Effects of Steel Slag Powder Content and Curing Condition on the Performance of Alkali-Activated Materials Based UHPC Matrix

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Mix Proportions and Specimens Preparations

2.3. Curing Condition

2.4. Testing Methods

3. Results and Discussion

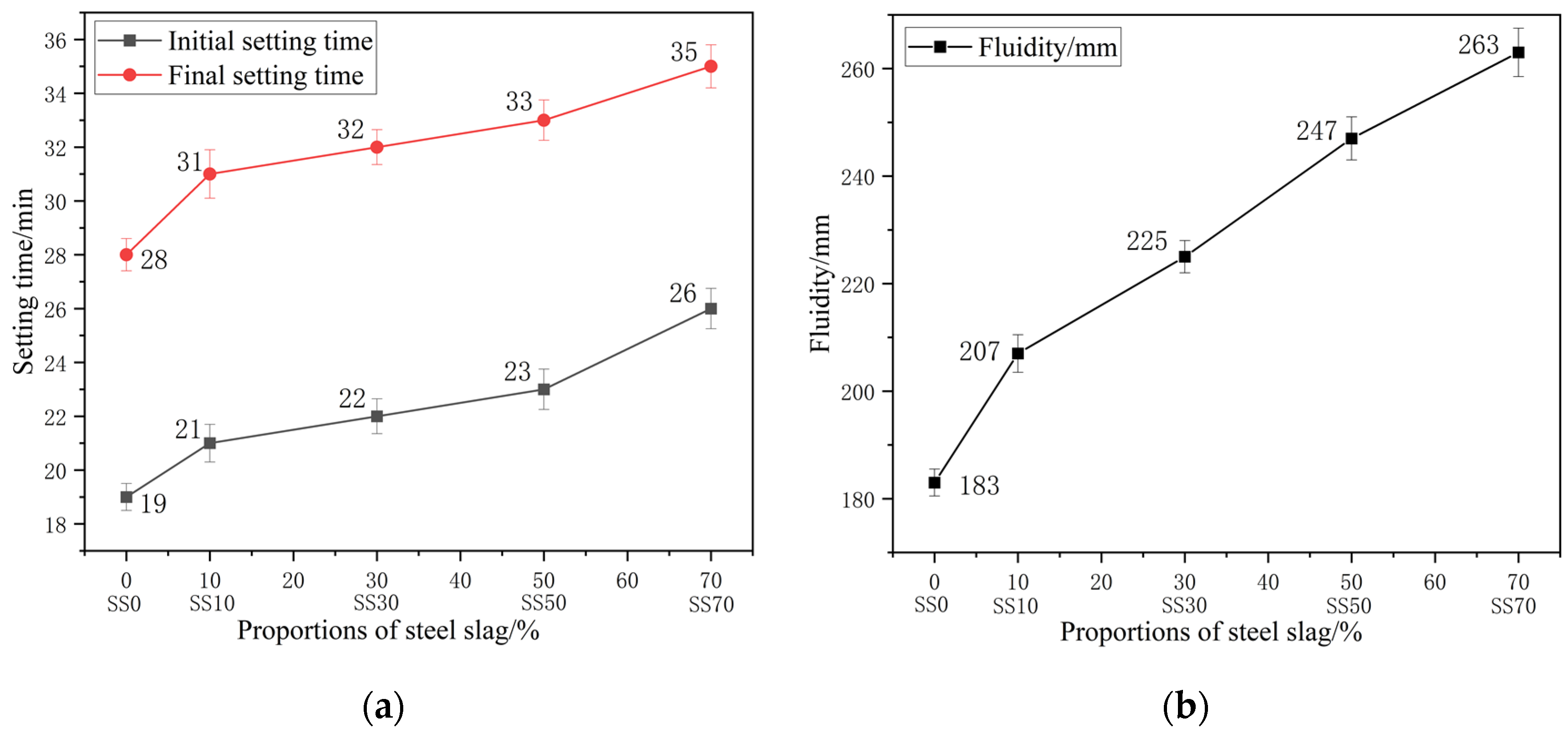

3.1. Influence of Steel Slag Powder Dosage on Workability

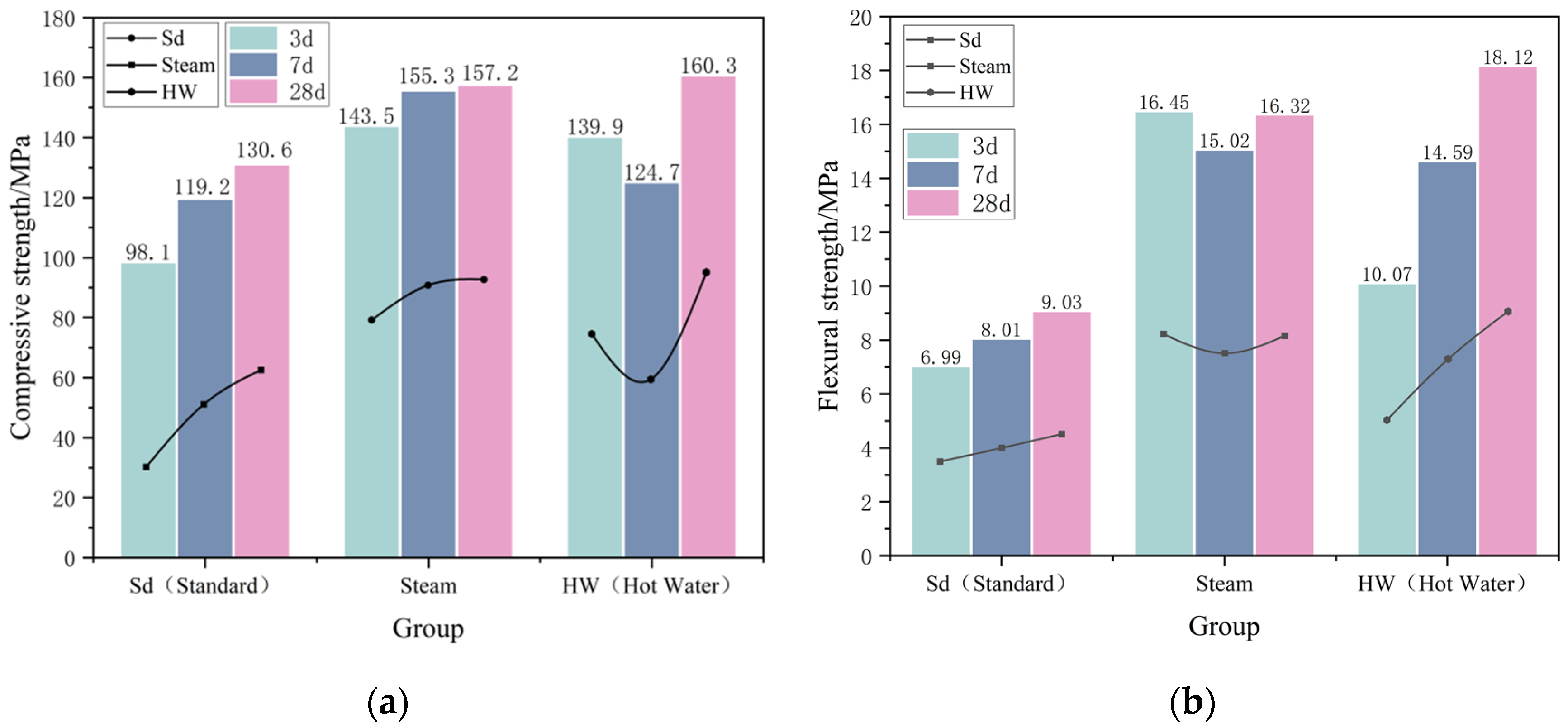

3.2. Influence of Steel Slag Powder on Mechanical Properties

3.3. Influence of Curing Condition on the Mechanical Properties

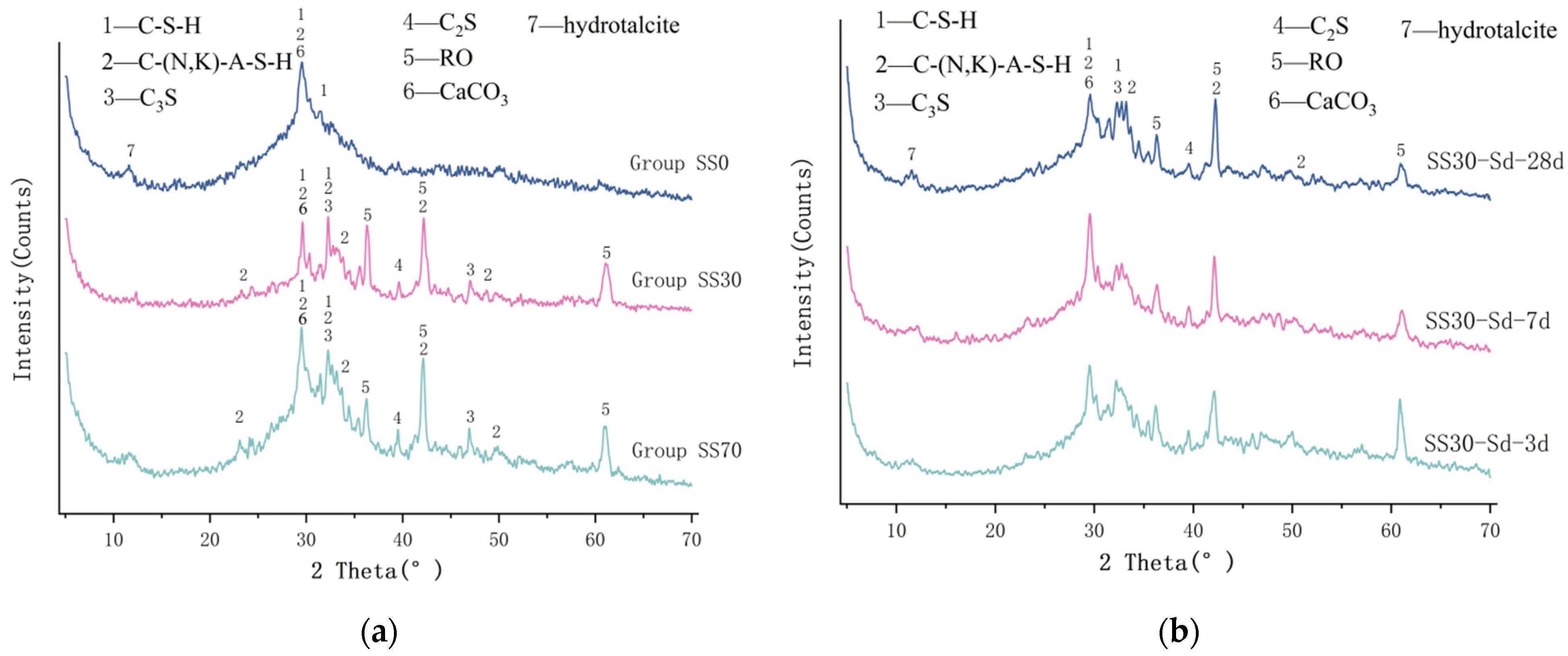

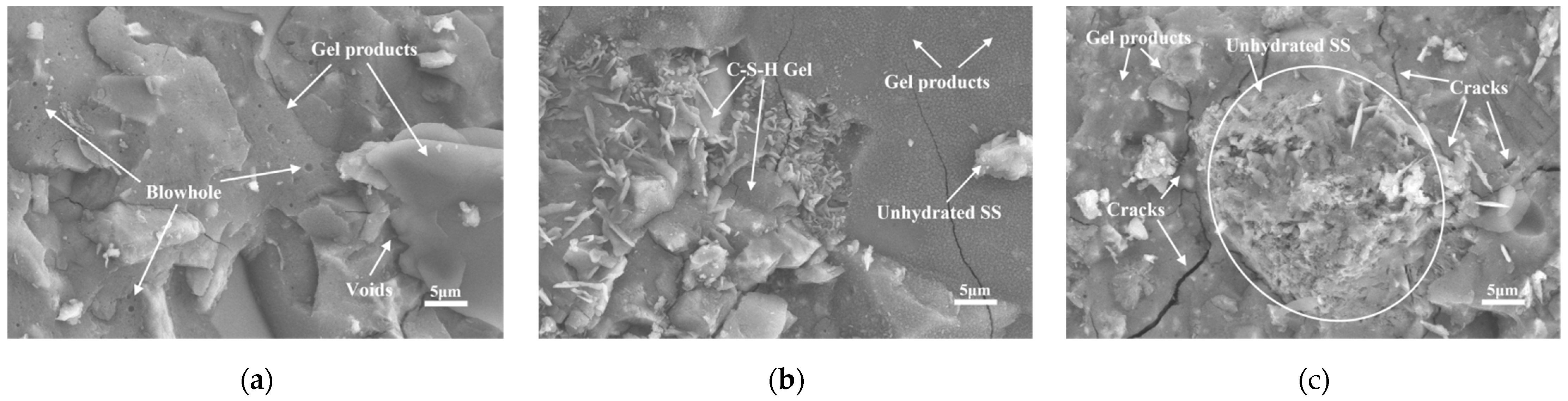

3.4. Analysis of Microstructure and Phase Composition

3.5. Analysis of Pore Structure

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bache, H.H. Compact Reinforced Composite Basic Principles; Aalborg Portland (Denmark). Cement- og Betonlaboratoriet: Aalborg, Denmark, 1987. [Google Scholar]

- Larrard, F.D.; Sedran, T. Optimization of ultra-high-performance concrete by the use of a packing model. Cem. Concr. Res. 1994, 24, 997–1009. [Google Scholar] [CrossRef]

- Teixeira Marvila, M.; Garcez de Azevedo, A.R.; de Matos, P.R.; Neves Monteiro, S.; Fontes Vieira, C.M. Materials for Production of High and Ultra-High Performance Concrete: Review and Perspective of Possible Novel Materials. Materials 2021, 14, 4304. [Google Scholar] [CrossRef] [PubMed]

- Turner, L.K.; Collins, F.G. Carbon dioxide equivalent (CO2-e) emissions: A comparison between geopolymer and OPC cement concrete. Constr. Build. Mater. 2013, 43, 125–130. [Google Scholar] [CrossRef]

- Fan, D.; Yu, R.; Shui, Z.; Liu, K.; Feng, Y.; Wang, S.; Li, K.; Tan, J.; He, Y. A new development of eco-friendly Ultra-High performance concrete (UHPC): Towards efficient steel slag application and multi-objective optimization. Constr. Build. Mater. 2021, 306, 124913. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Fan, M.X.; Zhou, Y.X.; Ji, D.D.; Li, J.H.; Yu, R. Development of a sustainable alkali activated ultra-high performance concrete (A-UHPC) incorporating recycled concrete fines. J. Build. Eng. 2023, 67, 105986. [Google Scholar] [CrossRef]

- Hamada, H.M.; Shi, J.; Abed, F.; Jawahery, M.S.A.; Majdi, A.; Yousif, S.T. Recycling solid waste to produce eco-friendly ultra-high performance concrete: A review of durability, microstructure and environment characteristics. Sci. Total Environ. 2023, 876, 162804. [Google Scholar] [CrossRef]

- Wang, D.; Shi, C.; Wu, Z.; Xiao, J.; Huang, Z.; Fang, Z. A review on ultra high performance concrete: Part II. Hydration, microstructure and properties. Constr. Build. Mater. 2015, 96, 368–377. [Google Scholar] [CrossRef]

- Ministry of Environmental Protection. People’s Republic of China Bulletin on the Environmental Condition of China in 2013; Ministry of Environmental Protection: Beijing, China, 2013.

- Guo, J.; Bao, Y.; Wang, M. Steel Slag in China: Treatment, Recycling, and Management. Waste Manag. 2018, 78, 318–330. [Google Scholar] [CrossRef]

- Yao, Y.; Wang, W.; Ge, Z.; Ren, C.; Yao, X.; Wu, S. Hydration study and characteristic analysis of a sulfoaluminate high-performance cementitious material made with industrial solid wastes. Cem. Concr. Composit. 2020, 112, 103687. [Google Scholar] [CrossRef]

- Yi, H.; Xu, G.; Cheng, H.; Wang, J.; Wan, Y.; Chen, H. An Overview of Utilization of Steel Slag. Procedia Environ. Sci. 2012, 16, 791–801. [Google Scholar] [CrossRef]

- Qasrawi, H.; Shalabi, F.; Asi, I. Use of low CaO unprocessed steel slag in concrete as fine aggregate. Constr. Build. Mater. 2009, 23, 1118–1125. [Google Scholar] [CrossRef]

- Zhang, X.; Yu, R.; Zhang, J.; Shui, Z. A low-carbon alkali activated slag based ultra-high performance concrete (UHPC): Reaction kinetics and microstructure development. J. Clean. Prod. 2022, 363, 132416. [Google Scholar] [CrossRef]

- Teixeira Marvila, M.; Garcez de Azevedo, A.R.; Tostes Linhares Júnior, J.A.; Fontes Vieira, C.M. Activated alkali cement based on blast furnace slag: Effect of curing type and concentration of Na20. J. Mater. Res. Technol. 2023, 23, 4551–4565. [Google Scholar] [CrossRef]

- Lao, J.-C.; Huang, B.-T.; Fang, Y.; Xu, L.-Y.; Dai, J.-G.; Shah, S.P. Strain-hardening alkali-activated fly ash/slag composites with ultra-high compressive strength and ultra-high tensile ductility. Cem. Concr. Res. 2023, 165, 107075. [Google Scholar] [CrossRef]

- Temuujin, J.; van Riessen, A.; MacKenzie, K. Preparation and characterization of fly ash based geopolymer mortars. Constr. Build. Mater. 2010, 24, 1906–1910. [Google Scholar] [CrossRef]

- Shi, C.; Day, R.L. Selectivity of Alkaline Activators for the Activation of Slags. Cem. Concr. Aggreg. 1996, 18, 8–14. [Google Scholar]

- Somna, K.; Chai, J.; Kajitvichyanukul, P.; Chindaprasirt, P. NaOH-activated ground fly ash geopolymer cured at ambient temperature. Fuel 2011, 90, 2118–2124. [Google Scholar] [CrossRef]

- Sun, X.; Zhao, Y.; Qiu, J.; Xing, J. Review: Alkali-activated blast furnace slag for eco-friendly binders. J. Mater. Sci. 2022, 57, 1599–1622. [Google Scholar] [CrossRef]

- Valente, M.; Sambucci, M.; Chougan, M.; Ghaffar, S.H. Reducing the emission of climate-altering substances in cementitious materials: A comparison between alkali-activated materials and Portland cement-based composites incorporating recycled tire rubber. J. Clean. Prod. 2021, 333, 130013. [Google Scholar] [CrossRef]

- Zeng, L.; Yu, Y.H.; Ren, Y.; Wang, S.; Peng, X.; Sun, X. Preparation of Aerated Concrete with Alkali Activated Steel Slag and Blast Furnace Slag. J. Build. Mater. 2019, 22, 206–213. (In Chinese) [Google Scholar]

- Wang, X.; Wang, K.; Li, J.; Wang, W.; Mao, Y.; Wu, S.; Yang, S. Heavy metals migration during the preparation and hydration of an eco-friendly steel slag-based cementitious material. J. Clean. Prod. 2021, 329, 129715. [Google Scholar] [CrossRef]

- Randl, N.; Steiner, T.; Ofner, S.; Baumgartner, E.; Mészöly, T. Development of UHPC mixtures from an ecological point of view. Constr. Build. Mater. 2014, 67, 373–378. [Google Scholar] [CrossRef]

- Abdulkareem, O.M.; Ben Fraj, A.; Bouasker, M.; Khouchaf, L.; Khelidj, A. Microstructural investigation of slag-blended UHPC: The effects of slag content and chemical/thermal activation. Constr. Build. Mater. 2021, 292, 123455. [Google Scholar] [CrossRef]

- Cui, K.; Liang, K.; Chang, J.; Lau, D. Investigation of the macro performance, mechanism, and durability of multiscale steel fiber reinforced low-carbon ecological UHPC. Constr. Build. Mater. 2022, 327, 126921. [Google Scholar] [CrossRef]

- Ahmed, T.; Elchalakani, M.; Karrech, A.; Dong, M.; Ali, M.S.M.; Yang, H. ECO-UHPC with High-Volume Class-F Fly Ash: New Insight into Mechanical and Durability Properties. J. Mater. Civ. Eng. 2021, 33, 04021174. [Google Scholar] [CrossRef]

- Du, J.; Liu, Z.; Christodoulatos, C.; Conway, M.; Bao, Y.; Meng, W. Utilization of off-specification fly ash in preparing ultra-high-performance concrete (UHPC): Mixture design, characterization, and life-cycle assessment. Resour. Conserv. Recycl. 2022, 180, 106136. [Google Scholar] [CrossRef]

- Chen, W.; Li, B.; Wang, J.; Thom, N. Effects of alkali dosage and silicate modulus on autogenous shrinkage of alkali-activated slag cement paste. Cem. Concr. Res. 2021, 141, 106322. [Google Scholar] [CrossRef]

- Choi, J.-I.; Lee, B.Y.; Ranade, R.; Li, V.C.; Lee, Y. Ultra-high-ductile behavior of a polyethylene fiber-reinforced alkali-activated slag-based composite. Cem. Concr. Composit. 2016, 70, 153–158. [Google Scholar] [CrossRef]

- Cai, R.; Ye, H. Clinkerless ultra-high strength concrete based on alkali-activated slag at high temperatures. Cem. Concr. Res. 2021, 145, 106465. [Google Scholar] [CrossRef]

- Cai, R.; Tian, Z.; Ye, H. Durability characteristics and quantification of ultra-high strength alkali-activated concrete. Cem. Concr. Compos. 2022, 134, 104743. [Google Scholar] [CrossRef]

- Huang, J.-Q.; Zan, H.-P.; Yu, Q.-J.; Zhao, S.-Y.; Qiao, F.; Yin, S.-H.; Wen, Z.-Y. Effect of Setting Retarder on the Performance of Alkali-activated Carbonatite-slag Grouting Material. J. Wuhan Univ. Technol. 2006, 28, 20–23. [Google Scholar]

- Bilim, C.; Karahan, O.; Atiş, C.D.; Ilkentapar, S. Influence of admixtures on the properties of alkali-activated slag mortars subjected to different curing conditions. Mater. Des. 2013, 44, 540–547. [Google Scholar] [CrossRef]

- Sasaki, K.; Kurumisawa, K.; Ibayashi, K. Effect of retarders on flow and strength development of alkali-activated fly ash/blast furnace slag composite. Constr. Build. Mater. 2019, 216, 337–346. [Google Scholar] [CrossRef]

- Su, T.; Zhou, Y.; Wang, Q. Recent advances in chemical admixtures for improving the workability of alkali-activated slag-based material systems. Constr. Build. Mater. 2020, 272, 121647. [Google Scholar]

- Yang, C.H.; Wu, F.; Chen, K. Research on set retarder of high and super high strength alkali-activated slag cement and concrete. Key Eng. Mater. 2011, 477, 164–169. [Google Scholar] [CrossRef]

- Holschemacher, K.; Tekle, B.H. Review and Experimental Investigation of Retarder for Alkali-Activated Cement. In Proceedings of the 75th RILEM Annual Week 2021; Springer: Berlin, Germany, 2023; pp. 614–625. [Google Scholar]

- You, N.; Li, B.; Cao, R.; Shi, J.; Chen, C.; Zhang, Y. The influence of steel slag and ferronickel slag on the properties of alkali-activated slag mortar. Constr. Build. Mater. 2019, 227, 116614. [Google Scholar] [CrossRef]

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Mix design and properties assessment of Ultra-High Performance Fibre Reinforced Concrete (UHPFRC). Cem. Concr. Res. 2014, 56, 29–39. [Google Scholar] [CrossRef]

- GB/T 1346-2011; Tests Methods for Water Requirement of Normal Consistency (MOD, ASTM C187M), Setting Time (MOD, ASTM C191M) and Soundness of the Portland Cement. General Administration of Quality Supervision, Inspection and Quarantine of PR China: Beijing, China, 2011.

- GB/T 2419-2005; Test Method for Fluidity of Cement Mortar. Inspection and Quarantine of PR China: Beijing, China, 2005.

- ASTM C109/C109M-99; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in or [50 mm] Cube Specimens), Annual Book of ASTM Standards. ASTM International: Philadelphia, PA, USA, 2021; p. 83.

- GB/T 17671-1999 (MOD, IOS 679: 1989); Method of testing cementsDetermination of strength. General Administration of Quality Supervision, Inspection and Quarantine of PR China: Beijing, China, 1999.

- Sun, J.; Chen, Z. Effect of silicate modulus of water glass on the hydration of alkali-activated converter steel slag. J. Therm. Anal. Calorim. 2019, 138, 47–56. [Google Scholar] [CrossRef]

- Wei, Y.; Chen, P.; Ming, Y.; Luo, J.; Zhang, G.; Wu, Y. Effects of Ultrafine and Highly Active Mineral Admixtures on Hydration and Shrinkage Properties of UHPC. Bull. Chin. Ceram. Soc. 2022, 41, 461–468. (In Chinese) [Google Scholar]

- Tang, W.J. Effect of Micro-Powder Mixture of Steel Slag and Granulated Blast Furnace Slag on Cement and Concrete Proper-ties. Ph.D. Thesis, China University of Geosciences, Beijing, China, 2009. (In Chinese). [Google Scholar]

- Song, W.; Zhu, Z.; Peng, Y.; Wan, Y.; Xu, X.; Pu, S.; Song, S.; Wei, Y. Effect of steel slag on fresh, hardened and microstructural properties of high-calcium fly ash based geopolymers at standard curing condition. Constr. Build. Mater. 2019, 229, 116933. [Google Scholar] [CrossRef]

- Wang, Q.; Yan, P.; Mi, G. Effect of blended steel slag–GBFS mineral admixture on hydration and strength of cement. Constr. Build. Mater. 2012, 35, 8–14. [Google Scholar] [CrossRef]

- Sun, X.; Peng, X.; Zhang, G.; Wang, S.; Zeng, L. Effect of steel slag content on properties of alkali-activated steel slag and slag based grouting material. New Build. Mater. 2017, 44, P10–P13. [Google Scholar]

- Zalnezhad, M.; Hesami, E. Effect of steel slag aggregate and bitumen emulsion types on the performance of microsurfacing mixture. J. Traffic Transport. Eng. (Engl. Ed.) 2020, 7, 215–226. [Google Scholar] [CrossRef]

- GB/T 31387-2015; Code for reactive powder concrete. General Administration of Quality Supervision, Inspection and Quarantine of PR China: Beijing, China, 2015.

- Wang, Q.; Li, M.; Shi, M. Hydration Properties of Cement-Steel Slag- Ground Granulated Blast Furnace Slag Complex Binder. J. Chin. Ceram. Soc. 2014, 42, 629–634. [Google Scholar]

- Yu, F.; Xiong, J.; Deng, C.; Zeng, J.; Fan, Z. Study on the Influence of Curing Methods on Compressive Strength of C100 Ultra-high Strength Concrete. Bull. Chin. Ceram. Soc. 2017, S1, 194–198+218. [Google Scholar]

- Chi, P.; Zhang, Y.; Yang, Y. Research on Mechanism of Dry-wet heat Curing of Concrete. China Concr. Cem. Prod. 2001, 3, 11–14. [Google Scholar]

- Peng, X.Q.; Liu, C.; Li, S.; Jiang, Y.; Zeng, L. Research on the setting and hardening performance of alkali-activated steel slag-slag based cementitious materials. J. Hunan Univ. (Nat. Sci.) 2015, 42, 47–52. [Google Scholar]

- Song, W.; Zhu, Z.; Pu, S.; Wan, Y.; Huo, W.; Song, S.; Zhang, J.; Yao, K.; Hu, L. Efficient use of steel slag in alkali-activated fly ash-steel slag-ground granulated blast furnace slag ternary blends. Constr. Build. Mater. 2020, 259, 119814. [Google Scholar] [CrossRef]

| CaO | SiO2 | Al2O3 | MgO | FexOy | MnO | P2O5 | TiO2 | f-CaO | LOI | |

|---|---|---|---|---|---|---|---|---|---|---|

| Steel Slag | 33.26 | 14.52 | 2.9 | 5.68 | 26.53 | 4.35 | 2.41 | - | - | 10.62 |

| GGBFS | 37.41 | 30.92 | 15.74 | 8.72 | 0.3 | - | - | 2.15 | 0.04 | 4.72 |

| Silica Fume | 0.38 | 97.51 | 0.16 | 0.88 | - | - | 0.25 | - | - | 0.98 |

| Group | Steel Slag | GGBFS | Silica Fume | Water | Activator | Curing Condition | |

|---|---|---|---|---|---|---|---|

| Na2O·9SiO2 | K2CO3 | ||||||

| SS0 | 0 | 90 | 10 | 0.23 | 9.5 | 6.7 | Steam |

| SS10 | 10 | 80 | |||||

| SS30 | 30 | 60 | |||||

| SS50 | 50 | 40 | |||||

| SS70 | 70 | 20 | |||||

| SS30-Sd | 30 | 60 | Standard | ||||

| SS30-HW | 30 | 60 | Hot water | ||||

| Group | Porosity/% | Average Pore Size/nm | Pore Size Distribution/% | |||

|---|---|---|---|---|---|---|

| <20 nm | 20~100 nm | 100~200 nm | >200 nm | |||

| SS0-3d | 5.07 | 47.21 | 60.59 | 6.50 | 8.94 | 23.98 |

| SS30-3d | 6.71 | 8.43 | 38.08 | 4.95 | 7.43 | 49.22 |

| SS70-3d | 4.98 | 48.35 | 55.51 | 7.34 | 13.06 | 23.26 |

| SS30-Sd-3d | 10.66 | 14.93 | 52.41 | 11.41 | 7.54 | 28.62 |

| SS30-Sd-7d | 6.72 | 12.06 | 49.24 | 7.90 | 7.90 | 34.95 |

| SS30-Sd-28d | 6.01 | 19.43 | 50.17 | 15.67 | 8.71 | 25.08 |

| SS30-HW-3d | 5.35 | 10.21 | 53.66 | 5.02 | 2.70 | 37.83 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, K.; Deng, H.; Hu, J.; Zhou, J.; Cai, X.; Liu, Z. Effects of Steel Slag Powder Content and Curing Condition on the Performance of Alkali-Activated Materials Based UHPC Matrix. Materials 2023, 16, 3875. https://doi.org/10.3390/ma16103875

Shi K, Deng H, Hu J, Zhou J, Cai X, Liu Z. Effects of Steel Slag Powder Content and Curing Condition on the Performance of Alkali-Activated Materials Based UHPC Matrix. Materials. 2023; 16(10):3875. https://doi.org/10.3390/ma16103875

Chicago/Turabian StyleShi, Kangyi, Hongyang Deng, Jinxuan Hu, Junqi Zhou, Xinhua Cai, and Zhiwei Liu. 2023. "Effects of Steel Slag Powder Content and Curing Condition on the Performance of Alkali-Activated Materials Based UHPC Matrix" Materials 16, no. 10: 3875. https://doi.org/10.3390/ma16103875

APA StyleShi, K., Deng, H., Hu, J., Zhou, J., Cai, X., & Liu, Z. (2023). Effects of Steel Slag Powder Content and Curing Condition on the Performance of Alkali-Activated Materials Based UHPC Matrix. Materials, 16(10), 3875. https://doi.org/10.3390/ma16103875