Fabrication of MgO-Y2O3 Composite Nanopowders by Combining Hydrothermal and Seeding Methods

Abstract

1. Introduction

2. Materials and Methods

2.1. Powders

2.2. HP Process

2.3. Characterization

3. Results and Discussion

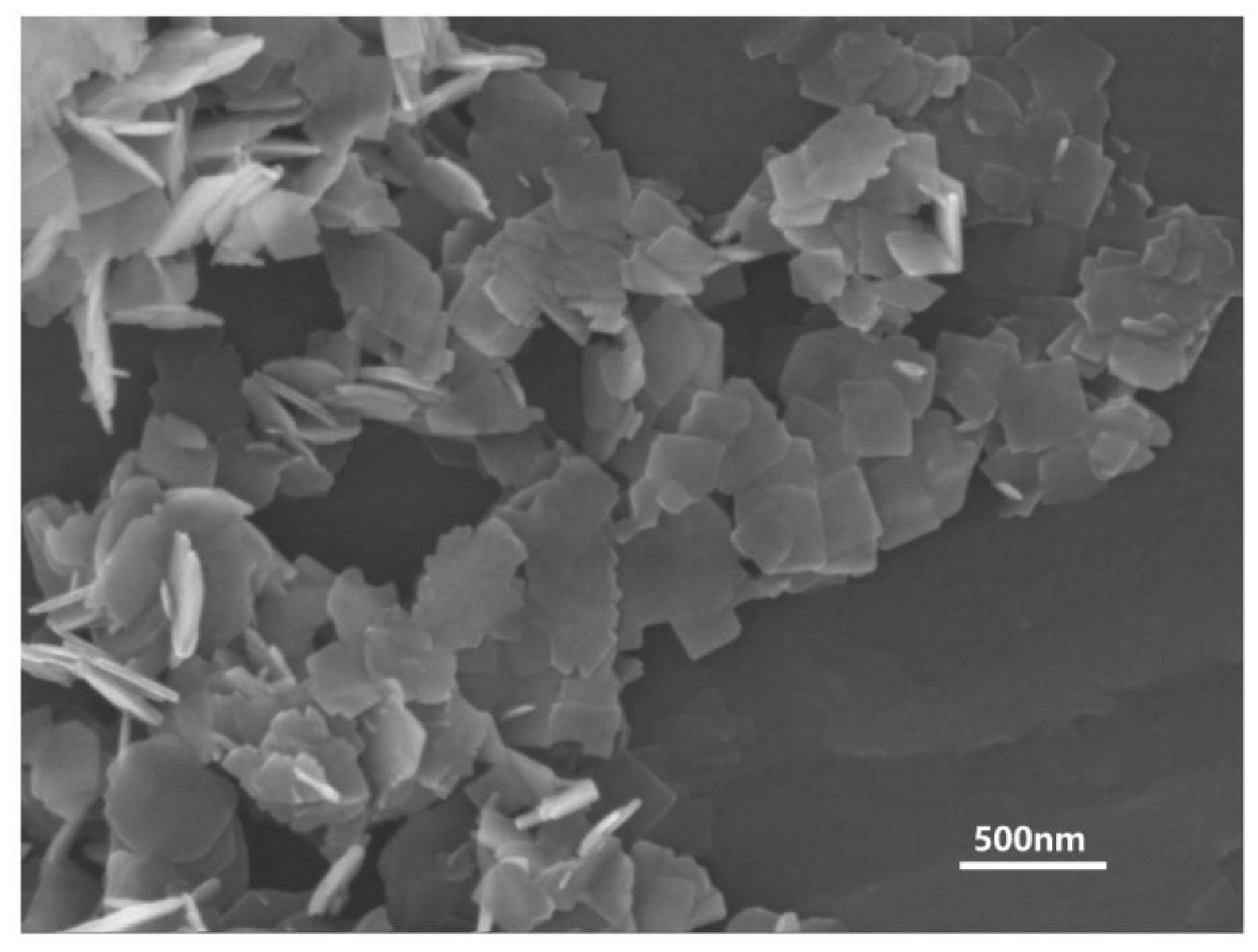

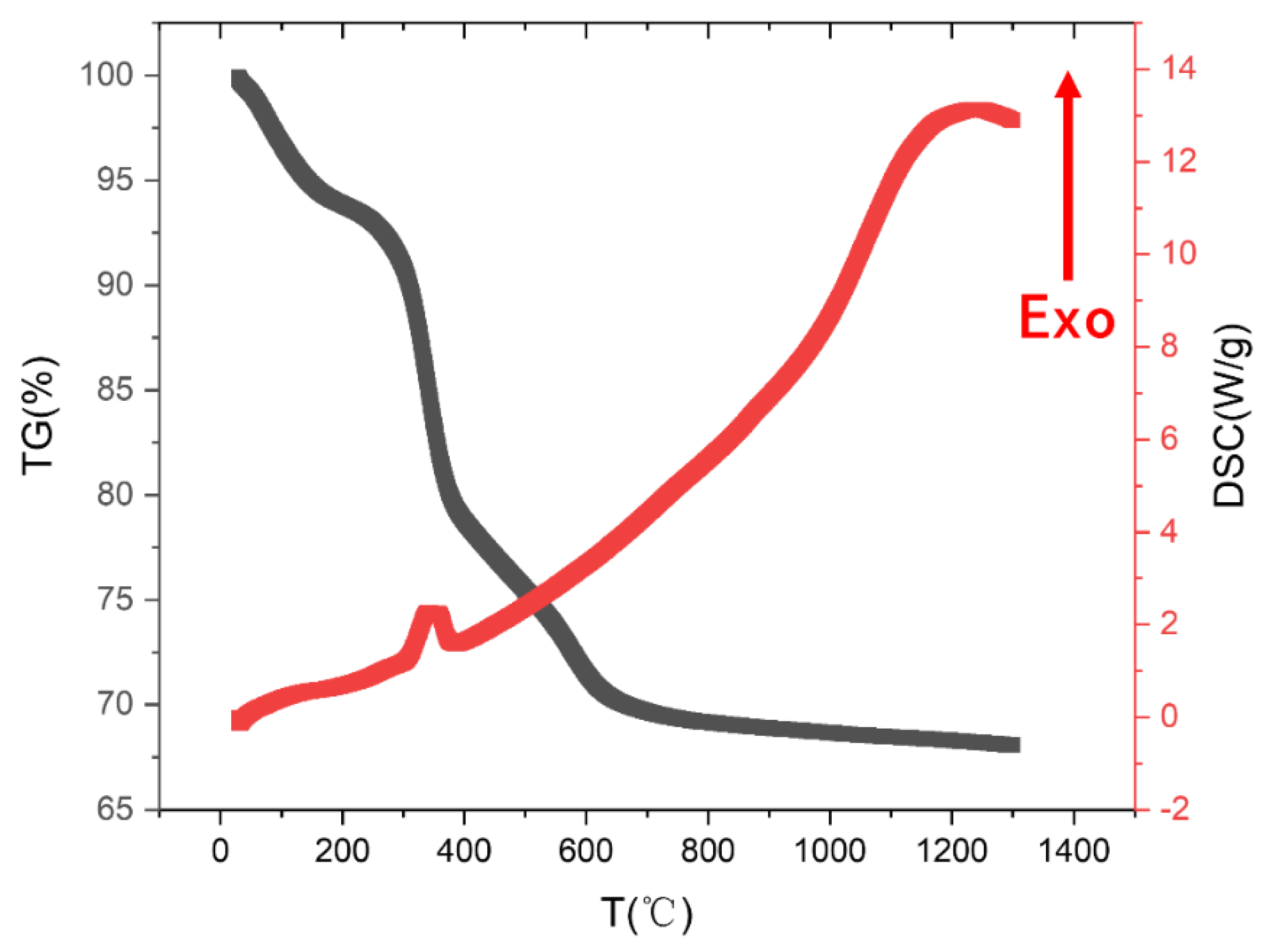

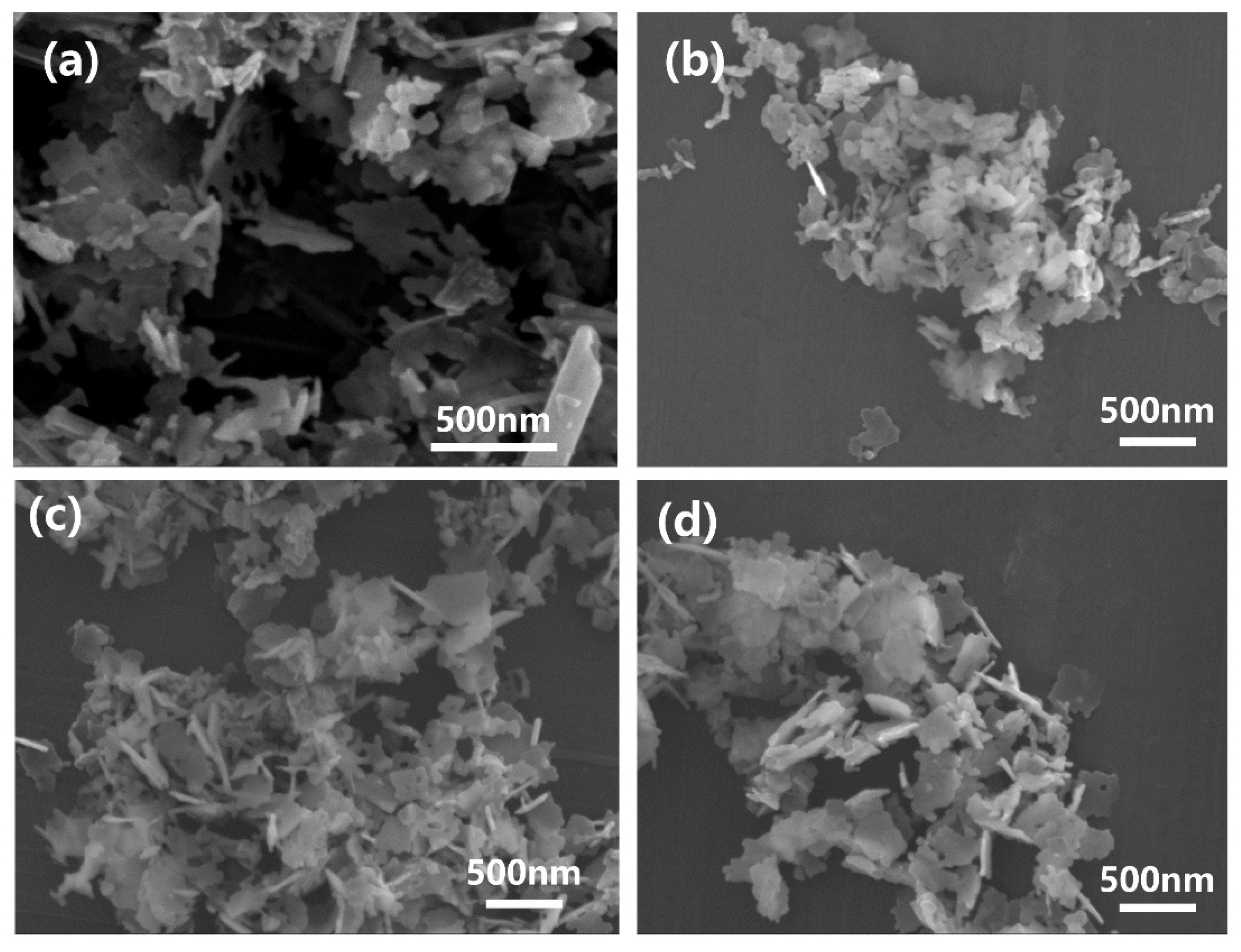

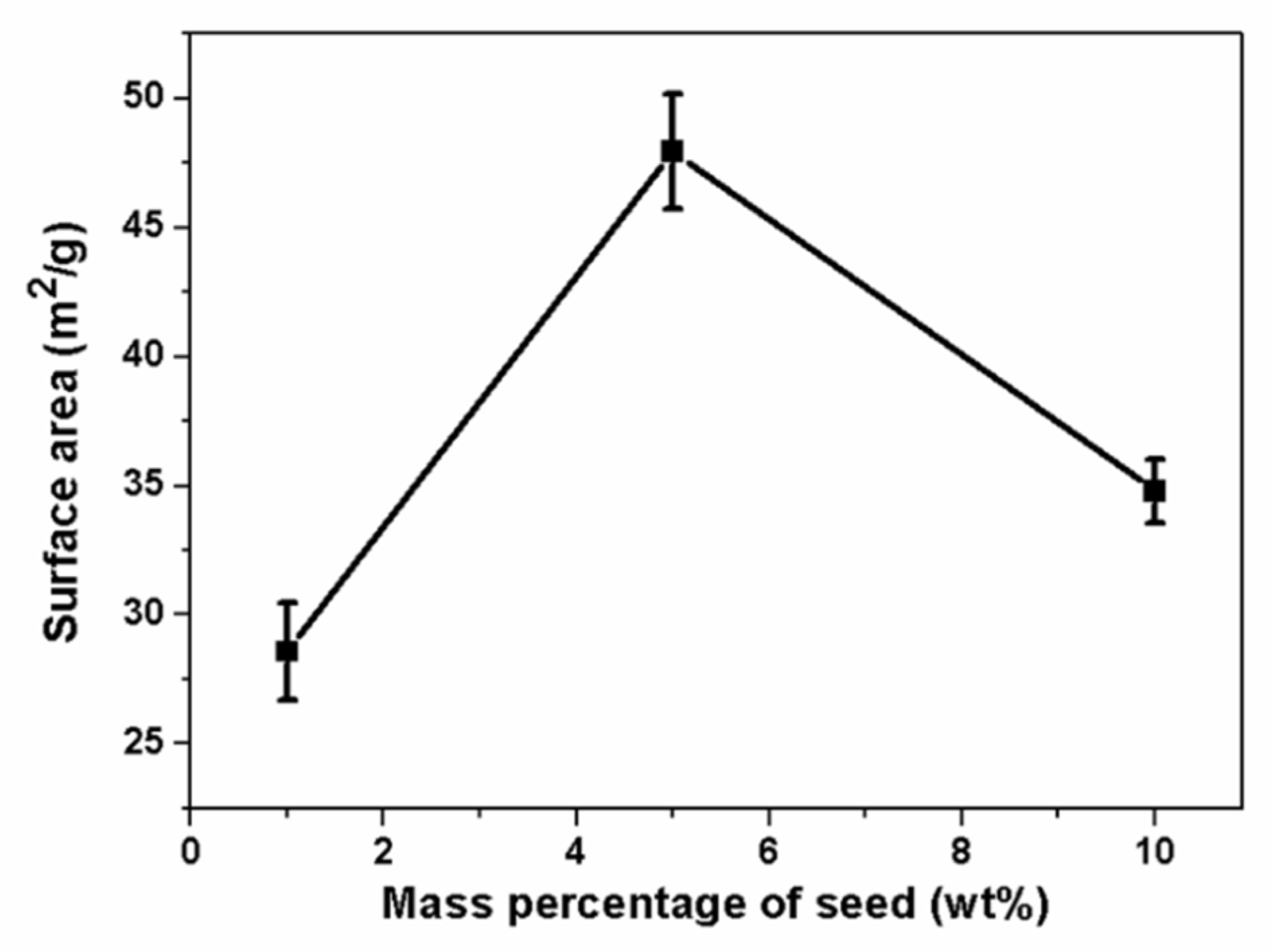

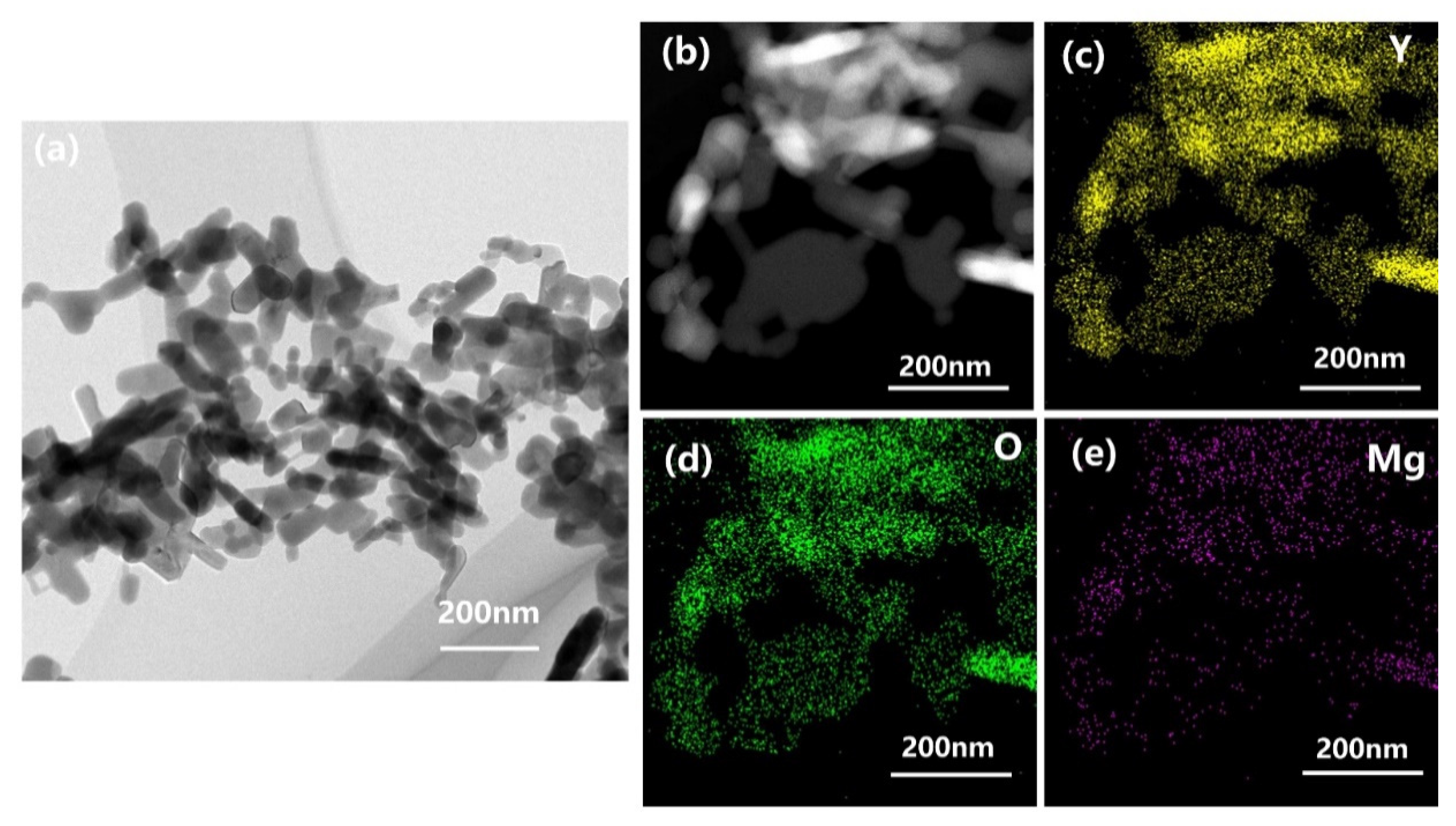

3.1. Characterization of the MgO-Y2O3 Nanopowders

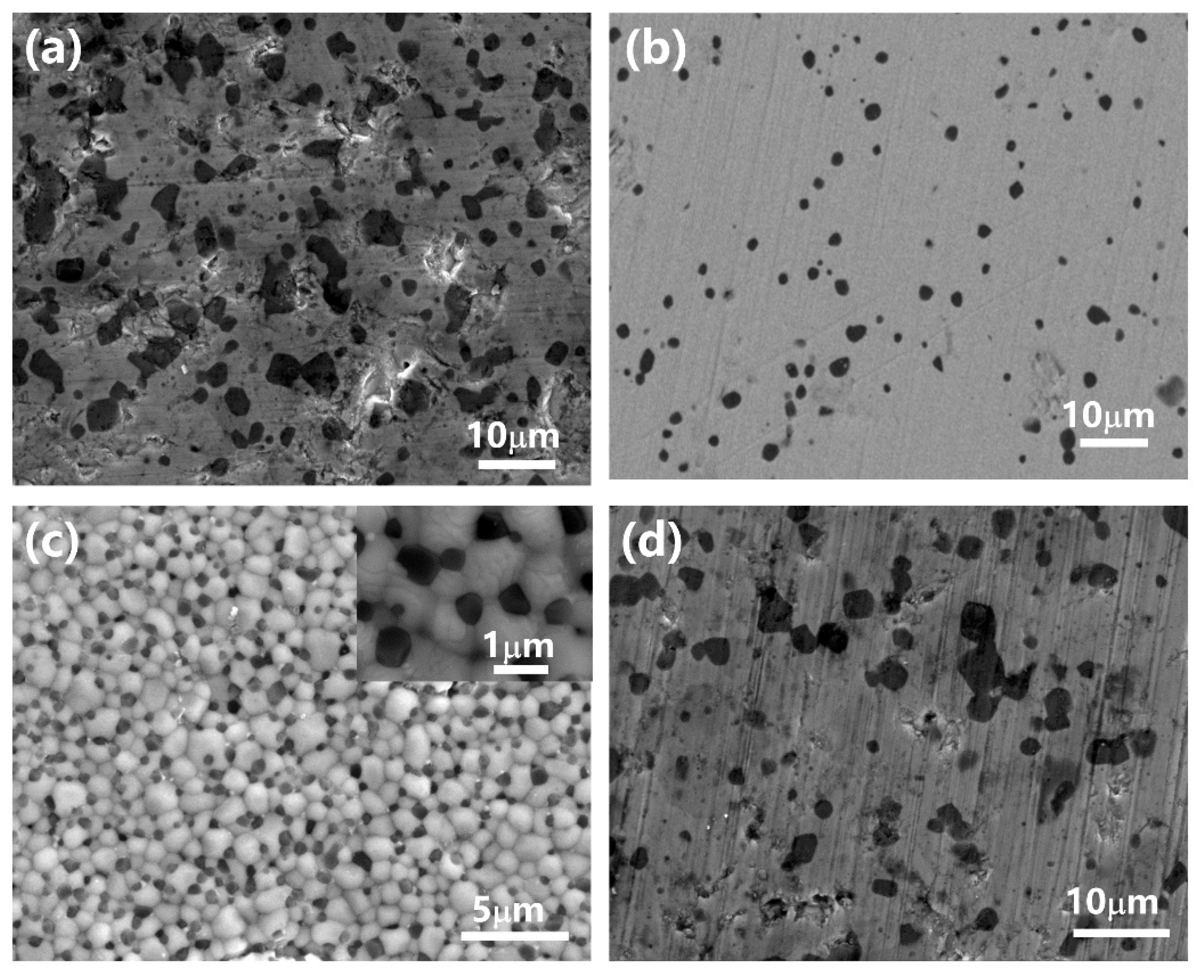

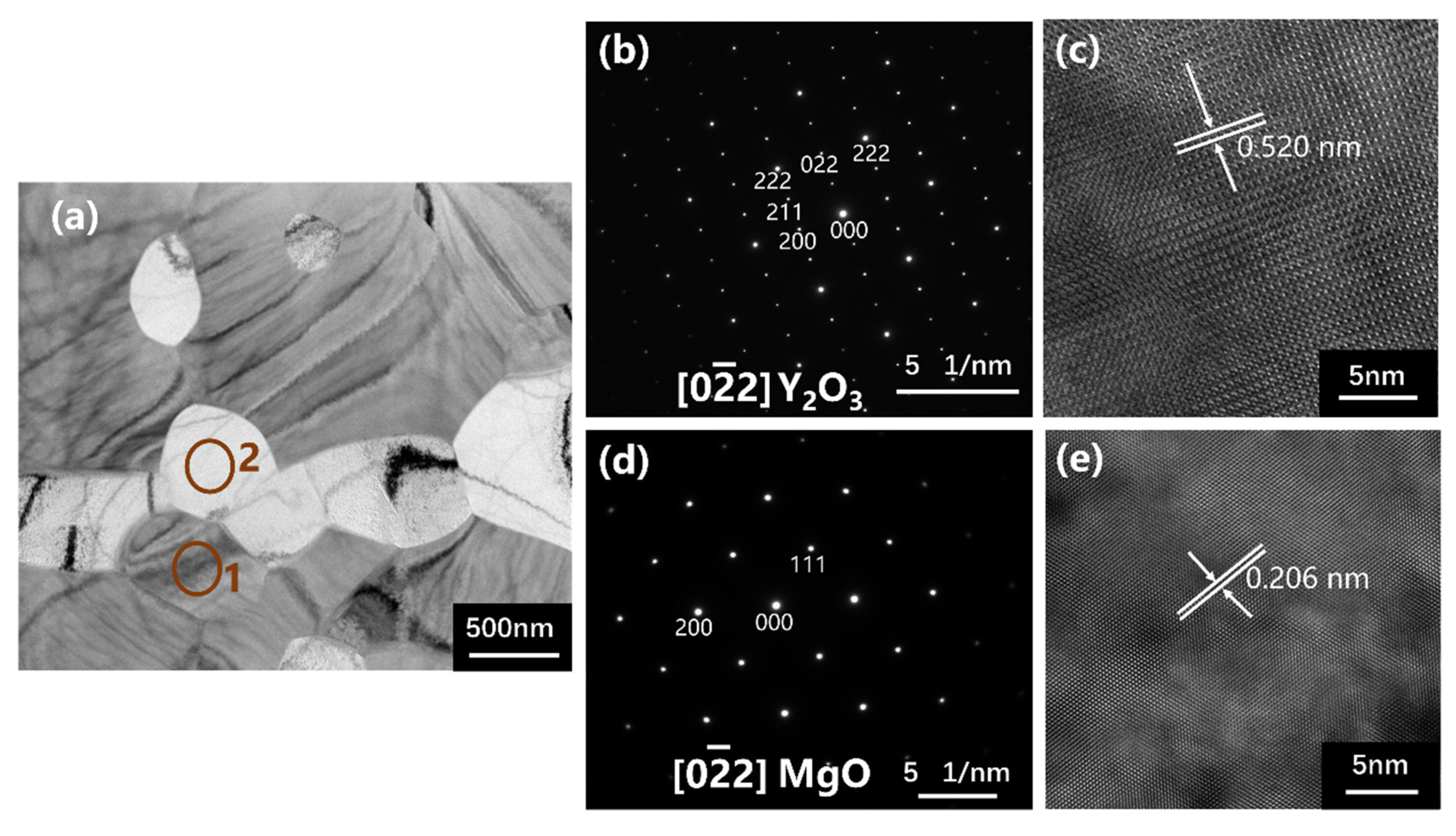

3.2. Characterization of the MgO-Y2O3 Ceramics

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mathew, C.T.; Thomas, J.K.; Swapna, Y.V.; Koshy, J.; Solomon, S. A Comprehensive analysis of the influence of resistive coupled microwave sintering on the optical, thermal and hardness properties of infrared transparent yttria-magnesia composites. Ceram. Int. 2017, 43, 17048–17056. [Google Scholar]

- He, Y.; Liu, K.; Xiang, B.; Zhou, C.; Zhang, L.; Liu, G.; Guo, X.; Zhai, J.; Li, T.; Kong, L.B. An overview on transparent ceramics with pyrochlore and fluorite structures. J. Adv. Dielectr. 2020, 10, 2030001. [Google Scholar] [CrossRef]

- Fu, Z.; Li, X.; Ren, Y.; Zhang, M.; Geng, X.; Zhu, Q.; Li, J.G.; Sun, X. Coating Y2O3 nano-particles with ZrO2-additive via precipitation method for colloidal processing of highly transparent Y2O3 ceramics. J. Eur. Ceram. Soc. 2019, 39, 4996–5004. [Google Scholar] [CrossRef]

- Zhang, L.; Pan, W.; Feng, J. Dependence of spectroscopic and thermal properties on concentration and temperature for Yb:Y2O3 transparent ceramics. J. Eur. Ceram. Soc. 2015, 35, 2547–2554. [Google Scholar] [CrossRef]

- Lukowiak, A.; Zur, L.; Tran, T.; Meneghetti, M.; Berneschi, S.; Nunzi Conti, G.; Pelli, S.; Trono, C.; Bhaktha, B.N.; Zonta, D.; et al. Sol-gel-derived glass-ceramic photorefractive films for photonic structures. Crystals 2017, 7, 61. [Google Scholar] [CrossRef]

- Dai, Y.; Zhang, Z.; Wang, X.; Lu, Z.; Kou, H.; Su, L.; Wu, A. Growth and characterization of Ce-doped luag single crystal fibers from transparent ceramics by laser-heated pedestal method. Crystals 2021, 11, 1149. [Google Scholar] [CrossRef]

- Fan, J.; Xu, Y.; Qin, X.; Mao, X.; Zhang, L. Comparative study on transmittance and radiance of sapphire, YAG, spinel, MgF2 and Y2O3 at high temperatures. Infrared Technol. 2017, 39, 951–957. [Google Scholar]

- Han, C. Development trends and analysis of the infrared countermeasure technology. Ship Electron. Eng. 2009, 29, 43–46. [Google Scholar]

- Zhang, W.; Wu, J.; Hu, X. A test method to real laser seeker based on electro-optic countermeasure. Infrared Laser Eng. 2013, 42, 637–642. [Google Scholar]

- Rhodes, W.H. Controlled transient solid second-phase sintering of yttria. J. Am. Ceram. Soc. 1981, 64, 13–19. [Google Scholar] [CrossRef]

- Mao, X.; Li, X.; Feng, M.; Fan, J.; Jiang, B.; Zhang, L. Cracks in transparent La-doped yttria ceramics and the formation mechanism. J. Eur. Ceram. Soc. 2015, 35, 3137–3143. [Google Scholar] [CrossRef]

- Yin, D.; Wang, J.; Ni, M.; Liu, P.; Dong, Z.; Tang, D. Fabrication of highly transparent Y2O3 ceramics with CaO as sintering aid. Materials 2021, 14, 444. [Google Scholar] [CrossRef] [PubMed]

- Huang, Z.; Deng, J.; Wang, H.; Zhang, Y.; Duan, J.; Tang, Z.; Yang, Y.; He, D.; Qi, J.; Lu, T. A New method for the preparation of transparent Y2O3 nanocrystalline ceramic with an average grain size of 20 nm. Scr. Mater. 2020, 182, 57–61. [Google Scholar] [CrossRef]

- Yavetskiy, R.P.; Baumer, V.N.; Dulina, N.A.; Pazura, Y.I.; Petrusha, I.A.; Tkach, V.N.; Tolmachev, A.V.; Turkevich, V.Z. An approach to Y2O3:Eu3+ optical nanostructured ceramics. J. Eur. Ceram. Soc. 2012, 32, 257–260. [Google Scholar] [CrossRef]

- Horvath, S.F.; Harmer, M.P. Analytical transmission electron microscopy of La2O3-doped Y2O3. J. Mater. Sci. 1989, 24, 863–872. [Google Scholar] [CrossRef]

- Yoshida, H.; Morita, K.; Kim, B.N.; Hiraga, K.; Kodo, M.; Soga, K.; Yamamoto, T. Densification of nanocrystalline yttria by low temperature spark plasma sintering. J. Am. Ceram. Soc. 2008, 91, 1707–1710. [Google Scholar] [CrossRef]

- Ma, H.J.; Jung, W.K.; Park, Y.; Kim, D.K. A novel approach of an infrared transparent Er:Y2O3 -MgO nanocomposite for eye-safe laser ceramics. J. Mater. Chem. C 2018, 6, 11096–11103. [Google Scholar] [CrossRef]

- Blair, V.L.; Fleischman, Z.D.; Merkle, L.D.; Ku, N.; Moorehead, C.A. Co-precipitation of rare-earth-doped Y2O3 and MgO nanocomposites for mid-infrared solid-state lasers. Appl. Opt. 2017, 56, 154–158. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, J.; Ning, K.; Luo, D.; Yang, H.; Yin, D.; Tang, D.; Kong, L.B. Densification of yttria transparent ceramics: The utilization of activated sintering. J. Am. Ceram. Soc. 2016, 99, 1671–1675. [Google Scholar] [CrossRef]

- Ikegami, T.; Kobayashi, M.; Moriyoshii, Y.; Shirasaki, S.I.; Suzuki, H. Characterization of sintered MgO compacts with fluorine. J. Am. Ceram. Soc. 1980, 63, 640–643. [Google Scholar] [CrossRef]

- Chen, M.; He, J.; Zhang, Y.; Ding, Z.; Luo, J. Densification and grain growth behaviour of high-purity MgO ceramics by hot-pressing. Ceram. Int. 2017, 43, 1775–1780. [Google Scholar] [CrossRef]

- Harris, D.C. Durable 3-5 µm Transmitting infrared window materials. Infrared Phys. Technol. 1998, 39, 185–201. [Google Scholar] [CrossRef]

- Harris, D.C.; Cambrea, L.R.; Johnson, L.F.; Seaver, R.T.; Baronowski, M.; Gentilman, R.; Scott Nordahl, C.; Gattuso, T.; Silberstein, S.; Rogan, P.; et al. Properties of an infrared-transparent MgO:Y2O3 nanocomposite. J. Am. Ceram. Soc. 2013, 96, 3828–3835. [Google Scholar] [CrossRef]

- Mangalaraja, R.V.; Mouzon, J.; Hedström, P.; Kero, I.; Ramam, K.V.S.; Camurri, C.P.; Odén, M. Combustion synthesis of Y2O3 and Yb-Y2O3. J. Mater. Process. Technol. 2008, 208, 415–422. [Google Scholar] [CrossRef]

- Zhang, L.; Ben, Y.; Wu, J.; Yang, H.; Wong, C.; Zhang, Q.; Chen, H. Alumina assisted grain refinement and physical performance enhancement of yttria transparent ceramics by two-step sintering. Mater. Sci. Eng. 2017, 684, 466–469. [Google Scholar] [CrossRef]

- Kumar, R.S.; Priyanka, K.H.S.; Khanra, A.K.; Johnson, R. A Novel approach of synthesizing nano Y2O3 powders for the fabrication of submicron IR transparent ceramics. Ceram. Int. 2021, 47, 16986–16999. [Google Scholar] [CrossRef]

- Kargar, H.; Ghasemi, F.; Darroudi, M. Bioorganic polymer-based synthesis of cerium oxide nanoparticles and their cell viability assays. Ceram. Int. 2015, 41, 1589–1594. [Google Scholar] [CrossRef]

- Ikeg, T.; Mori, T.; Yajima, Y.; Takenouchi, S.; Misawa, T.; Moriyoshi, Y. And doping by sulfate ions. J. Ceram. Soc. Jpn. 1999, 107, 297–299. [Google Scholar]

- Vaez, S.H.; Razavi, R.S.; Loghman-Estarki, M.R.; Alhaji, A.; Ghorbani, S.; Mishra, A.K. Development of magnesia-yttria nanocomposite powder by new non-alkoxide sol-gel method. Ceram. Int. 2017, 43, 1217–1226. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, J.; Ning, K.; Ma, J.; Luo, D.; Yin, D.; Yang, H.; Tang, D.; Kong, L.B. Densification of zirconia doped yttria transparent ceramics using co-precipitated powders. Ceram. Int. 2016, 42, 10770–10778. [Google Scholar] [CrossRef]

- Yoshimura, M.; Byrappa, K. Hydrothermal processing of materials: Past, present and future. J. Mater. Sci. 2008, 43, 2085–2103. [Google Scholar] [CrossRef]

- Sharma, P.K.; Jilavi, M.H.; NAû, R.; Schmidt, H. Seeding effect in hydrothermal synthesis of nanosize yttria. J. Mater. Sci. 1998, 17, 823–825. [Google Scholar]

- Jung, W.K.; Ma, H.J.; Park, Y.; Kim, D.K. A robust approach for highly transparent Y2O3 ceramics by stabilizing oxygen defects. Scr. Mater. 2017, 137, 1–4. [Google Scholar] [CrossRef]

- Fu, Z.; Li, X.; Zhang, M.; Zhu, Q.; Li, J.; He, J.; Wang, X.; Sun, X. Achieving fabrication of highly transparent Y2O3 ceramics via air pre-sintering by deionization treatment of suspension. J. Am. Ceram. Soc. 2021, 104, 2689–2701. [Google Scholar] [CrossRef]

- Wang, W.; Chen, J.; Sun, X.; Sun, G.; Liang, Y.; Bi, J. Mechanical properties and microstructure of hot-pressed silica matrix composites. Materials 2022, 15, 3666. [Google Scholar] [CrossRef]

- Halikia, I.; Neou-Syngouna, P.; Kolitsa, D. Isothermal kinetic analysis of the thermal decomposition of magnesium hydroxide using thermogravimetric data. Thermochim. Acta 1998, 320, 75–88. [Google Scholar] [CrossRef]

- Iwasaki, S.; Kodani, S.; Koga, N. Physico-geometrical kinetic modeling of the thermal decomposition of magnesium hydroxide. J. Phys. Chem. C 2020, 124, 2458–2471. [Google Scholar] [CrossRef]

- Shen, Z.; Zhu, Q.; Feng, T.; Qian, K.; Xie, J.; Liu, L.; Zhang, G.; Wang, W.; Yuan, Q.; Feng, M.; et al. Fabrication of infrared-transparent Y2O3-MgO composites using nanopowders synthesized via thermal decomposition. Ceram. Int. 2021, 47, 13007–13014. [Google Scholar] [CrossRef]

- Mehta, P.K. History and Status of Performance Tests for Evaluation of Soundness of Cements. Cement Standards-Evolution and Trends; ASTM: West Conshohocken, PA, USA, 1978; p. 663. [Google Scholar]

- Kabir, H.; Hooton, R.D.; Popoff, N.J. Evaluation of cement soundness using the ASTM C151 autoclave expansion test. Cem. Conc. Res. 2020, 136, 106159. [Google Scholar] [CrossRef]

- Ma, H.J.; Jung, W.K.; Baek, C.; Kim, D.K. Influence of microstructure control on optical and mechanical properties of infrared transparent Y2O3-MgO nanocomposite. J. Eur. Ceram. Soc. 2017, 37, 4902–4911. [Google Scholar] [CrossRef]

- Pratapa, S.; O’Connor, B.; Hunter, B. A comparative study of single-line and rietveld strain-size evaluation procedures using MgO ceramics. J. Appl. Crystallogr. 2002, 35, 155–162. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, S.; Lan, H.; Sun, X.; Feng, S.; Zhang, W. Fabrication of MgO-Y2O3 Composite Nanopowders by Combining Hydrothermal and Seeding Methods. Materials 2023, 16, 126. https://doi.org/10.3390/ma16010126

Yang S, Lan H, Sun X, Feng S, Zhang W. Fabrication of MgO-Y2O3 Composite Nanopowders by Combining Hydrothermal and Seeding Methods. Materials. 2023; 16(1):126. https://doi.org/10.3390/ma16010126

Chicago/Turabian StyleYang, Shangyu, Hao Lan, Xiaoming Sun, Shaowei Feng, and Weigang Zhang. 2023. "Fabrication of MgO-Y2O3 Composite Nanopowders by Combining Hydrothermal and Seeding Methods" Materials 16, no. 1: 126. https://doi.org/10.3390/ma16010126

APA StyleYang, S., Lan, H., Sun, X., Feng, S., & Zhang, W. (2023). Fabrication of MgO-Y2O3 Composite Nanopowders by Combining Hydrothermal and Seeding Methods. Materials, 16(1), 126. https://doi.org/10.3390/ma16010126