Tests of Dental Properties of Composite Materials Containing Nanohybrid Filler

Abstract

1. Introduction

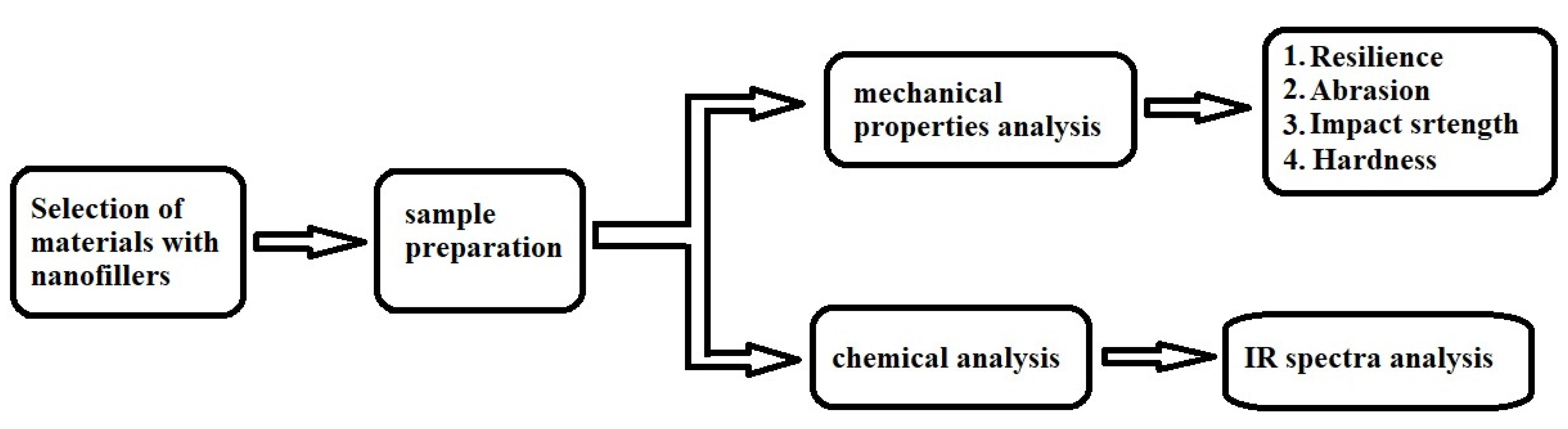

2. Materials and Methods

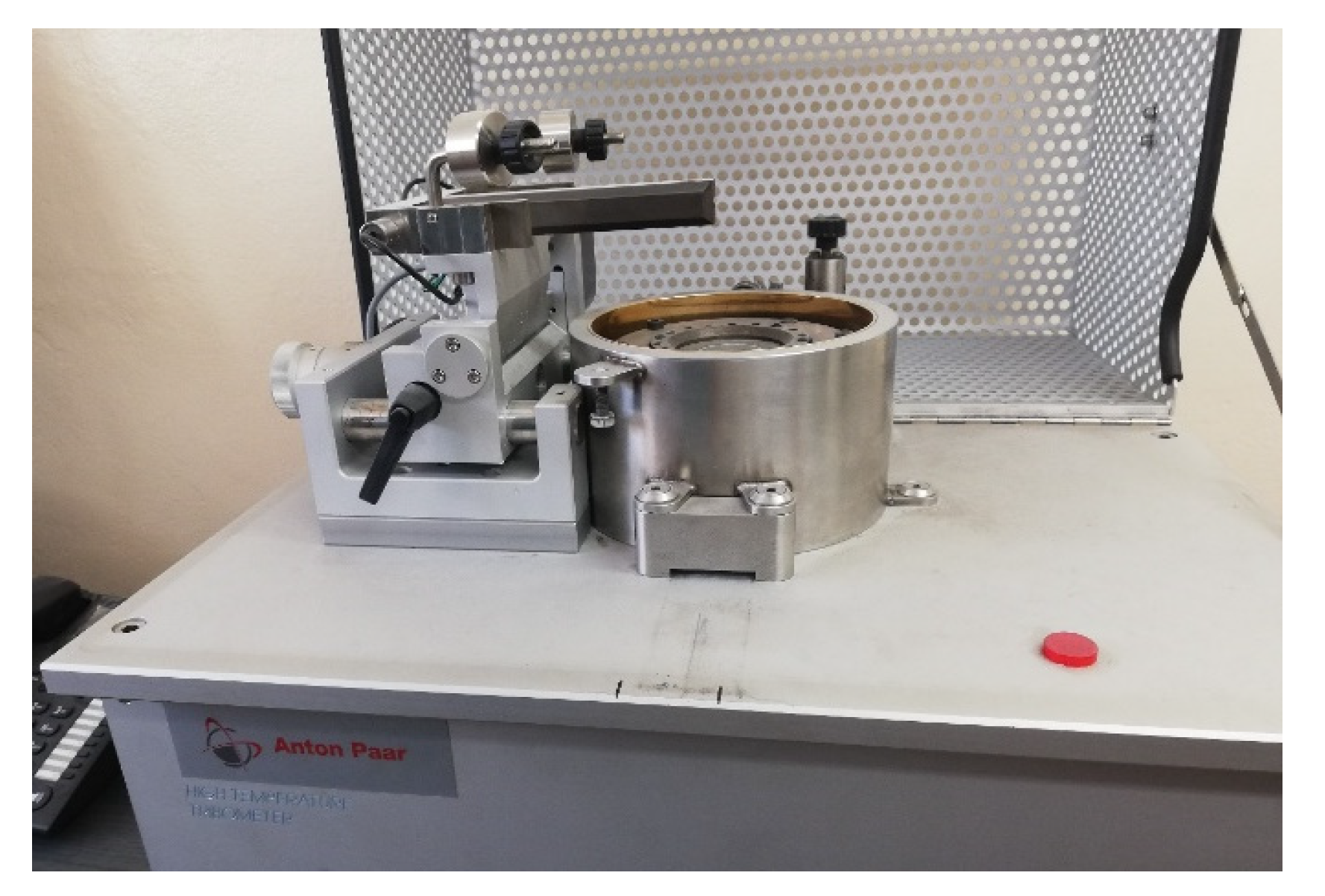

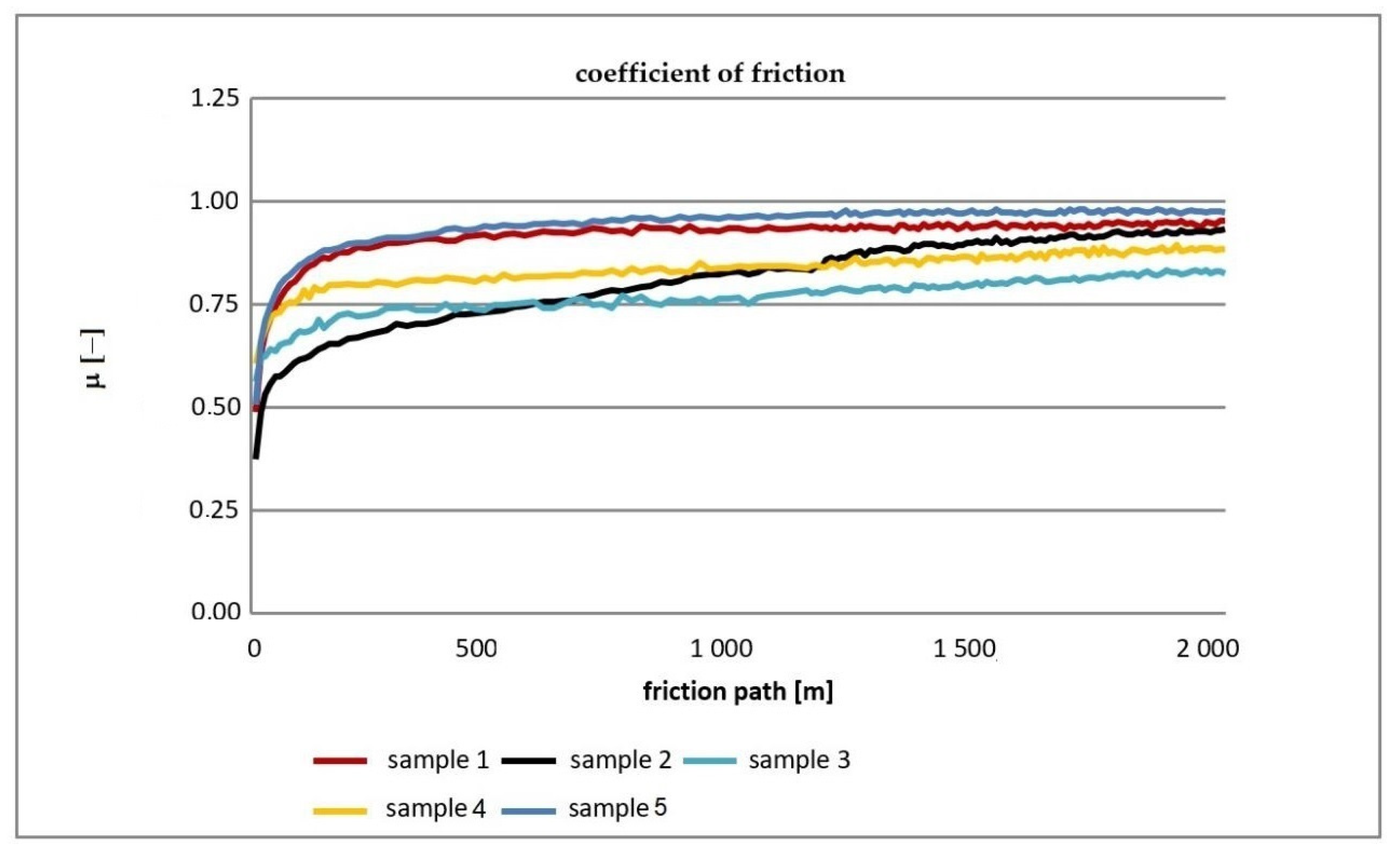

- Measurements of the coefficient of friction and pin-on-disc friction wear and determination of the degree of wear using the Taylor Hobson profilometer;

- Impact measurements using a Charpy pendulum hammer;

- Hardness measurements with the ball indentation method.

- Identification of substances, determination of bond types and functional groups, and study of substituent effects in molecules of tested compounds.

3. Resilience

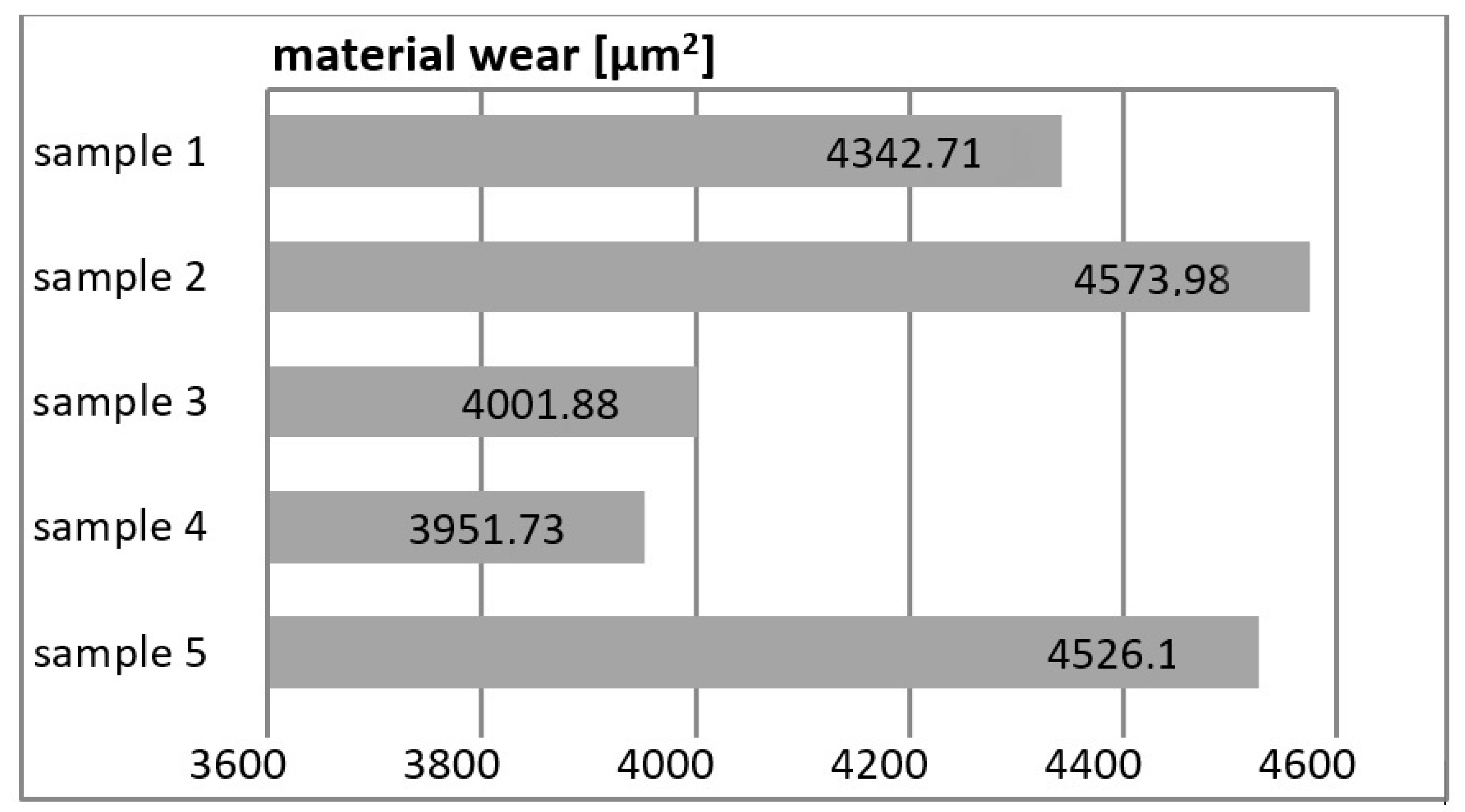

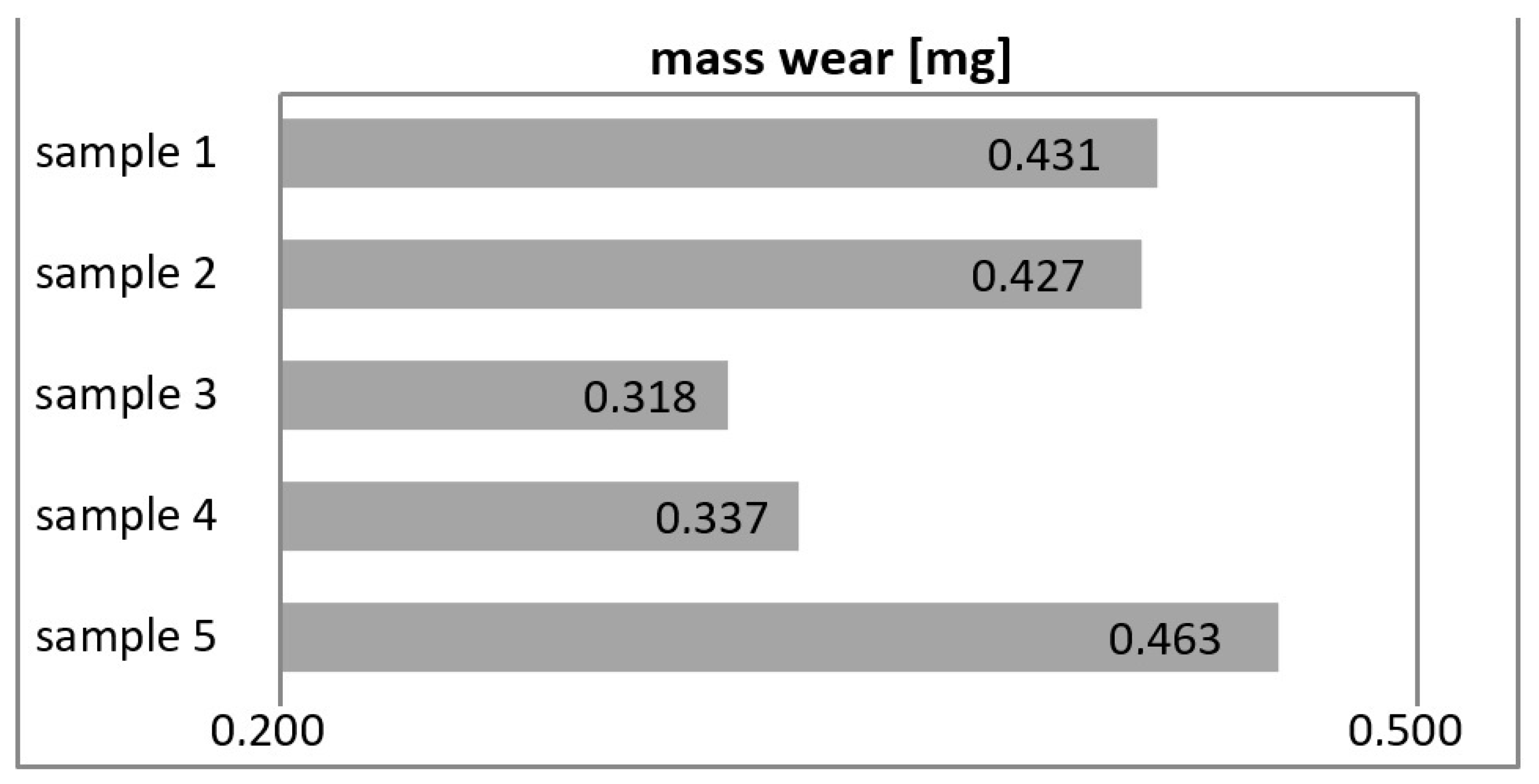

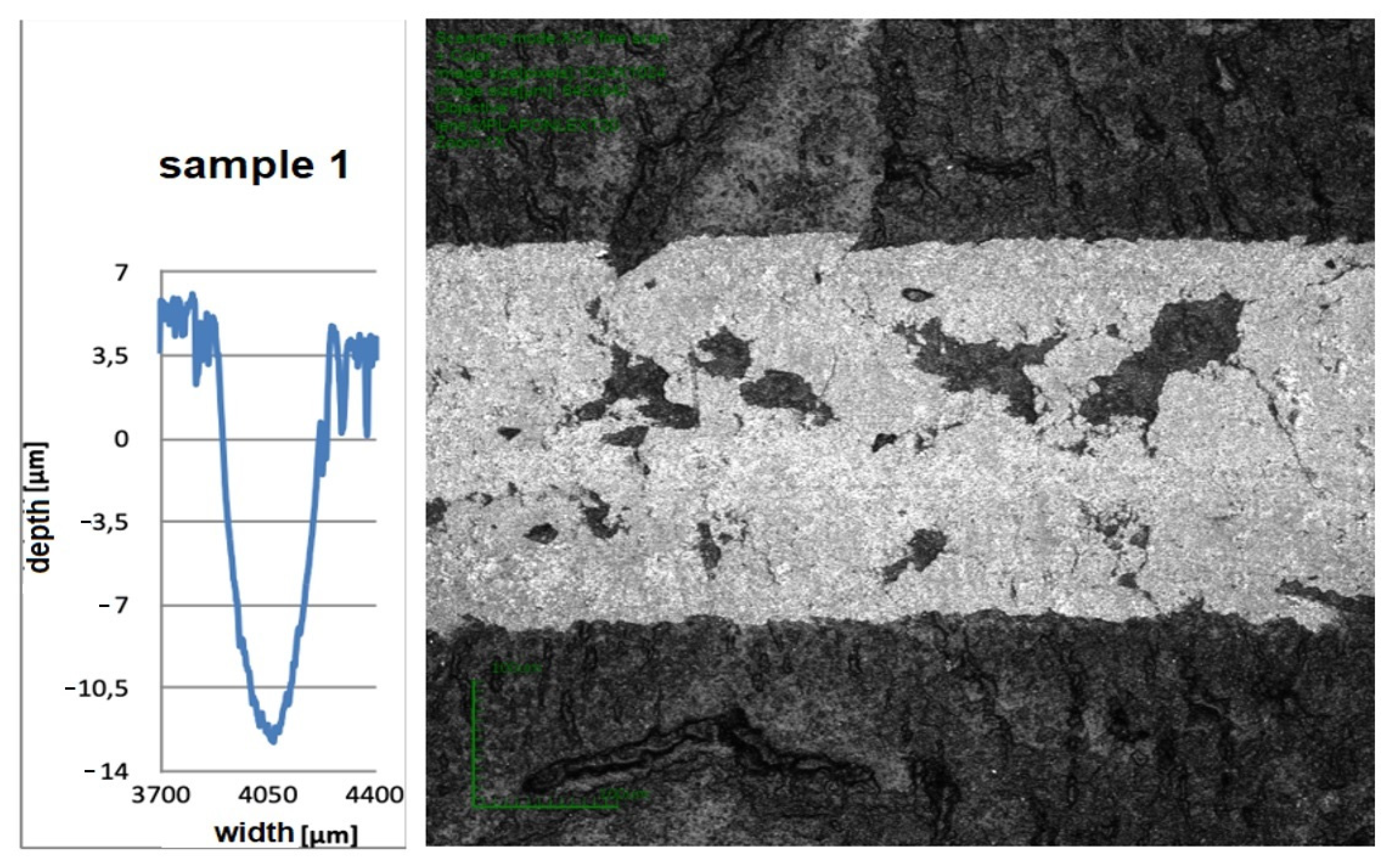

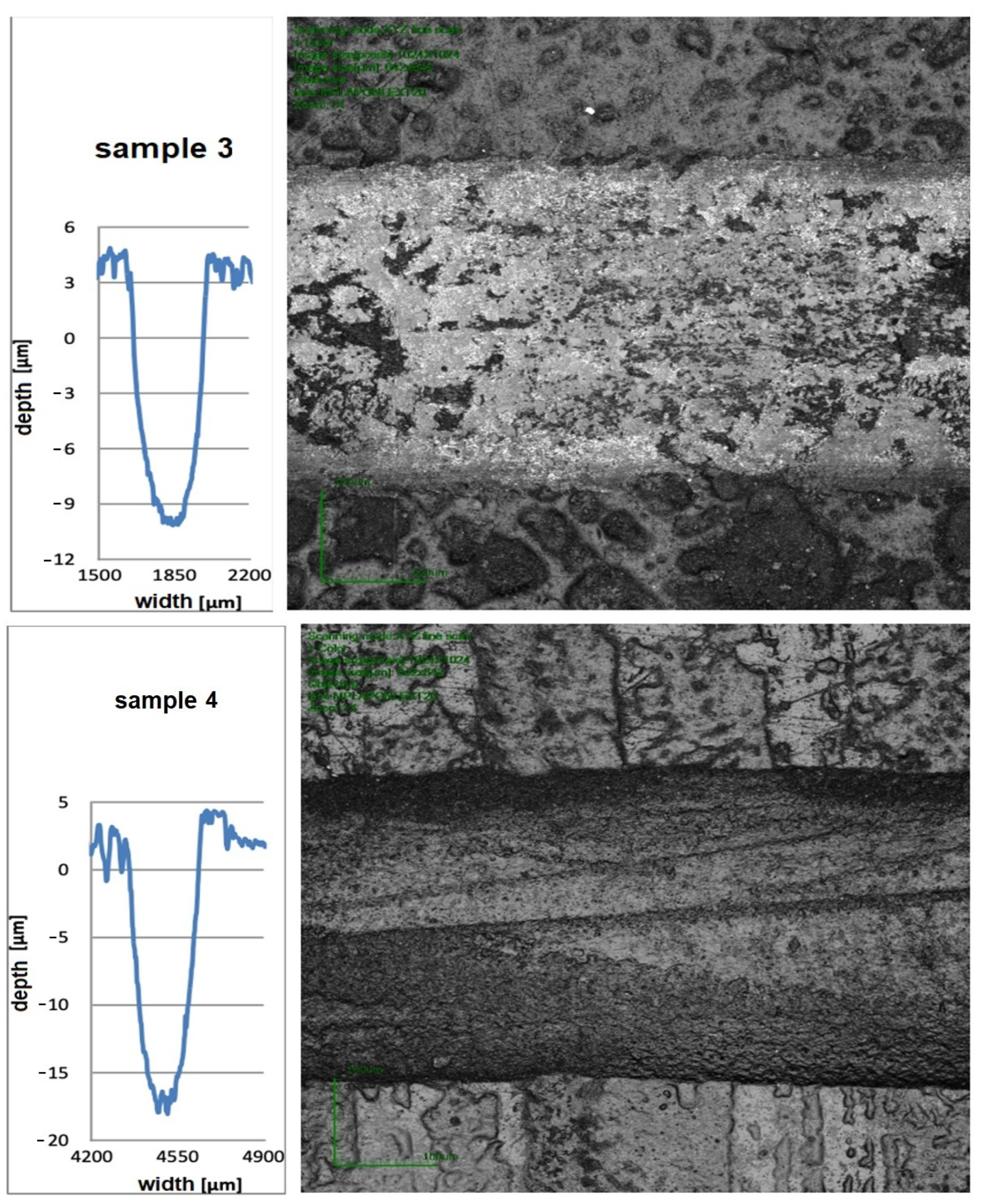

4. Abrasion

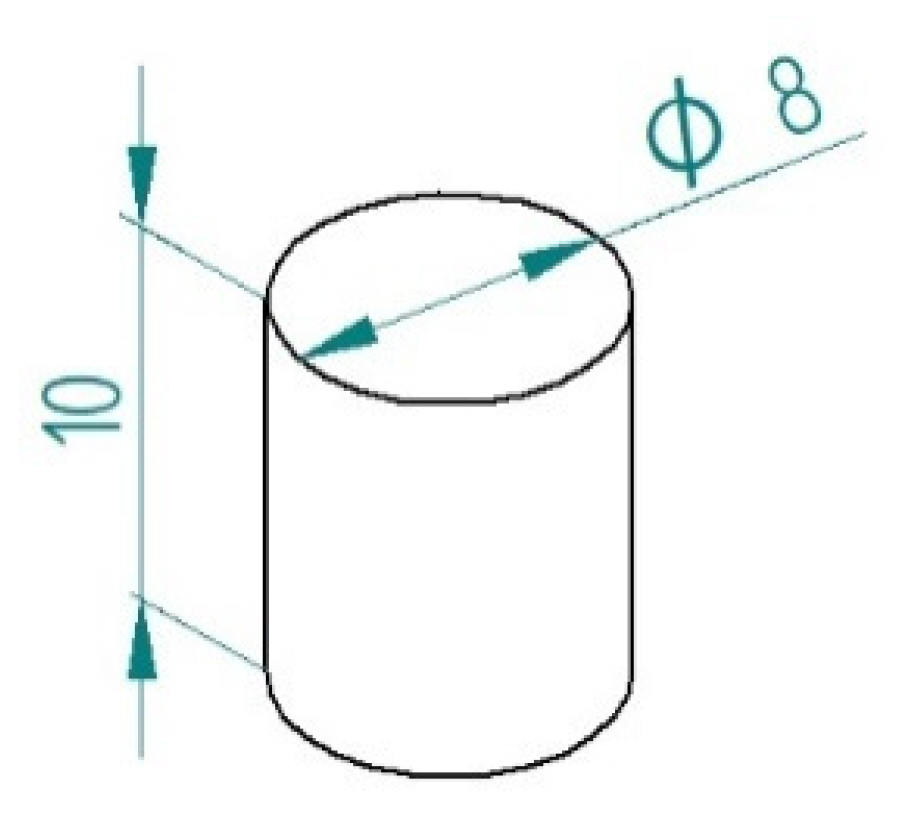

- Probe diameter: 10 mm;

- Length of the friction path: 2000 m;

- Load: 3 Mpa;

- Measurement temperature: 24 °C;

- Number of measurements on one sample: 3.

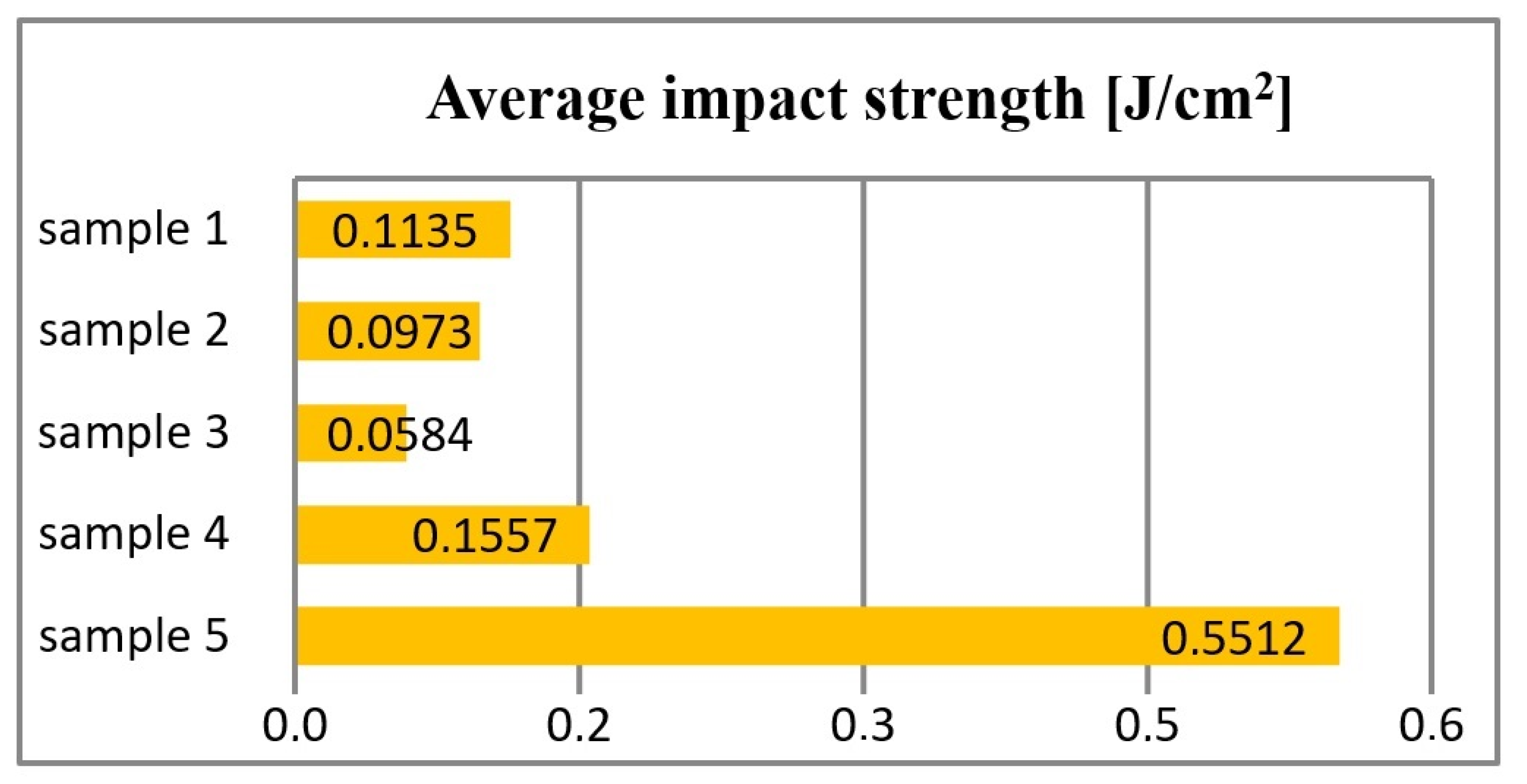

5. Impact Strength

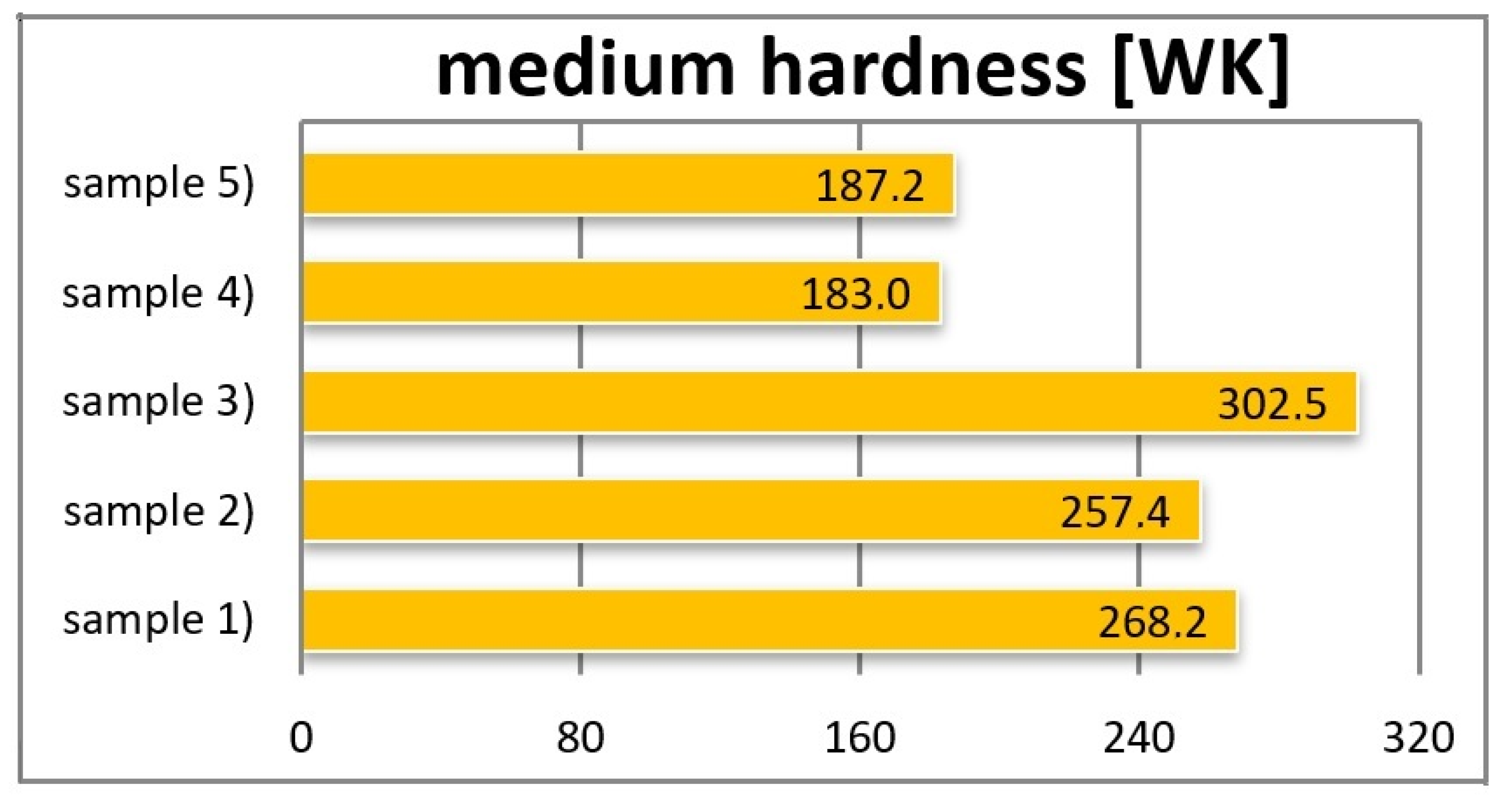

6. Hardness

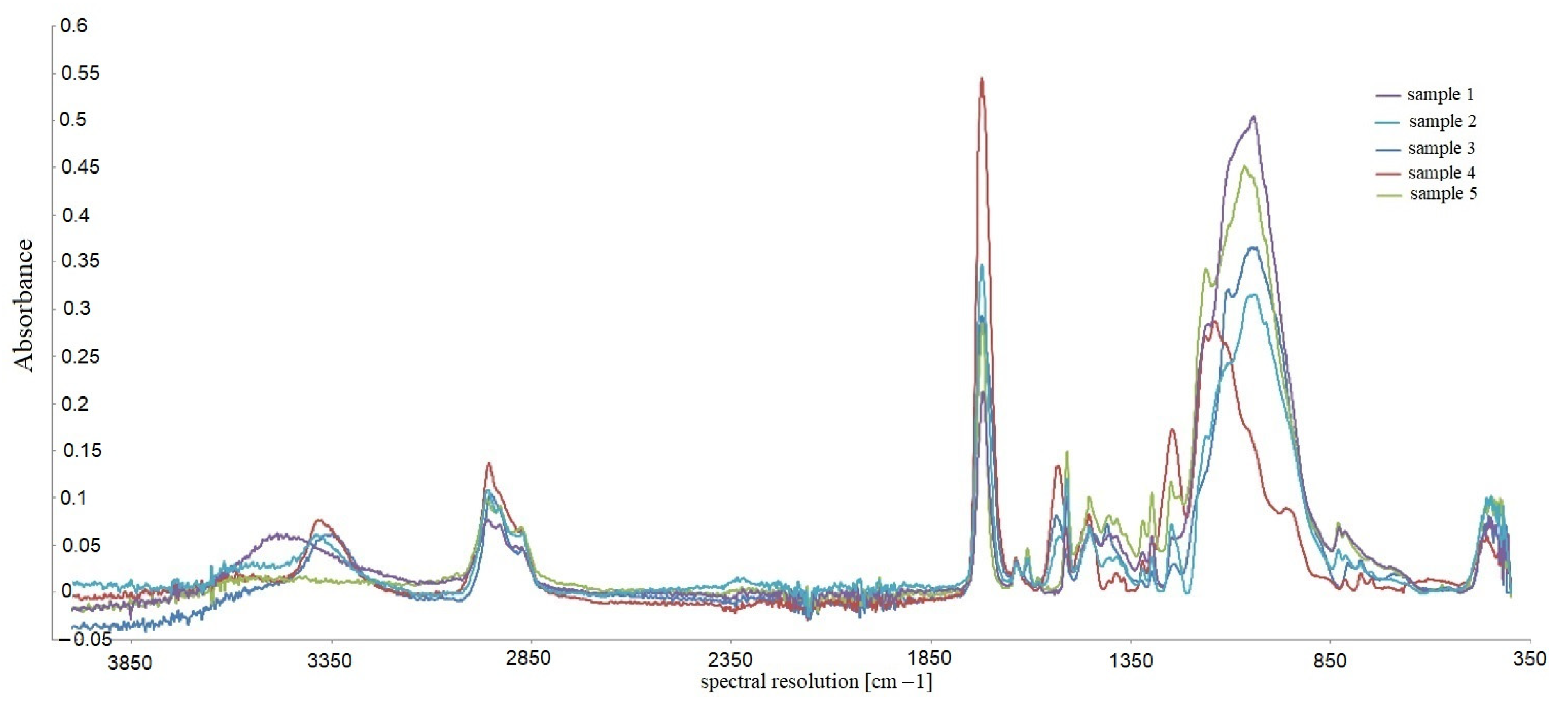

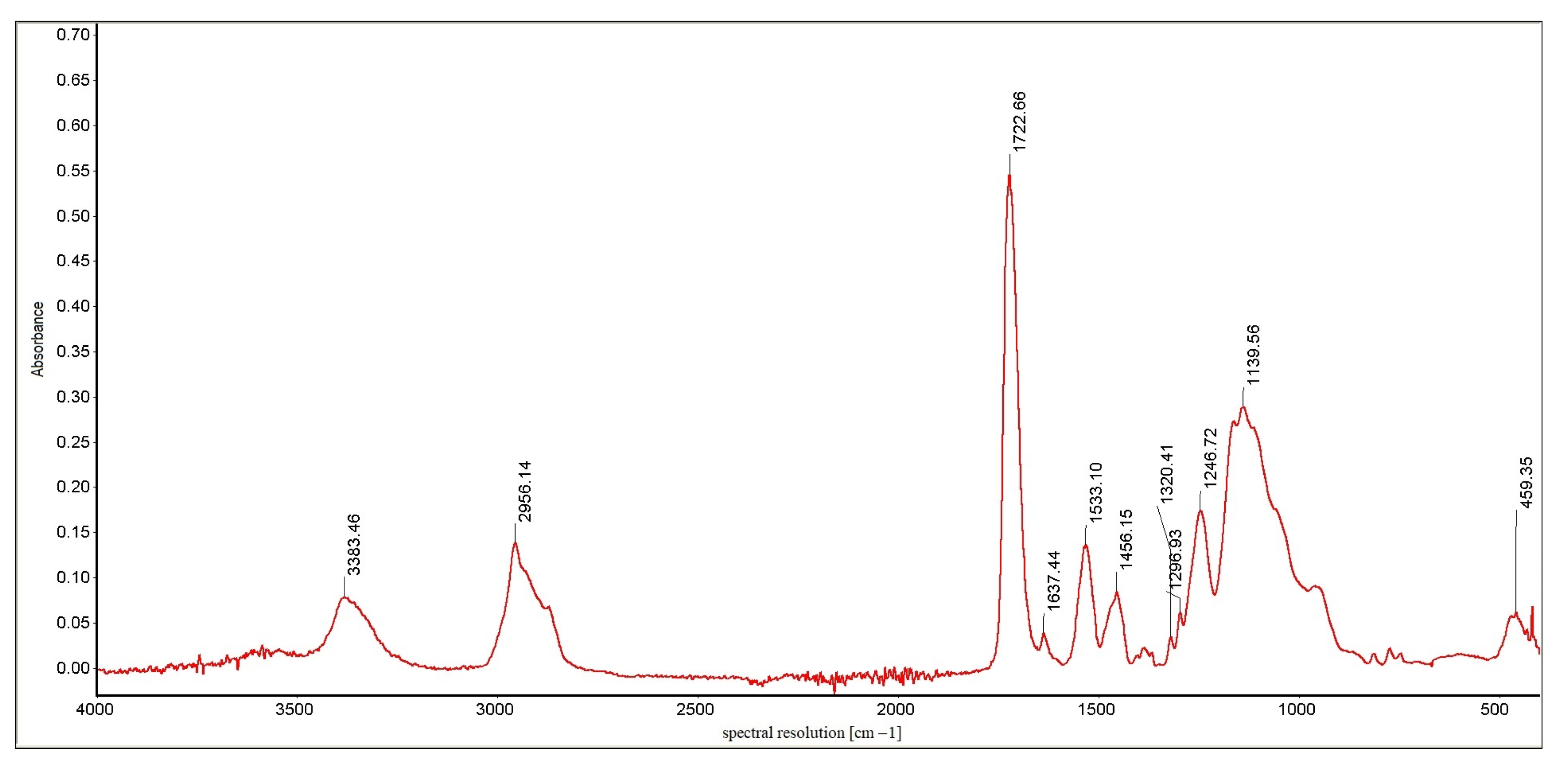

7. Chemical Analysis

8. Discussion

9. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Huang, W.; Ren, L.; Cheng, Y.; Xu, M.; Luo, W.; Zhan, D.; Sano, H.; Fu, J. Evaluation of the Color Stability, Water Sorption, and Solubility of Current Resin Composites. Materials 2022, 15, 6710. [Google Scholar] [CrossRef] [PubMed]

- Garoushi, S.; Lassila, L.; Vallittu, P.K. Impact of Fast High-Intensity versus Conventional Light-Curing Protocol on Selected Properties of Dental Composites. Materials 2021, 14, 1381. [Google Scholar] [CrossRef] [PubMed]

- Pokrowiecki, R.; Pałka, K.; Mielczarek, A. Nanomaterials in Dentistry: A Cornerstone or a Black Box? Nanomedicine 2018, 13, 639–667. [Google Scholar] [CrossRef]

- Tambrallimath, V.; Keshavamurthy, R.; Bavan, S.D.; Patil, A.Y.; Yunus Khan, T.M.; Badruddin, I.A.; Kamangar, S. Mechanical Properties of PC-ABS-Based Graphene-Reinforced Polymer Nanocomposites Fabricated by FDM Process. Polymers 2021, 13, 2951. [Google Scholar] [CrossRef]

- Ionescu, A.C.; Comba, A.; Brambilla, E.; Ilie, N.; Breschi, L.; Cadenaro, M.; Scotti, N. Influence of Curing Time on the Microbiological Behavior of Bulk-Fill Nanohybrid Resin Composites. Polymers 2021, 13, 2948. [Google Scholar] [CrossRef]

- Patil, A.Y.; Banapurmath, N.R.; Kotturshettar, B.B.; Lekha, K.; Roseline, M. Limpet Teeth-Based Polymer Nanocomposite: A Novel Alternative Biomaterial for Denture Base Application. In Fiber-Reinforced Nanocomposites: Fundamentals and Applications; Elsevier: Amsterdam, The Netherlands, 2020; pp. 477–523. ISBN 978-0-12-819904-6. [Google Scholar]

- Han, J.; Zhang, H.; Choe, H.-S.; Lin, H.; Zheng, G.; Hong, G. Abrasive Wear and Surface Roughness of Contemporary Dental Composite Resin. Dent. Mater. J. 2014, 33, 725–732. [Google Scholar] [CrossRef]

- Ismail, I.J.; Diya, B.M.; Ebrahim, F.J. Addition of Nanohybrids Particles and Fiber to Heat Cured PMMA Denture Base Materials. Int. J. Med. Res. Health Sci. 2018, 7, 20–29. [Google Scholar]

- Yilmaz, E.Ç. Effects of Thermal Change and Third-Body Media Particle on Wear Behaviour of Dental Restorative Composite Materials. Mater. Technol. 2019, 34, 645–651. [Google Scholar] [CrossRef]

- Yilmaz, E.Ç. Effect of Artificial Saliva on the Mechanical and Tribological Behavior of Nano-/Micro-Filled Biocomposite Materials for Biomedical Applications. J. Dent. Res. Rev. 2020, 7, 37. [Google Scholar] [CrossRef]

- Ilie, N.; Sarosi, C.; Rosu, M.-C.; Moldovan, M. Synthesis and Characterization of Graphene Oxide-Zirconia (GO-ZrO2) and Hydroxyapatite-Zirconia (HA-ZrO2) Nano-Fillers for Resin-Based Composites for Load-Bearing Applications. J. Dent. 2021, 105, 103557. [Google Scholar] [CrossRef]

- Frankenberger, R.; Reinelt, C.; Glatthoefer, C.; Kraemer, N. Clinical Performance and SEM Marginal Quality of Extended Posterior Resin Composite Restorations after 12 Years. Dent. Mater. 2020, 36, E217–E228. [Google Scholar] [CrossRef] [PubMed]

- Parasher, A.; Ginjupalli, K.; Somayaji, K.; Kabbinale, P. Comparative Evaluation of the Depth of Cure and Surface Roughness of Bulk-Fill Composites: An in Vitro Study. Dent. Med. Probl. 2020, 57, 39–44. [Google Scholar] [CrossRef] [PubMed]

- Di Crescenzo, A.; Bardini, L.; Sinjari, B.; Traini, T.; Marinelli, L.; Carraro, M.; Germani, R.; Di Profio, P.; Caputi, S.; Di Stefano, A.; et al. Surfactant Hydrogels for the Dispersion of Carbon-Nanotube-Based Catalysts. Chem. A Eur. J. 2013, 19, 16415–16423. [Google Scholar] [CrossRef]

- Pieniak, D.; Walczak, A.; Niewczas, A.M. Comparative Study of Wear Resistance of the Composite with Microhybrid Structure and Nanocomposite. Acta Mech. Autom. 2016, 10, 306–309. [Google Scholar] [CrossRef]

- Amaya-Pajares, S.P.; Koi, K.; Watanabe, H.; da Costa, J.B.; Ferracane, J.L. Development and Maintenance of Surface Gloss of Dental Composites after Polishing and Brushing: Review of the Literature. J. Esthet. Restor. Dent. 2022, 34, 15–41. [Google Scholar] [CrossRef]

- Keshavamurthy, R.; Tambrallimath, V.; Rajhi, A.A.; R. M, S.A.; Patil, A.Y.; Yunus Khan, T.M.; Makannavar, R. Influence of Solid Lubricant Addition on Friction and Wear Response of 3D Printed Polymer Composites. Polymers 2021, 13, 2905. [Google Scholar] [CrossRef]

- Gurgan, S.; Vural, U.K.; Miletic, I. Comparison of Mechanical and Optical Properties of a Newly Marketed Universal Composite Resin with Contemporary Universal Composite Resins: An in Vitro Study. Microsc. Res. Tech. 2022, 85, 1171–1179. [Google Scholar] [CrossRef]

- Can, D.B.; Dundar, A.; Barutcugil, C.; Ozyurt, O.K. Evaluation of Surface Characteristic and Bacterial Adhesion of Low-Shrinkage Resin Composites. Microsc. Res. Tech. 2021, 84, 1783–1793. [Google Scholar] [CrossRef]

- Barve, D.; Dave, P.; Gulve, M.; Saquib, S.; Das, G.; Sibghatullah, M.; Chaturvedi, S. Assessment of Microhardness and Color Stability of Micro-Hybrid and Nano-Filled Composite Resins. Niger. J. Clin. Pract. 2021, 24, 1499–1505. [Google Scholar] [CrossRef]

- Kemaloglu, H.; Atalayin, C.; Ergucu, Z.; Onal, B. Follow-up of Flowable Resin Composites Performed with a Universal Adhesive System in Non-Carious Cervical Lesions: A Randomized, Controlled 24-Month Clinical Trial. Am. J. Dent. 2020, 33, 39–42. [Google Scholar]

- Kaizer, M.R.; de Oliveira-Ogliari, A.; Cenci, M.S.; Opdam, N.J.M.; Moraes, R.R. Do Nanofill or Submicron Composites Show Improved Smoothness and Gloss? A Systematic Review of in Vitro Studies. Dent. Mater. 2014, 30, E41–E78. [Google Scholar] [CrossRef] [PubMed]

- Sideridou, I.D.; Vouvoudi, E.C.; Adamidou, E.A. Dynamic Mechanical Thermal Properties of the Dental Light-Cured Nanohybrid Composite Kalore, GC: Effect of Various Food/Oral Simulating Liquids. Dent. Mater. 2015, 31, 154–161. [Google Scholar] [CrossRef] [PubMed]

- Sinjari, B.; Santilli, M.; D’Addazio, G.; Rexhepi, I.; Gigante, A.; Caputi, S.; Traini, T. Influence of Dentine Pre-Treatment by Sandblasting with Aluminum Oxide in Adhesive Restorations. An In Vitro Study. Materials 2020, 13, 3026. [Google Scholar] [CrossRef]

- Endo, T.; Finger, W.J.; Kanehira, M.; Utterodt, A.; Komatsu, M. Surface Texture and Roughness of Polished Nanofill and Nanohybrid Resin Composites. Dent. Mater. J. 2010, 29, 213–223. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Panitiwat, P.; Salimee, P. Effect of Different Composite Core Materials on Fracture Resistance of Endodontically Treated Teeth Restored with FRC Posts. J. Appl. Oral Sci. 2017, 25, 203–210. [Google Scholar] [CrossRef] [PubMed]

- Yesil, Z.D.; Alapati, S.; Johnston, W.; Seghi, R.R. Evaluation of the Wear Resistance of New Nanocomposite Resin Restorative Materials. J. Prosthet. Dent. 2008, 99, 435–443. [Google Scholar] [CrossRef]

- Ritto, F.P.; da Silva, E.M.; Borges, A.L.S.; Borges, M.A.P.; Sampaio-Filho, H.R. Fabrication and Characterization of Low-Shrinkage Dental Composites Containing Montmorillonite Nanoclay. Odontology 2022, 110, 35–43. [Google Scholar] [CrossRef]

- Randolph, L.D.; Palin, W.M.; Leloup, G.; Leprince, J.G. Filler Characteristics of Modern Dental Resin Composites and Their Influence on Physico-Mechanical Properties. Dent. Mater. 2016, 32, 1586–1599. [Google Scholar] [CrossRef]

- Talu, S.; Bramowicz, M.; Kulesza, S.; Lainovic, T.; Vilotic, M.; BlaZic, L. Influence of the Artificial Saliva Storage on 3-D Surface Texture Characteristics of Contemporary Dental Nanocomposites. J. Microsc. 2016, 264, 198–206. [Google Scholar] [CrossRef]

- Thomaidis, S.; Kakaboura, A.; Mueller, W.D.; Zinelis, S. Mechanical Properties of Contemporary Composite Resins and Their Interrelations. Dent. Mater. 2013, 29, E132–E141. [Google Scholar] [CrossRef]

- Moraes, R.R.; Goncalves, L.S.; Lancellotti, A.C.; Consani, S.; Correr-Sobrinho, L.; Sinhoreti, M.A. Nanohybrid Resin Composites: Nanofiller Loaded Materials or Traditional Microhybrid Resins? Oper. Dent. 2009, 34, 551–557. [Google Scholar] [CrossRef] [PubMed]

- Iliadi, A.; Koletsi, D.; Eliades, T.; Eliades, G. Particulate Production and Composite Dust during Routine Dental Procedures. A Systematic Review with Meta-Analyses. Materials 2020, 13, 2513. [Google Scholar] [CrossRef] [PubMed]

- Suzuki, T.; Kyoizumi, H.; Finger, W.J.; Kanehira, M.; Endo, T.; Utterodt, A.; Hisamitsu, H.; Komatsu, M. Resistance of Nanofill and Nanohybrid Resin Composites to Toothbrush Abrasion with Calcium Carbonate Slurry. Dent. Mater. J. 2009, 28, 708–716. [Google Scholar] [CrossRef] [PubMed]

- Mohammadnia, M.S.; Hemmati, S.; Fasihi-Ramandi, M.; Bahari, M. Synthesis of Novel Surface-Modified Nanohydroxyapatite Containing Chitosan-Functionalized Graphene Oxide Decorated with Glycidyl Methacrylate (GO-CS-GMA) via ATRP for Biomedical Application. Polym. Bull. 2022, 79, 9833–9858. [Google Scholar] [CrossRef]

- Menezes, L.R.; da Silva, E.O.; da Silva Rocha, A.C.; Ramos Salles de Oliveira, D.C.; de Barros Campos, P.R. The Applicability of Organomodified Nanoclays as New Fillers for Mechanical Reinforcement of Dental Composites. J. Compos. Mater. 2018, 52, 963–970. [Google Scholar] [CrossRef]

- Lopes-Rocha, L.; Mendes, J.M.; Garcez, J.; Sá, A.G.; Pinho, T.; Souza, J.C.M.; Torres, O. The Effect of Different Dietary and Therapeutic Solutions on the Color Stability of Resin-Matrix Composites Used in Dentistry: An In Vitro Study. Materials 2021, 14, 6267. [Google Scholar] [CrossRef]

- Kazak, M.; Subasi, M.G.; Ozdas, D.O.; Zorlu, S.; Cilingir, A.; Gunal, S. The Effects of Nutritional Habits on Leucite-Based Ceramic Repaired with Nanohybrid Composites. J. Adhes. Sci. Technol. 2019, 33, 1705–1714. [Google Scholar] [CrossRef]

- Verma, R.; Azam, M.S.; Kumar, S.R. Performance Evaluation of Glass Ionomer and Alumina-Silica Nanoparticle Reinforced Dental Composite Using Preference Selection Index. Polym. Compos. 2022, 43, 3745–3752. [Google Scholar] [CrossRef]

- Taymour, N.; Fahmy, A.E.; Gepreel, M.A.H.; Kandil, S.; Abd El-Fattah, A. Improved Mechanical Properties and Bioactivity of Silicate Based Bioceramics Reinforced Poly(Ether-Ether-Ketone) Nanocomposites for Prosthetic Dental Implantology. Polymers 2022, 14, 1632. [Google Scholar] [CrossRef]

- Yilmaz, E.Ç. Effect of Sliding Movement Mechanism on Contact Wear Behavior of Composite Materials in Simulation of Oral Environment. J. Bio Tribo. Corros. 2019, 5, 63. [Google Scholar] [CrossRef]

- Ghazi, I.F.; Salih, S.; Oleiwi, J.K.; Mutar, M.A. Flexural Properties of New Nanocomposites for Dental Restorative That Based on (Bis-GMA) Material and Polymerized by Light Curing. J. Nanostruct. 2021, 11, 773–782. [Google Scholar] [CrossRef]

- Alkatheeri, M.S. An Updated Review on the Properties of Graphene Nano Filled Composites and Their Applications in Dentistry. Biosci. Biotechnol. Res. Commun. 2020, 13, 365–372. [Google Scholar] [CrossRef]

- Rastelli, A.N.S.; Jacomassi, D.P.; Faloni, A.P.S.; Queiroz, T.P.; Rojas, S.S.; Bernardi, M.I.B.; Bagnato, V.S.; Hernandes, A.C. The Filler Content of the Dental Composite Resins and Their Influence on Different Properties. Microsc. Res. Tech. 2012, 75, 758–765. [Google Scholar] [CrossRef] [PubMed]

- Curtis, A.R.; Palin, W.M.; Fleming, G.J.P.; Shortall, A.C.C.; Marquis, P.M. The Mechanical Properties of Nanofilled Resin-Based Composites: The Impact of Dry and Wet Cyclic Pre-Loading on Bi-Axial Flexure Strength. Dent. Mater. 2009, 25, 188–197. [Google Scholar] [CrossRef] [PubMed]

- Singh, N.K.; Alqudami, A.; Annapoorni, S.; Sharma, V.; Muralidhar, K. Enhanced Bio-Molecular Sensing Capability of LSPR, SPR-ATR Coupled Technique. In Proceedings of the Transport and Optical Properties of Nanomaterials, Allahabad, India, 5–8 January 2009; Singh, M.R., Lipson, R.H., Eds.; Amer Inst Physics: Melville, Australia, 2009; Volume 1147, pp. 331–338. [Google Scholar]

- Dhoot, G.; Auras, R.; Rubino, M.; Dolan, K.; Soto-Valdez, H. Determination of Eugenol Diffusion through LLDPE Using FTIR-ATR Flow Cell and HPLC Techniques. Polymer 2009, 50, 1470–1482. [Google Scholar] [CrossRef]

- Nikolaidis, A.K.; Koulaouzidou, E.A.; Gogos, C.; Achilias, D.S. Synthesis of Novel Dental Nanocomposite Resins by Incorporating Polymerizable, Quaternary Ammonium Silane-Modified Silica Nanoparticles. Polymers 2021, 13, 1682. [Google Scholar] [CrossRef]

- Montoya, C.; Jain, A.; Jose Londono, J.; Correa, S.; Lelkes, P.; Melo, M.A.; Orrego, S. Multifunctional Dental Composite with Piezoelectric Nanofillers for Combined Antibacterial and Mineralization Effects. ACS Appl. Mater. Interfaces 2021, 13, 43868–43879. [Google Scholar] [CrossRef]

- Krishnakumar, S.; Senthilvelan, T. Polymer composites in dentistry and orthopedic applications—A review. Mater. Today Proc. 2021, 46, 9707–9713. [Google Scholar] [CrossRef]

- Jayakumar, S.; Mani, V.; Saravanan, T.; Rajamanickam, K.; Prabhu, A.D.; Philip, J. Multifiller Nanocomposites Containing Gadolinium Oxide and Bismuth Nanoparticles with Enhanced X-Ray Attenuation Property. J. Appl. Polym. Sci. 2021, 138, e51252. [Google Scholar] [CrossRef]

- Caracostea, A.; Morar, N.; Florea, A.; Soanca, A.; Badea, M.E. Two-Body Wear Simulation Influence on Some Direct and Indirect Dental Resin Biocomposites—A Qualitative Analysis. Acta Bioeng. Biomech. 2016, 18, 61–72. [Google Scholar] [CrossRef]

- Gonulol, N.; Ozer, S.; Tunc, E.S. Water Sorption, Solubility, and Color Stability of Giomer Restoratives. J. Esthet. Restor. Dent. 2015, 27, 300–306. [Google Scholar] [CrossRef] [PubMed]

- Raszewski, Z.; Nowakowska-Toporowska, A.; Nowakowska, D.; Wieckiewicz, W. Update on Acrylic Resins Used in Dentistry. Mini-Rev. Med. Chem. 2021, 21, 2130–2137. [Google Scholar] [CrossRef] [PubMed]

- Elmergawy, F.H.; Nassif, M.S.; El-Borady, O.M.; Mabrouk, M.; El-Korashy, D.I. Physical and Mechanical Evaluation of Dental Resin Composite after Modification with Two Different Types of Montmorillonite Nanoclay. J. Dent. 2021, 112, 103731. [Google Scholar] [CrossRef] [PubMed]

- Bindu, M.G.; Satapathy, B.K.; Jaggi, H.S.; Ray, A.R. Size-Scale Effects of Silica on Bis-GMA/TEGDMA Based Nanohybrid Dental Restorative Composites. Compos. Pt. B-Eng. 2013, 53, 92–102. [Google Scholar] [CrossRef]

- Karimzadeh, A.; Ayatollahi, M.R.; Nikkhooyifar, M.; Bushroa, A.R. Nanomechanical Properties and Wear Resistance of Dental Restorative Materials. Struct. Eng. Mech. 2017, 64, 819–826. [Google Scholar] [CrossRef]

| NAME | RESIN | FILLERS |

|---|---|---|

| Charisma Diamond (1) | -TCD-Di-HEA -UDMA 36% | glass bar- aluminum- fluorine (0.005 μm–0.20 μm) 64% |

| Gradia Direct Lo Flo (2) | UDMA 37% | -fluoro-alumino-silicon glass -nano-silicon filler -HDR filler 63% |

| Charisma Flow (3) | -EBADMA -TEGDMA 62% | -silicon school -Ba-Al-F -SiO2 38% |

| Charisma (4) paste | Bis-GMA 36% | -boron-aluminum-fluorine glass (0.02–0.2 μm) -silicon dioxide (0.02–0.07 μm) 64% |

| Charisma Opal Flow (5) | -UDMA -EBADMA 39% | -silicon glass nanofiller: Ba-Al, YbF3, SiO2 (0.02 μm to 5 μm) 41% |

| Composite Material | Hardness—Ball Method [MPa] | Hardness—Vickers Method [MPa] |

|---|---|---|

| Sample (1) | 49.8 | 417.2 |

| Sample (2) | 50.1 | 431.4 |

| Sample (3) | 58.4 | 560.2 |

| Sample (4) | 61.5 | 726.7 |

| Sample (5) | 34.1 | 411.7 |

| Composite Material | Wed Hardness [WK] |

|---|---|

| Sample 1 | 268.2 |

| Sample 2 | 257.4 |

| Sample 3 | 302.5 |

| Sample 4 | 183.0 |

| Sample 5 | 187.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zubrzycki, J.; Klepka, T.; Marchewka, M.; Zubrzycki, R. Tests of Dental Properties of Composite Materials Containing Nanohybrid Filler. Materials 2023, 16, 348. https://doi.org/10.3390/ma16010348

Zubrzycki J, Klepka T, Marchewka M, Zubrzycki R. Tests of Dental Properties of Composite Materials Containing Nanohybrid Filler. Materials. 2023; 16(1):348. https://doi.org/10.3390/ma16010348

Chicago/Turabian StyleZubrzycki, Jarosław, Tomasz Klepka, Magdalena Marchewka, and Robert Zubrzycki. 2023. "Tests of Dental Properties of Composite Materials Containing Nanohybrid Filler" Materials 16, no. 1: 348. https://doi.org/10.3390/ma16010348

APA StyleZubrzycki, J., Klepka, T., Marchewka, M., & Zubrzycki, R. (2023). Tests of Dental Properties of Composite Materials Containing Nanohybrid Filler. Materials, 16(1), 348. https://doi.org/10.3390/ma16010348