Residual Stress Measurement Techniques for Metal Joints, Metallic Coatings and Components in the Railway Industry: A Review

Abstract

1. Introduction

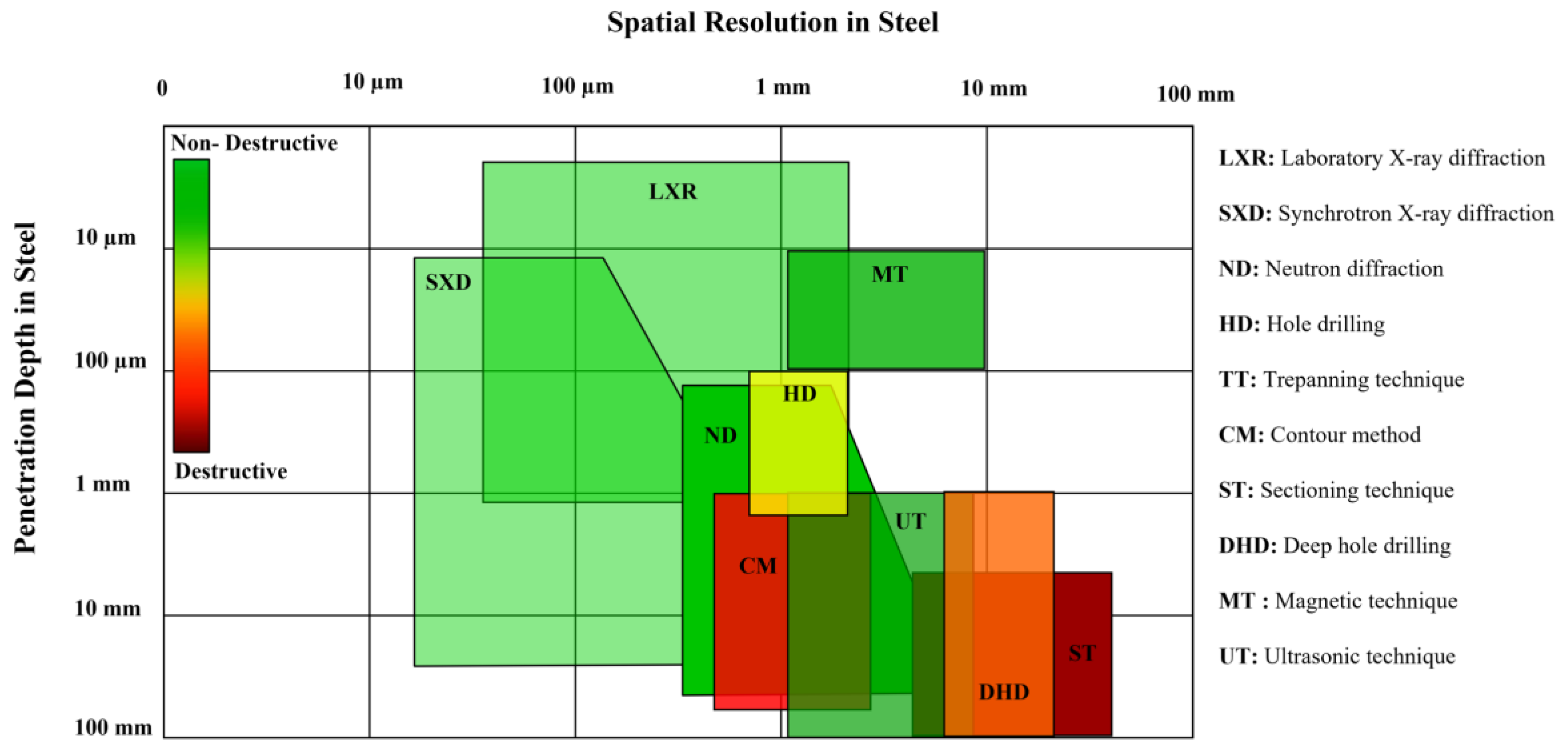

2. Residual Stress Measurement Techniques for Railway Components

2.1. Destructive Methods

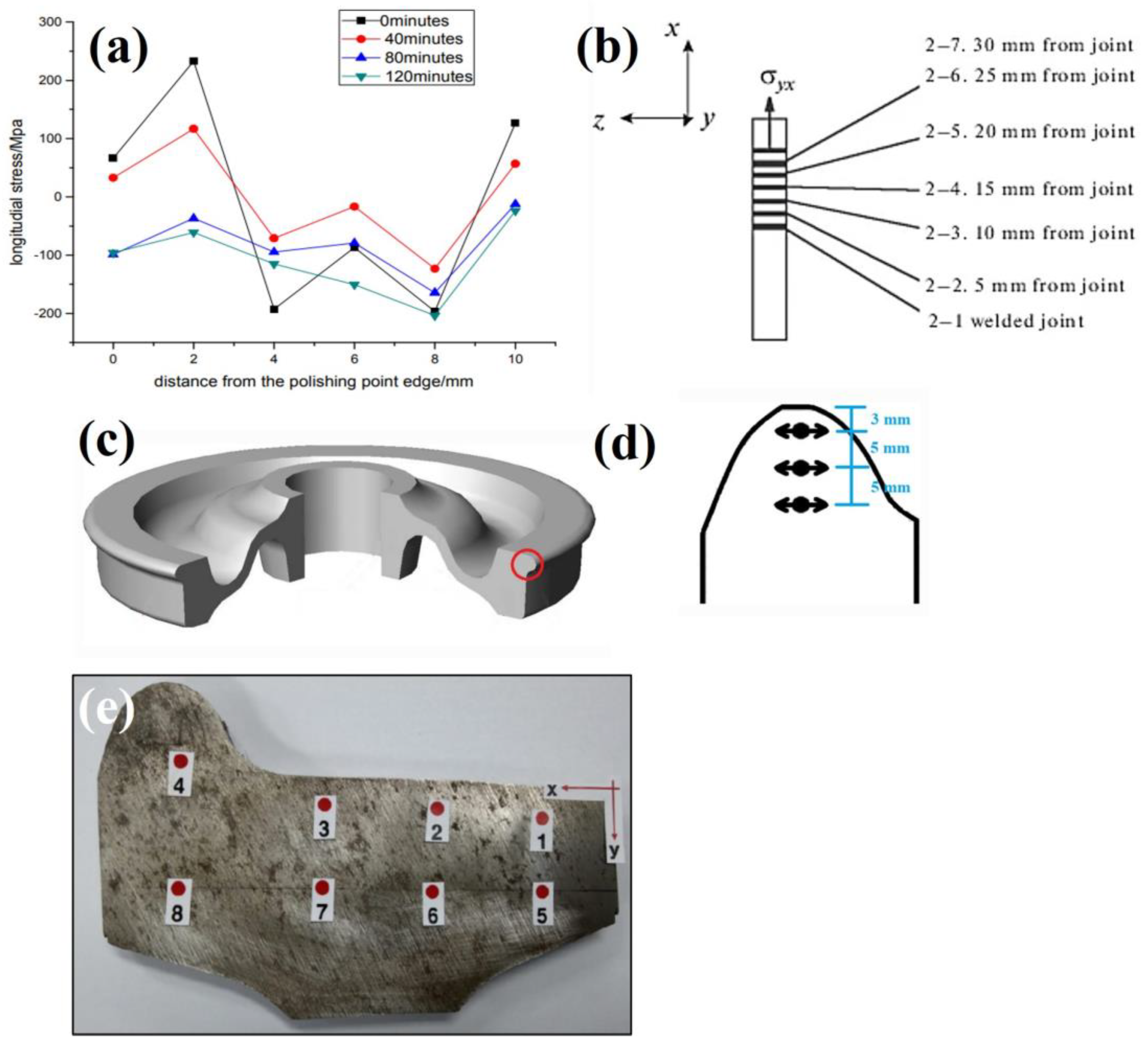

2.1.1. Sectioning

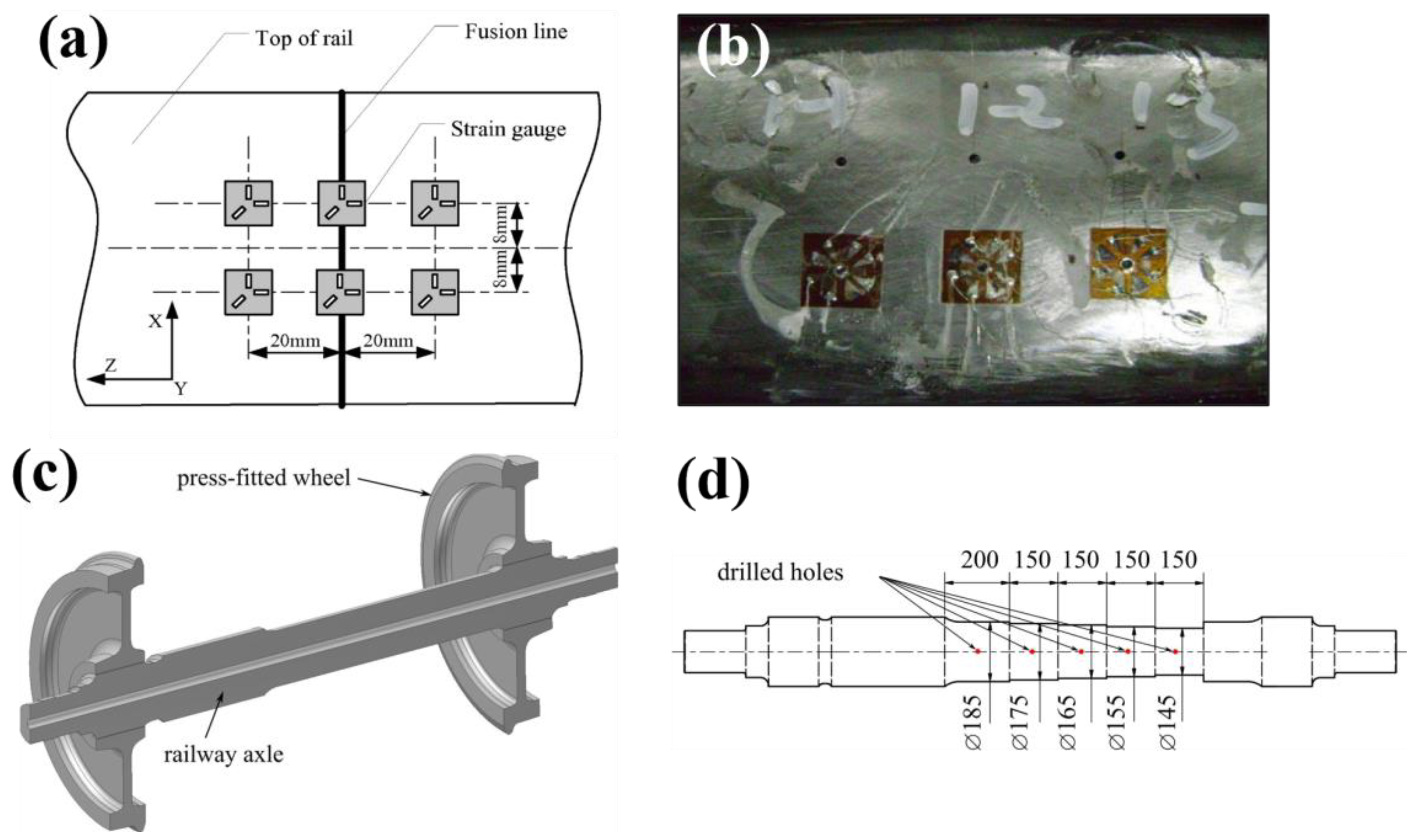

2.1.2. Hole Drilling

2.2. Contour Method

3. Non-Destructive Techniques

3.1. Diffraction Methods

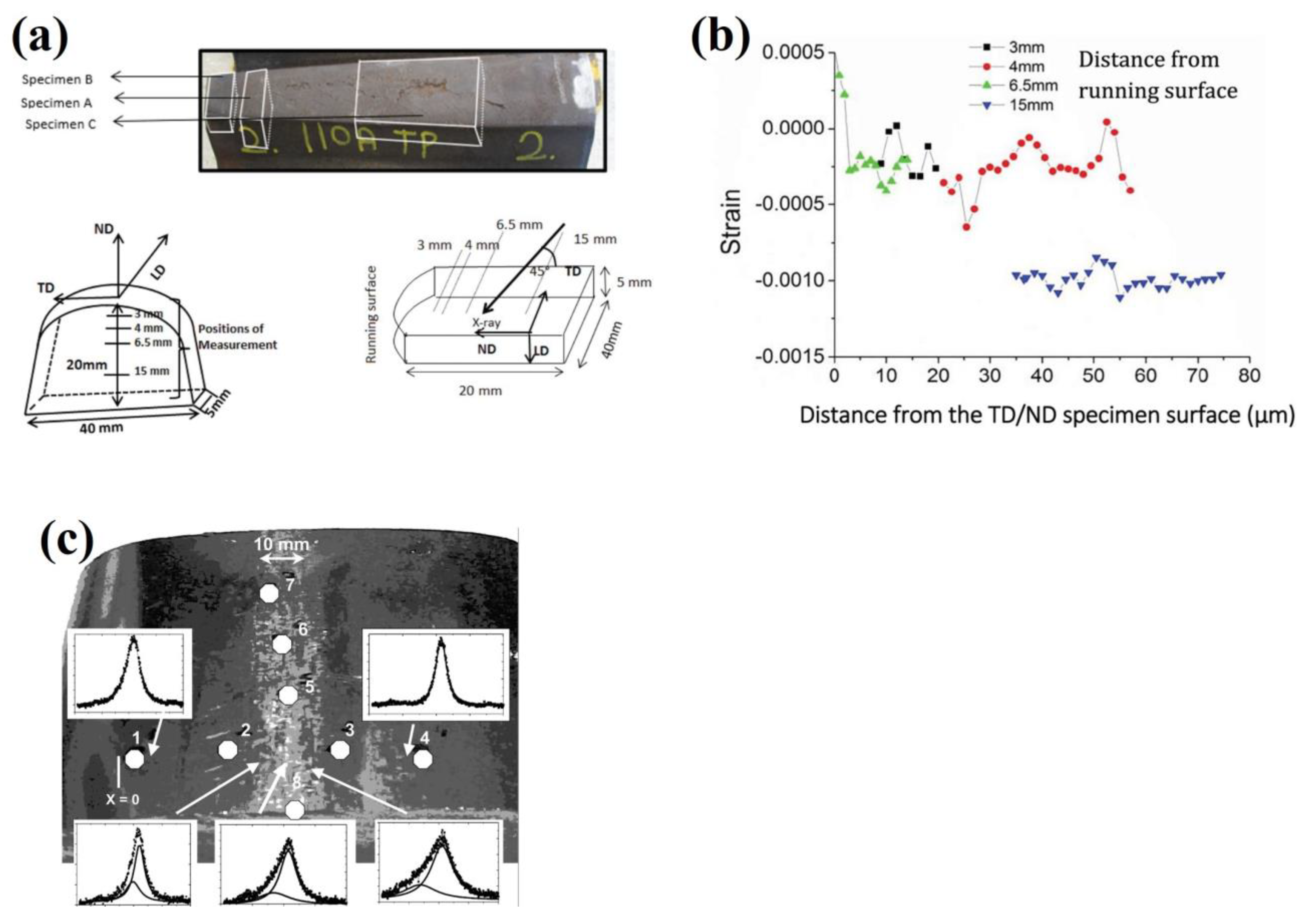

3.1.1. Laboratory X-ray Diffraction

3.1.2. Synchrotron X-ray Diffraction

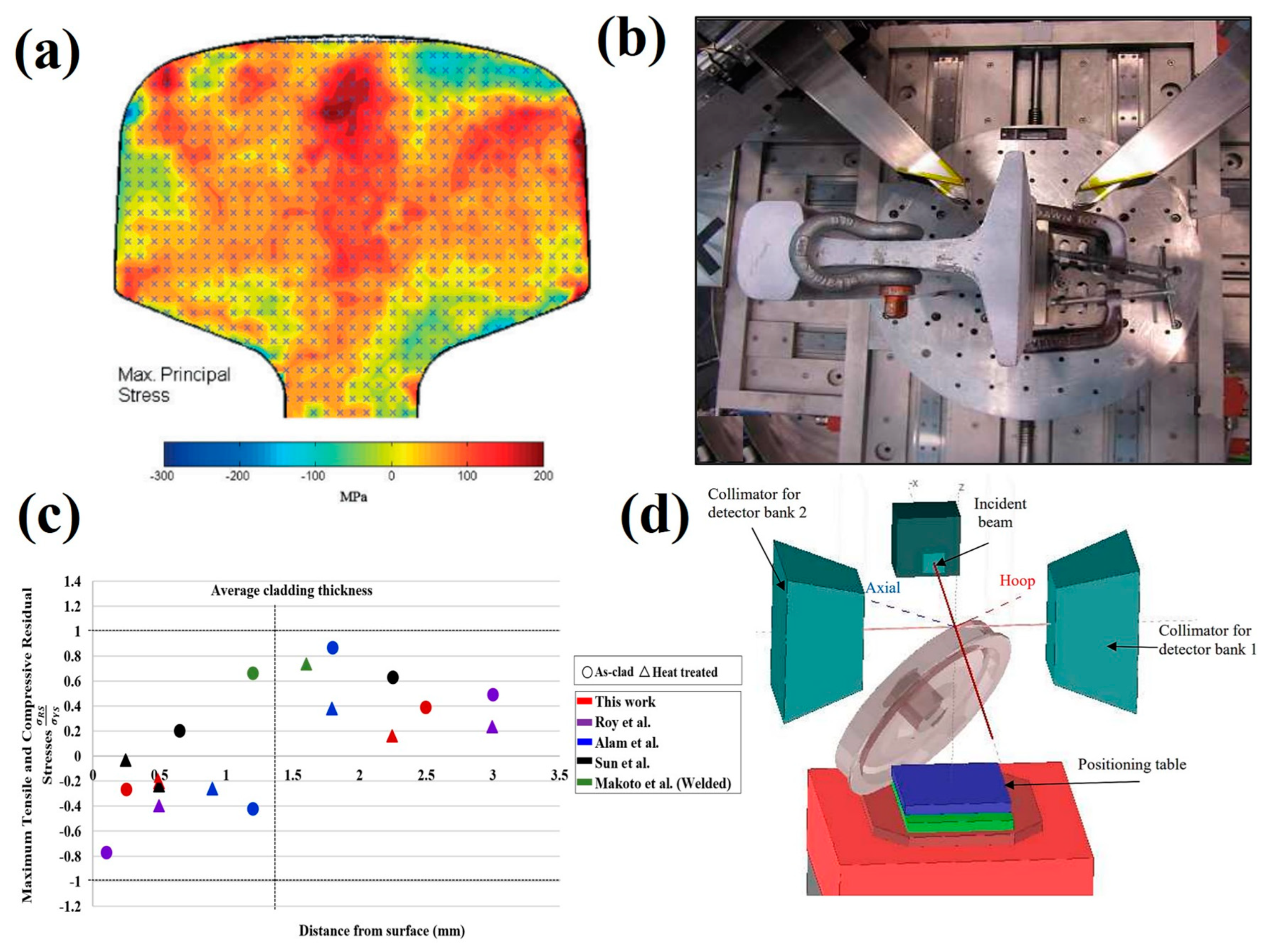

3.1.3. Neutron Diffraction

3.2. Magnetic

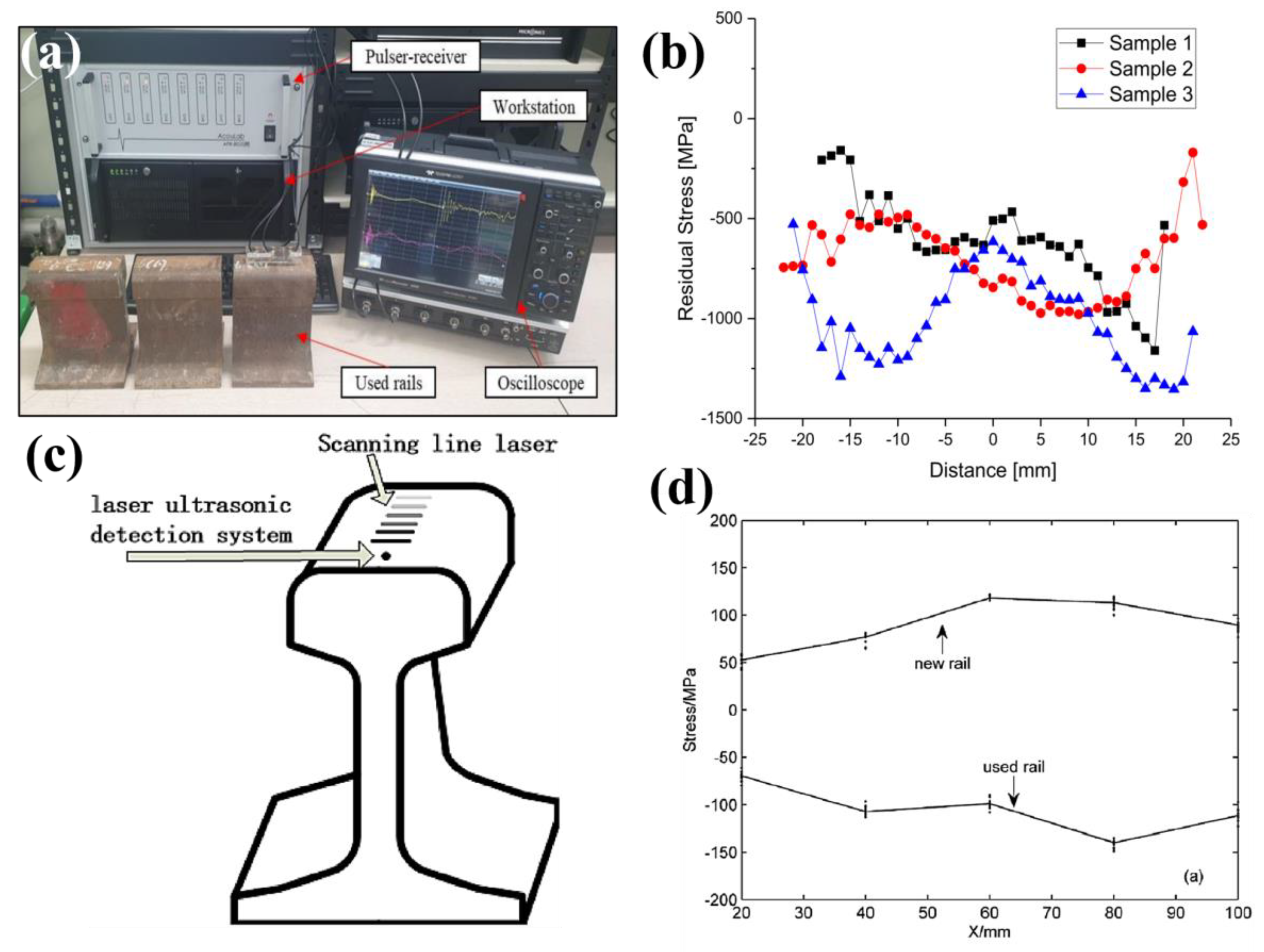

3.3. Ultrasonic

4. Conclusions

5. Future Developments

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

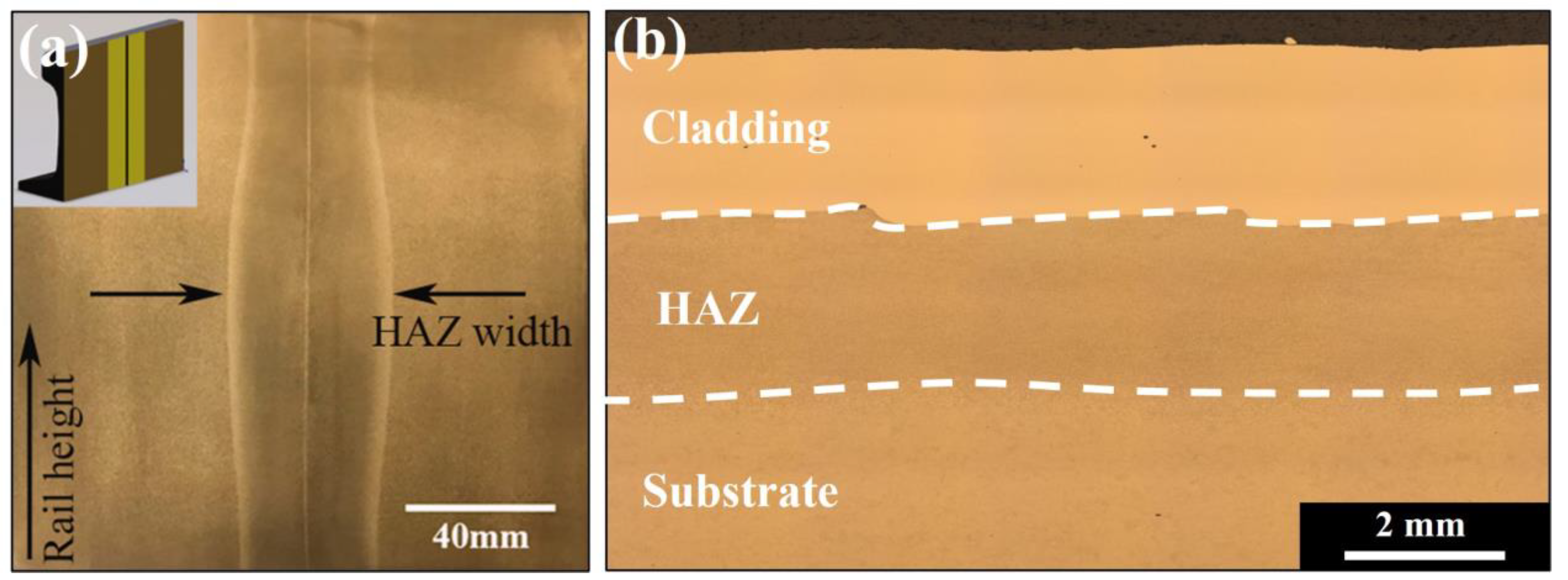

- Lai, Q.; Abrahams, R.; Yan, W.; Qiu, C.; Mutton, P.; Paradowska, A.; Soodi, M. Investigation of a novel functionally graded material for the repair of premium hypereutectoid rails using laser cladding technology. Compos. B. Eng. 2017, 130, 174–191. [Google Scholar] [CrossRef]

- Klenam, D.E.P.; Chown, L.H.; Papo, M.J.; Cornish, L.A. Phase proportions, carbon equivalent, mechanical properties and their effect on material cost of railway axle steels. MRS Adv. 2018, 3, 2169–2181. [Google Scholar] [CrossRef]

- Song, Y.; Zhang, M.; Øiseth, O.; Rønnquist, A. Wind deflection analysis of railway catenary under crosswind based on nonlinear finite element model and wind tunnel test. Mech. Mach. Theory 2022, 168, 104608. [Google Scholar] [CrossRef]

- Ding, T.; Chen, G.X.; Bu, J.; Zhang, W.H. Effect of temperature and arc discharge on friction and wear behaviours of carbon strip/copper contact wire in pantograph–catenary systems. Wear 2011, 271, 1629–1636. [Google Scholar] [CrossRef]

- Bombarda, D.; Vitetta, G.M.; Ferrante, G. Rail Diagnostics Based on Ultrasonic Guided Waves: An Overview. Appl. Sci. 2021, 11, 1071. [Google Scholar] [CrossRef]

- Kendall, O.; Fasihi, P.; Abrahams, R.; Paradowska, A.; Reid, M.; Lai, Q.; Qiu, C.; Mutton, P.; Soodi, M.; Yan, W. Application of a New Alloy and Post Processing Procedures for Laser Cladding Repairs on Hypereutectoid Rail Components. Materials 2022, 15, 5447. [Google Scholar] [CrossRef]

- Ronevich, J.A.; Song, E.J.; Feng, Z.; Wang, Y.; D’Elia, C.; Hill, M.R. Fatigue crack growth rates in high pressure hydrogen gas for multiple X100 pipeline welds accounting for crack location and residual stress. Eng. Fract. Mech. 2020, 228, 106846. [Google Scholar] [CrossRef]

- Vasileiou, A.N.; Smith, M.C.; Francis, J.A.; Balakrishnan, J.; Wang, Y.L.; Obasi, G.; Burke, M.G.; Pickering, E.J.; Gandy, D.W.; Irvine, N.M. Development of microstructure and residual stress in electron beam welds in low alloy pressure vessel steels. Mater. Des. 2021, 209, 109924. [Google Scholar] [CrossRef]

- Cui, C.; Zhang, Q.; Bao, Y.; Kang, J.; Bu, Y. Fatigue performance and evaluation of welded joints in steel truss bridges. J. Constr. Steel Res. 2018, 148, 450–456. [Google Scholar] [CrossRef]

- Josefson, B.L.; Bisschop, R.; Messaadi, M.; Hantusch, J. Residual stresses in thermite welded rails: Significance of additional forging. Weld World 2020, 64, 1195–1212. [Google Scholar] [CrossRef]

- Stone, D.H.; Iwand, H.C.; Kristan, J.; Lehnhoff, G.R. Flash Butt Rail Weld Vertical Fractures. J. Fail. Anal. Prev. 2015, 15, 33–38. [Google Scholar] [CrossRef]

- Jun, H.-K.; Seo, J.-W.; Jeon, I.-S.; Lee, S.-H.; Chang, Y.-S. Fracture and fatigue crack growth analyses on a weld-repaired railway rail. Eng. Fail. Anal. 2016, 59, 478–492. [Google Scholar] [CrossRef]

- Rossini, N.S.; Dassisti, M.; Benyounis, K.Y.; Olabi, A.G. Methods of measuring residual stresses in components. Mater. Des. 2012, 35, 572–588. [Google Scholar] [CrossRef]

- Huang, X.; Liu, Z.; Xie, H. Recent progress in residual stress measurement techniques. Acta Mech. Solida Sin. 2013, 26, 570–583. [Google Scholar] [CrossRef]

- Gur, C.H. Review of Residual Stress Measurement by Magnetic Barkhausen Noise Technique. Mater. Perform. Charact. 2018, 7, 504–525. [Google Scholar] [CrossRef]

- Singh, R.; Schruefer, S.; Wilson, S.; Gibmeier, J.; Vassen, R. Influence of coating thickness on residual stress and adhesion-strength of cold-sprayed Inconel 718 coatings. Surf. Coat. Tech. 2018, 350, 64–73. [Google Scholar] [CrossRef]

- Micheletto, A.; Cookson, J.; Pang, Y.; Chen, B.; Mutton, P. The structural integrity of flash-butt welded premium rail steel–Evaluation of strength, microstructure and defects. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2021, 235, 1006–1012. [Google Scholar] [CrossRef]

- Robles Hernández, F.C.; Okonkwo, A.O.; Kadekar, V.; Metz, T.; Badi, N. Laser cladding: The alternative for field thermite welds life extension. Mater. Des. 2016, 111, 165–173. [Google Scholar] [CrossRef]

- Gui, W.; Zhong, C.; Gu, J.; Ding, Y.; Wang, X.; Wu, T.; Liang, Y.; Qin, J.; Qu, Y.; Lin, J. Laser-clad Inconel 625 coatings on Q245R structure steel: Microstructure, wear and corrosion resistance. NPJ Mater. Degrad. 2022, 6, 37. [Google Scholar] [CrossRef]

- Grohol, C.M.; Shin, Y.C.; Frank, A. Laser cladding of aluminum alloy 6061 via off-axis powder injection. Surf. Coat. Technol. 2021, 415, 127099. [Google Scholar] [CrossRef]

- Houdková, Š.; Pala, Z.; Smazalová, E.; Vostřák, M.; Česánek, Z. Microstructure and sliding wear properties of HVOF sprayed, laser remelted and laser clad Stellite 6 coatings. Surf. Coat. Technol. 2017, 318, 129–141. [Google Scholar] [CrossRef]

- Kim, J.D.; Kang, K.H.; Kim, J.N. Nd: YAG laser cladding of marine propeller with hastelloy C-22. Appl. Phys. A 2004, 79, 1583–1585. [Google Scholar] [CrossRef]

- Mortazavian, E.; Wang, Z.; Teng, H. Effect of heat treatment on microstructure and hardness of a worn rail repaired using laser powder deposition. Int. J. Transp. Sci. Technol. 2022, 11, 406–422. [Google Scholar] [CrossRef]

- Tamanna, N.; Rumana Kabir, I.; Naher, S. A numerical investigation of similar and dissimilar clad materials on H13 steel substrate in the Laser Cladding process. Adv. Mater. Process. Technol. 2019, 5, 598–606. [Google Scholar] [CrossRef]

- Fanicchia, F.; Maeder, X.; Ast, J.; Taylor, A.A.; Guo, Y.; Polyakov, M.N.; Michler, J.; Axinte, D.A. Residual stress and adhesion of thermal spray coatings: Microscopic view by solidification and crystallisation analysis in the epitaxial CoNiCrAlY single splat. Mater. Des. 2018, 153, 36–46. [Google Scholar] [CrossRef]

- Unal, O.; Maleki, E.; Karademir, I.; Husem, F.; Efe, Y.; Das, T. Effects of conventional shot peening, severe shot peening, re-shot peening and precised grinding operations on fatigue performance of AISI 1050 railway axle steel. Int. J. Fatigue 2022, 155, 106613. [Google Scholar] [CrossRef]

- Li, X.; Ma, R.; Liu, X.; Lv, Q.; Wang, X.; Tian, Z. Effect of laser shock peening on fatigue properties of U75VG rail flash-butt welding joints. Opt. Laser Technol. 2022, 149, 107889. [Google Scholar] [CrossRef]

- Taraphdar, P.K.; Mahapatra, M.M.; Pradhan, A.K.; Singh, P.K.; Sharma, K.; Kumar, S. Measurement of Through-Thickness Residual Stresses Under Restrained Condition in Pressure Vessel Steel Weld. In Advances in Systems Engineering. Lecture Notes in Mechanical Engineering; Saran, V.H., Misra, R.K., Eds.; Springer: Singapore, 2021. [Google Scholar] [CrossRef]

- Lolla, T.; Siefert, J.; Babu, S.S.; Gandy, D. Delamination failures of Stellite hardfacing in power plants: A microstructural characterisation study. Sci. Technol. Weld. Join. 2014, 19, 476–486. [Google Scholar] [CrossRef]

- Nassiraei, H.; Rezadoost, P. SCFs in tubular X-joints retrofitted with FRP under out-of-plane bending moment. Mar. Struct. 2021, 79, 103010. [Google Scholar] [CrossRef]

- Nassiraei, H.; Rezadoost, P. Probabilistic analysis of the SCFs in tubular T/Y-joints reinforced with FRP under axial, in-plane bending, and out-of-plane bending loads. Struct. 2022, 35, 1078–1097. [Google Scholar] [CrossRef]

- Li, Y.; Chen, J.; Wang, J.; Zhao, H.; Chen, L. Study on the residual stress distribution of railway rails. Proc. Inst. Mech. Eng. C J Mech. Eng. Sci. 2020, 234, 4682–4694. [Google Scholar] [CrossRef]

- Salehi, I.; Cookson, J.; Mutton, P.; Mennie, C. Assessment of Overheated Wheels for Increased Serviceability Using the Ultrasonic Birefringence Residual Stress Measurement Technique. In Proceedings of the International Heavy Haul Association Perth Australia, Perth, Australia, 21–24 June 2015. [Google Scholar]

- Withers, P.J.; Bhadeshia, H.K.D.H. Residual stress. Part 1–Measurement techniques. Mater. Sci. Technol. 2001, 17, 355–365. [Google Scholar] [CrossRef]

- Withers, P.J.; Bhadeshia, H.K.D.H. Residual stress. Part 2–Nature and origins. Mater. Sci. Technol. 2001, 17, 366–375. [Google Scholar] [CrossRef]

- Schajer, G.S. Residual Stresses: Measurement by Destructive Testing. In Encyclopedia of Materials: Science and Technology; Buschow, K.H.J., Cahn, R.W., Flemings, M.C., Ilschner, B., Kramer, E.J., Mahajan, S., Veyssière, P., Eds.; Elsevier: Oxford, UK, 2001; pp. 8152–8158. [Google Scholar] [CrossRef]

- Hwang, Y.-I.; Kim, G.; Yong-Il, K.; Jeong-Hak, P.; Man Yong, C.; Ki-Bok, K. Experimental Measurement of Residual Stress Distribution in Rail Specimens Using Ultrasonic LCR Waves. Appl. Sci. 2021, 11, 9306. [Google Scholar] [CrossRef]

- Kang, C.; Wenner, M.; Marx, S. Experimental investigation on the rail residual stress distribution and its influence on the bending fatigue resistance of rails. Constr. Build. Mater. 2021, 284, 122856. [Google Scholar] [CrossRef]

- Jun, H.-K.; Kim, D.-W.; Jeon, I.-S.; Lee, S.-H.; Chang, Y.-S. Investigation of residual stresses in a repair-welded rail head considering solid-state phase transformation. Fatigue Frac. Eng. Mater. Struct. 2017, 40, 1059–1071. [Google Scholar] [CrossRef]

- Rieger, M.; Moser, C.; Brunnhofer, P.; Simunek, D.; Weber, F.-J.; Deisl, A.; Gänser, H.-P.; Pippan, R.; Enzinger, N. Fatigue crack growth in full-scale railway axles–Influence of secondary stresses and load sequence effects. Int. J. Fatigue 2020, 132, 105360. [Google Scholar] [CrossRef]

- Schindler, H.-J. Effect of Residual Stresses on Safe Life Prediction of Railway Axles. Procedia Struct. Integr. 2017, 4, 48–55. [Google Scholar] [CrossRef]

- Seo, J.-W.; Kwon, S.-J.; Lee, C.-W.; Lee, D.-H.; Goo, B.-C. Fatigue strength and residual stress evaluation of repair welding of bogie frame for railway vehicles. Eng. Fail. Anal. 2021, 119, 104980. [Google Scholar] [CrossRef]

- Carpenter, K.; Tabei, A. On Residual Stress Development, Prevention, and Compensation in Metal Additive Manufacturing. Materials 2020, 13, 255. [Google Scholar] [CrossRef] [PubMed]

- Ma, N.; Cai, Z.; Huang, H.; Deng, D.; Murakawa, H.; Pan, J. Investigation of welding residual stress in flash-butt joint of U71Mn rail steel by numerical simulation and experiment. Mater. Des. 2015, 88, 1296–1309. [Google Scholar] [CrossRef]

- Zhu, Z.Y.; Tian, A.Q.; Zhou, H.M.; Chen, Y.H.; Chen, P.; Xu, H.; Zhu, Y.H. Effect of the Welding Heat Input on Residual Stresses in Butt-Weld of High-Speed Train, Advanced Materials Research; Trans Tech Publications Ltd.: Bäch, Switzerland, 2011; Volume 337, pp. 255–261. [Google Scholar] [CrossRef]

- Rao, D.; Ge, J.; Chen, L. Vibratory stress relief in manufacturing the rails of a maglev system. J Manuf. Sci. Eng. 2004, 126, 388. [Google Scholar] [CrossRef]

- Pokorný, P.; Dlhý, P.; Poduška, J.; Fajkoš, R.; Vojtek, T.; Náhlík, L.; Grasso, M.; Hutař, P. Influence of heat treatment-induced residual stress on residual fatigue life of railway axles. Theor. Appl. Fract. Mech. 2020, 109, 102732. [Google Scholar] [CrossRef]

- ASTM E837-13a; Standard Test Method for Determining Residual Stresses by the Hole-Drilling Strain-Gauge Method. American Society for Testing and Materials: West Conshohocken, PA, USA, 2013. [CrossRef]

- Narayanan, A.; Mostafavi, M.; Pirling, T.; Kabra, S.; Lewis, R.; Pavier, M.J.; Peel, M.J. Residual stress in laser cladded rail. Tribol. Int. 2019, 140, 105844. [Google Scholar] [CrossRef]

- Ringsberg, J.W.; Skyttebol, A.; Josefson, B.L. Investigation of the rolling contact fatigue resistance of laser cladded twin-disc specimens: FE simulation of laser cladding, grinding and a twin-disc test. Int. J. Fatigue 2005, 27, 702–714. [Google Scholar] [CrossRef]

- Moazam, M.A.; Honarpisheh, M. Residual Stresses Measurement in UIC 60 Rail by Ring-Core Method and Sectioning Technique. AUT J. Mech. Eng. 2018, 2, 99–106. [Google Scholar] [CrossRef]

- Steinzig, M.; Ponslet, E. Residual stress measurement using the hole drilling method and laser speckle interferometry: Part 1. Exp. Tech. 2003, 27, 43–46. [Google Scholar] [CrossRef]

- Prime, M.B. Cross-Sectional Mapping of Residual Stresses by Measuring the Surface Contour After a Cut. J. Eng. Mater. Technol. 2000, 123, 162–168. [Google Scholar] [CrossRef]

- Hosseinzadeh, F.; Kowal, J.; Bouchard, P.J. Towards good practice guidelines for the contour method of residual stress measurement. J. Eng. 2014, 2014, 453–468. [Google Scholar] [CrossRef]

- Schajer, G.S.; Schajer, G.S. Practical Residual Stress Measurement Methods; John Wiley & Sons Inc.: Chichester, UK, 2013. [Google Scholar]

- Kaiser, R.; Stefenelli, M.; Hatzenbichler, T.; Antretter, T.; Hofmann, M.; Keckes, J.; Buchmayr, B. Experimental characterization and modelling of triaxial residual stresses in straightened railway rails. J. Strain Anal. Eng. Des. 2014, 50, 190–198. [Google Scholar] [CrossRef]

- Banerjee, A. Determining Residual Stresses in Rails Using Contour Method: Research on Residual Stress Estimation. Railw. Track Struct. 2020, 116, 4+. [Google Scholar]

- Elmesalamy, A.; Francis, J.A.; Li, L. A comparison of residual stresses in multi pass narrow gap laser welds and gas-tungsten arc welds in AISI 316L stainless steel. Int. J. Press. Vessels Pip. 2014, 113, 49–59. [Google Scholar] [CrossRef]

- Liu, C.; Wang, C.; Cheng, X.; Yan, Y.; Yang, J.; Guo, Y. Experimental Investigation on the Residual Stresses in a Thick Joint with a Partial Repair Weld Using Multiple-Cut Contour Method. Materials 2018, 11, 633. [Google Scholar] [CrossRef]

- Hill, M.R.; Olson, M.D. Repeatability of the Contour Method for Residual Stress Measurement. Exp. Mech. 2014, 54, 1269–1277. [Google Scholar] [CrossRef]

- Yan, S.H.; Zhu, Z.Y.; Chen, H.; Li, D.; Liu, Y.; Gou, G.Q. Research on Measurement of Residual Stresses in Flash-Butt-Weld Rails Using X-ray Diffraction, Advanced Materials Research; Trans Tech Publications Ltd.: Bäch, Switzerland, 2011; Volume 291–294, pp. 934–940. [Google Scholar] [CrossRef]

- Yu, Y.X.; He, B.L.; Shi, J.P.; Liu, J. The Effect of Residual Stress on Fatigue Life of Welded Cruciform Joints of 16MnR for Train Bogie. Adv. Mater. Res. 2013, 815, 695–699. [Google Scholar] [CrossRef]

- Ji, H.; Gou, G.Q.; Chen, H.; Li, D.; Ma, C.P.; Tian, A.Q.; Guo, Z.C. Residual Stress Characterization of A7N01-T5 Welds for High Speed Train by X-ray Diffraction and Verification, Advanced Materials Research; Trans Tech Publications Ltd.: Bäch, Switzerland, 2011; Volume 291–294, pp. 896–900. [Google Scholar] [CrossRef]

- Betsofen, S.Y.; Grigorovich, K.V.; Ashmarin, A.A.; Abdurashitov, A.Y.; Lebedev, M.A. Peculiarities of Formation of Residual Stresses in Welded Joints and Stellite Weld Cladding on Rail Steel. Inorg. Mater. Appl. Res. 2020, 11, 634–640. [Google Scholar] [CrossRef]

- Rezende, A.B.; Fonseca, S.T.; Minicucci, D.J.; Fernandes, F.M.; Farina, P.F.S.; Mei, P.R. Residual Stress Characterization by X-ray Diffraction and Correlation with Hardness in a Class D Railroad Wheel. J. Mater. Eng. Perform. 2020, 29, 6223–6227. [Google Scholar] [CrossRef]

- Coo, B.; Lee, Y. Railway Vehicle Wheel Restoration by Submerged Arc Welding and Its Characterization. Sci. For. 2019, 2, 33. [Google Scholar] [CrossRef]

- Sasaki, T.; Mizuno, R.; Takago, S.; Mishima, Y. Standardization of Cosα Method for X-ray Stress Measurement. Mater. Sci. Forum 2021, 1016, 1240–1245. [Google Scholar] [CrossRef]

- Regazzi, D.; Beretta, S.; Carboni, M. An investigation about the influence of deep rolling on fatigue crack growth in railway axles made of a medium strength steel. Eng. Fract. Mech. 2014, 131, 587–601. [Google Scholar] [CrossRef]

- Takahashi, S.; Kato, T.; Suzuki, H.; Sasaki, T. Residual Stress Evaluation of Railway Wheels by X-ray Diffraction and Finite Element Method. Adv. Mater. Res. 2010, 89, 545–550. [Google Scholar] [CrossRef]

- Dhar, S.; Danielsen, H.K.; Xu, R.; Zhang, Y.; Grumsen, F.B.; Rasmussen, C.; Juul Jensen, D. Residual strain–stress in manganese steel railway crossing determined by synchrotron and laboratory X-rays. Mater. Sci. Technol. 2021, 37, 6–13. [Google Scholar] [CrossRef]

- Dhar, S.; Zhang, Y.; Xu, R.; Danielsen, H.K.; Juul Jensen, D. Synchrotron X-ray measurement of residual strain within the nose of a worn manganese steel railway crossing. IOP Conf. Ser. Mater. Sci. Eng. 2017, 219, 012016. [Google Scholar] [CrossRef]

- Kelleher, J.; Prime, M.; Buttle, D.; Mummery, P.; Webster, P.; Shackleton, J.; Withers, P. The Measurement of Residual Stress in Railway Rails by Diffraction and other Methods. J. Neutron Res. 2003, 11, 187–193. [Google Scholar] [CrossRef]

- Pyzalla, A.; Wang, L.; Wild, E.; Wroblewski, T. Changes in microstructure, texture and residual stresses on the surface of a rail resulting from friction and wear. Wear 2001, 251, 901–907. [Google Scholar] [CrossRef]

- Wang, L.; Pyzalla, A.; Stadlbauer, W.; Werner, E.A. Microstructure features on rolling surfaces of railway rails subjected to heavy loading. Mater. Sci. Eng. A. 2003, 359, 31–43. [Google Scholar] [CrossRef]

- Zhang, Y.; Jessop, C.; Nikas, D.; Yu, T.; Liu, W.; Ahlström, J. Stress relief during annealing of railway wheel steel characterized by synchrotron X-ray micro-diffraction. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1249, 012043. [Google Scholar] [CrossRef]

- Österle, W.; Rooch, H.; Pyzalla, A.; Wang, L. Investigation of white etching layers on rails by optical microscopy, electron microscopy, X-ray and synchrotron X-ray diffraction. Mater. Sci. Eng. 2001, 303, 150–157. [Google Scholar] [CrossRef]

- Webster, P. Residual Stresses in Railway Rails-The Fame38 Project. Available online: https://www.esrf.fr/UsersAndScience/Publications/Highlights/2002/Industry/IND1 (accessed on 15 November 2022).

- Korsunsky, A.M.; Song, X.; Hofmann, F.; Abbey, B.; Xie, M.; Connolley, T.; Reinhard, C.; Atwood, R.; Connor, L.; Drakopoulos, M. Residual stress measurement on the I12 JEEP beamline at Diamond Light Source. Diam. Light Source Proc. 2010, 1, e107. [Google Scholar] [CrossRef]

- Luzin, V.; Prask, H.J.; Gnaupel-Herold, T.; Gordon, J.; Wexler, D.; Rathod, C.; Pal, S.; Daniel, W.; Atrens, A. Neutron residual stress measurements in rails. Neutron News 2013, 24, 9–13. [Google Scholar] [CrossRef]

- Jun, T.S.; Hofmann, F.; Belnoue, J.; Song, X.; Hofmann, M.; Korsunsky, A.M. Triaxial residual strains in a railway rail measured by neutron diffraction. J. Strain Anal. Eng. Des. 2009, 44, 563–568. [Google Scholar] [CrossRef]

- Magiera, J. Experimental-Numerical Study of Manufacture Induced 3D Rail Residual Stress. Solid State Phenom. 2015, 240, 17–24. [Google Scholar] [CrossRef]

- Tawfik, D.; Kirstein, O.; Mutton, P.J.; Chiu, W.K. Verification of residual stresses in flash-butt-weld rails using neutron diffraction. Phys. B Condens. 2006, 385–386, 894–896. [Google Scholar] [CrossRef]

- Khodabakhshi, B.; Paradowska, A.M.; Ibrahim, R.; Mutton, P.J. Measurement of Residual Stresses in Aluminothermic Rail Welds Using Neutron Diffraction Technique. Mater. Sci. Forum 2014, 777, 237–242. [Google Scholar] [CrossRef]

- Roy, T.; Paradowska, A.; Abrahams, R.; Law, M.; Mutton, P.; Soodi, M.; Yan, W. Residual stress in laser cladded heavy-haul rails investigated by neutron diffraction. J. Mater. Process. Technol. 2020, 278, 116511. [Google Scholar] [CrossRef]

- Dlhý, P.; Poduška, J.; Pokorný, P.; Jambor, M.; Náhlík, L.; Kajánek, D.; Fajkoš, R.; Hutař, P. Estimation of residual stress distribution in railway axles. Eng. Fail. Anal. 2022, 135, 106142. [Google Scholar] [CrossRef]

- Alessandroni, M.; Paradowska, A.M.; Perelli Cippo, E.; Senesi, R.; Andreani, C.; Gorini, G.; Montedoro, P.; Chiti, F.; Sala, D.; Spinelli, D. Investigation of Residual Stress Distribution of Wheel Rims Using Neutron Diffraction. Mater. Sci. Forum 2011, 681, 522–526. [Google Scholar] [CrossRef]

- Grosse, M.; Ottlinger, P. Strain measurements at railway wheels. Mater. Sci. Eng. A 2006, 437, 88–92. [Google Scholar] [CrossRef]

- Rathod, C.; Wexler, D.; Luzin, V.; Boyd, P.; Dhanasekar, M. A Neutron Diffraction Investigation of Residual Stresses in Rail Ends after Severe Deformation of Rail Surfaces. Mater. Sci. Forum 2014, 777, 213–218. [Google Scholar] [CrossRef]

- Witt, J. All Aboard the Neutron Train: Mapping Residual Stresses for More Robust Rails. Available online: https://neutrons.ornl.gov/content/all-aboard-neutron-train-mapping-residual-stresses-more-robust-rails (accessed on 27 November 2022).

- Mirković, N.; Brajovic, L. Methods for Determinination of Residual Stress in Rail. In Proceedings of the XVIII International Scientific-Expert Conference on Railways, Niš, Serbia, 11–12 October 2018. [Google Scholar]

- Buttle, D.; Dalzell, W.; Thayer, P.J. Non-destructive residual stress measurement in rail heads and rolling contact fatigue. Insight Non-Destr. Test. Cond. Monit. 2002, 44, 364–368. [Google Scholar]

- Lo, K.H.; Mummery, P.; Buttle, D.J. Characterisation of residual principal stresses and their implications on failure of railway rails. Eng. Fail. Anal. 2010, 17, 1273–1284. [Google Scholar] [CrossRef]

- Hwang, Y.-I.; Yong-Il, K.; Dae-Cheol, S.; Mu-Kyung, S.; Woo-Sang, L.; Kwon, S.; Ki-Bok, K. Experimental Consideration of Conditions for Measuring Residual Stresses of Rails Using Magnetic Barkhausen Noise Method. Materials 2021, 14, 5374. [Google Scholar] [CrossRef] [PubMed]

- Neslušan, M.; Minárik, P.; Grenčík, J.; Trojan, K.; Zgútová, K. Non-destructive evaluation of the railway wheel surface damage after long-term operation via Barkhausen noise technique. Wear 2019, 420–421, 195–206. [Google Scholar] [CrossRef]

- Neslušan, M.; Čížek, J.; Zgútová, K.; Kejzlar, P.; Šramek, J.; Čapek, J.; Hruška, P.; Melikhova, O. Microstructural transformation of a rail surface induced by severe thermoplastic deformation and its non-destructive monitoring via Barkhausen noise. Wear 2018, 402–403, 38–48. [Google Scholar] [CrossRef]

- Rezende, A.B.; Fonseca, S.T.; Miranda, R.S.; Fernandes, F.M.; Grijalba, F.A.F.; Farina, P.F.S.; Mei, P.R. Effect of niobium and molybdenum addition on the wear resistance and the rolling contact fatigue of railway wheels. Wear 2021, 466–467, 203571. [Google Scholar] [CrossRef]

- Balanovsky, A.E.; Shtayger, M.G.; Kondra’ev, V.V.; Karlina, A.I.; Govorkov, A.S. Comparative analysis of structural state of welded joints rails using method of Barkhausen effect and ultrasound. J. Phys. Conf. Ser. 2018, 1118, 012006. [Google Scholar] [CrossRef]

- Wang, J.; Feng, Q. Residual stress determination of rail tread using a laser ultrasonic technique. Laser Phys. 2015, 25, 056104. [Google Scholar] [CrossRef]

- Wang, P.; Ji, X.; Yan, X.; Zhu, L.; Wang, H.; Tian, G.; Yao, E. Investigation of temperature effect of stress detection based on Barkhausen noise. Sens. Actuators A Phys. 2013, 194, 232–239. [Google Scholar] [CrossRef]

- Kudryavtsev, Y.; Kleiman, J. Ultrasonic Measurement of Residual Stresses in Welded Railway Bridge. Ultrasound 2000, 6, 8. [Google Scholar]

- EN 13674-1:2017; Railway Applications-Track-Rail-Part 1: Vignole Railway Rails 46 kg/m and Above. Institute for Standardization of Serbia: Belgrade, Serbia, 2017.

- EN 13262:2020; Railway Applications-Wheelsets and Bogies-Wheels-Product Requirements. Institute for Standardization of Serbia: Belgrade, Serbia, 2020.

- ASTM E837-20; Standard Test Method for Determining Residual Stresses by the Hole-Drilling Strain-Gage Method. ASTM International: West Conshohocken, PA, USA, 2021.

- Grant, P.V.; Lord, J.D.; Whitehead, P.S. The Measurement of Residual Stresses by the Incremental Hole Drilling Technique; National Physical Laboratory: Teddington, UK, 2006. [Google Scholar]

- Guo, J.; Fu, H.; Pan, B.; Kang, R. Recent progress of residual stress measurement methods: A review. Chin. J. Aeronaut. 2021, 34, 54–78. [Google Scholar] [CrossRef]

- EN 15305:2008; Non-destructive Testing-Test Method for Residual Stress analysis by X-ray Diffraction. SIST: Ljubljana, Slovenia, 2008.

- ASTM E2860; Standard Test Method for Residual Stress Measurement by X-ray Diffraction for Bearing Steels. ASTM International: West Conshohocken, PA, USA, 2021.

- Fitzpatrick, M.E.; Fry, A.T.; Holdway, P.; Kandil, F.A.; Shackleton, J.; Suominen, L. Determination of Residual Stresses by X-ray Diffraction; National Physical Laboratory: Teddington, UK, 2005. [Google Scholar]

- ISO 21432:2020; Non-Destructive Testing—Standard Test Method for Determining Residual Stresses by Neutron Diffraction. Institute for Standardization of Serbia: Belgrade, Serbia, 2020.

- Daymond, M.R.; Johnson, M.W.; Sivia, D.S. Analysis of neutron diffraction strain measurement data from a round robin sample. J. Strain Anal. Eng. Des. 2002, 37, 73–85. [Google Scholar] [CrossRef]

- International Atomic Energy Agency. Measurement of Residual Stress in Materials Using Neutrons: Proceedings of a Technical Meeting Held in Vienna 13-17 October 2003; International Atomic Energy Agency: Viena, Austria, 2005. [Google Scholar]

- National Physical Laboratory. The Measurement of Residual Stresses by Magnetic Methods-MAPS and Barkhausen; National Physical Laboratory: Teddington, UK, 2006. [Google Scholar]

- Kudryavtsev, Y.; Kleiman, J.; Gushcha, O.; Smilenko, V.; Brodovy, V. Ultrasonic Technique and Device for Residual Stress Measurement. In Proceedings of the SEM X International Congress & Expositons on Experimental and Applied Mechanics, Costa Mesa, CA, USA, 7–10 June 2004. [Google Scholar] [CrossRef]

- Zhu, X.; Lanza di Scalea, F. Thermal Stress Measurement in Continuous Welded Rails Using the Hole-Drilling Method. Exp. Mech. 2017, 57, 165–178. [Google Scholar] [CrossRef]

- Song, M.J.; Choi, W.; Lim, N.-H.; Kim, D.; Woo, W.; Lee, S.Y. Residual Stress Analysis of New Rails Using Contour Method. J. Korean Soc. Railw. 2018, 6, 393–399. [Google Scholar] [CrossRef]

- Turan, M.E.; Aydin, F.; Sun, Y.; Cetin, M. Residual stress measurement by strain gauge and X-ray diffraction method in different shaped rails. Eng. Fail. Anal. 2019, 96, 525–529. [Google Scholar] [CrossRef]

- Hwang, Y.-I.; Lee, H.; Kim, Y.-I.; Kim, K.-B. Methodology for Mapping the Residual Stress Field in Serviced Rails Using LCR Waves. J. Nondestruct. Eval. 2022, 41, 63. [Google Scholar] [CrossRef] [PubMed]

- Murav’ev, V.V.; Volkova, L.V.; Gromov, V.E.; Glezer, A.M. Estimation of the residual stresses in rails using electromagnetic–acoustic introduction–reception of waves. Russ. Metall. 2016, 2016, 992–995. [Google Scholar] [CrossRef]

- Yang, P.; Zhao, J.; Lan-shu, C.; Dong, J. DIC-Hole Drilling Method for In-Situ Residual Stress Measurement; EDP Sciences: Les Ulis, France, 2019; Volume 275. [Google Scholar] [CrossRef]

- Arabul, E.; Lunt, A.J.G. A Novel Low-Cost DIC-Based Residual Stress Measurement Device. Appl. Sci. 2022, 12, 7233. [Google Scholar] [CrossRef]

- Deal, A.; Spinelli, I.; Chuang, A.; Gao, Y.; Broderick, T. Measuring residual stress in Ti-6Al-4V with HR-EBSD, using reference patterns from annealed material. Mater. Charact. 2021, 175, 111027. [Google Scholar] [CrossRef]

| Facility | Country | Instrument | Experimental Slits Size | Railway Related Studies |

|---|---|---|---|---|

| APS | United States | 34-ID-E | 0.3–0.5 µm Horizontal 0.3–0.7 µm Vertical | Dhar et al. [70] Zhang et al. [75] |

| DESY | Germany | G3 P05 | 0.1–6000 µm Horizontal 0.1–1200 µm Vertical | Pyzalla et al. [73] Wang et al. [74] Österle et al. [76] |

| ESRF | France | BM16 and ID11 | 0.2–1200 µm Horizontal 0.07–1000 µm Vertical | Kelleher et al. [72] Österle et al. [76] Webster et al. [77] |

| Diamond | United Kingdom | JEEP | Min: 2–13 µm2 Max: 50 × 50 µm2 | Korsunsky et al. [78] |

| Facility | Location | Instrument | Sample Capacity (kg) | Experimental Beam Size | Railway Related Studies |

|---|---|---|---|---|---|

| ANSTO | Australia | Kowari | 1000 | 0.2–20 mm horizontal and vertical incident and receiving slits. 2, 3, 5 mm and 10 mm receiving radial collimators. | Kendall et al. [6] Tawfik et al. [82] Khodabakhshi et al. [83] Roy at al. [84] Rathod et al. [88] |

| FRM-II | Germany | Stress-spec | 300 | Slits from 0.5 mm up to several mm | Kaiser et al. [56] Jun et al. [80] |

| ISIS | United Kingdom | Engin-X | 1000 | 0.5–20 mm horizontal and vertical incident and receiving slits. Collimators Sizes: 0.5, 1, 2 and 4 mm | Narayanan et al. [49] Alessandroni et al. [86] |

| ILL | France | SALSA | 500 | Slits and collimators arrangements from 0.3 mm up to several mm | Narayanan et al. [49] |

| NIST | USA | BT-8 | 100 | Collimators Sizes: 0.5, 1, 2 and 4 mm | Luzin et al. [79] Magiera et al. [81] |

| SINQ | Switzerland | POLDI | 200 | Slits and collimators Sizes: 0.6, 1.5, 3.8 mm | Grosse et al. [87] |

| ORNL | USA | HB-2B | 50 | Slits from 0.3 mm up to several mm | Witt [89] |

| Technique | Depth | Spatial Resolution | Accuracy | Stresses | Applications | Standards |

|---|---|---|---|---|---|---|

| Sectioning | Not applicable | 5 mm | 30 MPa steel | Uniaxial/Biaxial | Welds/Joints Large structures Rails, Axles Bogie Frames | EN 13674-1 [101] EN 13262:2020 [102] |

| Hole Drilling | Approximately equal to the hole diameter (approx. 2 mm) | 100 μm | 30 MPa steel | Biaxial | Welds/joints Large structures Metal coatings Rails, axles. | ASTM E837-20 [103] NPL Best Practice Guidelines [104] |

| Contour Method | 2–600 mm | 300 μm | 20 MPa steel | Uniaxial | Medium structures Rails | Best Practice Guidelines by Prime et al. [53] Hosseinzadeh et al. [54] |

| Laboratory X-ray Diffraction | 20 µm Layer removal: 1–4 mm [105] | 10 μm | 20 MPa steel | Biaxial | Coatings (Laser cladding) Rails, Wheels Axles, Bogies | EN 15305:2008 [106] ASTM E2860 [107] |

| Synchrotron Diffraction | 20 mm in Fe 100 mm in Al | 5 μm | 10 MPa | Triaxial | Rails Welds Coatings (Laser cladding) | NPL Best Practice Guidelines for X-ray diffraction can also be applied [108] |

| Neutron Diffraction | 30 mm in Fe 100 mm in Al | 500 μm | 10 MPa | Triaxial | Medium structures Coatings/LMD Welds/joins Rails, wheels, axles, bogies, IRJs | ISO 21,432 [109] Best Practice Guidelines by Daymond et al. [110] IAEA [111] |

| Magnetic | MAPS 0.1–5 mm [89] MBN 10 μm–1 mm | 1 mm | 10 MPa | Biaxial | Large structures Rails Wheels Welds/joints | NPL Best Practice Guidelines [112] |

| Ultrasonic | 2–150 mm [113] | 5 mm | 10 MPa | Biaxial | Large structures (e.g., rail bridges) Wheels Rails Welds/joins | EN 13262:2020 [102] |

| Technique | Destructive | Cost and Availability | Advantages | Disadvantages | Railway Related Studies |

|---|---|---|---|---|---|

| Sectioning | Yes | Low cost, Widely available | Easy to implement Complex shapes and geometry Low resolution | Destructive Low resolution Not for surface measurements | Kang et al. [38] Jun et al. [39] Rieger et al. [40] Schindler et al. [41] Seo et al. [42] |

| Hole Drilling | Semi | Low cost Widely available | Easy to implement Surface and near surface measurements Incremental measurements | Low resolution Near surface only Wont capture steep stress gradients | Ma et al. [44] Zhu et al. [45] Rao et al. [46] Pokorný et al. [47] Narayanan et al. [49] Ringsberg et al. [50] Moazam et al. [51] Zhu et al. [114] |

| Contour Method | Yes | Moderate cost Specialised equipment required | No d0 required Larger components measured Not effected by microstructure | Destructive Complex post processing Not suitable for high stresses | Kaiser et al. [56] Banerjee [57] Song et al. [115] |

| Laboratory X-ray Diffraction | No | Moderate cost Specialised equipment required | In situ In-depth measurements with layer removal Accurate surface measurements | Limited to surface Small samples measurement Influenced by surface roughness | Yan et al. [61] Yu et al. [62] Ji et al. [63] Betsofen et al. [64] Rezende et al. [65] Coo et al. [66] Sasaki et al. [67] Regazzi et al. [68] Takahashi et al. [69] Turan et al. [116] |

| Synchrotron Diffraction | No | High cost Specialised facilities | High Resolution Fast measurement times | Specialised facilities with limited access High level of expertise required | Dhar et al. [70] Dhar et al. [71] Kelleher et al. [72] Pyzalla et al. [73] Wang et al. [74] Zhang et al. [75] Österle et al. [76] |

| Neutron Diffraction | No | High cost Specialised facilities | High resolution Non destructive Fast data processing Microstructural information | High level of expertise Specialised facilities with limited access Can be semi-destructive | Kendall et al. [6] Narayanan et al. [49] Luzin et al. [79] Jun et al. [80] Magiera et al. [81] Tawfik et al. [82] Khodabakhshi et al. [83] Roy et al. [84] Alessandroni et al. [86] Grosse et al. [87] Rathod et al. [88] |

| Magnetic | No | Moderate cost Specialised equipment required | In situ Fast measurements Only for ferromagnetic materials | Not suitable for high stresses Influenced by microstructure Surface measurement | Buttle et al. [91] Lo et al. [92] Hwang et al. [93] Neslušan et al. [94] Rezende et al. [96] Balanovsky et al. [97] Wang et al. [99] |

| Ultrasonic | No | Moderate cost Specialised equipment required | Portable Surface or through thickness measurements | Calibration coefficients required | Hwang et al. [37] Wang et al. [98] Kudryavtsev et al. [100] Salehi et al. [33] Hwang et al. [117] Murav’ev et al. [118] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kendall, O.; Paradowska, A.; Abrahams, R.; Reid, M.; Qiu, C.; Mutton, P.; Yan, W. Residual Stress Measurement Techniques for Metal Joints, Metallic Coatings and Components in the Railway Industry: A Review. Materials 2023, 16, 232. https://doi.org/10.3390/ma16010232

Kendall O, Paradowska A, Abrahams R, Reid M, Qiu C, Mutton P, Yan W. Residual Stress Measurement Techniques for Metal Joints, Metallic Coatings and Components in the Railway Industry: A Review. Materials. 2023; 16(1):232. https://doi.org/10.3390/ma16010232

Chicago/Turabian StyleKendall, Olivia, Anna Paradowska, Ralph Abrahams, Mark Reid, Cong Qiu, Peter Mutton, and Wenyi Yan. 2023. "Residual Stress Measurement Techniques for Metal Joints, Metallic Coatings and Components in the Railway Industry: A Review" Materials 16, no. 1: 232. https://doi.org/10.3390/ma16010232

APA StyleKendall, O., Paradowska, A., Abrahams, R., Reid, M., Qiu, C., Mutton, P., & Yan, W. (2023). Residual Stress Measurement Techniques for Metal Joints, Metallic Coatings and Components in the Railway Industry: A Review. Materials, 16(1), 232. https://doi.org/10.3390/ma16010232