Microstructure and Mechanical Properties of As-Aged Mg-Zn-Sn-Mn-Al Alloys

Abstract

:1. Introduction

2. Experimental Procedures

3. Results and Discussion

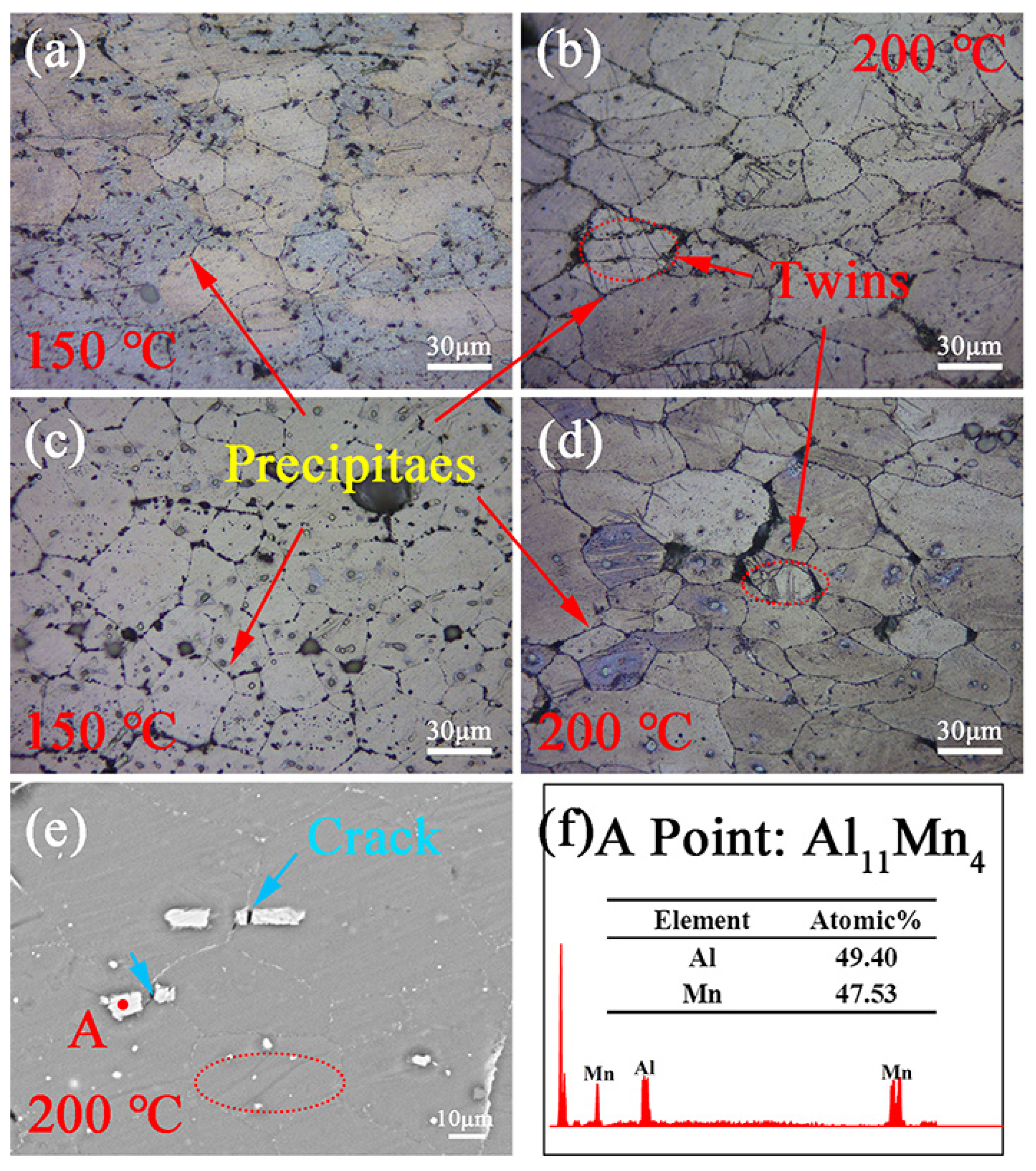

3.1. Microstructures of As-Aged ZTM641-xAl Alloys

3.2. Mechanical Properties

3.2.1. Mechanical Properties at Room Temperature

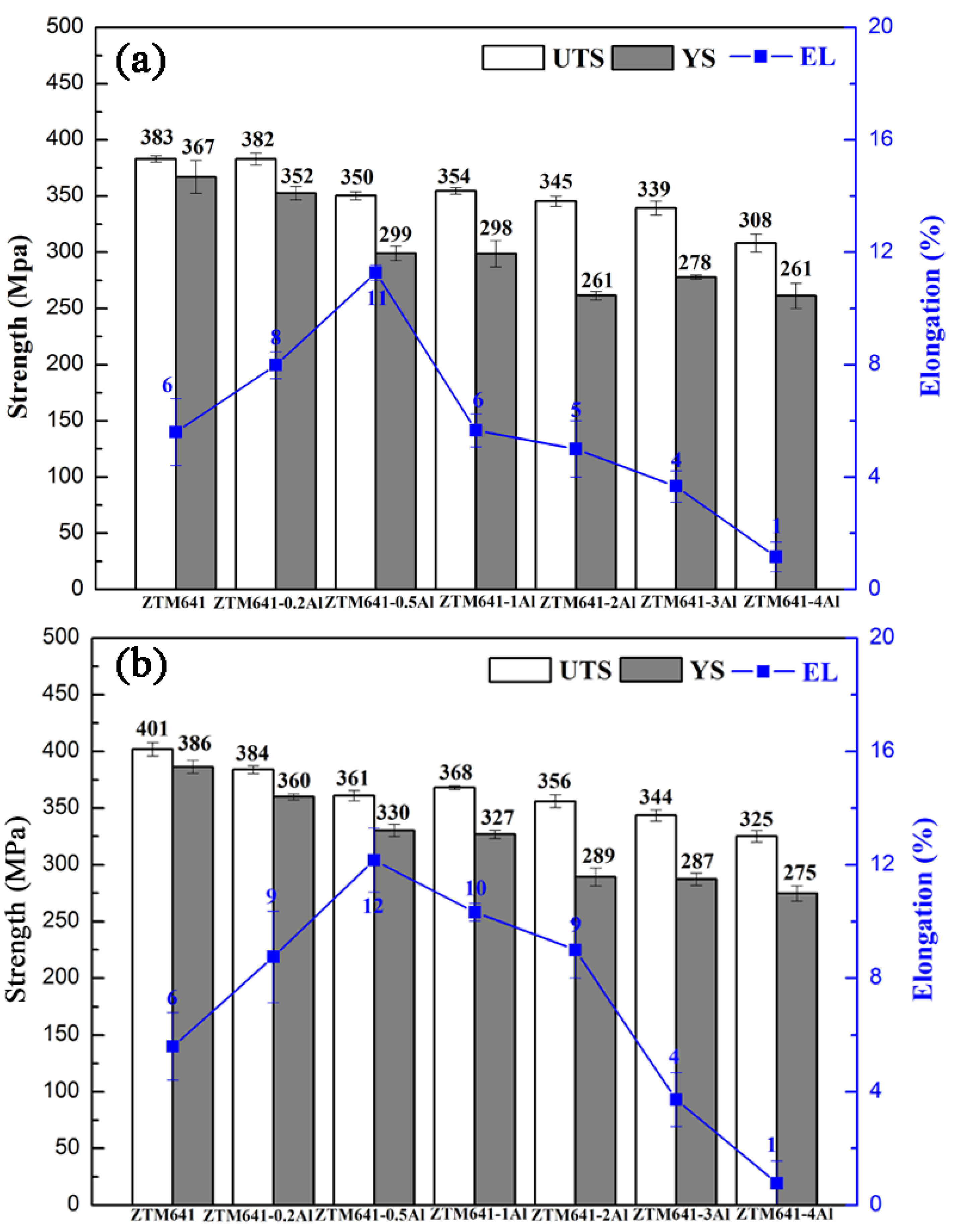

3.2.2. Mechanical Properties at Elevated Temperature

4. Conclusions

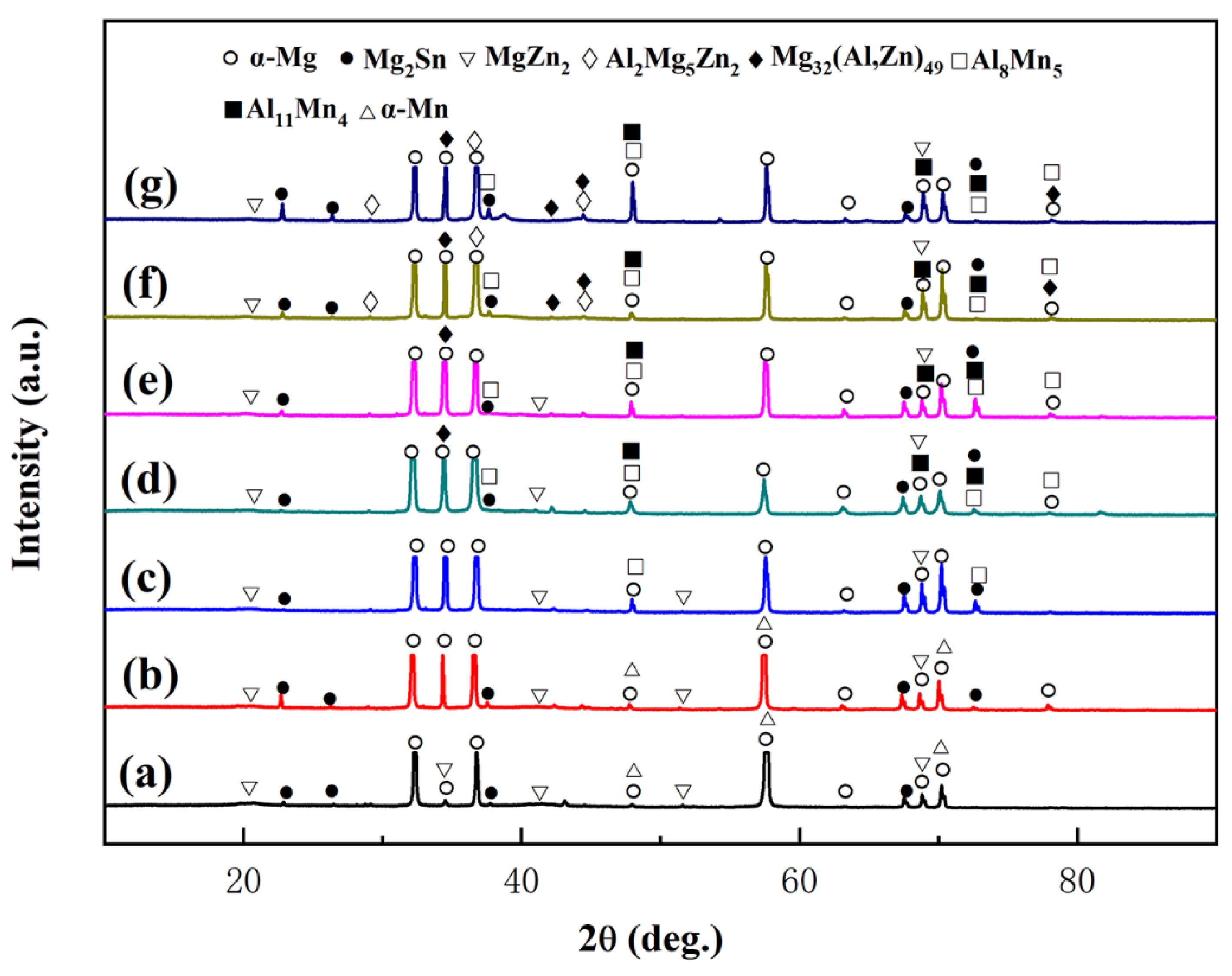

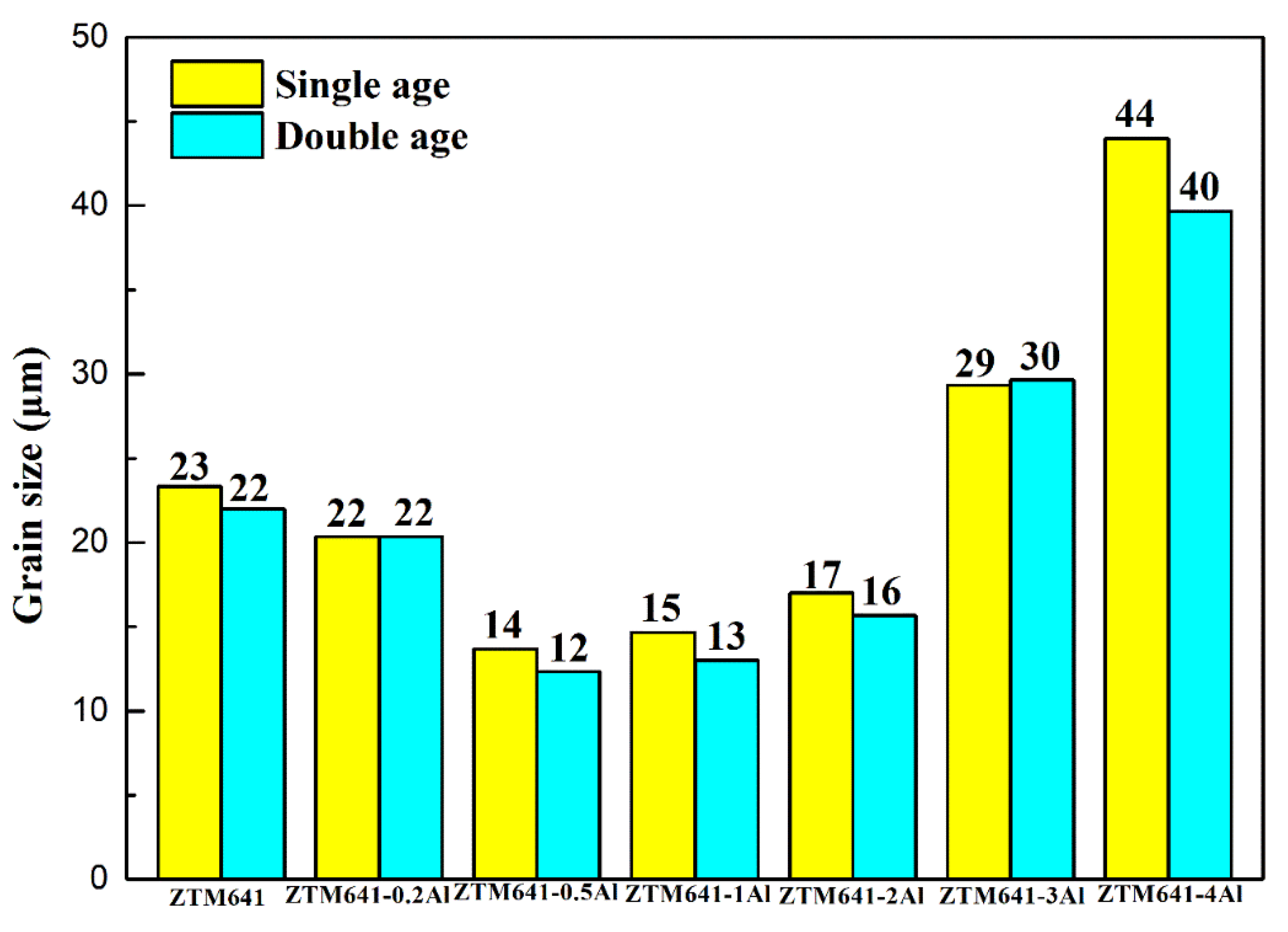

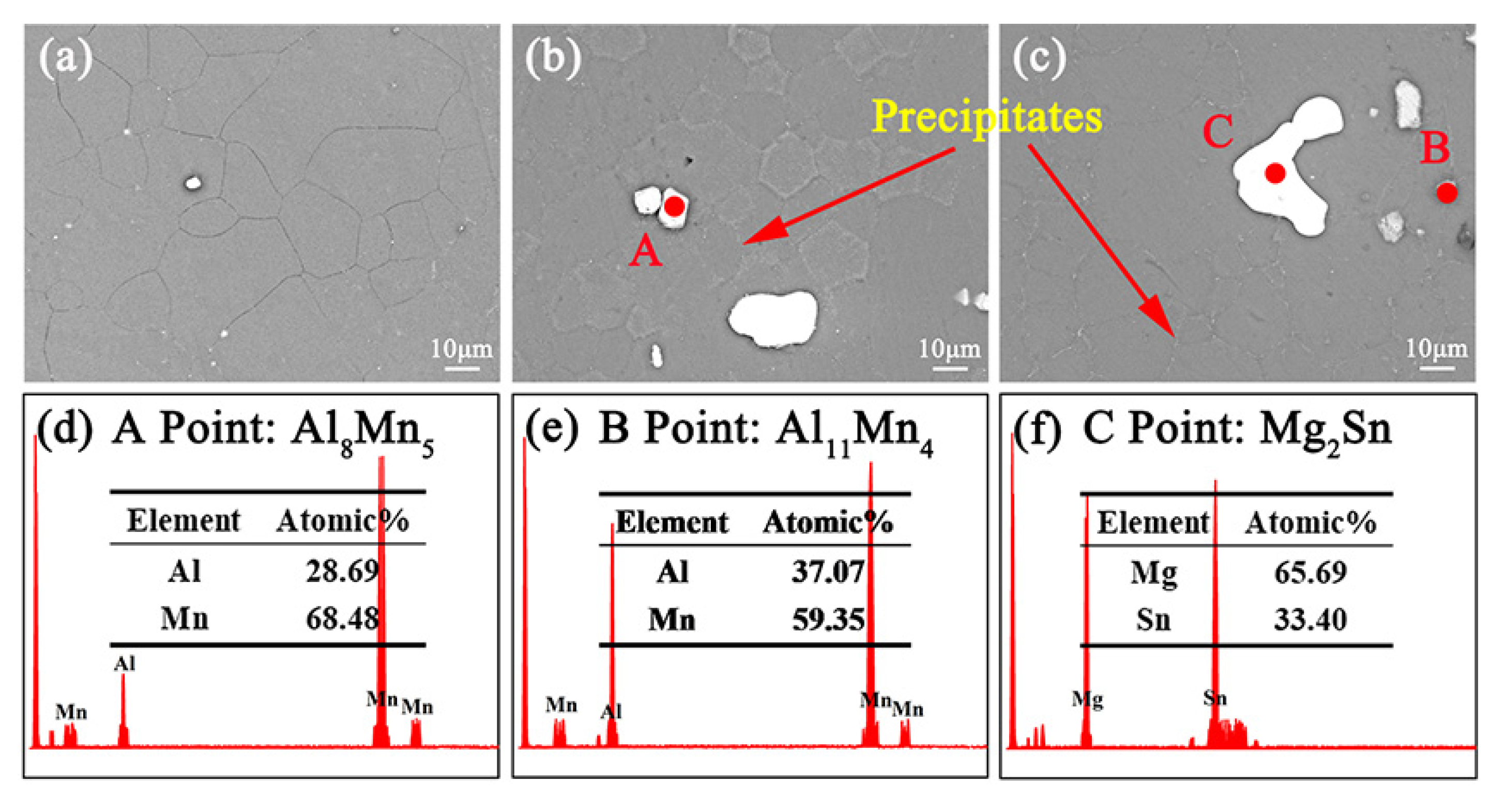

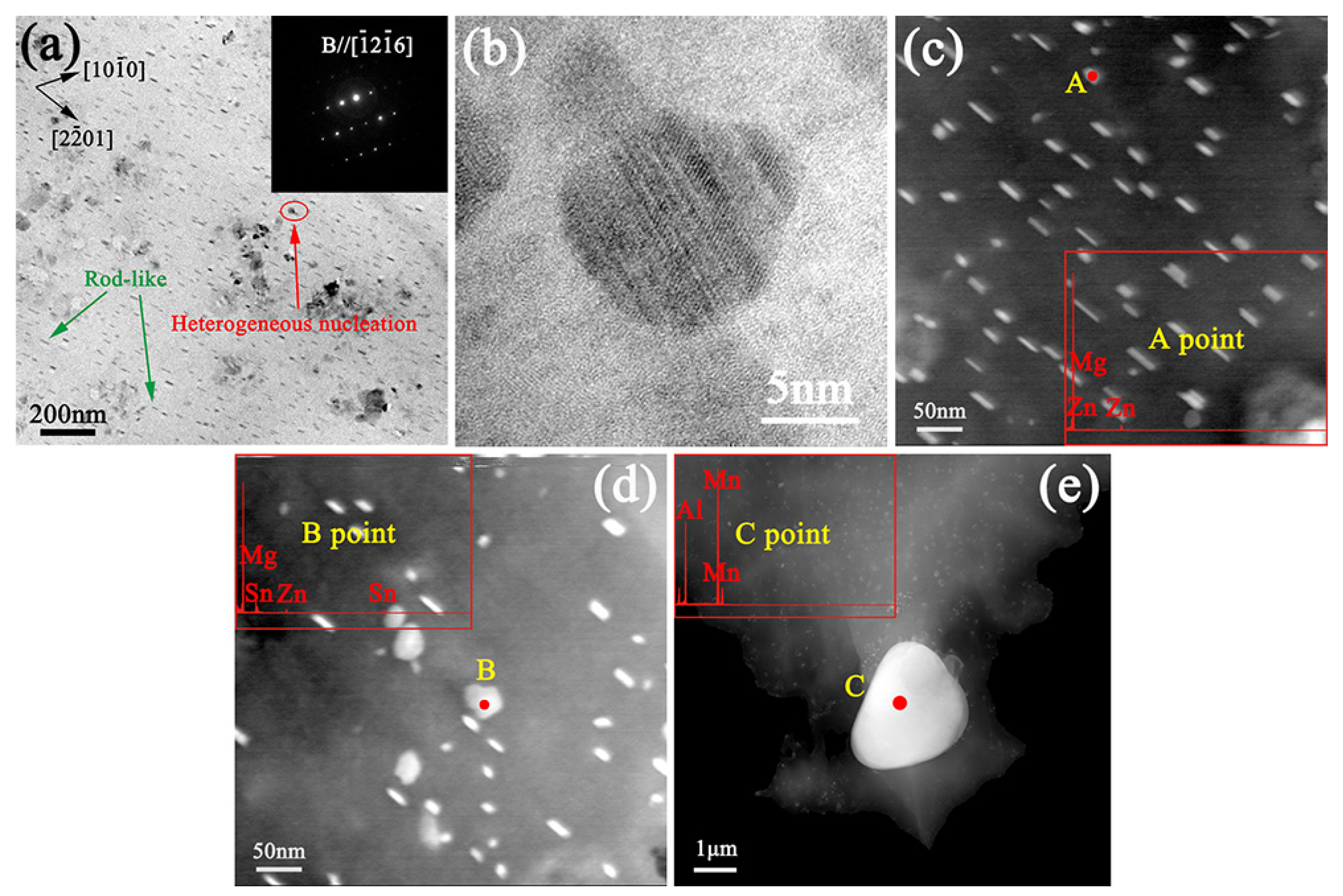

- There is a difference between the single-aged and double-aged microstructure. The aged ZTM641 alloy mainly consists of α-Mg, α-Mn, MgZn2 and Mg2Sn phases. The Al element mainly forms Al8Mn5, Al11Mn4, Al2Mg5Zn2 and Mg32(Al,Zn)49 phases. With increases in the addition of Al, the average grain size first decreases and then increases, and the undissolved phases increase. The average grain size of ZTM641-0.5Al alloy is the smallest, and the single-aged and double-aged grain sizes are 14 μm and 12 μm, respectively.

- The mechanical properties of double-aged alloys are superior to single-aged alloys. The Al element can improve the comprehensive properties at room temperature, 150 °C and 200 °C. The double-aged ZTM641-0.2Al alloy exhibits favorable mechanical properties at room temperature, the UTS, YS and elongation are 384 MPa, 360 MPa and 9%, respectively. Furthermore, the double-aged ZTM641-0.2Al alloy exhibits comprehensive mechanical properties at 150 °C, that is, the UTS, YS and elongation are 212 MPa, 196 MPa and 29%, respectively, which is about 45% higher than that of elongation of ZTM641.

- At room temperature, the ZTM641-xAl alloys exhibit mixed fracture. At 200 °C, with increases in the Al content, the fracture mechanisms of alloys are mixed fracture, ductile fracture and mixed fracture, respectively. Furthermore, the elongation of ZTM641-xAl (x ≤ 0.5%) decreases when the temperature rises from 150 °C to 200 °C, which is mainly due to coarse phases at the grain boundaries that can easily cause microcracks.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Agnew, S.R.; Nie, J.F. Preface to the viewpoint set on: The current state of magnesium alloy science and technology. Scr. Mater. 2010, 63, 671–673. [Google Scholar] [CrossRef]

- Hono, K.; Mendis, C.L.; Sasaki, T.T.; Oh-ishi, K. Towards the development of heat-treatable high-strength wrought Mg alloys. Scr. Mater. 2010, 63, 710–715. [Google Scholar] [CrossRef]

- Wang, J.F.; Gao, S.; Song, P.F.; Huang, X.F.; Shi, Z.Z.; Pan, F.S. Effects of phase composition on the mechanical properties and damping capacities of as-extruded Mg–Zn–Y–Zr alloys. J. Alloy. Compd. 2011, 509, 8567–8572. [Google Scholar] [CrossRef]

- Kaya, S.; Yılan, F.; Urtekin, L. Influences of Cr on the microstructural, wear and mechanical performance of high-chromium white cast iron grinding balls. J. Mater. Manuf. 2022, 1, 23–30. [Google Scholar]

- Coban, H.; Koklu, U. Drilling of AZ31 Magnesium Alloy under dry and cryogenic conditions. J. Mater. Manuf. 2022, 1, 7–13. [Google Scholar]

- Gao, L.; Yan, H.; Luo, J.; Luo, A.A.; Chen, R.S. Microstructure and mechanical properties of a high ductility Mg–Zn–Mn–Ce magnesium alloy. J. Magnes. Alloy. 2013, 1, 283–291. [Google Scholar] [CrossRef] [Green Version]

- He, X.; Chen, J.H.; Yan, H.G.; Su, B.; Zhang, G.H.; Miao, C.M. Effects of minor Sr addition on microstructure and mechanical properties of the as-cast Mg-4.5Zn-4.5Sn-2Al-based alloy system. J. Alloy. Compd. 2013, 579, 39–44. [Google Scholar]

- Yang, H.G.; Li, Y.B.; Cui, H.Z. High-temperature creep behavior of Mg-9Gd-4Y-0.5Zr alloy. Heat Treat. Met. 2012, 37, 25–29. [Google Scholar]

- Gao, X.; Nie, J.F. Structure and thermal stability of primary intermetallic particles in an Mg-Zn casting alloy. Scr. Mater. 2007, 57, 655–658. [Google Scholar] [CrossRef]

- Oh-ishi, K.; Hono, K.; Shin, K.S. Effect of pre-aging and Al addition on age-hardening and microstructure in Mg-6wt% Zn alloys. Mater. Sci. Eng. A 2008, 496, 425–433. [Google Scholar] [CrossRef]

- Doan, J.P.; Ansel, G. Some effects of zirconium on extrusion properties of magnesium-base alloys containing zinc. Trans. AIME 2020, 171, 286–305. [Google Scholar]

- Wang, B.; Pan, F.S.; Chen, X.H.; Guo, W.; Mao, J.J. Microstructure and mechanical properties of as-extruded and as-aged Mg–Zn–Al–Sn alloys. Mater. Sci. Eng. A 2016, 656, 165–173. [Google Scholar] [CrossRef]

- Jia, Z.; Yu, Y.Z.; Yu, B.; Fu, L.; Hu, W.Y.; Shao, Y.C. Effect of Ca and Zr additions on microstructure and mechanical properties of as-extruded Mg-3Sn alloy. Materials 2022, 15, 6343. [Google Scholar] [CrossRef] [PubMed]

- Mendis, C.L.; Bettles, C.J.; Gibson, M.A.; Hutchinson, C.R. An enhanced age hardening response in Mg–Sn based alloys containing Zn. Mater. Sci. Eng. A 2006, 435–436, 163–171. [Google Scholar] [CrossRef]

- Zhang, J.; Li, Z.S.; Guo, Z.X.; Pan, F.S. Solidification microstructural constituent and its crystallographic morphology of permanent-mould-cast Mg-Zn-Al alloys. Trans. Nonferrous Met. Soc. China 2006, 16, 452–458. [Google Scholar] [CrossRef]

- Wan, X.F.; Ni, H.J.; Huang, M.Y.; Zhang, H.L.; Sun, J.H. Microstructure, mechanical properties and creep resistance of Mg-(8%–12%)Zn-(2%–6%) Al alloys. Trans. Nonferrous Met. Soc. China 2013, 23, 896–903. [Google Scholar] [CrossRef]

- Shi, G.L.; Zhang, D.F.; Zhao, X.B.; Zhang, K.; Li, X.G.; Li, Y.J.; Ma, M.L. Precipitate evolution in Mg-6 wt%Zn-1 wt%Mn alloy. Rare Met. Mater. Eng. 2013, 42, 2447–2452. [Google Scholar]

- Yin, D.S.; Zhang, E.L.; Zeng, S.Y. Effect of Zn on mechanical property and corrosion property of extruded Mg-Zn-Mn alloy. Trans. Nonferrous Met. Soc. China 2008, 18, 763–768. [Google Scholar] [CrossRef]

- Wang, Q.H.; Wang, L.; Zhai, H.W.; Chen, Y.; Chen, S. Establishment of constitutive model and analysis of dynamic recrystallization kinetics of Mg-Bi-Ca Alloy during hot deformation. Materials 2022, 15, 7986. [Google Scholar] [CrossRef]

- Hou, C.H.; Qi, F.G.; Ye, Z.S.; Zhao, N.; Zhang, D.F.; Ouyang, X.P. Effects of Mn addition on the microstructure and mechanical properties of Mg–Zn–Sn alloys. Mater. Sci. Eng. A 2020, 774, 138933. [Google Scholar] [CrossRef]

- Kim, S.H.; Lee, J.U.; Ye, J.K.; Jung, J.G.; Park, S.H. Controlling the microstructure and improving the tensile properties of extruded Mg-Sn-Zn alloy through Al addition. J. Alloy. Compd. 2018, 751, 1–11. [Google Scholar] [CrossRef]

- Chen, X.; Li, S.L.; Wan, Y.C. The effect of initial grain size on the nanocrystallization of aZ31 Mg alloy during rotary swaging. Materials 2022, 15, 7979. [Google Scholar] [CrossRef] [PubMed]

- Hou, C.H.; Ye, Z.S.; Qi, F.G.; Wang, Q.; Li, L.H.; Ouyang, X.P.; Zhao, N. Effect of Al addition on microstructure and mechanical properties of Mg−Zn−Sn−Mn alloy. Trans. Nonferrous Met. Soc. China 2021, 31, 1951–1968. [Google Scholar] [CrossRef]

- Hu, G.S.; Zhang, D.F.; Dong, Y.F.; Chen, X.; Jiang, L.Y.; Pan, F.S. Microstructures and mechanical properties of as-extruded and heat treated Mg–6Zn–1Mn–4Sn–1.5Nd alloy. Trans. Nonferrous Met. Soc. China 2015, 25, 1439–1445. [Google Scholar] [CrossRef]

- Qi, F.G.; Zhang, D.F.; Zhang, X.H.; Xu, X.X. Effect of Sn addition on the microstructure and mechanical properties of Mg–6Zn–1Mn (wt.%) alloy. J. Alloy. Compd. 2014, 585, 656–666. [Google Scholar] [CrossRef]

- Song, X.Y.; Gu, N.J.; Liu, G.Q.; Wang, B.Q. Computer simulation of the influence of second-phase particle quantity on matrix grain growth. Acta Metall. Sin. 2000, 36, 592–596. [Google Scholar]

- Yu, Z.W.; Hu, M.D.; Tang, A.T.; Wu, M.S.; He, J.J.; Gao, Z.Y.; Wang, F.Y.; Li, C.Y.; Chen, B.; Liu, J.G. Effect of aluminium on the microstructure and mechanical properties of as-cast magnesium–manganese alloys. Mater. Sci. Technol. 2017, 33, 2086–2096. [Google Scholar] [CrossRef]

- Qi, F.G.; Luo, W.Z.; Wu, C.P.; Zhao, N.; Ye, Z.S.; Hou, C.H.; Zhang, D.F. Microstructure evolution and mechanical properties of ZM81-xSn wrought magnesium alloys. Rare Met. Mater. Eng. 2020, 49, 0778–0786. [Google Scholar]

- Wei, L.Y.; Dunlop, G.L.; Westengen, H. The intergranular microstructure of cast Mg-Zn and Mg-Zn-rare earth alloys. Metall. Mater. Trans. A-Phys. Metall. Mater. Sci. 1995, 26, 1947–1955. [Google Scholar] [CrossRef]

- Gao, X.; Nie, J.F. Characterization of strengthening precipitate phases in a Mg–Zn alloy. Scr. Mater. 2007, 56, 645–648. [Google Scholar] [CrossRef]

- Gorny, A.; Katsman, A. Precipitation- and stress-influenced coarsening in Mg-based Mg–Zn–Sn–Y and Mg–Zn–Sn–Sb alloys. J. Mater. Res. 2008, 23, 1228–1236. [Google Scholar] [CrossRef]

- Gorny, A.; Katsman, A.; Shepelev, D. Precipitation sequence in Mg-Zn-Sn based alloys. Mater. Res. Soc. Symp. Proc. 2006, 979, 61–66. [Google Scholar] [CrossRef]

- Clark, J.B. Transmission electron microscopy study of age hardening in a Mg-5 wt.% Zn alloy. Acta Metall. 1965, 13, 1281–1289. [Google Scholar] [CrossRef]

- Chun, J.; Byrne, J. Precipitate strengthening mechanisms in magnesium zinc alloy single crystals. J. Mater. Sci. 1969, 4, 861–872. [Google Scholar] [CrossRef]

- Nie, J.F. Precipitation and hardening in magnesium alloys. Metall. Mater. Trans. A 2012, 43, 3891–3939. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Dou, Y.C.; Dong, H.B. Intrinsic ductility of Mg-based binary alloys: A first-principles study. Scr. Mater. 2014, 89, 13–16. [Google Scholar] [CrossRef]

- Cohen, S.; Goren-Muginstein, G.; Avraham, S.; Rashkova, B.; Dehm, G. Precipitation hardening in Mg-Z-Sn alloys with minor additions of Ca and Si. Z. Für Met. 2005, 96, 1081–1087. [Google Scholar] [CrossRef]

- Nam, N.D. Corrosion behavior of Mg–5Al based magnesium alloy with 1 wt.% Sn, Mn and Zn additions in 3.5 wt.% NaCl solution. J. Magnes. Alloy. 2014, 2, 190–195. [Google Scholar] [CrossRef]

- Smith, C.S. Grains, phases, and interfaces an interpretation of microstructure. Met. Technol. 1948, 175, 15–51. [Google Scholar]

- Xiao, Y.; Zhang, X.M.; Chen, J.M.; Jiang, H. Microstructures and mechanical properties of extruded Mg-9Gd-4Y-0.6Zr-T5 at elevated temperatures. Trans. Nonferrous Met. Soc. China 2006, 16, 709–714. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hou, C.; Ye, Z.; Qi, F.; Lu, L.; She, J.; Wang, L.; Ouyang, X.; Zhao, N.; Chen, J. Microstructure and Mechanical Properties of As-Aged Mg-Zn-Sn-Mn-Al Alloys. Materials 2023, 16, 109. https://doi.org/10.3390/ma16010109

Hou C, Ye Z, Qi F, Lu L, She J, Wang L, Ouyang X, Zhao N, Chen J. Microstructure and Mechanical Properties of As-Aged Mg-Zn-Sn-Mn-Al Alloys. Materials. 2023; 16(1):109. https://doi.org/10.3390/ma16010109

Chicago/Turabian StyleHou, Caihong, Zhisong Ye, Fugang Qi, Liwei Lu, Jia She, Lifei Wang, Xiaoping Ouyang, Nie Zhao, and Jing Chen. 2023. "Microstructure and Mechanical Properties of As-Aged Mg-Zn-Sn-Mn-Al Alloys" Materials 16, no. 1: 109. https://doi.org/10.3390/ma16010109