Investigation into Friction and Wear Characteristics of 316L Stainless-Steel Wire at High Temperature

Abstract

1. Introduction

2. Materials and Methods

3. Results

3.1. Friction and Wear Characteristics Analysis under Different Temperatures

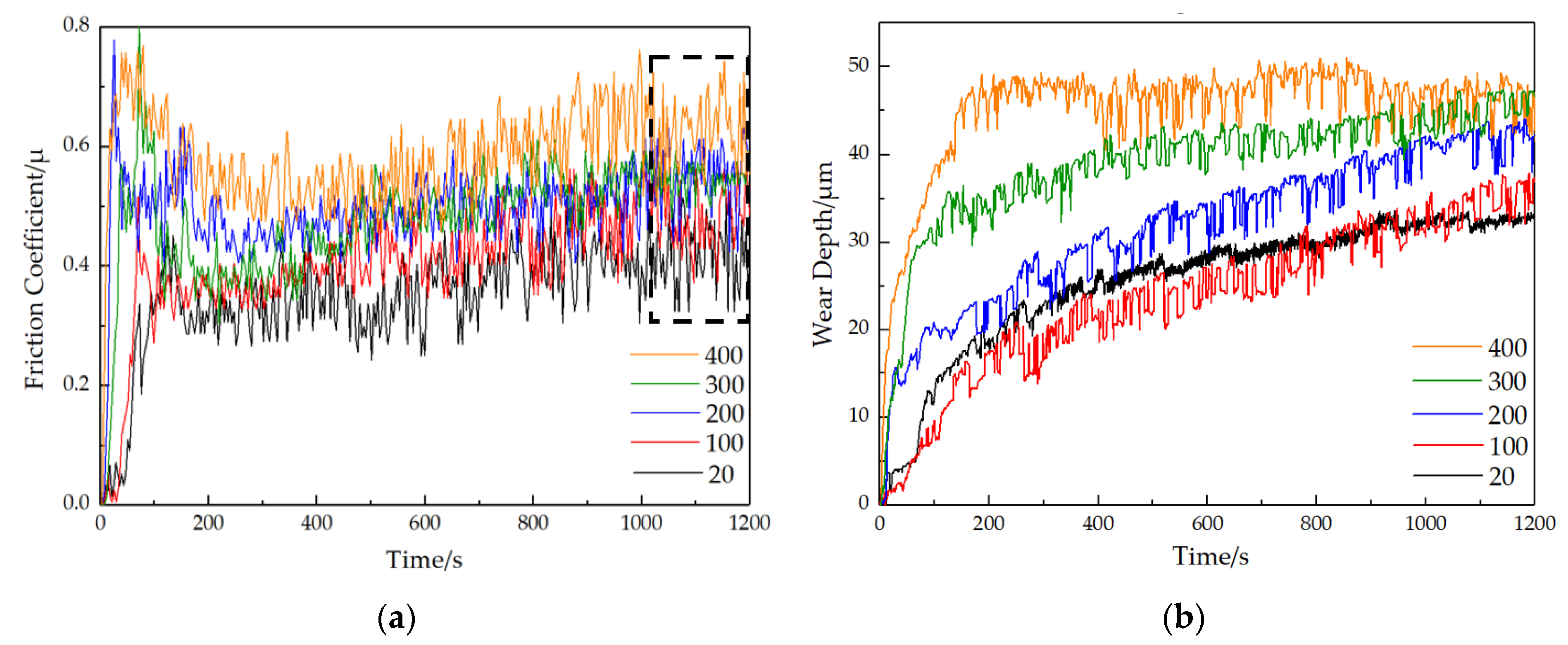

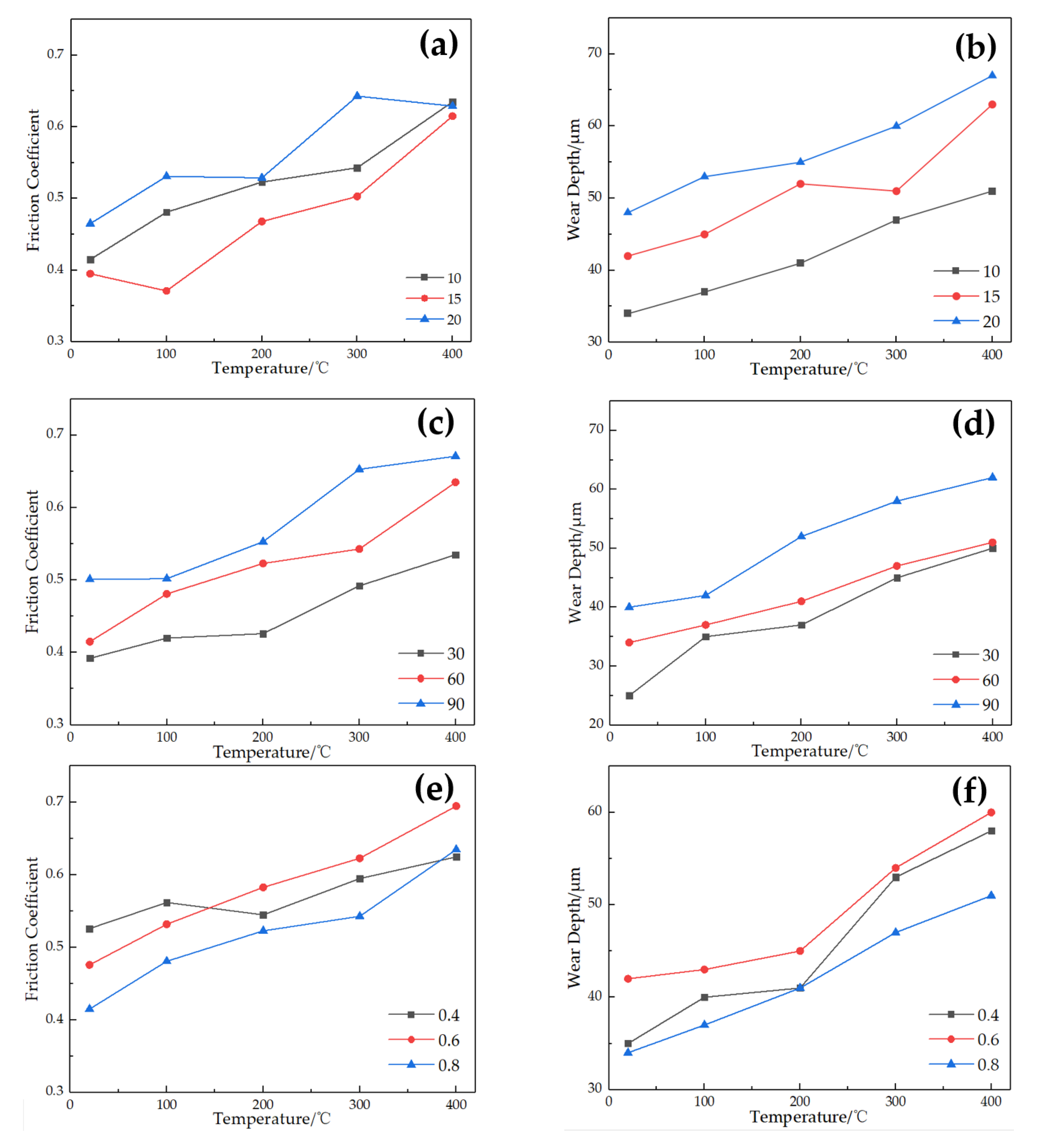

3.1.1. Friction Coefficient and Wear Depth Analysis under Different Temperatures

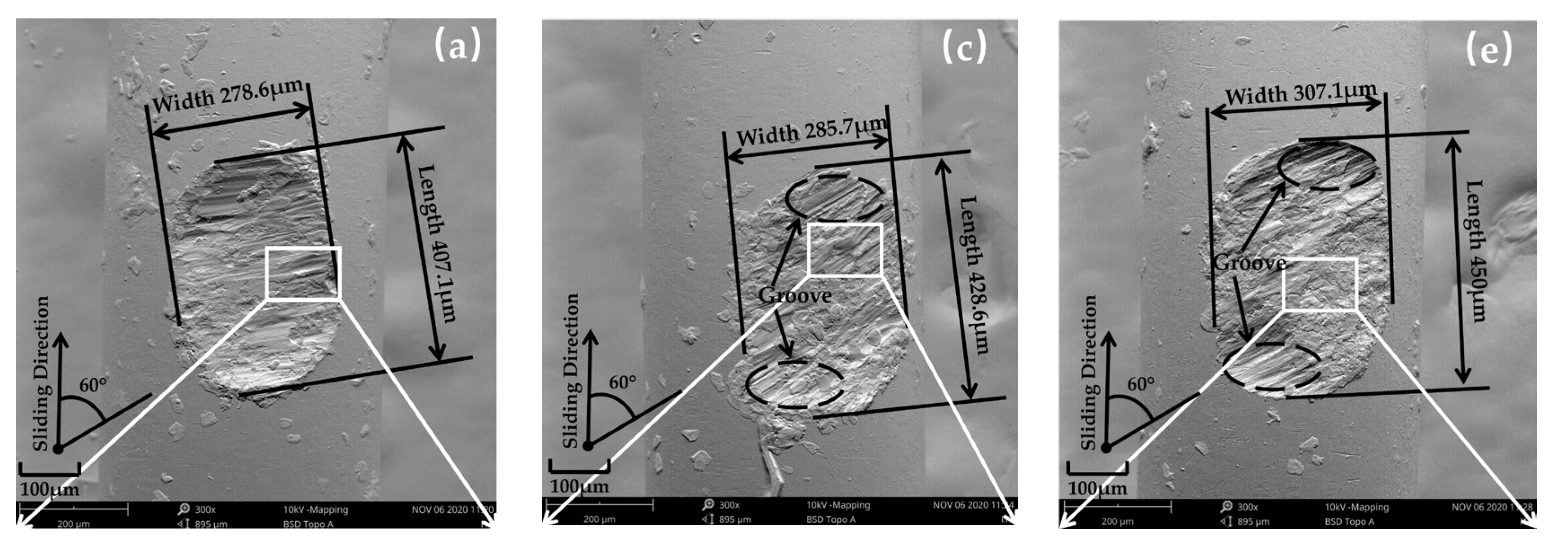

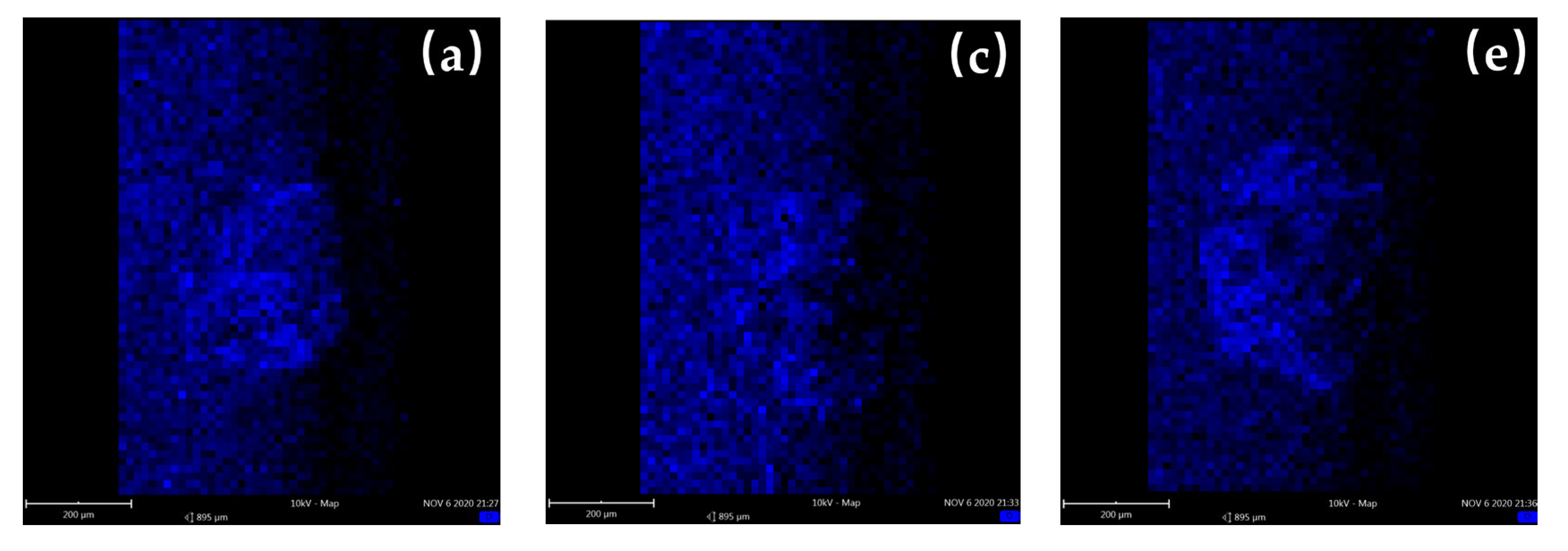

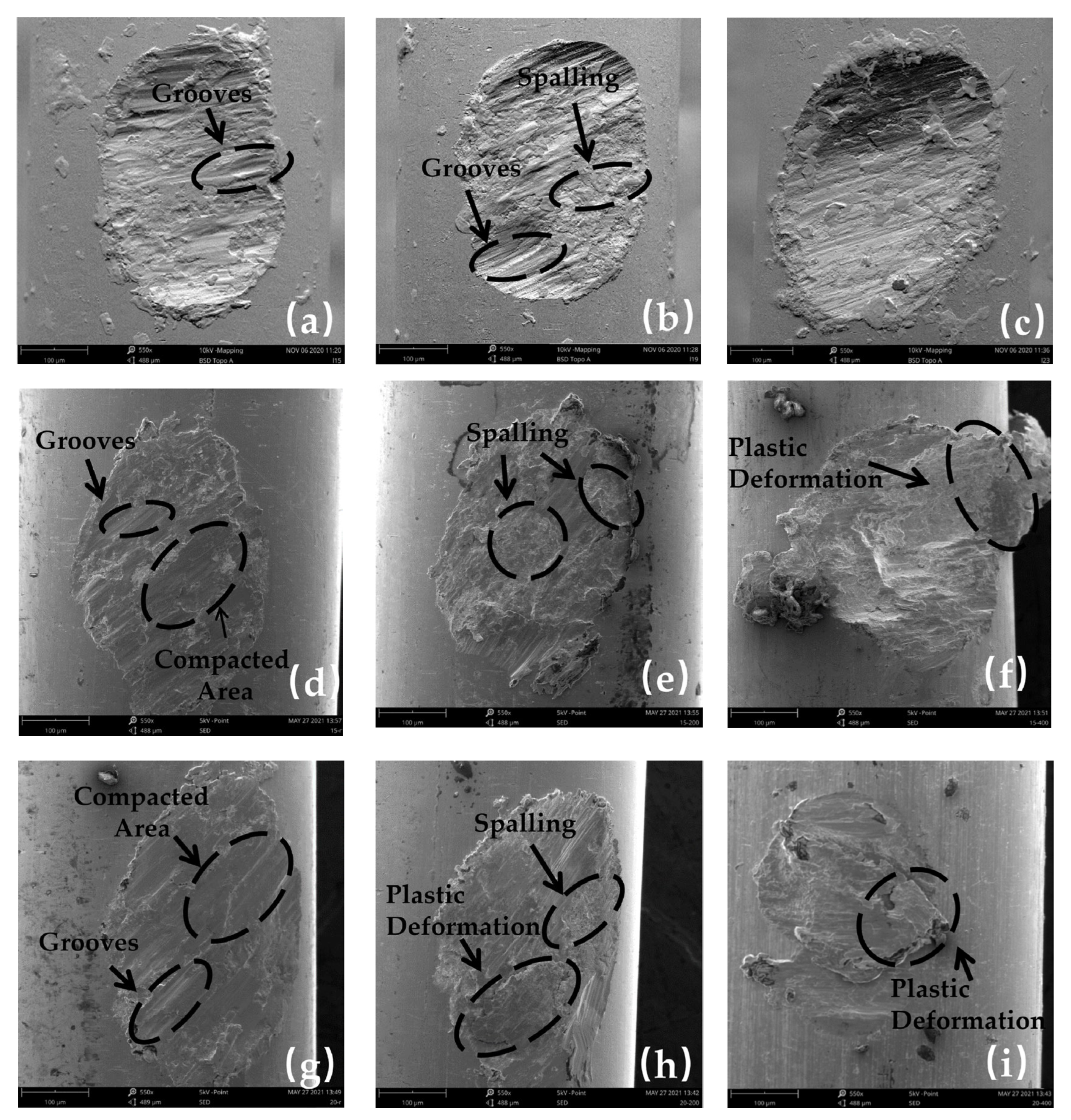

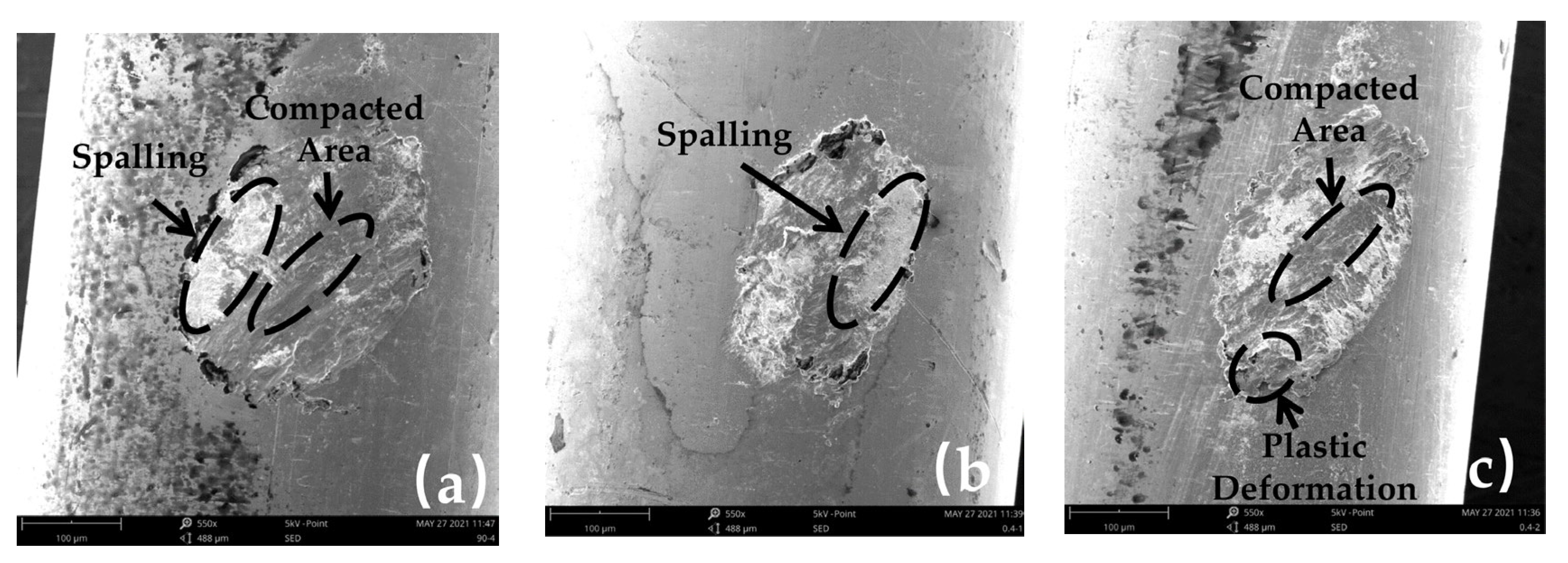

3.1.2. Wear Mechanism Analysis under Different Temperatures

3.2. Friction and Wear Characteristics Analysis under Different Test Paraments

3.2.1. Friction Coefficient and Wear Depth Analysis under Different Test Parameters

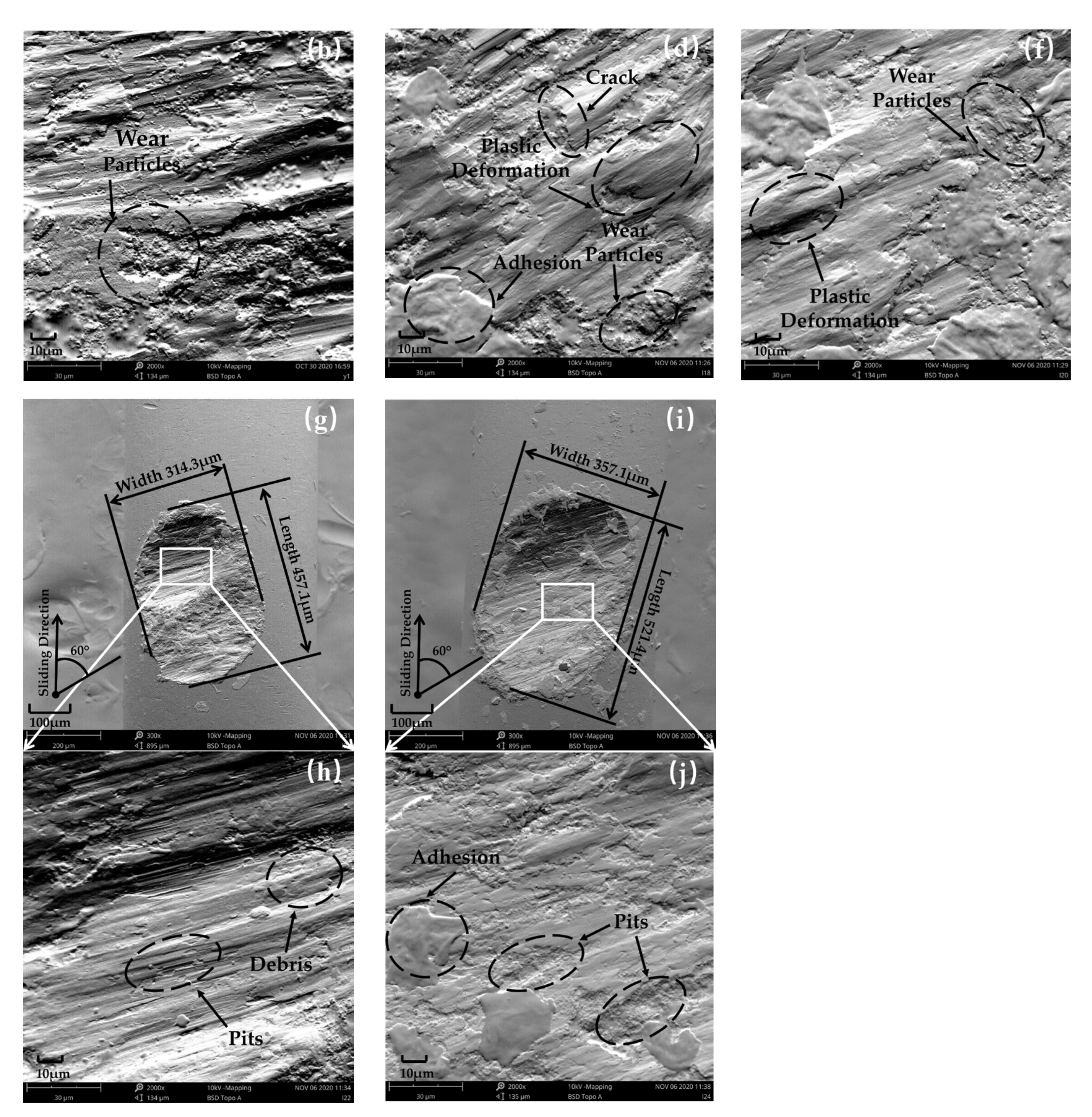

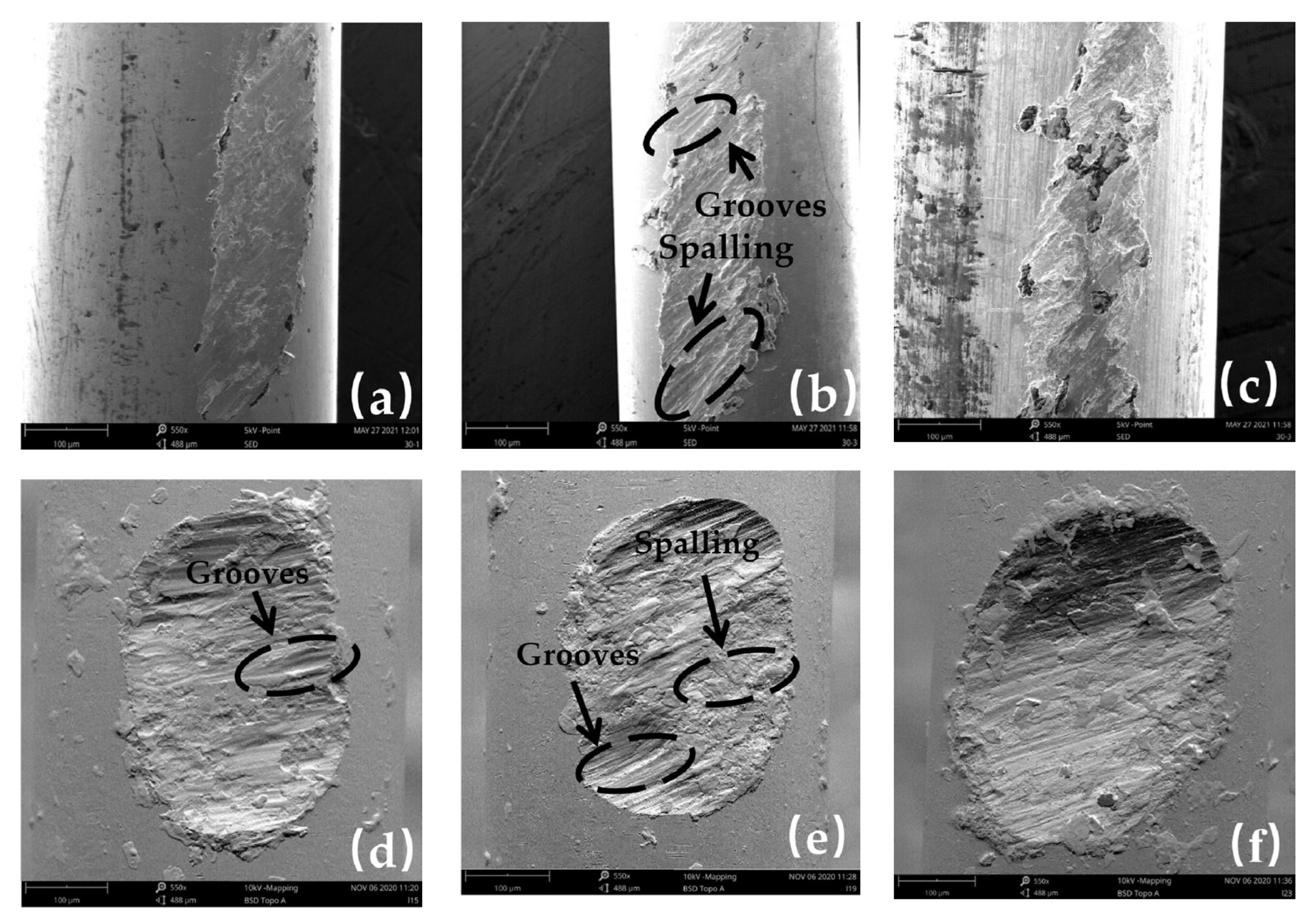

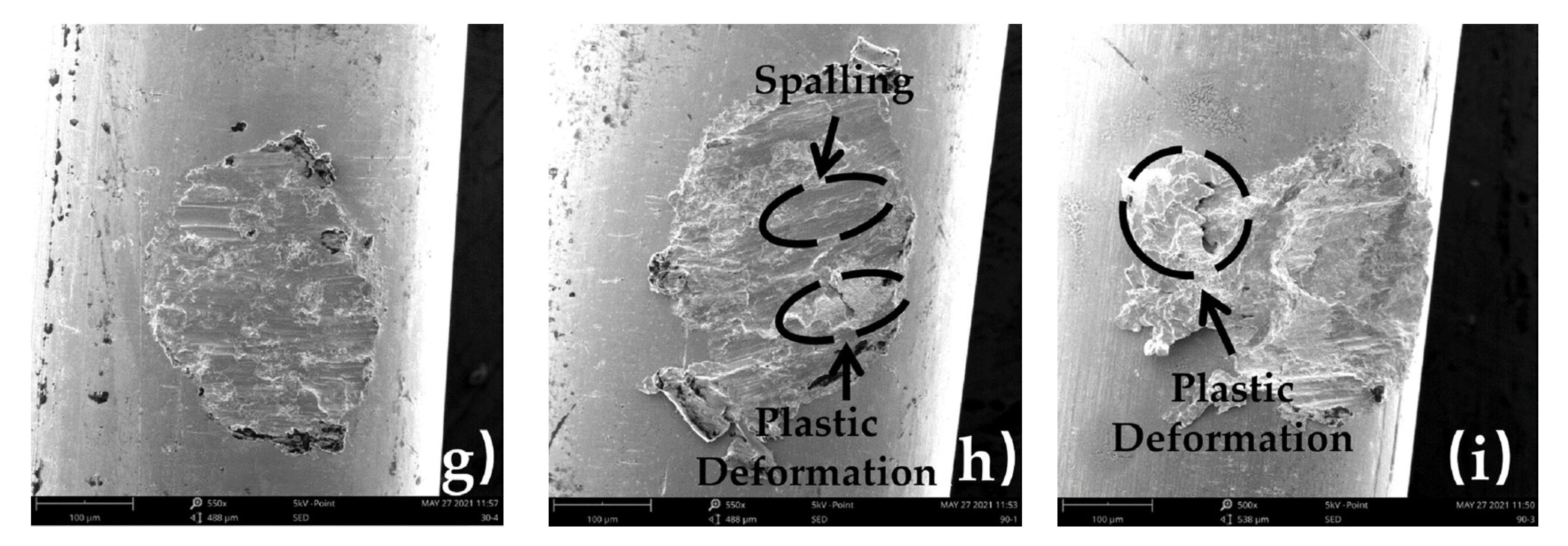

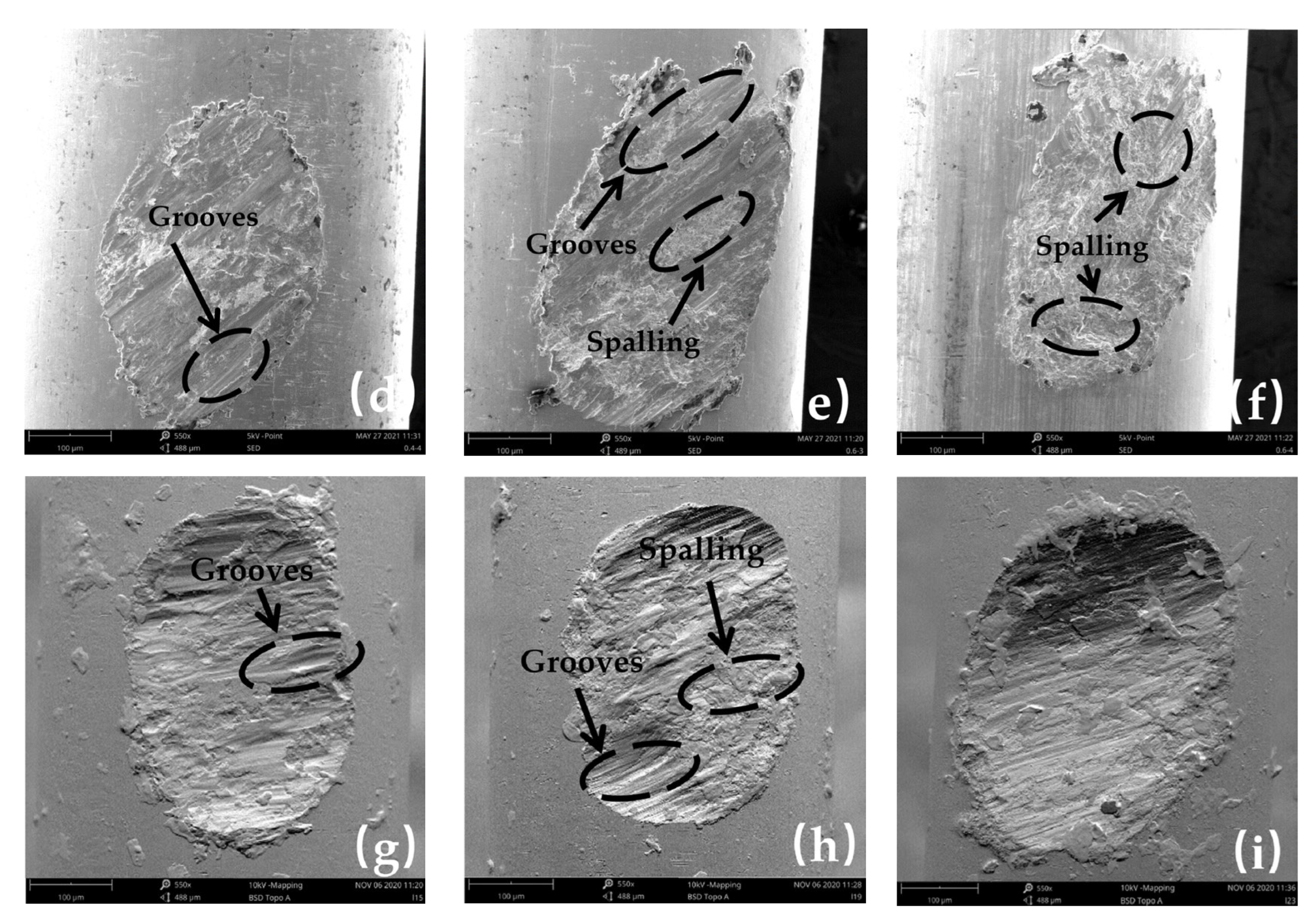

3.2.2. Wear Mechanism Analysis under Different Test Parameters

- (a)

- Influence of Loads on Wear Mechanism

- (b)

- Influences of Crossing Angles on Wear Mechanism

- (c)

- Influence of Strokes on Wear Mechanism

4. Conclusions

- (1)

- The friction coefficient and wear depth of 316L stainless-steel wires increase with increasing temperature, and the friction process can be divided into unstable wear stage and stable wear stage. The temperature increase will accelerate the arrival of the stable wear stage.

- (2)

- The wear mechanisms of 316L stainless-steel wire in a range of 20 °C to 400 °C are oxidation wear, abrasive wear, and adhesive wear. When below 200 °C, the proportion of adhesive wear increases while abrasive wear decreases with increasing temperature; the oxidation wear is not the main influence rule. When the temperature rises to more than 200 °C, oxidation wear dominates and the oxide film produced can play a better role in reducing wear.

- (3)

- Load, crossing angle, and stoke also affect the tribological behaviors significantly. The effect of load is closely related to surface stress, thus, resulting in nonmonotonic friction coefficient with increasing load. Different crossing angles will obviously change the shape and area of the worn surfaces, leading to different surface stresses and friction coefficients. When the crossing angle reaches 90°, the area of the worn surfaces is the smallest and the wear is the highest. Higher stroke will reduce both surface stress and debris removal efficiency, helping to reduce wear. Constant other factors, lower loads, smaller crossing angle, and higher stroke are more likely to improve the wear resistance.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Zheng, X.; Ren, Z.; Shen, L.; Zhang, B.; Bai, H. Dynamic Performance of Laminated High-Damping and High-Stiffness Composite Structure Composed of Metal Rubber and Silicone Rubber. Materials 2021, 14, 187. [Google Scholar] [CrossRef] [PubMed]

- Zheng, X.; Wang, W.; Wu, Y.; Bai, H. Study of the Dynamic Model and Vibration Performance of Pot-Shaped Metal Rubber. Materials 2022, 15, 5878. [Google Scholar] [CrossRef] [PubMed]

- Cruzado, A.; Leen, S.B.; Urchegui, M.A.; Gómez, X. Finite element simulation of fretting wear and fatigue in thin steel wires. Int. J. Fatigue 2013, 55, 7–21. [Google Scholar] [CrossRef]

- Chattrakul, K.; Sornsuwit, N. Study of surface appearance and composition effect on AISI 304 and 304L stainless steel wear against nylon wire. Mater. Today: Proc. 2018, 5, 9319–9325. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, D.; Chen, K.; Xu, L.; Ge, S. Corrosion fatigue behaviors of steel wires used in coalmine. Mater. Des. 2014, 53, 58–64. [Google Scholar] [CrossRef]

- Dong, X.; Huang, M. Load Effect on 1Cr18Ni9 Stainless Steel Wires’ Fretting Behaviors in Metal Rubber Dampers. Appl. Mech. Mater. 2013, 291–294, 2744–2748. [Google Scholar] [CrossRef]

- Courtois, L.; Maire, E.; Perez, M.; Rodney, D.; Bouaziz, O.; Brechet, Y. Mechanical Properties of Monofilament Entangled Materials. Adv. Eng. Mater. 2012, 14, 1128–1133. [Google Scholar] [CrossRef]

- Huang, M.; Li, K.; Dong, X. Study on Friction Characteristics of Laser Textured Metal Rubber Microfilaments under Solid Lubricating Grease. Prot. Met. Phys. Chem. Surf. 2021, 57, 361–366. [Google Scholar] [CrossRef]

- Yin, Y.; Zhang, D.; Shen, Y. Effect of grease lubricant on fretting wear properties of steel wires. Mocaxue Xuebao 2011, 31, 492–497. [Google Scholar]

- Wu, Y.; Jiang, L.; Bai, H.; Lu, C.; Li, S. Mechanical Behavior of Entangled Metallic Wire Materials under Quasi-Static and Impact Loading. Materials 2019, 12, 3392. [Google Scholar] [CrossRef]

- Huang, M.; Li, K.; Dong, X.; Qiao, X. Effect of Wire Diameter on Friction and Wear Behavior of 316L Stainless Steel Wire. Mocaxue Xuebao 2021, 41, 206–212. [Google Scholar]

- Chen, Y.; Zhang, Y.; Qin, W. Mechanical analysis of non-perpendicularly crossed steel wires in frictional wear. Int. J. Mech. Sci. 2019, 156, 170–181. [Google Scholar] [CrossRef]

- Li, T.; Bai, H.; Cao, F. A quasi-static compression constitutive model for knitted-dapped metal rubber considering temperature effect. Hangkong Xuebao 2018, 39, 422062. [Google Scholar]

- Ding, Z.; Bai, H.; Wu, Y.; Ren, Z.; Shao, Y. A Constitutive Model of Plate-Like Entangled Metallic Wire Material in Wide Temperature Range. Materials 2019, 12, 2538. [Google Scholar] [CrossRef] [PubMed]

- Ma, Y.; Zhang, Q.; Zhang, D.; Scarpa, F.; Liu, B.; Hong, J. The mechanics of shape memory alloy metal rubber. Acta Mater. 2015, 96, 89–100. [Google Scholar] [CrossRef]

- Ma, Y.; Zhang, Q.; Zhang, D.; Scarpa, F.; Liu, B.; Hong, J. A novel smart rotor support with shape memory alloy metal rubber for high temperatures and variable amplitude vibrations. Smart Mater. Struct. 2014, 23, 125016. [Google Scholar] [CrossRef]

- Dong, X.; Liu, G.; Yang, J.; Bai, H. Microstructure of cool-drawing austenitic stainless steel wires used for metal rubber. Hang Kong Cai Liao Xue Bao 2007, 27, 35–39. [Google Scholar]

- Ma, Y.; Tong, X.; Zhu, B.; Zhang, D.; Hong, J. Theoretical and experimental investigation on thermophysical properties of metal rubber. Wuli Xuebao 2013, 62, 48101. [Google Scholar]

- Li, T.; Bai, H.; Xue, X.; Wu, Y. Fatigue Properties of Knitted-dapped Metal Rubbers under High Temperature Environment. Zhongguo Jixie Gongcheng 2019, 30, 1009. [Google Scholar]

- Li, X.; Zhou, Y.; Ji, X.; Li, Y.; Wang, S. Effects of sliding velocity on tribo-oxides and wear behavior of Ti–6Al–4V alloy. Tribol. Int. 2015, 91, 228–234. [Google Scholar] [CrossRef]

- Hardell, J.; Prakash, B. High-temperature friction and wear behaviour of different tool steels during sliding against Al–Si-coated high-strength steel. Tribol. Int. 2008, 41, 663–671. [Google Scholar] [CrossRef]

- Hernandez, S.; Hardell, J.; Prakash, B. High-Temperature Friction and Wear of Boron Steel and Tool Steel in Open and Closed Tribosystems. Tribol. Trans. 2018, 61, 448–458. [Google Scholar]

- Parthasarathi, N.; Borah, U.; Albert, S. Effect of temperature on sliding wear of AISI 316L(N) stainless steel—Analysis of measured wear and surface roughness of wear tracks. Mater. Des. 2013, 51, 676–682. [Google Scholar]

- Ledbetter, H.M. Temperature behaviour of Young’s moduli of forty engineering alloys. Cryogenics 1982, 22, 653–656. [Google Scholar] [CrossRef]

- Stott, F.H. The role of oxidation in the wear of alloys. Tribol. Int. 1998, 31, 61–71. [Google Scholar]

- Stott, F.H. High-temperature sliding wear of metals. Tribol. Int. 2002, 35, 489–495. [Google Scholar]

- Yu, H.; Lu, L.; Wang, Z.; Chen, C. Microstructure and Wear Resistance of a Composite Coating Prepared by Laser Alloying with Ni-Coated Graphite on Ti-6Al-4V Alloy. Materials 2022, 15, 5512. [Google Scholar] [CrossRef]

- Mateescu, A.O.; Mateescu, G.; Balan, A.; Ceaus, C.; Stamatin, I.; Cristea, D.; Samoila, C.; Ursutiu, D. Stainless Steel Surface Nitriding in Open Atmosphere Cold Plasma: Improved Mechanical, Corrosion and Wear Resistance Properties. Materials 2021, 14, 4836. [Google Scholar] [CrossRef]

- Hu, H.; Guo, Y.; Yan, J.; Qiu, J.; Wang, Y. Dry sliding wear behavior of MoSi2-Mo5Si3-Mo5SiB2 composite at different temperatures and loads. Wear 2019, 428–429, 237–245. [Google Scholar] [CrossRef]

- Cruzado, A.; Hartelt, M.; Wäsche, R.; Urchegui, M.A.; Gómez, X. Fretting wear of thin steel wires. Part 2: Influence of crossing angle. Wear 2011, 273, 60–69. [Google Scholar] [CrossRef]

- Harish, T.V.; Rajeev, V.R. Effect of Variation in Stroke Length on Dry Reciprocating Wear of Aluminium Alloys. Mater. Today Proc. 2018, 5, 1341–1347. [Google Scholar] [CrossRef]

- Chang, X.; Peng, Y.; Zhu, Z.; Wang, D.; Gong, X.; Zou, S.; Sun, S.; Xu, W. Tribological properties of winding hoisting rope between two layers with different sliding parameters. Adv. Mech. Eng. 2016, 8, 168781401667991. [Google Scholar] [CrossRef]

| C (wt.%) | Si (wt.%) | Mn (wt.%) | P (wt.%) | Cr (wt.%) | Ni (wt.%) | Mo (wt.%) |

|---|---|---|---|---|---|---|

| 0.02 | 0.49 | 1.03 | 0.03 | 17.26 | 12.0 | 2.05 |

| Test Variables | Group 1 | Group 2 | Group 3 | Group 4 |

|---|---|---|---|---|

| Temperature (°C) | 20; 100; 200; 300; 400 | 20; 100; 200; 300; 400 | 20; 100; 200; 300; 400 | 20; 100; 200; 300; 400 |

| Sliding velocity (mm/min) | 240 | 240 | 240 | 240 |

| Load (N) | 10 | 10;15;20 | 10 | 10 |

| Crossing angle (°) | 60 | 60 | 30;60;90 | 60 |

| Stroke (mm) | 0.8 | 0.8 | 0.8 | 0.4; 0.6; 0.8 |

| Temperature/°C | 20 | 100 | 200 | 300 | 400 |

|---|---|---|---|---|---|

| Friction Coefficient | 0.415 | 0.481 | 0.523 | 0.543 | 0.635 |

| Wear Depth | 34 μm | 37 μm | 41 μm | 47 μm | 51 μm |

| Temperature/°C | 20 | 100 | 200 | 300 | 400 |

|---|---|---|---|---|---|

| Width/μm | 0.415 | 0.481 | 0.523 | 0.543 | 0.635 |

| Length/μm | 34 μm | 37 μm | 41 μm | 47 μm | 51 μm |

| Area/μm2 | 89,078.3 | 96,172.8 | 108,538.1 | 112,835.4 | 146,234.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, M.; Fu, Y.; Qiao, X.; Chen, P. Investigation into Friction and Wear Characteristics of 316L Stainless-Steel Wire at High Temperature. Materials 2023, 16, 213. https://doi.org/10.3390/ma16010213

Huang M, Fu Y, Qiao X, Chen P. Investigation into Friction and Wear Characteristics of 316L Stainless-Steel Wire at High Temperature. Materials. 2023; 16(1):213. https://doi.org/10.3390/ma16010213

Chicago/Turabian StyleHuang, Mingji, Yili Fu, Xiaoxi Qiao, and Ping Chen. 2023. "Investigation into Friction and Wear Characteristics of 316L Stainless-Steel Wire at High Temperature" Materials 16, no. 1: 213. https://doi.org/10.3390/ma16010213

APA StyleHuang, M., Fu, Y., Qiao, X., & Chen, P. (2023). Investigation into Friction and Wear Characteristics of 316L Stainless-Steel Wire at High Temperature. Materials, 16(1), 213. https://doi.org/10.3390/ma16010213