Material Defects in Friction Stir Welding through Thermo–Mechanical Simulation: Dissimilar Materials with Tool Wear Consideration

Abstract

1. Introduction

- (a)

- Numerical models are available to predict FSW outcomes with similar materials; however, studies on the defect prediction and material mixing in dissimilar FSW are lacking;

- (b)

- The tool wear in the numerical simulation of defect formation has not been considered in research. The material flow and change in weld quality with modified pin profiles due to tool wear have been largely unexplored. The reported numerical models of the FSW consider the dimensions of an unaltered tool. In contrast, the tool wears while welding, which produces defective joints due to improper material mixing and inclusions from tool wear [20].

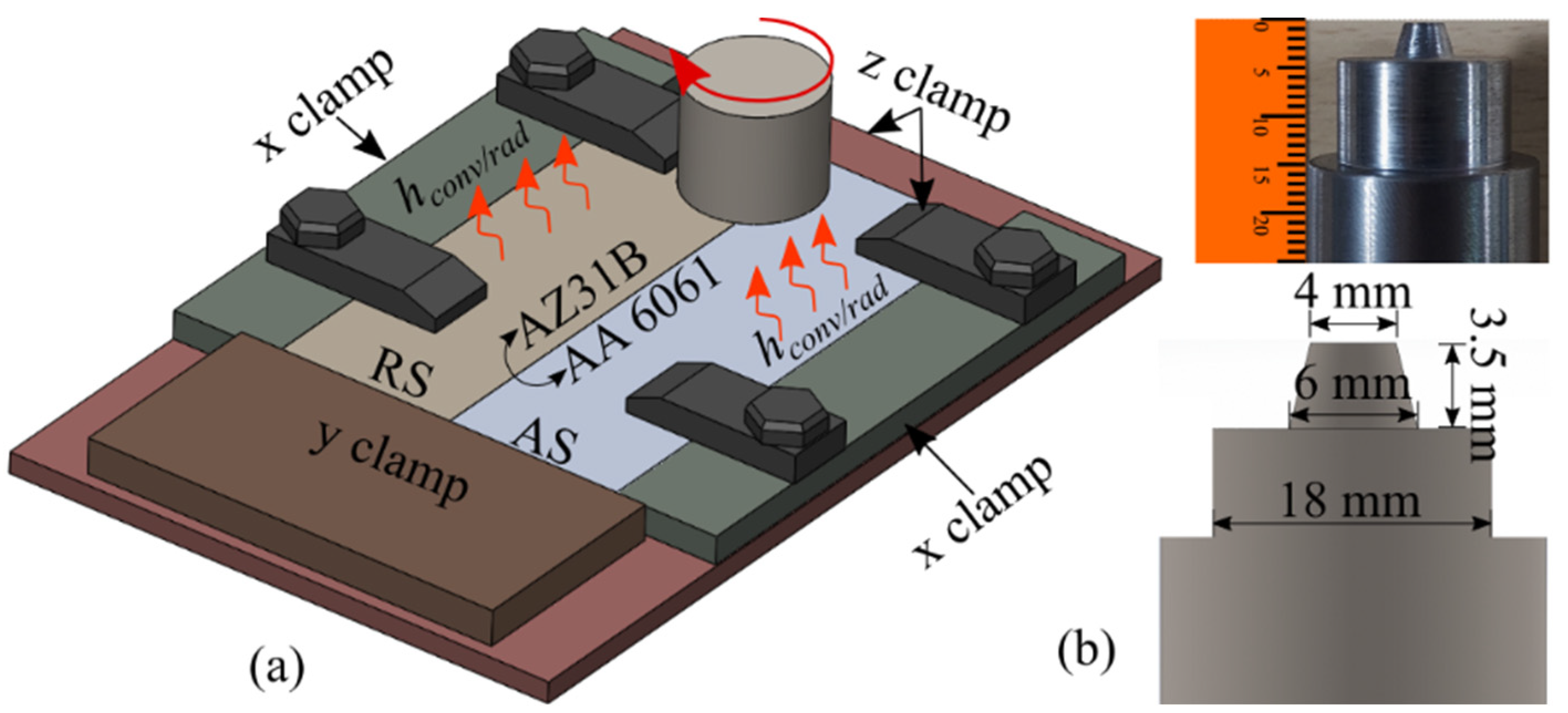

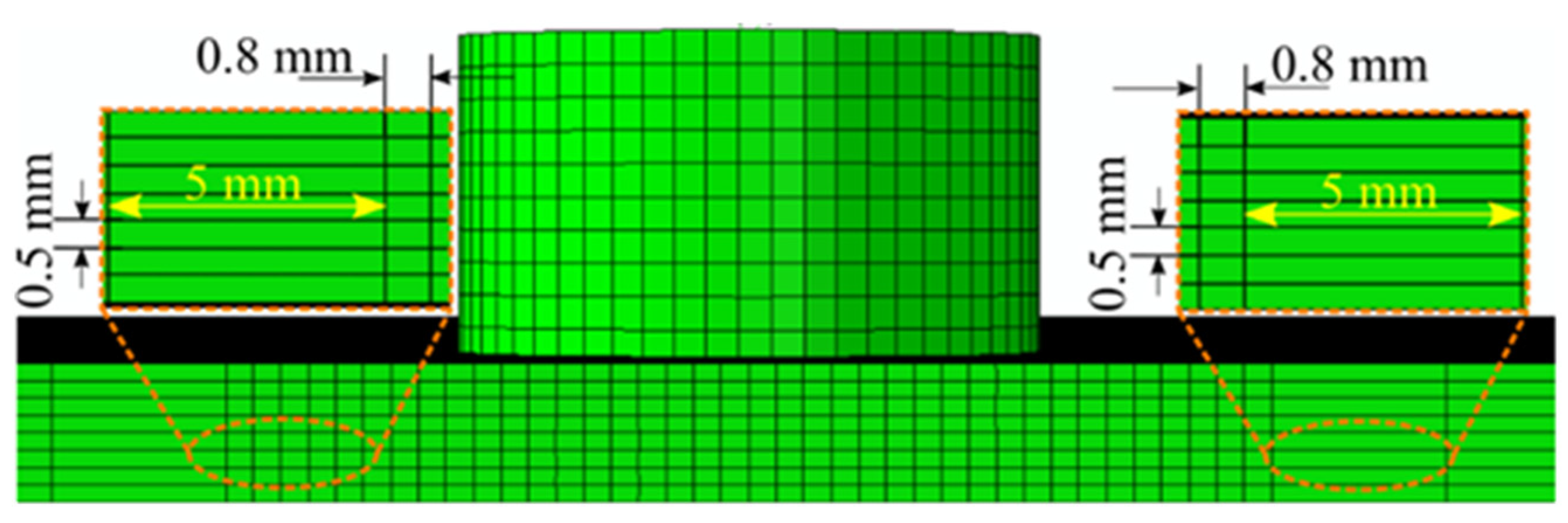

2. Materials and Methods

3. The Theoretical Model

| Materials | A (MPa) | M (MPa) | C | m | n | Troom (°C) | Tmelt (°C) |

|---|---|---|---|---|---|---|---|

| AA6061 | 324 | 114 | 0.002 | 1.34 | 0.42 | 24 | 583 |

| AZ31B | 279 | 159 | 0.013 | 1.573 | 0.327 | 22 | 605 |

| Materials | d1 | d2 | d3 | d4 | d5 |

|---|---|---|---|---|---|

| AA6061 | 0.071 | 1.248 | 1.142 | 0.147 | 0 |

| AZ31B | −0.35 | 0.6025 | −0.4537 | 0.206 | 7.2 |

| (°C) | 25 | 100 | 149 | 201 | 260 | 316 | 371 | 427 | 482 |

|---|---|---|---|---|---|---|---|---|---|

| E (GPa) | 66.94 | 63.21 | 61.32 | 56.80 | 51.15 | 47.17 | 43.51 | 28.77 | 20.20 |

| 0.33 | 0.334 | 0.335 | 0.336 | 0.338 | 0.36 | 0.40 | 0.41 | 0.42 | |

| 945 | 978 | 1000 | 1030 | 1052 | 1080 | 1100 | 1130 | 1276 | |

| 2690 | 2690 | 2670 | 2660 | 2660 | 2630 | 263 | 2600 | - | |

| 23.5 | 246 | 25.7 | 26.6 | 27.6 | 28.5 | 29.6 | 30.7 | - |

| (°C) | 20 | 75 | 100 | 125 | 150 | 200 | 250 |

|---|---|---|---|---|---|---|---|

| E (GPa) | 40.2 | 37.3 | 34.3 | 30.9 | 30.4 | 29.4 | 27.5 |

| T | 25 | 100 | 200 | 300 | 350 | - | - |

| 96.4 | 101 | 105 | 109 | 113 | - | - | |

| T | 20 | 100 | 200 | 300 | 350 | - | - |

| 1050 | 1130 | 1170 | 1210 | 1260 | - | - | |

| T | 100 | 200 | 300 | - | - | - | - |

| 2.64 | 2.70 | 2.79 | - | - | - | - |

4. Results and Discussion

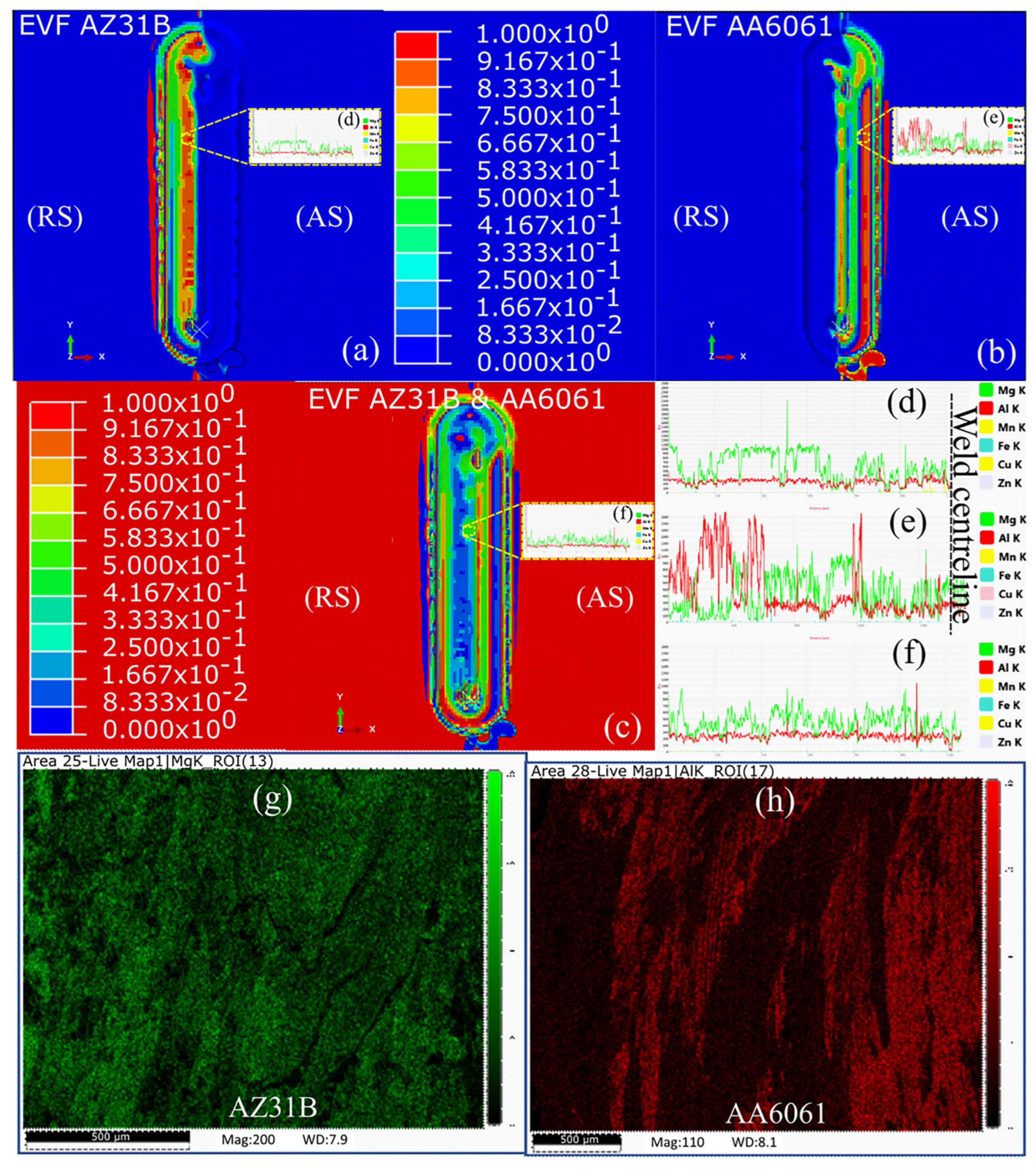

4.1. Material Mixing

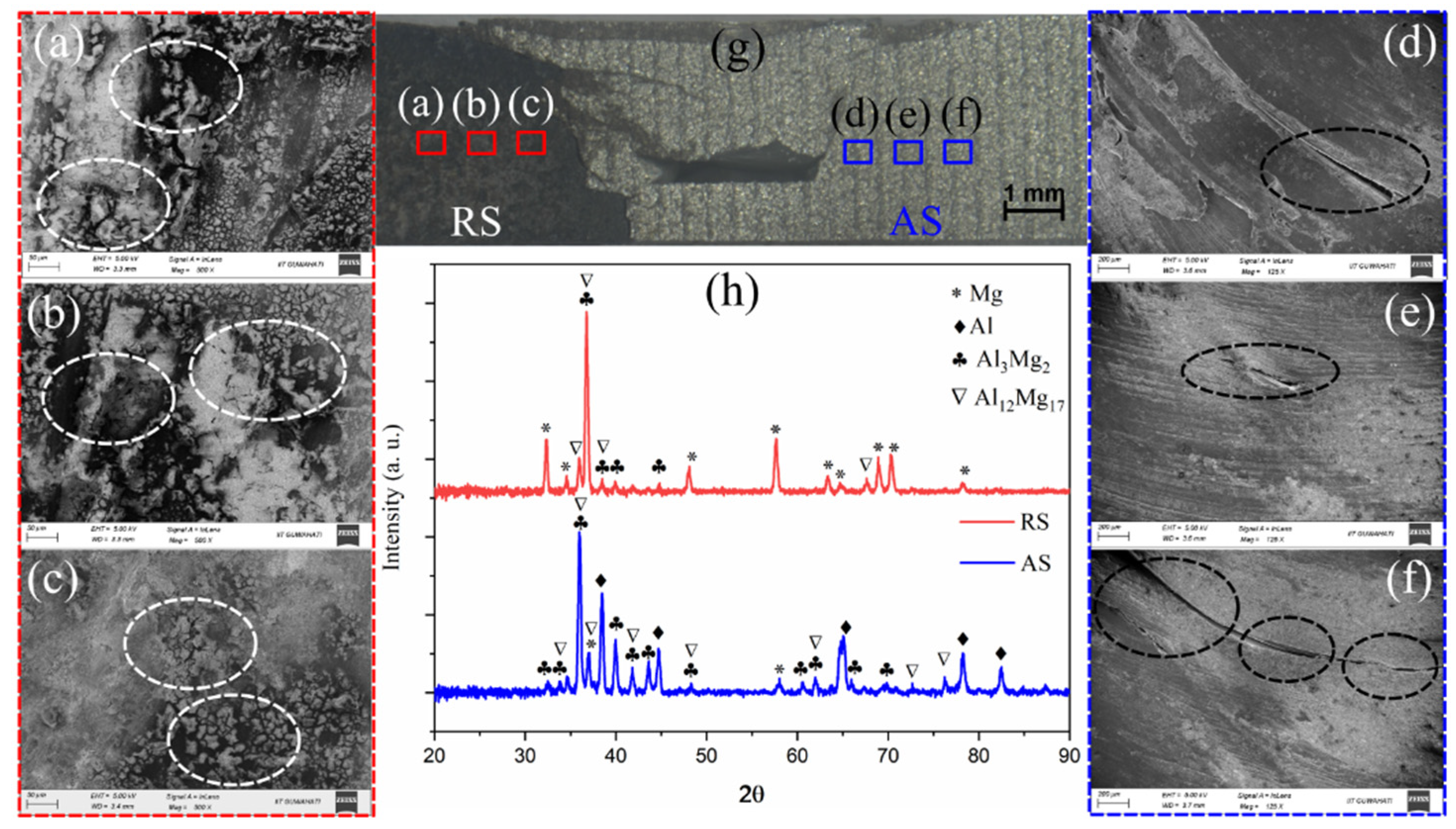

4.2. Defect Prediction

4.3. The Effect of Plate Position on the Material Flow

4.4. The Modification of Tool Profile Due to Wear

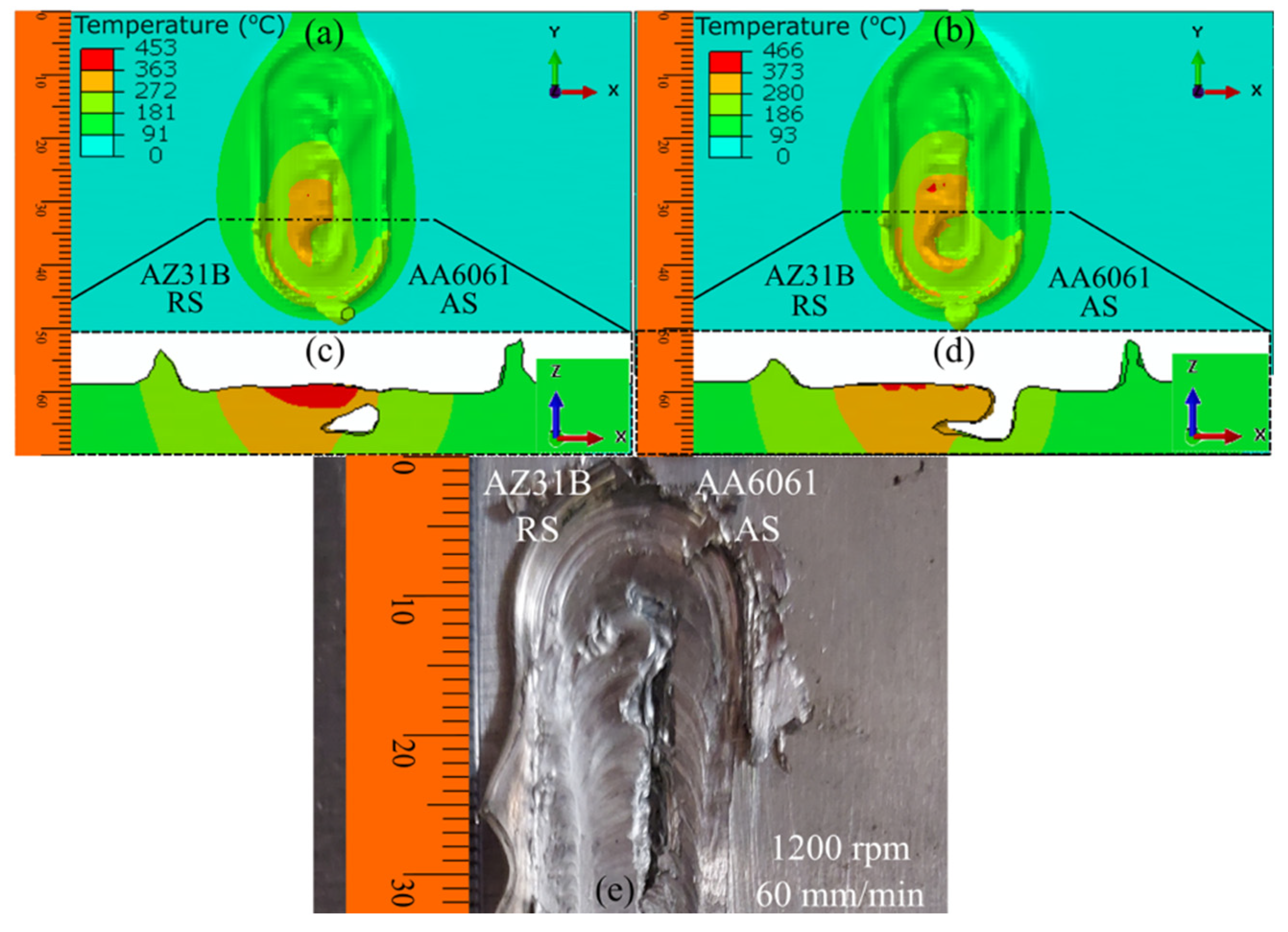

The Tool-Wear-Induced Defects

5. Conclusions and Outlook

- The developed numerical model could predict the presence and variation of specific materials within the SZ. The same was validated by the FESEM–EDS results. The numerical model could successfully predict the material mixing and interface line on the surface and the welding cross-section;

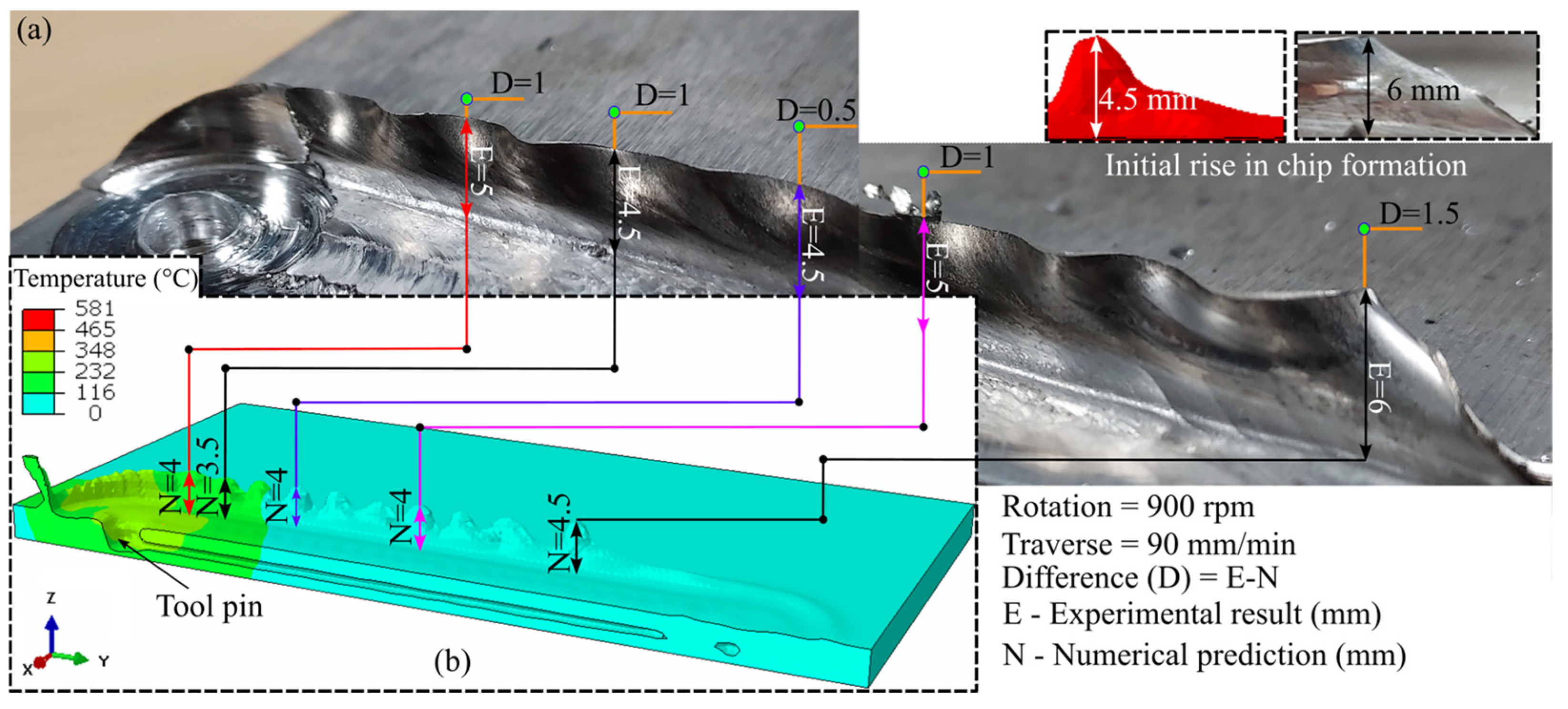

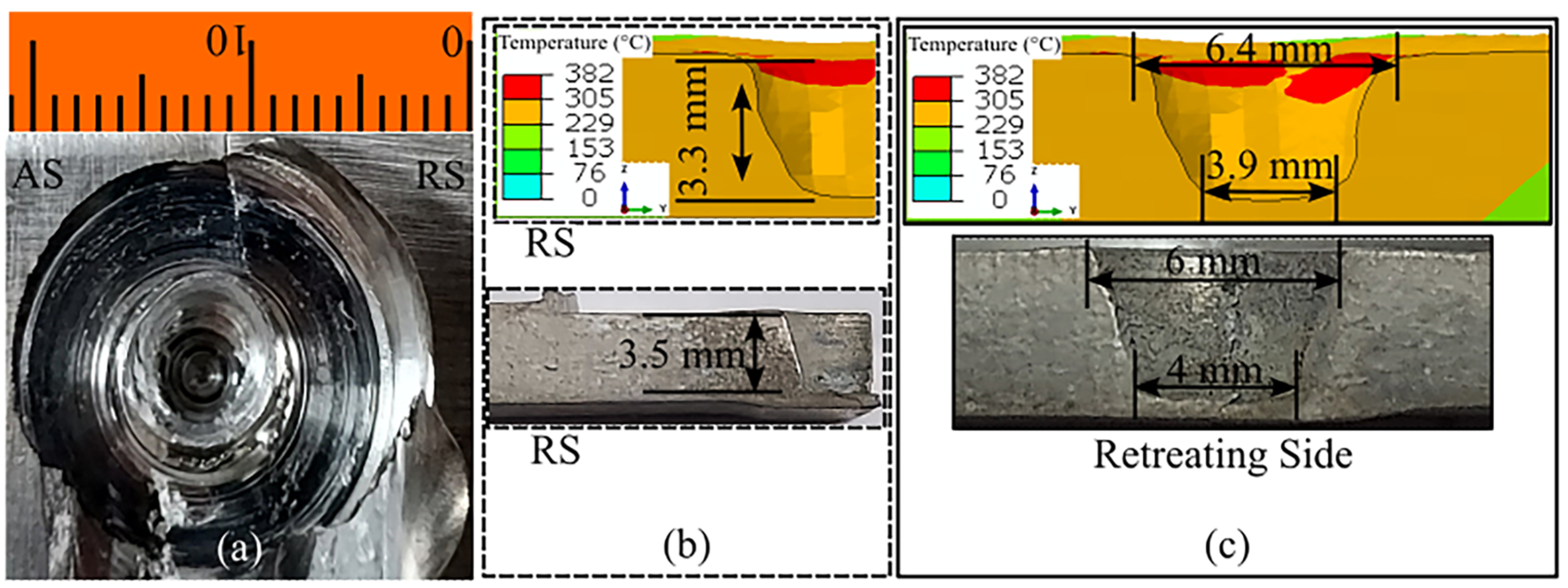

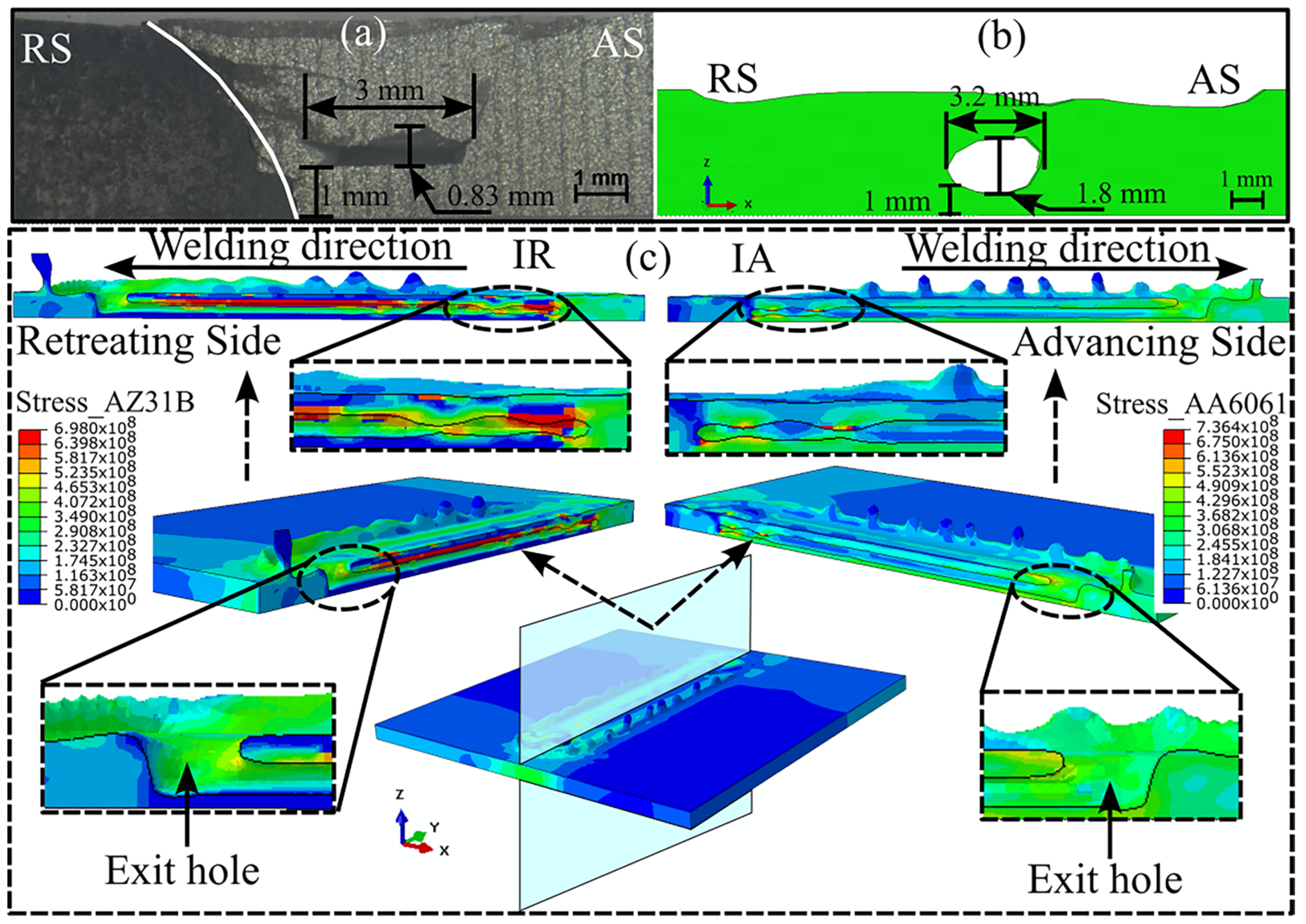

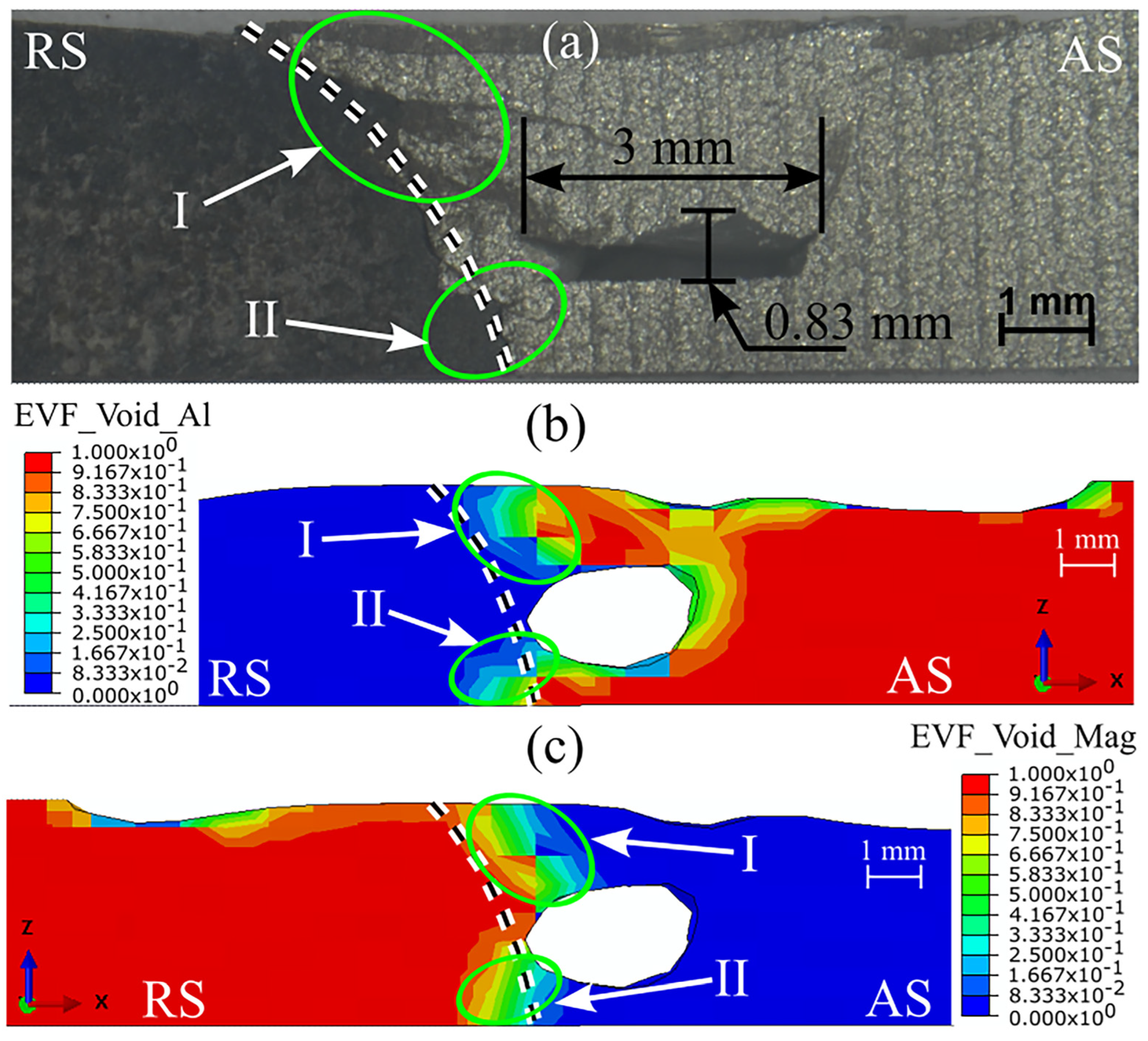

- The model could simultaneously and accurately predict various surface and subsurface defects such as flash formation, exit hole, surface tunnel, and subsurface tunnel defects. The maximum deviations in flash height, exit hole diameter, surface tunnel width, and subsurface tunnel height prediction were 1, 0.4, 1.2, and 1 mm, respectively;

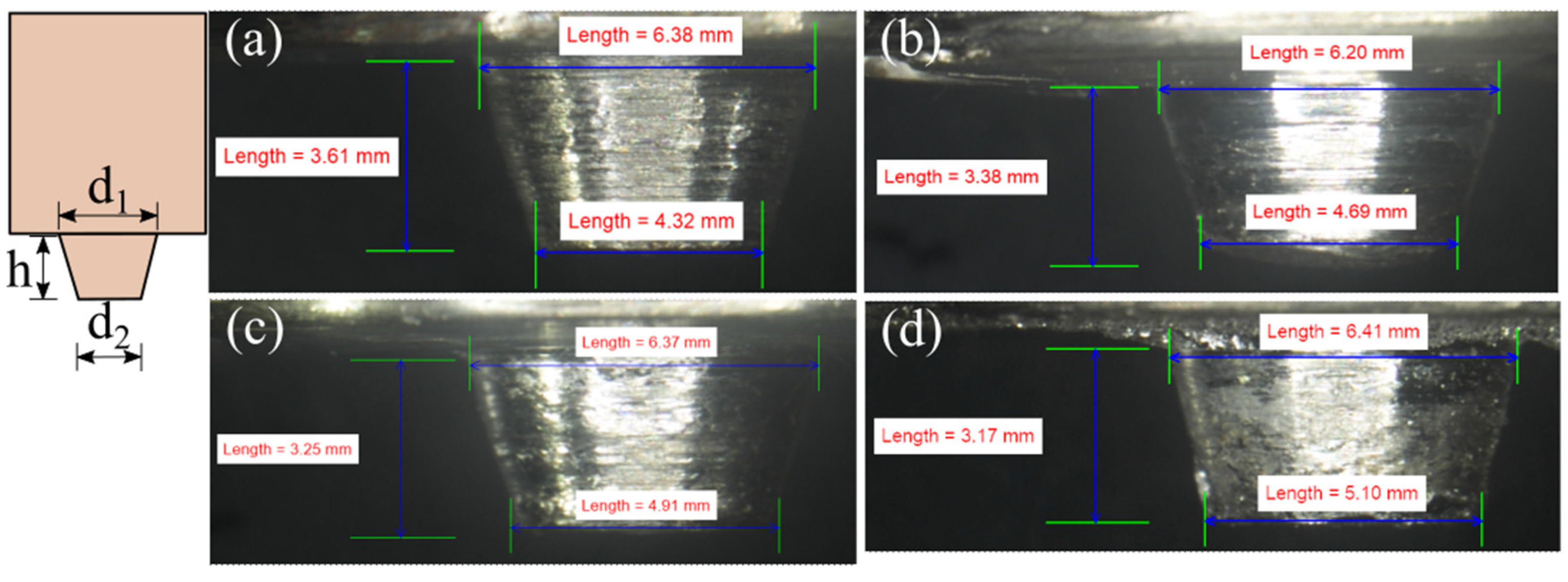

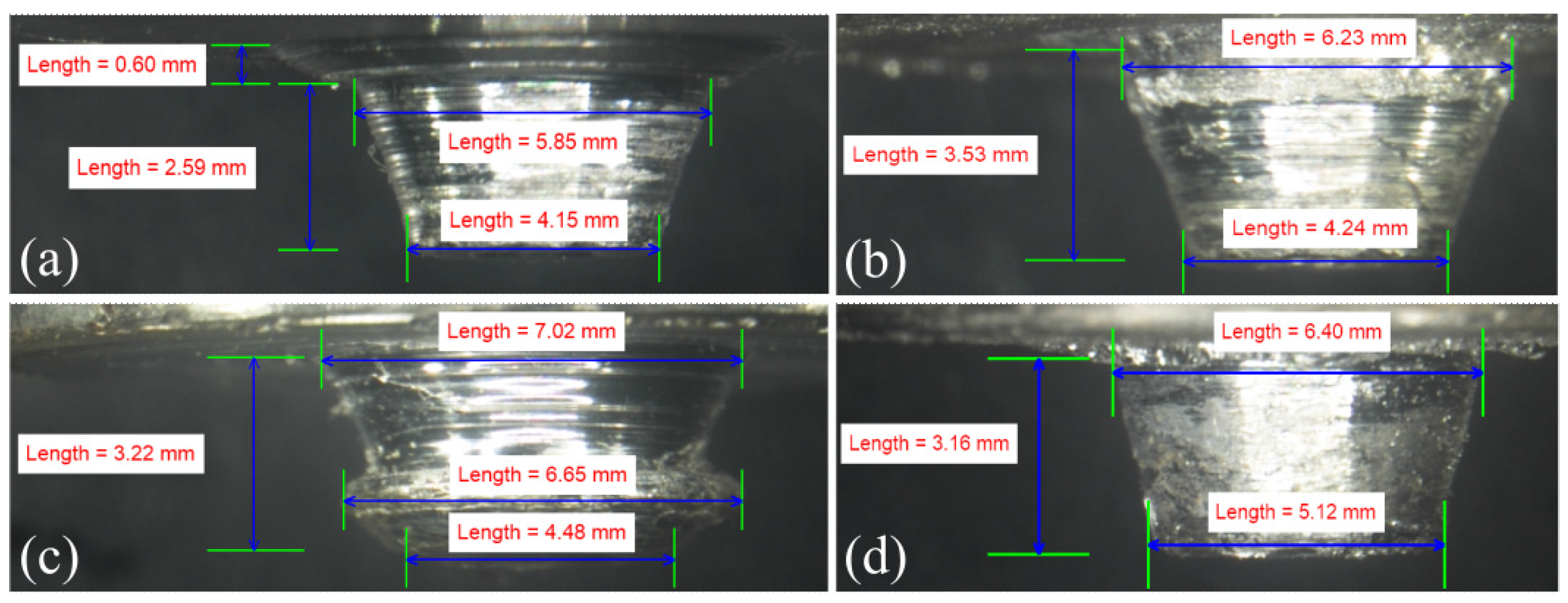

- The tool pin loses its dimensional integrity with multiple runs of welding. We observed major deviations in the tool height and minor diameter compared with the initial condition, whereas the change in the major diameter was negligible. The pin height changed by approximately 12.19% and 10.23% when welding at 900 and 1200 rpm, respectively. The minor diameter changed by 18.06% for 900 rpm and 28.32% for 1200 rpm;

- The tool shape also varies due to the material adhering to the tool from the SZ. The results of the FESEM–EDS analysis indicated the presence of more AA6061 (58.86%) from the AS compared with the AZ31B (40.97%) from the RS in the adhered material;

- We observed a surface tunnel with a height of more than 50% of the plate thickness when we used AZ31B on the AS and AAA6061 on the RS. The surface tunnel defect was absent when the we interchanged the position of the plate;

- The model could predict the difference in weld quality and defect formation when the condition of the tool was modified.

- In the course of this investigation, we focused on the development of a new model integrating the tool wear and dissimilar materials in the numerical modelling of FSW. More data on the different combinations of materials can illustrate the efficacy of the method, which deserves further investigation. In addition to the defects studied here, the surface topography and its comparison with the actual experiment is worth studying.

Author Contributions

Funding

Informed Consent Statement

Conflicts of Interest

References

- Das, D.; Bag, S.; Pal, S.; Ruhul Amin, M. A Finite Element Model for the Prediction of Chip Formation and Surface Morphology in Friction Stir Welding Process. J. Manuf. Sci. Eng. 2021, 144, 041015. [Google Scholar] [CrossRef]

- Hernández, C.A.; Ferrer, V.H.; Mancilla, J.E.; Martínez, L.C. Three-dimensional numerical modeling of the friction stir welding of dissimilar steels. Int. J. Adv. Manuf. Technol. 2017, 93, 1567–1581. [Google Scholar] [CrossRef]

- Singh, A.K.; Sahlot, P.; Paliwal, M.; Arora, A. Heat Transfer Modeling of Dissimilar FSW of Al 6061/AZ31 Using Experimentally Measured Thermo-Physical Properties. Int. J. Adv. Manuf. Technol. 2019, 105, 771–783. [Google Scholar] [CrossRef]

- Pandian, V.; Kannan, S. Numerical Prediction and Experimental Investigation of Aerospace-Grade Dissimilar Aluminium Alloy by Friction Stir Welding. J. Manuf. Process. 2020, 54, 99–108. [Google Scholar] [CrossRef]

- Ghiasvand, A.; Suksatan, W.; Tomków, J.; Rogalski, G.; Derazkola, H.A. Investigation of the Effects of Tool Positioning Factors on Peak Temperature in Dissimilar Friction Stir Welding of AA6061-T6 and AA7075-T6 Aluminum Alloys. Materials 2022, 15, 702. [Google Scholar] [CrossRef] [PubMed]

- Bokov, D.O.; Jawad, M.A.; Suksatan, W.; Abdullah, M.E.; Świerczyńska, A.; Fydrych, D.; Derazkola, H.A. Effect of Pin Shape on Thermal History of Aluminum-Steel Friction Stir Welded Joint: Computational Fluid Dynamic Modeling and Validation. Materials 2021, 14, 7883. [Google Scholar] [CrossRef] [PubMed]

- Al-Badour, F.; Merah, N.; Shuaib, A.; Bazoune, A. Thermo-mechanical finite element model of friction stir welding of dissimilar alloys. Int. J. Adv. Manuf. Technol. 2014, 72, 607–617. [Google Scholar] [CrossRef]

- Akbari, M.; Asadi, P.; Behnagh, R.A. Modeling of Material Flow in Dissimilar Friction Stir Lap Welding of Aluminum and Brass Using Coupled Eulerian and Lagrangian Method. Int. J. Adv. Manuf. Technol. 2021, 113, 721–734. [Google Scholar] [CrossRef]

- Kadian, A.K.; Biswas, P. The study of material flow behaviour in dissimilar material FSW of AA6061 and Cu-B370 alloys plates. J. Manuf. Process. 2018, 34, 96–105. [Google Scholar] [CrossRef]

- Yang, C.; Wu, C.; Shi, L. Modeling the dissimilar material flow and mixing in friction stir welding of aluminum to magnesium alloys. J. Alloys Compd. 2020, 843, 156021. [Google Scholar] [CrossRef]

- Derazkola, H.A.; Eyvazian, A.; Simchi, A. Submerged friction stir welding of dissimilar joints between an Al-Mg alloy and low carbon steel: Thermo-mechanical modeling, microstructural features, and mechanical properties. J. Manuf. Process. 2020, 50, 68–79. [Google Scholar] [CrossRef]

- Shokri, V.; Sadeghi, A.; Sadeghi, M.H. Thermomechanical modeling of friction stir welding in a Cu-DSS dissimilar joint. J. Manuf. Process. 2018, 31, 46–55. [Google Scholar] [CrossRef]

- Aghajani Derazkola, H.; Khodabakhshi, F. Intermetallic compounds (IMCs) formation during Dissimilar Friction-Stir Welding of AA5005 Aluminum Alloy to St-52 Steel: Numerical Modeling and Experimental Study. Int. J. Adv. Manuf. Technol. 2019, 100, 2401–2422. [Google Scholar] [CrossRef]

- Patel, N.P.; Parlikar, P.; Dhari, R.S.; Mehta, K.; Pandya, M. Numerical modeling on cooling assisted friction stir welding of dissimilar Al-Cu joint. J. Manuf. Process. 2019, 47, 98–109. [Google Scholar] [CrossRef]

- Das, D.; Bag, S.; Pal, S. A Finite Element Model for Surface and Volumetric Defects in the FSW Process Using a Coupled Eulerian–Lagrangian Approach. Sci. Technol. Weld. Join. 2021, 26, 412–419. [Google Scholar] [CrossRef]

- Ajri, A.; Rohatgi, N.; Shin, Y.C. Analysis of defect formation mechanisms and their effects on weld strength during friction stir welding of Al 6061-T6 via experiments and finite element modeling. J. Adv. Manuf. Technol. 2020, 107, 4621–4635. [Google Scholar] [CrossRef]

- Das, D.; Bag, S.; Pal, S. Investigating Surface Defect by Tool-Material Interaction in Friction Stir Welding Using Coupled Eulerian-Lagrangian Approach. Manuf. Lett. 2021, 30, 23–26. [Google Scholar] [CrossRef]

- Ajri, A.; Shin, Y.C. Investigation on the effects of process parameters on defect formation in friction stir welded samples via predictive numerical modeling and experiments. J. Manuf. Sci. Eng. 2017, 139, 111009. [Google Scholar] [CrossRef]

- Mastanaiah, P.; Sharma, A.; Reddy, G.M. Dissimilar Friction Stir Welds in AA2219-AA5083 Aluminium Alloys: Effect of Process Parameters on Material Inter-Mixing, Defect Formation, and Mechanical Properties. Trans. Indian Inst. Met. 2016, 69, 1397–1415. [Google Scholar] [CrossRef]

- Farias, A.D.; Batalha, G.F.; Prados, E.F.; Magnabosco, R.; Delijaicov, S. Tool wear evaluations in friction stir processing of commercial titanium Ti–6Al–4V. Wear 2013, 302, 1327–1333. [Google Scholar] [CrossRef]

- Chauhan, P.; Jain, R.; Pal, S.K.; Singh, S.B. Modeling of defects in friction stir welding using coupled Eulerian and Lagrangian method. J. Manuf. Process. 2018, 34, 158–166. [Google Scholar] [CrossRef]

- Yaduwanshi, D.K.; Bag, S.; Pal, S. Numerical Modeling and Experimental Investigation on Plasma-Assisted Hybrid Friction Stir Welding of Dissimilar Materials. Mater. Des. 2016, 92, 166–183. [Google Scholar] [CrossRef]

- Zhu, Z.; Wang, M.; Zhang, H.; Zhang, X.; Yu, T.; Wu, Z. A Finite Element Model to Simulate Defect Formation during Friction Stir Welding. Metals 2017, 7, 256. [Google Scholar] [CrossRef]

- Salloomi, K.N. Defect Monitoring in Dissimilar Friction Stir Welding of Aluminum Alloys Using Coupled Eulerian- Lagrangian (CEL) Finite Element Model Finite Element Model. Adv. Mater. Process. Technol. 2022, 1–17. [Google Scholar] [CrossRef]

- Patil, S.; Tay, Y.Y.; Baratzadeh, F.; Lankarani, H. Modeling of friction-stir butt-welds and its application in automotive bumper impact performance Part 2. Impact modeling and bumper crash performance. J. Mech. Sci. Technol. 2017, 31, 3225–3232. [Google Scholar] [CrossRef]

- Al-Badour, F.; Merah, N.; Shuaib, A.; Bazoune, A. Coupled Eulerian Lagrangian Finite Element Modeling of Friction Stir Welding Processes. J. Mater. Process. Technol. 2013, 213, 1433–1439. [Google Scholar] [CrossRef]

- Hou, Z.; Sheikh-Ahmad, J.; Jarrar, F.; Ozturk, F. Residual Stresses in Dissimilar Friction Stir Welding of AA2024 and AZ31: Experimental and Numerical Study. J. Manuf. Sci. Eng. Trans. 2018, 140, 1–10. [Google Scholar] [CrossRef]

- Varma, A.; Absar, S.; Ruszkiewicz, B.J.; Skovron, J.D.; Mears, L.; Choi, H.; Zhao, X. Numerical Study of Temperature Evolution During Friction Element Welding. J. Manuf. Sci. Eng. 2022, 144, 121012. [Google Scholar] [CrossRef]

- Abbassi, F.; Srinivasan, M.; Loganathan, C.; Narayanasamy, R.; Gupta, M. Experimental and numerical analyses of magnesium alloy hot workability. J. Magnes. Alloys 2016, 4, 295–301. [Google Scholar] [CrossRef]

- Sengupta, K.; Singh, D.K.; Mondal, A.K.; Bose, D.; Patra, D.; Dhar, A. Characterization of Tool Wear in Similar and Dissimilar Joints of MS and SS Using EAFSW. Mater. Today Proc. 2020, 44, 3967–3975. [Google Scholar] [CrossRef]

- Rai, R.; De, A.; Bhadeshia, H.K.D.H.; DebRoy, T. Friction stir welding tools. Sci. Technol. Weld. 2011, 16, 325–342. [Google Scholar] [CrossRef]

- Prabhu, L.; Kumar, S.S. Tribological characteristics of FSW tool subjected to joining of dissimilar AA6061-T6 and Cu alloys. Mater. Today Proc. 2020, 33, 741–745. [Google Scholar] [CrossRef]

- Majeed, T.; Mehta, Y.; Siddiquee, A.N. Analysis of Tool Wear and Deformation in Friction Stir Welding of Unequal Thickness Dissimilar Al Alloys. Proc. Inst. Mech. Eng. Part L J. Mater. Des. 2021, 235, 501–512. [Google Scholar] [CrossRef]

- Shi, H.; Chen, K.; Liang, Z.; Dong, F.; Yu, T.; Dong, X.; Zhang, L.; Shan, A. Intermetallic Compounds in the Banded Structure and Their Effect on Mechanical Properties of Al/Mg Dissimilar Friction Stir Welding Joints. J. Mater. Sci. Technol. 2017, 33, 359–366. [Google Scholar] [CrossRef]

- Mohammadi, J.; Behnamian, Y.; Mostafaei, A.; Izadi, H.; Saeid, T.; Kokabi, A.H.; Gerlich, A.P. Friction Stir Welding Joint of Dissimilar Materials between AZ31B Magnesium and 6061 Aluminum Alloys: Microstructure Studies and Mechanical Characterizations. Mater. Charact. 2015, 101, 189–207. [Google Scholar] [CrossRef]

- Mehta, K.; Astarita, A.; Carlone, P.; Della Gatta, R.; Vyas, H.; Vilaça, P.; Tucci, F. Investigation of Exit-Hole Repairing on Dissimilar Aluminum-Copper Friction Stir Welded Joints. J. Mater. Res. Technol. 2021, 13, 2180–2193. [Google Scholar] [CrossRef]

- Zhao, Y.; Jiang, S.; Yang, S.; Lu, Z.; Yan, K. Influence of Cooling Conditions on Joint Properties and Microstructures of Aluminum and Magnesium Dissimilar Alloys by Friction Stir Welding. Int. J. Adv. Manuf. Technol. 2016, 83, 673–679. [Google Scholar] [CrossRef]

- Chang, W.S.; Rajesh, S.R.; Chun, C.K.; Kim, H.J. Microstructure and Mechanical Properties of Hybrid Laser-Friction Stir Welding between AA6061-T6 Al Alloy and AZ31 Mg Alloy. J. Mater. Sci. Technol. 2011, 27, 199–204. [Google Scholar] [CrossRef]

- Somasekharan, A.C.; Murr, L.E. Microstructures in Friction-Stir Welded Dissimilar Magnesium Alloys and Magnesium Alloys to 6061-T6 Aluminum Alloy. Mater. Charact. 2004, 52, 49–64. [Google Scholar] [CrossRef]

| Material | Si | Cu | Fe | Zn | Mn | Al | Mg |

|---|---|---|---|---|---|---|---|

| AA6061 | 0.89 | 0.37 | 0.13 | - | - | 95.59 | 2.21 |

| AZ31B | - | - | - | 0.71 | 0.15 | 3.07 | 94.76 |

| Element | Si | Mo | V | Cr | Mn | Co | W | Fe |

|---|---|---|---|---|---|---|---|---|

| (wt%) | 1.89 | 1.81 | 0.60 | 4.72 | 0.62 | 1.03 | 1.98 | 87.35 |

| Weld No. | Plate Positioning (AS-RS) | RPM | Traverse Speed (mm/min) |

|---|---|---|---|

| Weld-I1 | Al-Mg | 900 | 30 |

| Weld-I2 | Al-Mg | 900 | 60 |

| Weld-I3 | Al-Mg | 900 | 90 |

| Weld-II1 | Al-Mg | 1200 | 30 |

| Weld-II2 | Al-Mg | 1200 | 60 |

| Weld-II3 | Al-Mg | 1200 | 90 |

| Weld No. | Pin Length (h) (mm) | Pin Length Change (%) | Pin Major Diameter (d1) (mm) | Pin Major Diameter (d1) Change (%) | Pin Minor Diameter (d2) (mm) | Pin Minor Diameter (d2) Change (%) |

|---|---|---|---|---|---|---|

| Tool-I | 3.61 | - | 6.38 | - | 4.32 | - |

| Weld-I1 | 3.38 | −6.37 | 6.20 | −2.82 | 4.69 | 8.56 |

| Weld-I2 | 3.25 | −9.97 | 6.37 | −0.16 | 4.91 | 13.66 |

| Weld-I3 | 3.17 | −12.19 | 6.41 | 0.47 | 5.10 | 18.06 |

| Tool-II | 3.52 | - | 6.24 | - | 3.99 | - |

| Weld-II1 | 3.52 | 0.00 | 6.27 | 0.48 | 4.15 | 4.01 |

| Weld-II2 | 3.48 | −1.14 | 6.65 | 6.57 | 5.00 | 25.31 |

| Weld-II3 | 3.16 | −10.23 | 6.40 | 2.56 | 5.12 | 28.32 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Das, D.; Bag, S.; Pal, S.; Sharma, A. Material Defects in Friction Stir Welding through Thermo–Mechanical Simulation: Dissimilar Materials with Tool Wear Consideration. Materials 2023, 16, 301. https://doi.org/10.3390/ma16010301

Das D, Bag S, Pal S, Sharma A. Material Defects in Friction Stir Welding through Thermo–Mechanical Simulation: Dissimilar Materials with Tool Wear Consideration. Materials. 2023; 16(1):301. https://doi.org/10.3390/ma16010301

Chicago/Turabian StyleDas, Debtanay, Swarup Bag, Sukhomay Pal, and Abhay Sharma. 2023. "Material Defects in Friction Stir Welding through Thermo–Mechanical Simulation: Dissimilar Materials with Tool Wear Consideration" Materials 16, no. 1: 301. https://doi.org/10.3390/ma16010301

APA StyleDas, D., Bag, S., Pal, S., & Sharma, A. (2023). Material Defects in Friction Stir Welding through Thermo–Mechanical Simulation: Dissimilar Materials with Tool Wear Consideration. Materials, 16(1), 301. https://doi.org/10.3390/ma16010301