Investigation of the Fabrication Suitability, Structural Performance, and Sustainability of Natural Fibers in Coreless Filament Winding

Abstract

1. Introduction

2. Materials and Methods

2.1. Composite Winding Material Selection

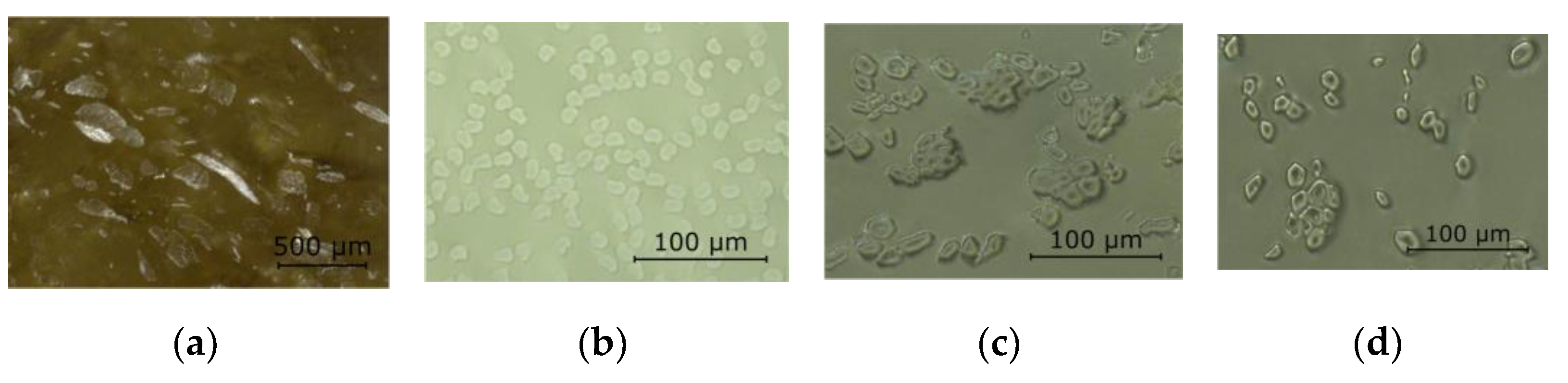

2.1.1. Fiber Materials

2.1.2. Matrix Materials

2.2. Adjustments of the Winding Equipment and Process

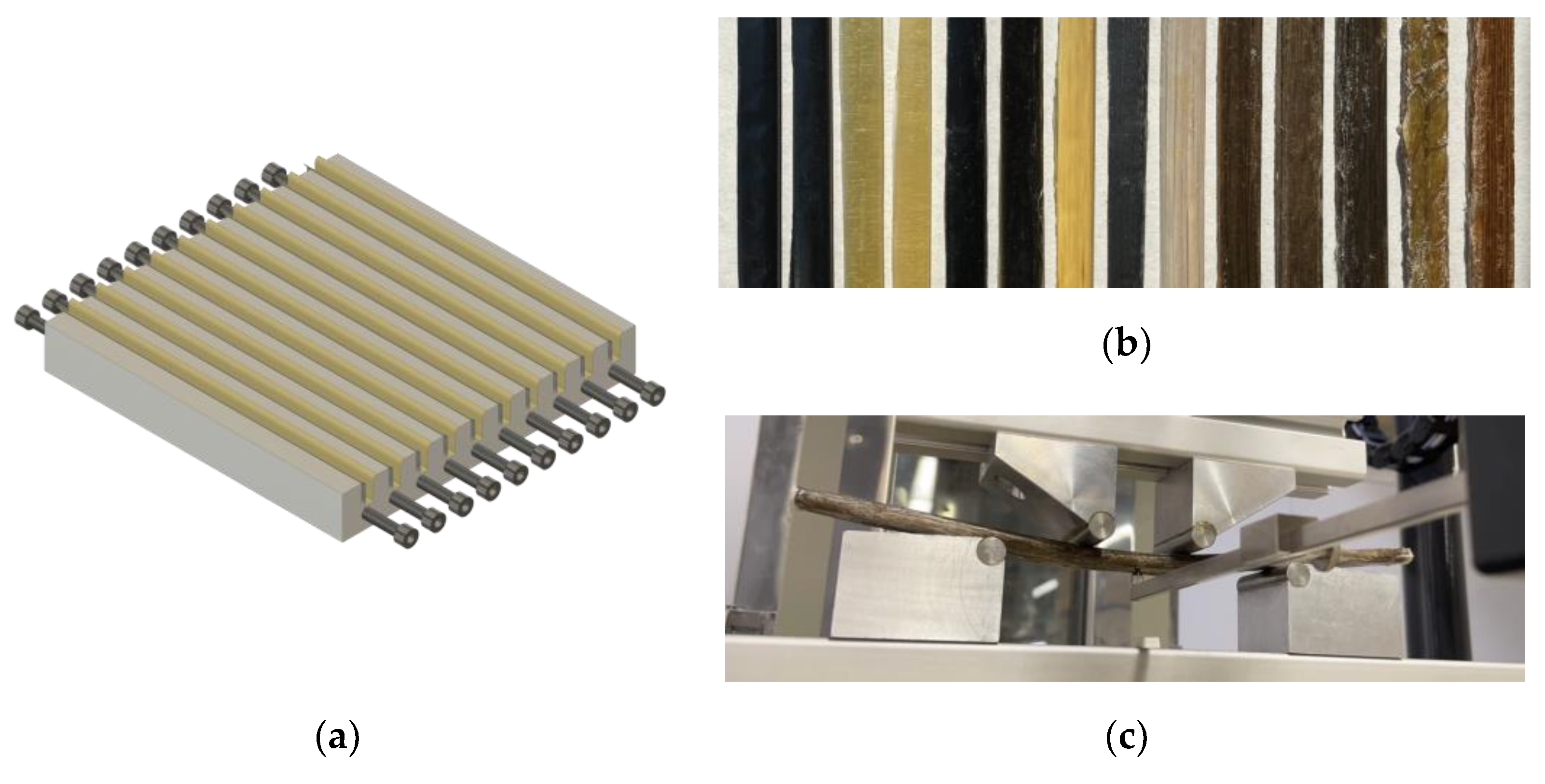

2.3. Structural Testing and Sample Parameters

2.3.1. Samples Geometry and Production

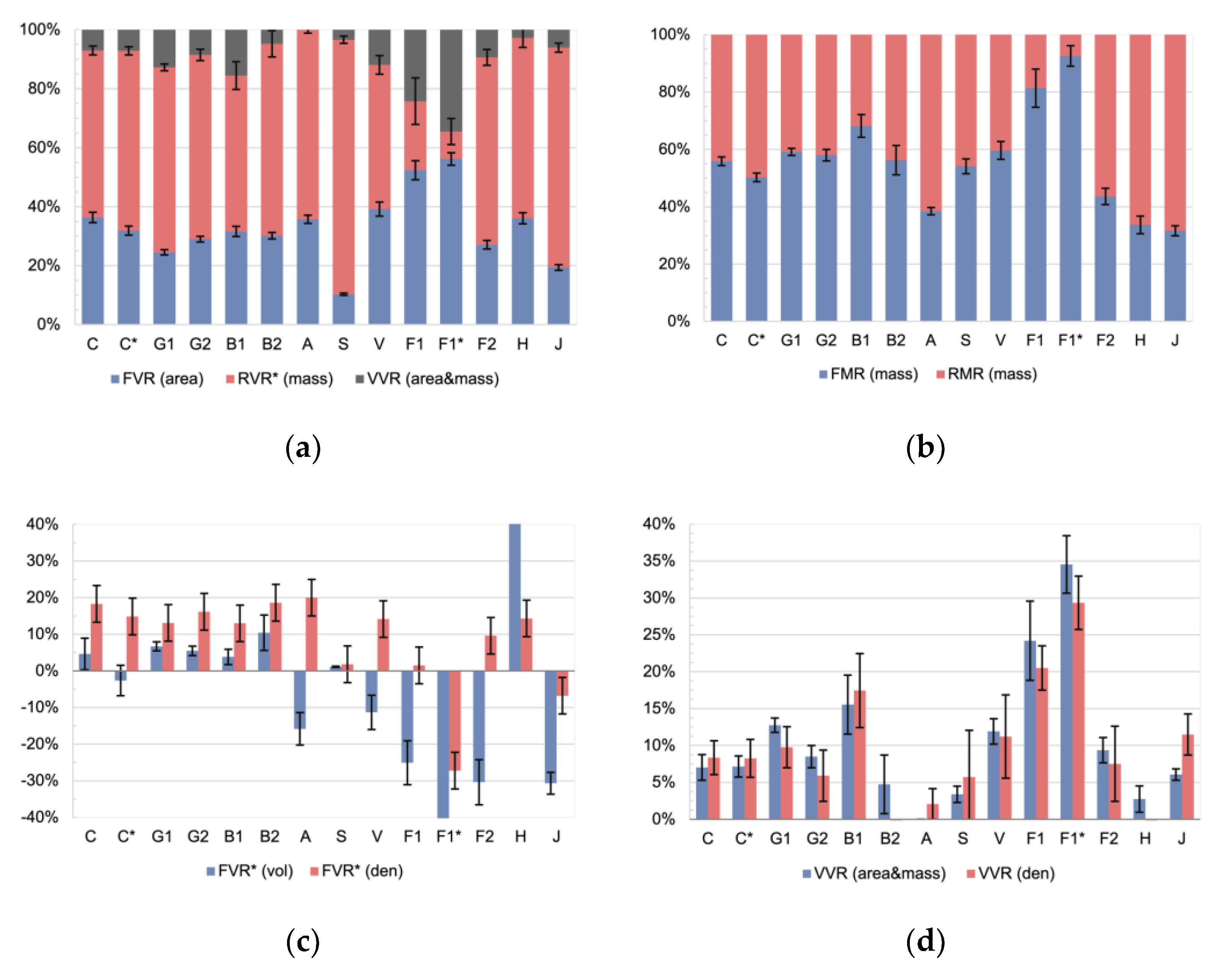

2.3.2. Composite Composition Calculation Methods

- d filament/fiber diameter,

- f number of filaments/fibers per roving/fiber bundle,

- r number of rovings/fiber bundles,

- a relevant cross-sectional area of the sample.

- T linear density of the roving/fiber bundle.

- fiber mass per sample, as total fiber length deployed during production,

- sample mass,

- l sample length,

- sample volume.

- resin mass per sample, as resin absorbed by the component during fabrication,

- theoretical compressed sample density,

- sample density.

3. Results

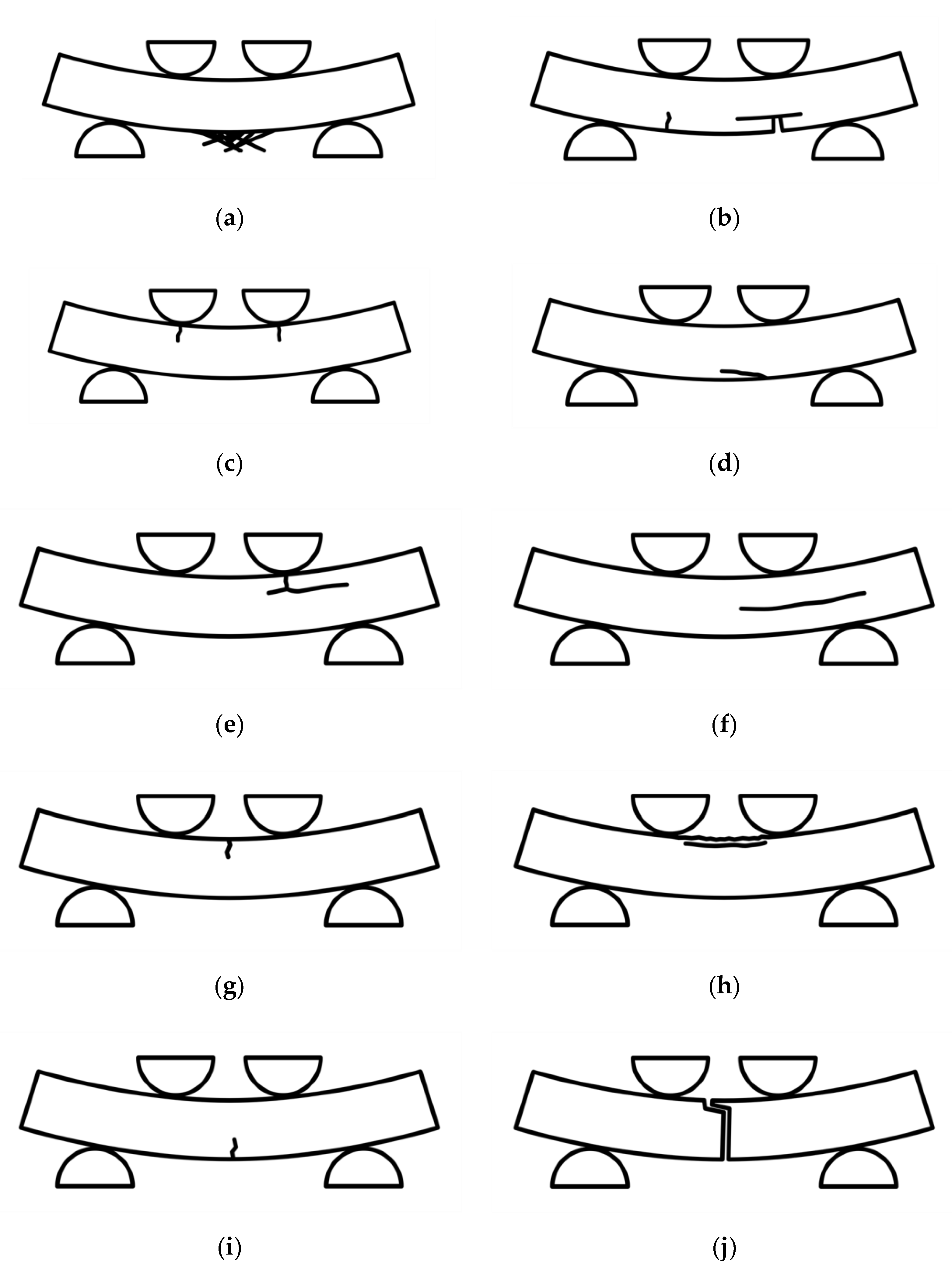

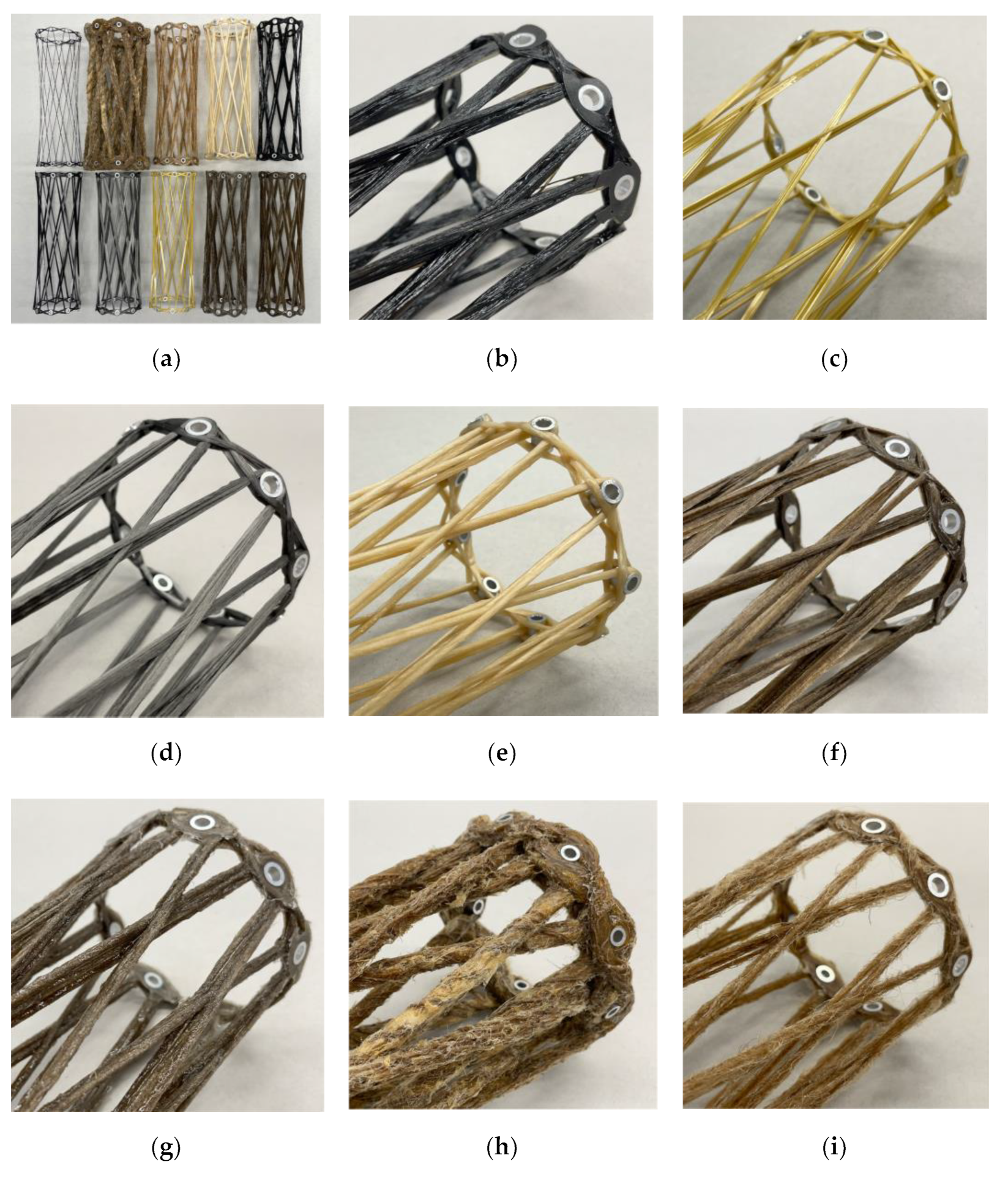

3.1. Fabrication Suitability

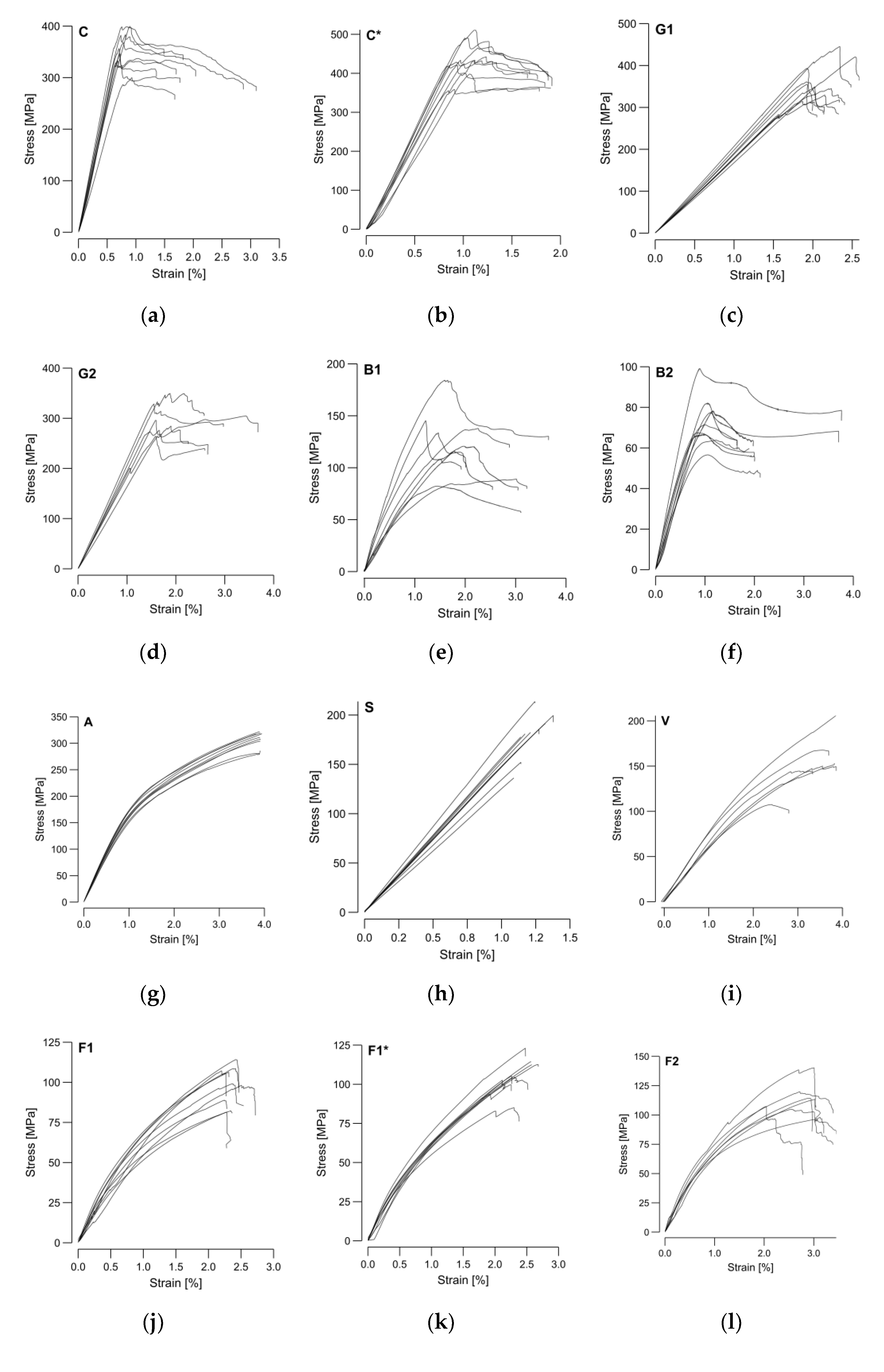

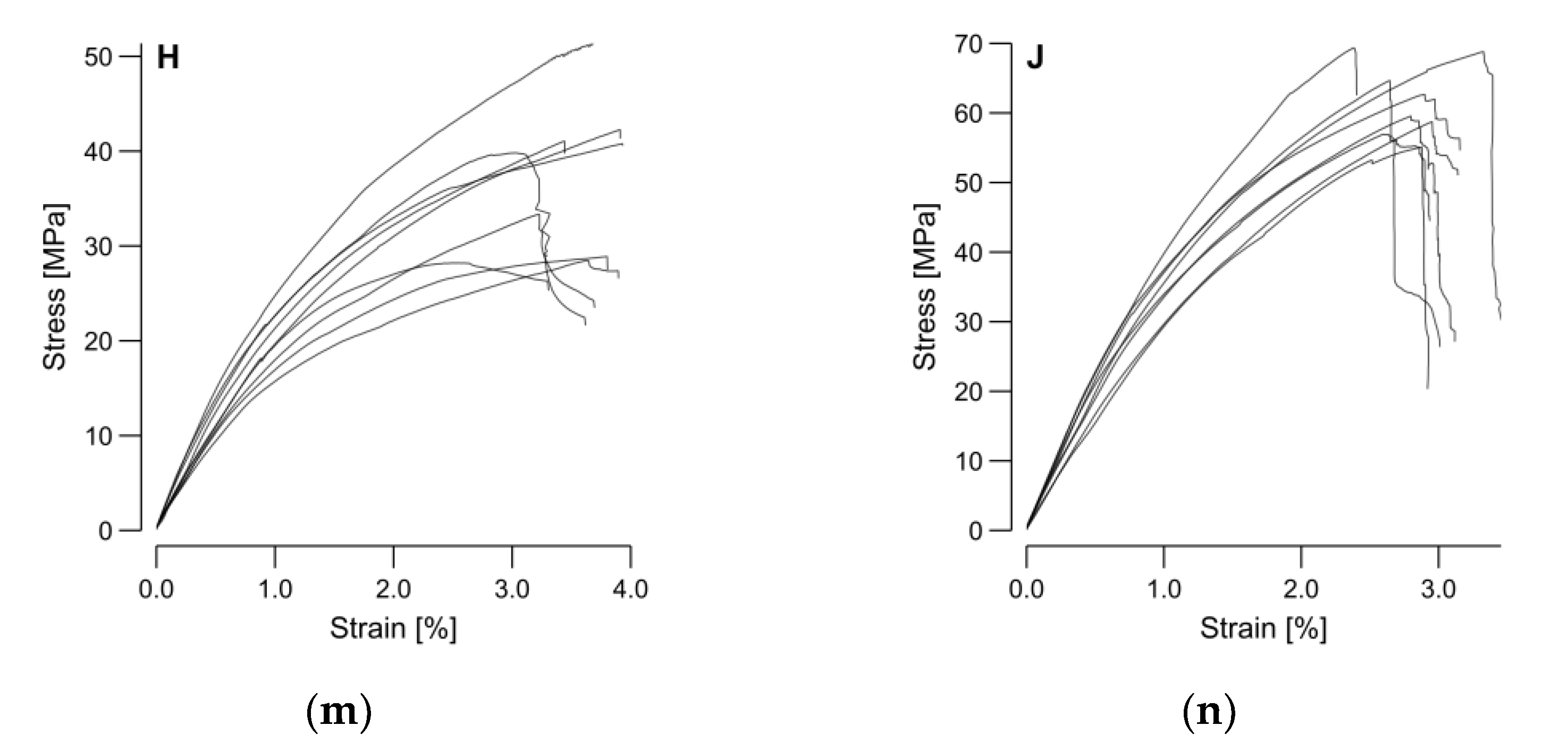

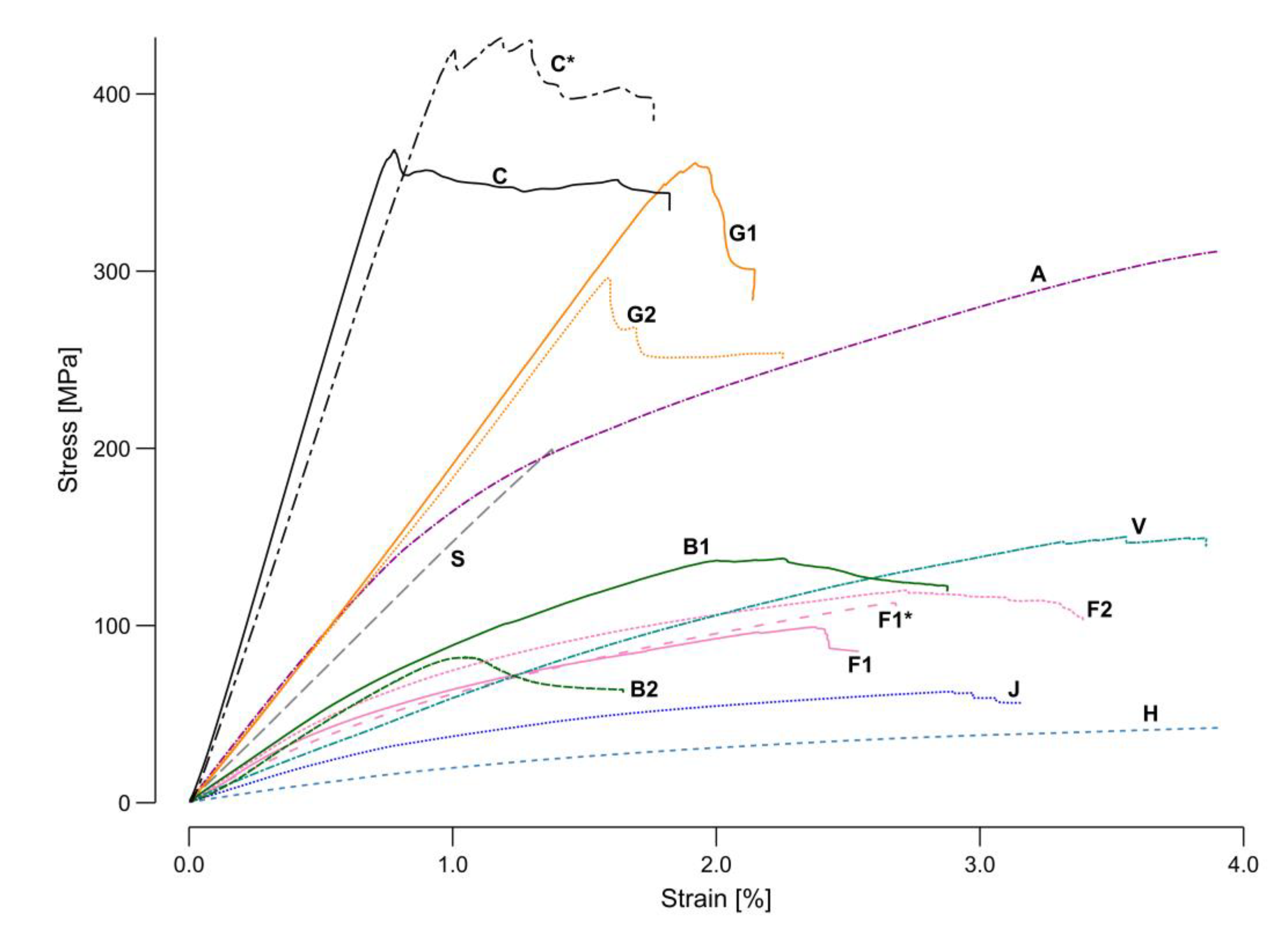

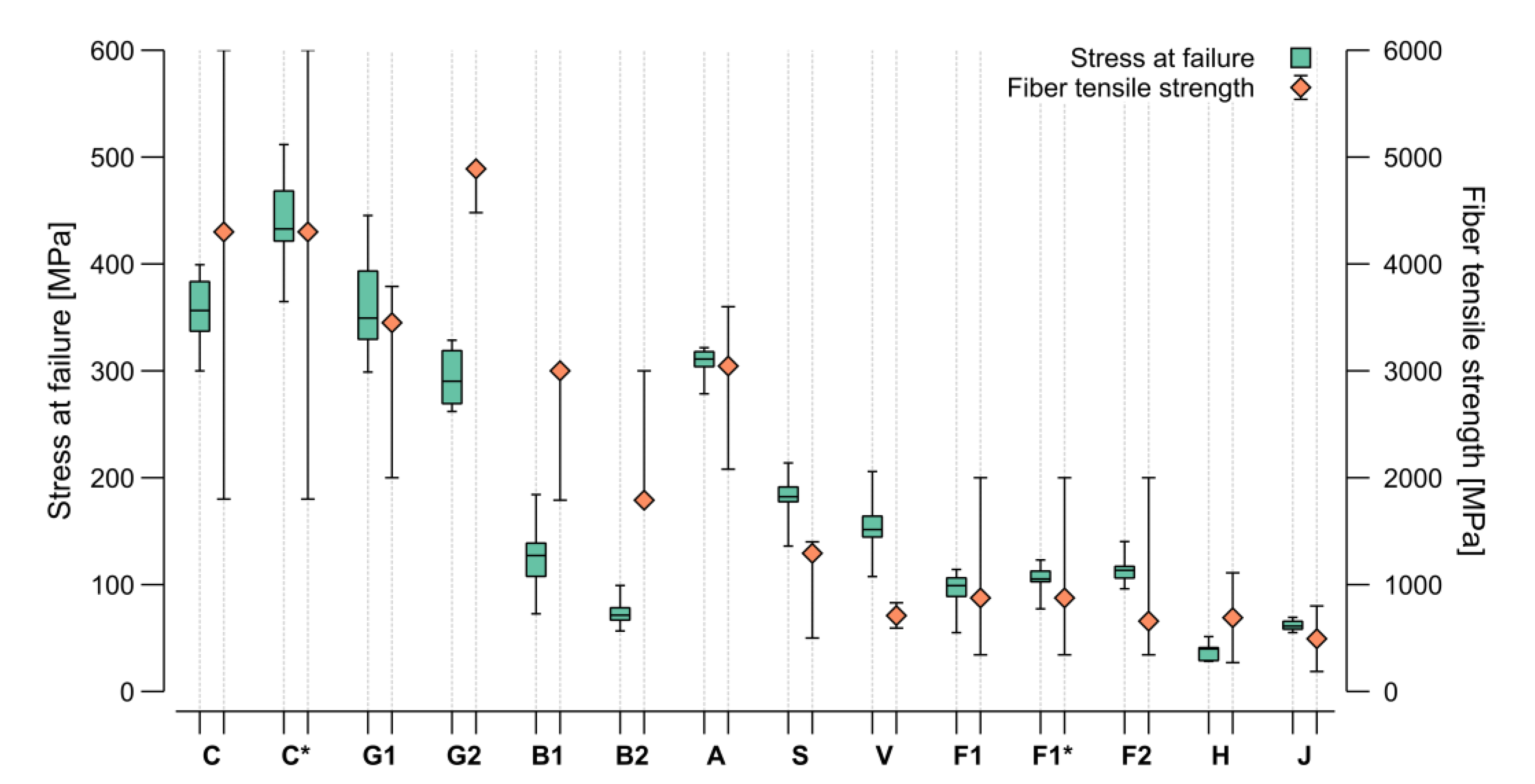

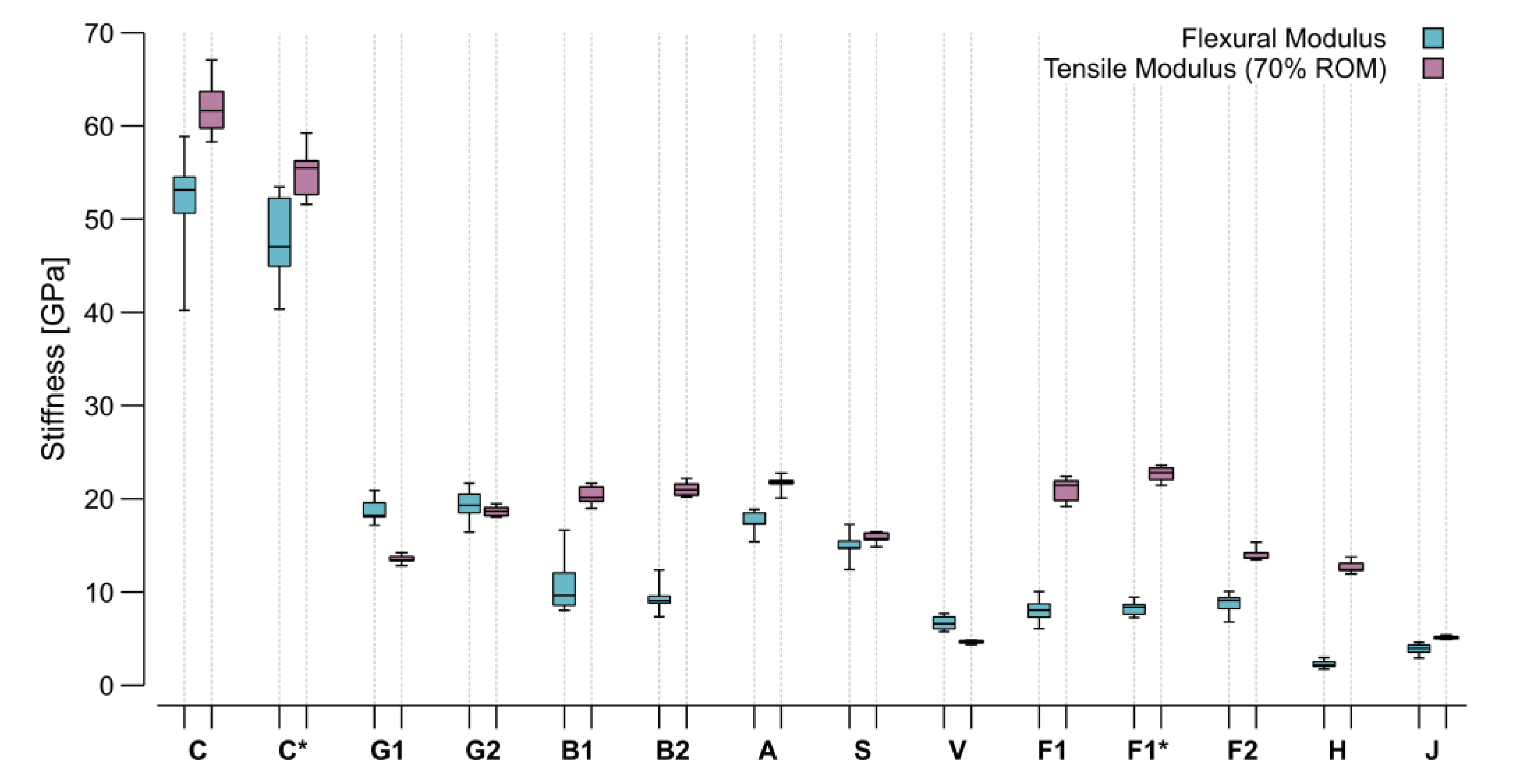

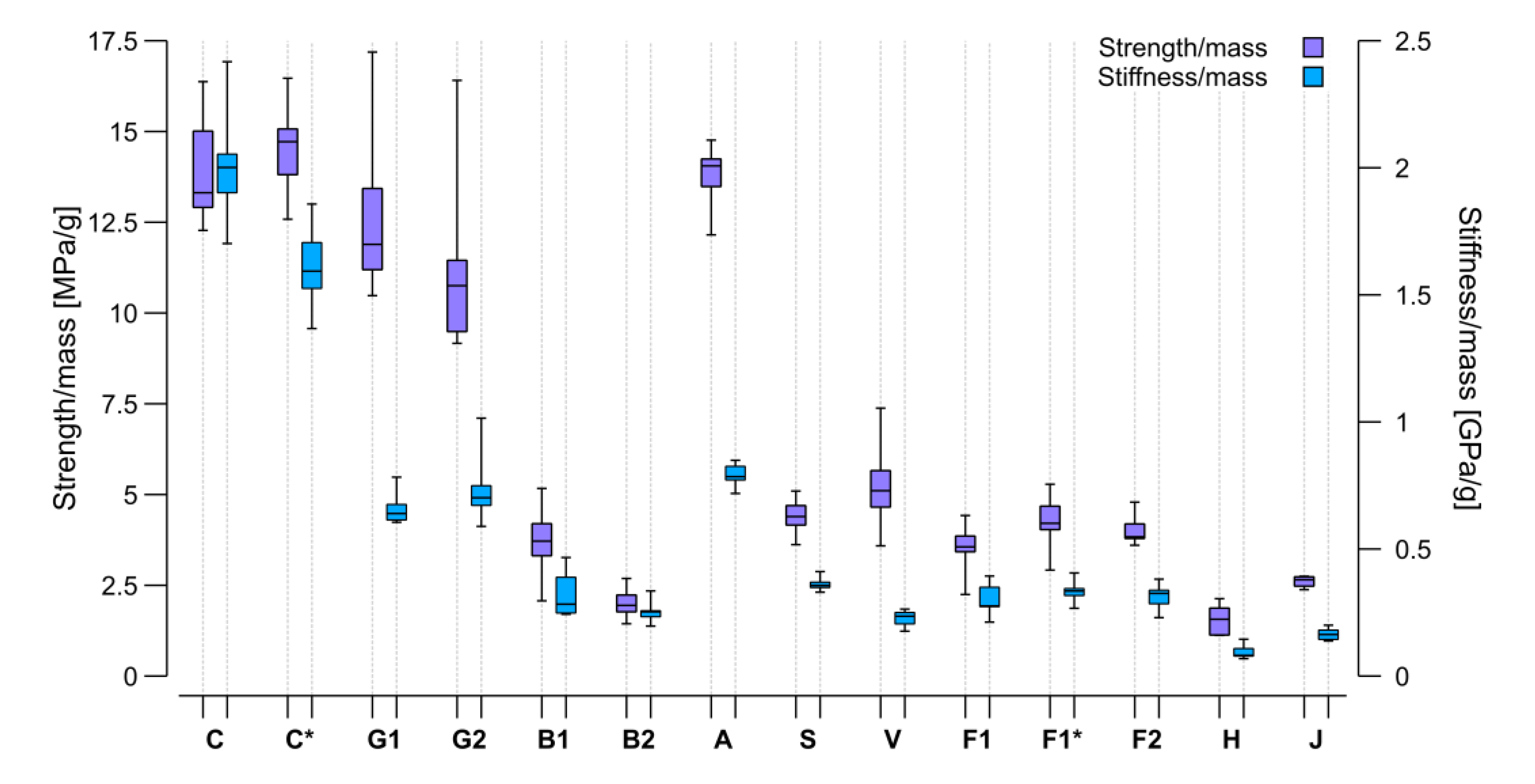

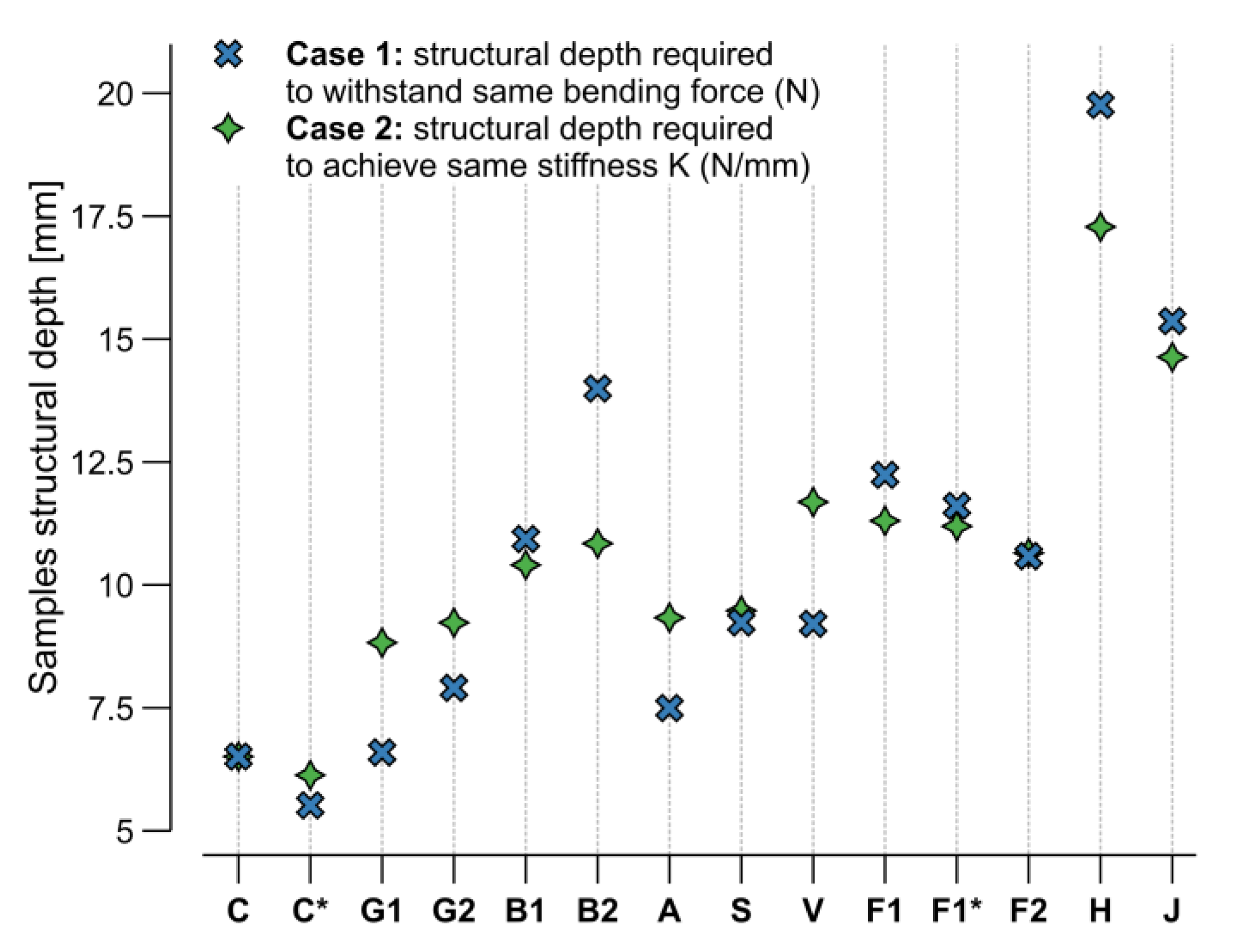

3.2. Structural Performance

- tensile modulus of the composite,

- tensile modulus of fibers,

- tensile modulus of matrix,

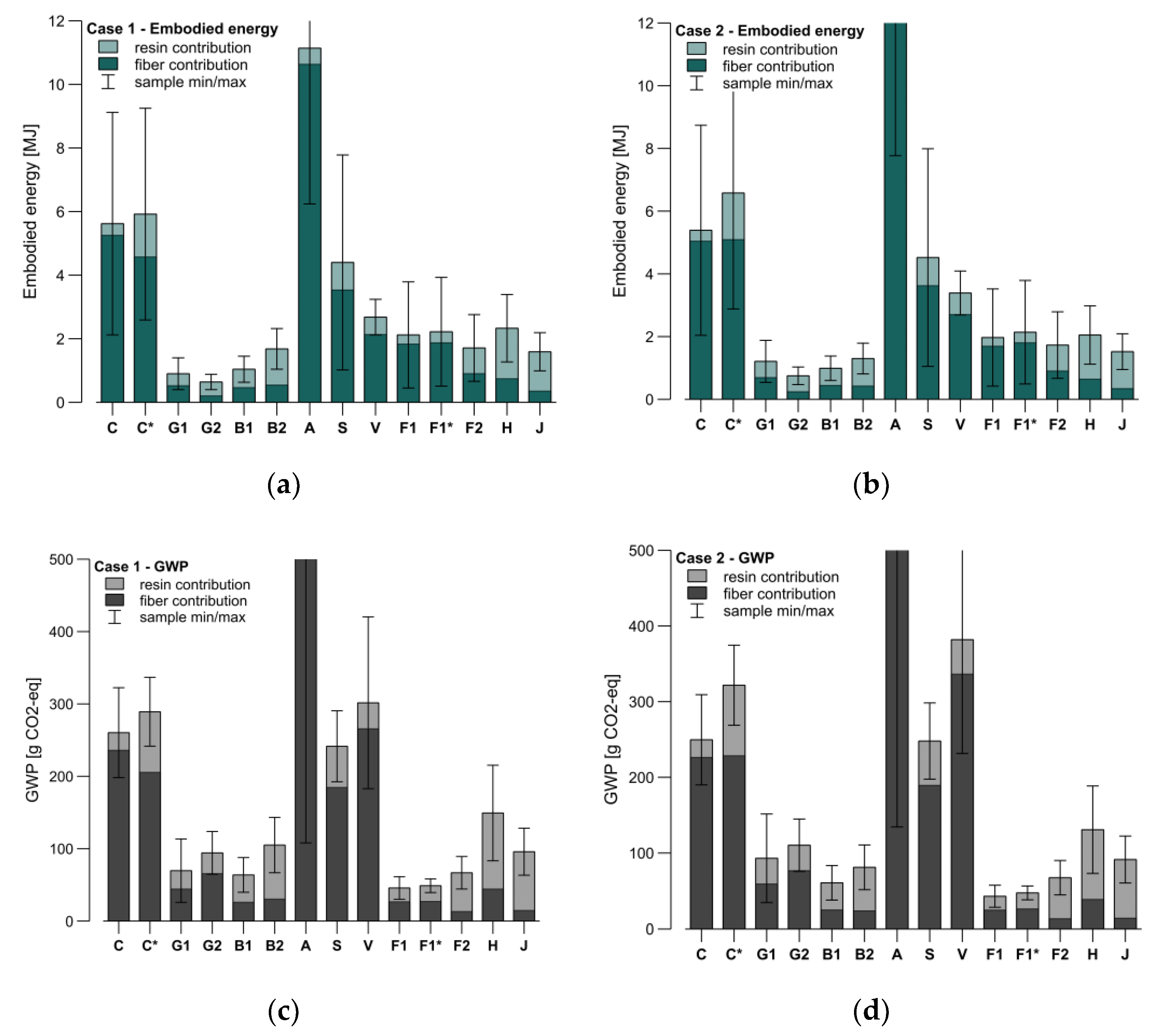

3.3. Sustainability Assessment

- spring stiffness of the carbon sample (C), as a function of the force () divided by the deformation ( at failure,

- flexural modulus of the samples,

- carbon sample (C) maximum deformation at failure.

4. Discussion

4.1. Limitations and Advantages of the Assessment

4.2. Impact of the Material’s Uncertainties

4.3. Scalability of the Equipment and Material System

4.4. Adverse Influences of the Natural Fibers’ Lower Mechanical Properties

5. Conclusions

- It was confirmed in this study that the inconsistencies of natural fibers add to uncertainties in the parameters of CFW components. This variability affects the geomaterial parameters, their inner composition, and as a result, also the structural performance.

- For CFW, the void content should not be neglected, and especially not for natural fibers. The volume-based calculation should rely on the FVR (area), whereas mass-related calculation should be based on the FMR (mass). Converting between FVR and FMR should be avoided, as this would include further uncertainties. Especially for natural fiber composites, methods based on the sample area and mass should be preferred over volume-based methods, such as cuboidal approximation or applying Archimedes’ principle.

- The hairiness, tension limitation, worse impregnation characteristics, and water absorption characteristics entailed by naturals fibers can be mitigated by winding equipment adjustments and process adaptations.

- The inclusion of natural fibers affects large-scale winding setup designs so that they tend to rely on pre-impregnated fibers or a direct impregnation with a resin feed. Adjustments to the size or arrangement of the winding pins or to the winding syntax are needed. Additional elements to help with impregnation and a continuous dryer and tension control, preferably actively controlled, are also needed.

- The resin contribution could be reduced by decreasing the footprint of the resin or by increasing the FMR. Further fabrication adjustments or a subsequent consolidation of the structure can help to reduce this issue.

- In materials with a low FMR, the resin contribution is significant, which can justify using resins with a low ecological impact, such as bio-based epoxies; however, its higher mass-specific price also needs to be considered. In addition, the difference in the obtained FVR between petroleum-based resin and bio-based resin, produced by differences in the fiber’s impregnability by these materials, should also be taken into account.

- The highest lightweight performance is still exhibited by carbon in terms of stiffness, while glass is the better option over carbon for strength because of its economic and ecological benefits. Carbon and glass are not sustainable options if embodied energy and GWP are considered; however, when other architectural or engineering applications such as long-span and low deflection demanding scenarios, the current material choice could still be considered the most viable option.

- Aramid does not offer a higher mass-specific stiffness than carbon but exhibits significantly higher energy consumption and GWP, making it non-preferable for CFW.

- Viscose and steel showed a higher GWP than carbon, although a lower embodied energy; however, viscose especially cannot be competitive with other natural fibers and, therefore, it should not be used for CFW. The recycling potential of steel fibers, which can be fully recycled by melting them down, makes them worthy of further investigation, especially in a scenario where the components are recycled multiple times.

- Based on the approach in this study, flax is found to be the best overall alternative to C/GFRP in CFW as it balances both sustainability markers equally and presents a relatively high mass-specific mechanical performance. Flax also presents an economic advantage over carbon.

- Other materials, such as jute, basalt and hemp, would become suitable options if the resin contribution would be significantly reduced. Specifically, hemp could show a smaller ecological impact since it is a card sliver and not a finished yarn, which removes production steps and, thus, saves resources.

- Under economic aspects, the usage of jute fibers would be interesting, as its price range is low compared to flax (Table 1). The basalt is economically more similar to glass. Here, the price advantage of E-glass over S-glass adds to its ecological benefit.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Fiber Material | Density | Tensile Modulus | Tensile Strength | Elong. at Break | Embodied Energy | GWP | Price |

|---|---|---|---|---|---|---|---|

| – | g/cm3 | GPa | MPa | % | MJ/kg | kg CO2-eq./kg | EUR/kg |

| Abaca | 0.83 [57] 1.5 [30,58] | 6.2–20 [30] 12 [58] 12–13.8 [57] 33.6 [59] | 400 [58] 400–980 [30] 418–486 [57] 813 [59] | 1–10 [30] 3–12 [58] | – | 0.1–0.92 [60] | 0.31 * [61] 1.377–2.268 * [46] |

| Acryl | 1.18–1.19 [62] | 2.76–3.3 [62] | 62–83 [62] | 3–6.4 [62] | 175 [63] 176.4 [64] | 5 [63] 26 [64] | 2–25 ** |

| Aramid | 0.98–1.450 [65] 1.44 [66] | 48–146 [66] 55–140 [67] 59–127 [68] 62–131 [69] | 2080 [70] 2120 [71] 2400–2700 [66] 2700–2800 [69] 2800 [68] 3600 [65] | 1.5–3.3 [66] 2–4.5 [67] 3.7 [68] | 600–1350 [72] 1651 [68] | 8.7 [73] 13.19 [74] 13.232 [68] 37.5 [72] 90–104 [72] | 74.49 * [72] |

| Bamboo | 0.6–1.1 [30] 0.91–1.5 [57] | 11–32 [30] 27–35.91 [57] 35.91 [58] | 140–800 [30] 500 [58] 503–575 [57] | 1.4 [58] 2.5–3.7 [30] | – | 0.0515 [75] 3.05 [76] | 0.225–0.45 * [46] 0.45 * [61] |

| Banana | 0.8 [59] 1.35 [30] | 8.5 [59] 12 [30] 17.85 [58] 27–32 [41] | 144–567 [57] 161.8 [59] 500 [30] 600 [58] 700–800 [41] | 1.5–9 [30] 2.5–3.7 [41] 3.36 [58] 21.8–30.6 [57] | – | 0.45–1.04 [77] | 0.8 * [61] |

| Basalt | 2.15 [78] 2.6 [79] 2.7 [80] | 42 [78] 60 [80] 90 [45] 100 [81] | 1790 [81] 2850 [45] 3000 [82] | 1.12 [80] 3.5 [83] | 6.63 [78] 18 [79] | 0.386 [78] 0.986 [84] | 15–20 ** |

| Boron | 2.3–2.61 [69] 2.57 [85] | 400–428 [69] | 3600 [69] | 1 [86] | – | 17.78–43.92 [87] | 180 * [88] 2600 [89] |

| Carbon | 1.4 [23] 1.7–2.1 [69] 1.75–1.8 [66] 1.76 [90] 1.82 [58] 2.2 [91] | 200–250 [66] 220–550 [69] 230–240 [23] 240–425 [90] 620–935 [91] | 1800–3500 [69] 2600 [91] 3000–5000 [66] 4000 [23] 4100–6000 [90] | 0.3–1.4 [69] 1.1–2.1 [90] 1.2–1.4 [66] 1.4–1.8 [23] | 130 [61] 183–286 [21,92] 198–595 [93] 338.97 [74] 390–420 [72] 460 [94] | 12.55 [74] 20 [95] 24–31 [94] | 11.26 * [61] 14.06–15.99 * [96] 24–120 * [72] |

| Coconut | 1.15 [58] | 2.3 [59] 2.5 [58] 18 [57] | 46.4 [59] 119.8 [57] 500 [58] | 2.84 [59] 3.36 [58] 5.5 [57] | – | 0.3286 [97] | 0.21 [98] |

| Coir | 1.15–1.2 [57] 1.15–1.46 [30] 1.2 [58] 1.25 [99] | 2.8–6 [30] 3–6 [92] 4–6 [59] 6 [41,99] | 95–230 [30] 106–270 [92] 108–252 [57] 175 [59] 220 [41,99] | 15–25 [99] 15–40 [57] 15–51.4 [30] 23.9–51.4 [41] 30 [59] | 10 [72] | – | 0.18–0.396 * [46] 0.18–0.45 * [61] 0.24–0.48 [92] |

| Cotton | 1.5–1.6 [30] 1.51 [99] | 5.5–12.6 [30] 6–13 [47] 12 [41,99] | 287–800 [30] 300–600 [47] 400 [41,99] | 3–10 [30,99] 7–8 [47] | 5.759–32.643 [100] 54 [64] 60 [63] | 0.4341 [97] 0.978–2.446 [100] 6 [63] 8 [64] | 1.35–3.78 * [61] 1.377–1.98 * [46] 1.61–4.59 [92] |

| Flax | 1.35–3.78 * [61] 1.377–1.98 * [46] 1.61–4.59 [92] | 27–80 [57] 27.6 [23] 27.6–103 [30] 30–110 [47] 45–100 [101] 60–80 [41,66,99] | 343–2000 [30] 345–1830 [57] 400–2000 [47] 500–1500 [23] 600–1100 [101] 780–1500 [41] 800–1500 [66,99] | 1.2–1.6 [66] 1.2–2.4 [41] 1.2–3 [47] 1.2–3.3 [30] 1.5–2.4 [101] 2.7–3.2 [23] [99] | 6.5 [21,102] 9.55 [103] 86 [104] | 0.4375 [97] 0.9 [105] | 0.28–1.377 * [46] 1.89–3.78 * [61] 2.29–11.47 [92] |

| E-glass | 2.5 [23] 2.5–2.59 [46] 2.5–2.6 [30] 2.52–2.6 [66] 2.54 [85] 2.55 [99] 2.56 [101] 2.6 [106] 2.62 [107] | 70 [23,106] 70–76 [30] 72 [101] 72–74 [47] 72–77 [66] 72.5 [85] 73 [99] | 2000–3400 [101] 2000–3500 [23,30] 2300–2500 [47] 2400 [99,106] 3400–3500 [66] 3450 [85] 3790 [108] | 0.5 [23] 1.8–3.2 [101] 1.8–4.8 [30] 3 [99] 3.2–3.5 [47] 3.3–4.8 [66] | 8.67 [74] 13–32 [21,92] 17.5 [35] 30 [61] 48.33 [47,99] 51.3 [106] | 0.512 [74] 1.8–4.6 [105] 2.04 [47,99] 2.95 [106] | 1.08–1.62 * [61] 1.44–2.925 * [46] |

| S-glass | 2.48 [107] 2.49 [85] 2.5 [58] | 85 [58] 85–103 [109] 85.6 [85] | 4480 [85] 4580 [58] 4630–4890 [109] | 4.6 [58] 5.7 [109] | 6.013 [110] 16 [35] | 2.452 [110] 4.6 [105] | 11.9 * [85] 21 [111] |

| Hemp | 1.4–1.5 [30,101] 1.47 [23] 1.48 [66,99] | 3–90 [92] 23.5–90 [30] 35 [101] 58–70 [57] 60–70 [47] 70 [23,66,99] | 270–900 [30] 389 [101] 550–900 [99] 550–1100 [47] 550–1110 [57] 600–900 [66] 690 [23] | 1–3.5 [30] 1.1–1.6 [101] 1.6 [57,66,99] 1.6–1.8 [47] 2–4 [23] | 8.89 [106] 18 [64] 30–50 [72] | 0.531 [106] 0.5637 [97] 3 [64,72] | 0.28–1.486 * [46] 0.57–1.73 [92] 0.9–1.89 * [61] |

| Jute | 1.3 [23] 1.3–1.45 [101] 1.3–1.49 [30] 1.3–1.5 [57] 1.46 [99] | 3–55 [92] 10–30 [41,47,99] 10–55 [57] 26.5 [23] 30 [30] 43 [101] | 187–773 [92] 320–550 [101] 320–800 [30] 393–773 [23] 393–800 [57] 400–800 [41,47,99] | 0.7–1.8 [47] 1–1.8 [30] 1.5–1.8 [23,41,57] 1.7 [101] 1.8 [99] | 10 [72] 30 [112] | 0.52–1.120 [112] 0.5703 [97] | 0.12–0.35 [92] 0.27–0.28 * [46] 0.36–0.5 * [61] |

| Kenaf | 1.22–1.4 [57] 1.4 [30] 1.45 [23,58] | 4.3–60 [57] 14.5–53 [30] 22–53 [92] 53 [23] | 223–930 [30] 250–1191 [57] 295–930 [92] 930 [23] | 1.5–2.7 [30] 1.6 [23,58] | 10 [72] | 5.59 [100] | 0.18 * [72] 0.279–0.585 * [46] 0.53–0.61 [92] |

| Palm | 1.03 [59] | 2.75 [59] | 377 [59] | 13.71 [59] | – | – | 0.07 [98] |

| Pineapple | 1.526 [59] | 60–82 [59] 82 [41] | 170–1627 [59] 180 [41] | 2.4 [59] 3.2 [41] | 16.93 [113] | 4.43 [114] | – |

| Polyamide | 1.82 [115] | 0.95 [116] | 44 [115] | 18 [116] | 130 [63] 248.4 [64] | 12.7 [117] 37 [64] | 1.01–1.55 [118] |

| Polyester | 1.38 [66] | 10 [66] | 1100 [66] | 22 [66] | 125 [63] 126 [64] | 2.8 [63] 12.7 [119] 19 [64] | 0.42–0.48 [118] |

| Ramie | 1.0–1.55 [30] 1.4–1.5 [101] 1.5 [58,99] | 24.5–128 [30,57] 44 [41,99] 44–128 [58] 61.4–128 [23] 128 [101] | 220–938 [58] 400–938 [23] 400–1000 [30,57] 500 [99] 500–870 [41] 500–1000 [101] | 1.2 [41] 1.2–4.0 [57,101] 2 [99] 2–3.8 [58] 3.6–3.8 [23] [30] | 10 [72] | 1 [72] | 1.377–2.17 * [46] 1.8 * [61] |

| Silk | 1.097 [120] 1.34 [121] | 0.5–1.1 [116] 6.2 [122] 10 [121] | 519.1 [122] 1500 [121] | 18–270 [116] | 520–580 [72] | 35 [72] | 30 * [72] |

| Sisal | 1.3–1.5 [59] 1.33 [99] 1.33–1.5 [30] 1.45 [58] 1.5 [23] | 9–28 [57] 9–38 [30] 9.4–22 [23,58] 17–22 [41] 28 [59] 38 [99] | 227–885 [57] 363–700 [30] 507–955 [59] 511–635 [23] 530–630 [41] 530–640 [58] 600–700 [99] | 2.0–2.5 [23] 2–2.9 [59] 2–3 [99] 2.0–7.0 [30] 2–14 [57] 3–7 [58] 3.64–5.12 [41] | 10 [72] | 1 [72] | 0.315–0.585 * [46] 0.54–0.63 * [61] |

| Stainless steel | 7.68 [79] 7.98 [123] 8 [124] | 200 [124] | 500–700 [124] 1400 [123] | 5 [123] | 14 [79] 30–60 [21] 30.37 [99] 32.1 [125] 49–80 [126] 110–210 [56] | 2.62 [99] 4.9–6.8 [126] 5.18414 [127] | 0.8–2.7 ** |

| Viscose | 1.5 [128,129] 1.52 [130] | 11 [57] 14.3–16.5 [128] 20 [129] | 593 [57] 682–778 [128] 830 [129] | 10.7–12.7 [128] 11 [57] 13 [129] | 71 [63] 100.8 [64] | 6.4 [131] 14 [132] 15 [64] | 2–12 ** |

| Wool | 1.3 [133] | 2–5 [34] | 100–350 [34] | 28–61 [34] | 46.8 [64] | 7 [64] 29.44 [134] | 2.42 * [72] |

| Resin Material | Density | Tensile Modulus | Tensile Strength | Elong. at Break | Embodied Energy | GWP | Price |

| – | g/cm3 | GPa | MPa | % | MJ/kg | kg CO2-eq./kg | EUR/kg |

| Epoxy | 1.1–1.4 [30,69] 1.123 [106] 1.2 [66] | 1.3–3.5 [69] 3–6 [30,66] 3.1–3.2 [101] 3.5 [106] 3.9 [135] | 35–100 [30,69] 47.7 [135] 60–125 [66] 69 [106] 76 [101] | 1–6 [30] 1.5 [135] 7.3 [101] | 76–80 [21,92] 122.4 [97] 135.04 [74] 139 [136] 140.71 [47] | 5.9 [47] 6.663 [97,106] 6.7 [136] 6.75 [74] | 7.66 ** |

| Epoxy | 1.05–1.1 [137] 1.12 [106] 1.159 [138] | 2–2.2 [137] 3–3.3 [138] 3.074 [106] | 60.0 [106] 70–90 [137] 71–81 [138] | 2.8–6.1 [138] 3 [137] | 21.42–43.52 ** | 1.42–2.85 ** 4.079 [97,106] | 15–20 ** |

| Phenolics | 1.2–1.3 [69] 1.3–2.0 [66] | 0.56–2.5 [66] 5–11 [69] | 20–60 [66] 50–60 [69] | 1 [139] | 130.34 [74] | 1.34 [140] 4.61 [74] | – |

| Polyester | 1.2 [66,69] 1.2–1.5 [30] 1.35 [141] | 2–3 [69] 2–4.5 [30] 3–4.2 [66] 3.23 [141] | 40–70 [66] 40–90 [30] 50–60 [69] 85 [141] | 2 [30] | 63–78 [21,92,102] 128 [136] | 3.79 [74] 7.6 [136] | – |

| Polyimides | 1.4 [69] | 3–4 [69] | 100–130 [69] | 5–30 [142] | 110–340 [143] | 5.8–19.5 [143] | – |

| Polyurethan | 1.05 [144] | 3.1 [135] | 62.8 [135] | 9.1 [135] | 77.83–102.2 [74] | 3.2–4.56 [74] | – |

References

- Kesarwani, S. Polymer composites in aviation sector. Int. J. Eng. Res. 2017, 6, 518–525. [Google Scholar] [CrossRef]

- Ravishankar, B.; Nayak, S.K.; Kader, M.A. Hybrid composites for automotive applications—A review. J. Reinf. Plast. Compos. 2019, 38, 835–845. [Google Scholar] [CrossRef]

- Naqvi, S.R.; Prabhakara, H.M.; Bramer, E.A.; Dierkes, W.; Akkerman, R.; Brem, G. A critical review on recycling of end-of-life carbon fibre/glass fibre reinforced composites waste using pyrolysis towards a circular economy. Resour. Conserv. Recycl. 2018, 136, 118–129. [Google Scholar] [CrossRef]

- Bakis, C.E.; Bank, L.C.; Brown, V.L.; Cosenza, E.; Davalos, J.; Lesko, J.; Machida, A.; Rizkalla, S.; Triantafillou, T. Fiber-reinforced polymer composites for construction: State-of-the-art review. J. Compos. Constr. 2002, 6, 73–87. [Google Scholar] [CrossRef]

- Yoshitake, I.; Tsuda, H.; Itose, J.; Hisabe, N. Effect of discrepancy in thermal expansion coefficients of CFRP and steel under cold temperature. Constr. Build. Mater. 2014, 59, 17–24. [Google Scholar] [CrossRef]

- Arrabiyeh, P.A.; May, D.; Eckrich, M.; Dlugaj, A.M. An overview on current manufacturing technologies: Processing continuous rovings impregnated with thermoset resin. Polym. Compos. 2021, 42, 5630–5655. [Google Scholar] [CrossRef]

- Bodea, S.; Mindermann, P.; Gresser, G.T.; Menges, A. Additive Manufacturing of Large Coreless Filament Wound Composite Elements for Building Construction. 3D Print. Addit. Manuf. 2021. [Google Scholar] [CrossRef]

- Gil Pérez, M.; Rongen, B.; Koslowski, V.; Knippers, J. Structural design, optimization and detailing of the BUGA fibre pavilion. Int. J. Space Struct. 2020, 35, 147–159. [Google Scholar] [CrossRef]

- Mindermann, P.; Rongen, B.; Gubetini, D.; Knippers, J.; Gresser, G.T. Material Monitoring of a Composite Dome Pavilion Made by Robotic Coreless Filament Winding. Materials 2021, 14, 5509. [Google Scholar] [CrossRef]

- Mindermann, P.; Gresser, G.T. Adaptive Winding Pin and Hooking Capacity Model for Coreless Filament Winding. J. Reinf. Plast. Compos. 2022. [Google Scholar] [CrossRef]

- La Magna, R.; Waimer, F.; Knippers, J. Coreless Winding and Assembled Core—Novel fabrication approaches for FRP based components in building construction. Constr. Build. Mater. 2016, 127, 1009–1016. [Google Scholar] [CrossRef]

- Gil Pérez, M.; Rongen, B.; Koslowski, V.; Knippers, J. Structural design assisted by testing for modular coreless filament-wound composites: The BUGA Fibre Pavilion. Constr. Build. Mater. 2021, 301, 124303. [Google Scholar] [CrossRef]

- Duque Estrada, R.; Kannenberg, F.; Wagner, H.J.; Yablonina, M.; Menges, A. Spatial winding: Cooperative heterogeneous multi-robot system for fibrous structures. Constr. Robot. 2020, 4, 205–215. [Google Scholar] [CrossRef]

- Mindermann, P.; Müllner, R.; Dieringer, E.; Ocker, C.; Klink, R.; Merkel, M.; Gresser, G.T. Design of Fiber-Composite/Metal–Hybrid Structures Made by Multi-Stage Coreless Filament Winding. Appl. Sci. 2022, 12, 2296. [Google Scholar] [CrossRef]

- Guo, Y.; Gil Pérez, M.; Serhat, G.; Knippers, J. A design methodology for fiber layup optimization of filament wound structural components. Structures 2022, 38, 1125–1136. [Google Scholar] [CrossRef]

- Gil Pérez, M.; Früh, N.; La Magna, R.; Knippers, J. Integrative structural design of a timber-fibre hybrid building system fabricated through coreless filament winding: Maison Fibre. J. Build. Eng. 2022, 49, 104114. [Google Scholar] [CrossRef]

- Bodea, S.; Zechmeister, C.; Dambrosio, N.; Dörstelmann, M.; Menges, A. Robotic coreless filament winding for hyperboloid tubular composite components in construction. Autom. Constr. 2021, 126, 103649. [Google Scholar] [CrossRef]

- Sorrentino, L.; Anamateros, E.; Bellini, C.; Carrino, L.; Corcione, G.; Leone, A.; Paris, G. Robotic filament winding: An innovative technology to manufacture complex shape structural parts. Compos. Struct. 2019, 220, 699–707. [Google Scholar] [CrossRef]

- Minsch, N.; Müller, M.; Gereke, T.; Nocke, A.; Cherif, C. 3D truss structures with coreless 3D filament winding technology. J. Compos. Mater. 2019, 53, 2077–2089. [Google Scholar] [CrossRef]

- United Nations. World Urbanization Prospects: The 2014 Revision; United Nations – Department of Economic and Social Affairs – Population Division: New York, NY, USA, 2014. [Google Scholar]

- Song, Y.S.; Youn, J.R.; Gutowski, T.G. Life cycle energy analysis of fiber-reinforced composites. Compos. A Appl. Sci. Manuf. 2009, 40, 1257–1265. [Google Scholar] [CrossRef]

- Zhang, L.; Balangé, L.; Braun, K.; Di Bari, R.; Horn, R.; Hos, D.; Kropp, C.; Leistner, P.; Schwieger, V. Quality as Driver for Sustainable Construction—Holistic Quality Model and Assessment. Sustainability 2020, 12, 7847. [Google Scholar] [CrossRef]

- Miao, M.; Finn, N. Conversion of natural fibres into structural composites. J. Text. Eng. 2008, 54, 165–177. [Google Scholar] [CrossRef]

- Gil Pérez, M.; Guo, Y.; Knippers, J. Integrative material and structural design methods for natural fibres filament-wound composite structures: The LivMatS Pavilion. Mater. Des. 2022, 217, 110624. [Google Scholar] [CrossRef]

- Mindermann, P.; Bodea, S.; Menges, A.; Gresser, G.T. Development of an Impregnation End-Effector with Fiber Tension Monitoring for Robotic Coreless Filament Winding. Processes 2021, 9, 806. [Google Scholar] [CrossRef]

- Polini, W.; Sorrentino, L. Influence of winding speed and winding trajectory on tension in robotized filament winding of full section parts. Compos. Sci. Technol. 2005, 65, 1574–1581. [Google Scholar] [CrossRef]

- Haas, J.; Hassan, O.N.; Beck, B.; Kärger, L.; Henning, F. Systematic approach for finite element analysis of thermoplastic impregnated 3D filament winding structures—General concept and first validation results. Compos. Struct. 2021, 268, 113964. [Google Scholar] [CrossRef]

- Strauß, S.; Senz, A.; Ellinger, J. Comparison of the Processing of Epoxy Resins in Pultrusion with Open Bath Impregnation and Closed-Injection Pultrusion. J. Compos. Sci. 2019, 3, 87. [Google Scholar] [CrossRef]

- Mindermann, P.; Gresser, G.T. Robotic 3D Deposition of Impregnated Carbon Rovings with Gradient Properties for Primary Structures. In Proceedings of the 69th International Astronautical Congress, Bremen, Germany, 1–5 October 2018. [Google Scholar]

- Yan, L.; Chouw, N.; Jayaraman, K. Flax fibre and its composites—A review. Compos. B Eng. 2014, 56, 296–317. [Google Scholar] [CrossRef]

- Scarponi, C.; Messano, M. Comparative evaluation between E-Glass and hemp fiber composites application in rotorcraft interiors. Compos. B Eng. 2015, 69, 542–549. [Google Scholar] [CrossRef]

- Xu, X.; Jayaraman, K.; Morin, C.; Pecqueux, N. Life cycle assessment of wood-fibre-reinforced polypropylene composites. J. Mater. Process. Technol. 2008, 198, 168–177. [Google Scholar] [CrossRef]

- International Organization for Standardization. Environmental Management—Life Cycle Assessment—Principles and Framework ISO 14040; ISO: London, UK, 2006; p. 157. [Google Scholar]

- Popescu, C.; Wortmann, F.-J. Wool–structure, mechanical properties and technical products based on animal fibres. In Industrial Applications of Natural Fibres: Structure, Properties and Technical Applications, 1st ed.; Stevens, C.V., Müssig, J., Eds.; Wiley Online Library: New York, NY, USA, 2010; Volume 10, p. 255. [Google Scholar] [CrossRef]

- Stiller, H. Material Intensity of Advanced Composite Materials: Results of Asudy for the Verbundwerkstofflabor Bremen eV; Wuppertal Institut für Klima: Wuppertal, Germany, 1999. [Google Scholar]

- Bond, J.A.; Bolt, H.M. Review of The Toxicology of Styrene. CRC Crit. Rev. Toxicol. 1989, 19, 227–249. [Google Scholar] [CrossRef] [PubMed]

- Kogevinas, M.; Gwinn, W.M.; Kriebel, D.; Phillips, D.H.; Sim, M.; Bertke, S.J.; Calaf, G.M.; Colosio, C.; Fritz, J.M.; Fukushima, S.; et al. Carcinogenicity of quinoline, styrene, and styrene-7,8-oxide. Lancet Oncol. 2018, 19, 728–729. [Google Scholar] [CrossRef]

- Mushtaq, N.; Chen, G.; Sidra, L.R.; Fang, X. Organosoluble and high T g polyimides from asymmetric diamines containing N-amino and N-aminophenyl naphthalimide moieties. RSC Adv. 2016, 6, 25302–25310. [Google Scholar] [CrossRef]

- Dąbrowska, A. Plant-Oil-Based Fibre Composites for Boat Hulls. Materials 2022, 15, 1699. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Tabil, L.G.; Panigrahi, S. Chemical treatments of natural fiber for use in natural fiber-reinforced composites: A review. J. Polym. Environ. 2007, 15, 25–33. [Google Scholar] [CrossRef]

- Satyanarayana, K.G.; Arizaga, G.G.C.; Wypych, F. Biodegradable composites based on lignocellulosic fibers—An overview. Prog. Polym. Sci. 2009, 34, 982–1021. [Google Scholar] [CrossRef]

- Davies, G.C.; Bruce, D.M. Effect of Environmental Relative Humidity and Damage on the Tensile Properties of Flax and Nettle Fibers. Text. Res. J. 1998, 68, 623–629. [Google Scholar] [CrossRef]

- Goutianos, S.; Peijs, T. The optimisation of flax fibre yarns for the development of high-performance natural fibre composites. Adv. Compos. Lett. 2003, 12, 096369350301200602. [Google Scholar] [CrossRef]

- Karuppannan Gopalraj, S.; Kärki, T. A review on the recycling of waste carbon fibre/glass fibre-reinforced composites: Fibre recovery, properties and life-cycle analysis. SN Appl. Sci. 2020, 2, 1–21. [Google Scholar] [CrossRef]

- Kessler, E.; Gadow, R.; Straub, J. Basalt, glass and carbon fibers and their fiber reinforced polymer composites under thermal and mechanical load. AIMS Mater. Sci. 2016, 3, 1561–1576. [Google Scholar] [CrossRef]

- Dittenber, D.B.; GangaRao, H.V. Critical review of recent publications on use of natural composites in infrastructure. Compos. A Appl. Sci. Manuf. 2012, 43, 1419–1429. [Google Scholar] [CrossRef]

- Charlet, K.; Jernot, J.-P.; Breard, J.; Gomina, M. Scattering of morphological and mechanical properties of flax fibres. Ind. Crops Prod. 2010, 32, 220–224. [Google Scholar] [CrossRef]

- Dambrosio, N.; Zechmeister, C.; Bodea, S.; Koslowski, V.; Gil Pérez, M.; Rongen, B.; Knippers, J.; Menges, A. Buga Fibre Pavilion: Towards an architectural application of novel fiber composite building systems. In Proceedings of the Acadia 2019: Ubiquity and Autonomy, 39th Annual Conference of the Association for Computer Aided Design in Architecture, Austin, TX, USA, 24–26 October 2019; pp. 140–149. [Google Scholar]

- Gil Pérez, M.; Dambrosio, N.; Rongen, B.; Menges, A.; Knippers, J. Structural optimization of coreless filament wound components connection system through orientation of anchor points in the winding frames. In Proceedings of the IASS Annual Symposia 2019: Form and Force, 7–10 October 2019. [Google Scholar]

- DIN EN ISO 14125:2011-05. Fibre-Reinforced Plastic Composites—Determination of Flexural Properties (ISO 14125:1998 + Cor.1:2001 + Amd.1:2011); German Version EN ISO 14125:1998 + AC:2002 + A1:2011. Available online: https://www.beuth.de/en/standard/din-en-iso-14125/139335738 (accessed on 8 March 2022).

- DIN 16459:2021-06. Determination of the Fiber Volume Content (FVG) of Fiber-Reinforced Plastics Using Thermogravimetric Analysis (TGA). Available online: https://www.beuth.de/de/norm/din-16459/336402982 (accessed on 20 March 2022).

- Mindermann, P.; Witt, M.-U.; Gresser, G.T. Pultrusion-winding: A novel fabrication method for coreless wound fiber-reinforced thermoset composites with distinct cross-section. Compos. A Appl. Sci. Manuf. 2022, 154, 106763. [Google Scholar] [CrossRef]

- Harris, B. Engineering Composite Materials; IoM: London, UK, 1999. [Google Scholar]

- Ausheyks, L.; Baz, S.; Dinkelmann, A.; Finckh, H.; Gresser, G.T.; Hehl, J.; Reichert, O.; Rimmel, O.; Schmidt, T.; May, D.; et al. Recycling of Long Carbon Fibers. Kunstst. Int. 2018, 14, 44–48. [Google Scholar]

- Howarth, J.; Mareddy, S.S.; Mativenga, P.T. Energy intensity and environmental analysis of mechanical recycling of carbon fibre composite. J. Clean. Prod. 2014, 81, 46–50. [Google Scholar] [CrossRef]

- Gil Pérez, M.; Zechmeister, C.; Kannenberg, F.; Mindermann, P.; Balangé, L.; Guo, Y.; Hügle, S.; Gienger, A.; Forster, D.; Bischoff, M.; et al. Computational co-design framework for coreless wound fibre–polymer composite structures. J. Comput. Des. Eng. 2022, 9, 310–329. [Google Scholar] [CrossRef]

- Mohit, H.; Selvan, V.A.M. A comprehensive review on surface modification, structure interface and bonding mechanism of plant cellulose fiber reinforced polymer based composites. Compos. Interfaces 2018, 25, 629–667. [Google Scholar] [CrossRef]

- Khan, T.; Sultan, M.T.B.H.; Ariffin, A.H. The challenges of natural fiber in manufacturing, material selection, and technology application: A review. J. Reinf. Plast. Compos. 2018, 37, 770–779. [Google Scholar] [CrossRef]

- Sahu, P.; Gupta, M. A review on the properties of natural fibres and its bio-composites: Effect of alkali treatment. Proc. Inst. Mech. Eng. L 2020, 234, 198–217. [Google Scholar] [CrossRef]

- Scherübl, B.R. The Realization of Natural Fibre-Reinforced Plastics in the Automotive Exteriors. Available online: http://eiha.org/media/attach/129/abaca.pdf (accessed on 23 March 2022).

- Peças, P.; Carvalho, H.; Salman, H.; Leite, M. Natural Fibre Composites and Their Applications: A Review. J. Compos. Sci. 2018, 2, 66. [Google Scholar] [CrossRef]

- MatWeb. Overview of Materials for Acrylic, Cast. Available online: https://www.matweb.com/search/datasheet.aspx?bassnum=o1303&ckck=1 (accessed on 23 March 2022).

- Ecosystem Studies, Cary Institute of. The Fabric for Our Lives. Which Fabric Is Best for Nature. Available online: https://www.caryinstitute.org/news-insights/blog-translational-ecology/fabric-our-lives (accessed on 3 March 2022).

- Rana, S.; Pichandi, S.; Karunamoorthy, S.; Bhattacharyya, A.; Parveen, S.; Fangueiro, R. Carbon footprint of textile and clothing products. In Handbook of Sustainable Apparel Production, 1st ed.; Muthu, S.S., Ed.; CRC Press: Boca Raton, FL, USA, 2015; Volume 1, pp. 141–166. [Google Scholar]

- Teijin Aramid, B.V. Product Brochure Twaron. Available online: https://www.teijinaramid.com/wp-content/uploads/2018/10/product_brochure_twaron.pdf (accessed on 23 March 2022).

- Knippers, J.; Cremers, J.; Gabler, M.; Lienhard, J. Construction Manual for Polymers + Membranes: Materials, Semi-Finished Products, form Finding, Design; Walter de Gruyter: Berlin, Germany, 2012. [Google Scholar] [CrossRef]

- Teijin Aramid, B.V. Datasheet—Twaron—Aramids by Teijin. Available online: https://www.teijinaramid.com/mooring-lines/d3c31495745a8bcd31b28f9ac5ae23a0.pdf (accessed on 2 March 2022).

- Institut für angewandte Forschung im Bauwesen. e.V. Merkblatt—Hochleistungsholztragwerke—Textile Fasern zum Einsatz im Bauwesen—Aramidfasern. Available online: http://iafb.de/fileadmin/static/forschungsprojekte/hochleistungsholztragwerke/merkblaetter/material/4-02_merkblatt_material_fasern-aramid.pdf (accessed on 3 March 2022).

- Thomas, S.; Abraham, J.; Manayan Parambil, A.; Krishnan, A.; Maria, H.J.; Ilschner, B.; Lees, J.K.; Dhingra, A.K.; McCullough, R.L. Composite Materials. In Ullmann’s Encyclopedia of Industrial Chemistry; John Wiley & Sons, Ltd: New York, NY, USA, 2016; pp. 1–44. [Google Scholar] [CrossRef]

- Teijin Aramid, B.V. Product Brochure Endumax LR. Available online: https://www.teijinaramid.com/wp-content/uploads/2018/12/18033tei-prod-broch-endumax_lr.pdf (accessed on 23 March 2022).

- Teijin, B.V. Datasheet Twaron 1000—Aramid Yarn. Available online: https://eurofibers.com/wp-content/uploads/2019/04/datasheet-twaron-1000-flat-yarn.pdf (accessed on 23 March 2022).

- Ansell, M. Natural Fibre Composites & Their Role in Engineering. Available online: https://people.bath.ac.uk/mssmpa/index/PAPERS%20&%20PRESENTATIONS/Ansell%20natural%20fibres%20BRE%20Sept%2011.pdf (accessed on 6 March 2022).

- Teijin Aramid, B.V. Twaron—Eco-Datasheet Filament Yarn and Pulp. Available online: https://www.teijinaramid.com/wp-content/uploads/2021/07/twaron_eco-datasheet_update_july2021.pdf (accessed on 2 March 2022).

- Hill, C.; Norton, A.; European Comission. LCA Database of Environmental Impacts to Inform Material Selection Process. Available online: https://ec.europa.eu/research/participants/documents/downloadpublic?documentids=080166e5c240650f&appid=ppgms (accessed on 6 March 2022).

- Vogtlander, J.; Van der Lugt, P. The Environmental Impact of Industrial Bamboo Products: Life-Cycle Assessment and Carbon Sequestration, INBAR Technical Report; The International Network for Bamboo and Rattan: Beijing, China, 2015; Volume 35. [Google Scholar] [CrossRef]

- Laleicke, P.F.; Cimino-Hurt, A.; Gardner, D.; Sinha, A. Comparative carbon footprint analysis of bamboo and steel scaffolding. J. Green Build. 2015, 10, 114–126. [Google Scholar] [CrossRef]

- Adsal, K.A.; Üçtug, F.G.; Arikan, O.A. Environmental life cycle assessment of utilizing stem waste for banana production in greenhouses in Turkey. Sustain. Prod. Consum. 2020, 22, 110–125. [Google Scholar] [CrossRef]

- Fort, J.; Kocí, J.; Cern, R. Environmental Efficiency Aspects of Basalt Fibers Reinforcement in Concrete Mixtures. Energies 2021, 14, 7736. [Google Scholar] [CrossRef]

- Inman, M.; Thorhallsson, E.R.; Azrague, K. A mechanical and environmental assessment and comparison of basalt fibre reinforced polymer (BFRP) rebar and steel rebar in concrete beams. Energy Procedia 2017, 111, 31–40. [Google Scholar] [CrossRef]

- Czigány, T. Basalt fiber reinforced hybrid polymer composites. In Proceedings of the Materials Science Forum 473–474, Balaton lakeside at Balatonfüred, Hungary, 12–14 October 2003; pp. 59–66. [Google Scholar] [CrossRef]

- Isomatex, S.A. Filava—Product Information and Technical Datasheet—Direct Roving SE/ME DR. Available online: https://www.isomatex.com/page/direct-roving-link.html (accessed on 23 March 2022).

- JEC Composites Magazine. Kamenny Vek: The Russian Basalt-Fibre Specialist. Available online: https://basfiber.com/system/storage/download/jec_magazine_no51_september_2009.pdf (accessed on 23 March 2022).

- MatWeb. Mafic Assembled Basalt Roving 2000 to 3500 Tex. Available online: https://www.matweb.com/search/datasheet.aspx?matguid=c651e59ea1e7429597911888a2fb2a5d (accessed on 23 March 2022).

- Azrague, K.; Rose Inman, M.; Alnæs, L.-I.; Schlanbusch, R.D.; Jóhannesson, B.; Sigfusson, T.I.; Thorhallsson, E.R.; Franzson, H.; Arnason, A.B.; Vares, S. Life Cycle Assessment as a tool for resource optimisation of continuous basalt fibre production in Iceland. In Proceedings of the Engineering Conferences International (ECI) Life Cycle Assessment and Other Assessment Tools for Waste Management and Resource Optimization, 6–11 June 2016. [Google Scholar]

- Joyce, P. PAX Short Course Fibers. Available online: https://www.usna.edu/users/mecheng/pjoyce/composites/short_course_2003/2_pax_short_course_fibers.pdf (accessed on 26 March 2022).

- Bunsell, A.R. High-performance Fibers. In Encyclopedia of Materials: Science and Technology; Buschow, K.H.J., Cahn, R.W., Flemings, M.C., Ilschner, B., Kramer, E.J., Mahajan, S., Veyssière, P., Eds.; Elsevier: Oxford, UK, 2005; pp. 1–10. [Google Scholar] [CrossRef]

- Hunkeler, D.; Saur, K.; Stranddorf, H.; Rebitzer, G.; Schmidt, W.; Jensen, A.A.; Christiansen, K. Life Cycle Management; SETAC Press: Pensacola, FL, USA, 2004. [Google Scholar]

- Christensen, R.M. Mechanics of Composite Materials; Courier Corporation: North Chelmsford, MA, USA, 2012; p. 31. [Google Scholar]

- Specialty Materials. Boron Fiber Product Price List 2022. Available online: https://www.specmaterials.com/boron-fiber-product-2022 (accessed on 26 March 2022).

- Teijin Carbon Europe GmbH. Product Data Sheet (EU)—Tenax Filament Yarn. Available online: https://www.teijincarbon.com/fileadmin/pdf/datenbl%c3%a4tter_en/product_data_sheet_tsg01en__eu_filament_.pdf (accessed on 6 March 2022).

- Mitsubishi Chemical Corporation. Data Sheet—Carbon Fiber Tow Continuous Fiber. Available online: https://www.m-chemical.co.jp/carbon-fiber/pdf/tow/carbon%20fiber%20tow%20(continuous%20fiber)%2020210930.pdf (accessed on 6 March 2022).

- Rana, S.; Fangueiro, R. Fibrous and Textile Materials for Composite Applications; Springer: Berlin, Germany, 2016. [Google Scholar] [CrossRef]

- Ai, L.; Su, J.; Wang, M.; Jiang, J. Bamboo-structured nitrogen-doped carbon nanotube coencapsulating cobalt and molybdenum carbide nanoparticles: An efficient bifunctional electrocatalyst for overall water splitting. ACS Sustain. Chem. Eng. 2018, 6, 9912–9920. [Google Scholar] [CrossRef]

- Das, S. Life cycle assessment of carbon fiber-reinforced polymer composites. Int. J. Life Cycle Assess. 2011, 16, 268–282. [Google Scholar] [CrossRef]

- Endo, M. Carbon fiber. In High-Performance and Specialty Fibers; Springer: Berlin, Germany, 2016; pp. 327–342. [Google Scholar]

- Schade, W.; Mader, S.; Lembke, M. Analysis of the light weight fiber reinforced plastics value chain with regard to the German industry in its global context. In M-Five Working Paper on Behalf of the ECF and Cambridge Econometrics; M-Five GmbH: Karlsruhe, Germany, 2017. [Google Scholar]

- Quintana, A.; Alba, J.; del Rey, R.; Guillén-Guillamón, I. Comparative Life Cycle Assessment of gypsum plasterboard and a new kind of bio-based epoxy composite containing different natural fibers. J. Clean. Prod. 2018, 185, 408–420. [Google Scholar] [CrossRef]

- Biodegradable; Compostable Pots. Coconut Fiber Price, Palm Fiber Price & Kenaf Fiber Price. Available online: https://biodegradable-pots.com/coconut-mat-price/ (accessed on 26 March 2022).

- Scarponi, C.; Andreotti, C. Industrial applications of natural fibres advanced composites: Environmental effects and comparative Life Cycle Analysis. Int. J. Mater. Prod. Technol. 2009, 36, 241–260. [Google Scholar] [CrossRef]

- La Rosa, A.D.; Grammatikos, S.A. Comparative Life Cycle Assessment of Cotton and Other Natural Fibers for Textile Applications. Fibers 2019, 7, 101. [Google Scholar] [CrossRef]

- Oksman, K. High quality flax fibre composites manufactured by the resin transfer moulding process. J. Reinf. Plast. Compos. 2001, 20, 621–627. [Google Scholar] [CrossRef]

- Kyono, T. Life Cycle Assessment of Carbon Fiber-Reinforced Plastic. In High-Performance and Specialty Fibers: Concepts, Technology and Modern Applications of Man-Made Fibers for the Future; Fiber Science, T.S., Techno, J., Eds.; Springer: Tokyo, Japan, 2016; pp. 355–361. [Google Scholar] [CrossRef]

- Joshi, S.V.; Drzal, L.; Mohanty, A.; Arora, S. Are natural fiber composites environmentally superior to glass fiber reinforced composites? Compos.-A Appl. Sci. Manuf. 2004, 35, 371–376. [Google Scholar] [CrossRef]

- Dissanayake, N.P.; Summerscales, J.; Grove, S.; Singh, M. Energy use in the production of flax fiber for the reinforcement of composites. J. Nat. Fibers 2009, 6, 331–346. [Google Scholar] [CrossRef]

- Tchana Toffe, G.; Oluwarotimi Ismail, S.; Montalvão, D.; Knight, J.; Ren, G. A Scale-up of Energy-Cycle Analysis on Processing Non-Woven Flax/PLA Tape and Triaxial Glass Fibre Fabric for Composites. J. Manuf. Mater. Process. 2019, 3, 92. [Google Scholar] [CrossRef]

- La Rosa, A.D.; Recca, G.; Summerscales, J.; Latteri, A.; Cozzo, G.; Cicala, G. Bio-based versus traditional polymer composites. A life cycle assessment perspective. J. Clean. Prod. 2014, 74, 135–144. [Google Scholar] [CrossRef]

- Wallenberger, F.T.; Watson, J.C.; Li, H.; PPG Industries, Inc. Glass Fibers. Available online: https://www.asminternational.org/documents/10192/1849770/06781g_p27-34.pdf (accessed on 26 March 2022).

- MatWeb. E-Glass Fiber, Generic. Available online: https://www.matweb.com/search/datasheet.aspx?matguid=d9c18047c49147a2a7c0b0bb1743e812&ckck=1 (accessed on 26 March 2022).

- materials, AGY: Strength in. Technical Product Guide. Available online: https://www.agy.com/wp-content/uploads/2014/03/agy_technical_product_guide-revised.pdf (accessed on 26 March 2022).

- Design Life-Cycle. Corning Gorilla Glass. Available online: http://www.designlife-cycle.com/corning-gorilla-glass (accessed on 26 March 2022).

- Howarth, J. Comparison of Performance, Cost-Effectiveness and Sustainability. In Fibrous and Textile Materials for Composite Applications; Rana, S., Fangueiro, R., Eds.; Springer: Singapore, 2016; pp. 375–394. [Google Scholar] [CrossRef]

- Ramesh, M.; Deepa, C.; Kumar, L.R.; Sanjay, M.; Siengchin, S. Life-cycle and environmental impact assessments on processing of plant fibres and its bio-composites: A critical review. J. Ind. Text. 2020, 1528083720924730. [Google Scholar] [CrossRef]

- Abdullah, N.; Jamiluddin, J.; Hagos, F.; Azmi, N. Experimental investigation on pineapple leaf fiber as biomass source for renewable energy application. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Kuantan, Malaysia, 30–31 July 2019; Volume 788, p. 012059. [Google Scholar] [CrossRef]

- Salsabila, P.R.; Boonraksa, A.; Indriani, I.; Ilma, S.; Sakina, B.R. Cradle-to-Gate Life Cycle Assessment of Pineapple Leaf Fibres. In Proceedings of the ICON ARCCADE 2021: The 2nd International Conference on Art, Craft, Culture and Design (ICON-ARCCADE 2021), Bandung, Indonesia, 29–30 September 2021. [Google Scholar]

- Sarwar, M.I.; Zulfiqar, S.; Ahmad, Z. Polyamide–silica nanocomposites: Mechanical, morphological and thermomechanical investigations. Polym. Int. 2008, 57, 292–296. [Google Scholar] [CrossRef]

- Vendrely, C.; Scheibel, T. Biotechnological production of spider-silk proteins enables new applications. Macromol. Biosci. 2007, 7, 401–409. [Google Scholar] [CrossRef]

- Open CO2.net. Emission Factor Data: Nylon (Clothing Fabric Production). Available online: https://www.openco2.net/en/emission-factors/product/nylon-clothing-fabric-production/181 (accessed on 6 March 2022).

- plasticker. Real Time Price List. Available online: https://plasticker.de/preise/pms_en.php?kat=mahlgut&aog=a&show=ok&make=ok (accessed on 26 March 2022).

- Open CO2.net. Emission Factor Data: Polyester (Clothing Fabric Production). Available online: https://www.openco2.net/en/emission-factors/product/polyester-clothing-fabric-production/156 (accessed on 6 March 2022).

- Geneseo. Density of Spider Silk. Available online: https://www.geneseo.edu/nuclear/density-spider-silk (accessed on 26 March 2022).

- Lepore, E.; Bosia, F.; Bonaccorso, F.; Bruna, M.; Taioli, S.; Garberoglio, G.; Ferrari, A.C.; Pugno, N.M. Spider silk reinforced by graphene or carbon nanotubes. 2D Mater. 2017, 4, 031013. [Google Scholar] [CrossRef]

- Blamires, S.J.; Liao, C.-P.; Chang, C.-K.; Chuang, Y.-C.; Wu, C.-L.; Blackledge, T.A.; Sheu, H.-S.; Tso, I.-M. Mechanical performance of spider silk is robust to nutrient-mediated changes in protein composition. Biomacromolecules 2015, 16, 1218–1225. [Google Scholar] [CrossRef]

- SA, PX Preciment. 1.4404—X 2 CrNiMo 17 12 2. Available online: https://pxgroup.com/sites/default/files/316l1.4404.pdf (accessed on 26 March 2022).

- Metalcor GmbH. Datasheet AISI 316 L). Available online: https://www.metalcor.de/en/datenblatt-pdf/12 (accessed on 6 March 2022).

- Albrecht, K.; Osswald, T.; Wartzack, S.; Muessig, J. Natural Fibre-Reinforced, Injection Moulded Polymers For Light Weight constructions–Simulation Of Sustainable Materials For The Automotive Industry. In Proceedings of the 20th International Conference on Engineering Design (ICED 15) Vol 4: Design for X, Design to X, Milan, Italy, 27–30 July 2015; Volume 15, pp. 313–322. [Google Scholar]

- Norgate, T.; Jahanshahi, S.; Rankin, W. Alternative routes to stainless steel—A life cycle approach. In Proceedings of the Tenth International Ferroalloys Congress, Cape Town, South Africa, 1–4 February 2004. [Google Scholar]

- Informationsblatt CO_2—Faktoren. Available online: https://www.bafa.de/shareddocs/downloads/de/energie/eew_infoblatt_co2_faktoren_2021.pdf?__blob=publicationfile&v=5 (accessed on 26 March 2022).

- Cordenka Rayon GmbH, Co. Technical Data Sheet Multifilament Yarn. Available online: https://a.storyblok.com/f/121148/x/98563c2da4/tds_rayon-multifilament-yarn.pdf (accessed on 6 March 2022).

- Erdmann, J.; Ganster, J.; Fink, H.-P. PLA meets Rayon: Tough PLA compounds reinforced with cellulose rayon for injection moulding. Bioplast. Magaz. 2012, 7, 22–25. [Google Scholar]

- Asanovic, K.A.; Kostic, M.M.; Mihailovic, T.V.; Cerovic, D.D. Compression and strength behaviour of viscose/polypropylene nonwoven fabrics. Indian J. Fibre Text. Res. 2019, 44, 329–337. [Google Scholar]

- Müller, B. Green Dipping Technologies—A Case Study How Regulatory Constraints Influence Innovation and Its Application. Available online: https://www.researchgate.net/profile/bernhard-mueller-7/publication/308398053_green_dipping_technologies_-_a_case_study/links/57e2a6da08aecd0198dd7e72/green-dipping-technologies-a-case-study.pdf (accessed on 6 March 2022).

- Open CO2.net. Emission Factor Data: Viscose/Rayon (Clothing Fabric Production). Available online: https://www.openco2.net/en/emission-factors/product/viscose-rayon-clothing-fabric-production/129 (accessed on 6 March 2022).

- Yükseloglu, S.M.; Çaliskan, M. Mechanical and thermal properties of wool waste fabric reinforced composites. Tekst 2015, 22, 97. [Google Scholar] [CrossRef]

- Open CO2.net. Emission Factor data: Wool Yarn, Production). Available online: https://www.openco2.net/en/emission-factors/product/wool-yarn-production/1744 (accessed on 6 March 2022).

- Huelsbusch, D.; Mueller, Y.; Barandun, G.A.; Niedermeier, M.; Walther, F. Mechanical properties of GFR-polyurethane and-epoxy for impact-resistant applications under service-relevant temperatures. In Proceedings of the ECCM17—17th European Conference on Composite Materials, Munich, Germany, 26–30 June 2016. [Google Scholar]

- Chard, J.M.; Basson, L.; Creech, G.; Jesson, D.A.; Smith, P.A. Shades of green: Life cycle assessment of a urethane methacrylate/unsaturated polyester resin system for composite materials. Sustainability 2019, 11, 1001. [Google Scholar] [CrossRef]

- Bio-Composites & More GmbH. PTP Resins. Available online: https://bio-composites.eu/ptp/ (accessed on 6 March 2022).

- Sicomin. Technical Datasheet: SR GreenPoxy 33/SZ 8525. Available online: http://sicomin.com/datasheets/product-pdf1165.pdf (accessed on 23 March 2022).

- Yeh, M.-K.; Tai, N.-H.; Lin, Y.-J. Mechanical properties of phenolic-based nanocomposites reinforced by multi-walled carbon nanotubes and carbon fibers. Compos.-A Appl. Sci. Manuf. 2008, 39, 677–684. [Google Scholar] [CrossRef]

- KEITI: Korea Environmental Industry & Technology Institute. Raw Materials and Energy. Available online: http://www.epd.or.kr/eng/lci/lcico200.do (accessed on 26 March 2022).

- Kumara, N.S.; Kumarb, G.; Kumarc, C.; Prabhud, M. Experimental investigation on mechanical behavior of E-glass and S-glass fiber reinforced with polyester resin. Int. J. Mech. Eng. 2018, 5, 19–26. [Google Scholar] [CrossRef]

- Matsumoto, T.; Mikami, D.; Hashimoto, T.; Kaise, M.; Takahashi, R.; Kawabata, S. Alicyclic polyimides—A colorless and thermally stable polymer for opto-electronic devices. J. Phys. Conf. Ser. 2009, 187, 012005. [Google Scholar] [CrossRef]

- Nijssen, J.P.A.; Faludi, J.; Ostayen, R.A.J. van. An eco-impact design metric for water lubricated bearings based on anticipatory Life Cycle Assessment. J. Clean. Prod. 2021, 321, 128874. [Google Scholar] [CrossRef]

- Yu, S.; Li, X.; Zhao, Y.; Zou, M. A Novel Lightweight Polyurethane Composite for Application on Ultra-High-Voltage Insulator Core Filler. Polymers 2020, 12, 2737. [Google Scholar] [CrossRef]

| Fiber Material | Origin | Density | Tensile Modulus | Tensile Strength | Elong. at Break | Embodied Energy | GWP | Price |

|---|---|---|---|---|---|---|---|---|

| – | – | g/cm3 | GPa | MPa | % | MJ/kg | kg CO2-eq./kg | EUR/kg |

| Abaca | leaf | 0.83–1.5 | 6.2–33.6 | 400–980 | 1–12 | – | 0.1–0.92 | €€ |

| Acryl | petrol. | 1.18–1.19 | 2.76–3.3 | 62–83 | 3–6.4 | 175–176.4 | 5–26 | €€€€ |

| Aramid | petrol. | 0.98–1.45 | 48–146 | 2120–3600 | 1.5–4.5 | 600–1651 | 8.7–104 | €€€€€€ |

| Bamboo | grass | 0.6–1.5 | 11–35.91 | 140–800 | 1.4–3.7 | – | 0.0515–3.05 | € |

| Banana | leaf | 0.8–1.35 | 8.5–32 | 144–800 | 1.5–30.6 | – | 0.45–1.04 | € |

| Basalt | mineral | 2.15–2.7 | 42–100 | 1790–3000 | 1.12–3.5 | 6.63–18 | 0.386–0.986 | €€€€ |

| Boron | mineral | 2.3–2.61 | 400–428 | 3600 | 1 | – | 17.78–43.92 | €€€€€€€ |

| Carbon | petrol. | 1.4–2.2 | 200–935 | 1800–6000 | 0.3–2.1 | 130–595 | 12.55–31 | €€€€€€ |

| Coconut | leaf | 1.15 | 2.3–18 | 46.4–500 | 2.84–5.5 | – | 0.3286 | € |

| Coir | fruit | 1.15–1.46 | 2.8–6 | 95–270 | 15–51.4 | 10 | – | € |

| Cotton | seed | 1.5–1.6 | 5.5–13 | 287–800 | 3–10 | 5.759–60 | 0.4341–8 | €€€ |

| Flax | bast | 1.4–1.5 | 27–110 | 343–2000 | 1.2–3.3 | 6.5–86 | 0.4375–0.9 | €€ |

| E-glass | mineral | 2.5–2.62 | 70–77 | 2000–3790 | 0.5–4.8 | 8.67–51.3 | 0.512–4.6 | €€€ |

| S-glass | mineral | 2.48–2.5 | 85–103 | 4480–4890 | 4.6–5.7 | 6.013–16 | 2.452–4.6 | €€€€ |

| Hemp | bast | 1.4–1.5 | 3–90 | 270–1100 | 1–4 | 8.89–50 | 0.531–3 | €€ |

| Jute | bast | 1.3–1.5 | 3–55 | 187–800 | 0.7–1.8 | 10–30 | 0.52–1.12 | € |

| Kenaf | bast | 1.22–1.45 | 4.3–60 | 223–1191 | 1.5–2.7 | 10 | 5.59 | € |

| Palm | leaf | 1.03 | 2.75 | 377 | 13.71 | – | – | € |

| Pineapple | leaf | 1.526 | 60–82 | 170–1627 | 2.4–3.2 | 16.93 | 4.43 | – |

| Polyamide | petrol. | 1.82 | 0.95 | 44 | 18 | 130–248.4 | 12.7–37 | €€ |

| Polyester | petrol. | 1.38 | 10 | 1100 | 22 | 125–126 | 2.8–19 | € |

| Ramie | bast | 1.0–1.55 | 24.5–128 | 220–1000 | 1.2–4.0 | 10 | 1 | €€ |

| Silk | animal | 1.097–1.34 | 0.5–10 | 519.1–1500 | 18–270 | 520–580 | 35 | €€€€€ |

| Sisal | leaf | 1.3–1.5 | 9–38 | 227–955 | 2–14 | 10 | 1 | € |

| Stainless steel | mineral | 7.68–8 | 200 | 500–1400 | 5 | 14–210 | 2.62–6.8 | €€ |

| Viscose | plant | 1.5–1.52 | 11–20 | 593–830 | 10.7–13 | 71–100.8 | 6.4–15 | €€€ |

| Wool | animal | 1.3 | 2–5 | 100–350 | 28–61 | 46.8 | 7–29.44 | €€€ |

| Resin Material | Origin | Density | Tensile Modulus | Tensile Strength | Elong. at Break | Embodied Energy | GWP | Price |

| – | – | g/cm3 | GPa | MPa | % | MJ/kg | kg CO2-eq./kg | EUR/kg |

| Epoxy | petrol. | 1.1–1.4 | 1.3–6 | 35–125 | 1–7.3 | 76–140.71 | 5.9–6.75 | €€€ |

| Epoxy | bio | 1.05–1.159 | 2–3.3 | 60–90 | 2.8–6.1 | 21.42–43.52 | 1.42–4.079 | €€€€ |

| Phenolics | petrol. | 1.2–2.0 | 0.56–11 | 20–60 | 1 | 130.34 | 1.34–4.61 | – |

| Polyester | petrol. | 1.2–1.5 | 2–4.5 | 40–90 | 2 | 63–128 | 3.79–7.6 | – |

| Polyimides | petrol. | 1.4 | 3–4 | 100–130 | 5–30 | 110–340 | 5.8–19.5 | – |

| Polyurethan | petrol. | 1.05 | 3.1 | 62.8 | 9.1 | 77.83–102.2 | 3.2–4.56 | – |

| ID | Fiber | Appearance | Avg. Fiber Length ** | Tensile Modulus | Tensile Strength | Density | Filaments/Fibers ** | Linear Density | Filament/ Fiber Diameter ** | Tear Length |

|---|---|---|---|---|---|---|---|---|---|---|

| – | – | – | mm | GPa | MPa | g/mm3 | – | tex | µm | km |

| C/C * | carbon | roving | – | 240 | 4300 | 1.78 | 24,000 | 1600 | 7 | 246 |

| G1 | E-glass | roving | – | 72.5 | 3450 | 2.62 | 1690 | 2400 | 24 | 134 |

| G2 | S-glass | roving | – | 86.9 | 4890 | 2.49 | 2570 | 406 | 9 | 201 |

| B1 | basalt | roving | – | 87.5 | 3000 | 2.60 | 4300 | 2540 | 17 | 118 |

| B2 | basalt | roving | – | 95 | 1790 | 2.60 | 9710 | 2400 | 11 | 70 |

| A | aramid | roving | – | 78 | 3045 | 1.45 | 1000 | 114 | 12 | 215 |

| S | steel | roving | – | 200 | 1293 | 8.00 | 4500 | 1920 | 8 | 16 |

| V | viscose | roving | – | 13.8 | 710 | 1.52 | 20,940 | 3600 | 12 | 48 |

| F1/F1 * | flax | tape | 4–900 | 55.1 | 875 | 1.45 | 12,810 | 2400 | 13 | 62 |

| F2 | flax | yarn | 4–900 | 68.3 | 658 | 1.45 | 10,410 | 2000 | 13 | 46 |

| H | hemp | crocheted card sliver | 5–140 | 46.5 | 690 | 0.86 | 2170 | 17,300 | 109 | 82 |

| J | jute | yarn | 0.8–120 | 29.0 | 493.5 | 1.46 | 1050 | 750 | 25 | 34 |

| Epoxy Resin Type | Density | Stiffness | Strength | Elong. at Break | Viscosity | TG | Pot Life | Embodied Energy | GWP |

|---|---|---|---|---|---|---|---|---|---|

| – | g/cm3 | GPa | MPa | % | mPa*s | °C | min | MJ/kg | kg CO2-eq./kg |

| petrol | 1.127 | 3.15 | 68 | 7 | 1975 | 106 | 420 | 76–139 | 6.66–6.75 |

| bio | 1.075 | 2.10 | 80 | 3 | 450 | 115 | ∞ | 21.42–43.52 | 1.42–2.85 |

| ID | Bundles | Height | Width | Length * | Mass | Vol. (geo.) | Vol. (arch.) |

|---|---|---|---|---|---|---|---|

| – | – | mm | mm | mm | g | cm3 | cm3 |

| C | 40 | 6.51 ± 0.07 | 15.57 ± 0.80 | 227 ± 6.05 | 25.89 ± 1.24 | 23.02 ± 1.25 | 20.48 ± 1.26 |

| C* | 40 | 6.61 ± 0.04 | 17.74 ± 0.87 | 234 ± 3.77 | 30.18 ± 1.93 | 27.48 ± 1.60 | 23.80 ± 1.16 |

| G1 | 32 | 6.47 ± 0.04 | 15.19 ± 0.65 | 224 ± 10.26 | 28.62 ± 1.61 | 21.97 ± 1.48 | 19.23 ± 1.13 |

| G2 | 152 | 6.53 ± 0.02 | 13.16 ± 2.01 | 253 ± 3.86 | 26.76 ± 4.28 | 21.58 ± 3.44 | 17.76 ± 2.83 |

| B1 | 36 | 6.62 ± 0.07 | 16.84 ± 0.92 | 250 ± 0.99 | 33.62 ± 1.88 | 27.88 ± 1.44 | 22.74 ± 1.15 |

| B2 | 36 | 6.62 ± 0.06 | 16.67 ± 0.64 | 242 ± 5.46 | 37.38 ± 3.64 | 26.64 ± 0.94 | 23.23 ± 1.36 |

| A | 300 | 6.51 ± 0.05 | 13.73 ± 0.52 | 251 ± 1.57 | 22.22 ± 0.77 | 22.43 ± 0.85 | 19.03 ± 0.54 |

| S | 46 | 6.47 ± 0.03 | 15.58 ± 0.59 | 250 ±1.97 | 40.88 ± 2.01 | 25.19 ± 0.96 | 21.46 ± 0.78 |

| V | 20 | 6.55 ± 0.06 | 18.49 ± 1.19 | 247 ± 4.30 | 29.61 ± 1.67 | 29.66 ± 2.14 | 25.66 ± 1.68 |

| F1 | 36 | 6.66 ± 0.12 | 17.13 ± 0.91 | 249 ± 0.63 | 26.62 ± 2.22 | 28.44 ± 1.78 | 24.59 ± 1.87 |

| F1* | 36 | 6.66 ± 0.03 | 17.13 ± 1.22 | 250 ± 1.10 | 26.62 ± 1.70 | 28.44 ± 2.10 | 24.59 ± 1.74 |

| F2 | 25 | 6.69 ± 0.14 | 18.74 ± 1.18 | 250 ± 1.73 | 28.27 ± 2.02 | 31.36 ± 2.11 | 25.24 ± 1.49 |

| H | 2 | 6.65 ± 0.06 | 16.82 ± 0.89 | 252 ± 2.29 | 24.99 ± 2.97 | 27.08 ± 3.24 | 23.87 ± 2.71 |

| J | 40 | 6.54 ± 0.07 | 16.25 ± 0.88 | 250 ± 1.52 | 23.79 ± 1.39 | 26.59 ± 1.41 | 22.94 ± 1.65 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mindermann, P.; Gil Pérez, M.; Knippers, J.; Gresser, G.T. Investigation of the Fabrication Suitability, Structural Performance, and Sustainability of Natural Fibers in Coreless Filament Winding. Materials 2022, 15, 3260. https://doi.org/10.3390/ma15093260

Mindermann P, Gil Pérez M, Knippers J, Gresser GT. Investigation of the Fabrication Suitability, Structural Performance, and Sustainability of Natural Fibers in Coreless Filament Winding. Materials. 2022; 15(9):3260. https://doi.org/10.3390/ma15093260

Chicago/Turabian StyleMindermann, Pascal, Marta Gil Pérez, Jan Knippers, and Götz T. Gresser. 2022. "Investigation of the Fabrication Suitability, Structural Performance, and Sustainability of Natural Fibers in Coreless Filament Winding" Materials 15, no. 9: 3260. https://doi.org/10.3390/ma15093260

APA StyleMindermann, P., Gil Pérez, M., Knippers, J., & Gresser, G. T. (2022). Investigation of the Fabrication Suitability, Structural Performance, and Sustainability of Natural Fibers in Coreless Filament Winding. Materials, 15(9), 3260. https://doi.org/10.3390/ma15093260