Three-Point Bending Properties of Hybrid Multi-Materials Using Adhesive Bonding Dependent on Strength Difference between Steel and Aluminum

Abstract

:1. Introduction

2. Materials and Methods

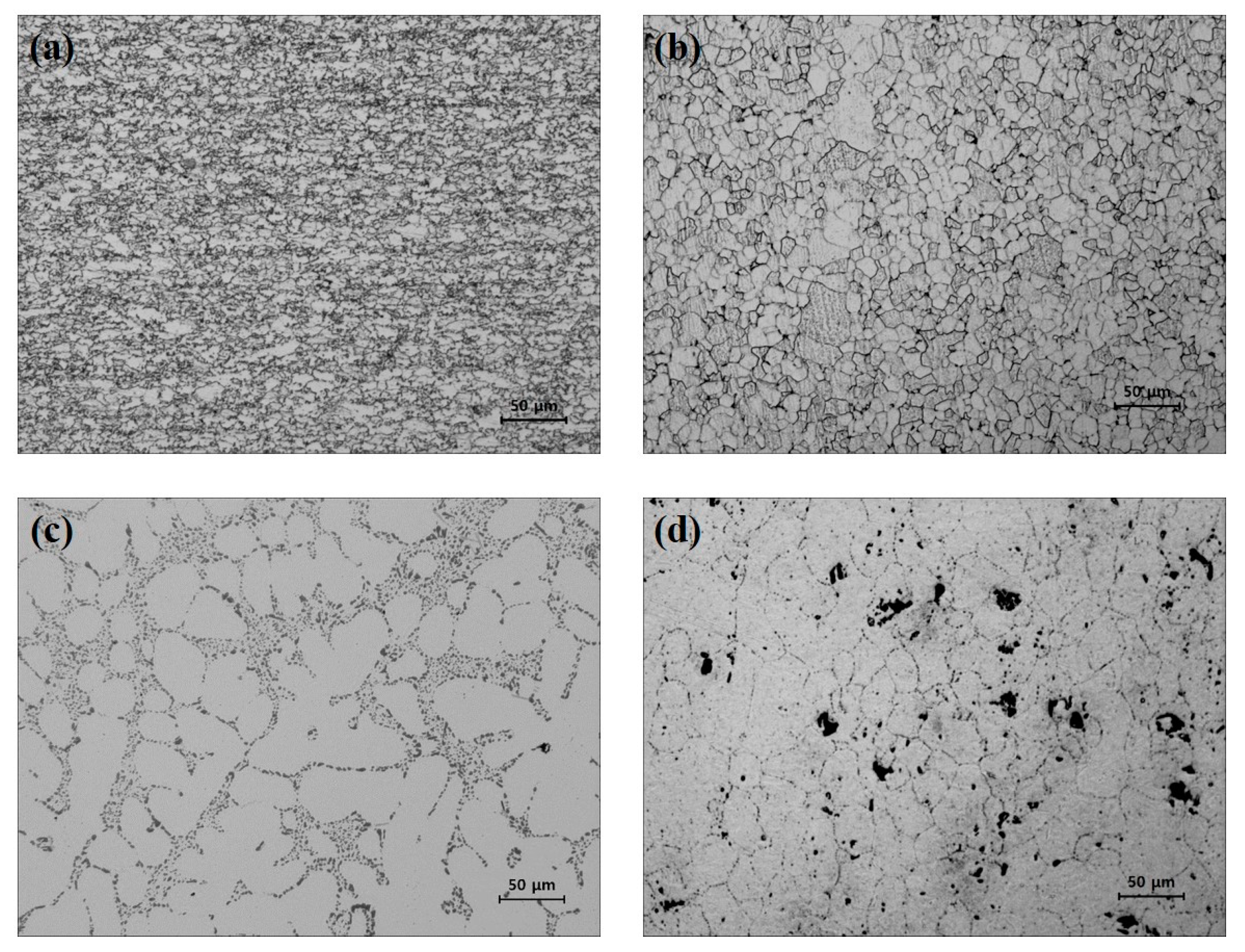

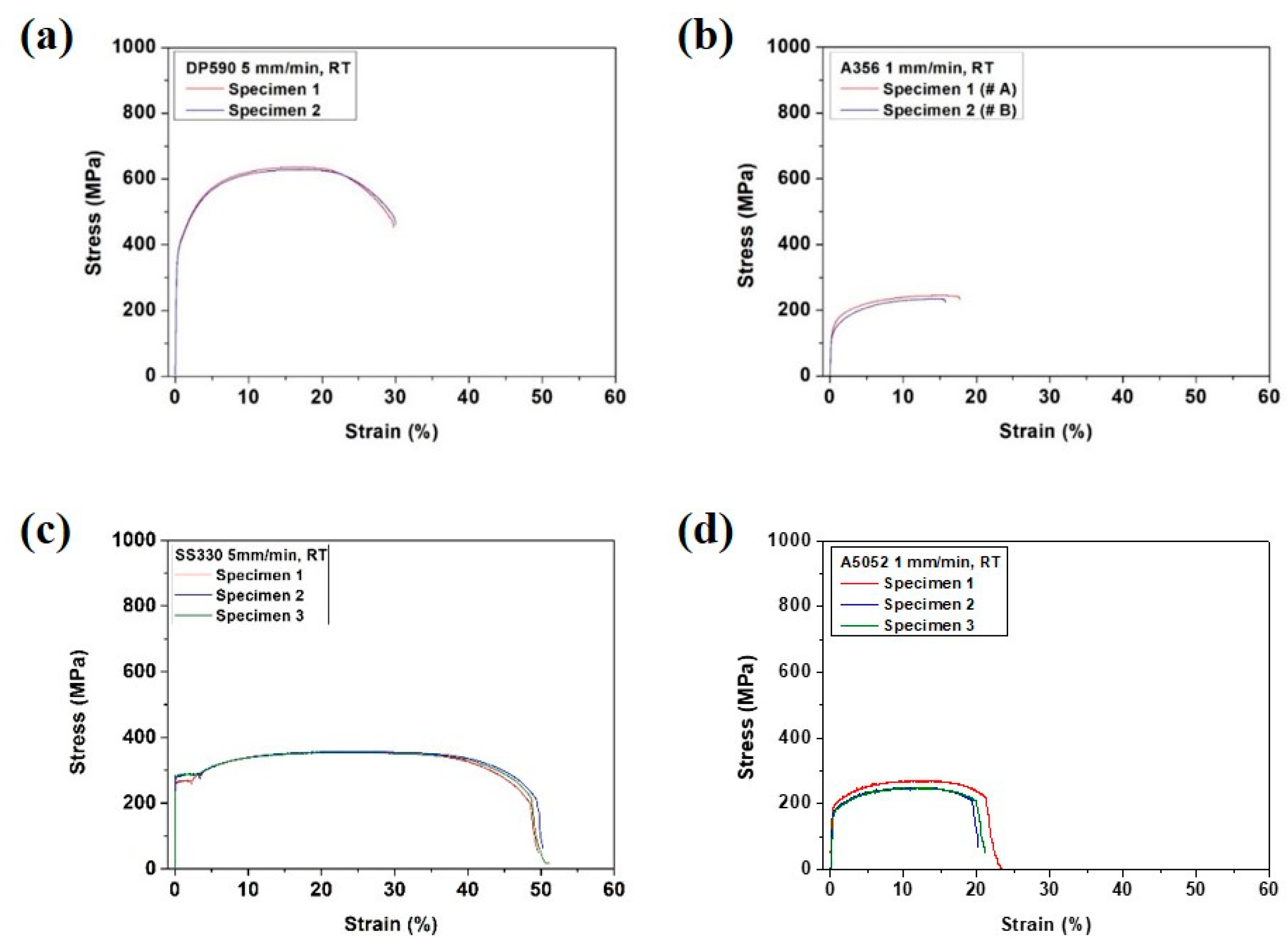

2.1. Materials and Microstructures

2.2. Adhesion Strength and Surface Roughness

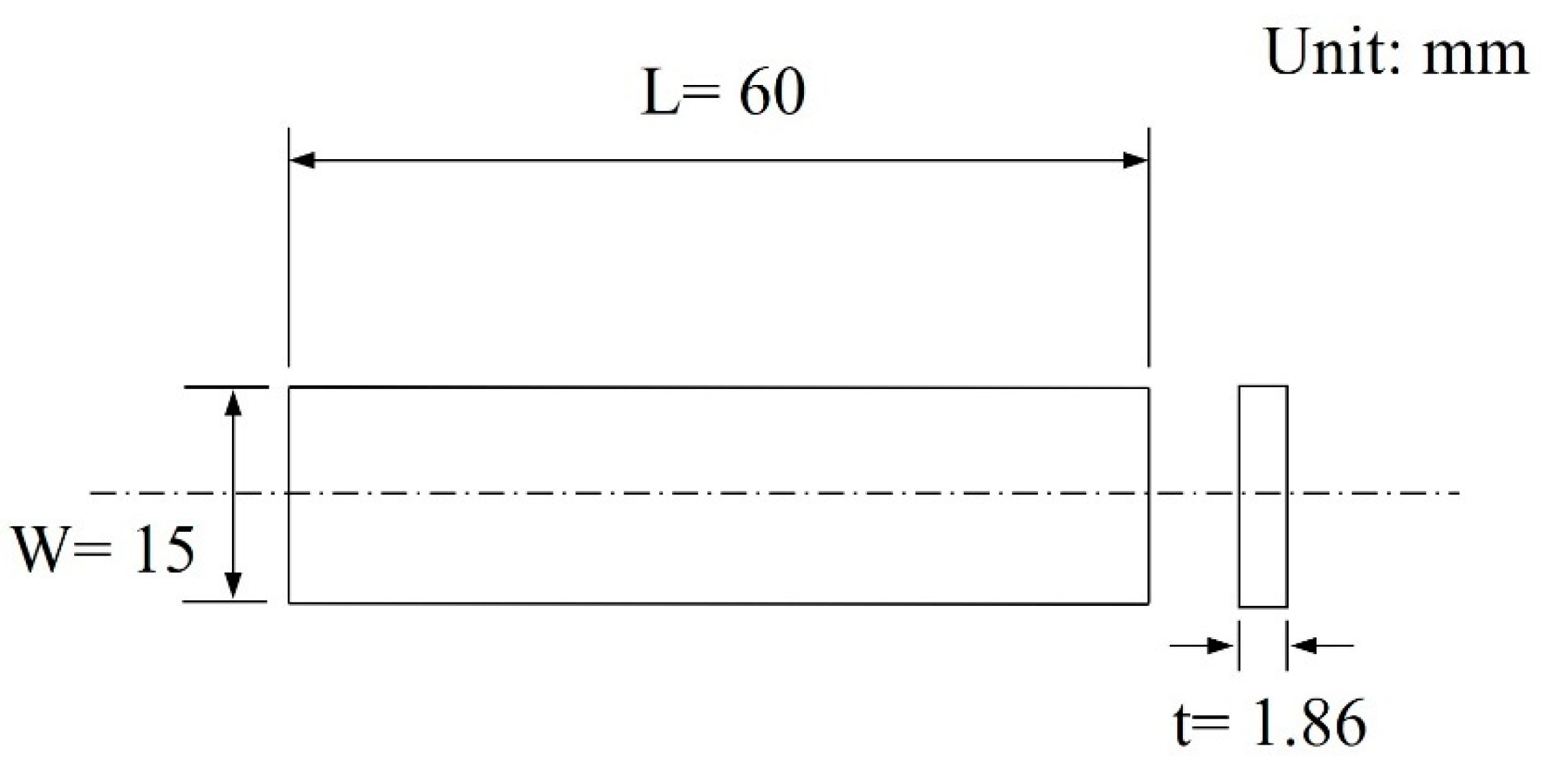

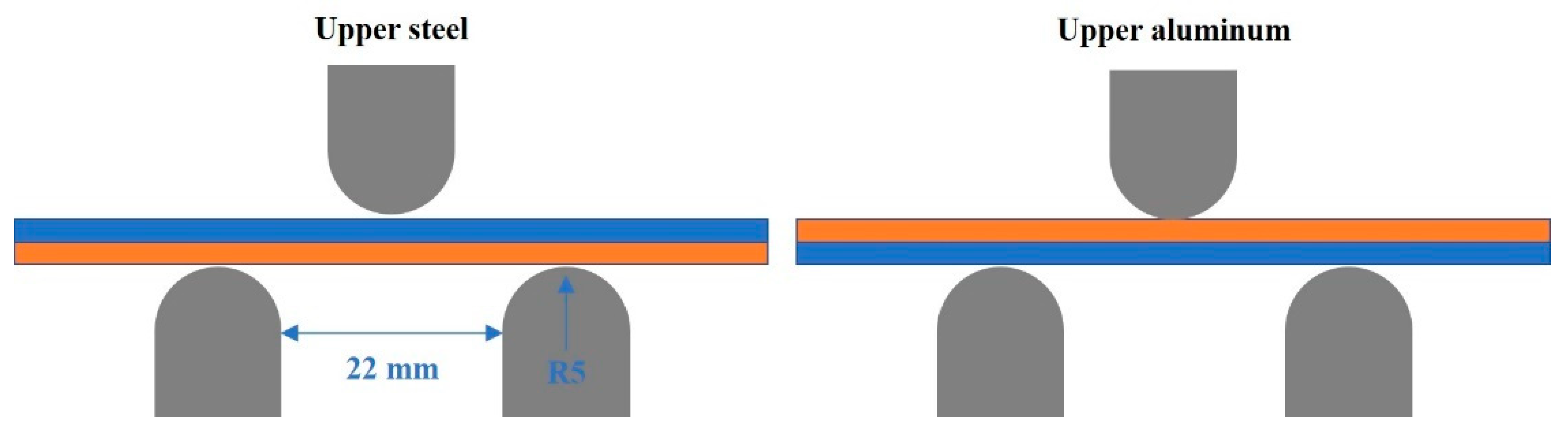

2.3. Three-Point Bending Test

2.4. FEA

3. Results and Discussion

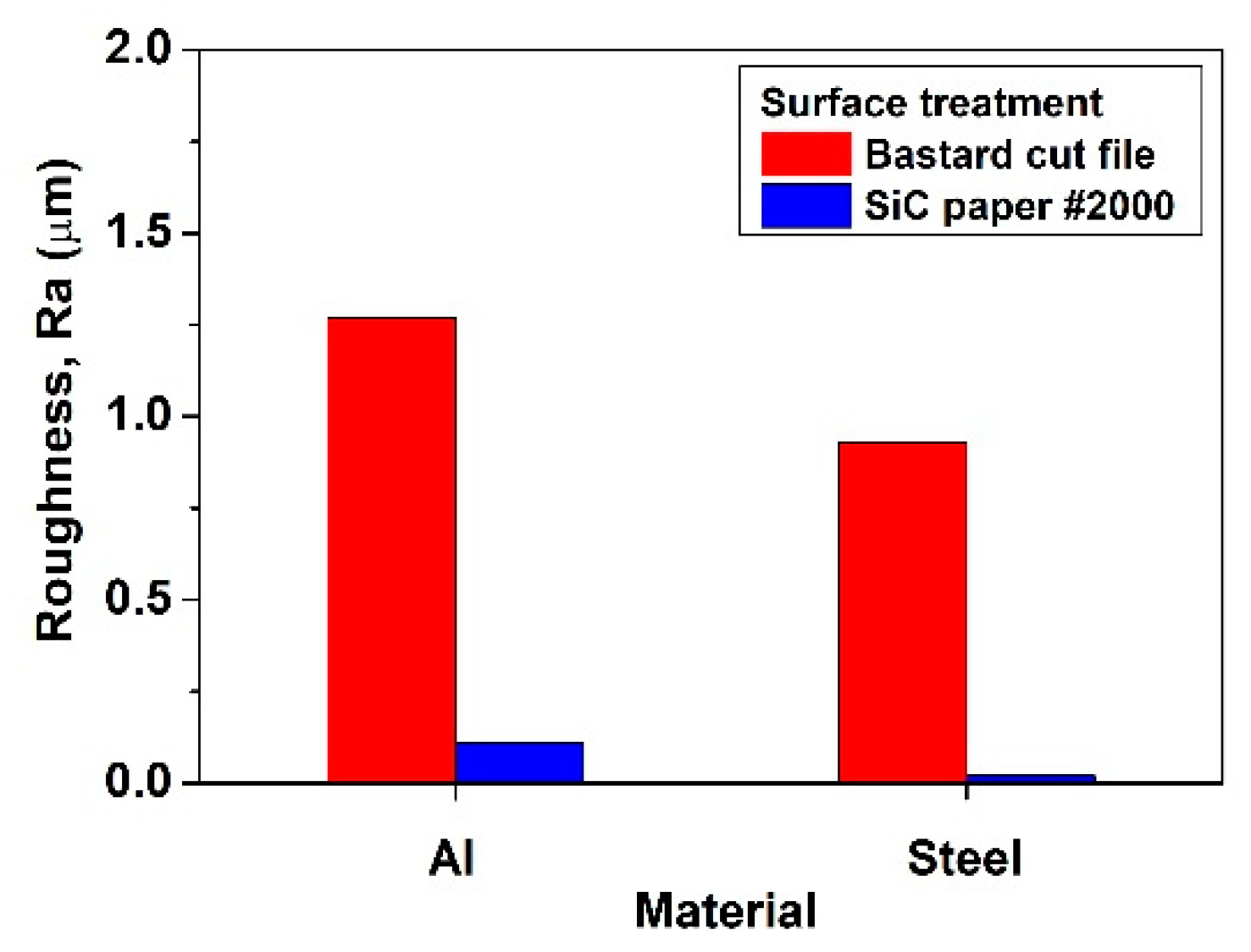

3.1. Surface Roughness

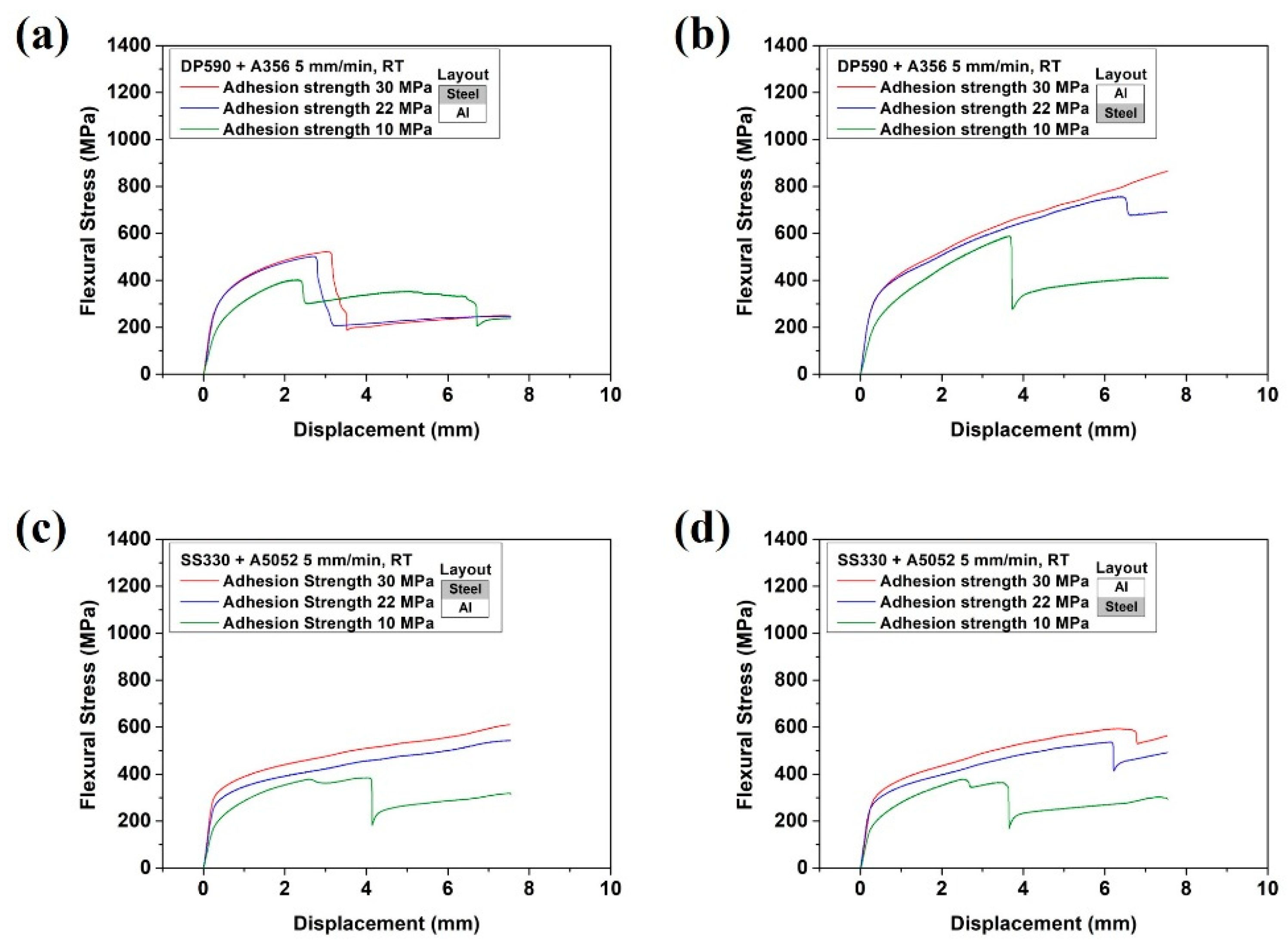

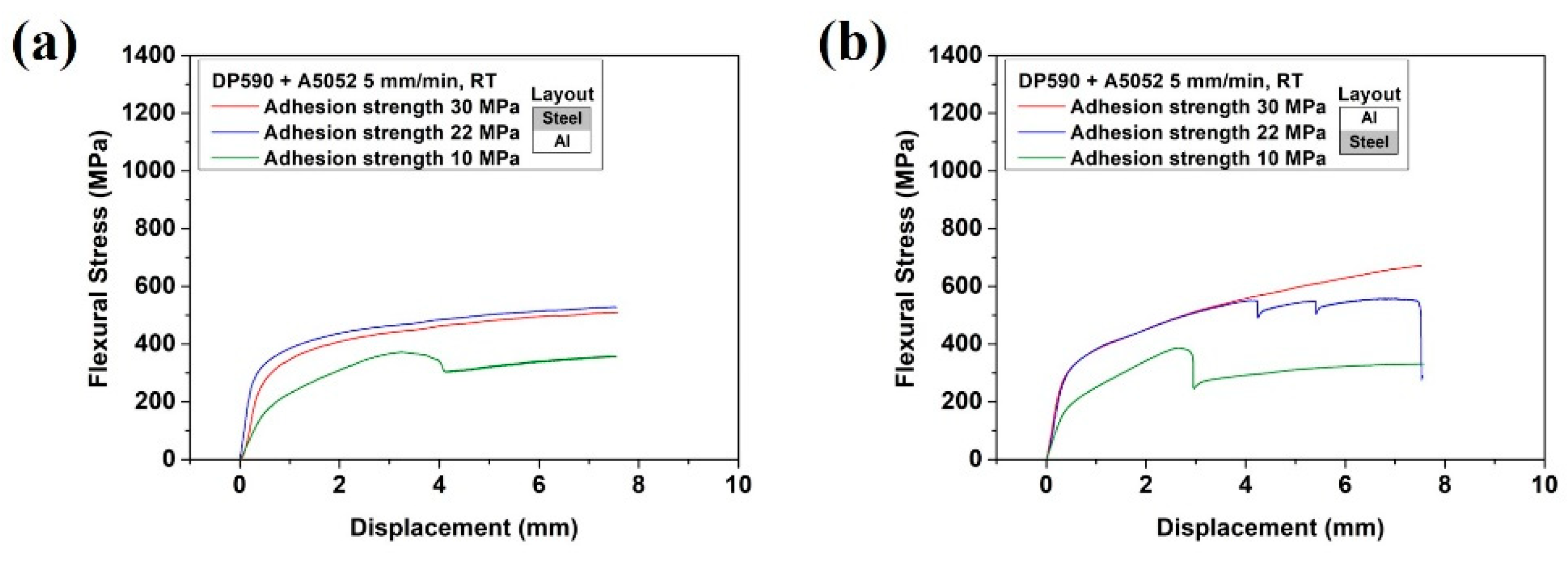

3.2. Bending Properties

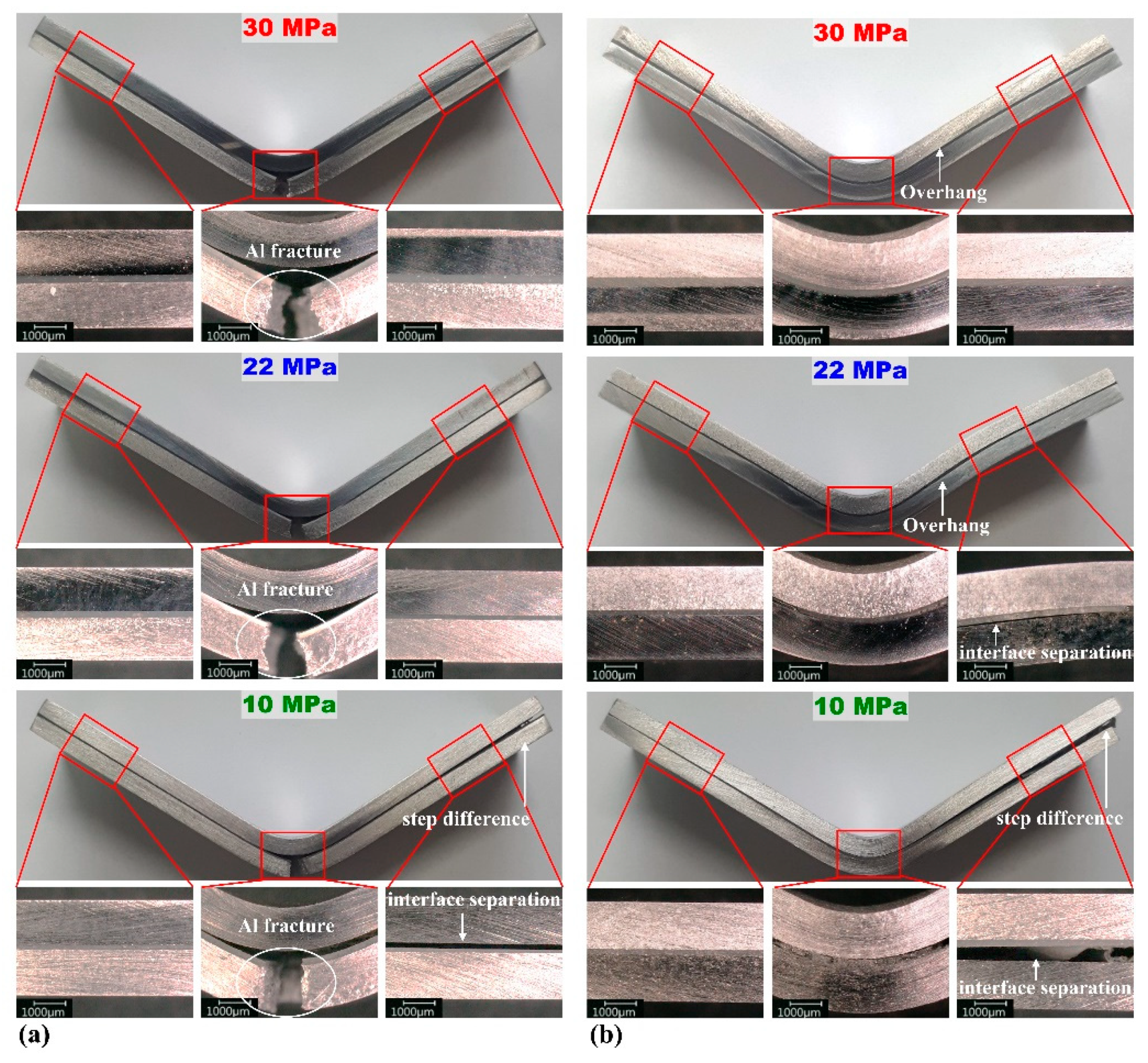

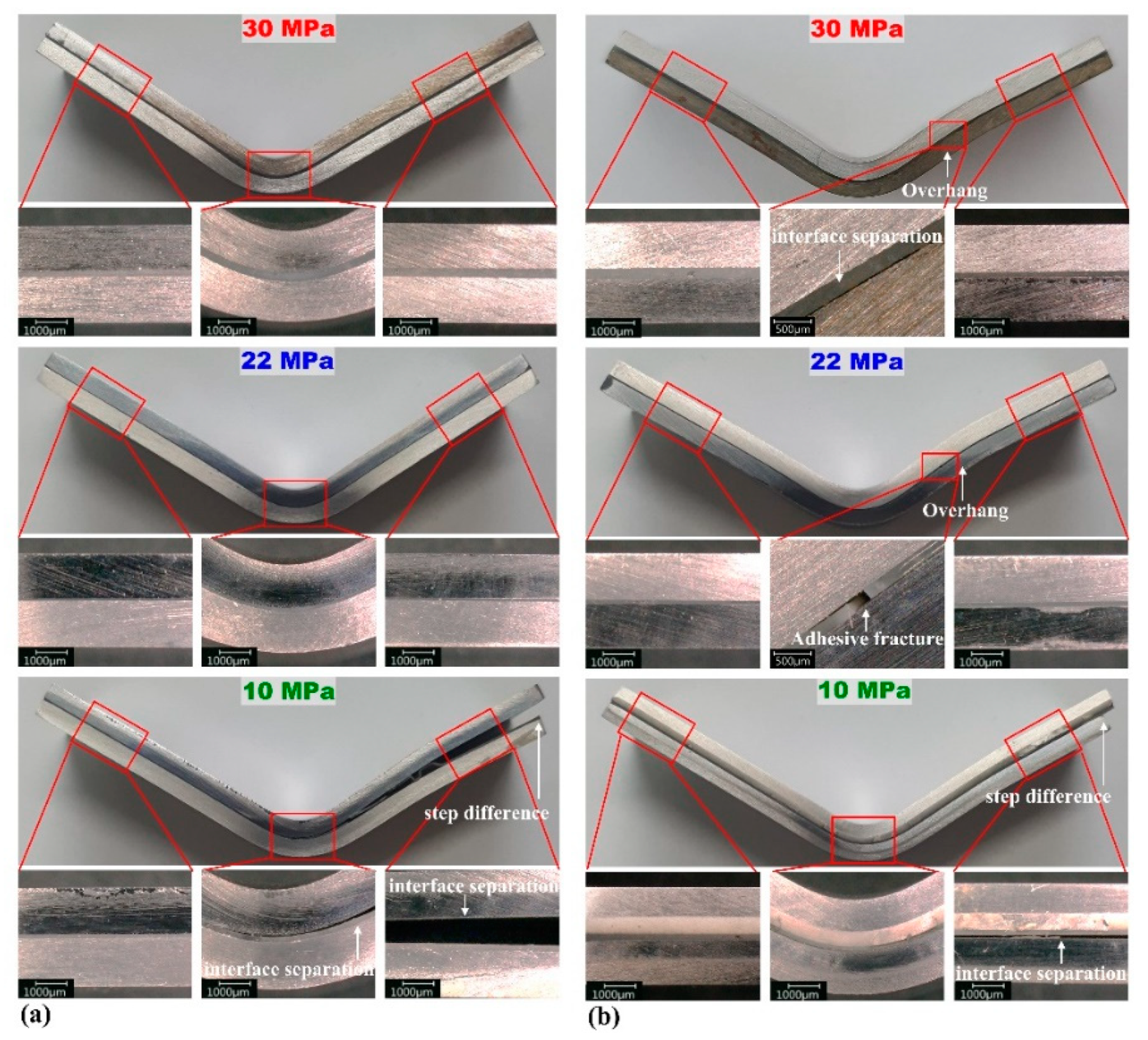

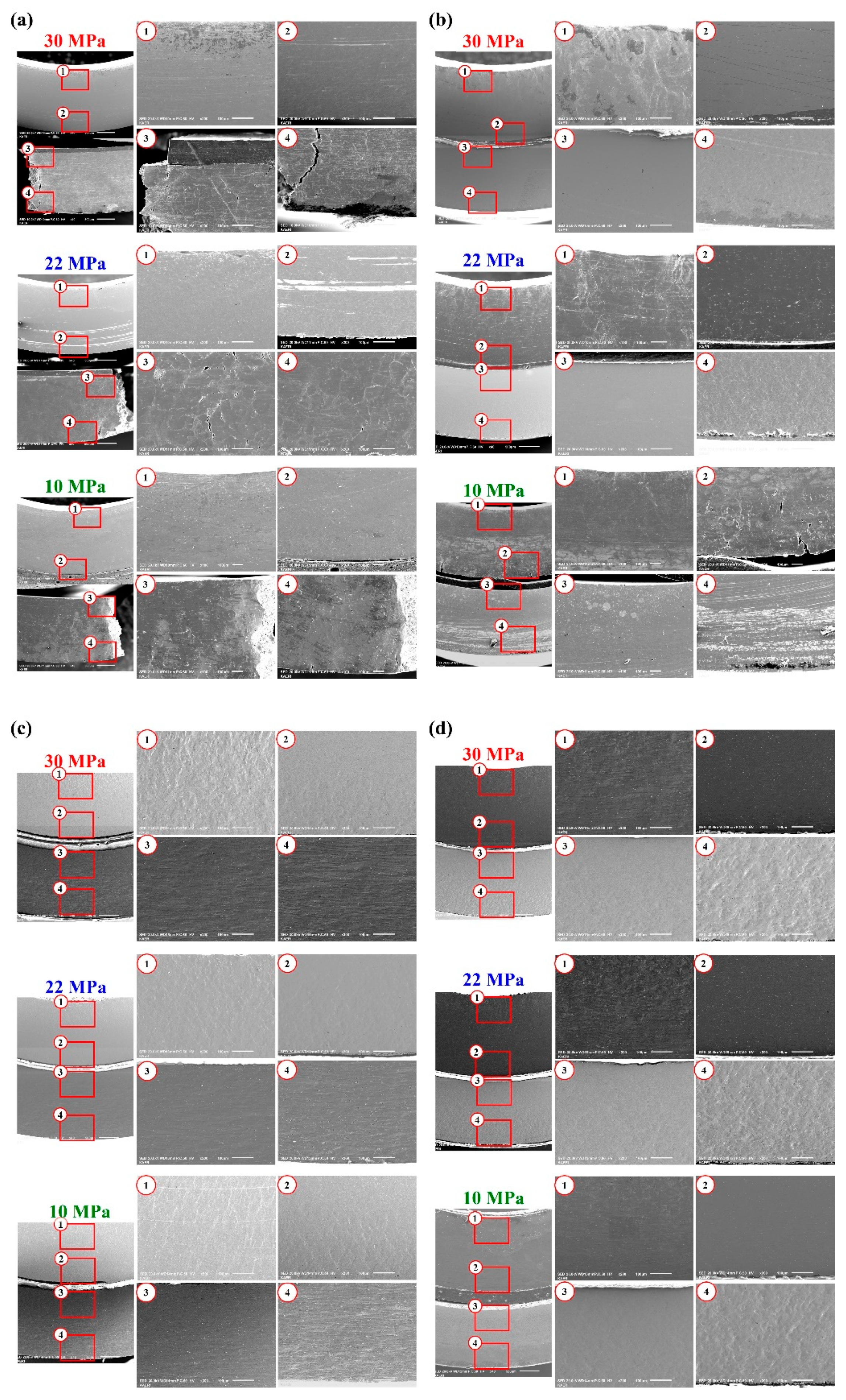

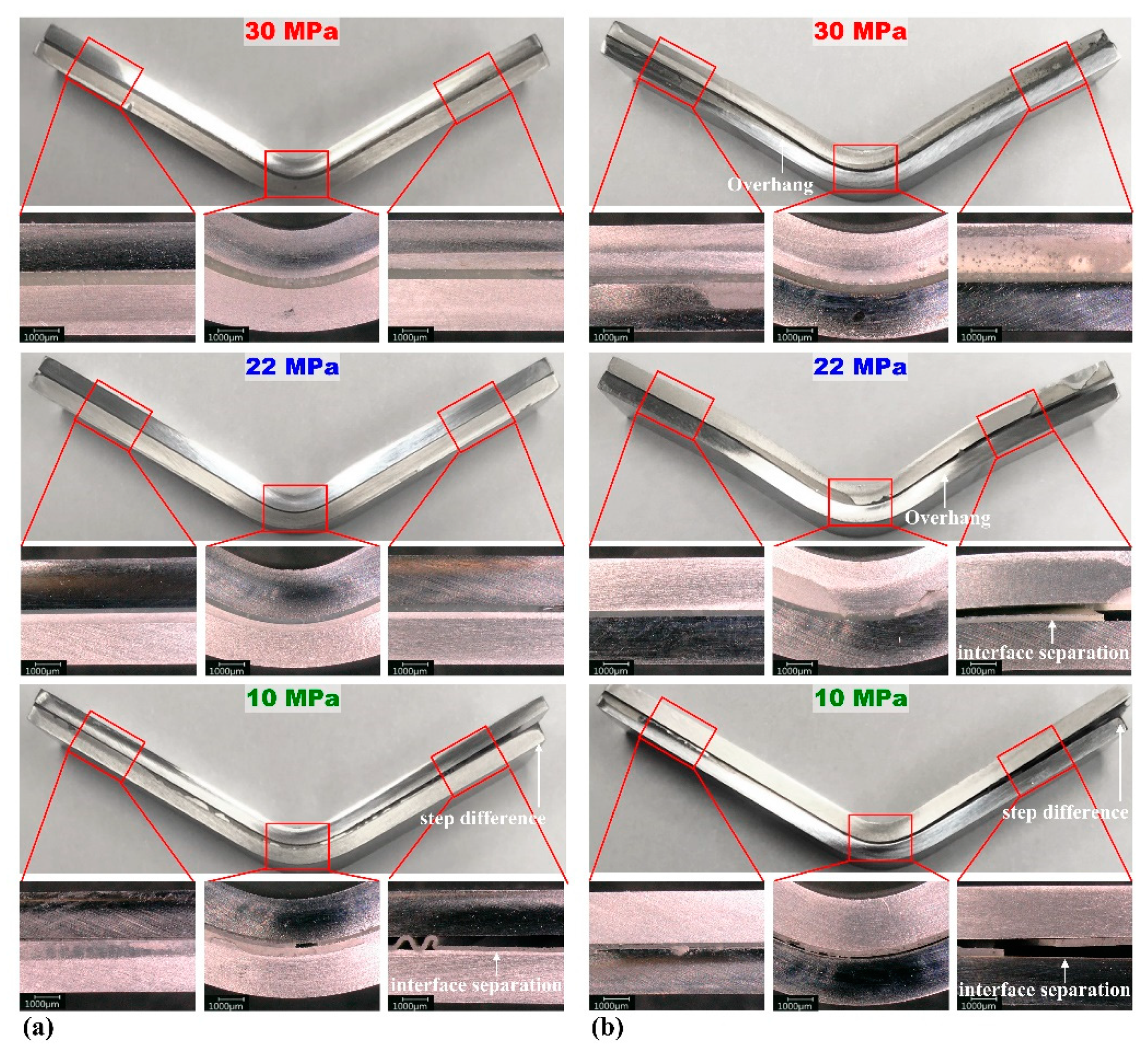

3.3. Observation of the Fracture Behavior

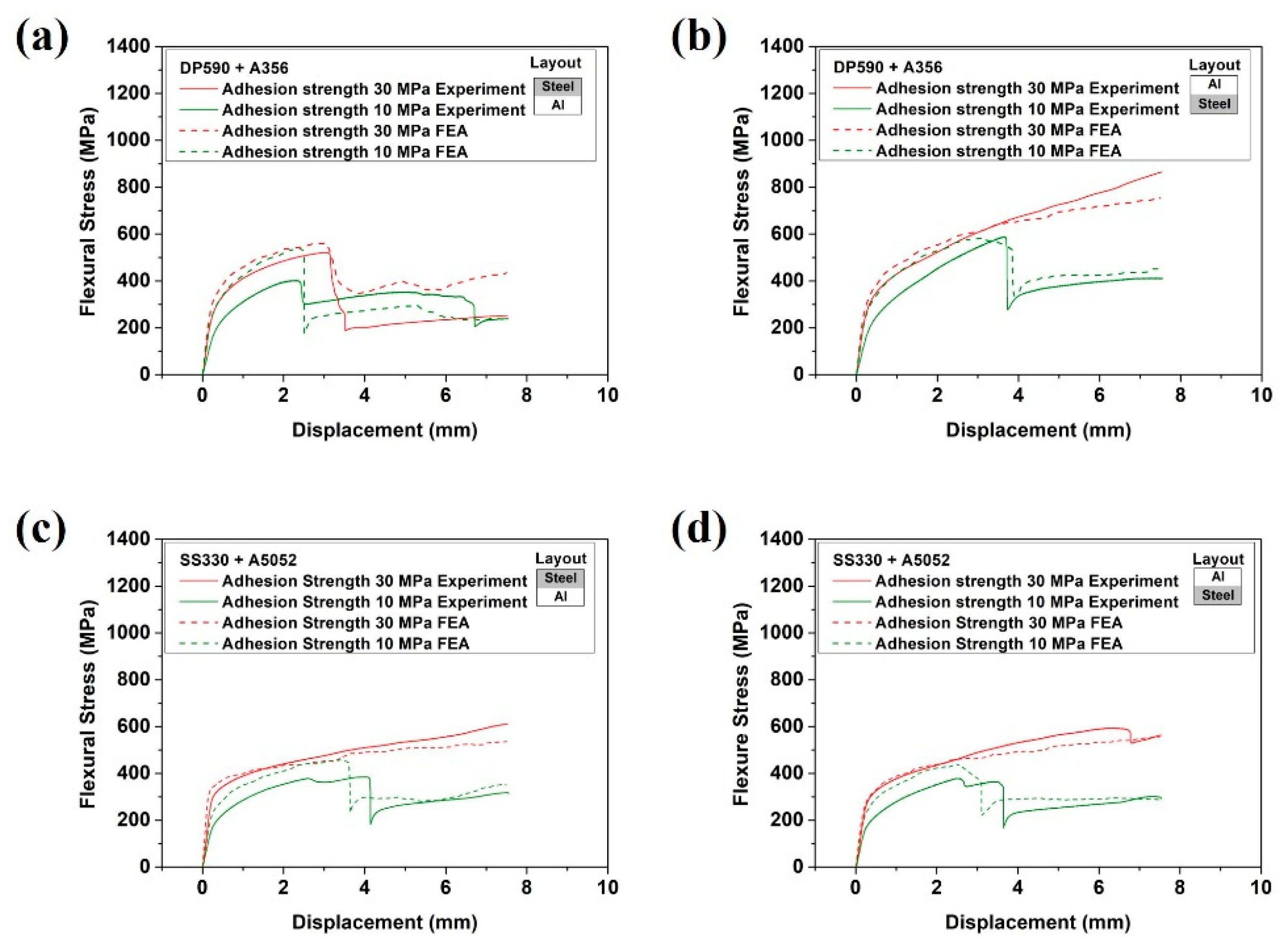

3.4. FEA Results

4. Conclusions

- (1)

- The surface roughness, curing time, and temperature were increased to improve the adhesion strength from 22 to 30 MPa. In other words, to increase the adhesion strength, it was necessary to consider not only the surface roughness of the specimen, but also the curing time and temperature.

- (2)

- According to the bending tests on the DP590–A356 and SS330–A5052 multi-materials, the bending stress increased with the adhesion strength. It was necessary to improve the adhesion strength for the joining of the two different materials. The stress drop section was more significant in DP590 (upper)–A356 (lower), SS330 (lower)–A5052 (upper), and DP590 (lower)–A5052 (upper). According to these results, the stress drop section was attributed to the ductility of aluminum, not to the difference in strength between steel and aluminum.

- (3)

- According to the bending tests, if the adhesive was toughed to not cause adhesive peeling, the flexural stress was larger when the aluminum was placed on the upper side. However, if the adhesion strength was low, the setting of aluminum with a good ductility in the lower position provided better properties in terms of the stress drop tendency.

- (4)

- The FEA results confirmed that the stress distribution was more spread at 10 MPa than at 30 MPa to both ends of the specimen. The flexural stress increased when the steel was placed at the lower position. In addition, the flexure stress–displacement curves obtained by the FEA and measured bending results were very similar, which verified the validity of the FEA results.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sherwood, C.P.; Mueller, B.C.; Nolan, J.M.; Zuby, D.S.; Lund, A.K. Development of a Frontal Small Overlap Crashworthiness Evaluation Test. Traffic Inj. Prev. 2013, 14, 128–135. [Google Scholar] [CrossRef] [PubMed]

- UNFCCC (United Nations Framework Convention on Climate Change). Adoption of the Paris Agreement; FCCC/CP/2015/L.9/Rev.1; United Nations: New York, NY, USA, 2015. [Google Scholar]

- Agudo, L.; Eyidi, D.; Schmaranzer, C.H.; Arenholz, E.; Jank, N.; Bruckner, J.; Pyzalla, A.R. Intermetallic Fe x Al y -phases in a steel/Al-alloy fusion weld. J. Mater. Sci. 2007, 42, 4205–4214. [Google Scholar] [CrossRef]

- Movahedi, M.; Kokabi, A.H.; Seyed Reihani, S.M.; Cheng, W.J.; Wang, C.J. Effect of annealing treatment on joint strength of aluminum/steel friction stir lap weld. Mater. Des. 2013, 44, 487–492. [Google Scholar] [CrossRef]

- Jin, J.Y.; Hong, S.I. Effect of heat treatment on tensile deformation characteristics and properties of Al3003/STS439 clad composite. Mater. Sci. Eng. A 2014, 596, 1–8. [Google Scholar] [CrossRef]

- Akramifard, H.R.; Mirzadeh, H.; Parsa, M.H. Cladding of aluminum on AISI 304L stainless steel by cold roll bonding: Mechanism, microstructure, and mechanical properties. Mater. Sci. Eng. A 2014, 613, 232–239. [Google Scholar] [CrossRef]

- Abe, Y.; Kato, T.; Mori, K. Joinability of aluminium alloy and mild steel sheets by self piercing rivet. J. Mater. Process. Technol. 2006, 177, 417–421. [Google Scholar] [CrossRef]

- Abe, Y.; Kato, T.; Mori, K. Self-piercing riveting of high tensile strength steel and aluminium alloy sheets using conventional rivet and die. J. Mater. Process. Technol. 2009, 209, 3914–3922. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, H.P.; Hicks, C.; Yang, X.; Carlson, B.E.; Zhou, Q. Experimental study of initial strengths and hygrothermal degradation of adhesive joints between thin aluminum and steel substrates. Int. J. Adhes. Adhes. 2013, 43, 14–25. [Google Scholar] [CrossRef]

- Al Robaidi, A.; Anagreh, N.; Massadeh, S.; Al Essa, A.M. The effect of different surface pretreatment methods on nano-adhesive application in high strength steel and aluminum bonding. J. Adhes. Sci. Technol. 2011, 25, 1725–1746. [Google Scholar] [CrossRef]

- Zhu, X.B.; Li, Y.B.; Chen, G.L.; Wang, P.C. Curing-induced distortion mechanism in adhesive bonding of aluminum AA6061-T6 and steels. J. Manuf. Sci. Eng. Trans. ASME 2013, 135, 051007. [Google Scholar] [CrossRef]

- Bamberg, P.A.M.G.P.; Reisgen, U.; Schiebahn, A.; Barbosa, J.D.V.; Marx, B.; Coelho, R.S. Digital image correlation analysis of the effects of the overlap length, adhesive thickness and adherends yield strength over similar and dissimilar joints of high strength steel and aluminum alloys. Int. J. Adhes. Adhes. 2018, 83, 69–75. [Google Scholar] [CrossRef]

- Chastel, Y.; Passemard, L. Joining technologies for future automobile multi-material modules. Procedia Eng. 2014, 81, 2104–2110. [Google Scholar] [CrossRef] [Green Version]

- Coelho, R.S.; Kostka, A.; dos Santos, J.F.; Kaysser-Pyzalla, A. Friction-stir dissimilar welding of aluminium alloy to high strength steels: Mechanical properties and their relation to microstructure. Mater. Sci. Eng. A 2012, 556, 175–183. [Google Scholar] [CrossRef]

- Mori, K.; Abe, Y.; Kato, T. Self-pierce riveting of multiple steel and aluminium alloy sheets. J. Mater. Process. Technol. 2014, 214, 2002–2008. [Google Scholar] [CrossRef]

- Thoppul, S.D.; Finegan, J.; Gibson, R.F. Mechanics of mechanically fastened joints in polymer-matrix composite structures—A review. Compos. Sci. Technol. 2009, 69, 301–329. [Google Scholar] [CrossRef]

- Tong, L.; Steven, G.P. Analysis and Design of Structural Bonded Joints, 1st ed.; Kluwer Academic Publishers: New York, NY, USA, 1999. [Google Scholar] [CrossRef]

- Adams, R.D.; Comyn, J.; Wake, W.C. Structural Adhesive Joints in Engineering, 2nd ed.; Chapman & Hall: London, UK, 1997. [Google Scholar] [CrossRef]

- Banea, M.D.; da Silva, L.F.M. Adhesively bonded joints in composite materials: An overview. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2009, 223, 1–18. [Google Scholar] [CrossRef]

- Dilger, K.; Burchardt, B.; Frauenhofer, M. Automotive Industry. In Handbook of Adhesion Technology; Springer International Publishing: Berlin/Heidelberg, Germany, 2017; pp. 1–35. [Google Scholar] [CrossRef]

- Boutar, Y.; Naïmi, S.; Mezlini, S.; da Silva, L.F.M.; Hamdaoui, M.; ben Sik Ali, M. Effect of adhesive thickness and surface roughness on the shear strength of aluminium one-component polyurethane adhesive single-lap joints for automotive applications. J. Adhes. Sci. Technol. 2016, 30, 1913–1929. [Google Scholar] [CrossRef]

- Zhai, L.L.; Ling, G.P.; Wang, Y.W. Effect of nano-Al2O3 on adhesion strength of epoxy adhesive and steel. Int. J. Adhes. Adhes. 2008, 28, 23–28. [Google Scholar] [CrossRef]

- Teng, J.G.; Fernando, D.; Yu, T.; Zhao, X.L. Treatment of steel surfaces for effective adhesive bonding. In Proceedings of the CICE 2010—The 5th International Conference on FRP Composites in Civil Engineering, Beijing, China, 27–29 September 2010. [Google Scholar] [CrossRef]

- Rudawska, A. Selected aspects of the effect of mechanical treatment on surface roughness and adhesive joint strength of steel sheets. Int. J. Adhes. Adhes. 2014, 50, 235–243. [Google Scholar] [CrossRef]

- Alfano, M.; Morano, C.; Moroni, F.; Musiari, F.; Danilo Spennacchio, G.; Di Lonardo, D. Fracture toughness of structural adhesives for the automotive industry. Procedia Struct. Integr. 2018, 8, 561–565. [Google Scholar] [CrossRef]

- Azari, S.; Ameli, A.; Papini, M.; Spelt, J.K. Analysis and design of adhesively bonded joints for fatigue and fracture loading: A fracture-mechanics approach. J. Adhes. Sci. Technol. 2013, 27, 1681–1711. [Google Scholar] [CrossRef]

- Loureiro, A.L.; da Silva, L.F.M.; Sato, C.; Figueiredo, M.A.V. Comparison of the mechanical behaviour between stiff and flexible adhesive joints for the automotive industry. J. Adhes. 2010, 86, 765–787. [Google Scholar] [CrossRef]

- Maurel-Pantel, A.; Lamberti, M.; Raffa, M.L.; Suarez, C.; Ascione, F.; Lebon, F. Modelling of a GFRP adhesive connection by an imperfect soft interface model with initial damage. Compos. Struct. 2020, 239, 112034. [Google Scholar] [CrossRef]

- ASTM D1002-10; Standard Test Method for Apparent Shear Strength of Single-Lap-Joint Adhesively Bonded Metal Specimens by Tension Loading (Metal-to-Metal). ASTM International: West Conshohocken, PA, USA, 2019.

- ISO 4287; Geometrical Product Specifications (GPS)—Surface Texture: Profile Method—Terms, Definitions and Surface Texture Parameters. ISO: Geneva, Switzerland, 1997.

- ASTM E290-14; Standard Test Methods for Bend Testing of Material for Ductility. ASTM International: West Conshohocken, PA, USA, 2014.

- Lim, J.D.; Susan, Y.S.Y.; Daniel, R.M.; Leong, K.C.; Wong, C.C. Surface roughness effect on copper-alumina adhesion. Microelectron. Reliab. 2013, 53, 1548–1552. [Google Scholar] [CrossRef]

- Ahn, J.H.; Shen, Y.F.; Kim, H.Y.; Jeong, H.D.; Cho, K.K. Development of a sensor information integrated expert system for optimizing die polishing. Robot. Comput. Integr. Manuf. 2001, 17, 269–276. [Google Scholar] [CrossRef]

- Tian, W.; Chao, B.; Xiong, X.; Li, Z. Effect of surface roughness on pitting corrosion of 2A12 aluminum alloy. Int. J. Electrochem. Sci. 2018, 13, 3107–3123. [Google Scholar] [CrossRef]

- Gamal, G.A.; Al-Mufadi, F.A.; Salman, S.M.M.; Zein, H. The relationship of surface roughness and hardness of BiSn solder alloys due to the variation of Sn content. Int. J. Sci. Eng. Res. 2018, 6, 103–109. [Google Scholar]

- Kim, I.K.; Hong, S.I. Effect of heat treatment on the bending behavior of tri-layered Cu/Al/Cu composite plates. Mater. Des. 2013, 47, 590–598. [Google Scholar] [CrossRef]

- Takiguchi, M.; Yoshida, F. Analysis of plastic bending of adhesive-bonded sheet metals taking account of viscoplasticity of adhesive. J. Mater. Process. Technol. 2003, 140, 441–446. [Google Scholar] [CrossRef]

- Li, Z.; Zhao, J.; Jia, F.; Zhang, Q.; Liang, X.; Jiao, S.; Jiang, Z. Analysis of bending characteristics of bimetal steel composite. Int. J. Mech. Sci. 2018, 148, 272–283. [Google Scholar] [CrossRef]

| (a) | |||||||||

| Si | C | P | Mn | Fe | |||||

| DP590 | 0.3 | 0.1 | 0.01 | 1 | Rem | ||||

| SS330 | 0.02 | 0.04 | 0.02 | 0.9 | Rem | ||||

| (b) | |||||||||

| Si | Mg | Fe | Zn | Cu | Ti | Mn | Cr | Al | |

| A356 | 7.0 | 0.4 | 0.15 | 0.1 | 0.2 | 0.2 | 0.1 | - | Rem |

| A5052 | 0.11 | 2.51 | 0.38 | - | 0.03 | 0.01 | 0.05 | 0.16 | Rem |

| YS (MPa) | UTS (MPa) | EL (%) | |

|---|---|---|---|

| DP590 | 374 | 632 | 29.8 |

| SS330 | 275 | 356 | 48.9 |

| A356 | 131 | 240 | 16.8 |

| A5052 | 176 | 252 | 21.8 |

| Steel | Aluminum | |

|---|---|---|

| Bastard cut file | 0.93 | 1.27 |

| SiC paper #2000 | 0.02 | 0.11 |

| Flexural Stress at Maximum Load (MPa) | Flexural Displacement at Maximum Load (mm) | Flexural Displacement at Fracture (mm) | |

|---|---|---|---|

| DP590 | 1004 | 7.5 | Not fractured |

| SS330 | 523 | 7.5 | Not fractured |

| A356 | 386 | 2.8 | 4.3 |

| A5052 | 377 | 7.5 | Not fractured |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeon, G.; Ha, D.; Park, Y.; Jeong, C. Three-Point Bending Properties of Hybrid Multi-Materials Using Adhesive Bonding Dependent on Strength Difference between Steel and Aluminum. Materials 2022, 15, 3328. https://doi.org/10.3390/ma15093328

Jeon G, Ha D, Park Y, Jeong C. Three-Point Bending Properties of Hybrid Multi-Materials Using Adhesive Bonding Dependent on Strength Difference between Steel and Aluminum. Materials. 2022; 15(9):3328. https://doi.org/10.3390/ma15093328

Chicago/Turabian StyleJeon, Geonwoo, Dongwoog Ha, Yunmin Park, and Changyeol Jeong. 2022. "Three-Point Bending Properties of Hybrid Multi-Materials Using Adhesive Bonding Dependent on Strength Difference between Steel and Aluminum" Materials 15, no. 9: 3328. https://doi.org/10.3390/ma15093328

APA StyleJeon, G., Ha, D., Park, Y., & Jeong, C. (2022). Three-Point Bending Properties of Hybrid Multi-Materials Using Adhesive Bonding Dependent on Strength Difference between Steel and Aluminum. Materials, 15(9), 3328. https://doi.org/10.3390/ma15093328