Study on the Mechanical Behavior of a Dual-Density Hybrid Lattice Structure under Quasi-Static and Dynamic Compressions

Abstract

:1. Introduction

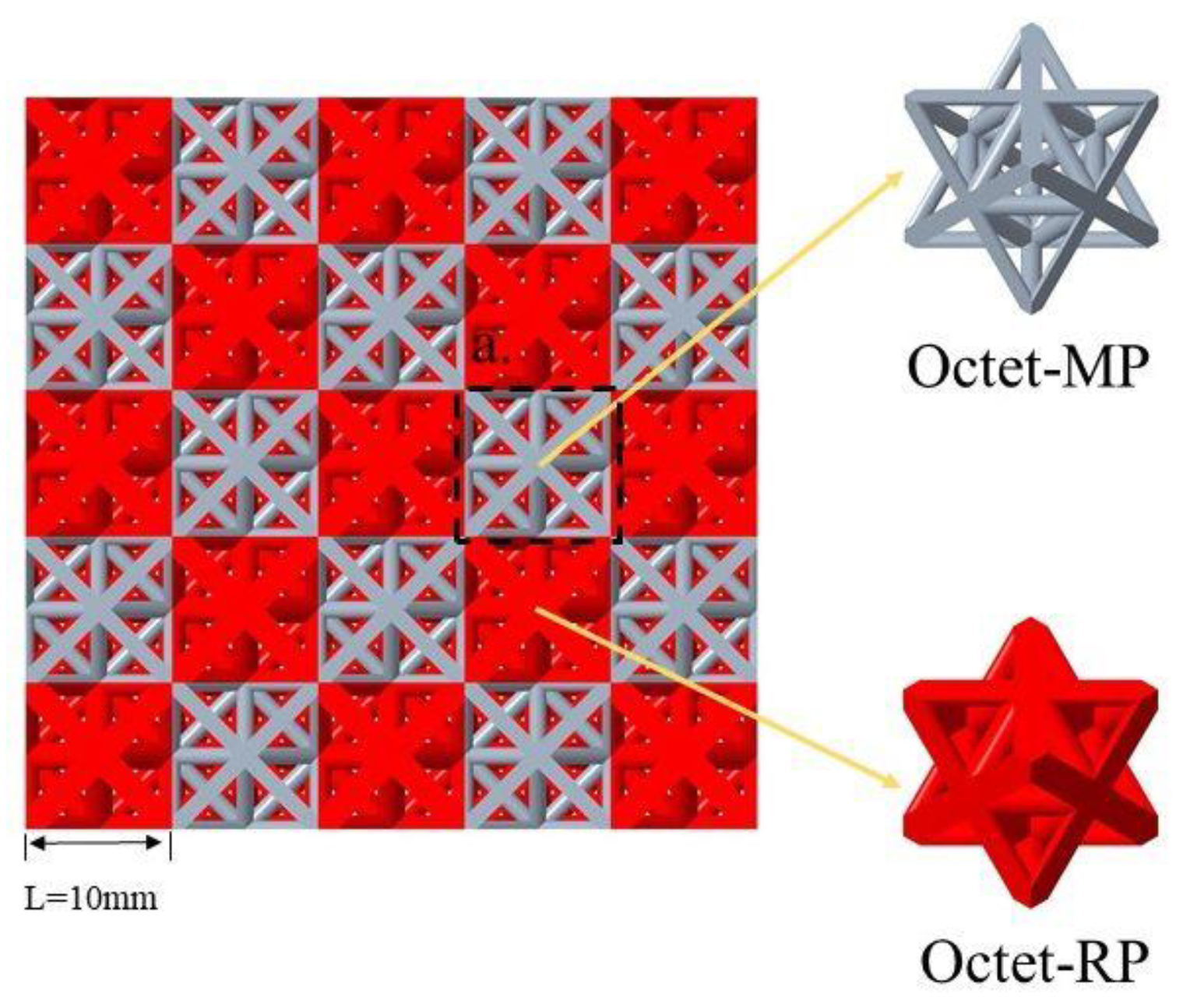

2. Design and Fabrication of Dual-Density Hybrid Lattice Structure

2.1. Model Design

2.2. Sample Preparation

3. Quasi-Static and Dynamic Compression Tests of Octet Lattice and DDHL

3.1. Quasi-Static Behavior of Octet Lattice and DDHL Structures

3.2. Comparison of Specific Energy Absorption between Octet Lattice and DDHL Structures

3.3. Dynamic Experimental Results of the DDHL Structure

4. Conclusions

- Compared with the Octet lattice, the specific energy absorption of the DDHL structure was significantly improved because the interfacial sliding between the matrix phase and the reinforcement phase brought additional energy dissipation.

- With the increase in the compressive strain rate, the effective specific absorption energy of the DDHL was enhanced, due to the gradual emergence of inertial effects.

- Under dynamic compressive loading, the deformation band initially formed by the matrix phase deformation of the DDHL structure was not obvious. Under a compressive strain rate of 100 s−1, the deformation mode of the DDHL exhibited a layer-by-layer collapse.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, X.M.; Su, Y.D.; Wu, B.; Zhang, R.; Wang, F.Y. Application for additive manufacturing of lattice materials on integrated aircraft structures and functions. Aeronaut. Manuf. Technol. 2018, 61, 16–25. [Google Scholar]

- Dai, G.X.; Wu, S.P. Research progress of light and ultralight porous metal materials. Foundry 2020, 69, 1–10. [Google Scholar]

- Tancogne-Dejean, T.; Diamantopoulou, M.; Gorji, M.B.; Bonatti, C.; Mohr, D. 3D plate-lattices: An emerging class of low-density metamaterial exhibiting optimal isotropic stiffness. Adv. Mater. 2018, 30, 1803334. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.H.; Dai, S.; Wu, X.W.; Ma, Y.B.; Deng, Z.C. Elastic isotropic design of PLA lattice structure fabricated by fuse considering material anisotropy. Chin. J. Theor. Appl. Mech. 2022, 54, 1291–1302. [Google Scholar]

- Zeng, S.; Zhu, R.; Jiang, W.; Cai, X.T.; Liu, J.Q. Research progress of metal lattice materials. Mater. Rep. 2012, 26, 18–23+35. [Google Scholar]

- Tao, S.J.; Wang, X.F.; Zeng, J.; Yi, B.; Peng, C.Q.; Wang, R.C. Dot-matrix materials and their 3D printing. Chin. J. Nonferr. Met. 2022, 32, 416–444. [Google Scholar]

- Kaur, I.; Singh, P. Critical evaluation of additively manufactured metal lattices for viability in advanced heat exchangers. Int. J. Heat Mass Transf. 2021, 168, 120858. [Google Scholar] [CrossRef]

- Zheng, X.Y.; Lee, H.; Weisgraber, T.H.; Shusteff, M.; DeOtte, J.; Duoss, E.B.; Kuntz, J.D.; Biener, M.M.; Ge, Q.; Jackson, J.A.; et al. Ultralight, ultrastiff mechanical metamaterials. Science 2014, 344, 1373–1377. [Google Scholar] [CrossRef]

- Yu, X.L.; Zhou, J.; Liang, H.; Jiang, Z.; Wu, L. Mechanical metamaterials associated with stiffness, rigidity and compressibility: A brief review. Prog. Mater. Sci. 2018, 94, 114–173. [Google Scholar] [CrossRef]

- Schaedler, T.A.; Ro, C.J.; Sorensen, A.E.; Eckel, Z.; Yang, S.S.; Carter, W.B.; Jacobsen, A.J. Designing metallic microlattices for energy absorber applications. Adv. Eng. Mater. 2014, 16, 276–283. [Google Scholar] [CrossRef]

- Yang, B.; Peng, X.H.; Zhao, Y.B.; Yin, D.; Fu, T.; Huang, C. Superior mechanical and thermal properties than diamond: Diamond/lonsdaleite biphasic structure. J. Mater. Sci. Technol. 2020, 48, 114–122. [Google Scholar] [CrossRef]

- Lim, C.W.; Li, T.H.; Zhao, Z. Lightweight architected Research progress of metal lattice materials lattice phononic crystals with broadband and multiband vibration mitigation characteristics. Extrem. Mech. Lett. 2020, 41, 100994. [Google Scholar]

- Chen, M.; Jiang, H.; Zhang, H.; Li, D.; Wang, Y. Design of an acoustic superlens using single-phase metamaterials with a star-shaped lattice structure. Sci. Rep. 2018, 8, 1861. [Google Scholar] [CrossRef] [PubMed]

- Evans, A.G. Lightweight Materials and Structures. MRS Bull. 2001, 26, 790–797. [Google Scholar] [CrossRef]

- Mullen, L.; Stamp, R.C.; Brooks, W.K.; Jones, E.; Sutcliffe, C.J. Selective Laser Melting: A regular unit cell approach for the manufacture of porous, titanium, bone in-growth constructs, suitable for orthopedic applications. J. Biomed. Mater. Res. Part B Appl. Biomater. 2009, 89, 325. [Google Scholar] [CrossRef]

- Yan, C.Z.; Hao, L.; Hussein, A.; Raymont, D. Evaluations of cellular lattice structures manufactured using selective laser melting. Int. J. Mach. Tools Manuf. 2012, 62, 32–38. [Google Scholar] [CrossRef]

- Karamooz, M.R.; Kadkhodaei, M.; Badrossamay, M.; Rezaei, R. Numerical investigation on mechanical properties of cellular lattice structures fabricated by fused deposition modeling. Int. J. Mech. Sci. 2014, 88, 154–161. [Google Scholar] [CrossRef]

- Xu, X.X. Study on mechanical properties of octet-truss lattice prepared by SLA. Chin. J. Appl. Mech. 2022, 39, 163–168. [Google Scholar]

- Yu, X.W.; Li, L.H.; Zhang, T.; Zhang, Z.W. Modeling of complex contour lattice structure based on triply periodic minimal surface and voxel distance field. J. Chongqing Univ. 2022, 45, 75–84. [Google Scholar]

- Yin, S.; Guo, W.H.; Wang, H.; Huang, Y.; Yang, R.; Hu, Z.; Chen, D.; Xu, J.; Ritchie, R.O. Strong and tough bioinspired additive-manufactured dual-phase mechanical metamaterial composites. J. Mech. Phys. Solids 2021, 149, 104341. [Google Scholar] [CrossRef]

- Yu, G.J.; Xiao, L.J.; Song, W.D. Deep learning-based heterogeneous strategy for customizing responses of lattice structures. Int. J. Mech. Sci. 2022, 229, 107531. [Google Scholar] [CrossRef]

- Xiao, R.; Li, X.; Jia, H.; Surjadi, J.U.; Li, J.; Lin, W.; Gao, L.; Chirarattananon, P.; Lu, Y. 3D printing of dual phase-strengthened microlattices for lightweight micro aerial vehicles. Mater. Des. 2021, 206, 109767. [Google Scholar] [CrossRef]

- Kladovasilakis, N.; Tsongas, K.; Tzetzis, D. Development of novel additive manufactured hybrid architected materials and investigation of their mechanical behavior. Mech. Mater. 2023, 176, 104525. [Google Scholar] [CrossRef]

- Lei, H.; Li, C.; Zhang, X.; Wang, P.; Zhou, H.; Zhao, Z.; Fang, D. Deformation behavior of heterogeneous multi-morphology lattice core hybrid structures. Addit. Manuf. 2021, 37, 101674. [Google Scholar] [CrossRef]

- Colin, B.; Dirk, M. Large deformation response of additively-manufactured FCC metamaterials: From octet truss lattices towards continuous shell mesostructures. Int. J. Plast. 2017, 92, 122–147. [Google Scholar]

- Ling, C.; Cernicchi, A.; Gilchrist, M.D.; Cardiff, P. Mechanical behaviour of additively-manufactured polymeric octet-truss lattice structures under quasi-static and dynamic compressive loading. Mater. Des. 2019, 162, 106–118. [Google Scholar] [CrossRef]

- Carlton, H.D.; Lind, J.; Messner, M.C.; Volkoff-Shoemaker, N.A.; Barnard, H.S.; Barton, N.R.; Kumar, M. Mapping local deformation behavior in single cell metal lattice structures. Acta Mater. 2017, 129, 239–250. [Google Scholar] [CrossRef]

- Helou, M.; Kara, S. Design, analysis and manufacturing of lattice structures: An overview. Int. J. Comput. Integr. Manuf. 2018, 31, 243–261. [Google Scholar] [CrossRef]

- Azman, A.H. Method for Integration of Lattice Structures in Design for Additive Manufacturing; Université Grenoble Alpes: Grenoble, France, 2017. [Google Scholar]

- Mei, X.C.; Cui, Z.; Sheng, Q.; Zhou, J.; Li, C. Application of the Improved POA-RF Model in Predicting the Strength and Energy Absorption Property of a Novel Aseismic Rubber-Concrete Material. Materials 2023, 16, 1286. [Google Scholar] [CrossRef]

- Zhu, H.X. Review of the application of 3D printing technology. Scientist 2017, 5, 12. [Google Scholar]

- Wang, X.Y.; Shen, F. 3D Review of printing technology. Jiangxi Chem. Ind. 2019, 3, 242–243. [Google Scholar]

- Xiang, Y.F. Comparative analysis of energy absorption capacity of polygonal tubes, multi-cell tubes and honeycombs by utilizing key performance indicators. Steel Constr. 2021, 21, 113553. [Google Scholar] [CrossRef]

- Wang, X.J.; Jia, K.C.; Liu, Y.; Zhou, H. In-Plane Impact Response of Graded Foam Concrete-Filled Auxetic Honeycombs. Materials 2023, 16, 745. [Google Scholar] [CrossRef] [PubMed]

- Ullah, I.; Brandt, M.; Feih, S. Failure and energy absorption characteristics of advanced 3D truss core structures. Mater. Des. 2016, 92, 937–948. [Google Scholar] [CrossRef]

- Wang, S.L.; Wang, H.Q.; Ding, Y.; Yu, F. Crushing behavior and deformation mechanism of randomly honeycomb cylindrical shell structure. Thin Walled Struct. 2020, 151, 106739. [Google Scholar] [CrossRef]

- Wang, S.L.; Zhang, M.; Wang, Y.; Huang, Z.; Fang, Y. Experimental studies on quasi-static axial crushing of additively-manufactured PLA random honeycomb-filled double circular tubes. Compos. Struct. 2021, 261, 113553. [Google Scholar] [CrossRef]

- Liu, Y.Q.; Jang, W.; Hu, W.M.; Ren, L.; Deng, E.; Wang, Y.; Song, C.; Feng, Q. Compressive strength and energy absorption characteristics of the negative stiffness honeycomb cell structure. Mater. Today Commun. 2023, 35, 105498. [Google Scholar] [CrossRef]

- Tan, P.J.; Reid, S.R.; Harrigan, J.J.; Zou, Z.; Li, S. Dynamic compressive strength properties of aluminium foams. Part I-experimental data and observations. J. Mech. Phys. Solids 2005, 53, 2174–2205. [Google Scholar] [CrossRef]

- Avalle, M.; Belingardi, G.; Montanini, R. Characterization of polymeric structural foams under compressive impact loading by means of energy-absorption diagram. Int. J. Impact Eng. 2001, 25, 455–472. [Google Scholar] [CrossRef]

- Rackliffe, M.E.; Jensen, D.W.; Lucas, W.K. Local and global buckling of ultra-lightweight IsoTruss® structures. Compos. Sci. Technol. 2006, 66, 283–288. [Google Scholar] [CrossRef]

| Property | Parameter | Numerical Value |

|---|---|---|

| physical property | density | 1.17–1.24 (g/cm3) |

| melting temperature | 149 (°C) | |

| crystallization temperature | 112 (°C) | |

| mechanical behavior | modulus of elasticity | 1879 ± 109 (MPa) |

| elongation at break | 1.4 ± 0.3 (%) |

| Number | Long | Wide | High | Weigh | Porosity |

|---|---|---|---|---|---|

| Octet-MP | 49.96 | 50.3 | 49.26 | 30.07 | 75.7% |

| Octet-RP | 49.9 | 49.78 | 49.78 | 41.83 | 66.2% |

| DDHL | 49.94 | 49.92 | 49.64 | 35.55 | 71.3% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Ye, J.; Ding, Y.; Wu, G. Study on the Mechanical Behavior of a Dual-Density Hybrid Lattice Structure under Quasi-Static and Dynamic Compressions. Materials 2023, 16, 3822. https://doi.org/10.3390/ma16103822

Li X, Ye J, Ding Y, Wu G. Study on the Mechanical Behavior of a Dual-Density Hybrid Lattice Structure under Quasi-Static and Dynamic Compressions. Materials. 2023; 16(10):3822. https://doi.org/10.3390/ma16103822

Chicago/Turabian StyleLi, Xinyu, Jiajian Ye, Yuanyuan Ding, and Guoyi Wu. 2023. "Study on the Mechanical Behavior of a Dual-Density Hybrid Lattice Structure under Quasi-Static and Dynamic Compressions" Materials 16, no. 10: 3822. https://doi.org/10.3390/ma16103822