A Neural Network Framework for Validating Information–Theoretics Parameters in the Applications of Acoustic Emission Technique for Mechanical Characterization of Materials

Abstract

:1. Introduction

2. Materials and Testing Methods

2.1. Materials

2.2. Test Methods and Data Acquisition

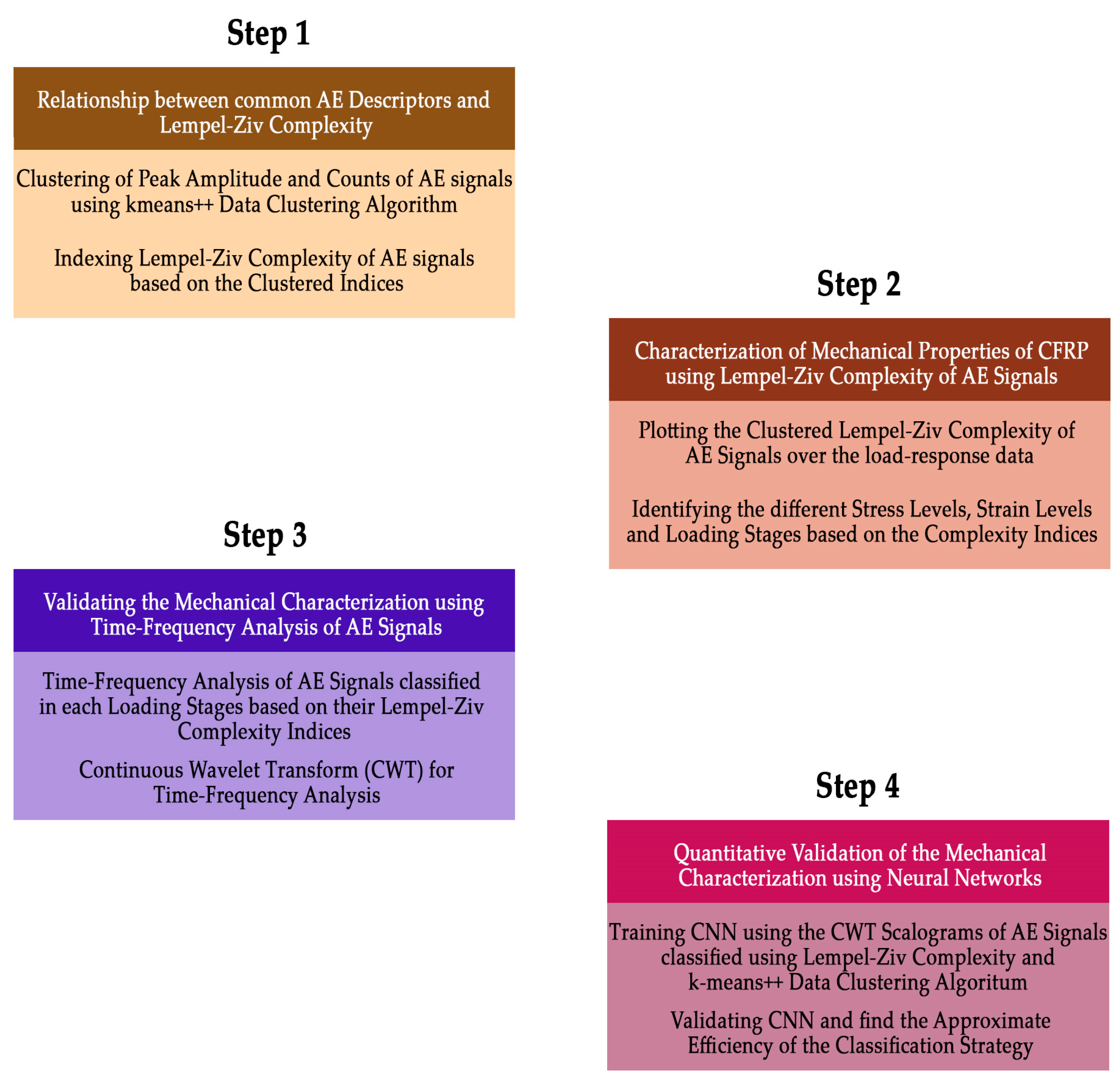

3. Proposed Methodology

3.1. LZ Complexity

3.2. k-means++ Data Clustering Algorithm

3.3. Continuous Wavelet Transform

3.4. Convolutional Neural Network

4. Results and Discussions

4.1. AE Data Clustered Based on Peak Amplitude and Counts

4.2. Relationship between the Acoustic Emission Descriptors, LZ Complexity, and Tensile Test Results

4.3. Validation of the Clustered Results Using Continuous Wavelet Transform

4.4. Quantitative Validation of the Clustered Results Using Convolutional Neural Network Framework

5. Conclusions

- The characteristics of the AE signals were analysed in terms of their amplitude, counts, and LZ complexity indices. The AE signals with amplitudes above 50 dB, counts greater than 150, and LZ complexity indices below 0.6 initiate at a region of critical failure (ROI). The transversal strains at ROI of the test specimens exhibit a very similar value of −459.84 µε with a very small standard deviation of 7.35. The longitudinal strains and the tensile stresses at ROI vary between specimens, which can be used to identify the specimen with poor strength or the specimen, which is susceptible to earlier damage. Thus, the critical ROI identified by the AE signals are capable of identifying the major failure occurrence of the test specimens.

- The AE signals from different clusters are validated for their similarity using CWT spectrograms.

- Finally, a quantitative similarity is calculated by using CNN. The results show that the classification procedure is more than 85% efficient for classifying the AE data for signals in Cluster 1, Cluster 2, and Cluster 3.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

Appendix B

References

- Hamstad, M.A. Thirty Years of Advances and Some Remaining Challenges in the Application of Acoustic Emission to Composite Materials. In Acoustic Emission beyond the Millennium; Elsevier: Amsterdam, The Netherlands, 2000; pp. 77–91. [Google Scholar]

- Barile, C.; Casavola, C.; Pappalettera, G.; Kannan, V.P. Application of Different Acoustic Emission Descriptors in Damage Assessment of Fiber Reinforced Plastics: A Comprehensive Review. Eng. Fract. Mech. 2020, 235, 107083. [Google Scholar] [CrossRef]

- Hamstad, M.A. A Review: Acoustic Emission, a Tool for Composite-Materials Studies. Exp. Mech. 1986, 26, 7–13. [Google Scholar] [CrossRef]

- Liu, P.F.; Chu, J.K.; Liu, Y.L.; Zheng, J.Y. A Study on the Failure Mechanisms of Carbon Fiber/Epoxy Composite Laminates Using Acoustic Emission. Mater. Des. 2012, 37, 228–235. [Google Scholar] [CrossRef]

- Zhuang, X.; Yan, X. Investigation of Damage Mechanisms in Self-Reinforced Polyethylene Composites by Acoustic Emission. Compos. Sci. Technol. 2006, 66, 444–449. [Google Scholar] [CrossRef]

- Chandarana, N.; Sanchez, D.M.; Soutis, C.; Gresil, M. Early Damage Detection in Composites during Fabrication and Mechanical Testing. Materials 2017, 10, 685. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Oskouei, A.R.; Zucchelli, A.; Ahmadi, M.; Minak, G. An Integrated Approach Based on Acoustic Emission and Mechanical Information to Evaluate the Delamination Fracture Toughness at Mode I in Composite Laminate. Mater. Des. 2011, 32, 1444–1455. [Google Scholar] [CrossRef]

- Baker, C.; Morscher, G.N.; Pujar, V.V.; Lemanski, J.R. Transverse Cracking in Carbon Fiber Reinforced Polymer Composites: Modal Acoustic Emission and Peak Frequency Analysis. Compos. Sci. Technol. 2015, 116, 26–32. [Google Scholar] [CrossRef]

- Fotouhi, M.; Pashmforoush, F.; Ahmadi, M.; Refahi Oskouei, A. Monitoring the Initiation and Growth of Delamination in Composite Materials Using Acoustic Emission under Quasi-Static Three-Point Bending Test. J. Reinf. Plast. Compos. 2011, 30, 1481–1493. [Google Scholar] [CrossRef]

- Aggelis, D.G.; Barkoula, N.-M.; Matikas, T.E.; Paipetis, A.S. Acoustic Structural Health Monitoring of Composite Materials: Damage Identification and Evaluation in Cross Ply Laminates Using Acoustic Emission and Ultrasonics. Compos. Sci. Technol. 2012, 72, 1127–1133. [Google Scholar] [CrossRef]

- Lempel, A.; Ziv, J. On the Complexity of Finite Sequences. IEEE Trans. Inf. Theory 1976, 22, 75–81. [Google Scholar] [CrossRef]

- Barile, C.; Casavola, C.; Pappalettera, G.; Paramsamy Kannan, V. Interpreting the Lempel–Ziv Complexity of Acoustic Emission Signals for Identifying Damage Modes in Composite Materials. Struct. Health Monit. 2022, 14759217221112832. [Google Scholar] [CrossRef]

- ASTM, A.M. ASTM D3039-Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Barile, C.; Paramsamy Kannan, V.; del Core, L.; Casavola, C. Tensile and Shear Behavior of Plain Weave Fabric Carbon Fiber Reinforced Polymer at Elevated Temperatures. Polym. Compos. 2022, 43, 6536–6547. [Google Scholar] [CrossRef]

- Bazli, M.; Abolfazli, M. Mechanical Properties of Fibre Reinforced Polymers under Elevated Temperatures: An Overview. Polymers 2020, 12, 2600. [Google Scholar] [CrossRef] [PubMed]

- Roundi, W.; el Mahi, A.; el Gharad, A.; Rebiere, J.-L. Acoustic Emission Monitoring of Damage Progression in Glass/Epoxy Composites during Static and Fatigue Tensile Tests. Appl. Acoust. 2018, 132, 124–134. [Google Scholar] [CrossRef]

- Godin, N.; Huguet, S.; Gaertner, R.; Salmon, L. Clustering of Acoustic Emission Signals Collected during Tensile Tests on Unidirectional Glass/Polyester Composite Using Supervised and Unsupervised Classifiers. Ndt E Int. 2004, 37, 253–264. [Google Scholar] [CrossRef]

- Fotouhi, M.; Sadeghi, S.; Jalalvand, M.; Ahmadi, M. Analysis of the Damage Mechanisms in Mixed-Mode Delamination of Laminated Composites Using Acoustic Emission Data Clustering. J. Thermoplast. Compos. Mater. 2017, 30, 318–340. [Google Scholar] [CrossRef] [Green Version]

- Tang, J.; Soua, S.; Mares, C.; Gan, T.-H. A Pattern Recognition Approach to Acoustic Emission Data Originating from Fatigue of Wind Turbine Blades. Sensors 2017, 17, 2507. [Google Scholar] [CrossRef] [Green Version]

- Li, L.; Swolfs, Y.; Straumit, I.; Yan, X.; Lomov, S.V. Cluster Analysis of Acoustic Emission Signals for 2D and 3D Woven Carbon Fiber/Epoxy Composites. J. Compos. Mater. 2016, 50, 1921–1935. [Google Scholar] [CrossRef] [Green Version]

- Aboy, M.; Hornero, R.; Abásolo, D.; Álvarez, D. Interpretation of the Lempel-Ziv Complexity Measure in the Context of Biomedical Signal Analysis. IEEE Trans. Biomed. Eng. 2006, 53, 2282–2288. [Google Scholar] [CrossRef] [Green Version]

- Barile, C.; Casavola, C.; Pappalettera, G.; Vimalathithan, P.K. Damage Characterization in Composite Materials Using Acoustic Emission Signal-Based and Parameter-Based Data. Compos. B Eng. 2019, 178, 107469. [Google Scholar] [CrossRef]

- Barile, C.; Casavola, C.; Pappalettera, G.; Vimalathithan, P.K. Damage Propagation Analysis in the Single Lap Shear and Single Lap Shear-Riveted CFRP Joints by Acoustic Emission and Pattern Recognition Approach. Materials 2020, 13, 3963. [Google Scholar] [CrossRef] [PubMed]

- Wickerhauser, M.V. Adapted Wavelet Analysis: From Theory to Software; AK Peters/CRC Press: Wellesley, MA, USA, 1996; ISBN 042906425X. [Google Scholar]

- Lilly, J.M. Element Analysis: A Wavelet-Based Method for Analysing Time-Localized Events in Noisy Time Series. Proc. R. Soc. A Math. Phys. Eng. Sci. 2017, 473, 20160776. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lilly, J.M.; Olhede, S.C. Higher-Order Properties of Analytic Wavelets. IEEE Trans. Signal Process. 2008, 57, 146–160. [Google Scholar] [CrossRef] [Green Version]

- Nasiri, A.; Bao, J.; Mccleeary, D.; Louis, S.-Y.M.; Huang, X.; Hu, J. Online Damage Monitoring of SiC F-SiC m Composite Materials Using Acoustic Emission and Deep Learning. IEEE Access 2019, 7, 140534–140541. [Google Scholar] [CrossRef]

- Lin, Y.; Nie, Z.; Ma, H. Structural Damage Detection with Automatic Feature-extraction through Deep Learning. Comput.-Aided Civ. Infrastruct. Eng. 2017, 32, 1025–1046. [Google Scholar] [CrossRef]

- Sikdar, S.; Liu, D.; Kundu, A. Acoustic Emission Data Based Deep Learning Approach for Classification and Detection of Damage-Sources in a Composite Panel. Compos. B Eng. 2022, 228, 109450. [Google Scholar] [CrossRef]

- Khan, A.; Ko, D.-K.; Lim, S.C.; Kim, H.S. Structural Vibration-Based Classification and Prediction of Delamination in Smart Composite Laminates Using Deep Learning Neural Network. Compos. B Eng. 2019, 161, 586–594. [Google Scholar] [CrossRef]

- Barile, C.; Casavola, C.; Pappalettera, G.; Kannan, V.P. Damage Monitoring of Carbon Fibre Reinforced Polymer Composites Using Acoustic Emission Technique and Deep Learning. Compos. Struct. 2022, 292, 115629. [Google Scholar] [CrossRef]

- Barile, C.; Casavola, C.; Pappalettera, G.; Kannan, V.P. Damage Progress Classification in AlSi10Mg SLM Specimens by Convolutional Neural Network and K-Fold Cross Validation. Materials 2022, 15, 4428. [Google Scholar] [CrossRef]

- Iandola, F.N.; Han, S.; Moskewicz, M.W.; Ashraf, K.; Dally, W.J.; Keutzer, K. SqueezeNet: AlexNet-Level Accuracy with 50x Fewer Parameters and <0.5 MB Model Size. arXiv 2016, arXiv:1602.07360. [Google Scholar]

- Mohammadi, R.; Najafabadi, M.A.; Saeedifar, M.; Yousefi, J.; Minak, G. Correlation of Acoustic Emission with Finite Element Predicted Damages in Open-Hole Tensile Laminated Composites. Compos. B Eng. 2017, 108, 427–435. [Google Scholar] [CrossRef]

- Ativitavas, N.; Pothisiri, T.; Fowler, T.J. Identification of Fiber-Reinforced Plastic Failure Mechanisms from Acoustic Emission Data Using Neural Networks. J. Compos. Mater. 2006, 40, 193–226. [Google Scholar] [CrossRef]

- de Oliveira, R.; Marques, A.T. Health Monitoring of FRP Using Acoustic Emission and Artificial Neural Networks. Comput. Struct. 2008, 86, 367–373. [Google Scholar] [CrossRef]

- Tessema, A.; Mitchell, W.; Koohbor, B.; Ravindran, S.; van Tooren, M.; Kidane, A. The Effect of Nano-Fillers on the in-Plane and Interlaminar Shear Properties of Carbon Fiber Reinforced Composite. J. Dyn. Behav. Mater. 2018, 4, 296–307. [Google Scholar] [CrossRef]

- Jarrah, M.; Najafabadi, E.P.; Khaneghahi, M.H.; Oskouei, A.V. The Effect of Elevated Temperatures on the Tensile Performance of GFRP and CFRP Sheets. Constr. Build. Mater. 2018, 190, 38–52. [Google Scholar] [CrossRef]

- Wisnom, M.R.; Jones, M.I. A Comparison between Interlaminar and In-Plane Shear Strength of Unidirectional Glass Fibre-Epoxy. Adv. Compos. Lett. 1994, 3, 096369359400300205. [Google Scholar] [CrossRef]

| Fire Module n | Layer Name | Layer Description |

|---|---|---|

| Squeeze | Firen-Squeeze | Number of Filters: X Filter Size: 1 × 1 Stride: 2 × 2 ReLU activation |

| Expand | Firen-Expand 1 × 1 | Number of Filters: X Filter Size: 1 × 1 Stride: 2 × 2 ReLU activation |

| Firen-Expand 3 × 3 | Number of Filters: X Filter Size: 1 × 1 Stride: 2 × 2 ReLU activation | |

| Concatenation | Firen-Concat |

| Training Parameters | |

|---|---|

| Initial Learning Rate | 0.001 |

| Learning Schedule | Piecewise |

| Drop Rate Factor | 0.1 |

| Drop Rate Period | 8 |

| Maximum Epochs | 20 |

| Minibatch Size | 75 |

| Cluster | Peak Amplitude Range | Counts Range |

|---|---|---|

| Cluster 1 | 35–55 dB | <25 |

| Cluster 2 | 40–60 dB | 26–55 |

| Cluster 3 | 45–65 dB | 56–150 |

| Cluster 4 | >65 dB | >150 |

| Specimen Name | UTS | Occurrence of Cluster 4 | Stress at ROI | Strain at ROI | |

|---|---|---|---|---|---|

| Time | Longitudinal | Transversal | |||

| Mpa | s | Mpa | µε | µε | |

| T-001 | 882 | 129.8 | 693 | 11225.94 | - |

| T-002 | 912 | 97.0 | 543 | 9309.64 | −468.18 |

| T-003 | 912 | 112.0 | 624 | 6243.14 * | −450.31 |

| T-004 | 819 | 79.0 | 436 | 7013.49 | - |

| T-005 | 816 | 66.9 | 327 | 6021.14 | −461.03 |

| Specimen Name | Cluster 1 | Cluster 2 | Cluster 3 | Cluster 4 |

|---|---|---|---|---|

| T-001 | 69.36 | 17.75 | 4.81 | 8.08 |

| T-002 | 68.09 | 21.39 | 8.23 | 2.30 |

| T-003 | 69.16 | 20.63 | 8.40 | 1.81 |

| T-004 | 65.61 | 23.34 | 9.04 | 2.01 |

| T-005 | 60.96 | 24.94 | 10.66 | 3.44 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barile, C.; Pappalettera, G.; Paramsamy Kannan, V.; Casavola, C. A Neural Network Framework for Validating Information–Theoretics Parameters in the Applications of Acoustic Emission Technique for Mechanical Characterization of Materials. Materials 2023, 16, 300. https://doi.org/10.3390/ma16010300

Barile C, Pappalettera G, Paramsamy Kannan V, Casavola C. A Neural Network Framework for Validating Information–Theoretics Parameters in the Applications of Acoustic Emission Technique for Mechanical Characterization of Materials. Materials. 2023; 16(1):300. https://doi.org/10.3390/ma16010300

Chicago/Turabian StyleBarile, Claudia, Giovanni Pappalettera, Vimalathithan Paramsamy Kannan, and Caterina Casavola. 2023. "A Neural Network Framework for Validating Information–Theoretics Parameters in the Applications of Acoustic Emission Technique for Mechanical Characterization of Materials" Materials 16, no. 1: 300. https://doi.org/10.3390/ma16010300

APA StyleBarile, C., Pappalettera, G., Paramsamy Kannan, V., & Casavola, C. (2023). A Neural Network Framework for Validating Information–Theoretics Parameters in the Applications of Acoustic Emission Technique for Mechanical Characterization of Materials. Materials, 16(1), 300. https://doi.org/10.3390/ma16010300