Influence of Long-Term Subcritical Annealing on the Unalloyed Steel Welded Joint Microstructure

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

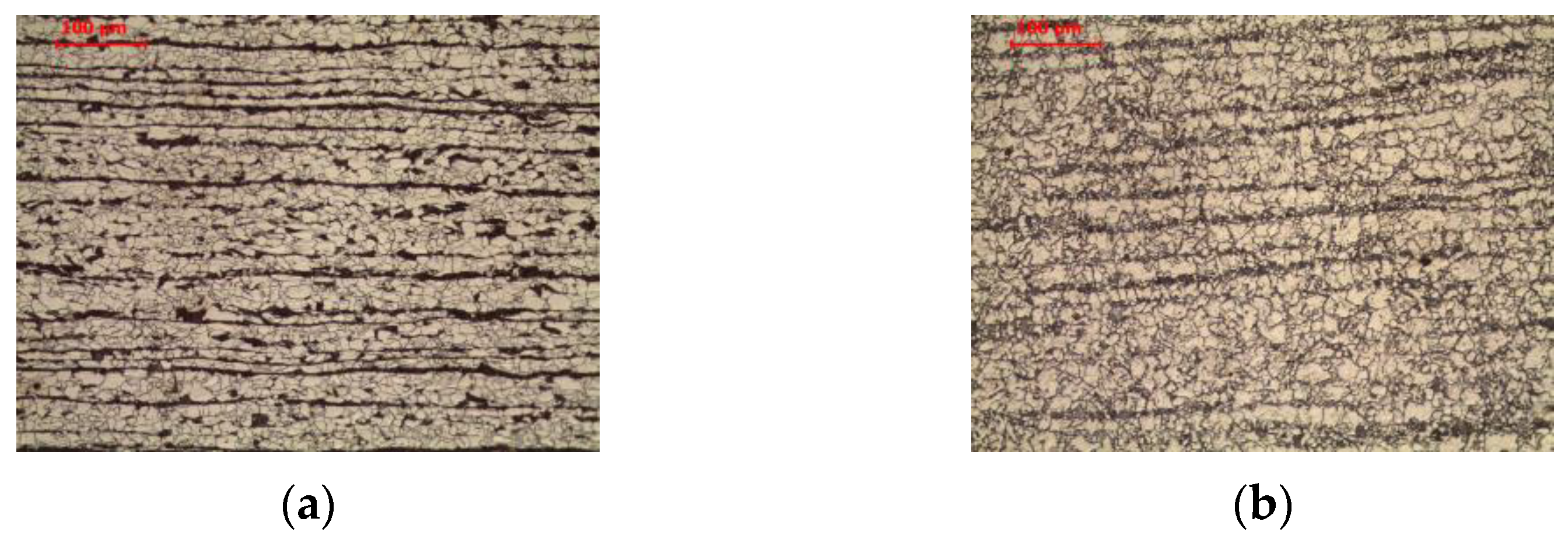

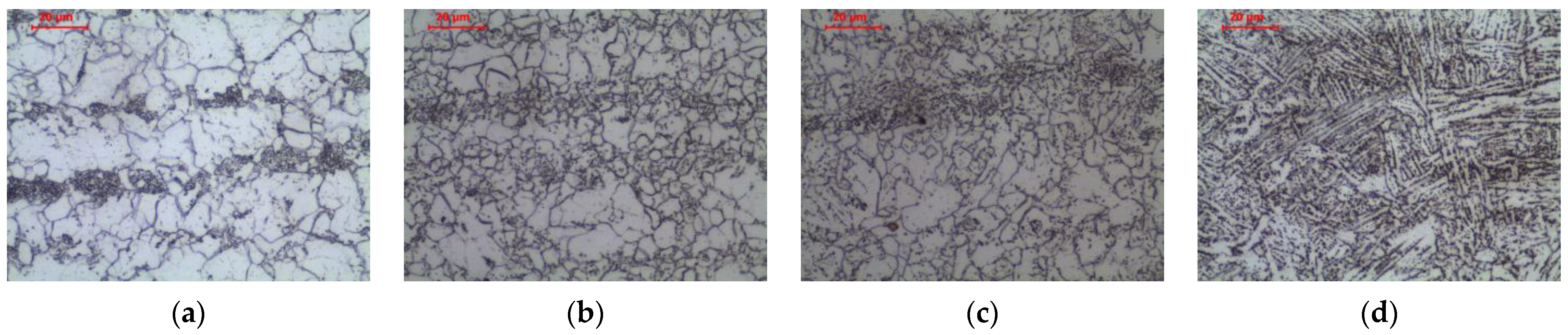

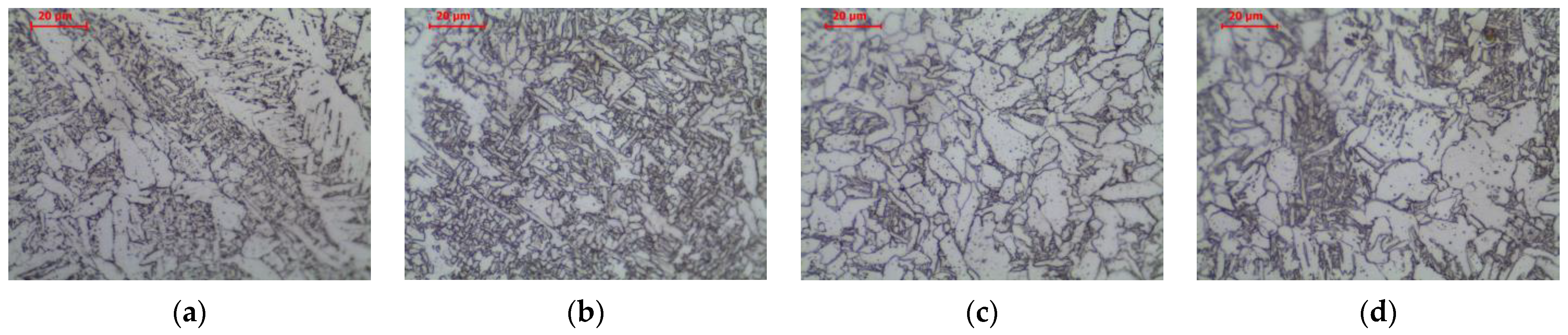

3.1. Microstructure of Base Materials

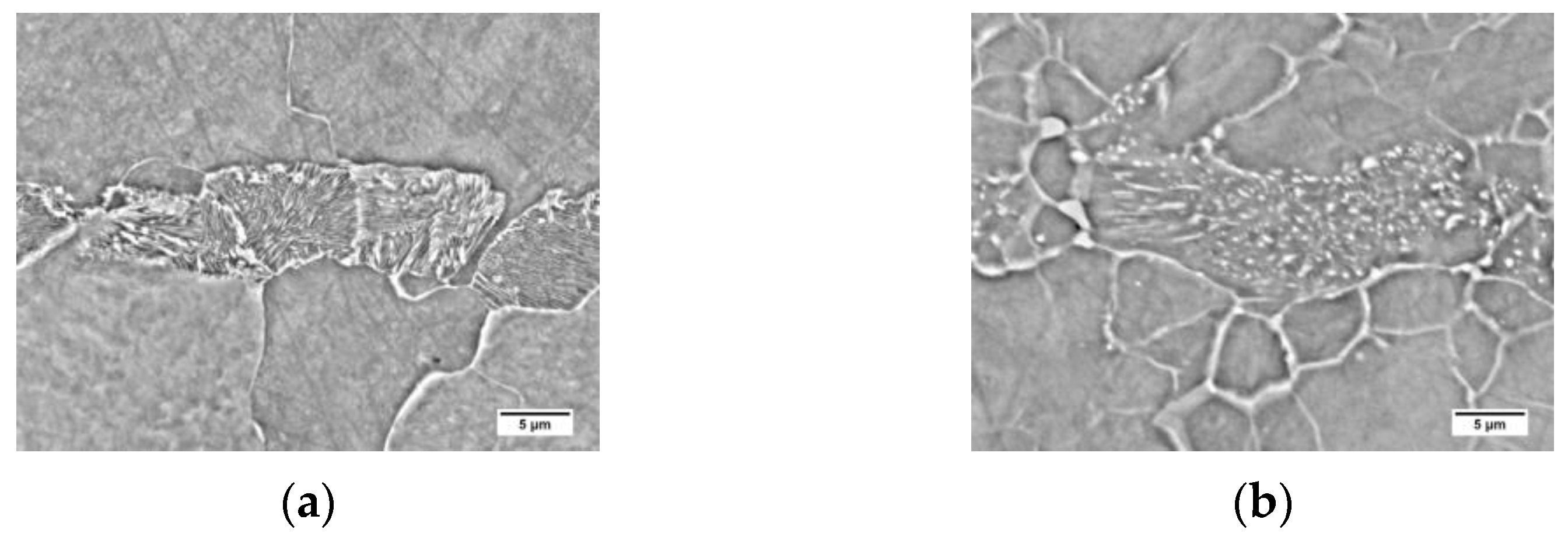

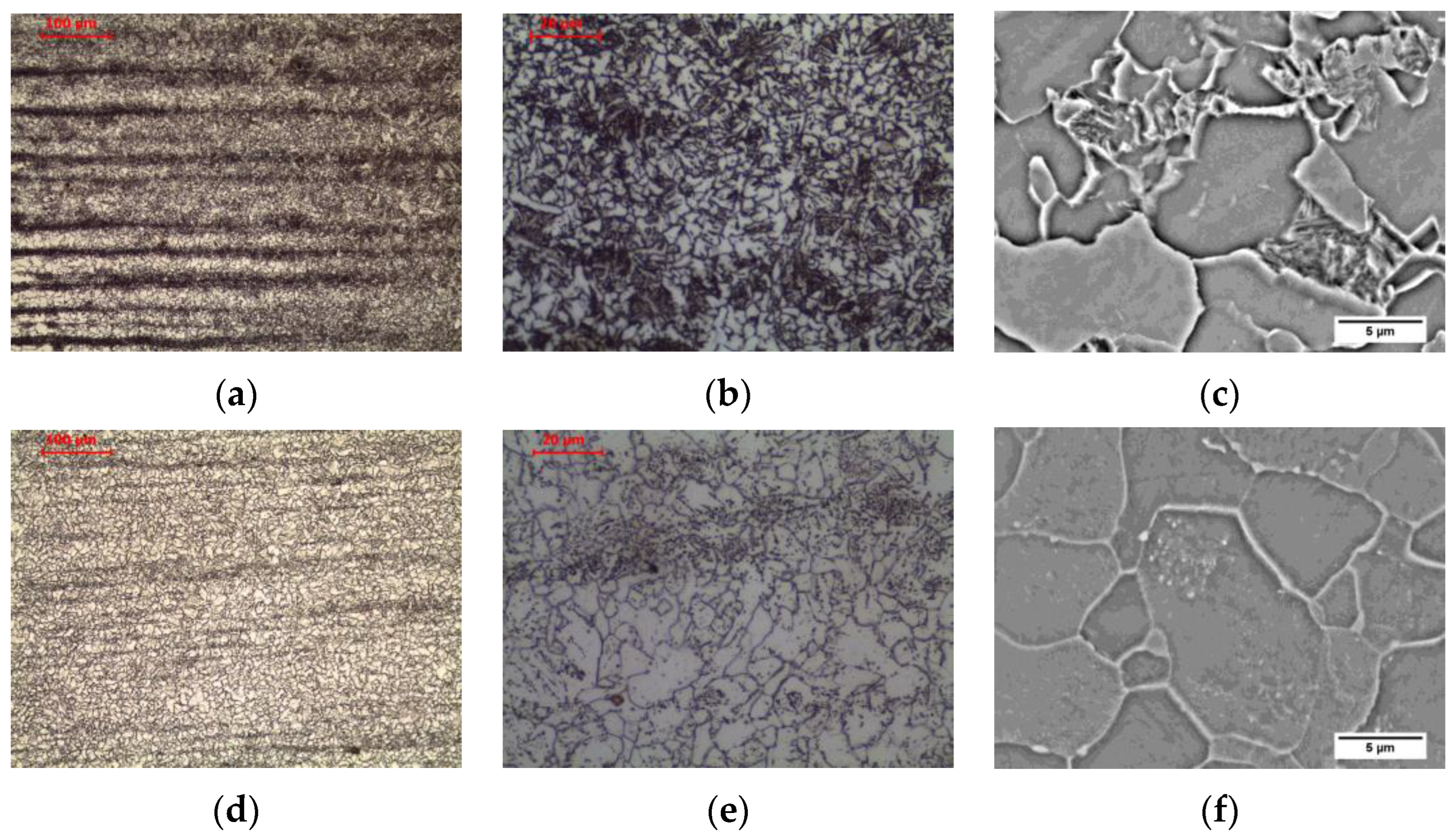

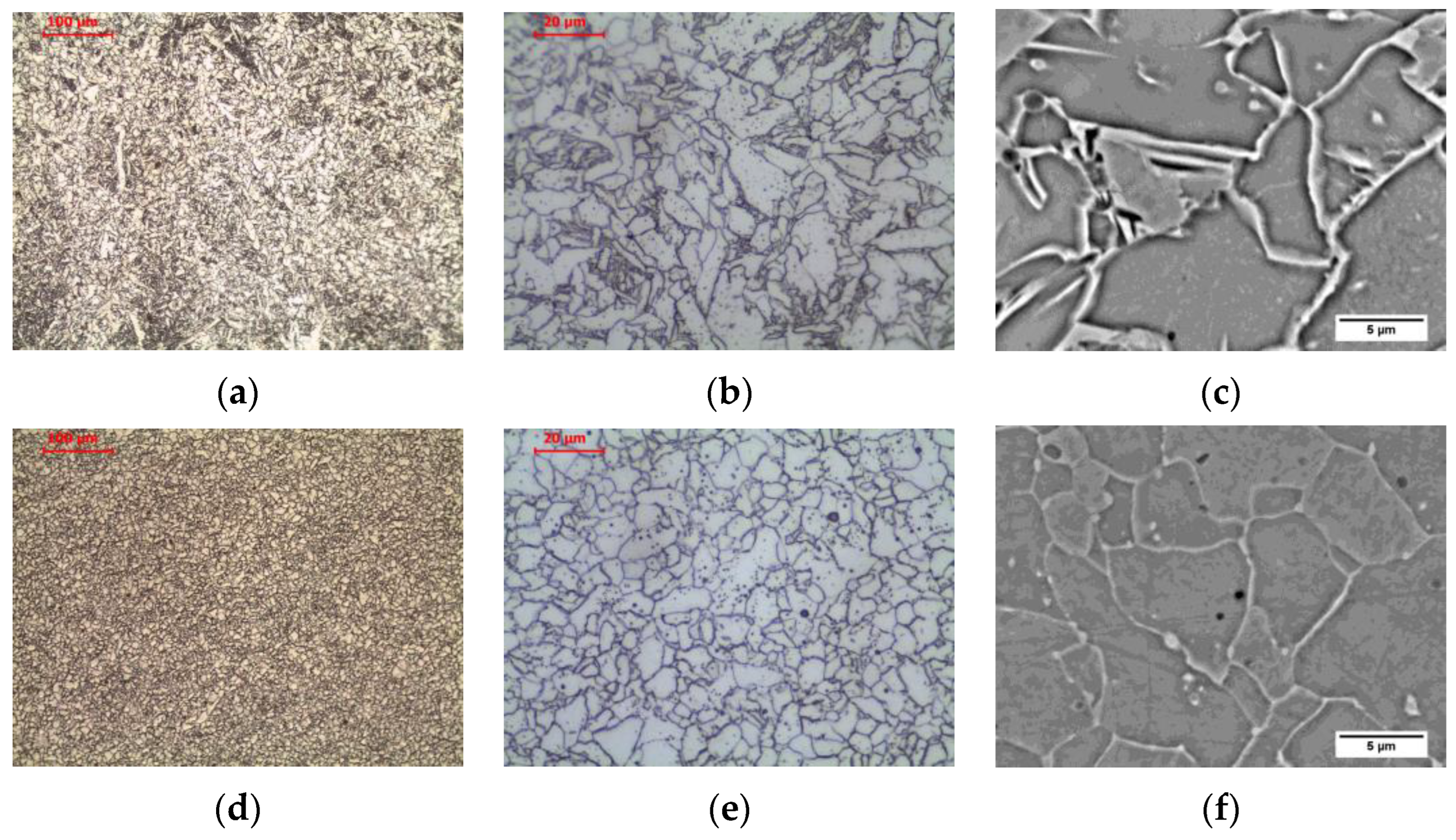

3.2. Microstructure of Heat-Affected Zones

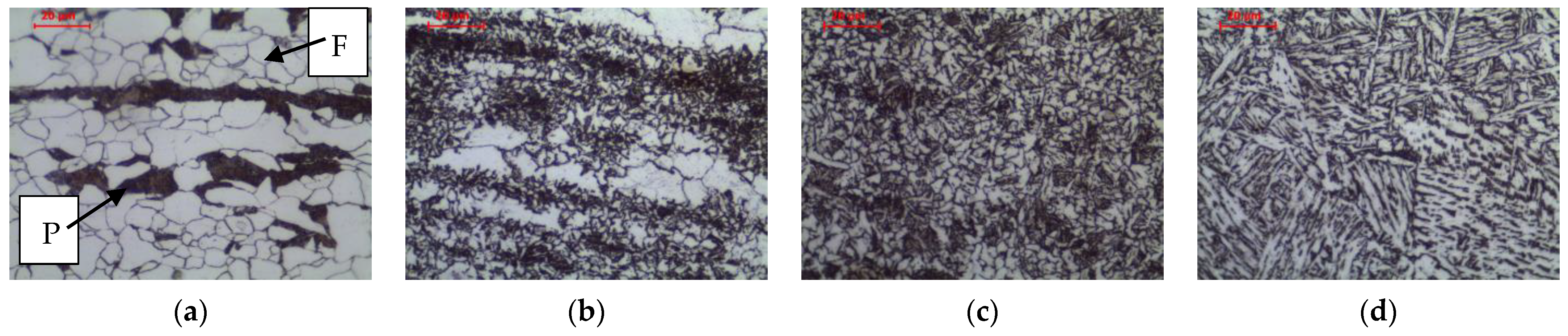

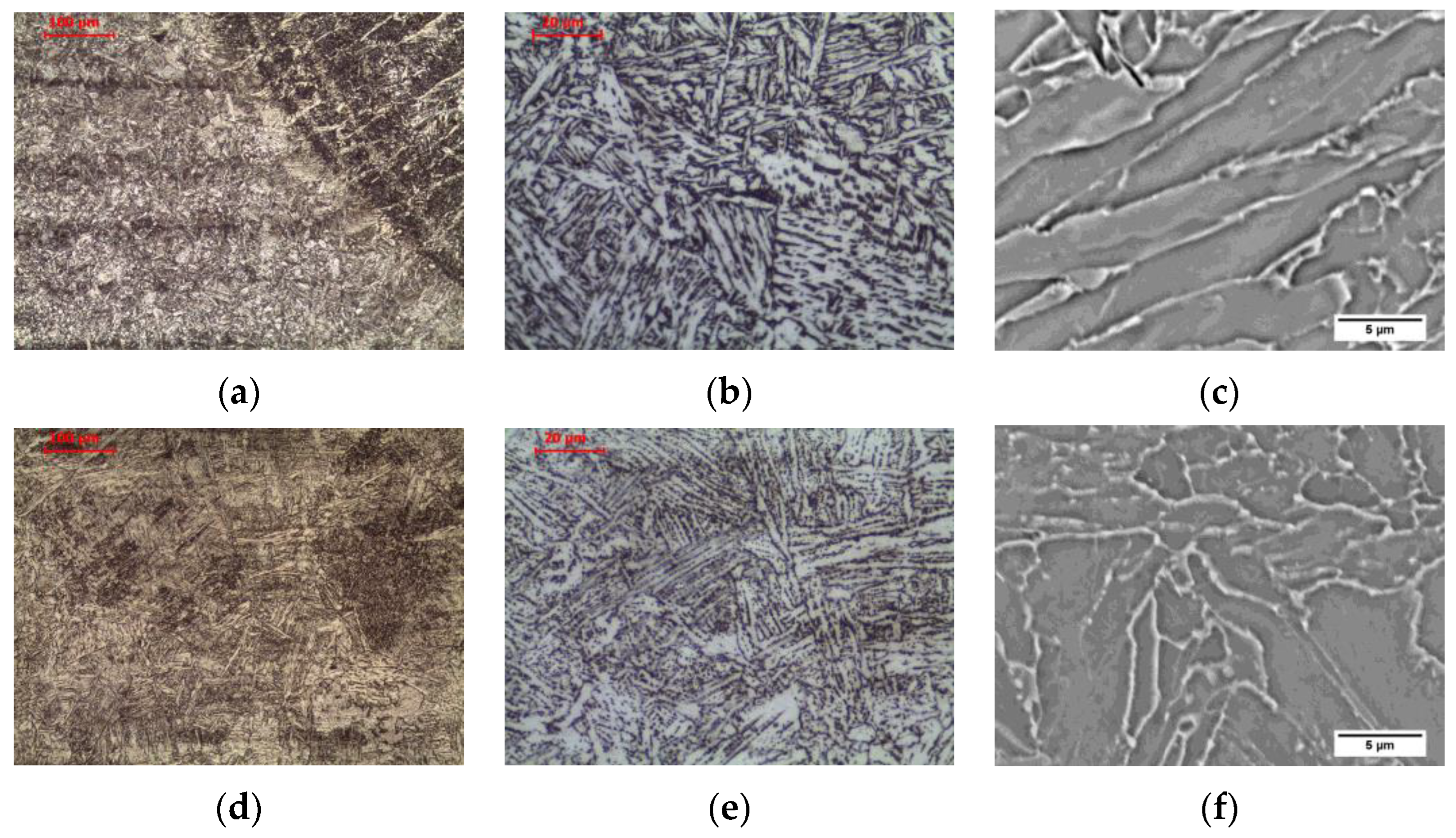

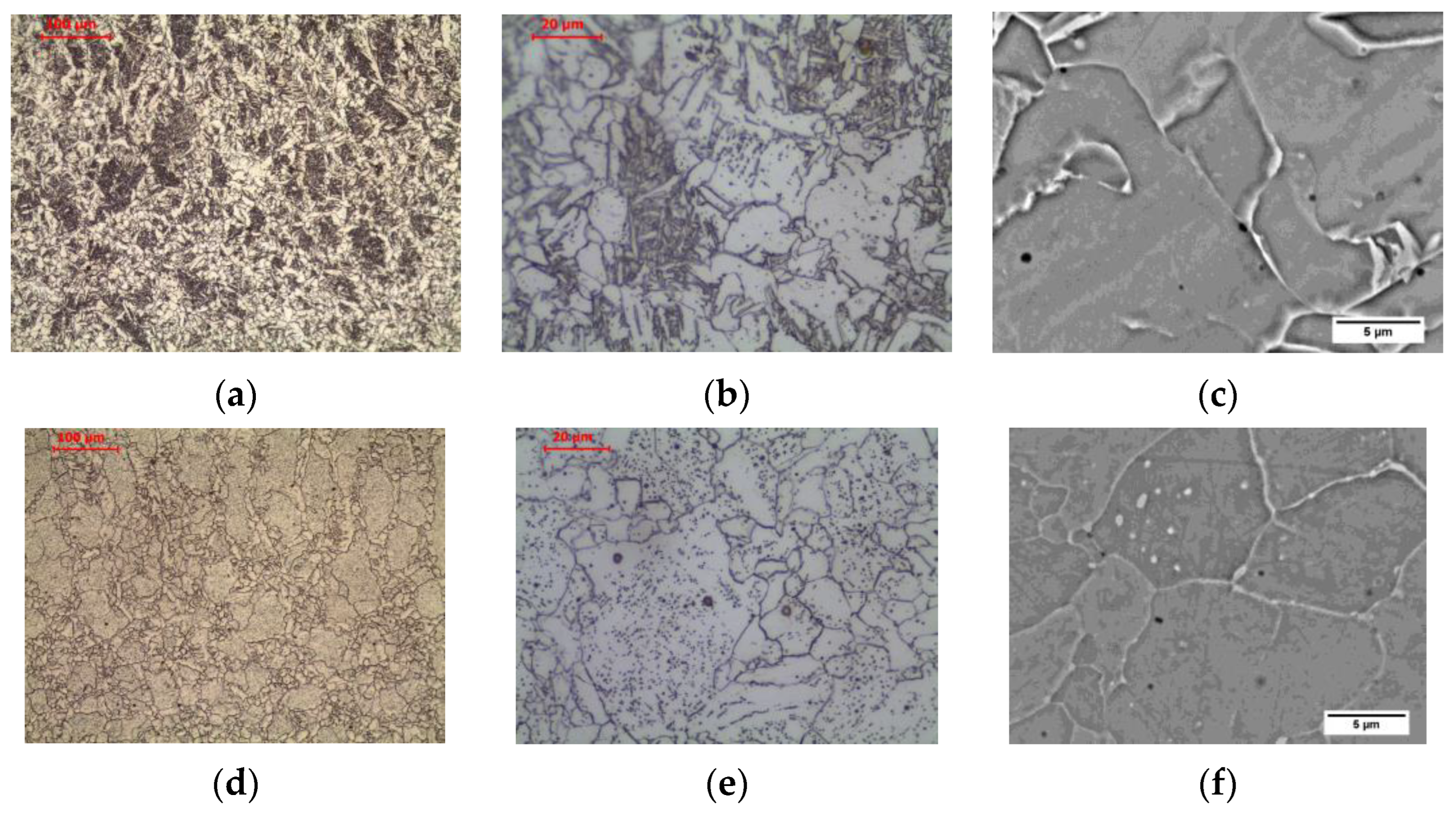

3.3. Microstructure of Weld Metals

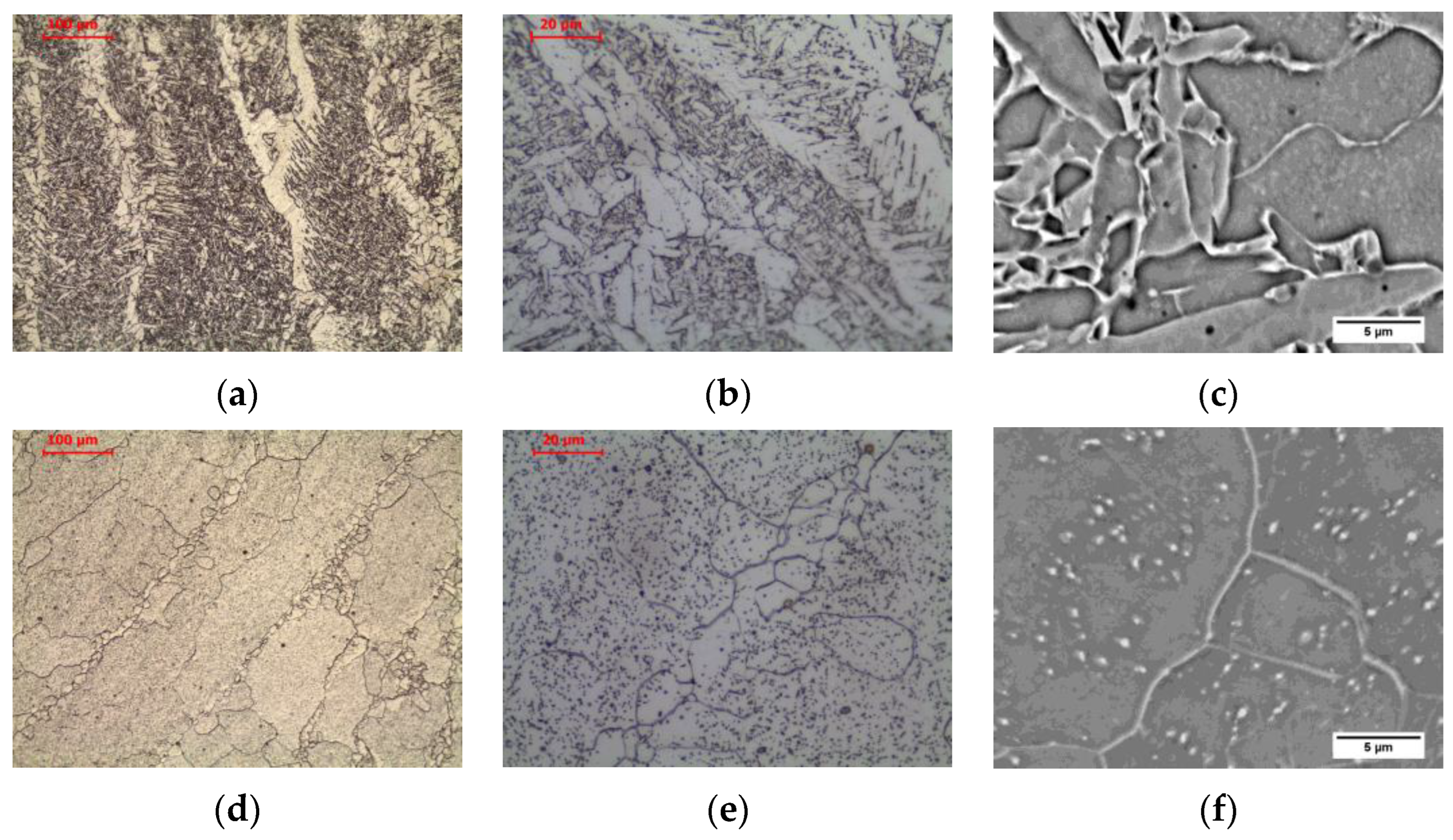

3.4. Microstructure of Heat-Affected Zones in Weld Metals

4. Conclusions

- -

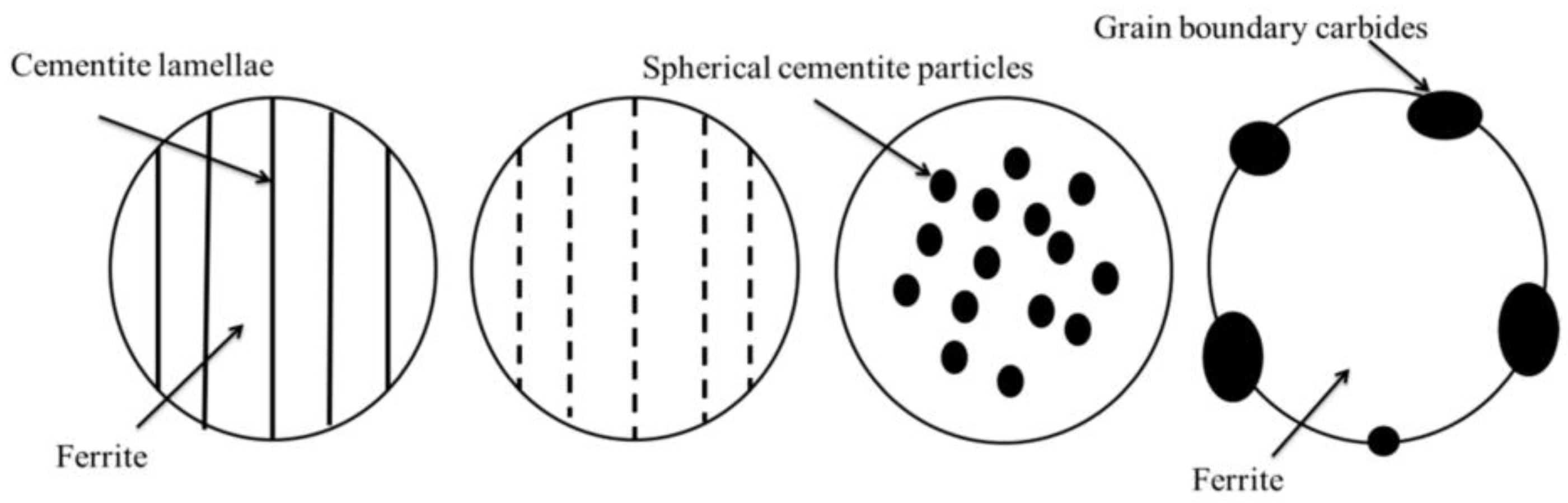

- The thermal cycle of welding leads to a heat-affected zone of coarse grain (CGHAZ), fine grain (FGHAZ), and uneven grain (ICHAZ), with the band structure inherited from the base material being retained in each case. Prolonged exposure at 600 °C leads to a change in the form of cementite in pearlite from lamellar to spheroidal in each of the zones, constantly maintaining the band structure.

- -

- In the case of the weld in the as-welded condition, polygonal, side-plate, and acicular ferrites are observed. As a result of long-term exposure to a temperature of 600 °C, cementite assumes a spherical shape, while side-plate and acicular ferrite disappear.

- -

- Microscopic examination of the weld in the area of influence of the next pass on the previous one reveals the heat-affected zone in which partial (ICHAZ) and complete (FGHAZ) recrystallization of the structure and the formation of new allomorphic ferrite grains occur. The CGHAZ area, which also undergoes complete recrystallization, has a structure composed of the three types of ferrite (polygonal, side-plate, acicular), of which the side-plate and acicular ferrite disappear after prolonged exposure at 600 °C.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nowacki, J.; Sajek, A.; Matkowski, P. The influence of welding heat input on the microstructure of joints of S1100QL steel in one-pass welding. Arch. Civ. Mech. Eng. 2016, 16, 777–783. [Google Scholar] [CrossRef]

- Sajek, A. Welding Thermal Cycles of Joints Made of S1100QL Steel by Saw and Hybrid Plasma-Mag Processes. Adv. Mater. Sci. 2020, 20, 75–86. [Google Scholar] [CrossRef]

- Tomków, J.; Landowski, M.; Fydrych, D.; Rogalski, G. Underwater wet welding of S1300 ultra-high strength steel. Mar. Struct. 2022, 81, 103120. [Google Scholar] [CrossRef]

- Tomków, J.; Fydrych, D.; Rogalski, G. Dissimilar underwater wet welding of HSLA steels. Int. J. Adv. Manuf. Technol. 2020, 109, 717–725. [Google Scholar] [CrossRef]

- Pikuła, J.; Łomozik, M.; Pfeifer, T. The influence of manual metal arc multiple repair welding of long operated waterwall on the structure and hardness of the heat affected zone of welded joints. Arch. Metall. Mater. 2017, 62, 327–333. [Google Scholar] [CrossRef]

- Stanisz, D.; Machniewicz, T.; Parzych, S.; Jeż, G.; Dvorkin, L.; Hebda, M. Microstructure and Mechanical Properties of Joints Depending on the Process Used. Materials 2022, 15, 5171. [Google Scholar] [CrossRef]

- Voiculescu, I.; Geanta, V.; Stefanescu, E.V.; Simion, G.; Scutelnicu, E. Effect of Diffusion on Dissimilar Welded Joint between Al0.8CoCrFeNi High-Entropy Alloy and S235JR Structural Steel. Metals 2022, 12, 548. [Google Scholar] [CrossRef]

- Wang, T.; Ao, S.S.; Manladan, S.M.; Cai, Y.C.; Luo, Z. Microstructure and Properties of Surface-Modified Plates and Their Welded Joints. Materials 2019, 12, 2883. [Google Scholar] [CrossRef]

- Pańcikiewicz, K. Structure and Properties of Welded Joints of 7CrMoVTiB10-10 (T24) Steel. Adv. Mater. Sci. 2018, 18, 37–47. [Google Scholar] [CrossRef]

- Chen, Z.; Kou, D.; Chen, Z.; Yang, F.; Ma, Y.; Li, Y. Evolution of Microstructure in Welding Heat-Affected Zone of G115 Steel with the Different Content of Boron. Materials 2022, 15, 2053. [Google Scholar] [CrossRef]

- Liu, D.; Dong, Y.; Li, R.; Jiang, J.; Li, X.; Wang, Z.; Zuo, X. Evaluation of Mechanical Properties and Microstructure of X70 Pipeline Steel with Strain-Based Design. Metals 2022, 12, 1616. [Google Scholar] [CrossRef]

- Pandey, C.; Mahapatra, M.M.; Kumar, P.; Saini, N. Some studies on P91 steel and their weldments. J. Alloys Compd. 2018, 743, 332–364. [Google Scholar] [CrossRef]

- Wang, X.; Wang, D.; Dai, L.; Deng, C.; Li, C.; Wang, Y.; Shen, K. Effect of Post-Weld Heat Treatment on Microstructure and Fracture Toughness of X80 Pipeline Steel Welded Joint. Materials 2022, 15, 6646. [Google Scholar] [CrossRef]

- Tian, S.; Xu, F.; Zhang, G.; Saifan, A.; Saleh, B.; Li, X. Influence of Post-Weld Heat Treatment on Microstructure and Toughness Properties of 13MnNiMoR High Strength Low Alloy Steel Weld Joint. Materials 2021, 14, 5336. [Google Scholar] [CrossRef] [PubMed]

- Sun, Q.; Li, X.; Li, K.; Cai, Z.; Han, C.; Li, S.; Gao, D.; Pan, J. Effects of Long-Term Service on Microstructure and Impact Toughness of the Weld Metal and Heat-Affected Zone in CrMoV Steel Joints. Metals 2022, 12, 278. [Google Scholar] [CrossRef]

- Sroka, M.; Zieliński, A.; Dziuba-Kałuża, M.; Kremzer, M.; Macek, M.; Jasiński, A. Assessment of the Residual Life of Steam Pipeline Material beyond the Computational Working Time. Metals 2017, 7, 82. [Google Scholar] [CrossRef]

- Stevenson, M. RECYCLING|Lead–Acid Batteries: Overview. In Encyclopedia of Electrochemical Power Sources; Elsevier: Amsterdam, The Netherlands, 2009; pp. 165–178. [Google Scholar]

- ISO 4885:2018; Ferrous Materials—Heat Treatments—Vocabulary. ISO: Geneva, Switzerland, 2018.

- Wang, S.; Cao, L.; Zhang, Z. Influence of Carbide Morphology on the Deformation and Fracture Mechanisms of Spheroidized 14CrMoR Steel. Metals 2019, 9, 1221. [Google Scholar] [CrossRef]

- Stodolny, J.; Gołaszewski, A.; Łotarewicz, A. Fragmentation Rate of Cementite Lamellas in Nanopearlite. JOM 2019, 71, 3298–3304. [Google Scholar] [CrossRef]

- Yang, C.-C.; Lu, N.-H. The Inspection of Spheroidized Annealing on SCM435 Cold-Forging Quality Steel Wires with Protective Atmosphere. Mater. Sci. Appl. 2019, 10, 677–686. [Google Scholar] [CrossRef]

- Arruabarrena, J.; Rodriguez-Ibabe, J.M. Enhancement of the AISI 5140 Cold Heading Wire Steel Spheroidization by Adequate Control of the Initial As-Rolled Microstructure. Metals 2021, 11, 219. [Google Scholar] [CrossRef]

- Feng, C.-C.; Lin, M.-H.; Chuang, W.-H.; Chen, Y.-C.; Ou, S.-F. Optimization of Hot Rolling Scheduling of Steel Strip with High Bending Performance. Materials 2022, 15, 1534. [Google Scholar] [CrossRef] [PubMed]

- Czarski, A.; Skowronek, T.; Matusiewicz, P. Stability of a Lamellar Structure—Effect of the True Interlamellar Spacing on the Durability of a Pearlite Colony. Arch. Metall. Mater. 2015, 60, 2499–2504. [Google Scholar] [CrossRef][Green Version]

- Matusiewicz, P.; Augustyn-Nadzieja, J.; Czarski, A.; Skowronek, T. Kinetics of pearlite spheroidization. Arch. Metall. Mater. 2017, 62, 231–234. [Google Scholar] [CrossRef]

- Li, Y.; Xing, W.; Li, X.; Chen, B.; Ma, Y.; Liu, K.; Min, Y. Effect of Mg Addition on the Microstructure and Properties of a Heat-Affected Zone in Submerged Arc Welding of an Al-Killed Low Carbon Steel. Materials 2021, 14, 2445. [Google Scholar] [CrossRef]

- Yamamoto, H.; Ito, K. Effects of Microstructural Modification Using Friction Stir Processing on Fatigue Strength of Butt-Welded Joints for High-Strength Steels. Mater. Sci. Appl. 2018, 9, 625–636. [Google Scholar] [CrossRef][Green Version]

- Khan, A.R.; Yu, S.F. Microstructure and Mechanical Properties of 3-Wire Electroslag Welded (ESW) High-Speed Pearlitic Rail Steel Joint. Key Eng. Mater. 2020, 837, 28–34. [Google Scholar] [CrossRef]

- Porcaro, R.R.; Faria, G.L.; Godefroid, L.B.; Apolonio, G.R.; Cândido, L.C.; Pinto, E.S. Microstructure and mechanical properties of a flash butt welded pearlitic rail. J. Mater. Process. Technol. 2019, 270, 20–27. [Google Scholar] [CrossRef]

- Haze, T.; Aihara, S. Metallurgical Factors Controlling HAZ Toughness in HT50 Steels. IIW Doc. IX-1423-86 1986. [Google Scholar]

- Jang, J.; Yoon, C.; Lee, S.; Lee, D.G. Effect of Continuous Welding on Microstructure and Mechanical Properties of Angle and T-Bar. Arch. Metall. Mater. 2020, 65, 1245–1248. [Google Scholar]

- Guk, S.; Augenstein, E.; Zapara, M.; Kawalla, R.; Prahl, U. Effect of Spheroidization Annealing on Pearlite Banding. Mater. Sci. Forum 2019, 949, 40–47. [Google Scholar] [CrossRef]

- Zhang, J.; Xin, W.; Luo, G.; Wang, R.; Meng, Q. Significant Influence of Welding Heat Input on the Microstructural Characteristics and Mechanical Properties of the Simulated CGHAZ in High Nitrogen V-Alloyed Steel. High Temp. Mater. Process. 2020, 39, 33–44. [Google Scholar] [CrossRef]

- Prado, J.M.; Lino, R.E.; Vaz, C.T. Effects of Heat Input and Niobium Addition on HAZ of Microalloyed Steels for Reinforcing Bars. Soldag. Inspeção 2020, 25, 1–10. [Google Scholar] [CrossRef]

- Jeong, H.; Han, K. Effect of Aluminum, Nitrogen and Silicon Content on the Toughness of C-Mn Steel Weld Heat Affected Zone. J. Weld. Join. 2020, 38, 73–80. [Google Scholar] [CrossRef]

- Jorge, J.C.F.; Souza, L.F.G.d.; Mendes, M.C.; Bott, I.S.; Araújo, L.S.; Santos, V.R.d.; Rebello, J.M.A.; Evans, G.M. Microstructure characterization and its relationship with impact toughness of C–Mn and high strength low alloy steel weld metals—A review. J. Mater. Res. Technol. 2021, 10, 471–501. [Google Scholar] [CrossRef]

- Vezzù, S.; Scappin, M.; Boaretto, D.; Timelli, G. On the Effect of Slight Variations of Si, Mn, and Ti on Inclusions Properties, Microstructure, and Mechanical Properties of YS460 C-Mn Steel Welds. Metallogr. Microstruct. Anal. 2019, 8, 292–306. [Google Scholar] [CrossRef]

- Lomozik, M. Effect of the welding thermal cycles on the structural changes in the heat affected zone and on its properties in joints welded in low-alloy steels. Weld. Int. 2000, 14, 845–850. [Google Scholar] [CrossRef]

- Wang, X.L.; Nan, Y.R.; Xie, Z.J.; Tsai, Y.T.; Yang, J.R.; Shang, C.J. Influence of welding pass on microstructure and toughness in the reheated zone of multi-pass weld metal of 550 MPa offshore engineering steel. Mater. Sci. Eng. A 2017, 702, 196–205. [Google Scholar] [CrossRef]

- Gutiérrez, P.H.; Rodríguez, F.C.; Mondragón, J.J.R.; Dávila, J.L.A.; Mata, M.P.G.; Chavez, C.A.G. Thermo-mechanic and Microstructural Analysis of an Underwater Welding Joint. Soldag. Inspeção 2016, 21, 156–164. [Google Scholar] [CrossRef][Green Version]

| Data Source | C | Si | Mn | P | S | N | Cu |

|---|---|---|---|---|---|---|---|

| OES (steel) | 0.123 | 0.183 | 1.14 | 0.0135 | 0.0046 | - | 0.027 |

| EN 10025-2 | ≤0.170 | - | ≤1.40 | ≤0.035 | ≤0.035 | ≤0.012 | ≤0.55 |

| OES (weld metal) | 0.0743 | 0.524 | 1.24 | 0.0161 | 0.0057 | - | 0.050 |

| EN ISO 14341-A | 0.06–0.14 | 0.5–0.8 | 0.9–1.3 | ≤0.025 | ≤0.035 | - | ≤0.35 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fajt, D.; Maślak, M.; Stankiewicz, M.; Zajdel, P.; Pańcikiewicz, K. Influence of Long-Term Subcritical Annealing on the Unalloyed Steel Welded Joint Microstructure. Materials 2023, 16, 304. https://doi.org/10.3390/ma16010304

Fajt D, Maślak M, Stankiewicz M, Zajdel P, Pańcikiewicz K. Influence of Long-Term Subcritical Annealing on the Unalloyed Steel Welded Joint Microstructure. Materials. 2023; 16(1):304. https://doi.org/10.3390/ma16010304

Chicago/Turabian StyleFajt, Dominika, Mariusz Maślak, Marek Stankiewicz, Paulina Zajdel, and Krzysztof Pańcikiewicz. 2023. "Influence of Long-Term Subcritical Annealing on the Unalloyed Steel Welded Joint Microstructure" Materials 16, no. 1: 304. https://doi.org/10.3390/ma16010304

APA StyleFajt, D., Maślak, M., Stankiewicz, M., Zajdel, P., & Pańcikiewicz, K. (2023). Influence of Long-Term Subcritical Annealing on the Unalloyed Steel Welded Joint Microstructure. Materials, 16(1), 304. https://doi.org/10.3390/ma16010304