Enhanced High−Temperature Wear Performance of H13 Steel through TiC Incorporation by Laser Metal Deposition

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

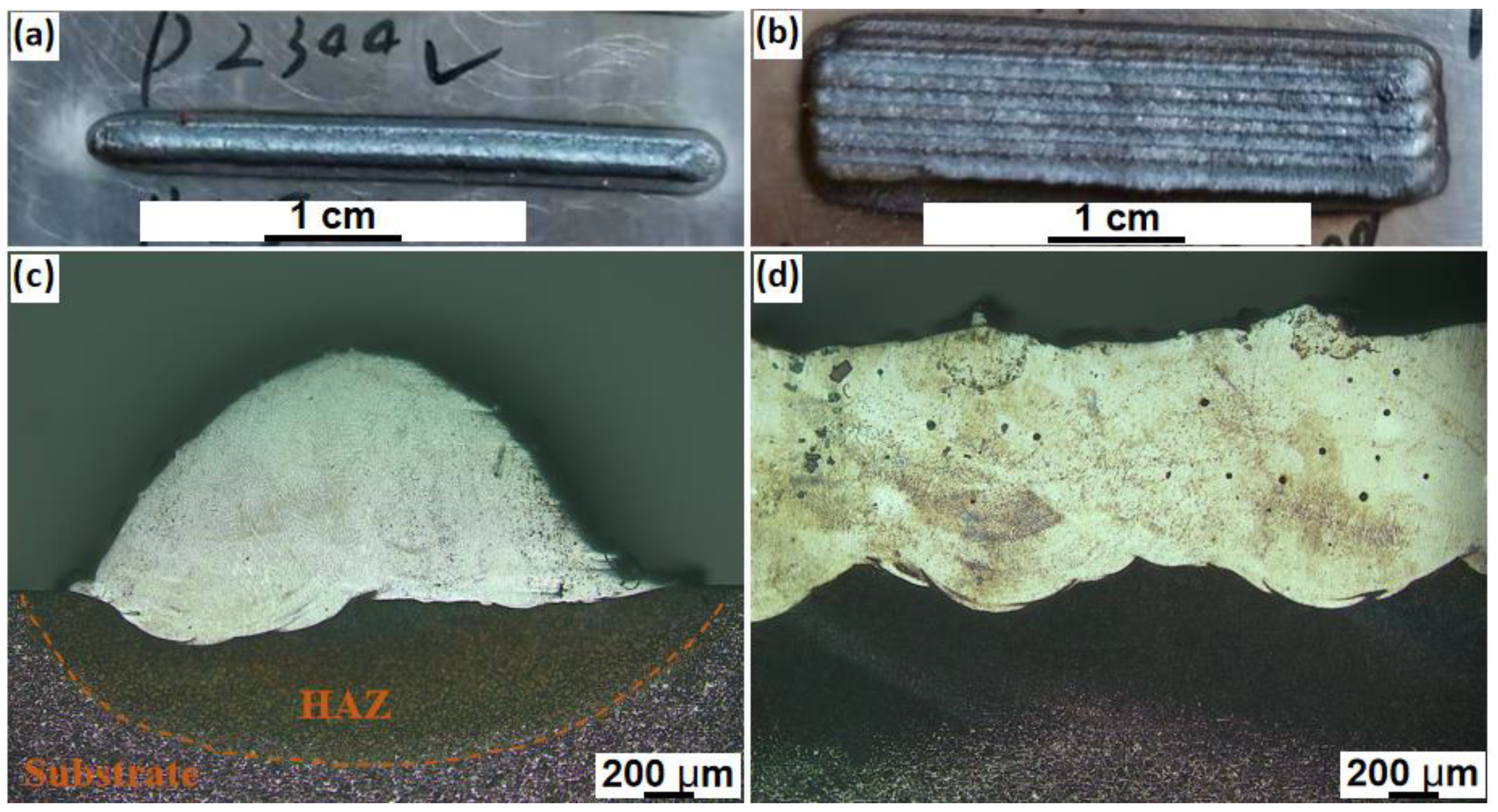

2.2. LMD Process

2.3. Microstructural Characterization

2.4. High−Temperature Abrasive Wear Test

3. Results and Discussion

3.1. Phase Identification

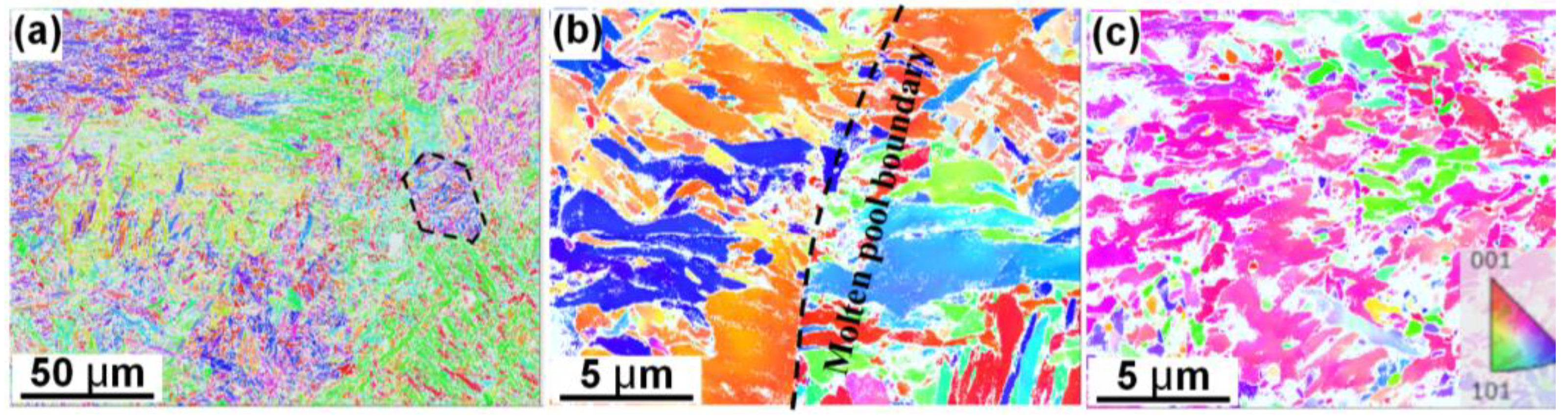

3.2. Microstructures

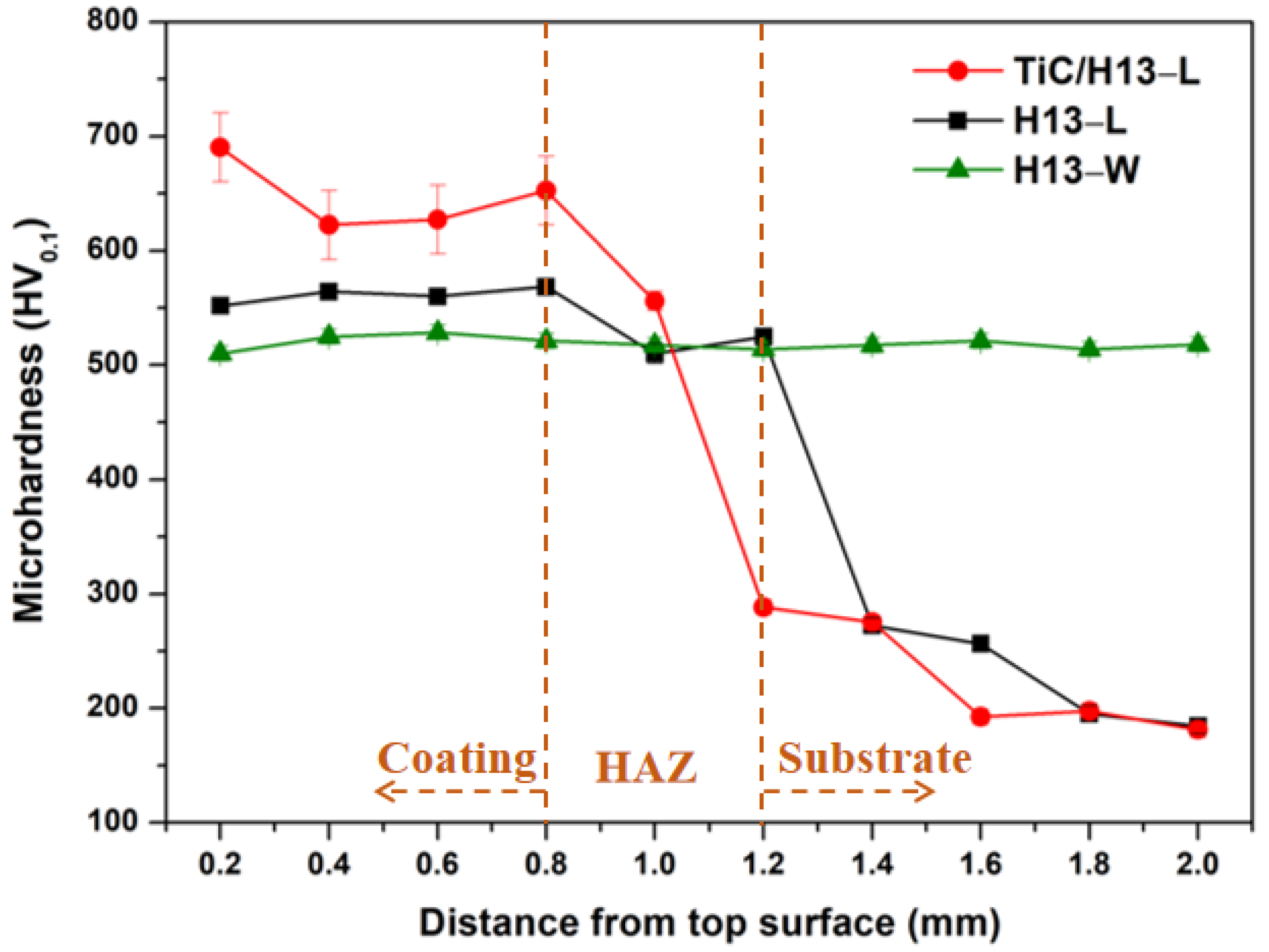

3.3. Microhardness

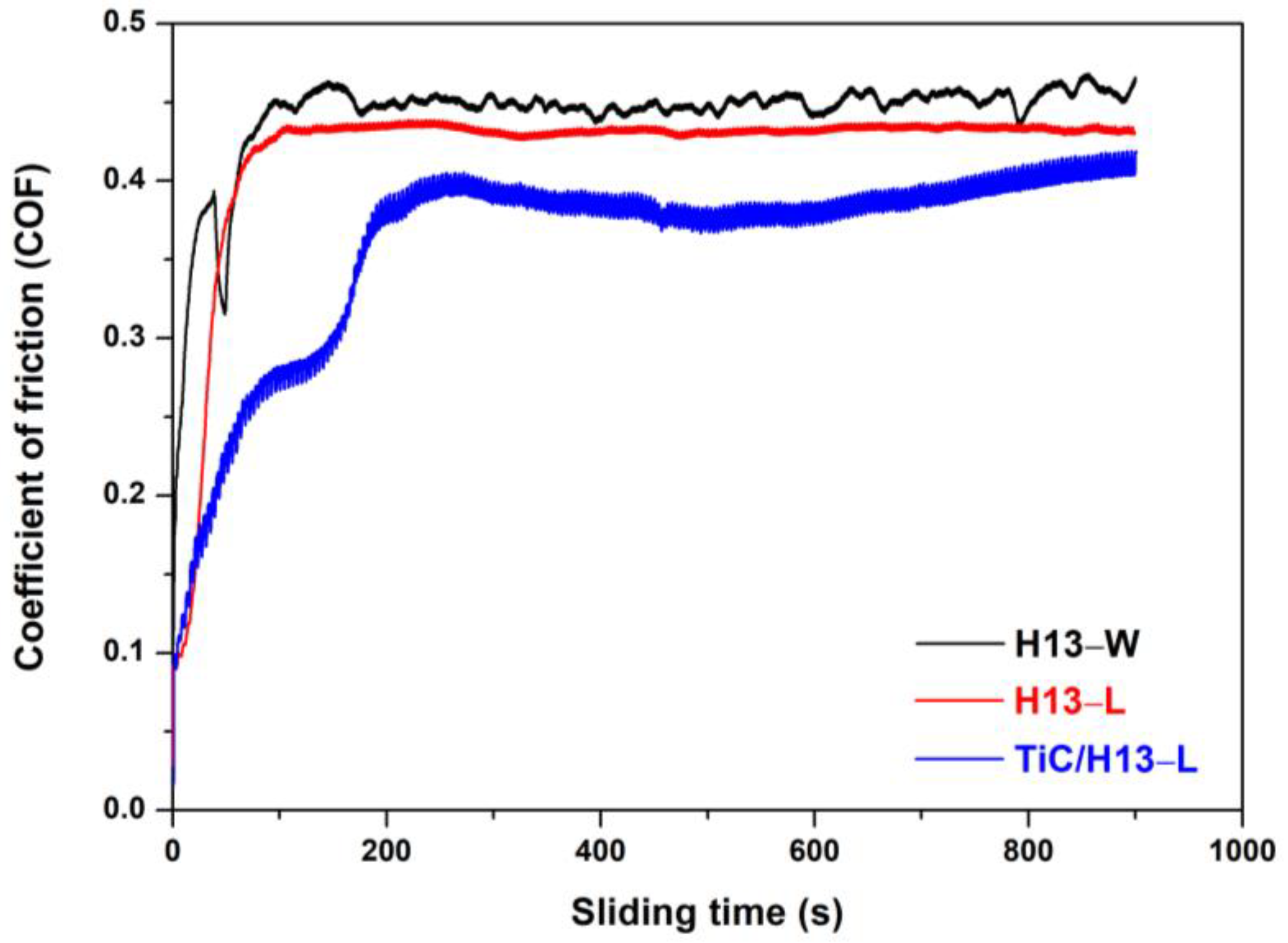

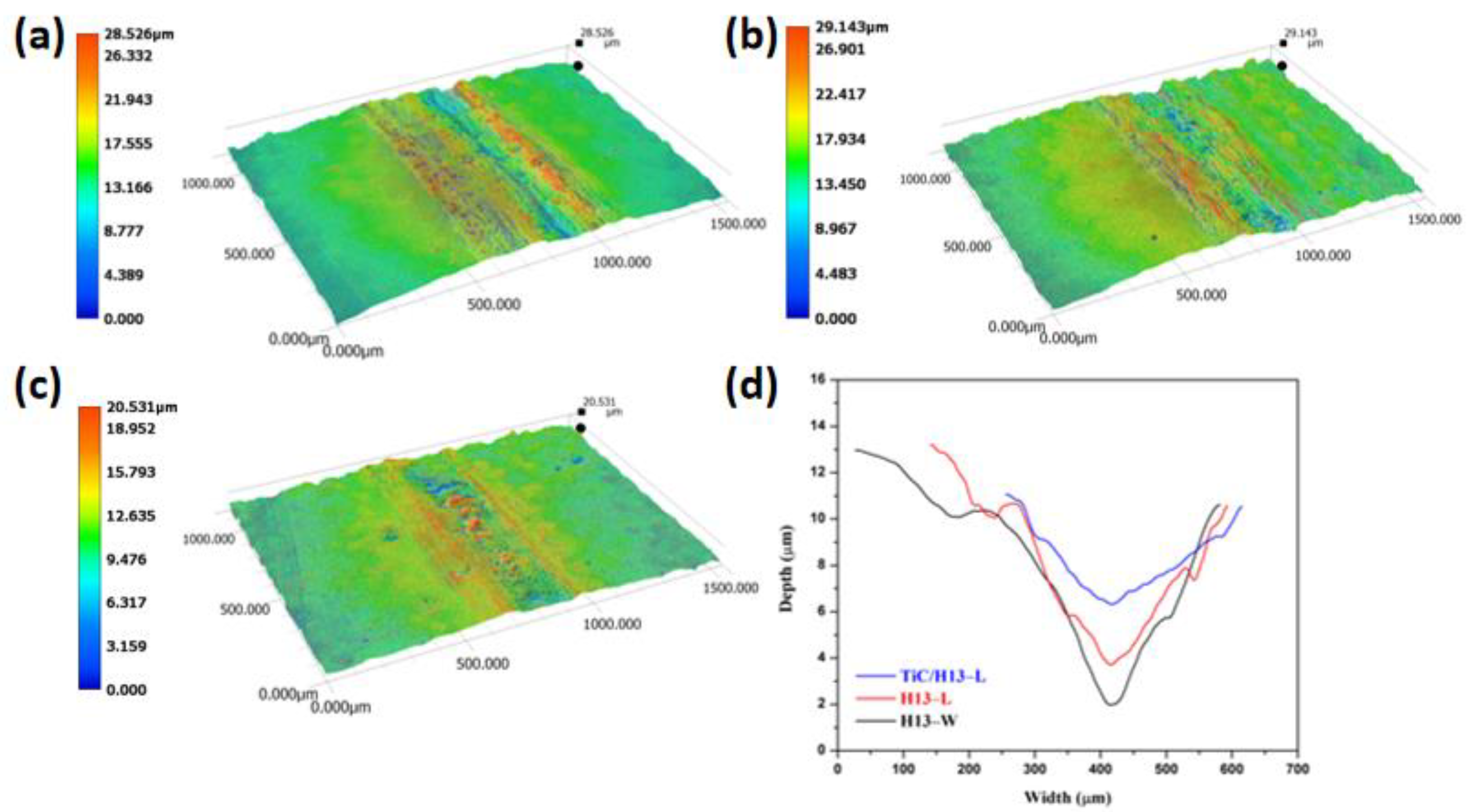

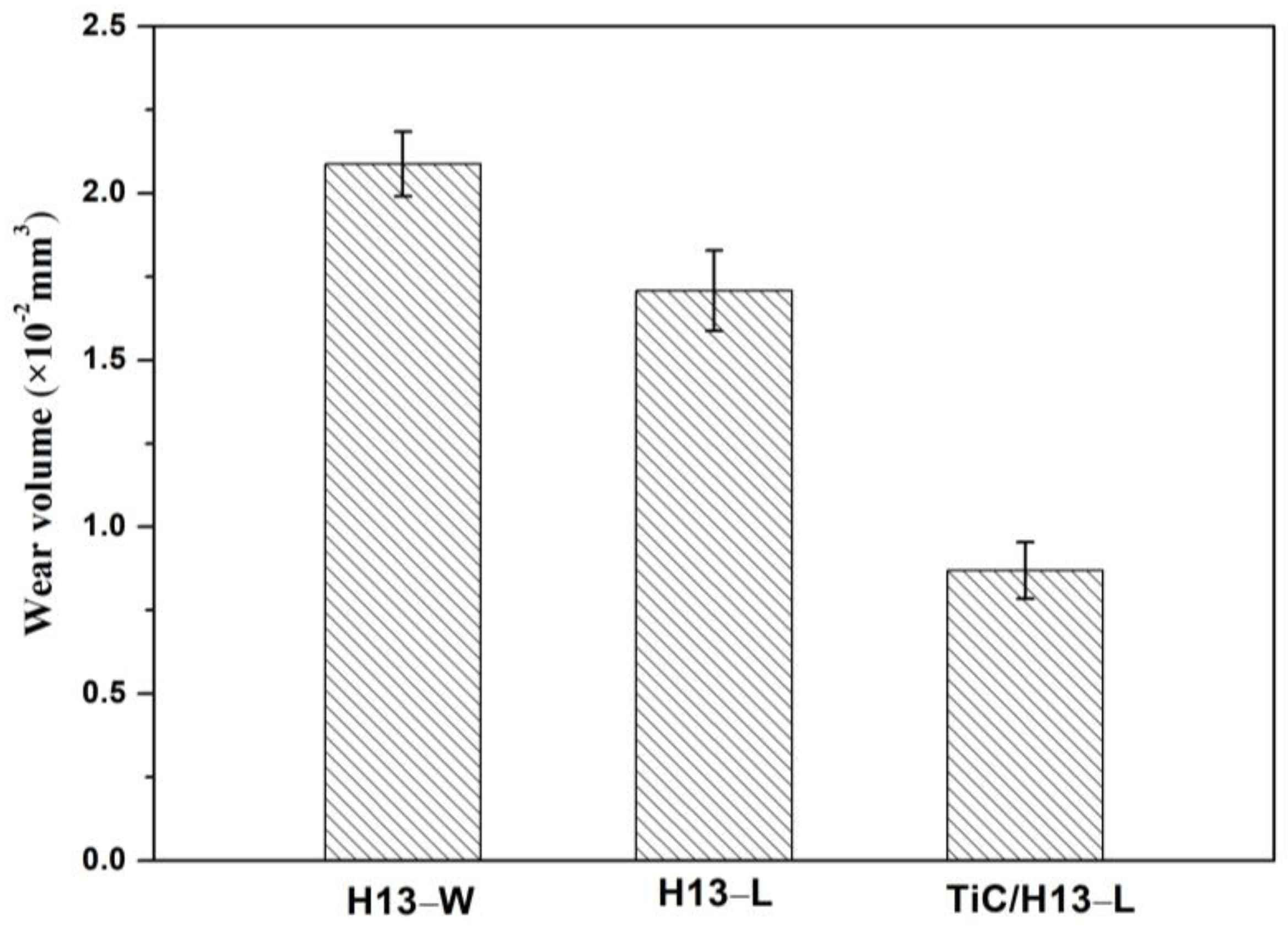

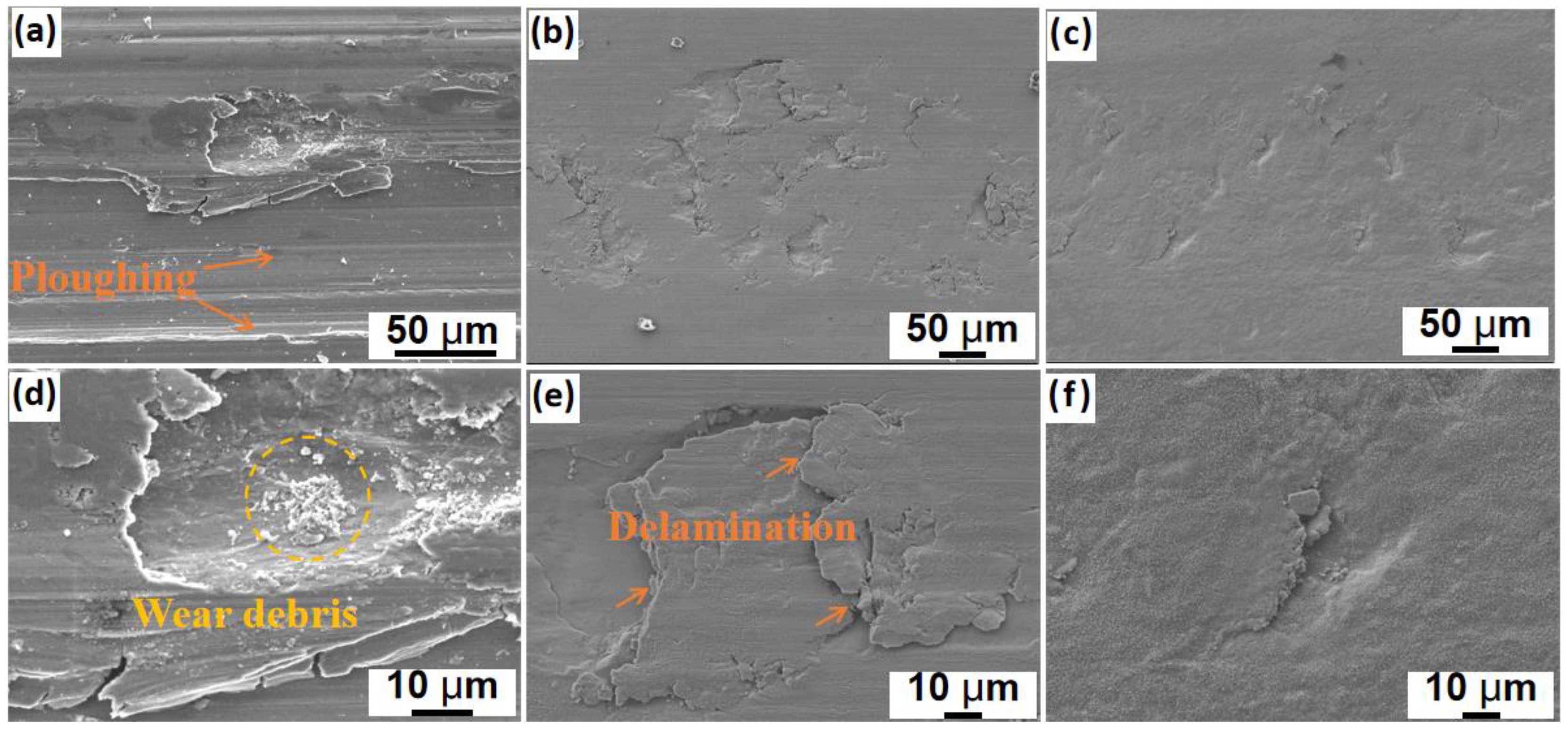

3.4. High−Temperature Wear Performance

4. Conclusions

- (1)

- The LMD-prepared TiC/H13 composite coating possessed refined martensite microstructures compared to the H13−W and H13−L samples, which could be a result of the high-temperature gradient, high undercooling, as well as the introduced TiC particles. The TiC ceramic particles demonstrated a finer size, uniform distribution, and good bonding with the H13 steel matrix.

- (2)

- The TiC/H13 composite coating exhibited a superior microhardness and high-temperature wear performance than its LMD- and wrought−processed H13 counterparts. The microhardness value for the composite TiC/H13 coating increased by nearly 30% more than the H13-W sample, e.g., from 508 HV0.1 to 648 HV0.1, while its wear track depth/width (from 11 μm/556 μm to 4.8 μm/360 μm) and wear volume (from 2.08 × 10−2 mm3 to 0.87 × 10−2 mm3) decreased significantly compared to its wrought counterpart.

- (3)

- Compared with the wrought H13 sample, the high microhardness and the high thermal stability of the LMD−prepared TiC/H13 composite coating promoted the dominant wear mechanism transformation from ploughing in the H13−W sample to mild delamination in the TiC/H13−L sample.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Roberts, G.; Krauss, G.; Kennedy, R. Tool Steels, 5th ed.; ASM International: Almere, The Netherlands, 1998. [Google Scholar]

- Lee, J.H.; Jang, J.-H.; Joo, B.-D.; Yim, H.-S.; Moon, Y.-H. Application of direct laser metal tooling for AISI H13 tool steel. Trans. Nonferrous Metals Soc. China 2009, 19, 284–287. [Google Scholar] [CrossRef]

- Zhu, J.; Zhang, Z.H.; Xie, J.X. Improving strength and ductility of H13 die steel by pre-tempering treatment and its mechanism. Mater. Sci. Eng. A 2019, 752, 101–114. [Google Scholar] [CrossRef]

- Jhavar, S.; Paul, C.P.; Jain, N.K. Causes of Failure and Repairing Options for Dies and Molds: A Review. Eng. Fail. Anal. 2013, 34, 519–535. [Google Scholar] [CrossRef]

- Wang, S.Q.; Chen, K.M.; Cui, X.H.; Jiang, Q.C.; Hong, B. Effect of Alloying Elements on Thermal Wear of Cast Hot-Forging Die Steels. J. Iron Steel Res. Int. 2006, 13, 53–59. [Google Scholar] [CrossRef]

- Salas, O.; Kearns, K.; Carrera, S.; Moore, J.J. Tribological behavior of candidate coatings for Al die casting dies. Surf. Coat. Technol. 2003, 172, 117–127. [Google Scholar] [CrossRef]

- Forati Rad, H.; Amadeh, A.; Moradi, H. Wear assessment of plasma nitrided AISI H11 steel. Mater. Des. 2011, 32, 2635–2643. [Google Scholar] [CrossRef]

- Telasang, G.; Dutta Majumdar, J.; Padmanabham, G.; Tak, M.; Manna, I. Effect of laser parameters on microstructure and hardness of laser clad and tempered AISI H13 tool steel. Surf. Coat. Tech. 2014, 258, 1108–1118. [Google Scholar] [CrossRef]

- Telasang, G.; Dutta Majumdar, J.; Padmanabham, G.; Tak, M.; Manna, I. Structure–property correlation in laser surface treated AISI H13 tool steel for improved mechanical properties. Mater. Sci. Eng. A 2014, 599, 255–267. [Google Scholar] [CrossRef]

- Braga, V.; Siqueira, R.H.M.; Atilio, I.; Mansur, R.; Vieira, D. Microstructural and mechanical aspects of laser metal deposited H13 powder for die repair. Mater. Today. Commun. 2021, 29, 102945. [Google Scholar] [CrossRef]

- Bailey, N.S.; Katinas, C.; Shin, Y.C. Laser direct deposition of AISI H13 tool steel powder with numerical modeling of solid phase transformation, hardness, and residual stresses. J. Mater. Porcess. Tech. 2017, 247, 223–233. [Google Scholar] [CrossRef]

- Zhao, X.; Lv, Y.H.; Dong, S.Y.; Yan, S.X.; He, P. The effect of thermal cycling on direct laser-deposited gradient H13 tool steel: Microstructure evolution, nanoprecipitation behaviour, and mechanical properties. Mater. Today Commun. 2020, 25, 101390. [Google Scholar] [CrossRef]

- Gong, G.H.; Ye, J.J.; Chi, Y.M.; Yu, H.J.; Chen, C.Z. Research status of laser additive manufacturing for metal: A review. J. Mater. Porcess. Tech. 2021, 15, 855–884. [Google Scholar] [CrossRef]

- Zhou, M.Y.; Ren, L.B.; Fan, L.L.; Quan, G.F.; Gupta, M. Progress in research on hybrid metal matrix composites. J. Alloy. Compd. 2020, 838, 155274. [Google Scholar] [CrossRef]

- Fang, Y.J.; Kim, M.-K.; Zhang, Y.L.; Duan, Z.Y.; Suhr, J. Particulate-reinforced iron-based metal matrix composites fabricated by selective laser melting: A systematic review. J. Manuf. Process. 2022, 74, 592–639. [Google Scholar] [CrossRef]

- Zhai, W.G.; Zhu, Z.G.; Zhou, W.; Nai, S.M.L.; Wei, J. Selective laser melting of dispersed TiC particles strengthened 316L stainless steel. Compos. Part B Eng. 2020, 199, 108291. [Google Scholar] [CrossRef]

- Liu, D.J.; Li, L.Q.; Li, F.Q.; Chen, Y.B. WCp/Fe metal matrix composites produced by laser melt injection. Surf. Coat. Tech. 2008, 202, 1771–1777. [Google Scholar] [CrossRef]

- Mandal, V.; Hussain, M.; Kumar, V.; Das, A.K.; Singh, N.K. Development of reinforced TiN-SS316 metal matrix composite (MMC) using direct Metal laser sintering (DMLS) and its characterization. Mater. Today Proc. 2017, 4, 9982–9986. [Google Scholar] [CrossRef]

- Li, J.; Zong, B.Y.; Wang, Y.M.; Zhuang, W.B. Experiment and modeling of mechanical properties on iron matrix composites reinforced by different types of ceramic particles. Mater. Sci. Eng. A 2010, 527, 7545–7551. [Google Scholar] [CrossRef]

- Ramesh, C.S.; Srinivas, C.K.; Channabasappa, B.H. Abrasive wear behaviour of laser sintered iron–SiC composites. Wear 2009, 267, 1777–1783. [Google Scholar] [CrossRef]

- Das, K.; Bandyopadhyay, T.K.; Das, S. A Review on the various synthesis routes of TiC reinforced ferrous based composites. J. Mater. Sci. 2002, 37, 3881–3892. [Google Scholar] [CrossRef]

- Chen, H.; Lu, Y.Y.; Sun, Y.S.; Wei, Y.F.; Liu, D.J. Coarse TiC particles reinforced H13 steel matrix composites produced by laser cladding. Surf. Coat. Tech. 2020, 395, 125867. [Google Scholar] [CrossRef]

- Meng, C.; Cao, R.; Li, J.Y.; Geng, F.Y.; Zhang, Y.W. Mechanical properties of TiC-reinforced H13 steel by bionic laser treatment. Opt. Laser Technol. 2021, 136, 106815. [Google Scholar] [CrossRef]

- Dadoo, A.; Boutorabi, S.M.A. Correlation between pulsed laser parameters and MC carbide morphology in H13 tool steel/TiC composite coating. Opt. Laser Technol. 2020, 127, 106120. [Google Scholar] [CrossRef]

- Jiang, W.H.; Kovacevic, R. Laser deposited TiC/H13 tool steel composite coatings and their erosion resistance. J. Mater. Process. Tech. 2007, 186, 331–338. [Google Scholar] [CrossRef]

- Song, B.; Dong, S.J.; Coddet, C. Rapid in situ fabrication of Fe/SiC bulk nanocomposites by selective laser melting directly from a mixed powder of microsized Fe and SiC. Scr. Mater. 2014, 75, 90–93. [Google Scholar] [CrossRef]

- Ungár, T.; Dragomir, I.; Révész, Á.; Borbély, A. The contrast factors of dislocations in cubic crystals: The dislocation model of strain anisotropy in practice. J. Appl. Crystallogr. 1999, 32, 992–1002. [Google Scholar] [CrossRef] [Green Version]

- Li, X.P.; Ji, G.; Chen, Z.; Addad, A.; Kruth, J.P. Selective laser melting of nano-TiB2 decorated AlSi10Mg alloy with high fracture strength and ductility. Acta Mater. 2017, 129, 183–193. [Google Scholar] [CrossRef]

- Shi, Y.J.; Wu, X.C.; Li, J.W.; Min, N. Tempering stability of Fe–Cr–Mo–W–V hot forging die steels. Int. J. Min. Met. Mater. 2017, 24, 1145. [Google Scholar] [CrossRef]

- Ding, H.N.; Liu, T.; Wei, J.B.; Luo, R.; Cheng, X.N. Microstructure and tempering softening mechanism of modified H13 steel with the addition of Tungsten, Molybdenum, and lowering of Chromium. Mater. Des. 2022, 224, 111317. [Google Scholar] [CrossRef]

- Dai, D.H.; Gu, D.D.; Ge, Q.; Li, Y.Z.; Shi, X.Y. Mesoscopic study of thermal behavior, fluid dynamics and surface morphology during selective laser melting of Ti-based composites. Comp. Mater. Sci. 2020, 177, 109598. [Google Scholar] [CrossRef]

- Maurya, P.; Kota, N.; Gibmeier, J.; Wanner, A.; Roy, S. Review on study of internal load transfer in metal matrix composites using diffraction techniques. Mater. Sci. Eng. A 2022, 840, 142973. [Google Scholar] [CrossRef]

- Rao, T.B.; Ponugoti, G.R. Characterization, Prediction, and Optimization of Dry Sliding Wear Behaviour of Al6061/WC Composites. Trans. Indian Inst. Met. 2021, 74, 159–178. [Google Scholar] [CrossRef]

- Lee, Y.-H.; Ko, S.; Park, H.; Lee, S.-K.; Cho, S. Effect of TiC particle size on high temperature oxidation behavior of TiC reinforced stainless steel. Appl. Surf. Sci. 2019, 480, 951–955. [Google Scholar] [CrossRef]

| Elements (wt%) | Cr | Mo | Mn | C | Si | V | P | S |

|---|---|---|---|---|---|---|---|---|

| Wrought H13 | 4.98 | 1.35 | 0.39 | 0.36 | 0.86 | 0.78 | 0.021 | 0.003 |

| H13 powder | 5.44 | 1.29 | 0.38 | 0.34 | 0.92 | 1.03 | 0.008 | 0.022 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, C.; Chen, Z.; Yan, Y.; Zhuo, Y.; Wang, C.; Jia, Q. Enhanced High−Temperature Wear Performance of H13 Steel through TiC Incorporation by Laser Metal Deposition. Materials 2023, 16, 99. https://doi.org/10.3390/ma16010099

Lu C, Chen Z, Yan Y, Zhuo Y, Wang C, Jia Q. Enhanced High−Temperature Wear Performance of H13 Steel through TiC Incorporation by Laser Metal Deposition. Materials. 2023; 16(1):99. https://doi.org/10.3390/ma16010099

Chicago/Turabian StyleLu, Chengqi, Zhenyu Chen, Yuqing Yan, Yuhao Zhuo, Chuanyang Wang, and Qingbo Jia. 2023. "Enhanced High−Temperature Wear Performance of H13 Steel through TiC Incorporation by Laser Metal Deposition" Materials 16, no. 1: 99. https://doi.org/10.3390/ma16010099

APA StyleLu, C., Chen, Z., Yan, Y., Zhuo, Y., Wang, C., & Jia, Q. (2023). Enhanced High−Temperature Wear Performance of H13 Steel through TiC Incorporation by Laser Metal Deposition. Materials, 16(1), 99. https://doi.org/10.3390/ma16010099