Quality of the Ceramic and Ni-Cr Alloy Joint after Al2O3 Abrasive Blasting

Abstract

:1. Introduction

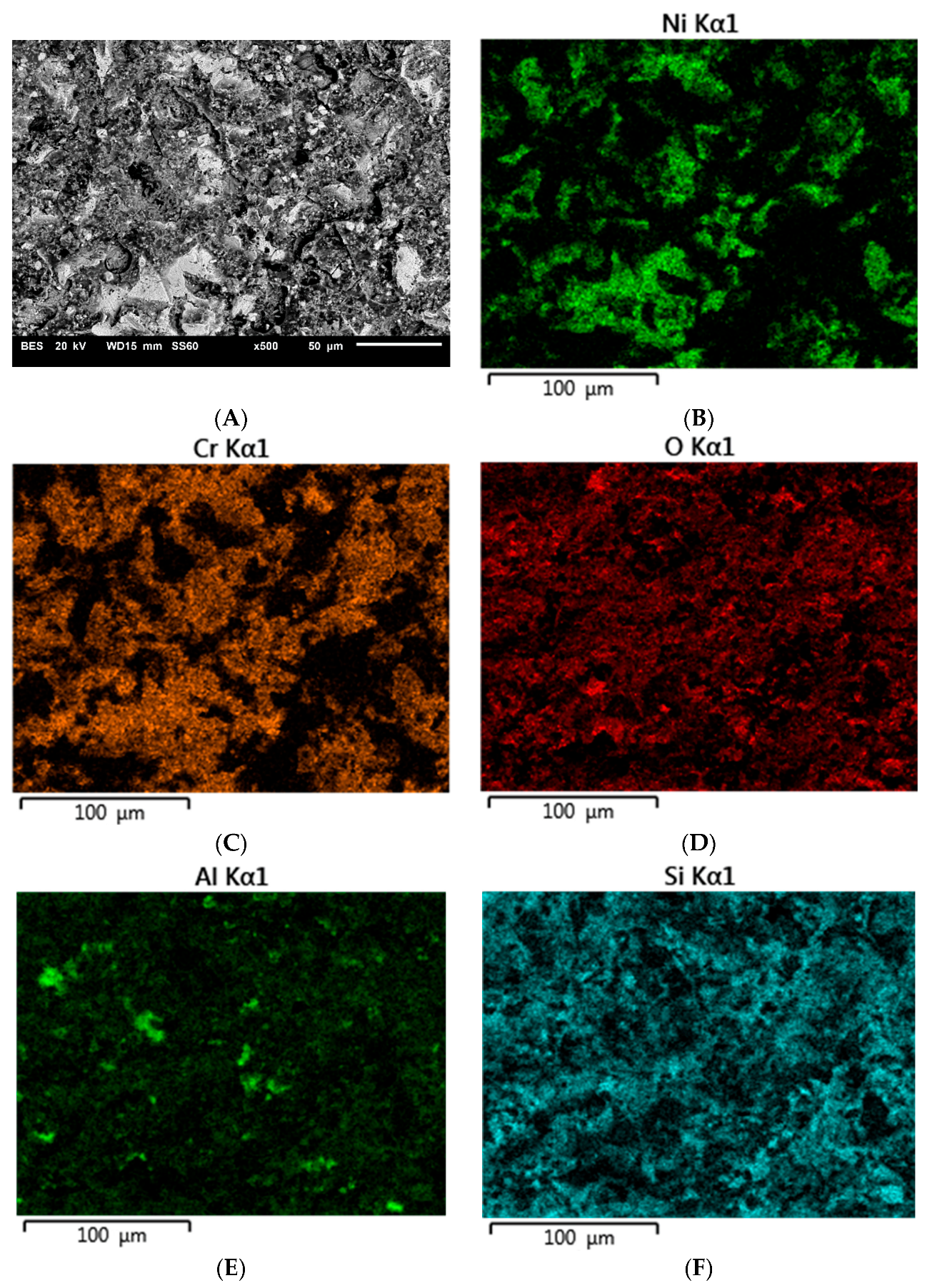

2. Materials and Methods

3. Results

4. Discussion

4.1. Shear Strength and Its Dependence on Thermal Loads

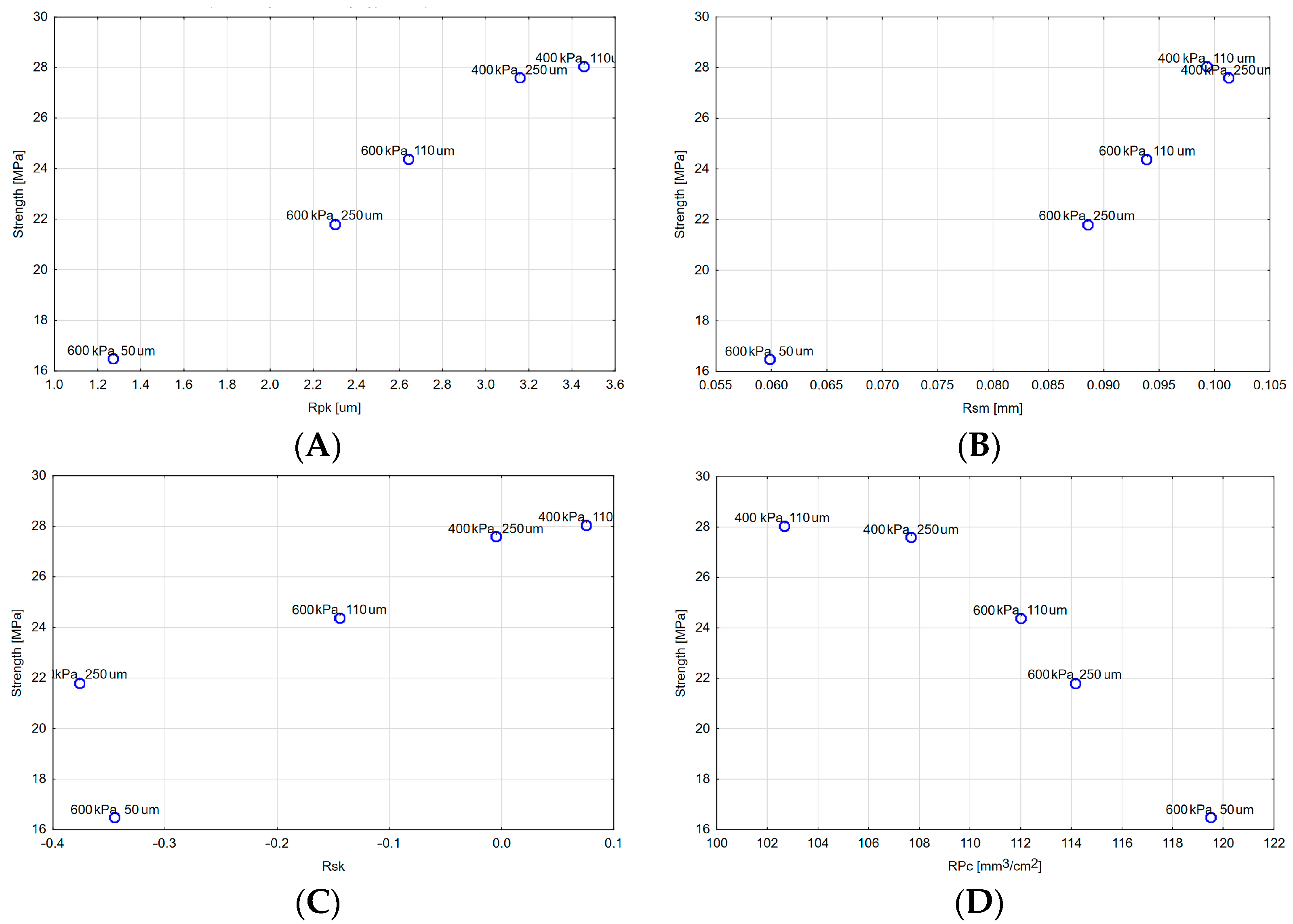

4.2. Influence of Surface Roughness Parameters on Shear Strength

5. Conclusions

- There is a close correlation between the strength of the Ni-Cr alloy–dental ceramic joint and the alloy roughness parameters after abrasive blasting: Rpk, Rsm, Rsk and RPc.

- The application of abrasive blasting under 600 kPa pressure makes the alloy–ceramic joint durable in the operating conditions under thermal load.

- The most optimal blasting parameters are 600 kPa pressure with 110 µm Al2O3 particles (p < 0.05). These parameters allow the highest bond strength to be achieved between the Ni-Cr alloy and dental ceramics.

- Variable thermal load reduces the strength of the bond, irrespective of abrasive blasting parameters.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Czepułkowska, W.; Wołowiec-Korecka, E.; Klimek, L. The Role of Mechanical, Chemical and Physical Bonds in Metal-Ceramic Bond Strength. Arch. Mater. Sci. Eng. 2018, 92, 5–14. [Google Scholar] [CrossRef]

- Schweitzer, D.; Goldstein, G.; Ricci, J.; Silva, N.; Hittelman, E. Comparison of Bond Strength of a Pressed Ceramic Fused to Metal versus Feldspathic Porcelain Fused to Metal. J. Prosthodont. 2005, 14, 239–247. [Google Scholar] [CrossRef] [PubMed]

- Śmielak, B.; Świniarski, J.; Wołowiec-Korecka, E.; Klimek, L. 2D-Finite Element Analysis of Inlay-, Onlay Bridges with Using Various Materials. Arch. Mater. Sci. Eng. 2016, 79, 71–78. [Google Scholar] [CrossRef]

- Śmielak, B.; Gołębiowski, M.; Klimek, L.; Wołowiec, E. Effect of Surface Treatment of Titanium Elements on the Bond Strength to Zirconium Dioxide. Solid State Phenom. 2014, 225, 151–158. [Google Scholar] [CrossRef]

- Śmielak, B.; Klimek, L.; Świniarski, J. The Use of the FEM to Identify the Optimal Groove Dimensions Ensuring the Least Stressed Connection between a Zirconia Coping and Veneering Ceramic. Materials 2018, 11, 2360. [Google Scholar] [CrossRef]

- Śmielak, B.; Klimek, L.; Wojciechowski, R.; Bąkała, M. Effect of Zirconia Surface Treatment on Its Wettability by Liquid Ceramics. J. Prosthet. Dent. 2019, 122, 410.e1–410.e6. [Google Scholar] [CrossRef]

- Külünk, T.; Kurt, M.; Ural, Ç.; Külünk, Ş.; Baba, S. Effect of Different Air-Abrasion Particles on Metal-Ceramic Bond Strength. J. Dent. Sci. 2011, 6, 140–146. [Google Scholar] [CrossRef]

- Pietnicki, K.; Wołowiec, E.; Klimek, L. The Effect of Abrasive Blasting on the Strength of a Joint between Dental Porcelain and Metal Base. Acta Bioeng. Biomech. 2014, 16, 63–68. [Google Scholar] [CrossRef]

- Gołębiowski, M.; Wołowiec, E.; Klimek, L. Airborne-Particle Abrasion Parameters on the Quality of Titanium-Ceramic Bonds. J. Prosthet. Dent. 2015, 113, 453–459. [Google Scholar] [CrossRef]

- Tarib, N.A.; Anuar, N.; Ahmad, M. Shear Bond Strength of Veneering Ceramic to Coping Materials with Different Pre-Surface Treatments. J. Adv. Prosthodont. 2016, 8, 339. [Google Scholar] [CrossRef]

- Taga, Y.; Kawai, K.; Nokubi, T. New Method for Divesting Cobalt-Chromium Alloy Castings: Sandblasting with a Mixed Abrasive Powder. J. Prosthet. Dent. 2001, 85, 357–362. [Google Scholar] [CrossRef] [PubMed]

- Inan, Ö.; Acar, A.; Halkaci, S. Effects of Sandblasting and Electrical Discharge Machining on Porcelain Adherence to Cast and Machined Commercially Pure Titanium. J. Biomed. Mater. Res. Part B Appl. Biomater. 2006, 78B, 393–400. [Google Scholar] [CrossRef] [PubMed]

- Czepułkowska, W.; Wołowiec-Korecka, E.; Klimek, L. The Condition of Ni-Cr Alloy Surface after Abrasive Blasting with Various Parameters. J. Mater. Eng. Perform. 2020, 29, 1439–1444. [Google Scholar] [CrossRef]

- Czepułkowska-Pawlak, W.; Wołowiec-Korecka, E.; Klimek, L. The Surface Condition of Ni-Cr after SiC Abrasive Blasting for Applications in Ceramic Restorations. Materials 2020, 13, 5824. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.-J.; Song, K.-Y.; Ahn, S.-G.; Choi, J.-Y.; Seo, J.-M.; Park, J.-M. Evaluation of Effect of Galvanic Corrosion between Nickel-Chromium Metal and Titanium on Ion Release and Cell Toxicity. J. Adv. Prosthodont. 2015, 7, 172–177. [Google Scholar] [CrossRef]

- Milheiro, B.; Nozaki, K.; Kleverlaan, C.; Muris, J.; Miura, H.; Feilzer, A. In Vitro Cytotoxicity of Metallic Ions Released from Dental Alloys. Odontology 2016, 104, 136–142. [Google Scholar] [CrossRef]

- Kula, Z.; Semenov, M.; Klimek, L. Carbon Coatings Deposited on Prosthodontic Ni-Cr Alloy. Appl. Sci. 2021, 11, 4551. [Google Scholar] [CrossRef]

- Nematia, A.; Saghafia, M.; Khamseh, S.; Alibakhshic, E.; Zarrintajd, P.; Saebe, M. Magnetron-Sputtered TixNy Thin Films Applied on Titanium-Based Alloys for Biomedical Applications: Composition-Microstructure-Property Relationships. Surf. Coat. Technol. 2018, 349, 251–259. [Google Scholar] [CrossRef]

- Banaszek, K.; Wiktorowska-Owczarek, A.; Kowalczyk, E.; Klimek, L. Possibilities of Applying Ti (C, N) Coatings on Prosthetic Elements-Research with the Use of Human Endothelial Cells. Acta Bioeng. Biomech. 2016, 18, 119–126. [Google Scholar]

- Banaszek, K.; Klimek, L.; Zgorzyńska, E.; Swarzyńska, A.; Walczewska, A. Cytotoxicity of Titanium Carbonitride Coatings for Prostodontic Alloys with Different Amounts of Carbon and Nitro Gen. Biomed. Mater. 2018, 13, 045003. [Google Scholar] [CrossRef]

- Banaszek, K.; Klimek, L. Ti(C, N) as Barrier Coatings. Coatings 2019, 9, 432. [Google Scholar] [CrossRef]

- Banaszek, K.; Klimek, L.; Dąbrowski, J.R.; Jastrzębski, W. Fretting Wear in Orthodontic and Prosthetic Alloys with Ti(C, N) Coatings. Processes 2019, 7, 874. [Google Scholar] [CrossRef]

- Banaszek, K.; Szymanski, W.; Pietrzyk, B.; Klimek, L. Adhesion of E. coli Bacteria Cells to Prosthodontic Alloys Surfaces Modified by TiO2 Sol-Gel Coatings. Adv. Mater. Sci. Eng. 2013, 2013, 179241. [Google Scholar] [CrossRef]

- Tróia, M.G.; Henriques, G.E.; Nóbilo, M.A.; Mesquita, M.F. The Effect of Thermal Cycling on the Bond Strength of Low-Fusing Porcelain to Commercially Pure Titanium and Titanium–Aluminium–Vanadium Alloy. Dent. Mater. 2003, 19, 790–796. [Google Scholar] [CrossRef] [PubMed]

- Oyafuso, D.; Özcan, M.; Bottino, M.; Itinoche, M. Influence of Thermal and Mechanical Cycling on the Flexural Strength of Ceramics with Titanium or Gold Alloy Frameworks. Dent. Mater. 2008, 24, 351–356. [Google Scholar] [CrossRef]

- Vásquez, V.; Özcan, M.; Nishioka, R.; Souza, R.; Mesquita, A.; Pavanelli, C. Mechanical and Thermal Cycling Effects on the Flexural Strength of Glass Ceramics Fused to Titanium. Dent. Mater. J. 2008, 27, 7–15. [Google Scholar] [CrossRef] [PubMed]

- Antanasova, M.; Kocjan, A.; Kovač, J.; Žužek, B.; Jevnikar, P. Influence of Thermo-Mechanical Cycling on Porcelain Bonding to Cobalt–Chromium and Titanium Dental Alloys Fabricated by Casting, Milling, and Selective Laser Melting. J. Prosthodont. Res. 2018, 62, 184–194. [Google Scholar] [CrossRef]

- De Vasconcellos, L.; Silva, L.; de Vasconcellos, L.; Balducci, I.; Takahashi, F.; Bottino, M. Effect of Airborne-Particle Abrasion and Mechanico-Thermal Cycling on the Flexural Strength of Glass Ceramic Fused to Gold or Cobalt–Chromium Alloy. J. Prosthodont. 2011, 20, 553–560. [Google Scholar] [CrossRef]

- Fisher, J.; Zbären, C.; Stawarczyk, B.; Hämmerle, C.H. The Effect of Thermal Cycling on Metal-Ceramic Bond Strength. J. Dent. 2009, 37, 549–553. [Google Scholar] [CrossRef]

- Shimoe, S.; Tanoue, N.; Yanagida, H.; Atsuta, M.; Koizumi, H.; Matsumura, H. Comparative Strength of Metal-Ceramic and Metal-Composite Bonds after Extended Thermocycling. J. Oral Rehabil. 2004, 31, 689–694. [Google Scholar] [CrossRef]

- De Vasconcellos, L.G.; Buso, L.; Lombardo, G.H.; Souza, R.O.; Nogueira, L.; Bottino, M.A.; Özcan, M. Opaque Layer Firing Temperature and Aging Effect on the Flexural Strength of Ceramic Fused to Cobalt-Chromium Alloy. J. Prosthodont. 2010, 19, 471–477. [Google Scholar] [CrossRef] [PubMed]

| Mo | Fe | Ta | Si | Co | Cr | Mn | Nb | Ni |

|---|---|---|---|---|---|---|---|---|

| 9.21 | 1.53 | 0.19 | 1.54 | 0.15 | 24.63 | 0.42 | 0.48 | residue |

| Al2O3 Abrasive Particle Size [µm] | Processing Pressure [kPa] | |

|---|---|---|

| 400 | 600 | |

| 50 | A45 | A65 |

| 110 | A41 | A61 |

| 250 | A42 | A62 |

| Layer No | Temp. (Max) [°C] | Resting Temp. [°C] | Drying Time [min] | Rise Temp. [°C] | Time [min] | V1 Temp. [°C] | V2 Temp. [°C] |

|---|---|---|---|---|---|---|---|

| Opaque | |||||||

| I | 980 | 403 | 6 | 80 | 1 | 550 | 979 |

| II | 970 | 403 | 6 | 80 | 1 | 550 | 969 |

| Dentine | |||||||

| I | 920 | 403 | 4 | 60 | 1 | 580 | 919 |

| II | 910 | 403 | 4 | 60 | 1 | 580 | 909 |

| Pressure [kPa] | Al2O3 Particle Size [µm] | Bond Strength [MPa] (Mean ± SD) | ||

|---|---|---|---|---|

| No Thermocycles | Thermocycles | Total (Particle Size × Pressure) | ||

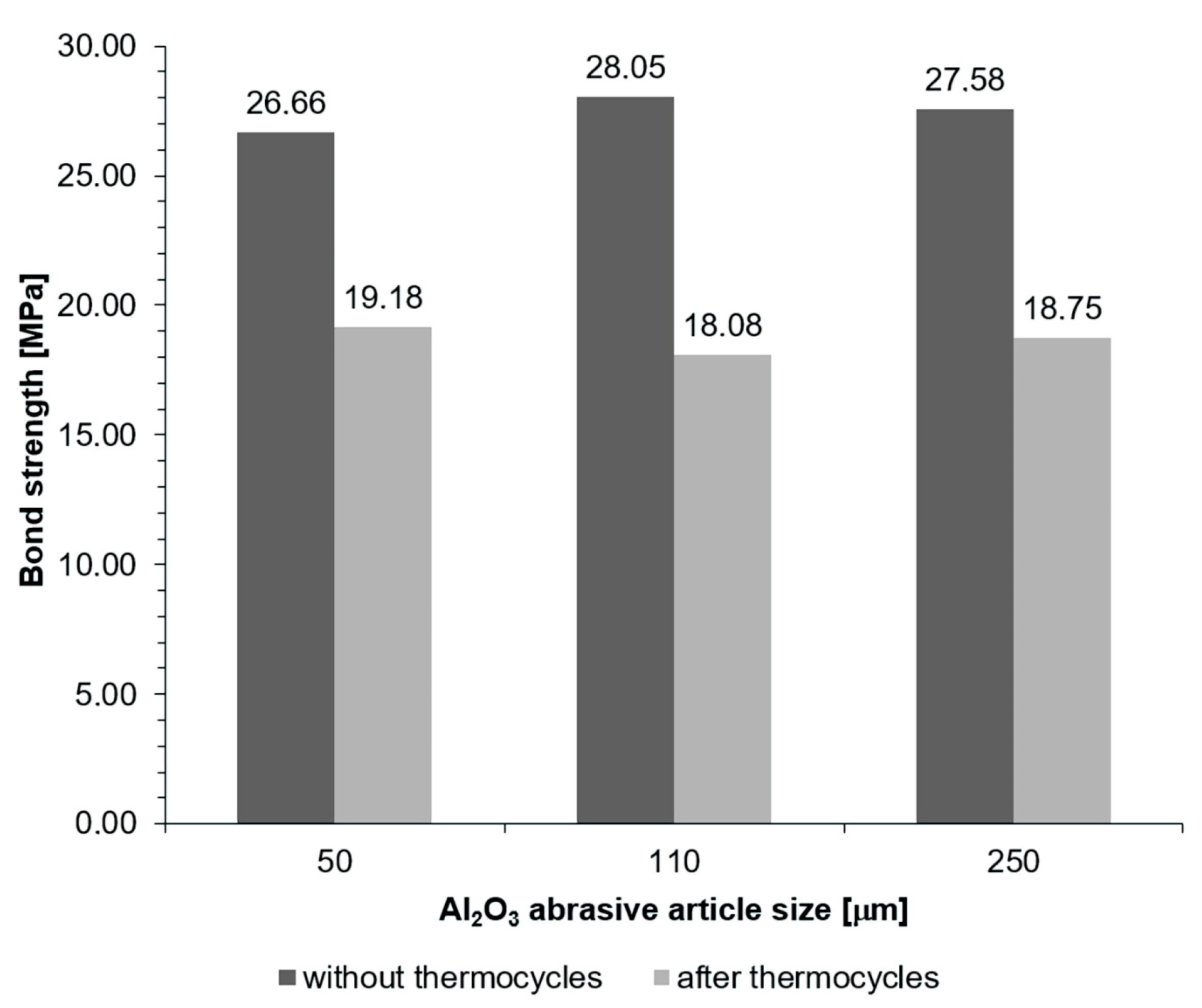

| 400 | 50 | 26.66 ± 5.49 | 19.18 ± 2.55 | 22.92 ± 5.67 |

| 400 | 110 | 28.05 ± 3.83 | 18.08 ± 3.43 | 23.07 ± 6.21 |

| 400 | 250 | 27.58 ± 2.99 | 18.75 ± 3.44 | 23.17 ± 5.50 |

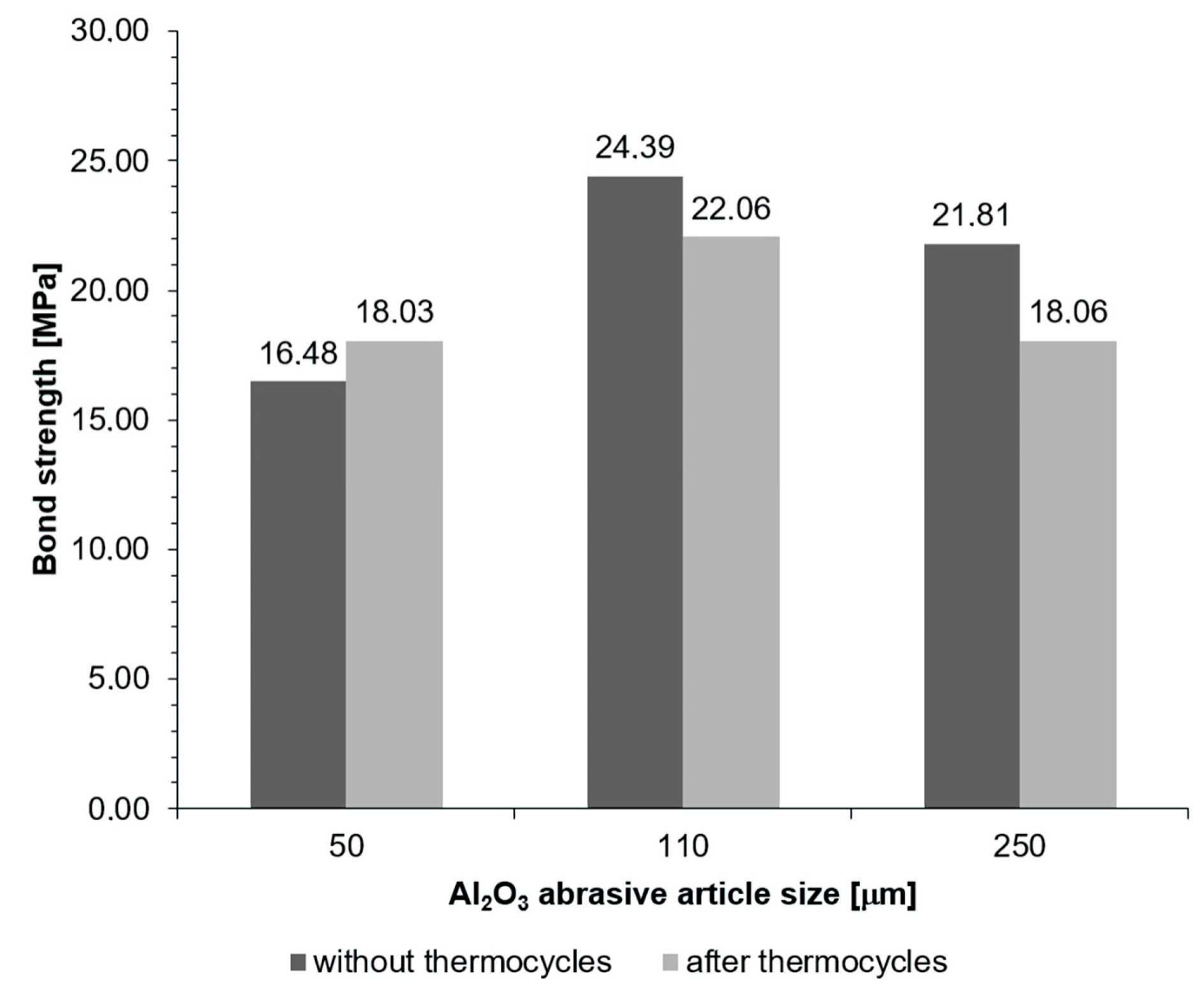

| 600 | 50 | 16.48 ± 3.39 | 18.03 ± 3.98 | 17.25 ± 3.70 |

| 600 | 110 | 24.39 ± 4.49 | 22.06 ± 3.23 | 23.22 ± 4.01 |

| 600 | 250 | 21.81 ± 4.53 | 18.06 ± 2.31 | 19.93 ± 4.01 |

| Total (Thermocycles) | 24.16 ± 5.74 | 19.03 ± 3.41 | 21.59 ± 5.36 | |

| 3-factor ANOVA | ||||

| Factor | F | p | Partial eta2 | Power |

| Pressure | 21.92 | 0.000 | 0.142 | 0.996 |

| Particle size | 8.03 | 0.001 | 0.108 | 0.953 |

| Thermocycles | 67.90 | 0.000 | 0.340 | 1.000 |

| Pressure × Particle size | 7.35 | 0.001 | 0.100 | 0.934 |

| Pressure × Thermocycles | 33.81 | 0.000 | 0.204 | 1.000 |

| Particle size × Thermocycles | 3.04 | 0.051 | 0.044 | 0.580 |

| Pressure × Particle size × Thermocycles | 0.86 | 0.426 | 0.013 | 0.195 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Klimek, L.; Wołowiec-Korecka, E.; Czepułkowska-Pawlak, W.; Kula, Z. Quality of the Ceramic and Ni-Cr Alloy Joint after Al2O3 Abrasive Blasting. Materials 2023, 16, 3800. https://doi.org/10.3390/ma16103800

Klimek L, Wołowiec-Korecka E, Czepułkowska-Pawlak W, Kula Z. Quality of the Ceramic and Ni-Cr Alloy Joint after Al2O3 Abrasive Blasting. Materials. 2023; 16(10):3800. https://doi.org/10.3390/ma16103800

Chicago/Turabian StyleKlimek, Leszek, Emilia Wołowiec-Korecka, Weronika Czepułkowska-Pawlak, and Zofia Kula. 2023. "Quality of the Ceramic and Ni-Cr Alloy Joint after Al2O3 Abrasive Blasting" Materials 16, no. 10: 3800. https://doi.org/10.3390/ma16103800

APA StyleKlimek, L., Wołowiec-Korecka, E., Czepułkowska-Pawlak, W., & Kula, Z. (2023). Quality of the Ceramic and Ni-Cr Alloy Joint after Al2O3 Abrasive Blasting. Materials, 16(10), 3800. https://doi.org/10.3390/ma16103800