In Search of a Double Perovskite in the Phase Triangle of Bromides CsBr-CuBr-InBr3

Abstract

:1. Introduction

2. Experimental

2.1. Methods of Analysis

2.2. Synthesis of Compounds in CsBr-CuBr-InBr3 Triangle

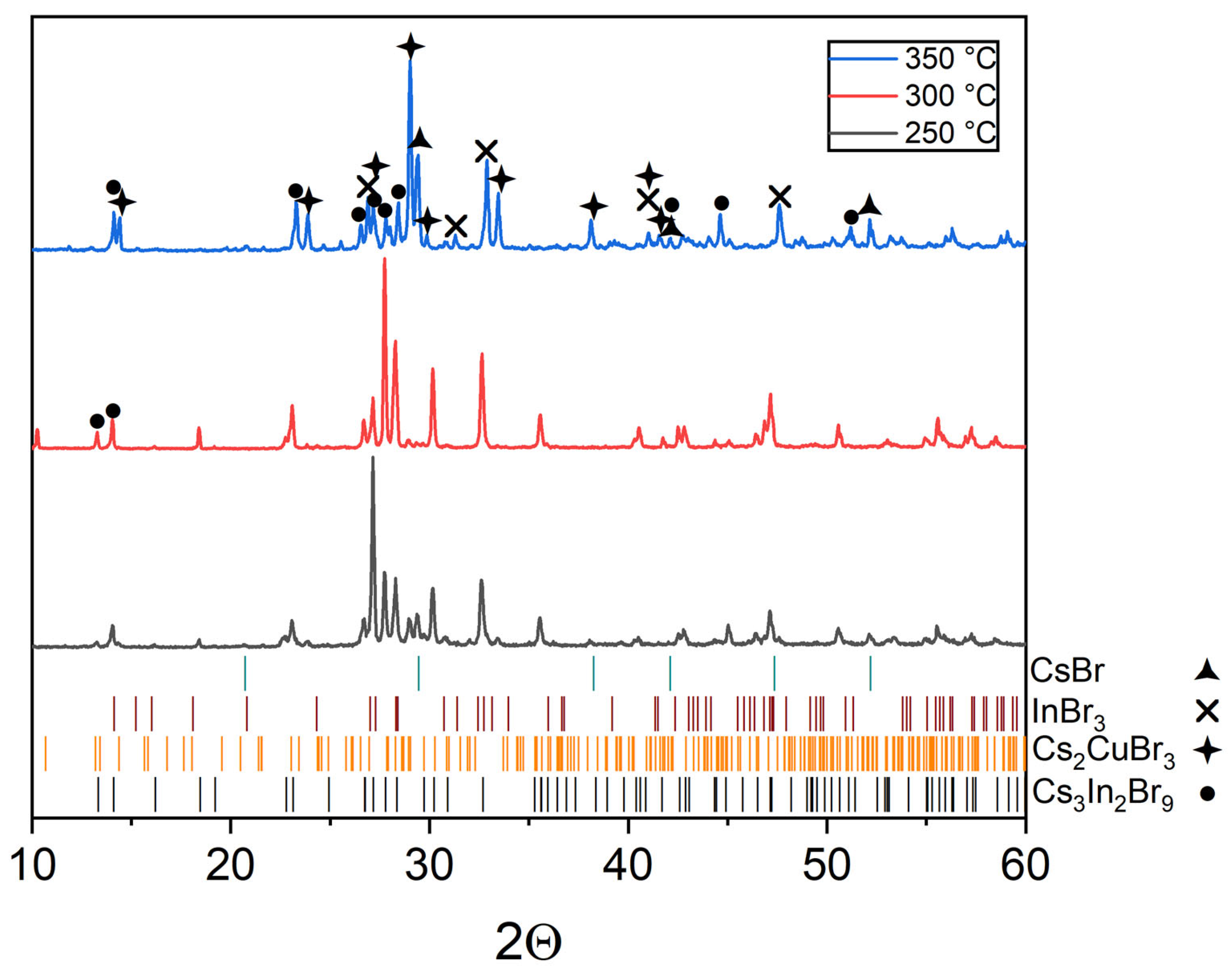

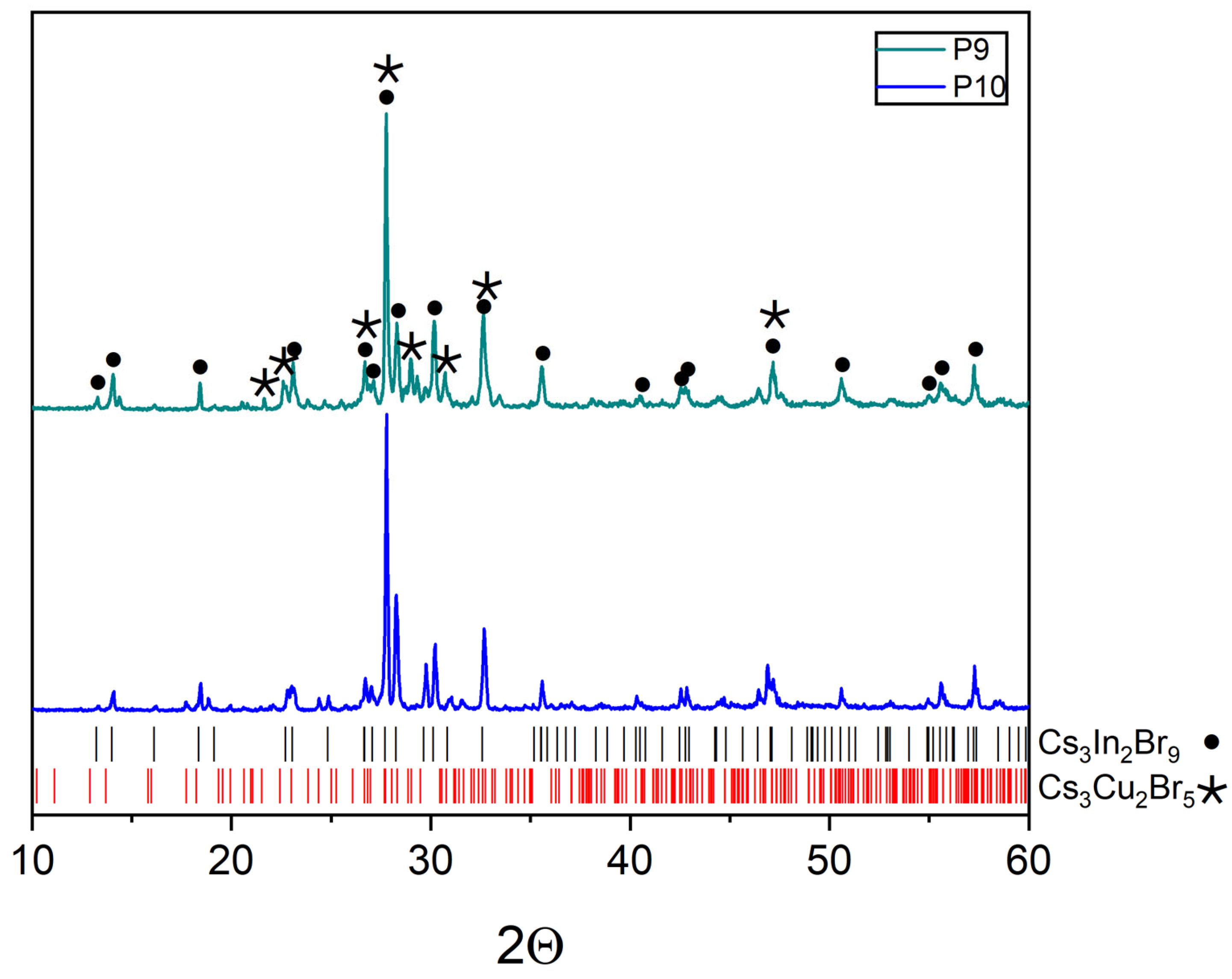

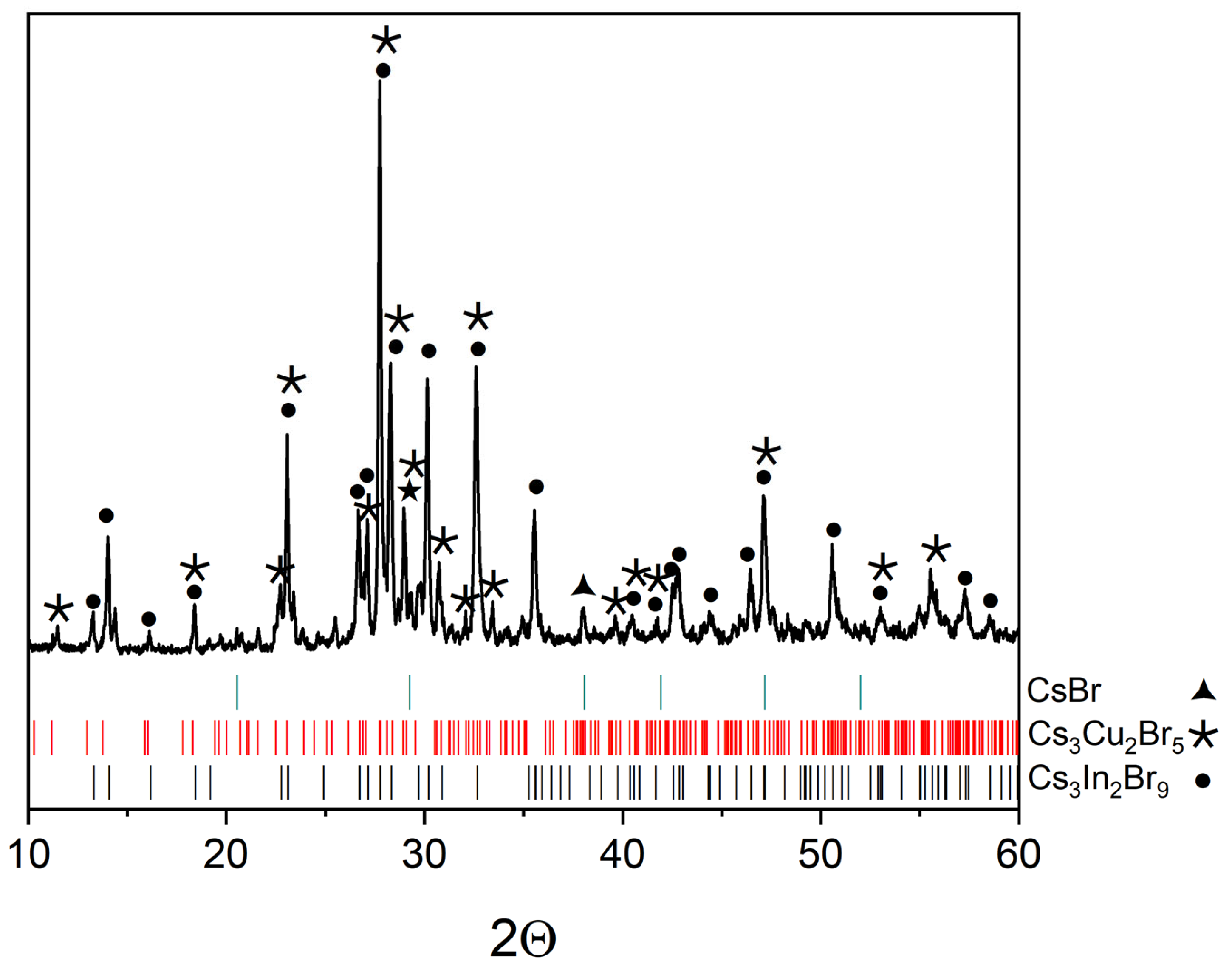

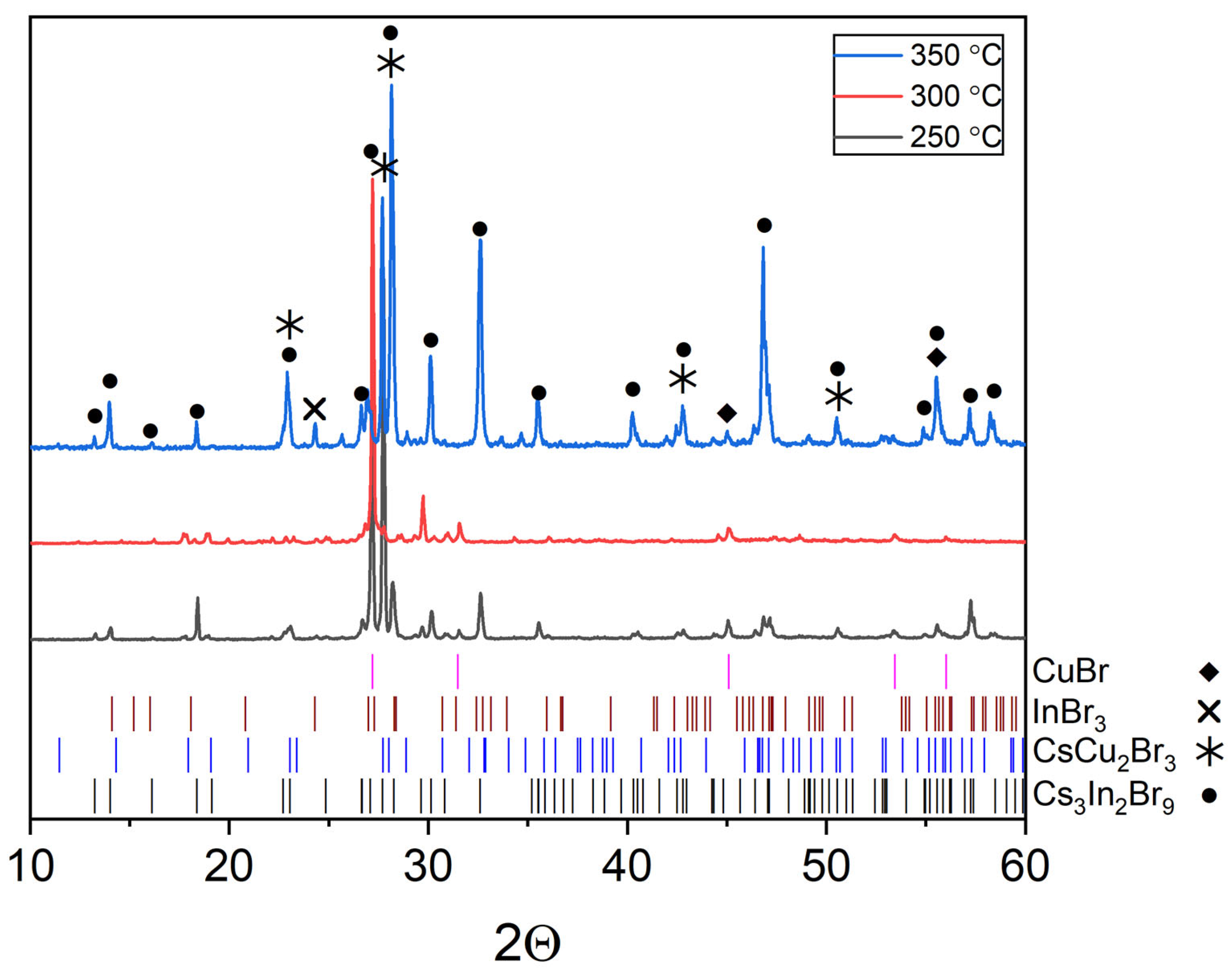

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sirotkin, O.S.; Sirotkin, R.O.; Shibaev, P.B. Effect of the character of homo- and heteronuclear chemical bond on the intermolecular interaction energy and properties of halogens and hydrogen halides. Russ. J. Inorg. Chem. 2011, 56, 1104–1108. [Google Scholar] [CrossRef]

- Umedov, S.T.; Grigorieva, A.V.; Lepnev, S.L.; Knotko, A.V.; Koji, N.; Shinichi, O.; Shevelkov, A.V. Indium Doping of Lead-Free Perovskite Cs2SnI6. Front. Chem. 2020, 8, 564. [Google Scholar] [CrossRef] [PubMed]

- Kojima, A.; Teshima, K.; Miyasaka, T.; Shirai, Y. Novel photoelectrochemical cell with mesoscopic electrodes sensitized by lead-halide compounds (2). In Proceedings of the 210th ECS Meeting, Cancun, Mexico, 29 October–3 November 2006. [Google Scholar]

- Kojima, A.; Teshima, K.; Shirai, Y.; Miyasaka, T. Organometal halide perovskites as visible-light sensitizers for photovoltaic cells. J. Am. Chem. Soc. 2009, 131, 6050–6051. [Google Scholar] [CrossRef]

- Kim, H.-S.; Lee, C.-R.; Im, J.-H.; Lee, K.-B.; Moehl, T.; Marchioro, A.; Moon, S.-J.; Humphry-Baker, R.; Yum, J.-H.; Moser, J.E.; et al. Lead Iodide perovskite sensitized all-solid-state submicron thin film mesoscopic solar cell with effciency exceeding 9%. Sci. Rep. 2012, 2, 591. [Google Scholar] [CrossRef] [PubMed]

- Lee, M.M.; Teuscher, J.; Miyasaka, T.; Murakami, T.N.; Snaith, H.J. Efficient hybrid solar cells based on meso-superstructured organometal halide perovskites. Science 2012, 338, 643–647. [Google Scholar] [CrossRef]

- National Renewable Energy Laboratory. Best Research Cell Efficiencies. Available online: https://www.nrel.gov/pv/assets/pdfs/best-research-cell-efficiencies-rev220630.pdf (accessed on 30 June 2022).

- Stranks, S.D.; Snaith, H.J. Metal-halide perovskites for photovoltaic and light-emitting devices. Nat. Nanotechnol. 2015, 10, 391–402. [Google Scholar] [CrossRef]

- Cho, H.; Jeong, S.H.; Park, M.H.; Kim, Y.H.; Wolf, C.; Lee, C.L.; Heo, J.H.; Sadhanala, A.; Myoung, N.; Yoo, S.; et al. Overcoming the electroluminescence efficiency limitations of perovskite light-emitting diodes. Science 2015, 350, 1222–1225. [Google Scholar] [CrossRef]

- Jin, X.; Ma, K.; Gao, H. Tunable Luminescence and Enhanced Polar Solvent Resistance of Perovskite Nanocrystals Achieved by Surface-Initiated Photopolymerization. J. Am. Chem. Soc. 2022, 144, 20411–20420. [Google Scholar] [CrossRef]

- Zhu, H.; Fu, Y.; Meng, F.; Wu, X.; Gong, Z.; Ding, Q.; Gustafsson, M.V.; Trinh, M.T.; Jin, S.; Zhu, X. Lead halide perovskite nanowire lasers with low lasing thresholds and high quality factors. Nat. Mater. 2015, 14, 636–642. [Google Scholar] [CrossRef]

- Chu, L.; Hu, R.; Liu, W.; Ma, Y.; Zhang, R.; Yang, J.; Li, X. Screen printing large-area organometal halide perovskite thin films for efficient photodetectors. Mater. Res. Bull. 2018, 98, 322. [Google Scholar] [CrossRef]

- Zhang, F.; Yang, B.; Zheng, K.; Yang, S.; Li, Y.; Deng, W.; He, R. Formamidinium lead bromide (FAPbBr3) perovskite microcrystals for sensitive and fast photodetectors. Nano-Micro Lett. 2018, 10, 43. [Google Scholar] [CrossRef] [PubMed]

- Shestimerova, T.A.; Bykov, M.A.; Grigorieva, A.V.; Wei, Z.; Dikarev, E.V.; Shevelkov, A.V. Synthesis and characterization of amantadinium iodoacetatobismuthate, a hybrid compound with mixed iodide–carboxylate anions. Mendeleev Commun. 2022, 32, 194–197. [Google Scholar] [CrossRef]

- Nah, Y.; Solanki, D.; Kim, D.H. All-inorganic non-perovskite copper halides for light emission. Cell Rep. Phys. Sci. 2022, 3, 101171. [Google Scholar] [CrossRef]

- Li, Y.; Shi, Z.; Liang, W.; Wang, L.; Li, S.; Zhang, F.; Ma, Z.; Wang, Y.; Tian, Y.; Wu, D.; et al. Highly stable and spectrum-selective ultraviolet photodetectors based on lead-free copper-based perovskites. Mater. Horiz. 2020, 7, 530–540. [Google Scholar] [CrossRef]

- Li, Z.; Liu, X.; Zuo, C.; Yang, W.; Fang, X. Supersaturation-Controlled Growth of Monolithically Integrated Lead-Free Halide Perovskite Single-Crystalline Thin Film for High-Sensitivity Photodetectors. Adv. Mater. 2021, 33, 2103010. [Google Scholar] [CrossRef]

- Babayigit, A.; Ethirajan, A.; Muller, M.; Conings, B. Toxicity of organometal halide perovskite solar cells. Nat. Mater. 2016, 75, 247–251. [Google Scholar] [CrossRef] [PubMed]

- Babayigit, A.; Thanh, D.D.; Ethirajan, A.; Manca, J.; Muller, M.; Boyen, H.-G.; Conings, B. Assessing the toxicity of Pb- and Sn-based perovskite solar cells in model organism Danio rerio. Sci. Rep. 2016, 6, 18721. [Google Scholar] [CrossRef]

- Conings, B.; Drijkoningen, J.; Gauguelin, N.; Babayigit, A.; D’Haen, J.; D’Olieslaeger, L.; Ethirajan, A.; Verbeeck, J.; Manca, J.; Mosconi, E.; et al. Intrinsic Thermal Instability of Methylammonium Lead Trihalide Perovskite. Adv. Energy Mater. 2015, 5, 1500477. [Google Scholar] [CrossRef]

- Juarez-Perez, E.J.; Ono, L.K.; Maeda, M.; Jiang, Y.; Hawash, Z.; Qi, Y. Photodecomposition and thermal decomposition in methylammonium halide lead perovskites and inferred design principles to increase photovoltaic device stability. J. Mater. Chem. A 2018, 6, 9604–9612. [Google Scholar] [CrossRef]

- Bryant, D.; Aristidou, N.; Pont, S.; Sanchez-Molina, I.; Chotchunangatchaval, T.; Wheeler, S.; Durrant, J.R.; Haque, S.A. Light and oxygen induced degradation limits the operational stability of methylammonium lead triiodide perovskite solar cells. Energy Environ. Sci. 2016, 9, 1655–1660. [Google Scholar] [CrossRef]

- Wilks, R.G.; Bar, M. Perovskite solar cells: Danger from within. Nat. Energy 2017, 2, 16204. [Google Scholar] [CrossRef]

- Volonakis, G.; Haghighirad, A.A.; Milot, R.L.; Sio, W.H.; Filip, M.R.; Wenger, B.; Johnston, M.B.; Herz, L.M.; Snaith, H.J.; Giustino, F. Cs2InAgCl6: A New Lead-Free Halide Double Perovskite with Direct Band Gap. J. Phys. Chem. Lett. 2017, 8, 772–778. [Google Scholar] [CrossRef] [PubMed]

- Cheng, P.; Wu, T.; Li, Y.; Jiang, L.; Deng, W.; Han, K. Combining theory and experiment in the design of a lead-free ((CH3NH3)2AgBiI6) double perovskite. New J. Chem. 2017, 41, 9598–9601. [Google Scholar] [CrossRef]

- Luo, J.; Wang, X.; Li, S.; Liu, J.; Guo, Y.; Niu, G.; Yao, L.; Fu, Y.; Gao, L.; Dong, Q.; et al. Efficient and stable emission of warm-white light from lead-free halide double perovskites. Nature 2018, 563, 541–545. [Google Scholar] [CrossRef]

- Filip, M.R.; Hillman, S.; Haghighirad, A.A.; Snaith, H.J.; Giustino, F. Band gaps of the lead-free halide double perovskites Cs2BiAgCl6 and Cs2BiAgBr6 from theory and experiment. J. Phys. Chem. Lett. 2016, 7, 2579–2585. [Google Scholar] [CrossRef] [PubMed]

- McClure, E.T.; Ball, M.R.; Windl, W.; Woodward, P.M. Cs2AgBiX6 (X = Br, Cl): New visible light absorbing, lead-free halide perovskite semiconductors. Chem. Mater. 2016, 28, 1348–1354. [Google Scholar] [CrossRef]

- Zhao, X.G.; Yang, D.; Sun, Y.; Li, T.; Zhang, L.; Yu, L.; Zunger, A. Cu–In Halide Perovskite Solar Absorbers. J. Am. Chem. Soc. 2017, 139, 6718–6725. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Xu, Q.; Sun, Q.; Hou, Z.; Yin, W. Stability Engineering of Halide Perovskite via Machine Learning. arXiv 2018, arXiv:1803.06042. [Google Scholar]

- Zheng, R.; Wang, Y.; Pan, J.; Malik, H.A.; Zhang, H.; Jia, C.; Weng, X.; Xie, J.; Deng, L. Toward easy-to-assemble, large-area smart windows: All-in-one cross-linked electrochromic material and device. ACS Appl. Mater. Interfaces 2020, 12, 27526–27536. [Google Scholar] [CrossRef]

- Xiao, Z.; Du, K.; Meng, W.; Mitzi, D.; Yan, Y. Chemical Origin of the Stability Difference between Cu(I)- and Ag(I)-Based Halide Double Perovskites. Angew. Chem. Int. Ed. 2017, 56, 12107–12111. [Google Scholar] [CrossRef]

- Ensslin, F.; Dreyer, H.Z. Über einige Salze des Indiums. I. Anorg. Allg. Chem. 1942, 249, 119–132. [Google Scholar] [CrossRef]

- Ensslin, F.; Ziemeck, B.; DeSchaepdryver, L.Z. Zur Chemie des Indiums. VI. Die Löslichkeit von Indium(III)-chlorid, Indium(III)-bromid und Indium(III)-jodid im Wasser bei verschiedenen Temperaturen. Anorg. Chem. 1947, 254, 293–296. [Google Scholar] [CrossRef]

- Du, K.; Meng, W.; Wang, X.; Yan, Y.; Mitzi, D. Bandgap Engineering of Lead-Free Double Perovskite Cs2AgBiBr6 through Trivalent Metal Alloying. Angew. Chem. Int. Ed. 2017, 56, 8158–8162. [Google Scholar] [CrossRef] [PubMed]

- Wojakowska, A.; Krzyżak, E.; Wojakowski, A. Phase diagram for the CuBr–CsBr system. Thermochim. Acta 2000, 344, 55–59. [Google Scholar] [CrossRef]

- Huang, X.; Wang, S.; Devakumar, B.; Ma, N. One-step low-temperature solid-state synthesis of lead-free cesium copper halide Cs3Cu2Br5 phosphors with bright blue emissions. Mater. Today Chem. 2022, 23, 100678. [Google Scholar] [CrossRef]

- Meyer, G.Z. Zur Kenntnis der Chloro- und Bromo-Indate (III). A3In2Cl9 (A = Cs, Rb, In, Tl) und Cs3In2Br9−xClx (x = 0, 3, 6, 7, 8). Anorg. Allg. Chem. 1978, 445, 140–146. [Google Scholar] [CrossRef]

- Dudareva, A.G.; Bogatov, Y.E.; Ivanov-Emin, B.N.; Fedorov, P.I. Study of the interaction of indium tribromide with cesium bromide. J. Inorg. Chem. 1971, XVI, 2586. [Google Scholar]

- Zhou, L.; Liao, J.-F.; Huang, Z.-G.; Wei, J.-H.; Wang, X.-D.; Li, W.-G.; Su, C.-Y. Highly Red Emissive Lead-Free Indium-Based Perovskite Single Crystal for Sensitive Water Detection. Angew. Chem. Int. Ed. 2019, 58, 5277–5281. [Google Scholar] [CrossRef]

- Kamilov, R.K.; Yuldoshev, J.Z.; Knotko, A.V.; Grigorieva, A.V. Phase Equilibria in Ternary System CsBr-AgBr-InBr3. Materials 2023, 16, 559. [Google Scholar] [CrossRef]

- Jagner, S.; Helgesson, G. On the coordination number of the metal in crystalline halogenocuprates(I) and halogenoargentates(I). Adv. Inorg. Chem. 1991, 37, 1–45. [Google Scholar]

- Dudareva, A.G.; Bogatov, Y.E.; Konstandia, A.; Ivanov-Emin, B.N.; Fedorov, P.I. Physicochemical study of the interaction of indium tribromide with silver, zinc and lead(II) bromides in a melt. Chem. Chem. Technol. 1971, XIV, 1299. [Google Scholar]

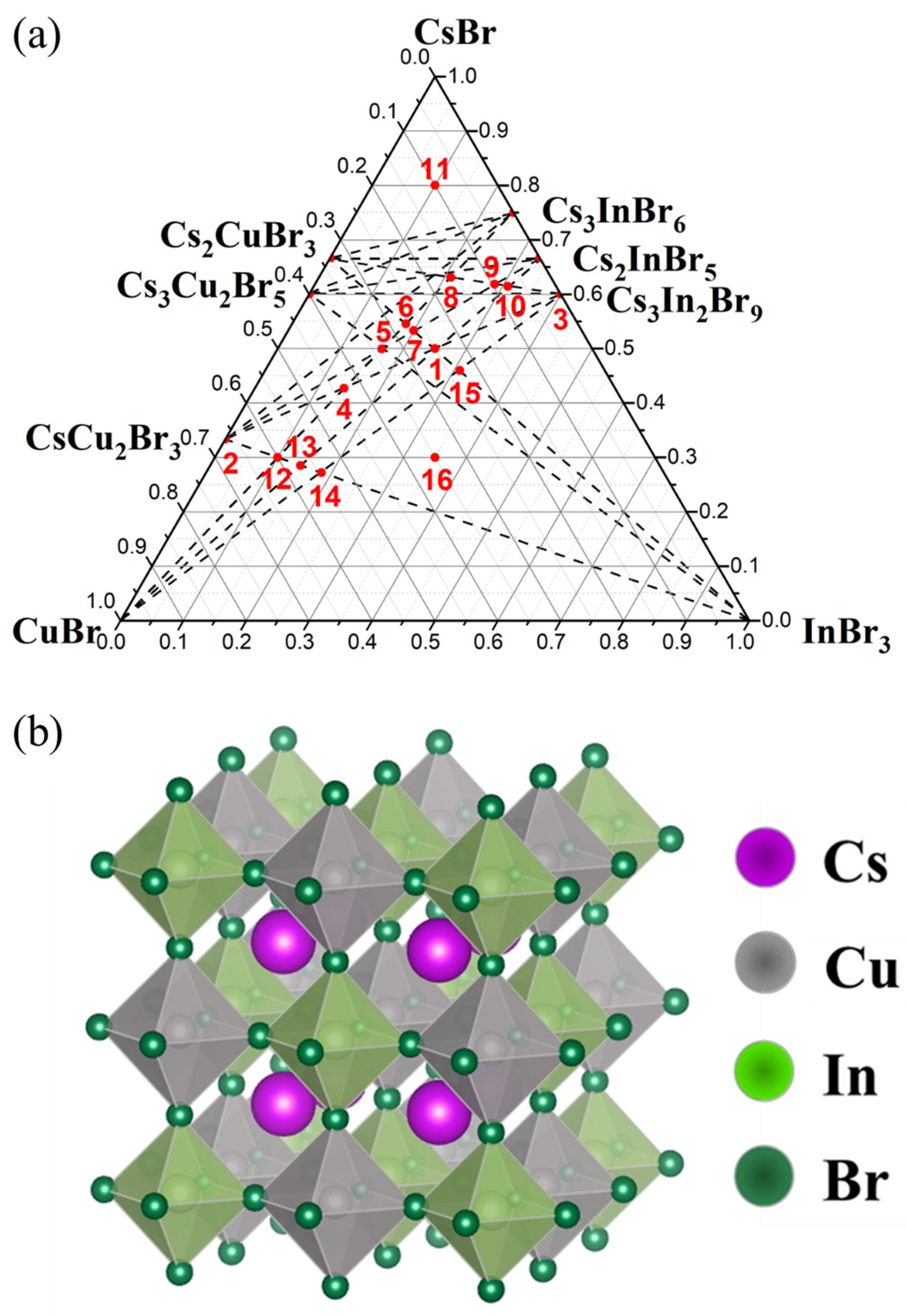

| Sample | Mole Fraction of Precursors | Weight of Precursors per 1 g of Product | ||||

|---|---|---|---|---|---|---|

| n(CsBr) | n(CuBr) | n(InBr3) | m(CsBr) | m(CuBr) | m(InBr3) | |

| Point 1 | 0.500 | 0.250 | 0.250 | 0.461(1) | 0.155(1) | 0.384(1) |

| Point 2 | 0.330 | 0.660 | - | 0.426(1) | 0.572(2) | - |

| Point 3 | 0.600 | - | 0.400 | 0.474(1) | - | 0.526(1) |

| Point 4 | 0.427 | 0.431 | 0.142 | 0.448(1) | 0.305(1) | 0.248(1) |

| Point 5 | 0.499 | 0.335 | 0.166 | 0.499(2) | 0.226(1) | 0.276(2) |

| Point 6 | 0.533 | 0.267 | 0.200 | 0.510(2) | 0.172(1) | 0.318(2) |

| Point 7 | 0.545 | 0.274 | 0.181 | 0.529(3) | 0.179(1) | 0.293(1) |

| Point 8 | 0.631 | 0.159 | 0.210 | 0.580(2) | 0.099(1) | 0.322(1) |

| Point 9 | 0.618 | 0.096 | 0.286 | 0.533(3) | 0.056(1) | 0.411(1) |

| Point 10 | 0.614 | 0.077 | 0.309 | 0.520(1) | 0.044(1) | 0.436(2) |

| Point 11 | 0.800 | 0.100 | 0.100 | 0.774(3) | 0.065(1) | 0.161(2) |

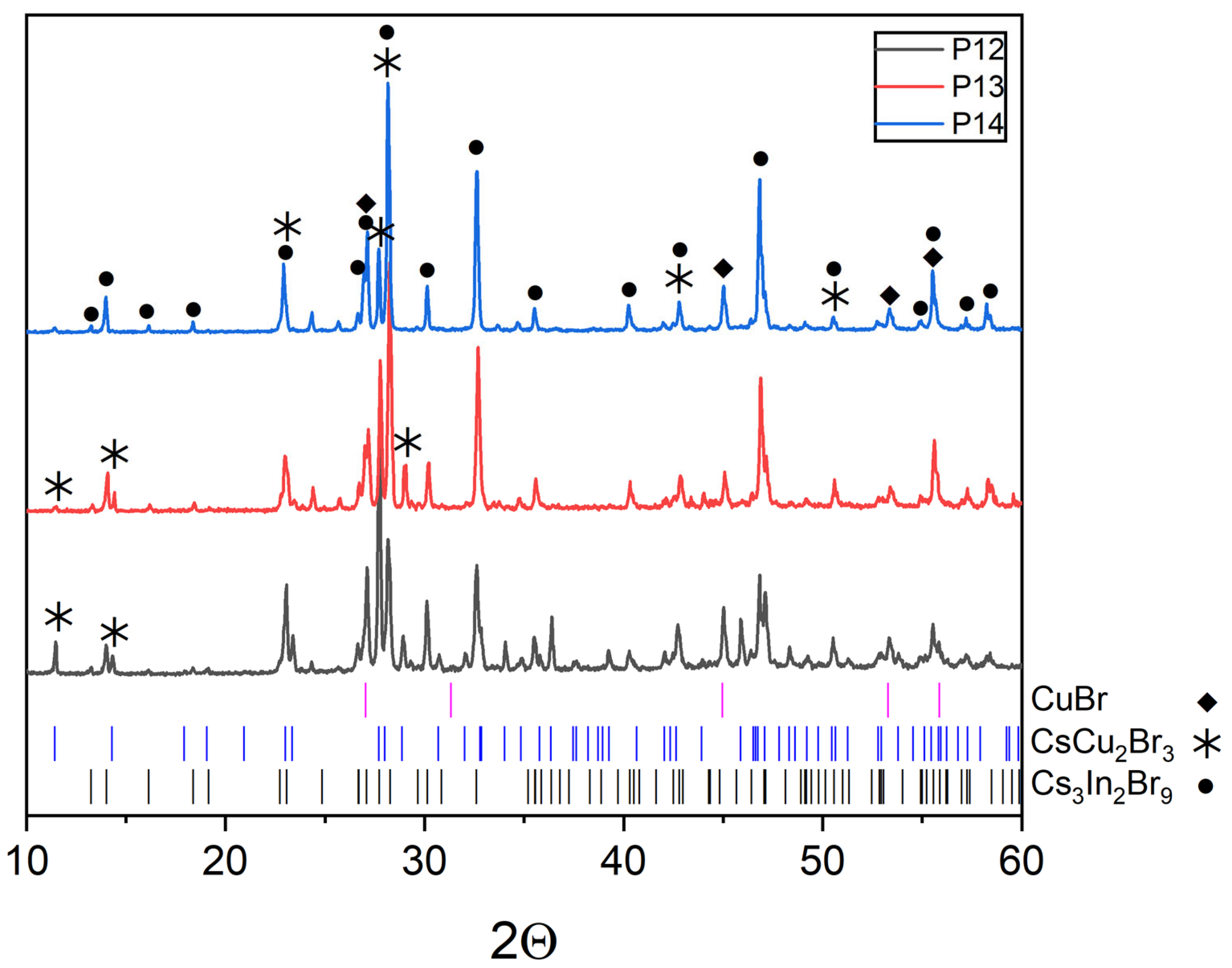

| Point 12 | 0.300 | 0.600 | 0.100 | 0.344(1) | 0.465(2) | 0.191(1) |

| Point 13 | 0.285 | 0.571 | 0.144 | 0.313(2) | 0.424(1) | 0.263(1) |

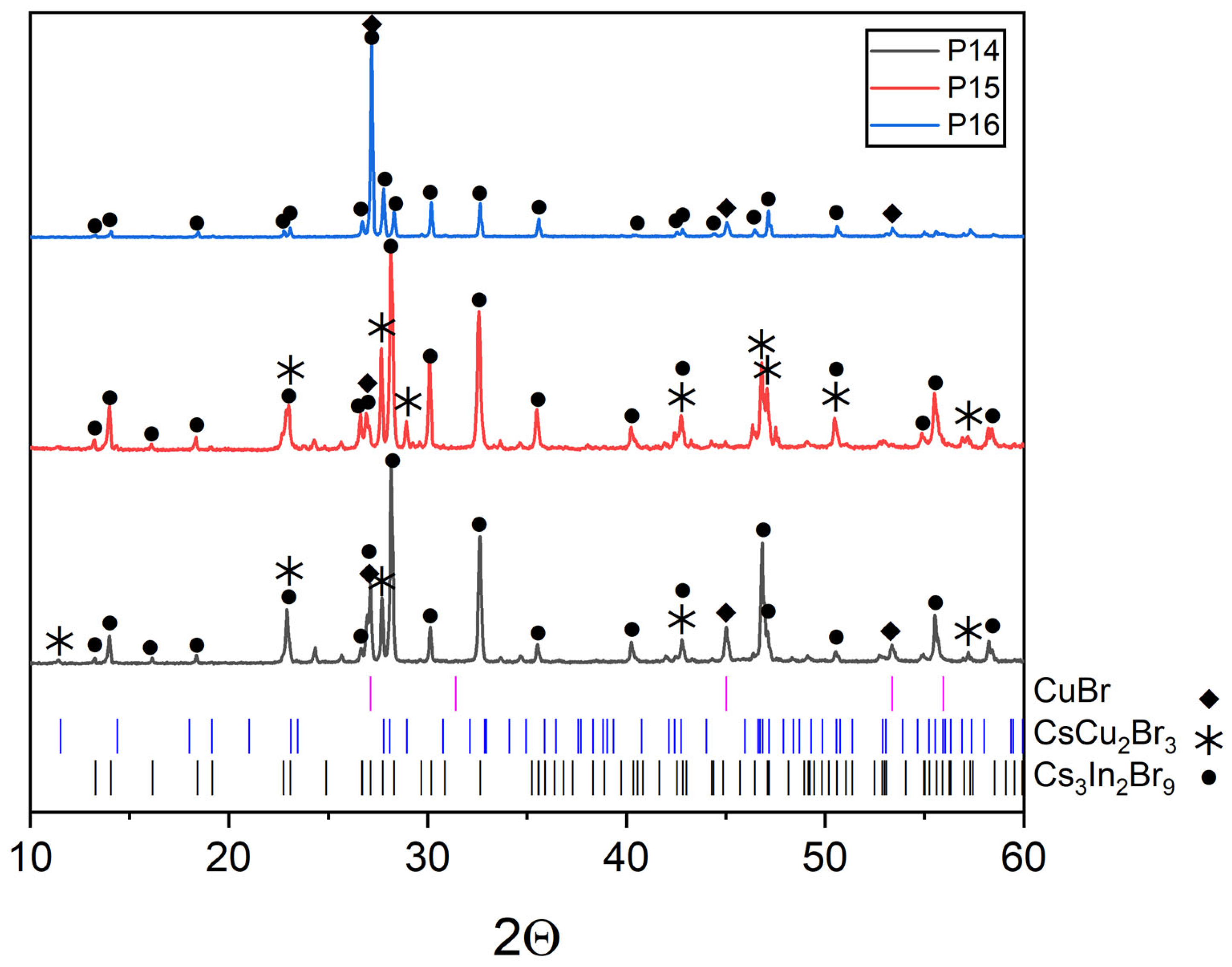

| Point 14 | 0.272 | 0.544 | 0.184 | 0.288(1) | 0.388(1) | 0.324(1) |

| Point 15 | 0.459 | 0.231 | 0.310 | 0.406(1) | 0.138(1) | 0.456(2) |

| Point 16 | 0.300 | 0.350 | 0.350 | 0.268(4) | 0.211(1) | 0.521(3) |

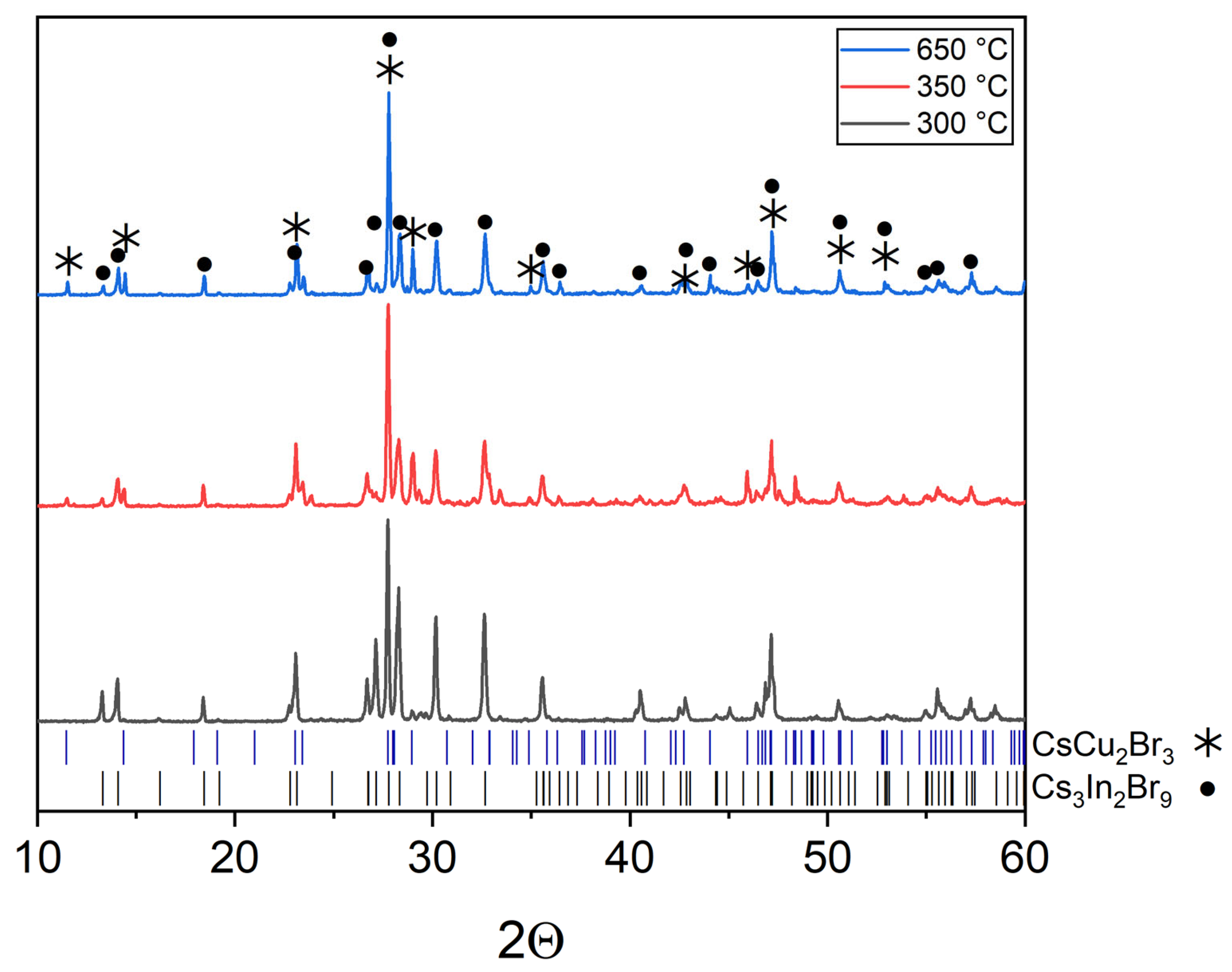

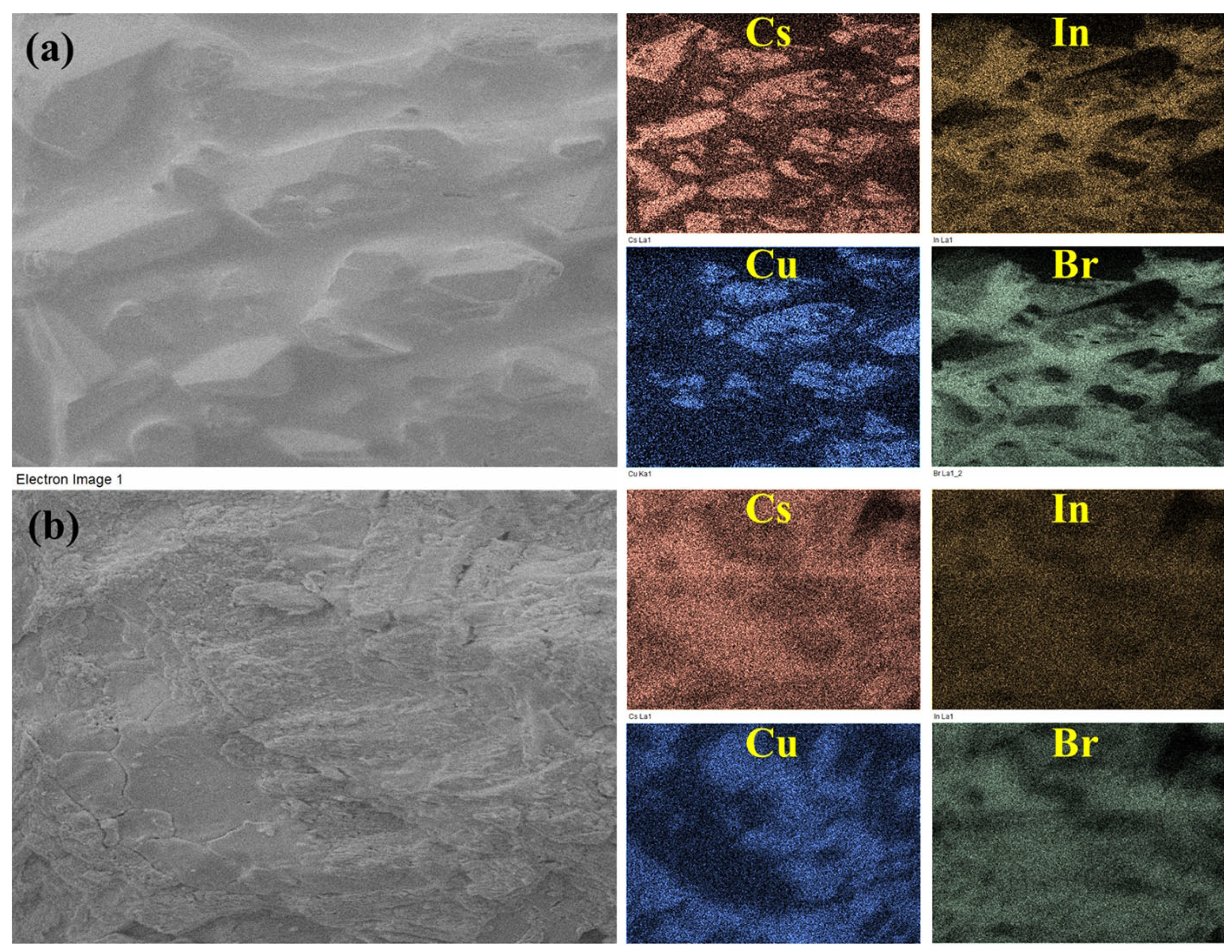

| Synthesis Temperature, °C | Cs | Cu | In | Br | Cation Ratio Cu/In |

|---|---|---|---|---|---|

| T = 300 °C (solid-phase synthesis) | 25 | 12 | 11 | 52 | 1.08 |

| T = 650 °C (crystallization from the melt) | 25 | 11 | 11 | 53 | 1.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kamilov, R.K.; Yuldoshev, J.Z.; Knotko, A.V.; Grigorieva, A.V. In Search of a Double Perovskite in the Phase Triangle of Bromides CsBr-CuBr-InBr3. Materials 2023, 16, 3744. https://doi.org/10.3390/ma16103744

Kamilov RK, Yuldoshev JZ, Knotko AV, Grigorieva AV. In Search of a Double Perovskite in the Phase Triangle of Bromides CsBr-CuBr-InBr3. Materials. 2023; 16(10):3744. https://doi.org/10.3390/ma16103744

Chicago/Turabian StyleKamilov, Rustam K., Jahongir Z. Yuldoshev, Alexander V. Knotko, and Anastasia V. Grigorieva. 2023. "In Search of a Double Perovskite in the Phase Triangle of Bromides CsBr-CuBr-InBr3" Materials 16, no. 10: 3744. https://doi.org/10.3390/ma16103744