Effect of Laser Micro-Texturing on Laser Joining of Carbon Fiber Reinforced Thermosetting Composites to TC4 Alloy

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

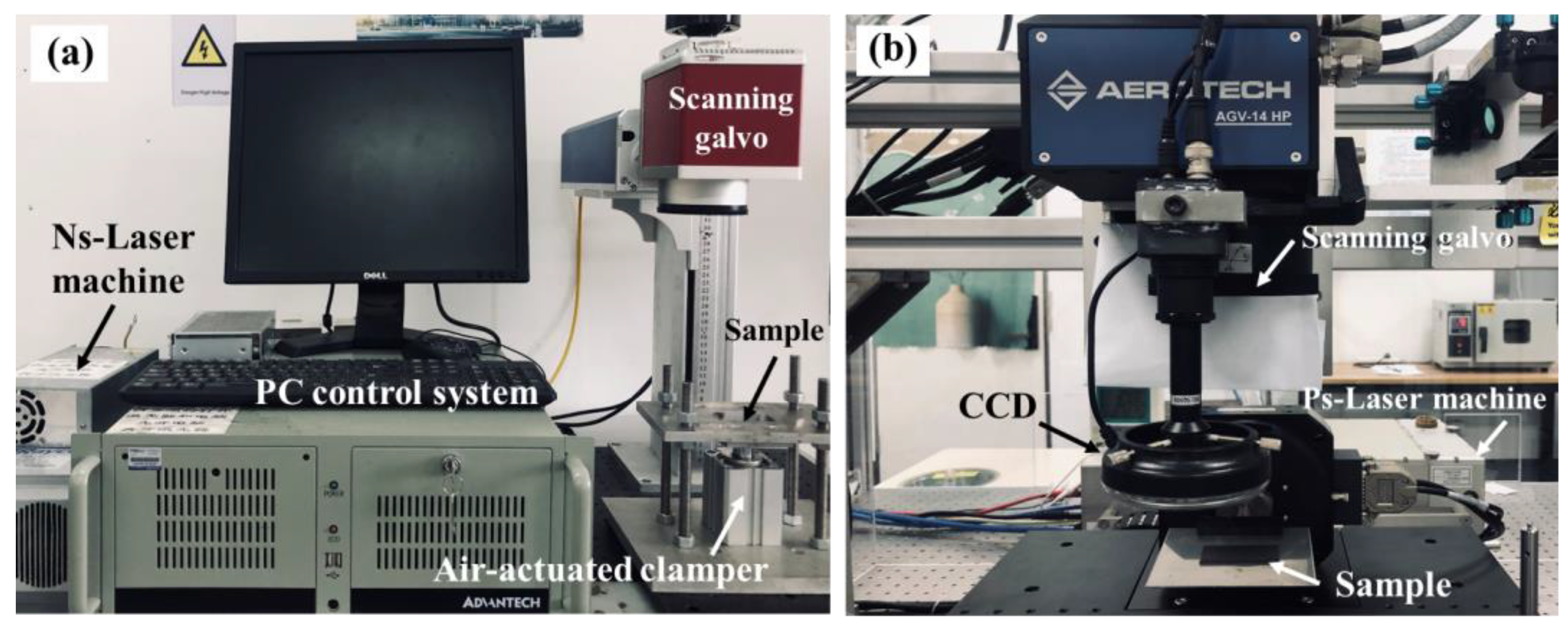

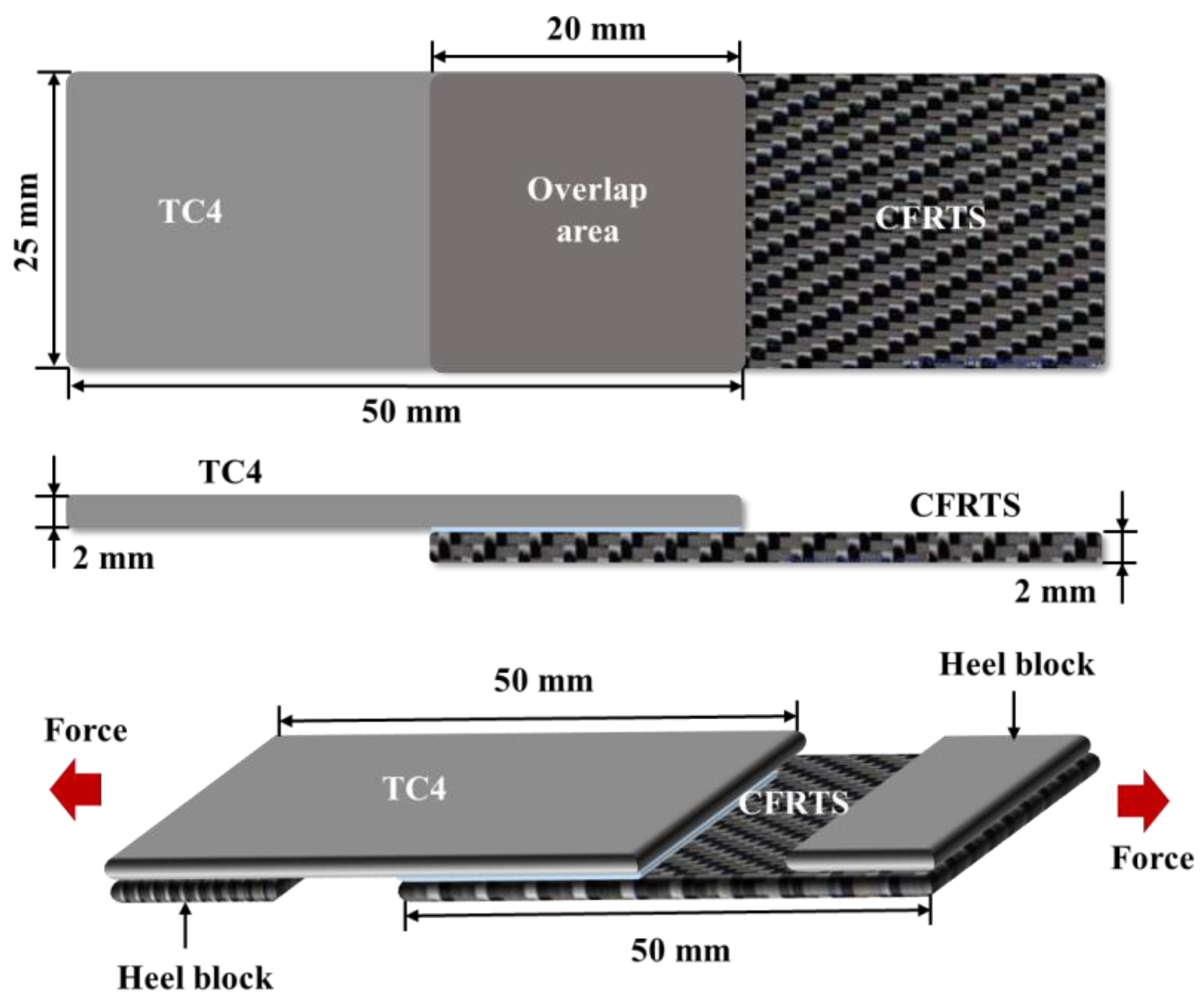

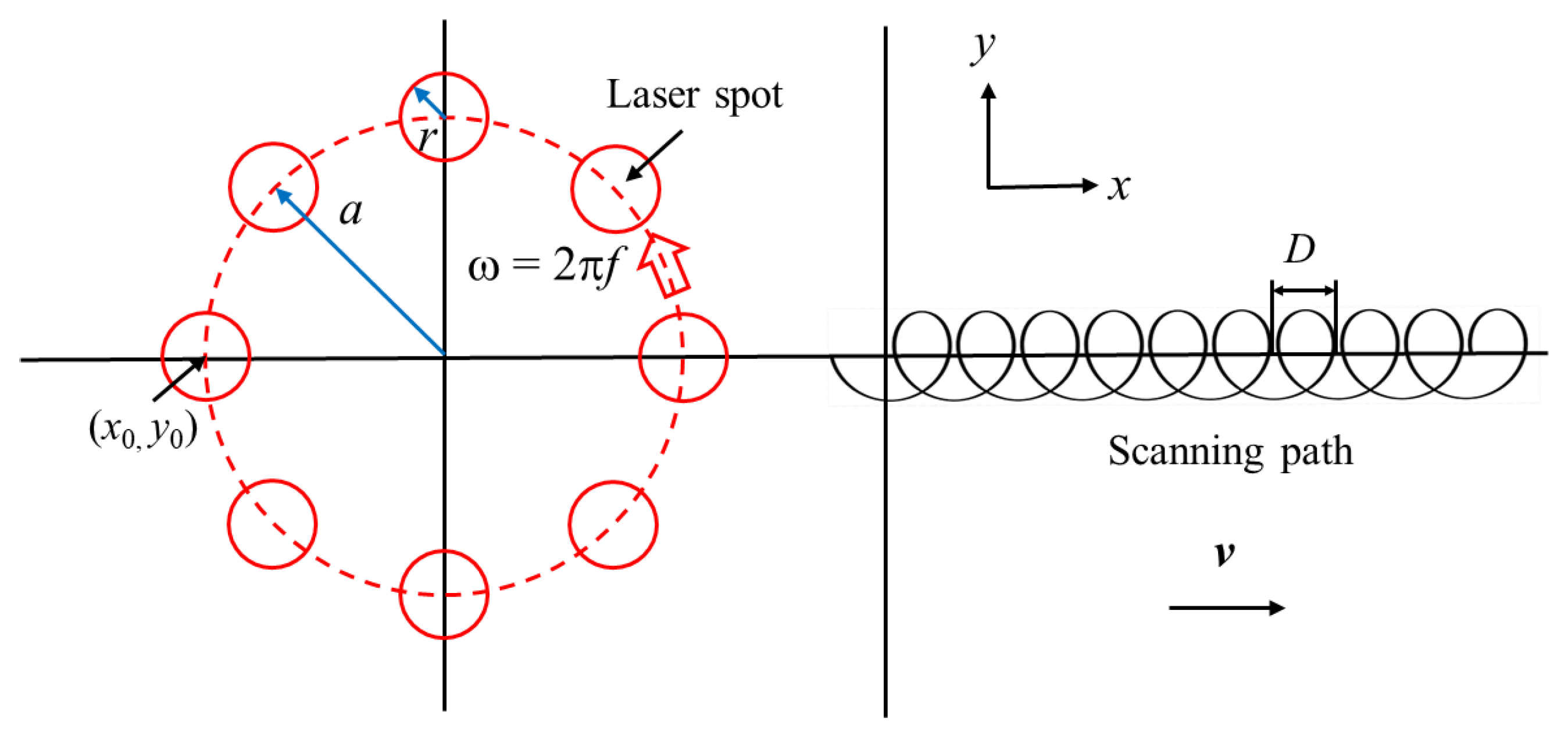

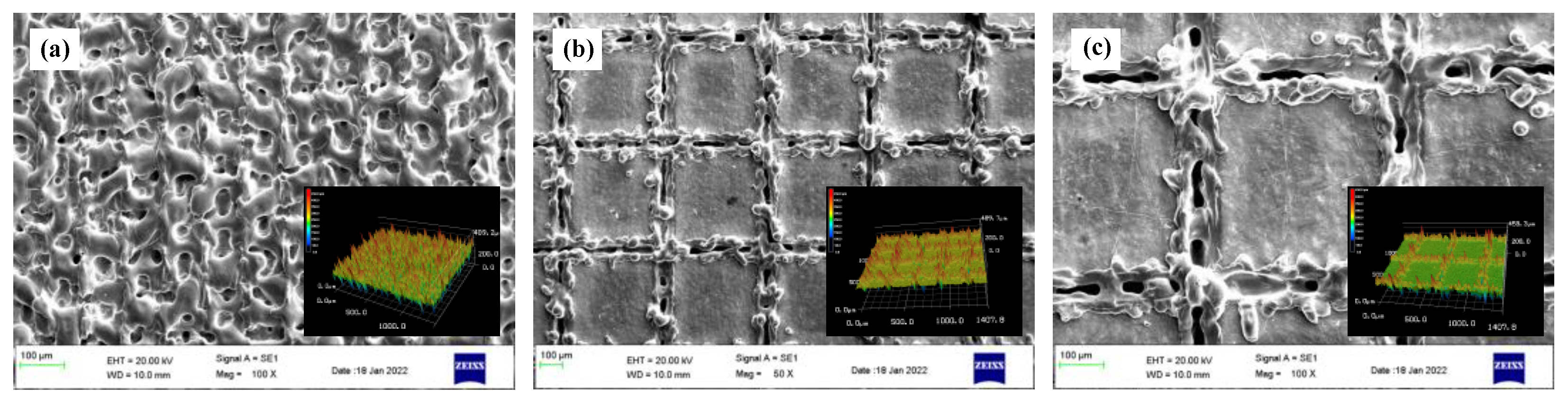

2.2. Experimental Procedure

2.3. Analysis Methods

2.4. Finite Element Simulation

2.4.1. Establishment of Heat Transfer Model

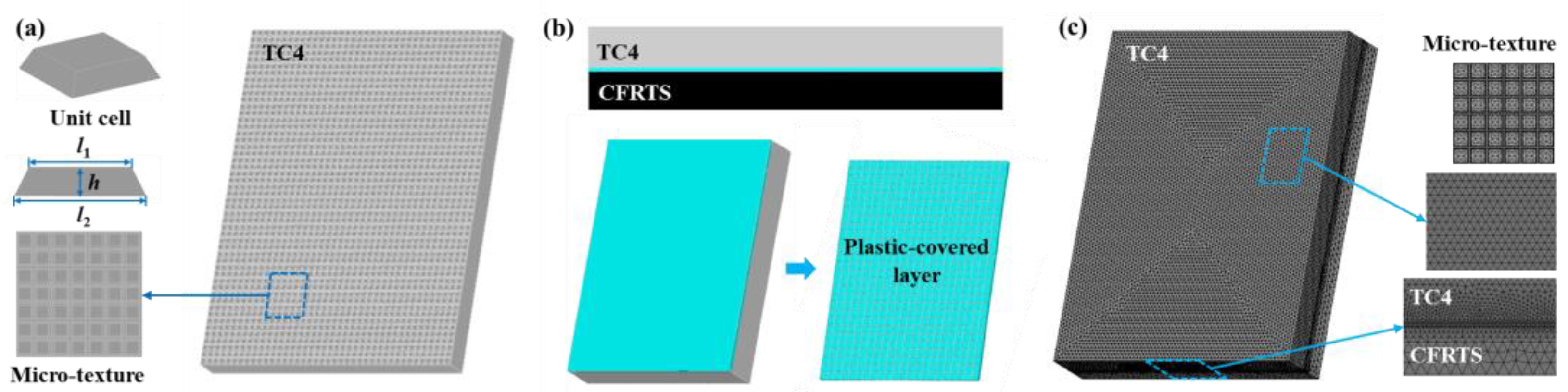

2.4.2. Establishment of Finite Element Model

3. Results and Discussions

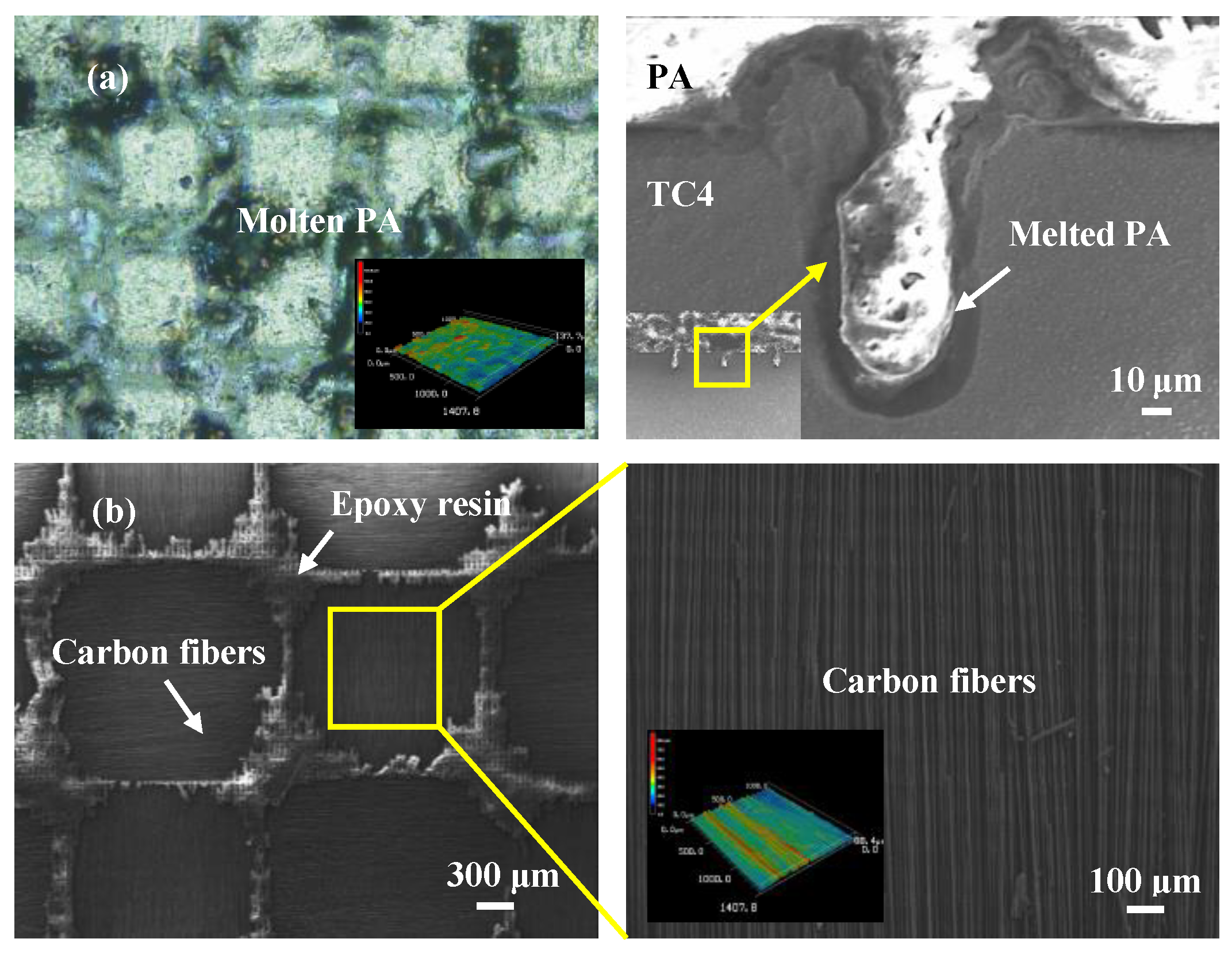

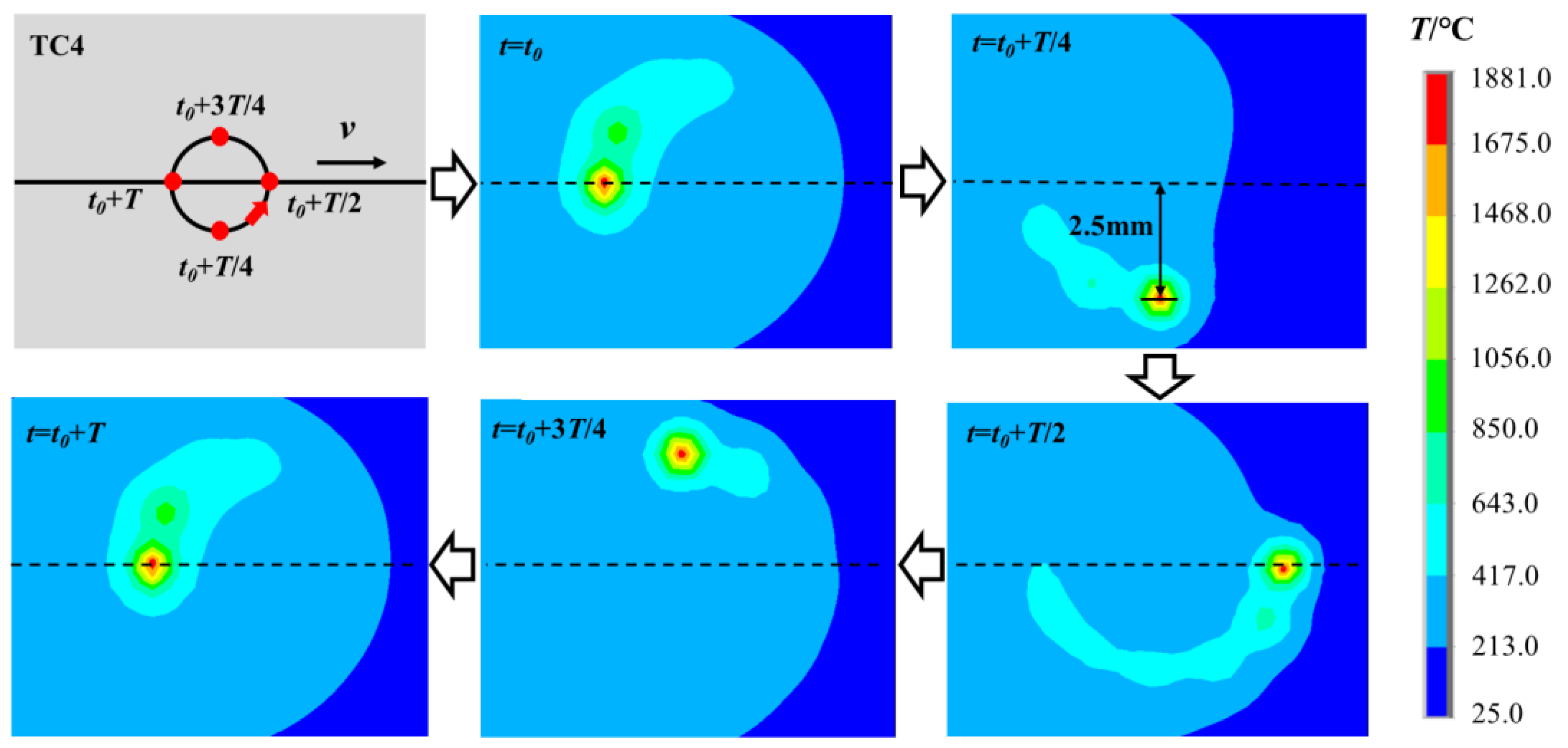

3.1. Basic Characteristics and Analysis of Temperature Field

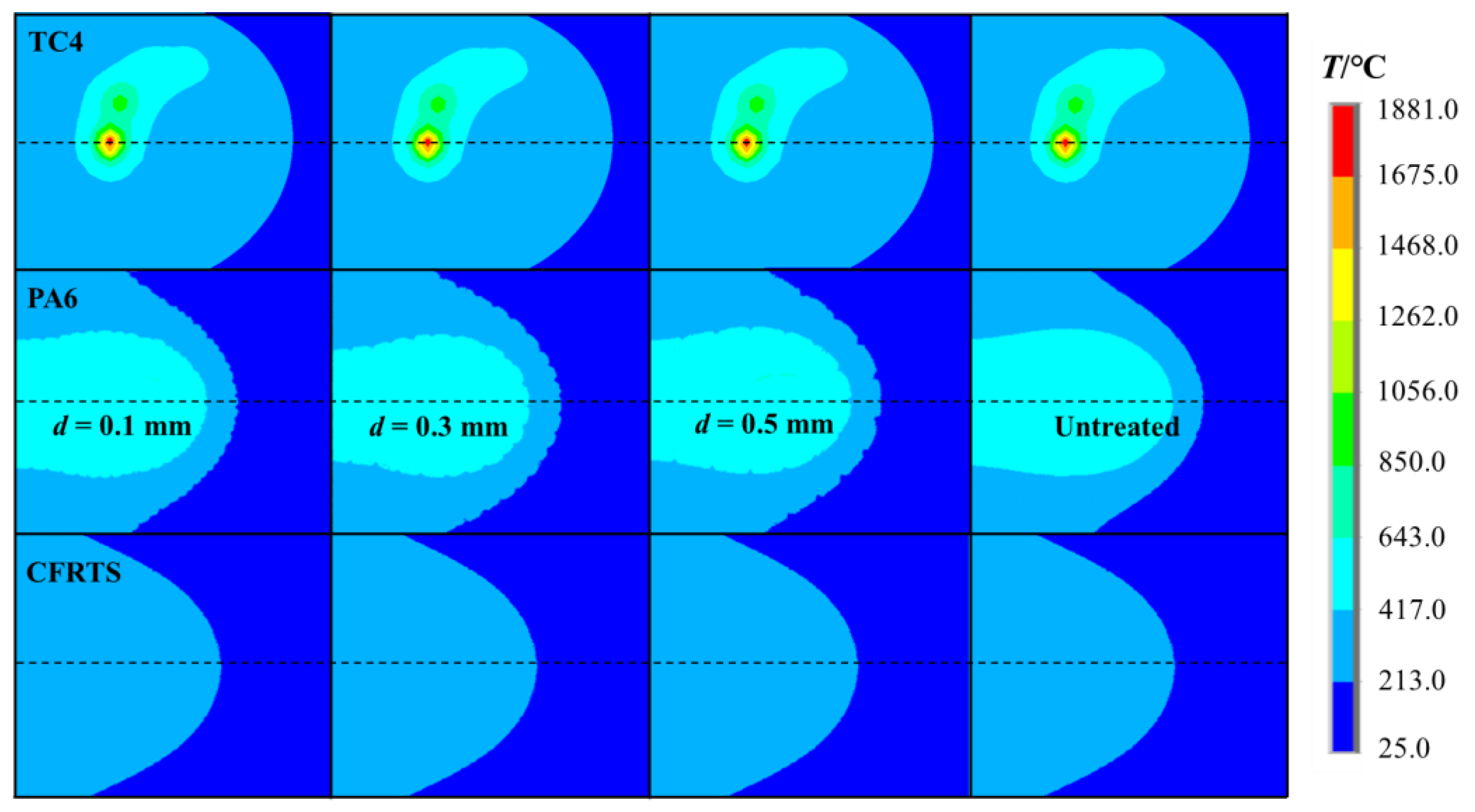

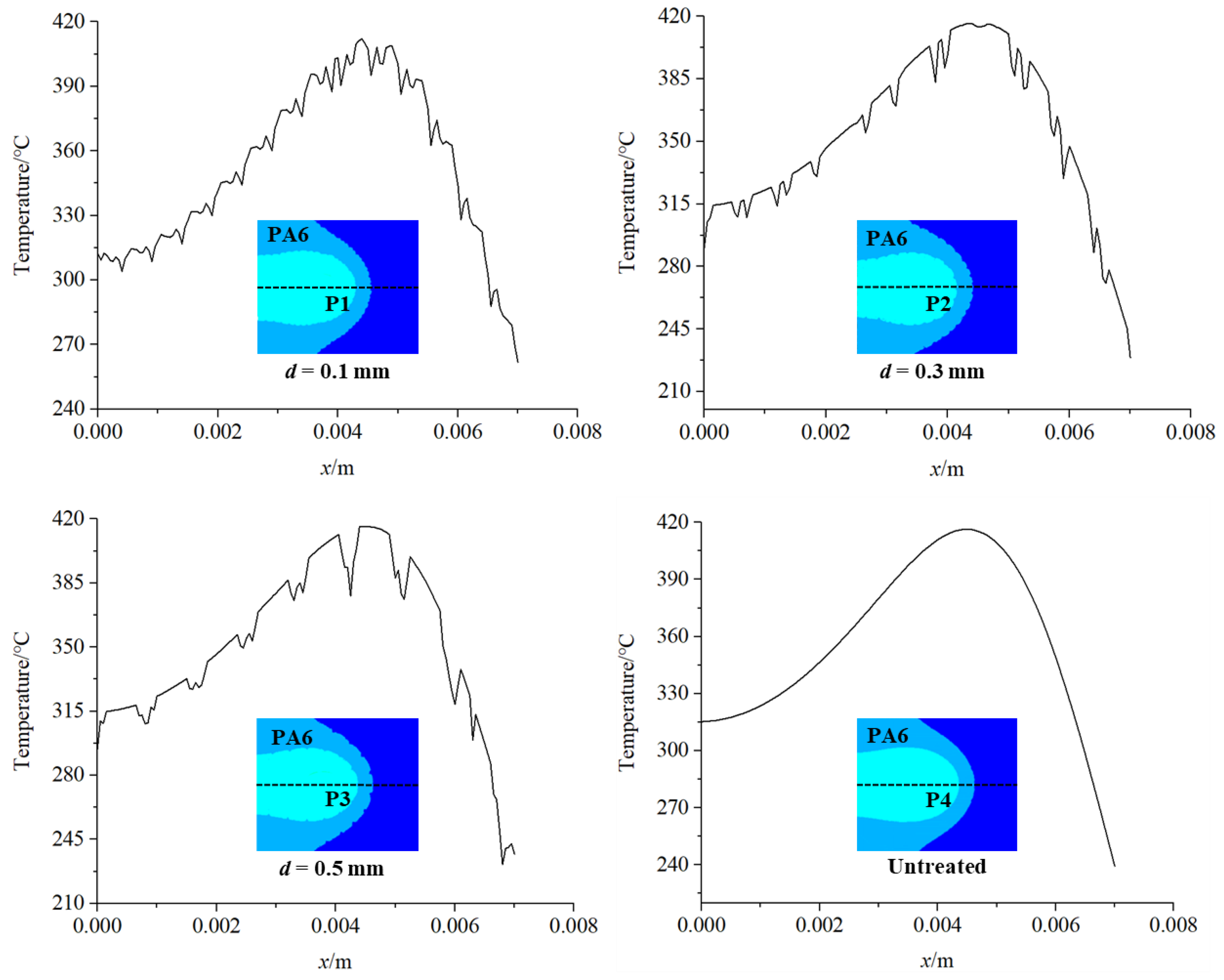

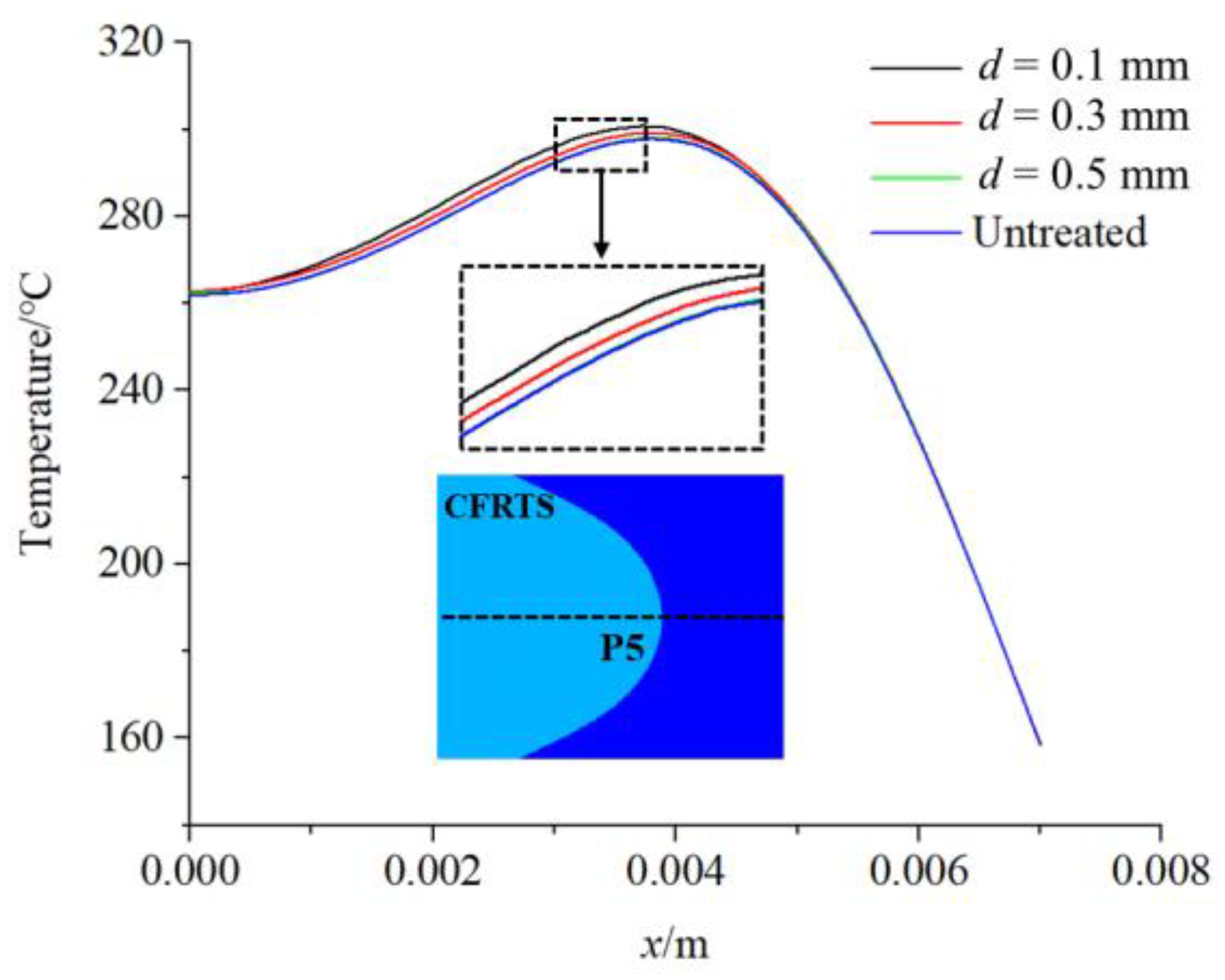

3.2. Effect of Micro-Textures on Temperature Field of Joint

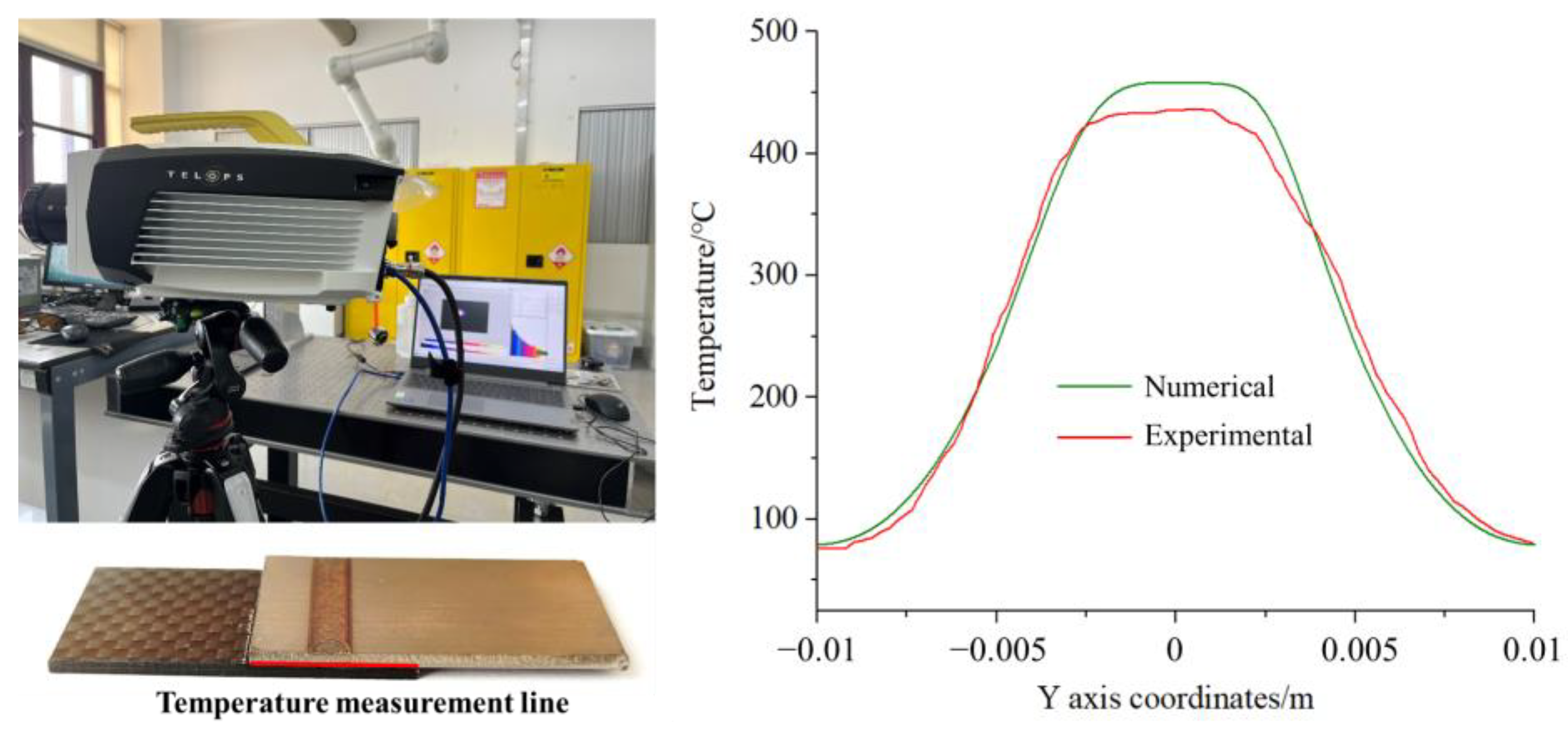

3.3. Reliability Verification of Finite Element Model

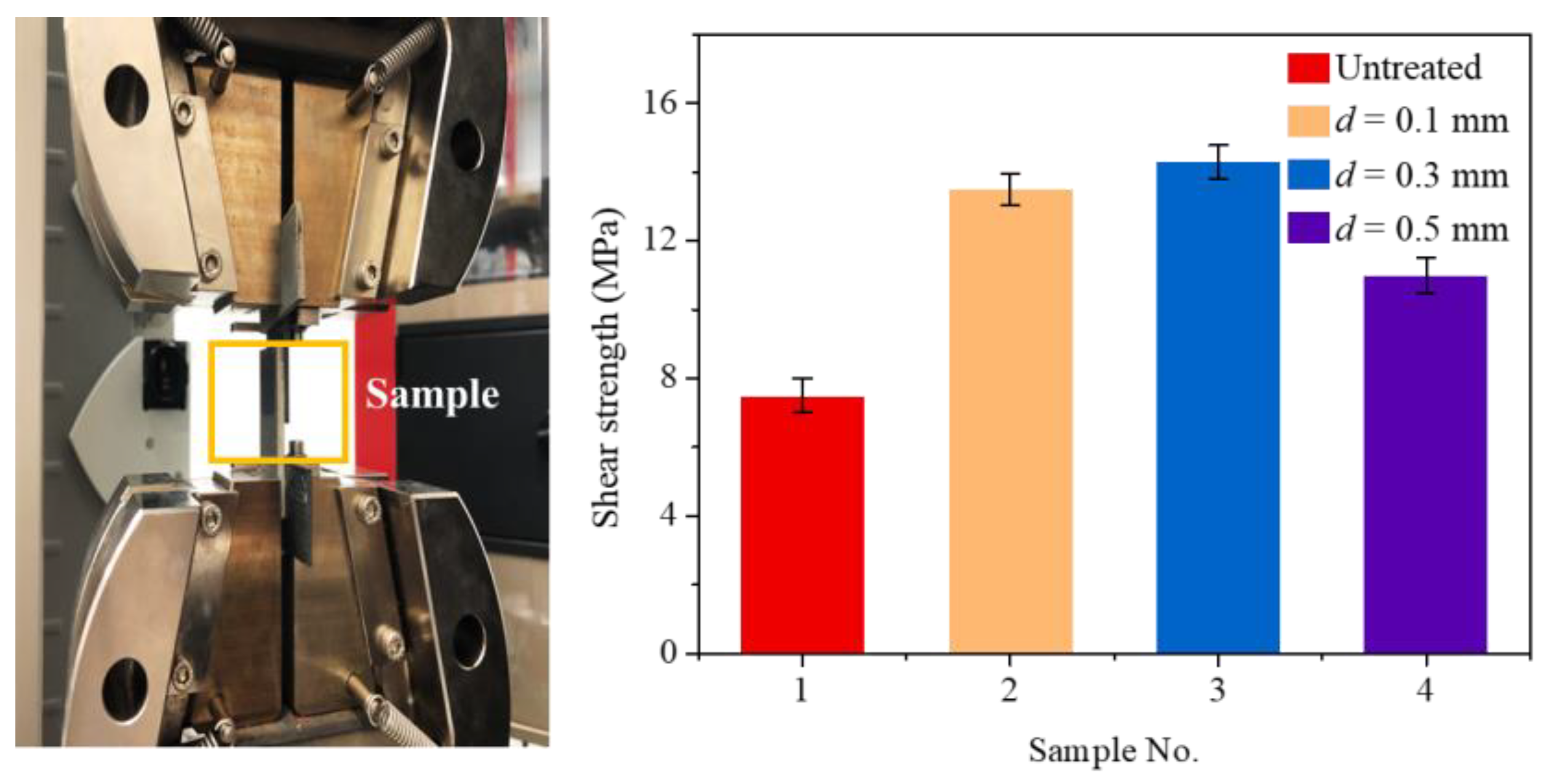

3.4. Effect of Micro-Textures on Mechanical Properties of Joints

4. Conclusions

- (1)

- The finite element simulation results of the temperature field show that two temperature peaks appear at the nodes on the weld centerline of the TC4 alloy surface due to the periodic rotary heating of the TC4 alloy by the laser beam, and that the temperature of each node changes with time in the form of broken line oscillation. The temperature change trend of the nodes on the center line of the weld on the CFRTS surface is basically the same as that on the TC4 alloy surface. However, due to the fast rotation speed of the laser, the heat is gradually homogenized when it is transferred downward, and there are no two obvious temperature peaks at each node on the CFRTS surface.

- (2)

- Considering the finite element model of laser micro-textures, the isothermal line of the PA6 interface is not smoothly distributed, and the temperature along the weld center line changes in an oscillating form. Without considering the micro-textures of the finite element model, the PA6 interface isotherm distribution smoothed along the weld center line direction of the temperature change smoothly. Micro-textures cause a change in heat input on the surface of CFRTS, and the smaller the micro-textures, the higher the heat input on the surface of CFRTS. This is because the micro-texture groove increases the contact area between TC4 alloy and PA6 resin, which is conducive to heat conduction.

- (3)

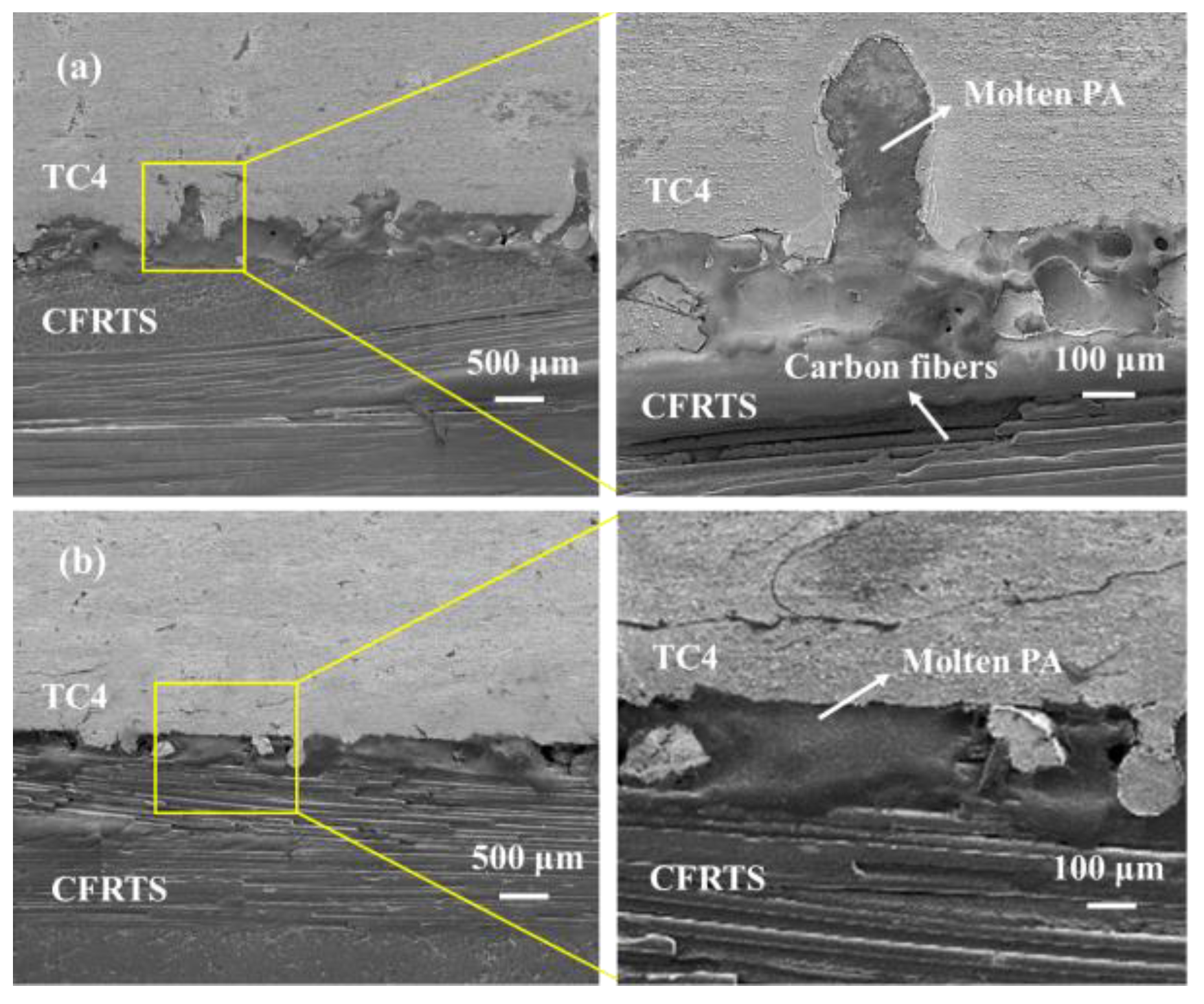

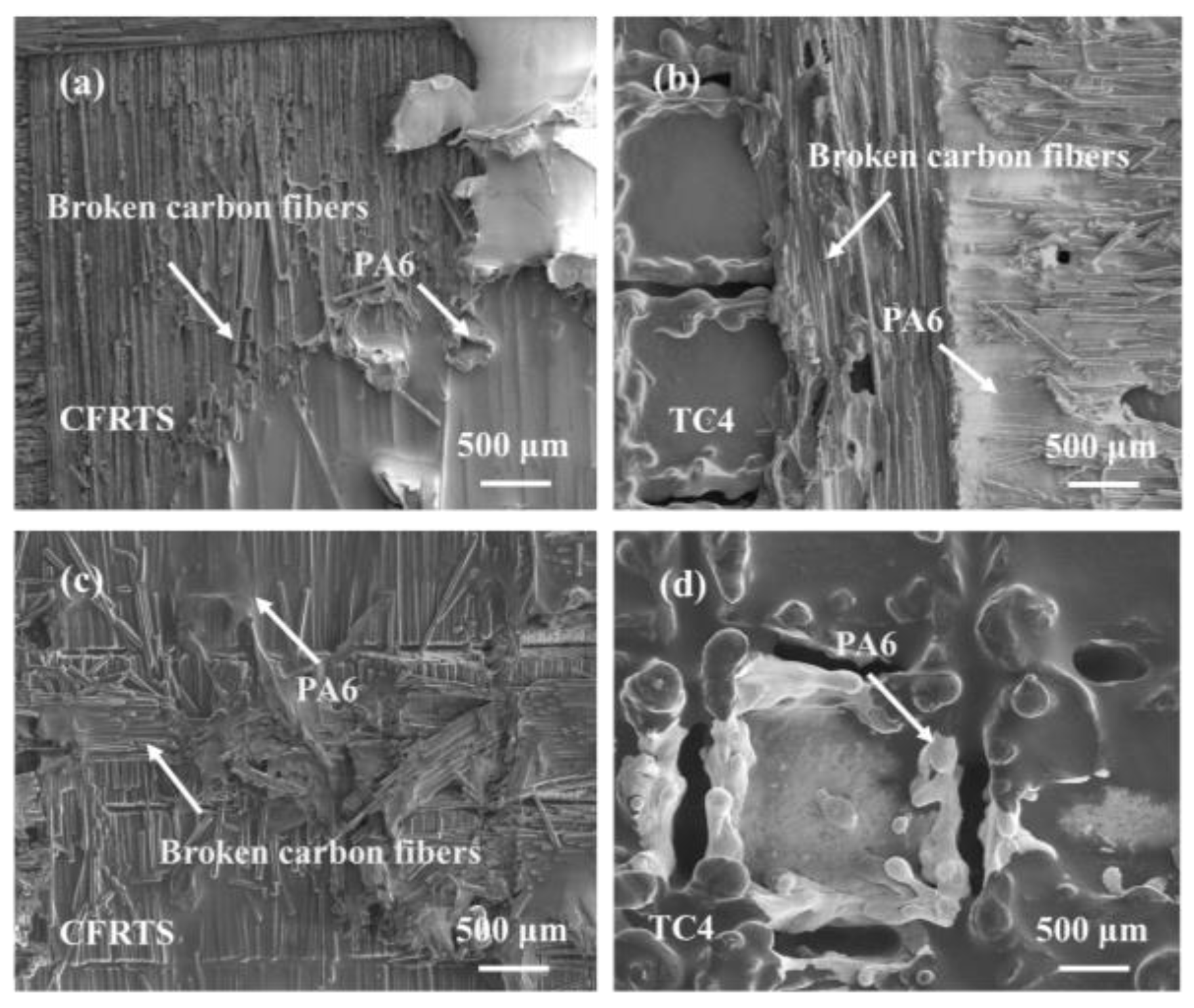

- When the micro-texture scanning spacing is 0.3 mm, the bonding strength of the joint is the highest, about 14.3 MPa. The interlocking structure formed by CFRTS and titanium alloy at the interface is an important reason for the significant improvement in joint strength. At the highest bonding strength, the failure mode of the joint is the cohesive failure of carbon fiber tearing in CFRTS and the interfacial failure of PA6 resin and TC4 alloy.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Al-Lami, A.; Hilmer, P.; Sinapius, M. Eco-efficiency assessment of manufacturing carbon fiber reinforced polymers (CFRP) in aerospace industry. Aerosp. Sci. Technol. 2018, 79, 669–678. [Google Scholar] [CrossRef]

- Ishikawa, T.; Amaoka, K.; Masubuchi, Y. Overview of automotive structural composites technology developments in Japan. Compos. Sci. Technol. 2018, 155, 221–246. [Google Scholar] [CrossRef]

- Kim, K.W.; Kim, D.K.; Kin, B.S. Cure behaviors and mechanical properties of carbon fiber-reinforced nylon6/epoxy blended matrix composites. Compos. Part B 2016, 112, 15–21. [Google Scholar] [CrossRef]

- Guermazi, N.; Tarjem, A.B.; Ksouri, I. On the durability of FRP composites for aircraft structures in hygrothermal conditioning. Compos. Part B 2016, 85, 294–304. [Google Scholar] [CrossRef]

- Zhang, D.; Zhang, Q.; Fan, X. Review on Joining Process of Carbon Fiber-Reinforced Polymer and Metal: Methods and Joining Process. Rare Metal Mat. Eng. 2018, 47, 3686–3696. [Google Scholar]

- Jung, K.W.; Kawahito, Y.; Takahashi, M. Laser direct joining of carbon fiber reinforced plastic to aluminum alloy. J. Laser Appl. 2013, 47, 179–188. [Google Scholar] [CrossRef]

- Lambiase, F.; Genna, S. Laser-assisted direct joining of ASI304 stainless steel with polycarbonate sheets: Thermal analysis, mechanical characterization, and bonds morphology. Opt. Laser Technol. 2017, 88, 205–214. [Google Scholar] [CrossRef]

- Li, Y.; Bu, H.; Yang, H. Effect of laser heat input on the interface morphology during laser joining of CFRTP and 6061 aluminum alloy. J. Manuf. Process. 2020, 50, 366–379. [Google Scholar] [CrossRef]

- Wang, T.; Su, X.; Chen, Y. Joint formation and fracture characteristics of laser welded CFRP/TC4 joints. J. Manuf. Process. 2019, 45, 1–8. [Google Scholar] [CrossRef]

- Jiao, J.; Xu, Z.; Wang, Q. CFRTP and stainless steel laser joining: Thermal defects analysis and joining parameters optimization. Opt. Laser Technol. 2018, 103, 170–176. [Google Scholar] [CrossRef]

- Sheng, L.; Jiao, J.; Du, B. Influence of Processing Parameters on Laser Direct Joining of CFRTP and Stainless Steel. Adv. Mater. Sci. Eng. 2018, 2018, 1–15. [Google Scholar] [CrossRef]

- Reda, A.S.S.; Abdel, S.F.; Tarek, M. Novel Surface Topography and Microhardness Characterization of Laser Clad Layer on TC4 Titanium Alloy Using Laser-Induced Breakdown Spectroscopy and Machine Learning. Metall. Mater. Trans. A 2022, 53, 3639–3653. [Google Scholar]

- Pakuła, D.; Staszuk, M.; Dziekońska, M. Laser Micro-Texturing of Sintered Tool Materials Surface. Materials 2019, 12, 3152. [Google Scholar] [CrossRef] [PubMed]

- Pramanik, A.; Basak, A.K.; Dong, Y. Joining of carbon fiber reinforced polymer (CFRP) composites and aluminium alloys—A review. Compos. Part A 2017, 101, 1–29. [Google Scholar] [CrossRef]

- Zhang, Z.; Shan, J.; Tan, X. Improvement of the laser joining of CFRP and aluminum via laser pre-treatment. Int. J. Adv. Manuf. Tech. 2017, 90, 9–12. [Google Scholar] [CrossRef]

- Heckert, A.; Zaeh, M.F. Laser surface pre-treatment of aluminium for hybrid joints with glass fibre reinforced thermoplastics. Phys. Proc. 2014, 56, 1171–1181. [Google Scholar] [CrossRef]

- Tan, C.; Su, J.; Feng, Z. Laser joining of CFRTP to titanium alloy via laser surface texturing. Chin. J. Aeronaut. 2021, 34, 103–114. [Google Scholar] [CrossRef]

- Liu, Y.; Su, J.; Tan, C. Effect of laser texturing on mechanical strength and microstructural properties of hot-pressing joining of carbon fiber reinforced plastic to Ti6A14V. J. Manuf. Process. 2021, 65, 30–41. [Google Scholar] [CrossRef]

- Liu, Y.; Su, J.; Ma, G. Effect of the laser texturing width on hot-pressing joining of AZ31B and CFRTP. Opt. Laser Technol. 2021, 143, 107350. [Google Scholar] [CrossRef]

- Lambiase, F.; Genna, S.; Kant, R. A procedure for calibration and validation of FE modelling of laser-assisted metal to polymer direct joining. Opt. Laser Technol. 2018, 98, 363–372. [Google Scholar] [CrossRef]

- Lambiase, F.; Genna, S.; Kant, R. Optimization of laser-assisted joining through an integrated experimental-simulation approach. Int. J. Adv. Manuf. Tech. 2018, 97, 2655–2666. [Google Scholar] [CrossRef]

- Tan, C.; Su, J.; Zhu, B. Effect of scanning speed on laser joining of carbon fiber reinforced PEEK to titanium alloy. Opt. Laser Technol. 2020, 129, 106273. [Google Scholar] [CrossRef]

- Liu, H.; Wei, L.; Meng, D. Simulation and experimental study of laser transmission welding considering the influence of interfacial contact status. Mater. Des. 2016, 92, 246–260. [Google Scholar] [CrossRef]

- Jiao, J.; Xu, Z.; Wang, Q. Research on carbon fiber reinforced thermal polymer/stainless steel laser direct joining. J. Laser Appl. 2018, 30, 032419. [Google Scholar] [CrossRef]

- Xu, J.; Jing, C.; Jiao, J. Experimental Study on Carbon Fiber-Reinforced Composites Cutting with Nanosecond Laser. Materials 2022, 15, 6686. [Google Scholar] [CrossRef]

- Jiao, J.; Zou, Q.; Ye, Y. Carbon fiber reinforced thermoplastic composites and TC4 alloy laser assisted joining with the metal surface laser plastic-covered method. Compos. Part B 2021, 213, 108738. [Google Scholar] [CrossRef]

- Zou, Q.; Jiao, J.; Xu, J. Effects of laser hybrid interfacial pretreatment on enhancing the carbon fiber reinforced thermosetting composites and TC4 alloy heterogeneous joint. Mater. Today Commun. 2022, 20, 103142. [Google Scholar] [CrossRef]

- Jiao, J.; Wang, Q.; Wang, F. Numerical and experimental investigation on joining CFRTP and stainless steel using fiber lasers. J. Mater. Process. Technol. 2016, 240, 362–369. [Google Scholar] [CrossRef]

| Material | Thermal Conductivity (W·m−1·°C−1) | Specific Heat (J·kg−1·°C−1) | Density (g·cm−3) |

|---|---|---|---|

| Epoxy resin | 0.2 | 550 | 1200 |

| T300 | 10.5 | 795.5 | 1760 |

| PA6 | 0.25 | 2500 | 1150 |

| Temperature (°C) | Thermal Conductivity (W·m−1·°C−1) | Specific Heat (J·kg−1·°C−1) | Density (g·cm−3) |

|---|---|---|---|

| 25 | 7.0 | 546 | 4420 |

| 200 | 8.75 | 584 | 4395 |

| 600 | 14.2 | 673 | 4336 |

| 1000 | 18.3 | 641 | 4282 |

| 1400 | 24.6 | 714 | 4225 |

| 1650 | 28.4 | 759 | 4189 |

| P (W) | V (mm·s−1) | D (mm) | a (mm) | r (mm) | Pn (MPa) |

|---|---|---|---|---|---|

| 95 | 50 | 0.5 | 2.5 | 0.15 | 0.8 |

| d (mm) | l1 (mm) | l2 (mm) | h (mm) | w (mm) |

|---|---|---|---|---|

| 0.1 | 0.072 | 0.116 | 0.095 | 0.047 |

| 0.3 | 0.211 | 0.298 | 0.096 | 0.049 |

| 0.5 | 0.423 | 0.497 | 0.093 | 0.045 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiao, J.; Xu, J.; Jing, C.; Cheng, X.; Wu, D.; Ru, H.; Zeng, K.; Sheng, L. Effect of Laser Micro-Texturing on Laser Joining of Carbon Fiber Reinforced Thermosetting Composites to TC4 Alloy. Materials 2023, 16, 270. https://doi.org/10.3390/ma16010270

Jiao J, Xu J, Jing C, Cheng X, Wu D, Ru H, Zeng K, Sheng L. Effect of Laser Micro-Texturing on Laser Joining of Carbon Fiber Reinforced Thermosetting Composites to TC4 Alloy. Materials. 2023; 16(1):270. https://doi.org/10.3390/ma16010270

Chicago/Turabian StyleJiao, Junke, Jihao Xu, Chenghu Jing, Xiangyu Cheng, Di Wu, Haolei Ru, Kun Zeng, and Liyuan Sheng. 2023. "Effect of Laser Micro-Texturing on Laser Joining of Carbon Fiber Reinforced Thermosetting Composites to TC4 Alloy" Materials 16, no. 1: 270. https://doi.org/10.3390/ma16010270

APA StyleJiao, J., Xu, J., Jing, C., Cheng, X., Wu, D., Ru, H., Zeng, K., & Sheng, L. (2023). Effect of Laser Micro-Texturing on Laser Joining of Carbon Fiber Reinforced Thermosetting Composites to TC4 Alloy. Materials, 16(1), 270. https://doi.org/10.3390/ma16010270