Effect of Vacancy Behavior on Precipitate Formation in a Reduced-Activation V−Cr−Mn Medium-Entropy Alloy

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Experimental Methods

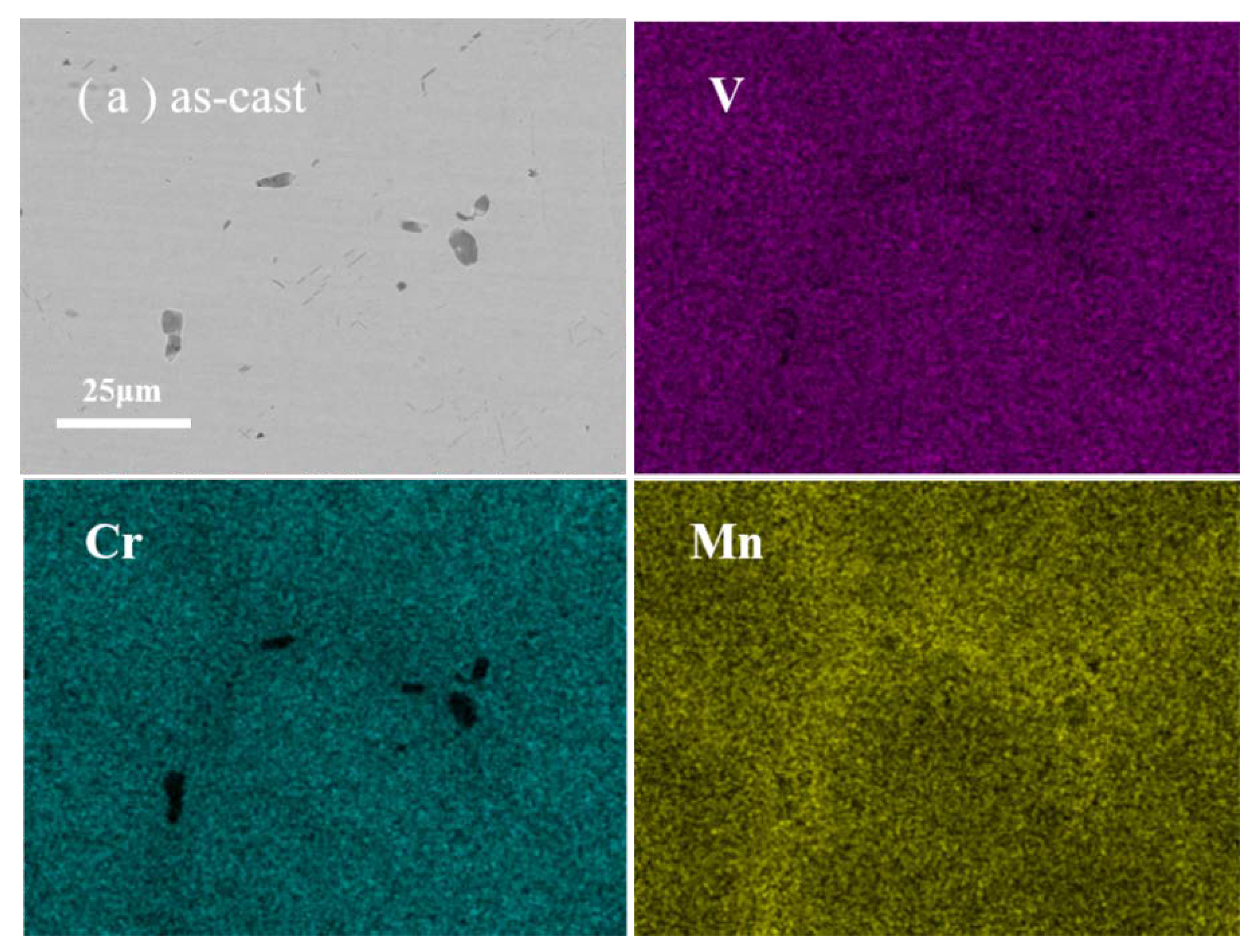

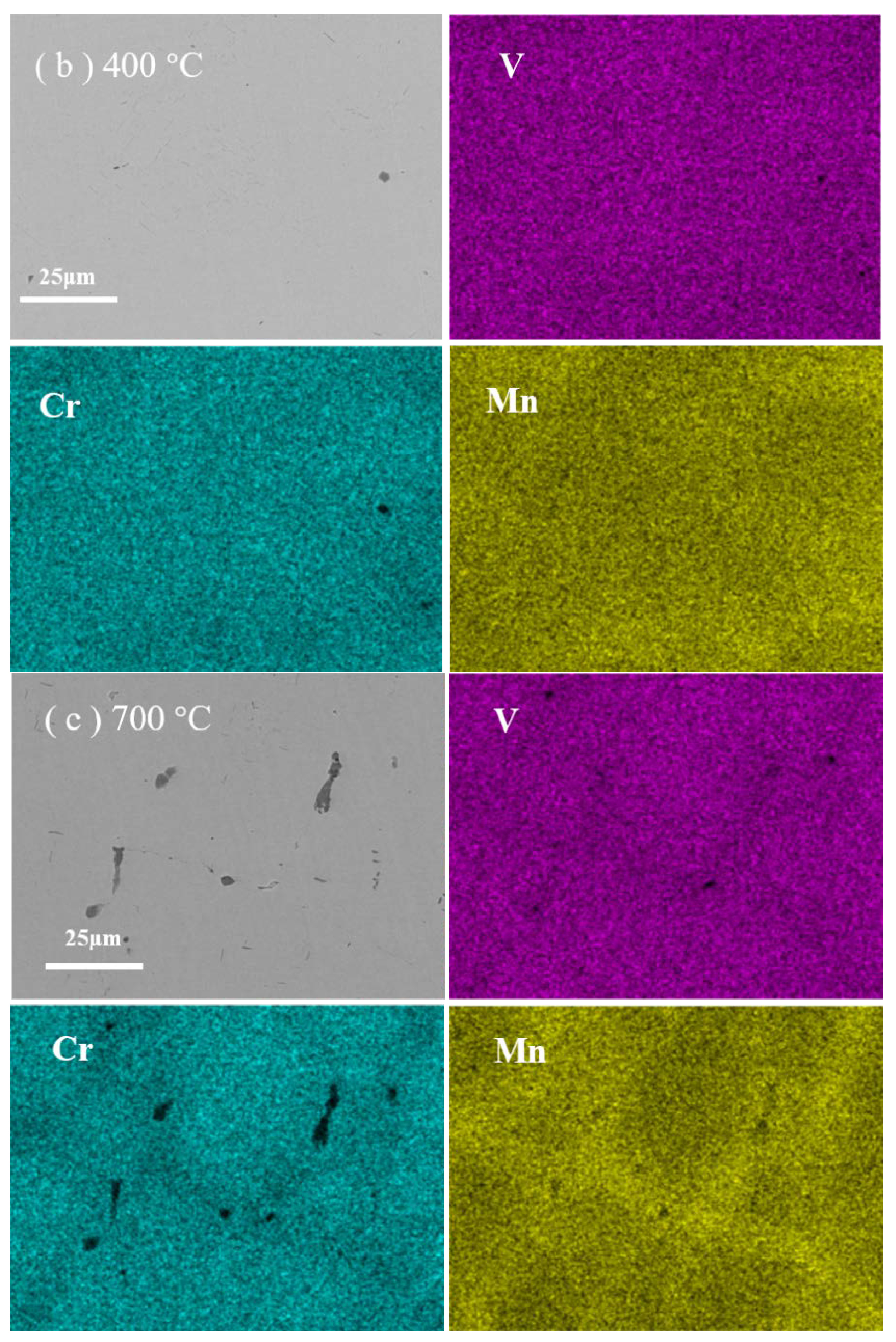

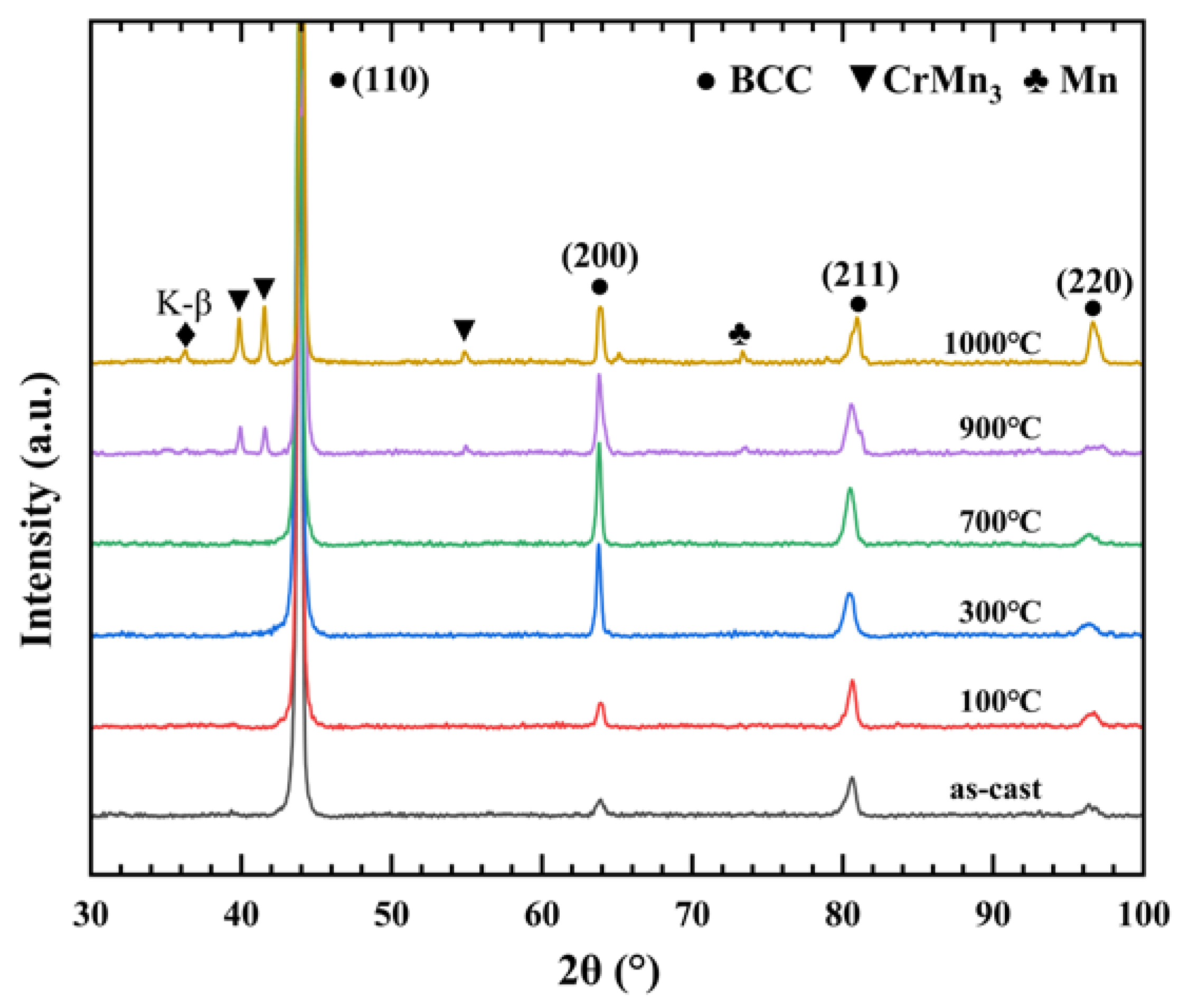

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jones, R.H.; Heinisch, H.L.; McCarthy, K.A. Low activation materials. J. Nucl. Mater. 1999, 271, 518–525. [Google Scholar] [CrossRef]

- Rocco, P.; Zucchetti, M. Criteria for defining low activation materials in fusion-reactor applications. Fusion Eng. Des. 1992, 15, 235–244. [Google Scholar] [CrossRef]

- Seki, Y.; Tabara, T.; Aoki, I.; Ueda, S.; Nishio, S.; Kurihara, R. Impact of low activation materials on fusion reactor design. J. Nucl. Mater. 1998, 258, 1791–1797. [Google Scholar] [CrossRef]

- Ayyagari, A.; Salloom, R.; Muskeri, S.; Mukherjee, S. Low activation high entropy alloys for next generation nuclear applications. Materialia 2018, 4, 99–103. [Google Scholar] [CrossRef]

- Zhu, T.; Jin, S.X.; Yan, Q.Z.; Wang, B.Y.; Song, L.G.; Hong, Z.Y.; Zhang, P.; Zhang, Q.L.; Fan, P.; Yuan, D.Q.; et al. Radiation-induced precipitates in ferritic-martensitic steels and their radiation resistance effects. Mater. Today Commun. 2022, 33, 104629. [Google Scholar] [CrossRef]

- Zhu, T.; Cao, X.Z.; Jin, S.X.; Zhang, P.; Lu, E.Y.; Kuang, P.; Gong, Y.H.; Guo, L.P.; Xu, Q.; Wang, B.Y. Thermal evolution of irradiation defects in ferritic/martensitic steel during isochronal annealing. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2018, 436, 35–39. [Google Scholar] [CrossRef]

- Barron, P.J.; Carruthers, A.W.; Fellowes, J.W.; Jones, N.G.; Dawson, H.; Pickering, E.J. Towards V-based high-entropy alloys for nuclear fusion applications. Scr. Mater. 2020, 176, 12–16. [Google Scholar] [CrossRef]

- Muroga, T.; Chen, J.M.; Chernov, V.M.; Kurtz, R.J.; Le Flem, M. Present status of vanadium alloys for fusion applications. J. Nucl. Mater. 2014, 455, 263–268. [Google Scholar] [CrossRef]

- Carruthers, A.W.; Li, B.S.; Rigby, M.; Raquet, L.C.; Mythili, R.; Ghosh, C.; Dasgupta, A.; Armstrong, D.E.J.; Gandy, A.S.; Pickering, E.J. Novel reduced-activation TiVCrFe based high entropy alloys. J. Alloys Compd. 2021, 856, 157399. [Google Scholar] [CrossRef]

- Jodi, D.E.; Listyawan, T.A.; Hruska, P.; Cizek, J.; Park, N.; Lee, U. Study of vacancies in Fe-x(CoCrMnNi)(100-x) medium- and high-entropy alloys by positron annihilation spectroscopy. Scr. Mater. 2021, 194, 113654. [Google Scholar] [CrossRef]

- Zhu, T.; Zhong, Z.; Sato, K.; Song, Y.; Ye, F.; Wang, Q.; Dong, Y.; Zhang, P.; Yu, R.; Wang, B.; et al. Effects of hydrogen charging and deformation on tensile properties of a multi-component alloy for nuclear applications. Tungsten 2022, 4, 212–218. [Google Scholar] [CrossRef]

- Ye, F.; Zhu, T.; Wang, Q.; Song, Y.; Zhang, H.; Zhang, P.; Kuang, P.; Yu, R.; Cao, X.; Wang, B.Y. Positron annihilation study of open volume defects and Cr segregation in deformed CoCrFeMnNi alloy. Intermetallics 2022, 149, 107670. [Google Scholar] [CrossRef]

- Muroga, T.; Gasparotto, M.; Zinkle, S.J. Overview of materials research for fusion reactors. Fusion Eng. Des. 2002, 61–62, 13–25. [Google Scholar] [CrossRef]

- Zinkle, S.J.; Ghoniem, N.M. Operating temperature windows for fusion reactor structural materials. Fusion Eng. Des. 2000, 51–52, 55–71. [Google Scholar] [CrossRef]

- Mansur, L.K.; Rowcliffe, A.F.; Nanstad, R.K.; Zinkle, S.J.; Corwin, W.R.; Stoller, R.E. Materials needs for fusion, Generation IV fission reactors and spallation neutron sources—Similarities and differences. J. Nucl. Mater. 2004, 329, 166–172. [Google Scholar] [CrossRef]

- Chen, P.S.; Liao, Y.C.; Lin, Y.T.; Tsai, P.H.; Jang, J.S.C.; Hsieh, K.C.; Chen, C.Y.; Huang, J.C.; Wu, H.J.; Tsao, I.Y. Development of Novel Lightweight Al-Rich Quinary Medium-Entropy Alloys with High Strength and Ductility. Materials 2021, 14, 4223. [Google Scholar] [CrossRef]

- Nagasaka, T.; Heo, N.J.; Muroga, T.; Imamura, M. Examination of fabrication process parameters for improvement of low-activation vanadium alloys. Fusion Eng. Des. 2002, 61–62, 757–762. [Google Scholar] [CrossRef]

- Smith, D.L.; Chung, H.M.; Loomis, B.A.; Tsai, H.C. Reference vanadium alloy V-4Cr-4Ti for fusion application. J. Nucl. Mater. 1996, 233, 356–363. [Google Scholar] [CrossRef]

- Nagai, Y.; Takadate, K.; Tang, Z.; Ohkubo, H.; Sunaga, H.; Takizawa, H.; Hasegawa, M. Positron annihilation study of vacancy-solute complex evolution in Fe-based alloys. Phys. Rev. B 2003, 67, 224202. [Google Scholar] [CrossRef]

- Lian, X.Y.; Cao, X.Z.; Zhao, Y.J.; Jin, S.X.; Luo, J.B.; Zhu, T.; Gong, Y.H.; Wang, B.Y.; Yu, R.S. Evolution of Thermally-Induced Microstructural Defects in the Fe-9Cr Alloy. Phys. Status Solidi 2018, 215, 1700349. [Google Scholar] [CrossRef]

- Ahmad, M.; Ahmad, W.; Shaikh, M.A.; Ahmad, M.; Rajput, M.U. Precipitation study in inconel 625 alloy by positron annihilation spectroscopy. J. Mater. Sci. Technol. 2003, 19, 434–436. [Google Scholar] [CrossRef]

- Konstantinovic, M.J.; Bonny, G. Thermal stability and the structure of vacancy-solute clusters in iron alloys. Acta Mater. 2015, 85, 107–111. [Google Scholar] [CrossRef]

- Nagai, Y.; Hasegawa, M.; Tang, Z.; Hempel, A.; Yubuta, K.; Shimamura, T.; Kawazoe, Y.; Kawai, A.; Kano, F. Positron confinement in ultrafine embedded particles: Quantum-dot-like state in an Fe-Cu alloy. Phys. Rev. B 2000, 61, 6574–6578. [Google Scholar] [CrossRef]

- An, X.; Zhang, H.; Zhu, T.; Wang, Q.; Zhang, P.; Song, Y.; Wan, M.; Yang, T.; Cao, X. Exploration of vacancy defect formation and evolution in low-energy ion implanted pure titanium. Int. J. Hydrog. Energy 2022, 47, 8467–8479. [Google Scholar] [CrossRef]

- Alatalo, M.; Barbiellini, B.; Hakala, M.; Kauppinen, H.; Korhonen, T.; Puska, M.J.; Saarinen, K.; Hautojarvi, P.; Nieminen, R.M. Theoretical and experimental study of positron annihilation with core electrons in solids. Phys. Rev. B 1996, 54, 2397–2409. [Google Scholar] [CrossRef]

- AsokaKumar, P.; Alatalo, M.; Ghosh, V.J.; Kruseman, A.C.; Nielsen, B.; Lynn, K.G. Increased elemental specificity of positron annihilation spectra. Phys. Rev. Lett. 1996, 77, 2097–2100. [Google Scholar] [CrossRef]

- Lynn, K.G.; Dickman, J.E.; Brown, W.L.; Robbins, M.F.; Bonderup, E. Vacancies studied by positron-annihilation with high-momentum core electrons. Phys. Rev. B 1979, 20, 3566–3572. [Google Scholar] [CrossRef]

- Xie, H.; Liu, G.; Guo, J. Effects of Mn, V, Mo, Ti, Zr elements on microstructure and high temperature oxidation performance of AlFeCrCoCu-X high-entropy alloys. Chin. J. Nonferrous Met. 2015, 25, 103–110. [Google Scholar] [CrossRef]

- Elsayed, M.; Krause-Rehberg, R.; Eisenschmidt, C.; Eissmann, N.; Kieback, B. Defect Study in CoCrFeMnNi High Entropy Alloy by Positron Annihilation Lifetime Spectroscopy. Phys. Status Solidi 2018, 215, 1800036. [Google Scholar] [CrossRef]

- Robles, J.M.C.; Ogando, E.; Plazaola, F. Positron lifetime calculation for the elements of the periodic table. J. Phys. Condes. Matter 2007, 19, 176222. [Google Scholar] [CrossRef]

- Maheshwari, P.; Keskar, N.; Sudarshan, K.; Manikrishna, K.V.; Krishnan, M.; Pujari, P.K. Investigating defect evolution during thermal treatment in Ni-Cr alloy using positron annihilation spectroscopy. J. Mater. Sci. 2021, 56, 3498–3509. [Google Scholar] [CrossRef]

- Uedono, A.; Kirimura, T.; Wilson, C.J.; Croes, K.; Demuynck, S.; Tokei, Z.; Oshima, N.; Suzuki, R. Vacancy reactions near the interface between electroplated Cu and barrier metal layers studied by monoenergetic positron beams. J. Appl. Phys. 2013, 114, 074510. [Google Scholar] [CrossRef]

- Quiroga, M.A.; Macchi, C.; Somoza, A. Vacancy assisted solute transport mechanisms responsible for the solute atom agglomeration during the early stages of aging in Al-Cu-based alloys. Phys. Rev. Mater. 2022, 6, 033603. [Google Scholar] [CrossRef]

- Nagai, Y.; Murayama, M.; Tang, Z.; Nonaka, T.; Hono, K.; Hasegawa, M. Role of vacancy-solute complex in the initial rapid age hardening in an Al-Cu-Mg alloy. Acta Mater. 2001, 49, 913–920. [Google Scholar] [CrossRef]

- Li, P.H.; Wu, Y.C.; Jiang, J.; Xue, X.D.; Liu, Y.F.; Wang, S.J.; Zhai, T. Coincidence Doppler broadening study of the precipitates of a continuous cast AA2037 Al alloy after annealing and ageing. In Proceedings of the 7th International Workshop on Positron Studies of Defects (PSD), Delft University of Technology, Delft, The Netherlands, 28 August–2 September 2011; pp. 28–33. [Google Scholar]

- Cao, X.Z.; Xu, Q.; Sato, K.; Yoshiie, T. Migration behavior of vacancies in electron irradiated Fe-Cu alloys. In Proceedings of the 15th International Conference on Positron Annihilation (ICPA 15), Kolkata, India, 18–23 January 2009; pp. 2355–2358. [Google Scholar]

- Dupasquier, A.; Kogel, G.; Somoza, A. Studies of light alloys by positron annihilation techniques. Acta Mater. 2004, 52, 4707–4726. [Google Scholar] [CrossRef]

- Somoza, A.; Petkov, M.P.; Lynn, K.G.; Dupasquier, A. Stability of vacancies during solute clustering in Al-Cu-based alloys. Phys. Rev. B 2002, 65, 094107. [Google Scholar] [CrossRef]

- Honma, T.; Yanagita, S.; Hono, K.; Nagal, Y.; Hasegawa, A. Coincidence Doppler broadening and 3DAP study of the pre-precipitation stage of an Al-Li-Cu-Mg-Ag alloy. Acta Mater. 2004, 52, 1997–2003. [Google Scholar] [CrossRef]

- Nagai, Y.; Tang, Z.; Hasegawa, M. Chemical analysis of precipitates in metallic alloys using coincidence Doppler broadening of positron annihilation radiation. Radiat. Phys. Chem. 2000, 58, 737–742. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, T.; Zhu, T.; Wang, D.; Zhang, P.; Song, Y.; Ye, F.; Wang, Q.; Jin, S.; Yu, R.; Liu, F.; et al. Effect of Vacancy Behavior on Precipitate Formation in a Reduced-Activation V−Cr−Mn Medium-Entropy Alloy. Materials 2023, 16, 153. https://doi.org/10.3390/ma16010153

Wang T, Zhu T, Wang D, Zhang P, Song Y, Ye F, Wang Q, Jin S, Yu R, Liu F, et al. Effect of Vacancy Behavior on Precipitate Formation in a Reduced-Activation V−Cr−Mn Medium-Entropy Alloy. Materials. 2023; 16(1):153. https://doi.org/10.3390/ma16010153

Chicago/Turabian StyleWang, Tianjiao, Te Zhu, Dandan Wang, Peng Zhang, Yamin Song, Fengjiao Ye, Qianqian Wang, Shuoxue Jin, Runsheng Yu, Fuyan Liu, and et al. 2023. "Effect of Vacancy Behavior on Precipitate Formation in a Reduced-Activation V−Cr−Mn Medium-Entropy Alloy" Materials 16, no. 1: 153. https://doi.org/10.3390/ma16010153

APA StyleWang, T., Zhu, T., Wang, D., Zhang, P., Song, Y., Ye, F., Wang, Q., Jin, S., Yu, R., Liu, F., Kuang, P., Wang, B., Li, L., & Cao, X. (2023). Effect of Vacancy Behavior on Precipitate Formation in a Reduced-Activation V−Cr−Mn Medium-Entropy Alloy. Materials, 16(1), 153. https://doi.org/10.3390/ma16010153