer from red mud slurry and class F fly ash and its behavior at elevated temperatures. Constr. Build. Mater. 2019, 221, 308–317. [Google Scholar] [CrossRef]

- Yeddula, B.S.R.; Karthiyaini, S. Experimental investigations and GEP modelling of compressive strength of ferrosialate based geopolymer mortars. Constr. Build. Mater. 2020, 236, 117602. [Google Scholar] [CrossRef]

- Liu, Y.; Qin, Z.; Chen, B. Experimental research on magnesium phosphate cements modified by red mud. Constr. Build. Mater. 2020, 231, 117131. [Google Scholar] [CrossRef]

- Gholampour, A.; Ozbakkaloglu, T.; Ng, C.-T. Ambient-and oven-cured geopolymer concretes under active confinement. Constr. Build. Mater. 2019, 228, 116722. [Google Scholar] [CrossRef]

- Guo, X.; Yang, J. Intrinsic properties and micro-crack characteristics of ultra-high toughness fly ash/steel slag based geopolymer. Constr. Build. Mater. 2020, 230, 116965. [Google Scholar] [CrossRef]

- Hu, Y.; Tang, Z.; Li, W.; Li, Y.; Tam, V.W. Physical-mechanical properties of fly ash/GGBFS geopolymer composites with recycled aggregates. Constr. Build. Mater. 2019, 226, 139–151. [Google Scholar] [CrossRef]

- Khan, I.; Xu, T.; Castel, A.; Gilbert, R.I.; Babaee, M. Risk of early age cracking in geopolymer concrete due to restrained shrinkage. Constr. Build. Mater. 2019, 229, 116840. [Google Scholar] [CrossRef]

- Mohammed, B.S.; Haruna, S.; Wahab, M.; Liew, M.; Haruna, A. Mechanical and microstructural properties of high calcium fly ash one-part geopolymer cement made with granular activator. Heliyon 2019, 5, e02255. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- De Rossi, A.; Ribeiro, M.; Labrincha, J.; Novais, R.; Hotza, D.; Moreira, R. Effect of the particle size range of construction and demolition waste on the fresh and hardened-state properties of fly ash-based geopolymer mortars with total replacement of sand. Process Saf. Environ. Prot. 2019, 129, 130–137. [Google Scholar] [CrossRef]

- Nuaklong, P.; Wongsa, A.; Sata, V.; Boonserm, K.; Sanjayan, J.; Chindaprasirt, P. Properties of high-calcium and low-calcium fly ash combination geopolymer mortar containing recycled aggregate. Heliyon 2019, 5, e02513. [Google Scholar] [CrossRef] [Green Version]

- Yu, J.; Chen, Y.; Chen, G.; Wang, L. Experimental study of the feasibility of using anhydrous sodium metasilicate as a geopolymer activator for soil stabilization. Eng. Geol. 2020, 264, 105316. [Google Scholar] [CrossRef]

- Alrefaei, Y.; Wang, Y.-S.; Dai, J.-G. The effectiveness of different superplasticizers in ambient cured one-part alkali activated pastes. Cem. Concr. Compos. 2019, 97, 166–174. [Google Scholar] [CrossRef]

- Bouaissi, A.; Li, L.-y.; Abdullah, M.M.A.B.; Bui, Q.-B. Mechanical properties and microstructure analysis of FA-GGBS-HMNS based geopolymer concrete. Constr. Build. Mater. 2019, 210, 198–209. [Google Scholar] [CrossRef]

- Alonso, M.; Gascó, C.; Morales, M.M.; Suárez-Navarro, J.; Zamorano, M.; Puertas, F. Olive biomass ash as an alternative activator in geopolymer formation: A study of strength, radiology and leaching behaviour. Cem. Concr. Compos. 2019, 104, 103384. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, J.; Li, S.; Gao, Y.; Liu, C.; Qi, Y. Effect of different gypsums on the workability and mechanical properties of red mud-slag based grouting materials. J. Clean. Prod. 2020, 245, 118759. [Google Scholar] [CrossRef]

- Yang, T.; Wang, Y.; Sheng, L.; He, C.; Sun, W.; He, Q. Enhancing Cd (II) sorption by red mud with heat treatment: Performance and mechanisms of sorption. J. Environ. Manag. 2020, 255, 109866. [Google Scholar] [CrossRef] [PubMed]

- Shi, W.; Ren, H.; Huang, X.; Li, M.; Tang, Y.; Guo, F. Low cost red mud modified graphitic carbon nitride for the removal of organic pollutants in wastewater by the synergistic effect of adsorption and photocatalysis. Sep. Purif. Technol. 2020, 237, 116477. [Google Scholar] [CrossRef]

- Villaquirán-Caicedo, M.A. Studying different silica sources for preparation of alternative waterglass used in preparation of binary geopolymer binders from metakaolin/boiler slag. Constr. Build. Mater. 2019, 227, 116621. [Google Scholar] [CrossRef]

- Liang, G.; Zhu, H.; Zhang, Z.; Wu, Q.; Du, J. Investigation of the waterproof property of alkali-activated metakaolin geopolymer added with rice husk ash. J. Clean. Prod. 2019, 230, 603–612. [Google Scholar] [CrossRef]

- Cheah, C.B.; Tan, L.E.; Ramli, M. The engineering properties and microstructure of sodium carbonate activated fly ash/slag blended mortars with silica fume. Compos. Part B Eng. 2019, 160, 558–572. [Google Scholar] [CrossRef]

- Baenla, J.; Mbah, J.B.; Ndjock, I.D.L.; Elimbi, A. Partial replacement of low reactive volcanic ash by cassava peel ash in the synthesis of volcanic ash based geopolymer. Constr. Build. Mater. 2019, 227, 116689. [Google Scholar] [CrossRef]

- Tosti, L.; van Zomeren, A.; Pels, J.R.; Comans, R.N. Technical and environmental performance of lower carbon footprint cement mortars containing biomass fly ash as a secondary cementitious material. Resour. Conserv. Recycl. 2018, 134, 25–33. [Google Scholar] [CrossRef]

- Nuaklong, P.; Jongvivatsakul, P.; Pothisiri, T.; Sata, V.; Chindaprasirt, P. Influence of rice husk ash on mechanical properties and fire resistance of recycled aggregate high-calcium fly ash geopolymer concrete. J. Clean. Prod. 2020, 252, 119797. [Google Scholar] [CrossRef]

- Raisi, E.M.; Amiri, J.V.; Davoodi, M.R. Mechanical performance of self-compacting concrete incorporating rice husk ash. Constr. Build. Mater. 2018, 177, 148–157. [Google Scholar] [CrossRef]

- Yadav, A.L.; Sairam, V.; Muruganandam, L.; Srinivasan, K. An overview of the influences of mechanical and chemical processing on sugarcane bagasse ash characterisation as a supplementary cementitious material. J. Clean. Prod. 2020, 245, 118854. [Google Scholar] [CrossRef]

- Maldonado-Alameda, A.; Giro-Paloma, J.; Svobodova-Sedlackova, A.; Formosa, J.; Chimenos, J. Municipal solid waste incineration bottom ash as alkali-activated cement precursor depending on particle size. J. Clean. Prod. 2020, 242, 118443. [Google Scholar] [CrossRef]

- Nagrockienė, D.; Daugėla, A. Investigation into the properties of concrete modified with biomass combustion fly ash. Constr. Build. Mater. 2018, 174, 369–375. [Google Scholar] [CrossRef]

- Lee, Y.; Kang, S. Influence of Blended Activator on Microstructure, Crystal Phase and Physical Properties of Spent Catalyst Slag-Based Geopolymer. J. Nanosci. Nanotechnol. 2016, 16, 11313–11318. [Google Scholar] [CrossRef]

- Marathe, S.; Shetty, T.S.; Mithun, B.; Ranjith, A. Strength and durability studies on air cured alkali activated pavement quality concrete mixes incorporating recycled aggregates. Case Stud. Constr. Mater. 2021, 15, e00732. [Google Scholar] [CrossRef]

- Lemougna, P.N.; Wang, K.T.; Tang, Q.; Cui, X.M. Study on the development of inorganic polymers from red mud and slag system: Application in mortar and lightweight materials. Constr. Build. Mater. 2017, 156, 486–495. [Google Scholar] [CrossRef]

- Ye, N.; Yang, J.; Ke, X.; Zhu, J.; Li, Y.; Xiang, C.; Wang, H.; Li, L.; Xiao, B. Synthesis and characterization of geopolymer from Bayer red mud with thermal pretreatment. J. Am. Ceram. Soc. 2014, 97, 1652–1660. [Google Scholar] [CrossRef]

- Ahmed, M.M.; El-Naggar, K.; Tarek, D.; Ragab, A.; Sameh, H.; Zeyad, A.M.; Tayeh, B.A.; Maafa, I.M.; Yousef, A. Fabrication of thermal insulation geopolymer bricks using ferrosilicon slag and alumina waste. Case Stud. Constr. Mater. 2021, 15, e00737. [Google Scholar] [CrossRef]

- Júnior, L.U.T.; Taborda-Barraza, M.; Cheriaf, M.; Gleize, P.J.; Rocha, J.C. Effect of bottom ash waste on the rheology and durability of alkali activation pastes. Case Stud. Constr. Mater. 2022, 16, e00790. [Google Scholar]

- Alomayri, T.; Adesina, A.; Das, S. Influence of amorphous raw rice husk ash as precursor and curing condition on the performance of alkali activated concrete. Case Stud. Constr. Mater. 2021, 15, e00777. [Google Scholar] [CrossRef]

- Hassan, A.; Arif, M.; Shariq, M. Influence of microstructure of geopolymer concrete on its mechanical properties—A review. Adv. Sustain. Constr. Mater. Geotech. Eng. 2020, 35, 119–129. [Google Scholar]

- Shahedan, N.F.; Abdullah, M.M.A.B.; Mahmed, N.; Kusbiantoro, A.; Tammas-Williams, S.; Li, L.-Y.; Aziz, I.H.; Vizureanu, P.; Wysłocki, J.J.; Błoch, K. Properties of a New Insulation Material Glass Bubble in Geo-Polymer Concrete. Materials 2021, 14, 809. [Google Scholar] [CrossRef] [PubMed]

- Reddy, D.V.; Edouard, J.-B.; Sobhan, K. Durability of fly ash–based geopolymer structural concrete in the marine environment. J. Mater. Civ. Eng. 2013, 25, 781–787. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Chalee, W. Effect of sodium hydroxide concentration on chloride penetration and steel corrosion of fly ash-based geopolymer concrete under marine site. Constr. Build. Mater. 2014, 63, 303–310. [Google Scholar] [CrossRef]

- Pasupathy, K.; Berndt, M.; Sanjayan, J.; Rajeev, P.; Cheema, D.S. Durability of low-calcium fly ash based geopolymer concrete culvert in a saline environment. Cem. Concr. Res. 2017, 100, 297–310. [Google Scholar] [CrossRef]

- Alzeebaree, R.; Çevik, A.; Mohammedameen, A.; Niş, A.; Gülşan, M.E. Mechanical performance of FRP-confined geopolymer concrete under seawater attack. Adv. Struct. Eng. 2020, 23, 1055–1073. [Google Scholar] [CrossRef]

- Nuaklong, P.; Sata, V.; Chindaprasirt, P. Properties of metakaolin-high calcium fly ash geopolymer concrete containing recycled aggregate from crushed concrete specimens. Constr. Build. Mater. 2018, 161, 365–373. [Google Scholar] [CrossRef]

- Glasby, T.; Day, J.; Genrich, R.; Aldred, J. EFC geopolymer concrete aircraft pavements at Brisbane West Wellcamp Airport. Concrete 2015, 2015, 1–9. [Google Scholar]

- Ali, A.M.; Sanjayan, J.; Guerrieri, M. Performance of geopolymer high strength concrete wall panels and cylinders when exposed to a hydrocarbon fire. Constr. Build. Mater. 2017, 137, 195–207. [Google Scholar]

- Ferdous, W.; Manalo, A. Failures of mainline railway sleepers and suggested remedies—Review of current practice. Eng. Fail. Anal. 2014, 44, 17–35. [Google Scholar] [CrossRef]

- Mirza, O.; Shill, S.K.; Johnston, J. Performance of precast prestressed steel-concrete composite panels under static loadings to replace the timber transoms for railway bridge. Structures. 2019, 19, 30–40. [Google Scholar] [CrossRef]

- Shill, S.K.; Al-Deen, S.; Ashraf, M. Concrete durability issues due to temperature effects and aviation oil spillage at military airbase–A comprehensive review. Constr. Build. Mater. 2018, 160, 240–251. [Google Scholar] [CrossRef]

- Shill, S.K.; Al-Deen, S.; Ashraf, M. Thermal and Chemical Degradation of Portland Cement Concrete in the Military Airbase; EasyChair, 2019; pp. 2314–2516. Available online: https://easychair.org/publications/preprint/b24Q (accessed on 10 April 2022).

- Shill, S.K.; Al-Deen, S.; Ashraf, M. Saponification and scaling in ordinary concrete exposed to hydrocarbon fluids and high temperature at military airbases. Constr. Build. Mater. 2019, 215, 765–776. [Google Scholar] [CrossRef]

- Al-Deen, S.; Duanne, B.W.; Shill, S.K.; Ashraf, M. Durability Issues of Military Airfield Rigid Pavements due to Combined Influence of Chemical Oil Spills and Repeated Thermal Shocks from Jet Fighter Exhaust. In Proceedings of the Biennial National Conference of the Concrete Institute of Australia & International Congress on Durability of Concrete, Combined Conference, Adelaide, Australia, 2017, Melbourne, Australia; Deakin University, 2017; pp. 1–9. [Google Scholar]

- Shill, S.K.; Al-Deen, S.; Ashraf, M.; Hutchison, W. Resistance of fly ash based geopolymer mortar to both chemicals and high thermal cycles simultaneously. Constr. Build. Mater. 2020, 239, 117886. [Google Scholar] [CrossRef]

- Rickard, W.D.; Kealley, C.S.; Van Riessen, A. Thermally induced microstructural changes in fly ash geopolymers: Experimental results and proposed model. J. Am. Ceram. Soc. 2015, 98, 929–939. [Google Scholar] [CrossRef]

- Lahoti, M.; Wong, K.K.; Tan, K.H.; Yang, E.-H. Effect of alkali cation type on strength endurance of fly ash geopolymers subject to high temperature exposure. Mater. Des. 2018, 154, 8–19. [Google Scholar] [CrossRef]

- Tenn, N.; Allou, F.; Petit, C.; Absi, J.; Rossignol, S. Formulation of new materials based on geopolymer binders and different road aggregates. Ceram. Int. 2015, 41, 5812–5820. [Google Scholar] [CrossRef]

- Camacho-Tauta, J.; Reyes-Ortiz, O.; da Fonseca, A.V.; Rios, S.; Cruz, N.; Rodrigues, C. Full-scale evaluation in a fatigue track of a base course treated with geopolymers. Procedia Eng. 2016, 143, 18–25. [Google Scholar] [CrossRef] [Green Version]

- Sukprasert, S.; Hoy, M.; Horpibulsuk, S.; Arulrajah, A.; Rashid, A.S.A.; Nazir, R. Fly ash based geopolymer stabilisation of silty clay/blast furnace slag for subgrade applications. Road Mater. Pavement Des. 2021, 22, 357–371. [Google Scholar] [CrossRef]

- Dave, N.; Sahu, V.; Misra, A.K. Development of geopolymer cement concrete for highway infrastructure applications. J. Eng. Des. Technol. 2020, 18, 1321–1333. [Google Scholar] [CrossRef]

- Wongsa, A.; Sata, V.; Nematollahi, B.; Sanjayan, J.; Chindaprasirt, P. Mechanical and thermal properties of lightweight geopolymer mortar incorporating crumb rubber. J. Clean. Prod. 2018, 195, 1069–1080. [Google Scholar] [CrossRef]

- Mohammed, B.S.; Liew, M.S.; Alaloul, W.S.; Al-Fakih, A.; Ibrahim, W.; Adamu, M. Development of rubberized geopolymer interlocking bricks. Case Stud. Constr. Mater. 2018, 8, 401–408. [Google Scholar] [CrossRef]

- de Oliveira, L.B.; de Azevedo, A.R.; Marvila, M.T.; Pereira, E.C.; Fediuk, R.; Vieira, C.M.F. Durability of geopolymers with industrial waste. Case Stud. Constr. Mater. 2022, 16, e00839. [Google Scholar] [CrossRef]

- Provis, J.L.; Bernal, S.A. Geopolymers and related alkali-activated materials. Annu. Rev. Mater. Res. 2014, 44, 299–327. [Google Scholar] [CrossRef]

- Van Deventer, J.S.; Provis, J.L.; Duxson, P. Technical and commercial progress in the adoption of geopolymer cement. Miner. Eng. 2012, 29, 89–104. [Google Scholar] [CrossRef]

| Country | Gross National Product Per Capita (USD) | Waste Generation Rate (kg/cap/day) | Predicted Urban Waste Generation | |||

|---|---|---|---|---|---|---|

| 1995 | 2025 | Generation Rates (kg/cap/day) | Total Waste (tons/day) | Municipal Solid Waste (kg/cap/day) | Total (tons/day) | |

| High Income | ||||||

| Singapore | 26,730 | 36,000 | 1.1 | 4840 | 1.1 | 4840 |

| Middle Income | ||||||

| Thailand | 2740 | 6700 | 0.64 | 15,715 | 1.5 | 3673 |

| Indonesia | 980 | 2400 | 0.76 | 96,672 | 1.0 | 1272 |

| Philippines | 1050 | 2500 | 0.52 | 33,477 | 0.8 | 5150 |

| Malaysia | 3890 | 9440 | 0.81 | 15,663 | 1.4 | 2681 |

| Low Income | ||||||

| Vietnam | 240 | 950 | 0.61 | 19,983 | 1.0 | 3276 |

| Brunei | 260 | 750 | 0.66 | 149,140 | 0.95 | 2169 |

| Cambodia | 220 | 700 | 0.52 | 3544 | 1.1 | 7497 |

| Myanmar | 240 | 580 | 0.45 | 12,118 | 0.85 | 2289 |

| Laos | 350 | 850 | 0.55 | 1379 | 0.9 | 2257 |

| Type of Waste | Sources of Content | Potential Application | References |

|---|---|---|---|

| Hazardous Waste | Trash from galvanising, tannery waste, and metallurgical waste | Cement brick, tiles, boards | [7,8] |

| Mining Mineral Waste | Overburden waste tailing from the iron, coal wateriest waste, copper, gold, zinc and aluminium industries | Light-weight aggregate fuel, brick, tiles | [9,10] |

| Agro Waste | Cotton stalks, husk from packed rice and wheat straw, sawmill waste, jute and banana stalks, nut shells, sisal, and vegetable residue | Insulation boards, particle board, wall panel, roofing sheets, fibrous construction panel, fuel binder, acid resistant cement | [11,12,13] |

| Industrial Waste | Bauxite red mud, steel slag, construction detritus, coal combustion residues | Bricks, blocks, cement, paint, wood substitutes, tiles, concrete, and ceramic goods | [14,15,16] |

| Non-hazardous Waste | Gypsum waste, lime sludge limestone waste, marble production waste, | Cement clinker, super sulphate hydraulic binder, gypsum plaster, fibrous gypsum, boards, bricks and blocks | [17,18] |

| Municipal Solid Waste | Soft drink bottle, jar for food, cosmetics product | Replacement binder material, supplementary material in concrete, soil stabilization | [19,20] |

| Geopolymer Waste Material | Potential Application | Properties | Ref. |

|---|---|---|---|

| Ground granulated blast furnace slag, Fly ash, granite coarse aggregate | Concrete pavement | 50 MPa of compressive strength and 4.72 MPa of flexural strength | [90] |

| Red mud waste (bauxite residue), slag | Heavy metal removal, composite materials, Adsorbent and coagulant | 66 to 86 MPa of Compressive strength | [91,92] |

| Ferrosilicon slag, alumina waste | Thermal insulation brick | 10.9 MPa of compressive strength and 0.59 W/m.k of thermal conductivity | [93] |

| Metakaolin, bottom ash waste | Thermal insulation brick | 47.9 MPa of compressive strength, 1.32 W/m.k of thermal conductivity | [94] |

| Blast furnace slag, rice husk ash | Acid proof cement | 57 MPa of compressive strength | [95] |

| No. | Researcher | Materials | Findings |

|---|---|---|---|

| 1 | Sukprasert et al. [116] | Fly ash, silty clay, ground granulated blast furnace slag |

|

| 2 | Dave et al. [117] | Ground blast furnace slag, fly ash, silica fume |

|

| 3 | Wongsa et al. [118] | Crumb rubber, river sand, high calcium fly ash |

|

| 4 | Mohammed et al. [119] | Fly ash, crumb rubber |

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kheimi, M.; Aziz, I.H.; Abdullah, M.M.A.B.; Almadani, M.; Abd Razak, R. Waste Material via Geopolymerization for Heavy-Duty Application: A Review. Materials 2022, 15, 3205. https://doi.org/10.3390/ma15093205

Kheimi M, Aziz IH, Abdullah MMAB, Almadani M, Abd Razak R. Waste Material via Geopolymerization for Heavy-Duty Application: A Review. Materials. 2022; 15(9):3205. https://doi.org/10.3390/ma15093205

Chicago/Turabian StyleKheimi, Marwan, Ikmal Hakem Aziz, Mohd Mustafa Al Bakri Abdullah, Mohammad Almadani, and Rafiza Abd Razak. 2022. "Waste Material via Geopolymerization for Heavy-Duty Application: A Review" Materials 15, no. 9: 3205. https://doi.org/10.3390/ma15093205