Study on the Skin Hydration and Trans Epidermal Water Loss of Aloe Viscose Seamless Knitted Fabric for Autumn and Winter

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Selection of Yarn Scheme

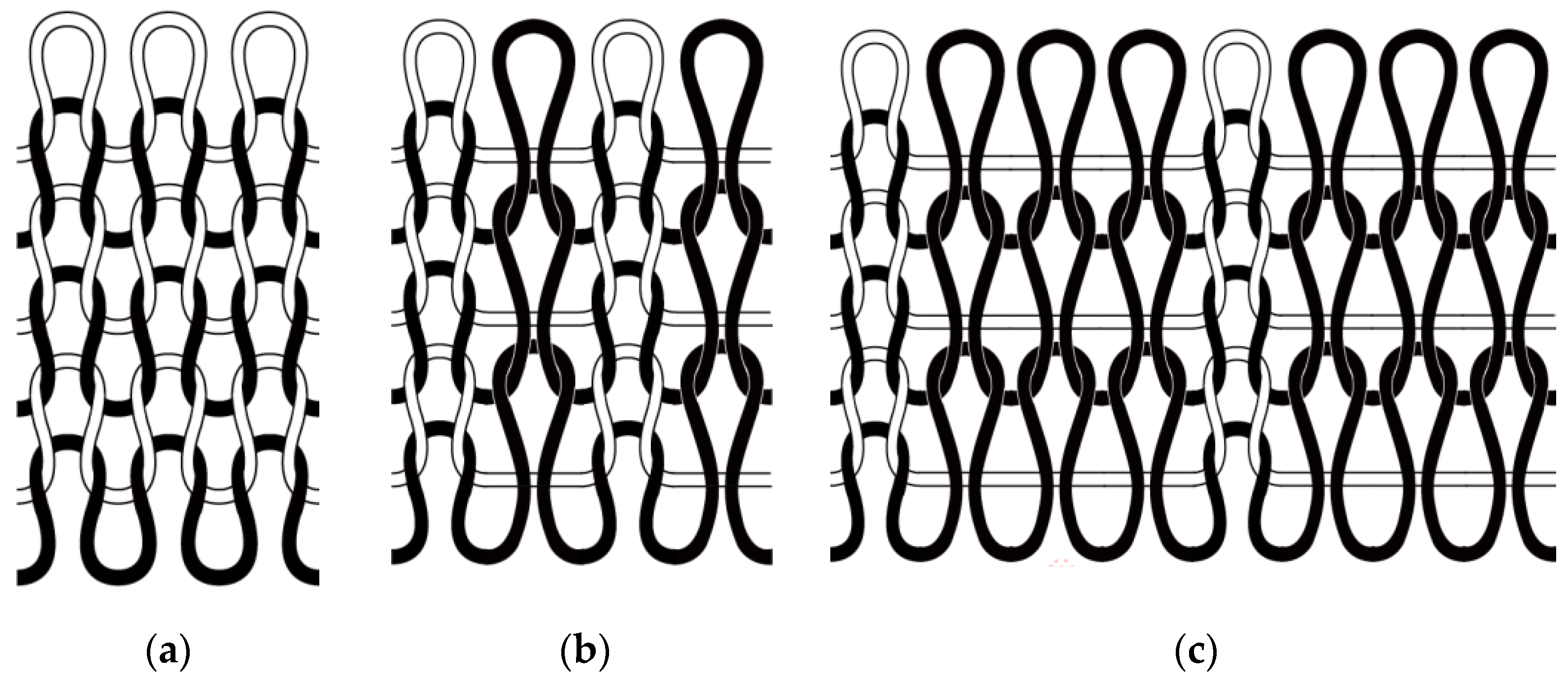

2.1.2. Fabric Structure Design

- Weft Plain;

- 2.

- Simulated rib;

2.1.3. Establishment of Sample Scheme

2.2. Methods

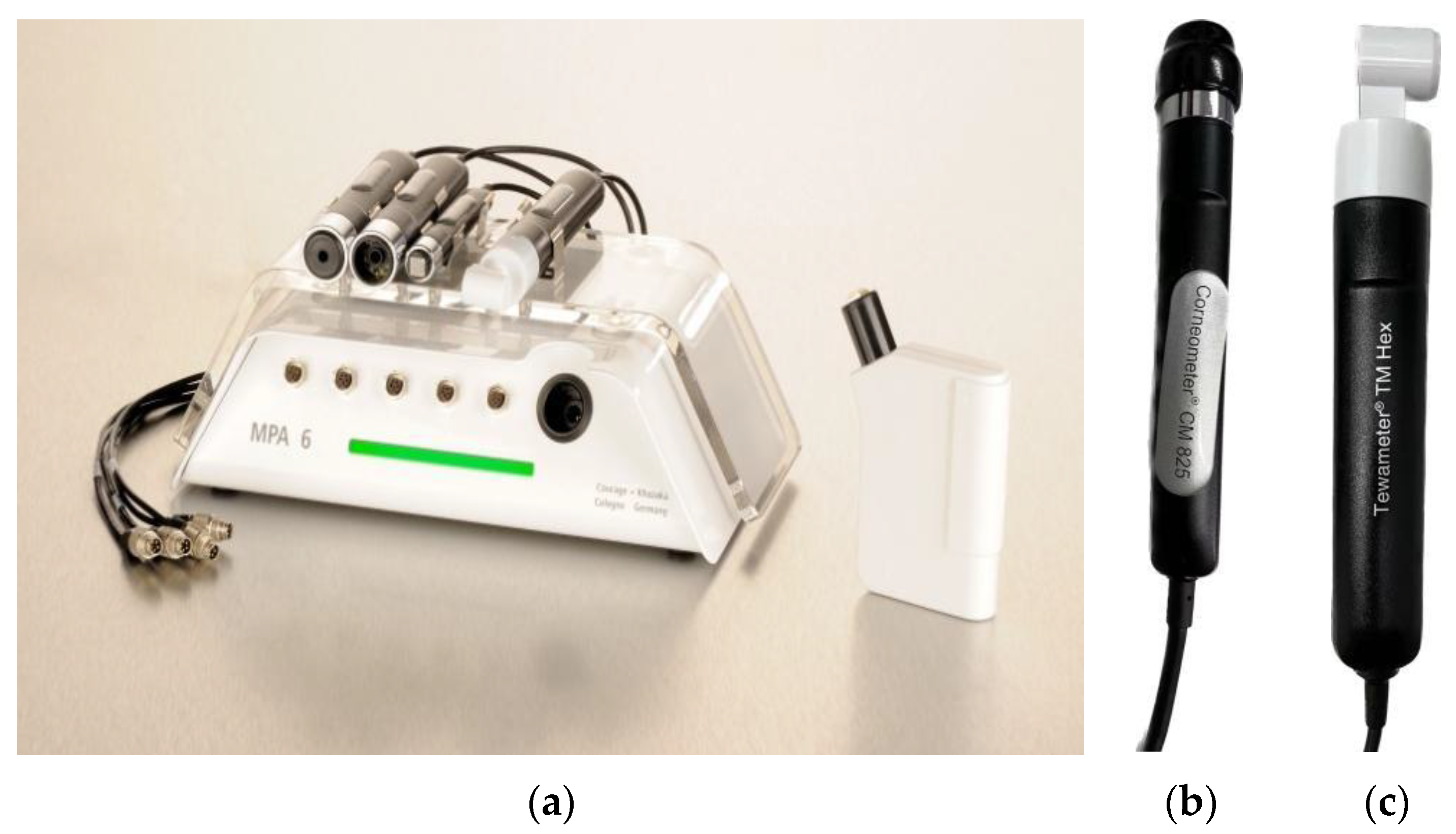

2.2.1. Test of Skin Hydration

- Experimental Equipment;

- 2.

- Experimental Materials and Test Conditions;

- 3.

- Experimental Steps.

2.2.2. Test of Trans Epidermal Water Loss

- Experimental Equipment;

- 2.

- Experimental Test Conditions;

- 3.

- Experimental Steps.

3. Results

3.1. Research on Fabric Structure Parameters and Skin Hydration

3.2. Research on Fabric Structure Parameters and TEWL

4. Conclusions

- In the moisture content test of skin, the influence of veil materials is significant, while the influence of tissue structure is not significant. The order of each sample is #12 > #8 > #9 > #11 > #4 > #6 > #3 > #10 > #7 > #5 > #2 > #15 > #14 > #13. In terms of the raw materials of the veil, aloe fabric is superior to viscose fabric. With the increase in the blending ratio of aloe viscose fiber in the yarn, the change rate of the moisture content of the cuticle increases. The sample scheme with a large change rate of the moisture content is that of the aloe viscose/viscose 100/0 yarn with a 1 + 3 simulated rib, which is sample #12;

- In the test of TEWL, the influence of veil raw materials and tissue structure is not significant. The sample scheme with a relatively small quantitative rate of TEWL is that with aloe viscose/viscose 75/25 yarn with a 1 + 1 simulated rib, which is sample #7.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ricci, G.; Patrizi, A.; Bellini, F.; Medri, M. Use of textiles in atopic dermatitis. Biofunctional Text. Ski. 2006, 33, 127–143. [Google Scholar]

- Gerhardt, L.C.; Lenz, A.; Spencer, N.D.; Münzer, T.; Derler, S. Skin-textile friction and skin elasticity in young and aged persons. Ski. Res. Technol. 2009, 15, 288–298. [Google Scholar] [CrossRef] [PubMed]

- Muñoz, V.; Gonzalez, J.S.; Martínez, M.A.; Alvarez, V.A. Functional textiles for skin care active substance encapsulation. J. Text. Eng. Fash. Technol. 2017. [Google Scholar] [CrossRef]

- Morin-Crini, N.; Lichtfouse, E.; Torri, G.; Crini, G. Applications of chitosan in food, pharmaceuticals, medicine, cosmetics, agriculture, textiles, pulp and paper, biotechnology, and environmental chemistry. Environ. Chem. Lett. 2019, 17, 1667–1692. [Google Scholar] [CrossRef]

- Han, Y.; Zhao, H.; Tan, Y.; Han, Q. Development and research status of skin care textiles. Text. Test. Stand. 2020, 5, 3. [Google Scholar]

- Zeng, W.; Chen, F.; Zhao, B.; Ma, L. Study on testing methods for moisture retention of textiles. Knitt. Ind. 2019, 07, 69–71. [Google Scholar]

- Hong, G.; Wang, X.; Yi, F. Research progress in the application of aloe in textile printing and dyeing. Dye. Finish. Technol. 2022, 44, 4. [Google Scholar]

- Han, Y.; He, Y.; Meng, J. A new skin care and health care fiber—Aloe fiber. Synth. Fiber 2011, 40, 26–27. [Google Scholar]

- Xu, Y.; Liu, L.; Fan, Z.; Lin, N.; Hou, L. Test analysis on the temperature regulating performance of phase change temperature regulating fiber. Cotton Text. Technol. 2021, 49, 28–32. [Google Scholar]

- Sun, L. Microcapsulated Aloe Blend Regenerated Cellulose Fiber Staple and Filament and Its Preparation Method. CN102691132A, 26 September 2012. Available online: https://www.patentstar.com.cn/Search/Detail?ANE=9EDA9EGB9FIF4ADA3ACA7FCA6FBA9BFE5FAADIHA9EEDDHIA (accessed on 26 September 2012).

- Dubey, R. Microencapsulation technology and applications. Def. Sci. J. 2009, 59, 82. [Google Scholar]

- Gouin, S. Microencapsulation: Industrial appraisal of existing technologies and trends. Trends Food Sci. Technol. 2004, 15, 330–347. [Google Scholar] [CrossRef]

- Yang, A. Research on the Expressiveness of Nonwoven Materials to Clothing Based on “Crystal Planting Fabrics”; Lu Xun Academy of Fine Arts: Shenyang, China, 2022. [Google Scholar] [CrossRef]

- Long, H.R. Knitting; China Textile Press: Beijing, China, 2004; p. 67. [Google Scholar]

- Zhang, X.; Cong, H.; Jiang, G. Process design and product development of weft knitted seamless underwear. Text. Guide 2013, 04, 85–88. [Google Scholar]

- Sezgin, H.; Berkalp, O.B. Analysis of the effects of fabric reinforcement parameters on the mechanical properties of textile-based hybrid composites by full factorial experimental design method. J. Ind. Text. 2018, 48, 580–598. [Google Scholar] [CrossRef]

- Kaminaka, C.; Yamamoto, Y.; Sakata, M.; Hamamoto, C.; Misawa, E.; Nabeshima, K.; Saito, M.; Tanaka, M.; Abe, F.; Jinnin, M. Effects of low-dose Aloe sterol supplementation on skin moisture, collagen score and objective or subjective symptoms: 12-week, double-blind, randomized controlled trial. J. Dermatol. 2020, 47, 998–1006. [Google Scholar] [CrossRef] [PubMed]

- Xie, M.; Liu, L.; Lv, C. Moisture content of stratum corneum and its influence on skin biological function. J. Clin. Dermatol. 2008, 37, 816–818. [Google Scholar]

- Huang, Y. Analysis and Study of Facial Skin Physiological Indicators in Patients with Mild to Moderate Acne and Normal People; Anhui Medical University: Hefei, China, 2017. [Google Scholar]

- Hua, W.; Li, L. Electrical measurement of water content in skin cuticle. Chin. J. Dermatol. Venereol. 2015, 29, 314–317. [Google Scholar] [CrossRef]

- QB/T 4256-2011; China Light Industry Federation Guidelines for Evaluation of Moisturizing Efficacy of Cosmetics. China Standards Press: Beijing, China, 2011.

- China Textile Engineering Society Test and Evaluation of Moisture Retention Property of Sodium Hyaluronate Textiles. T/CTES 1035-2021. China Standards Press: Beijing, China, 2021; pp. 1–5.

- Zhao, X. Application of TEWL in evaluation of skin barrier function. Guangdong Chem. Ind. 2014, 41, 133–134. [Google Scholar]

- Wang, X. Performance Research and Product Development of Seamless Weft Knitted Fabric for Hyaluronic Acid Viscose Fiber in Summer; Zhejiang University of Technology: Hangzhou, China, 2021. [Google Scholar] [CrossRef]

- Hui, Y.; Qiong, L.; Wanping, Z.; Xiaojian, W.; Jianjie, C. Research on the influence of 3 kinds of humectants on skin performance. Dly. Chem. Ind. 2013, 2, 139–143. [Google Scholar] [CrossRef]

- Wang, X.; Zhao, B.; Cong, L.; Pan, Q.; Yang, H.; Li, X. Evaluation of moisturizing effect of a group of compound moisturizing agents in cosmetics. China Deterg. Ind. 2022, 9, 62–67. [Google Scholar] [CrossRef]

- Su, J. Duncan multiple comparison and data filling method and its application. Shanghai Stat. 2003, 3, 23–24. [Google Scholar]

| Fabric Number | Veil Type | Fabric Weave |

|---|---|---|

| #1 | Aloe viscose/viscose 25/75 | weft plain |

| #2 | Aloe viscose/viscose 50/50 | weft plain |

| #3 | Aloe viscose/viscose 75/25 | weft plain |

| #4 | Aloe viscose/viscose 100/0 | weft plain |

| #5 | Aloe viscose/viscose 25/75 | 1 + 1 simulated rib |

| #6 | Aloe viscose/viscose 50/50 | 1 + 1 simulated rib |

| #7 | Aloe viscose/viscose 75/25 | 1 + 1 simulated rib |

| #8 | Aloe viscose/viscose 100/0 | 1 + 1 simulated rib |

| #9 | Aloe viscose/viscose 25/75 | 1 + 3 simulated rib |

| #10 | Aloe viscose/viscose 50/50 | 1 + 3 simulated rib |

| #11 | Aloe viscose/viscose 75/25 | 1 + 3 simulated rib |

| #12 | Aloe viscose/viscose 100/0 | 1 + 3 simulated rib |

| #13 | Aloe viscose/viscose 0/100 | weft plain |

| #14 | Aloe viscose/viscose 0/100 | 1 + 1 simulated rib |

| #15 | Aloe viscose/viscose 0/100 | 1 + 3 simulated rib |

| Sample Number | Change Rate of Skin Hydration of Covered/(%) | Change Rate of Skin Hydration of Uncovered/(%) |

|---|---|---|

| #1 | 3.07% | −4.17% |

| #2 | 4.06% | −2.36% |

| #3 | 4.96% | −1.43% |

| #4 | 5.20% | −0.42% |

| #5 | 4.55% | −1.26% |

| #6 | 5.15% | −0.31% |

| #7 | 4.63% | −0.79% |

| #8 | 6.50% | −1.02% |

| #9 | 5.88% | −0.55% |

| #10 | 4.90% | −1.74% |

| #11 | 5.49% | −1.23% |

| #12 | 8.03% | −1.89% |

| #13 | 0.11% | −2.55% |

| #14 | 0.47% | −1.73% |

| #15 | 1.19% | −0.60% |

| Source | df | Mean Square | F | Sig. | Partial ETA Square |

|---|---|---|---|---|---|

| Raw material | 4 | 154.43 | 5.50 | 0.00 | 0.11 |

| Structure | 2 | 44.29 | 1.58 | 0.21 | 0.02 |

| Subset of Alpha = 0.05 | |||

|---|---|---|---|

| Raw material | 1 | 2 | 3 |

| Viscose | 1.19% | ||

| 25/75 | 4.19% | ||

| 50/50 | 4.58% | ||

| 75/25 | 5.49% | ||

| 100/0 | 6.47% | ||

| Sample Number | Change Rate of TEWL of Covered Area/(%) | Change Rate of TEWL of Uncovered Area/(%) |

|---|---|---|

| #1 | −4.48% | −12.55% |

| #2 | −3.11% | −12.00% |

| #3 | −2.15% | −12.12% |

| #4 | −14.44% | −5.52% |

| #5 | −2.83% | −8.69% |

| #6 | −6.65% | −13.98% |

| #7 | −1.56% | −10.63% |

| #8 | −2.50% | −0.79% |

| #9 | −3.34% | −5.59% |

| #10 | −1.95% | −0.40% |

| #11 | −6.17% | −11.20% |

| #12 | −1.65% | −1.79% |

| #13 | −2.13% | −2.29% |

| #14 | −6.37% | −10.76% |

| #15 | −4.69% | −17.39% |

| Source | df | Mean Square | F | Sig. |

|---|---|---|---|---|

| Raw material | 4 | 113.45 | 0.25 | 0.92 |

| Structure | 2 | 469.75 | 0.98 | 0.38 |

| Source | df | Mean Square | F | Sig. |

|---|---|---|---|---|

| Raw material | 4 | 141.98 | 0.29 | 0.88 |

| Structure | 2 | 453.54 | 0.94 | 0.39 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Jin, Z.; Mao, L.; Tu, L.; Sun, Y.; Tao, J. Study on the Skin Hydration and Trans Epidermal Water Loss of Aloe Viscose Seamless Knitted Fabric for Autumn and Winter. Materials 2023, 16, 212. https://doi.org/10.3390/ma16010212

Wang X, Jin Z, Mao L, Tu L, Sun Y, Tao J. Study on the Skin Hydration and Trans Epidermal Water Loss of Aloe Viscose Seamless Knitted Fabric for Autumn and Winter. Materials. 2023; 16(1):212. https://doi.org/10.3390/ma16010212

Chicago/Turabian StyleWang, Xiaokang, Zimin Jin, Liumeng Mao, Lexi Tu, Yuqiang Sun, and Jianwei Tao. 2023. "Study on the Skin Hydration and Trans Epidermal Water Loss of Aloe Viscose Seamless Knitted Fabric for Autumn and Winter" Materials 16, no. 1: 212. https://doi.org/10.3390/ma16010212

APA StyleWang, X., Jin, Z., Mao, L., Tu, L., Sun, Y., & Tao, J. (2023). Study on the Skin Hydration and Trans Epidermal Water Loss of Aloe Viscose Seamless Knitted Fabric for Autumn and Winter. Materials, 16(1), 212. https://doi.org/10.3390/ma16010212