Cryomilling of Isotope-Enriched Ti Powders for HIVIPP Deposition to Manufacture Targets for Nuclear Cross Section Measurement

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Cryomilling Process: Instrumentation for Powder Preparation

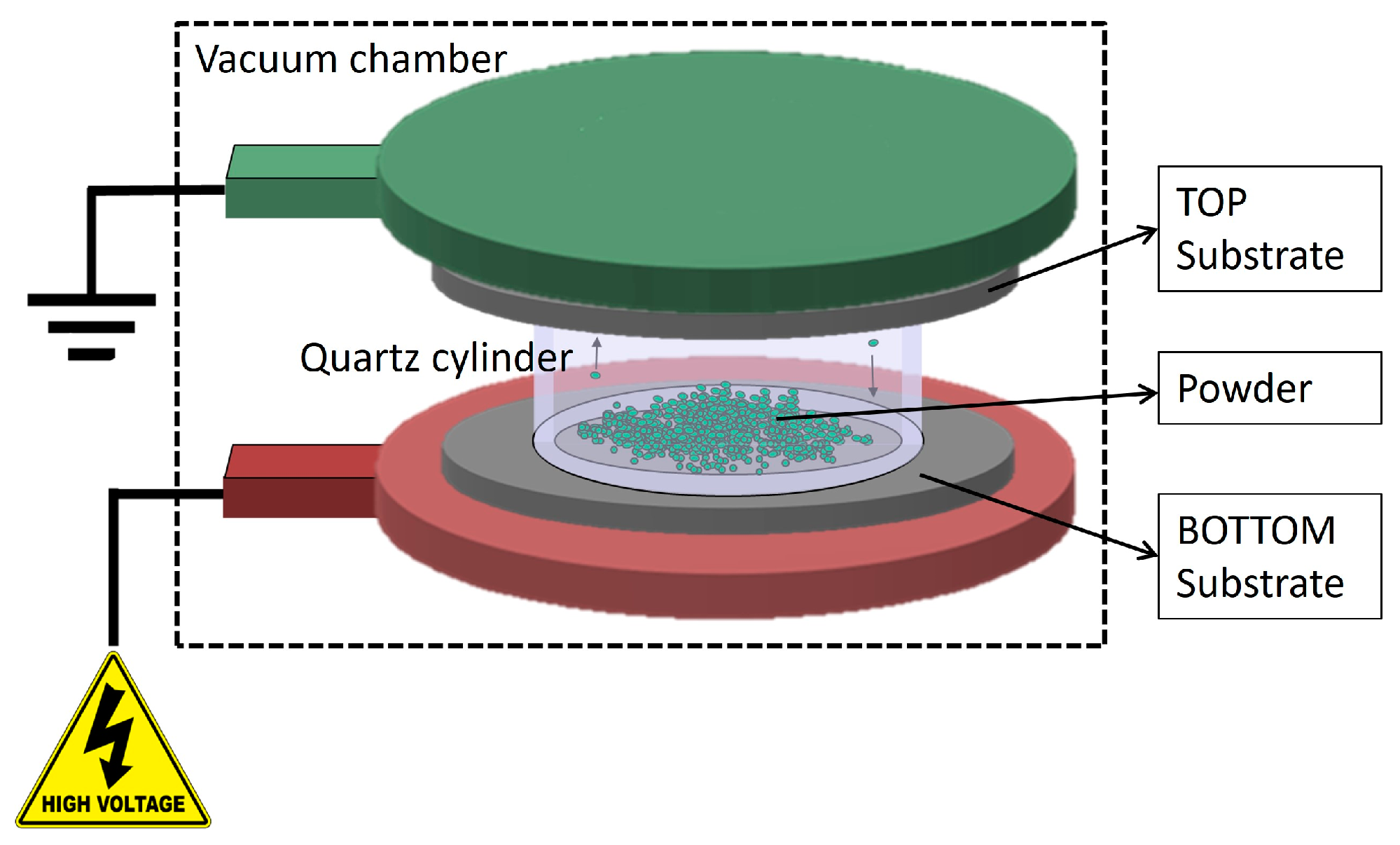

2.3. HIVIPP Deposition

- weighing the Al substrates;

- loading about 20 mg of Ti powder in the quartz cylinder;

- placing the sample holder in the vacuum chamber and starting the vacuum system with the cylinder open;

- when the pressure reaches about 1 × 10−7 mbar, close the cylinder and start the deposition increasing the voltage following a set ramp until the desired maximum value;

- after deposition, carefully recovering the undeposited powder into a dedicated glass vial for subsequent reuse, and then cleaning the samples with compressed air to eliminate the negligible residuals of the not-attached powder.

- weighing the samples to calculate the amount deposited.

2.4. Characterization Analysis

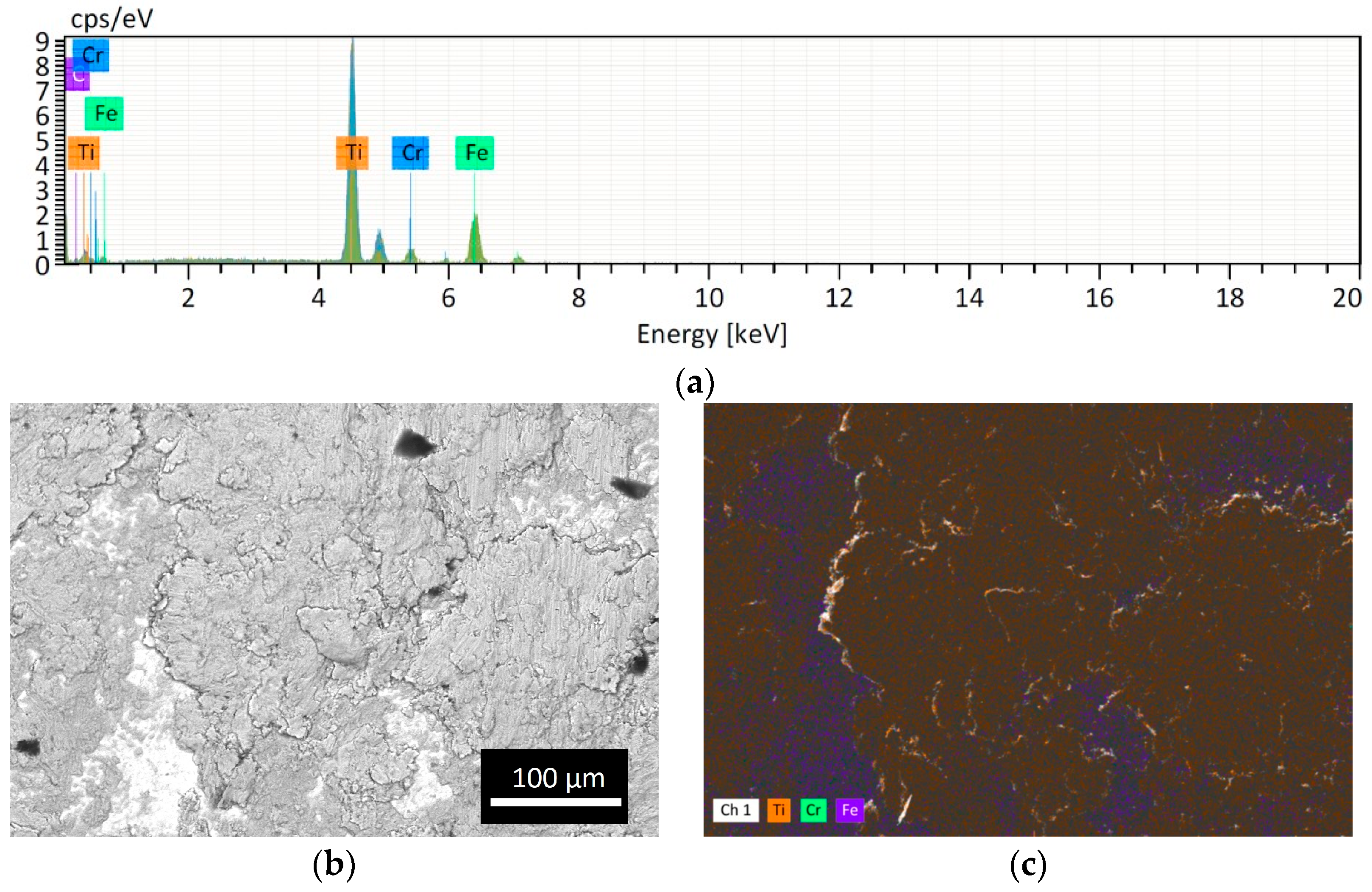

3. Results and Discussions

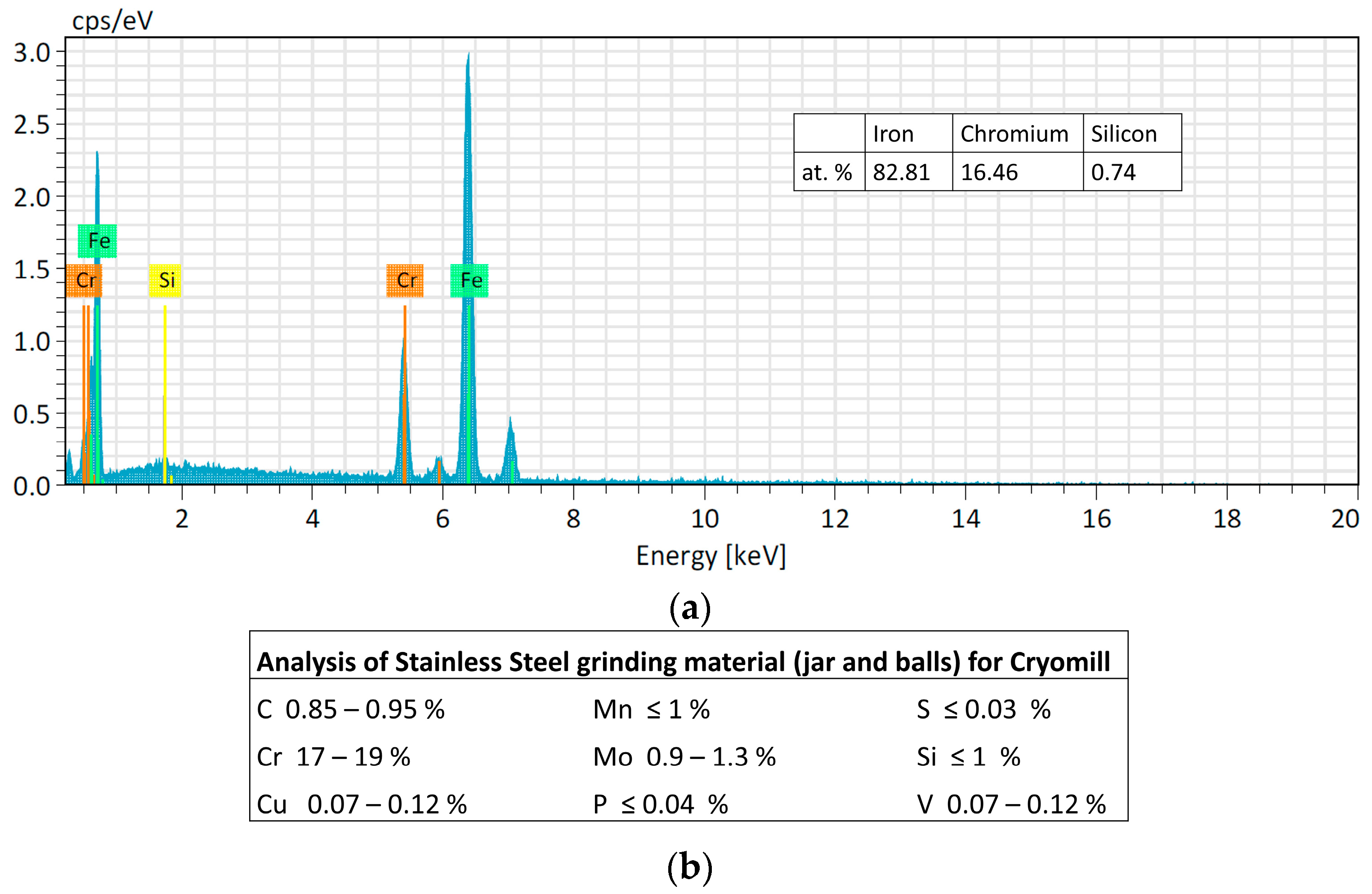

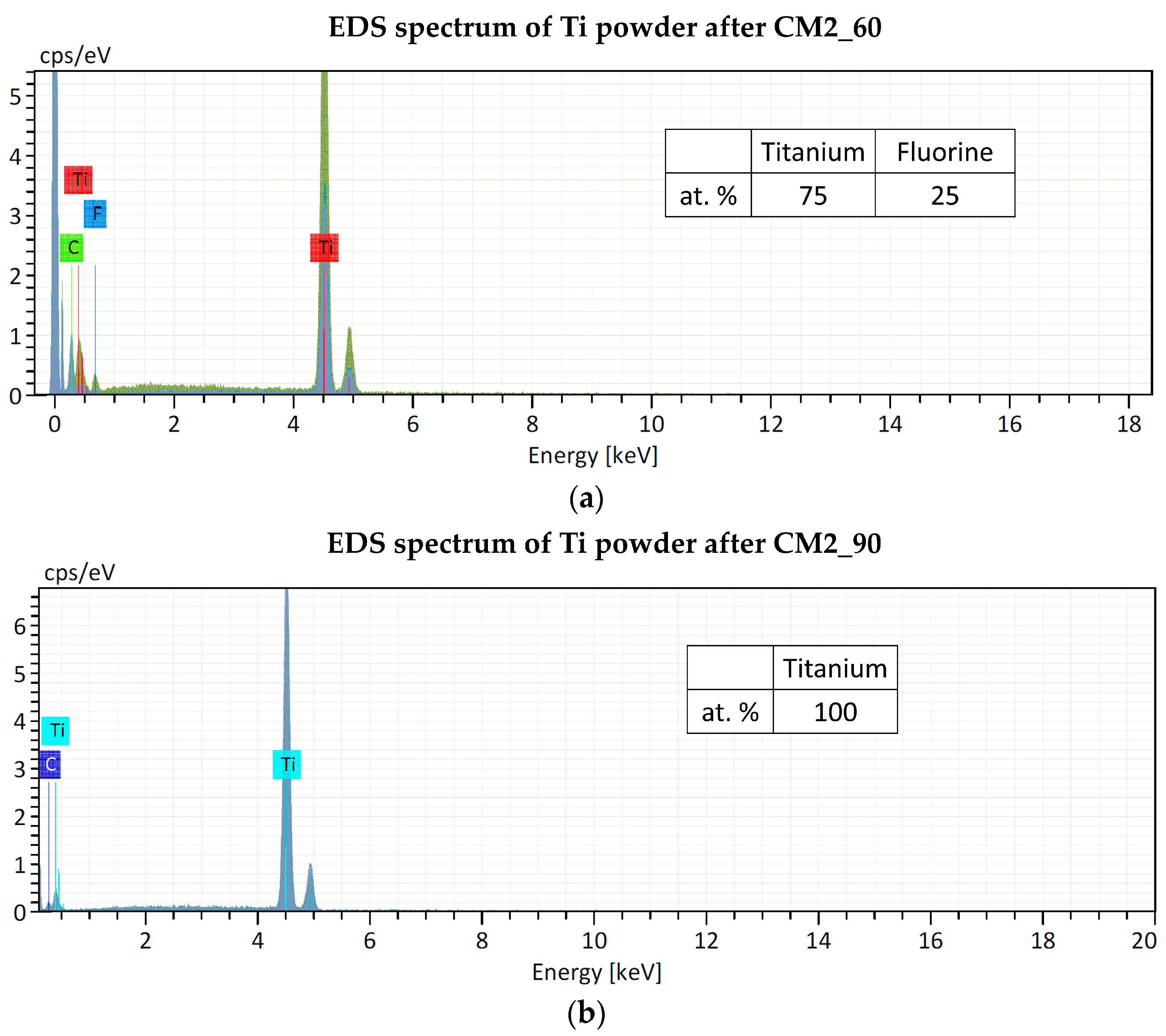

3.1. Powder Preparation with Cryomilling Process

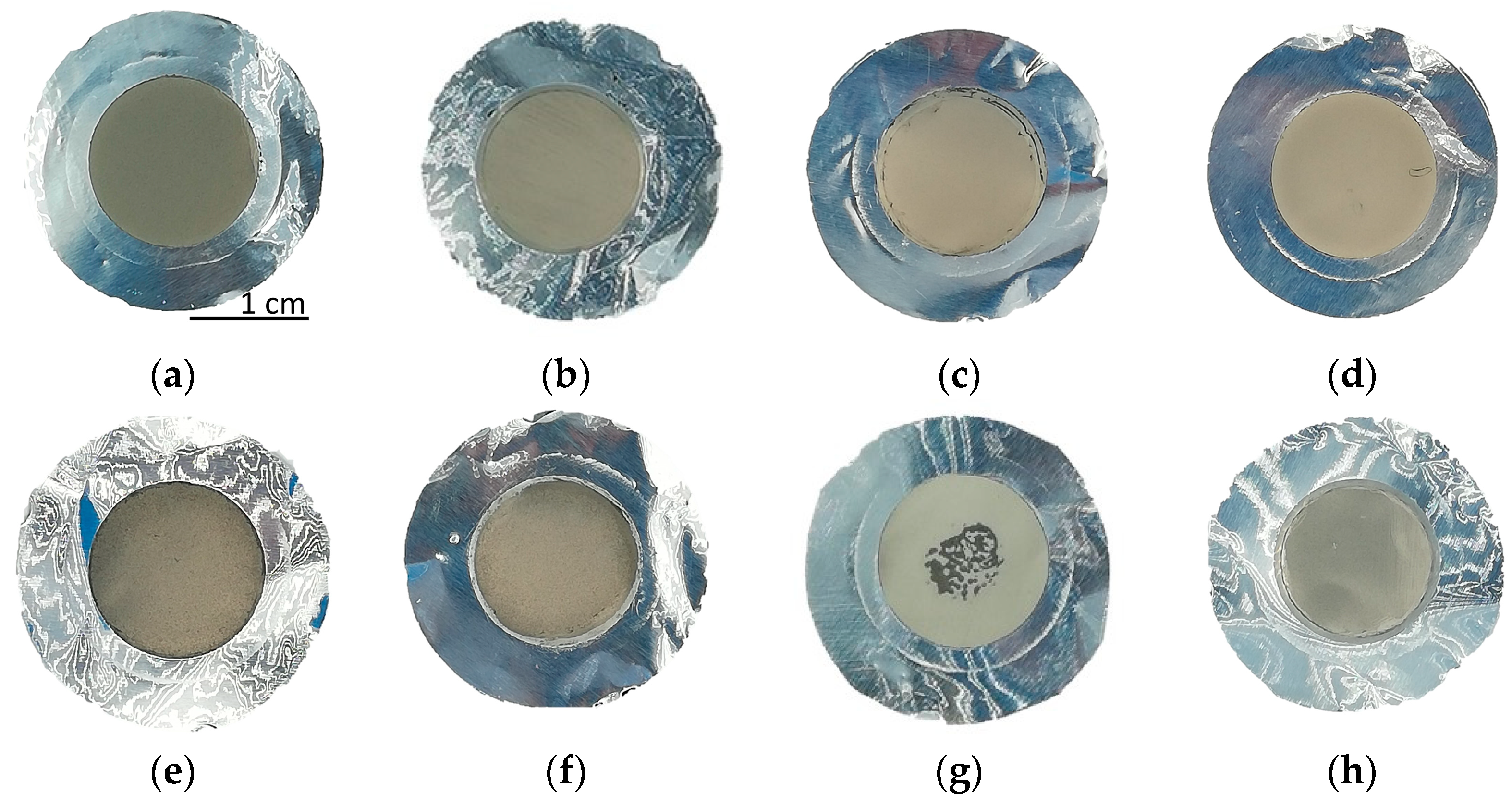

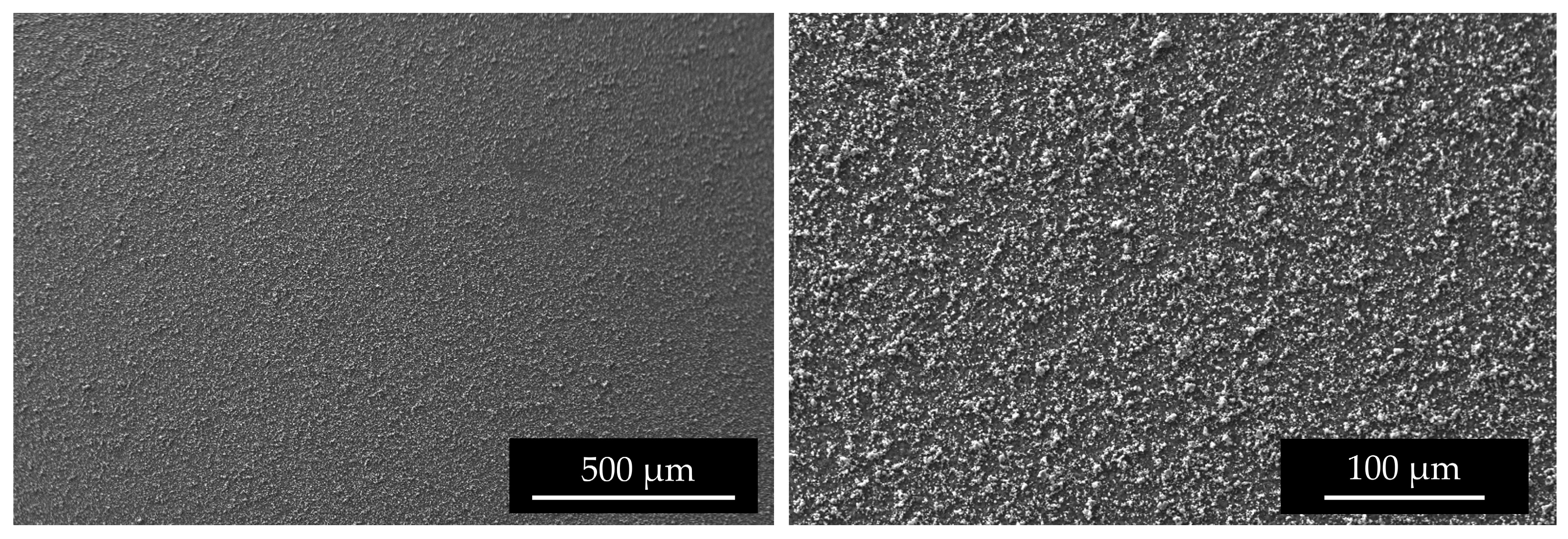

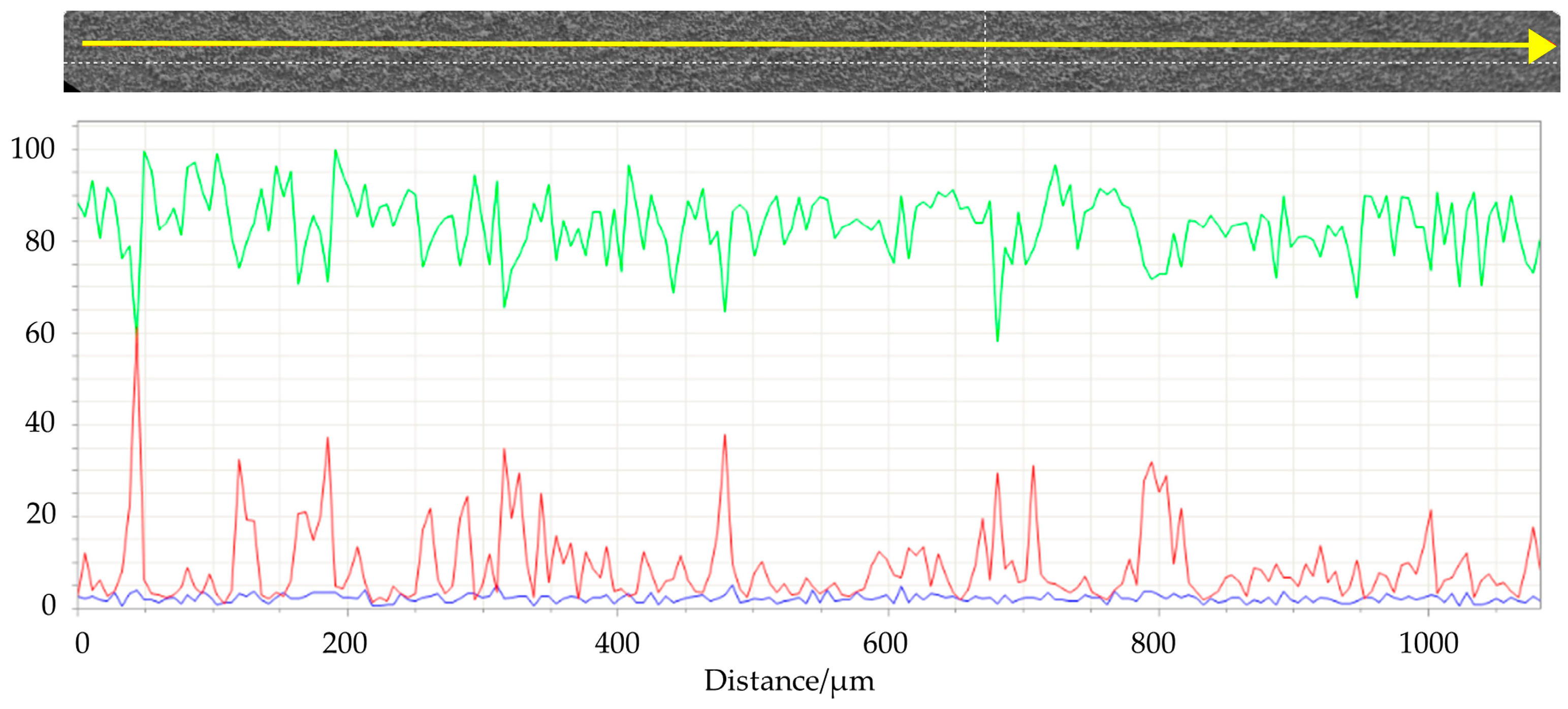

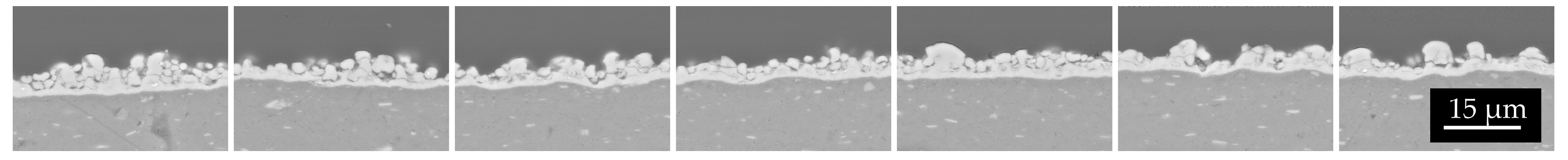

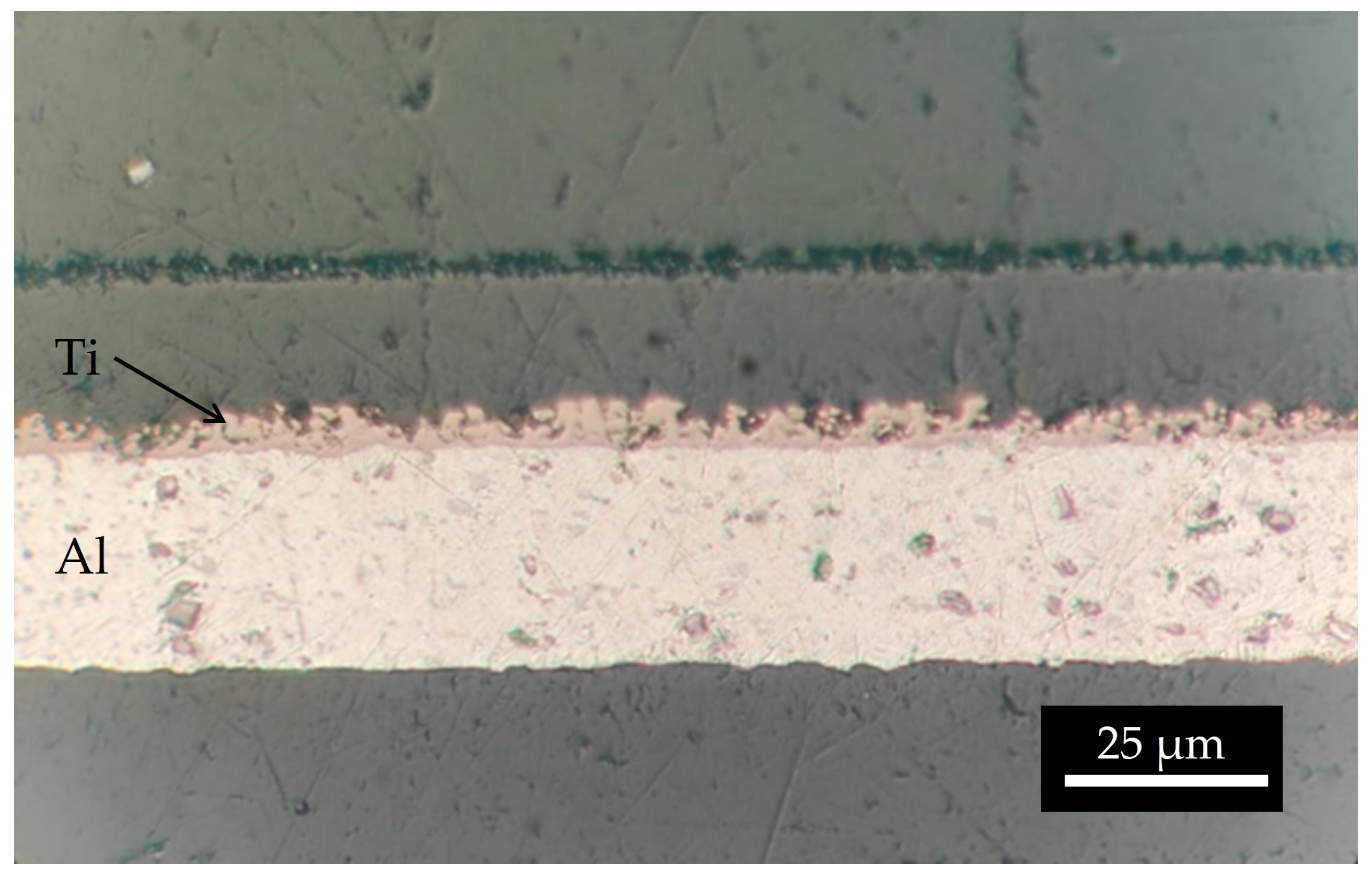

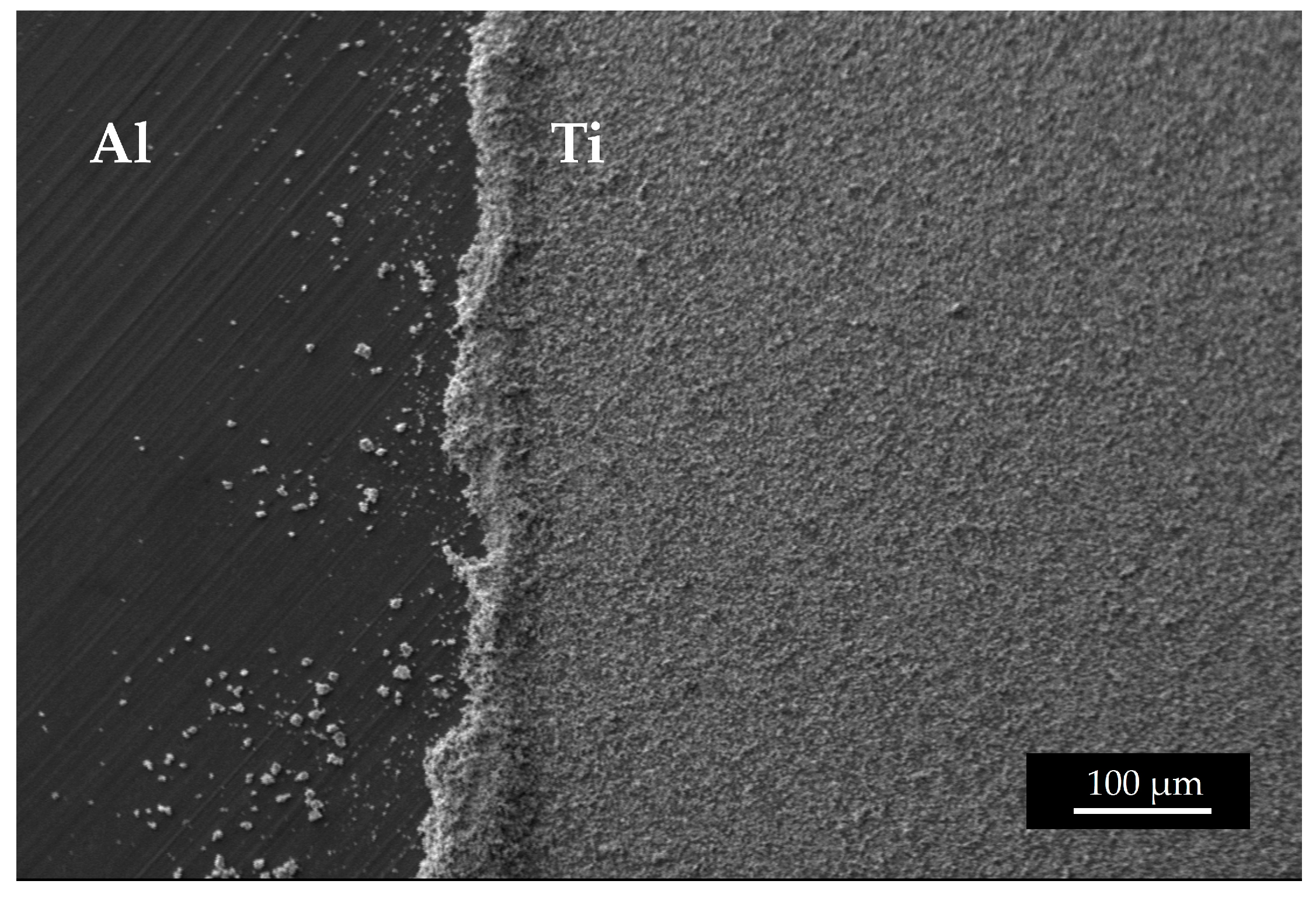

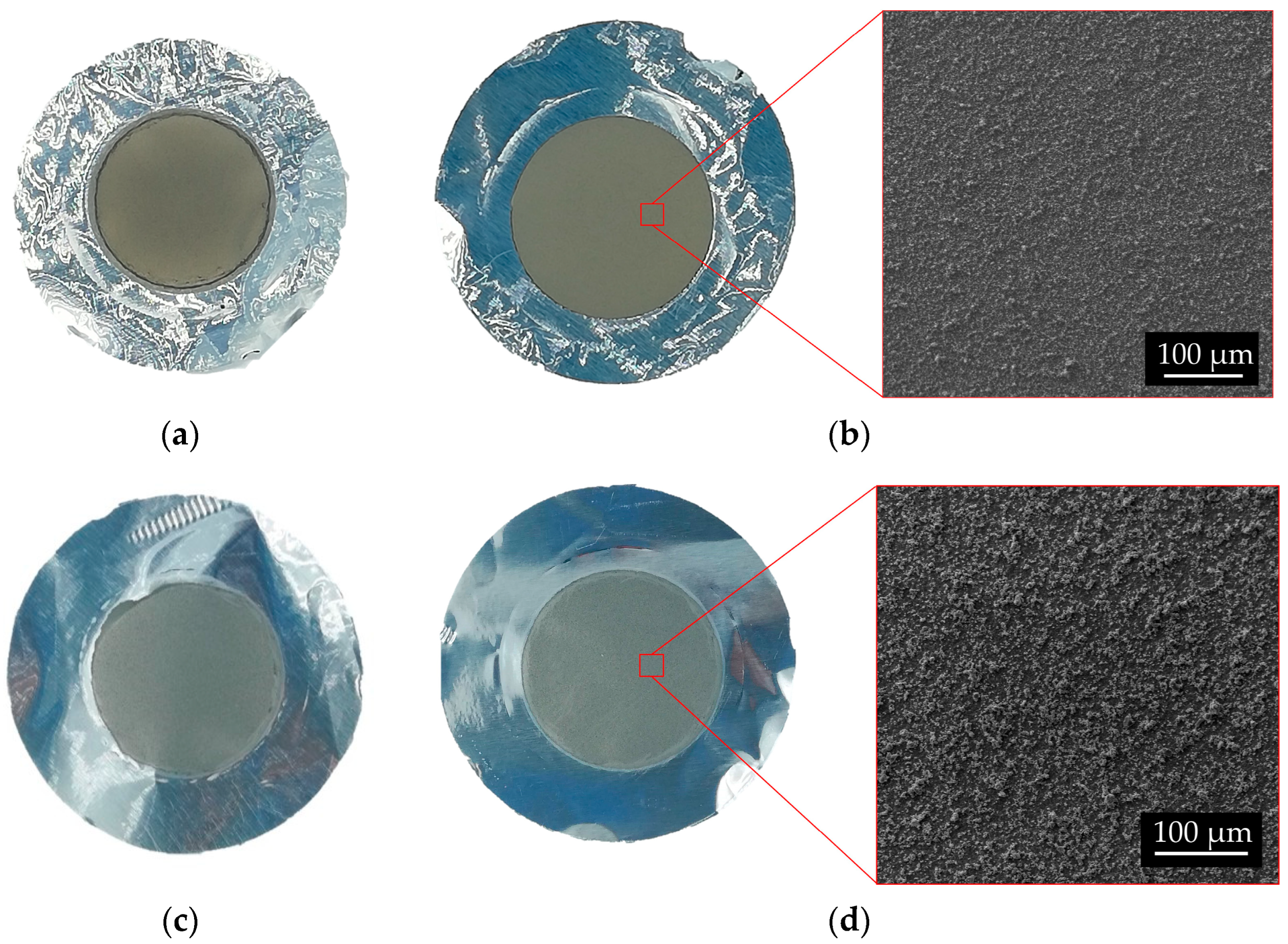

3.2. natTi Powder HIVIPP Depositions and Characterization

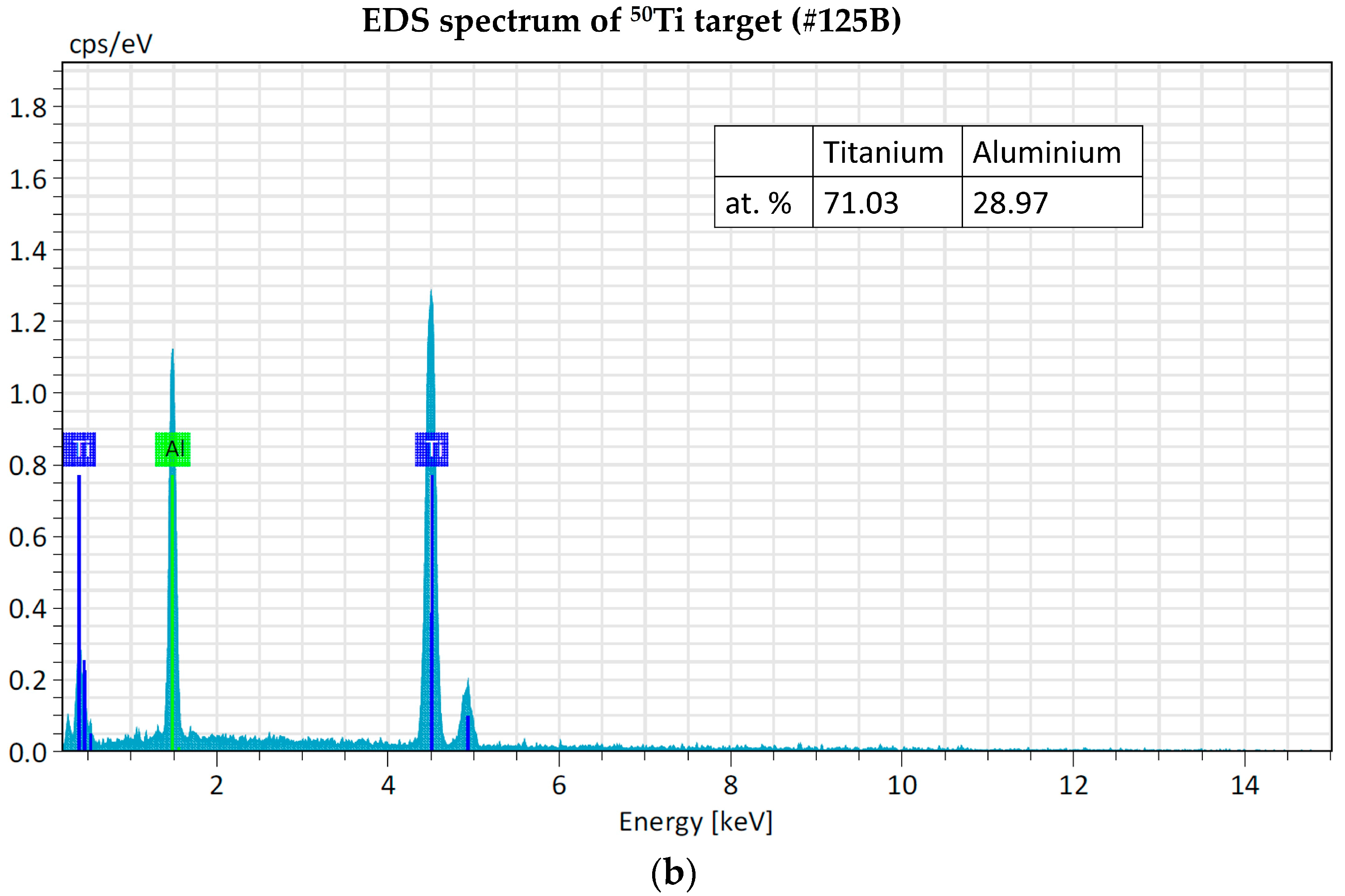

3.3. Enriched 49Ti and 50Ti HIVIPP Depositions and Characterization

3.4. Efficiency of Cryomilling and HIVIPP Processes

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Stolarz, A. Target Preparation for Research with Charged Projectiles. J. Radioanal. Nucl. Chem. 2014, 299, 913–931. [Google Scholar] [CrossRef] [Green Version]

- Qaim, S.M. Target Development for Medical Radioisotope Production at a Cyclotron. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 1989, 282, 289–295. [Google Scholar] [CrossRef]

- Mieszkowska, M.; Grdeń, M. Electrochemical Deposition of Nickel Targets from Aqueous Electrolytes for Medical Radioisotope Production in Accelerators: A Review. J. Solid State Electrochem. 2021, 25, 1699–1725. [Google Scholar] [CrossRef]

- Stolarz, A.; Kowalska, J.A.; Jasiński, P.; Janiak, T.; Samorajczyk, J. Molybdenum Targets Produced by Mechanical Reshaping. J. Radioanal. Nucl. Chem. 2015, 305, 947–952. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Deb, N.K.; Kalita, K.; Abhilash, S.R.; Giri, P.K.; Biswas, R.; Umapathy, G.R.; Kabiraj, D.; Chopra, S. Fabrication and Characterization of Thin Targets of Nickel (61,62Ni) Isotopes by Physical Vapour Deposition Technique for Nuclear Reaction Studies. Vacuum 2019, 163, 148–157. [Google Scholar] [CrossRef]

- Lommel, B.; Düllmann, C.E.; Kindler, B.; Renisch, D. Status and Developments of Target Production for Research on Heavy and Superheavy Nuclei and Elements. Eur. Phys. J. A 2023, 59, 14. [Google Scholar] [CrossRef]

- Sugai, I. A New Technique for Preparation of Targets of Powdered Materials. Nucl. Instrum. Methods 1977, 145, 409–415. [Google Scholar] [CrossRef]

- Skliarova, H.; Cisternino, S.; Cicoria, G.; Cazzola, E.; Gorgoni, G.; Marengo, M.; Esposito, J. Cyclotron Solid Targets Preparation for Medical Radionuclides Production in the Framework of LARAMED Project. J. Phys. Conf. Ser. 2020, 1548, 012022. [Google Scholar] [CrossRef]

- Esposito, J.; Bettoni, D.; Boschi, A.; Calderolla, M.; Cisternino, S.; Fiorentini, G.; Keppel, G.; Martini, P.; Maggiore, M.; Mou, L.; et al. LARAMED: A LAboratory for RAdioisotopes of MEDical Interest. Molecules 2018, 24, 20. [Google Scholar] [CrossRef] [Green Version]

- Pupillo, G.; Andrighetto, A.; Ballan, M.; Boschi, A.; Cisternino, S.; Corradetti, S. Research Activities on the Cyclotron-Based Production of Innovative Radionuclides: The Experience at the Legnaro National Laboratories of INFN. In Proceedings of the International Conference on Accelerators for Research and Sustainable Development: From Good Practices Towards Socioeconomic Impact, Vienna, Austria, 23–27 May 2022. IAEA-CN-301/073. [Google Scholar]

- Cisternino, S.; Cazzola, E.; Skliarova, H.; Amico, J.; Malachini, M.; Gorgoni, G.; Anselmi-Tamburini, U.; Esposito, J. Target Manufacturing by Spark Plasma Sintering for Efficient 89Zr Production. Nucl. Med. Biol. 2022, 104–105, 38–46. [Google Scholar] [CrossRef]

- Cisternino, S.; Skliarova, H.; Antonini, P.; Esposito, J.; Mou, L.; Pranovi, L.; Pupillo, G.; Sciacca, G. Upgrade of the HIVIPP Deposition Apparatus for Nuclear Physics Thin Targets Manufacturing. Instruments 2022, 6, 23. [Google Scholar] [CrossRef]

- Kotliarenko, A.; Azzolini, O.; Keppel, G.; Pira, C.; Esposito, J. Investigation of a Possible Material-Saving Approach of Sputtering Techniques for Radiopharmaceutical Target Production. Appl. Sci. 2021, 11, 9219. [Google Scholar] [CrossRef]

- Divisione Ricerca—Home INFN Legnaro. Available online: https://www.lnl.infn.it/divisione-ricerca/ (accessed on 16 February 2023).

- About EURO-LABS. Available online: https://web.infn.it/EURO-LABS/ (accessed on 18 May 2023).

- Ricerca Tecnologica (CSN5)—Home INFN Legnaro. Available online: https://www.lnl.infn.it/ricerca-tecnologica-csn5/#REMIX (accessed on 16 February 2023).

- Dellepiane, G.; Casolaro, P.; Mateu, I.; Scampoli, P.; Voeten, N.; Braccini, S. 47Sc and 46Sc Cross-Section Measurement for an Optimized 47Sc Production with an 18 MeV Medical PET Cyclotron. Appl. Radiat. Isot. 2022, 189, 110428. [Google Scholar] [CrossRef]

- Jalilian, A.R.; Gizawy, M.A.; Alliot, C.; Takacs, S.; Chakarborty, S.; Rovais, M.R.A.; Pupillo, G.; Nagatsu, K.; Park, J.H.; Khandaker, M.U.; et al. IAEA Activities on 67Cu, 186Re, 47Sc Theranostic Radionuclides and Radiopharmaceuticals. Curr. Radiopharm. 2021, 14, 306–314. Available online: https://www.eurekaselect.com/186361/article (accessed on 18 January 2021). [CrossRef] [PubMed]

- Domnanich, K.A.; Müller, C.; Benešová, M.; Dressler, R.; Haller, S.; Köster, U.; Ponsard, B.; Schibli, R.; Türler, A.; van der Meulen, N.P. 47Sc as Useful β–-Emitter for the Radiotheragnostic Paradigm: A Comparative Study of Feasible Production Routes. EJNMMI Radiopharm. Chem. 2017, 2, 5. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chernysheva, M.; Loveless, S.C.; Brossard, T.; Becker, K.; Cingoranelli, S.; Aluicio-Sarduy, E.; Song, J.; Ellison, P.; Nolen, J.; Rotsch, D.A.; et al. Accelerator Production of Scandium Radioisotopes: Sc-43, Sc-44, and Sc-47. Curr. Radiopharm. 2021, 14, 359–373. [Google Scholar] [CrossRef]

- Haddad, F.; Ferrer, L.; Guertin, A.; Carlier, T.; Michel, N.; Barbet, J.; Chatal, J.-F. ARRONAX, a High-Energy and High-Intensity Cyclotron for Nuclear Medicine. Eur. J. Nucl. Med. Mol. Imaging 2008, 35, 1377–1387. [Google Scholar] [CrossRef] [PubMed]

- Qaim, S.M. Nuclear Data for Production and Medical Application of Radionuclides: Present Status and Future Needs. Nucl. Med. Biol. 2017, 44, 31–49. [Google Scholar] [CrossRef] [PubMed]

- Pupillo, G.; Mou, L.; Manenti, S.; Groppi, F.; Esposito, J.; Haddad, F. Nuclear Data for Light Charged Particle Induced Production of Emerging Medical Radionuclides. Radiochim. Acta 2022, 110, 689–706. [Google Scholar] [CrossRef]

- Nardo, L.D.; Pupillo, G.; Mou, L.; Furlanetto, D.; Rosato, A.; Esposito, J.; Meléndez-Alafort, L. Preliminary Dosimetric Analysis of DOTA-Folate Radiopharmaceutical Radiolabelled with 47Sc Produced through NatV(p,x)47Sc Cyclotron Irradiation. Phys. Med. Biol. 2021, 66, 025003. [Google Scholar] [CrossRef]

- Sugai, I. Target Preparation by Means of the Vibrational Motion of Particles at One Atmosphere. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 1999, 438, 58–64. [Google Scholar] [CrossRef]

- Sugai, I.; Takeda, Y.; Kawakami, H. Preparation of Thick Enriched Isotopic Si Targets by the HIVIPP Method. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2006, 561, 38–44. [Google Scholar] [CrossRef]

- Sugai, I.; Takeda, Y.; Oyaizu, M.; Kawakami, H.; Sasa, K.; Ishii, S.; Shima, K. First Results of Target Preparation by the HIVIPP Method in Pressures Higher than One Bar. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2008, 590, 83–90. [Google Scholar] [CrossRef]

- Sugai, I.; Takeda, Y.; Kawakami, H. Production of Uniform and Thick Enriched Isotopic Te Targets by Means of the HIVIPP Method. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2010, 613, 407–411. [Google Scholar] [CrossRef]

- Skliarova, H.; Cisternino, S.; Pranovi, L.; Mou, L.; Pupillo, G.; Rigato, V.; Rossi Alvarez, C. HIVIPP Deposition and Characterization of Isotopically Enriched 48Ti Targets for Nuclear Cross-Section Measurements. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2020, 981, 164371. [Google Scholar] [CrossRef]

- El-Eskandarany, M.S. 4—Controlling the Powder-Milling Process. In Mechanical Alloying, 3rd ed.; El-Eskandarany, M.S., Ed.; William Andrew Publishing: Norwich, NY, USA, 2020; pp. 55–92. ISBN 978-0-12-818180-5. [Google Scholar]

- Zhou, F.; Nutt, S.R.; Bampton, C.C.; Lavernia, E.J. Nanostructure in an Al-Mg-Sc Alloy Processed by Low-Energy Ball Milling at Cryogenic Temperature. Met. Mat. Trans A 2003, 34, 1985–1992. [Google Scholar] [CrossRef]

- Khodsiani, Z.; Mansuri, H.; Mirian, T. The Effect of Cryomilling on the Morphology and Particle Size Distribution of the NiCoCrAlYSi Powders with and without Nano-Sized Alumina. Powder Technol. 2013, 245, 7–12. [Google Scholar] [CrossRef]

- Kozlík, J.; Becker, H.; Harcuba, P.; Stráský, J.; Janeček, M. Cryomilled and Spark Plasma Sintered Titanium: The Evolution of Microstructure. IOP Conf. Ser. Mater. Sci. Eng. 2017, 194, 012023. [Google Scholar] [CrossRef] [Green Version]

- Suryanarayana, C. Mechanical Alloying and Milling. Prog. Mater. Sci. 2001, 46, 184. [Google Scholar] [CrossRef]

- Witkin, D.B.; Lavernia, E.J. Synthesis and Mechanical Behavior of Nanostructured Materials via Cryomilling. Prog. Mater. Sci. 2006, 51, 1–60. [Google Scholar] [CrossRef]

- Lv, P.; Guzik, M.N.; Sartori, S.; Huot, J. Effect of Ball Milling and Cryomilling on the Microstructure and First Hydrogenation Properties of TiFe+4 Wt.% Zr Alloy. J. Mater. Res. Technol. 2019, 8, 1828–1834. [Google Scholar] [CrossRef]

- Kozlík, J.; Stráský, J.; Harcuba, P.; Ibragimov, I.; Janeček, M. Characterization of Commercially Pure Ti Powders Prepared by Cryogenic Milling. Acta Phys. Pol. A 2018, 134, 783–786. [Google Scholar] [CrossRef]

- Kozlík, J.; Stráský, J.; Harcuba, P.; Ibragimov, I.; Chráska, T.; Janeček, M. Cryogenic Milling of Titanium Powder. Metals 2018, 8, 31. [Google Scholar] [CrossRef] [Green Version]

- Mogale, N.F.; Matizamhuka, W.R. Spark Plasma Sintering of Titanium Aluminides: A Progress Review on Processing, Structure-Property Relations, Alloy Development and Challenges. Metals 2020, 10, 1080. [Google Scholar] [CrossRef]

- Kumar, N.; Biswas, K. Fabrication of Novel Cryomill for Synthesis of High Purity Metallic Nanoparticles. Rev. Sci. Instrum. 2015, 86, 083903. [Google Scholar] [CrossRef] [PubMed]

- Sun, F.; Rojas, P.; Zúñiga, A.; Lavernia, E.J. Nanostructure in a Ti Alloy Processed Using a Cryomilling Technique. Mater. Sci. Eng. A 2006, 430, 90–97. [Google Scholar] [CrossRef]

- Hofmeister, C.; Yao, B.; Sohn, Y.H.; Delahanty, T.; van den Bergh, M.; Cho, K. Composition and Structure of Nitrogen-Containing Dispersoids in Trimodal Aluminum Metal–Matrix Composites. J. Mater. Sci. 2010, 45, 4871–4876. [Google Scholar] [CrossRef]

- Das, S. Metallographic Sample Preparation Techniques. In Materials Characterization Techniques: Principles and Applications; Sridhar, G., Ghosh, S., Chowdhury, N.G., Eds.; National Metallurgical Laboratory (Council of Scientific & Industrial Research): Jamshedpur, India, 1999; pp. 163–176. [Google Scholar]

- Pupillo, G.; Mou, L.; Martini, P.; Pasquali, M.; Boschi, A.; Cicoria, G.; Duatti, A.; Haddad, F.; Esposito, J. Production of 67Cu by Enriched 70Zn Targets: First Measurements of Formation Cross Sections of 67Cu, 64Cu, 67Ga, 66Ga, 69mZn and 65Zn in Interactions of 70Zn with Protons above 45 MeV. Radiochim. Acta 2020, 108, 593–602. [Google Scholar] [CrossRef]

- Stodel, C. Methods of Targets’ Characterization. EPJ Web Conf. 2020, 229, 02001. [Google Scholar] [CrossRef]

- Mayer, M. Rutherford Backscattering Spectrometry (RBS). In Proceedings of the Workshop on Nuclear Data for Science and Technology: Materials Analysis, Trieste, Italy, 19–30 May 2003; p. 26. [Google Scholar]

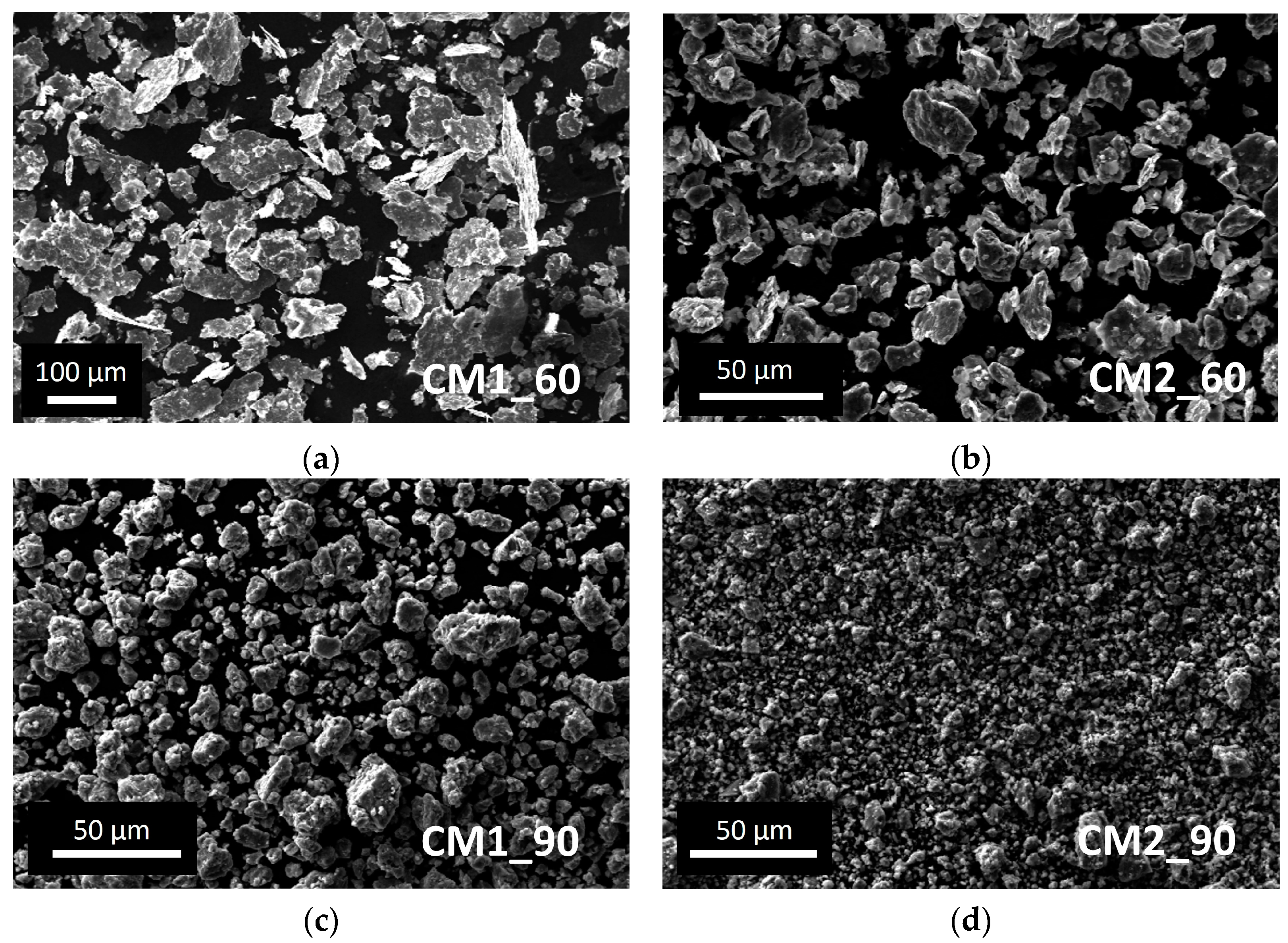

| Milling Parameters | Balls No. | Starting Material Amount [mg] | Results | Exp Name | |

|---|---|---|---|---|---|

| Powder Size Range ≈ | % Powder Lost | ||||

| # cycle = 20 CM time = 60 min | 1 | 143.6 | 30–200 µm | 5% | CM1_60 |

| 2 | 139.4 | 5–30 µm | 15% | CM2_60 | |

| # cycle = 30 CM time = 90 min | 1 | 161.7 | 2–20 µm | 37% | CM1_90 |

| 2 | 143.3 | <10 µm | 28% | CM2_90 | |

| Material | HIVIPP Parameters | Powder Size | Results [µg/cm2] | Exp # | |

|---|---|---|---|---|---|

| Top (T) | Bottom (B) | ||||

| natTi | 10 kV; 10 h | <10 µm CM2_90 | 441.6 | 476.6 | 96 |

| 476.6 | 260.0 | 97 | |||

| 346.6 | 303.3 | 104 (u) | |||

| 539.2 | 462.2 | 105 (u) | |||

| 2–20 µm CM1_90 | 801.6 | 520.0 | 102 | ||

| 15 kV; 10 h | <10 µm CM2_90 | 547.0 | 455.0 | 98 | |

| 563.3 | 563.3 | 99 | |||

| 866.6 * | 411.6 | 101 | |||

| 15 kV; 21.5 h | 1451.5 * | 671.6 | 100 (u) | ||

| Enriched Material | HIVIPP Parameters | Results by Weighing [µg/cm2] | Exp # | |

|---|---|---|---|---|

| Top | Bottom | |||

| 49Ti | 10 kV; 10 h | 270.0 | 166.8 | 106 |

| 435.5 | 498.3 | 107 | ||

| 407.3 | 449.0 | 109 | ||

| 404.6 | 465.4 | 110 | ||

| 383.5 | 449.5 | 111 | ||

| 536.7 | 457.1 | 113 (u) | ||

| 494.0 | 546.0 | 114 (u) | ||

| 485.3 | 547.0 | 115 (u) | ||

| 12 kV; 15 h | 649.9 * | 541.6 | 108 | |

| 582.8 * | 588.7 | 112 (u) | ||

| 50Ti | 12 kV; 22.5 h | 606.6 | 664.6 | 118 |

| 12 kV; 10 h | 517.8 | 455.0 | 119 | |

| 558.9 | 506.4 | 120 | ||

| 444.1 | 433.3 | 121 | ||

| 465.8 | 425.5 | 122 | ||

| 554.6 | 566.3 | 123 | ||

| 1075.1 | 719.3 | 124 (u) | ||

| 940.2 | 638.7 | 125 (u) | ||

| 979.2 | 623.9 | 126 (u) | ||

| 977.1 | 604.4 | 127 (u) | ||

| Powder [mg] | % | Thickness | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Starting | Rec | Dep | Lost | Rec | Dep | Lost | Eff rec | Eff dep | [µg/cm2] | |

| 49Ti ne = 10 | 20.0 ± 1.5 | 17.9 ± 1.4 | 1.4 ± 0.3 | 0.6 ± 0.4 | 89.8 ± 1.9 | 7.0 ± 1.6 | 3.2 ± 2.0 | 96.6 ± 2.1 | 69.9 ± 17.7 | 468.0 ± 110.4 (n = 20) |

| 50Ti ne = 10 | 19.1 ± 0.9 | 15.7 ± 1.3 | 1.0 ± 0.3 | 1.4 ± 0.4 | 82.2 ± 3.5 | 10.3 ± 2.9 | 7.4 ± 2.4 | 91.7 ± 2.6 | 58.1 ± 10.6 | 637.8 ± 200.2 (n = 20) |

| 49Ti and 50Ti ne = 20 | 19.5 ± 0.6 | 16.8 ± 1.6 | 1.2 ± 0.3 | 1.0 ± 0.5 | 86.0 ± 5.3 | 8.7 ± 2.4 | 5.3 ± 3.0 | 94.2 ± 3.4 | 64.0 ± 8.4 | 552.9 ± 120.1 (n = 40) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cisternino, S.; De Dominicis, L.; Mou, L.; Esposito, J.; Gennari, C.; Calliari, I.; Pupillo, G. Cryomilling of Isotope-Enriched Ti Powders for HIVIPP Deposition to Manufacture Targets for Nuclear Cross Section Measurement. Materials 2023, 16, 3926. https://doi.org/10.3390/ma16113926

Cisternino S, De Dominicis L, Mou L, Esposito J, Gennari C, Calliari I, Pupillo G. Cryomilling of Isotope-Enriched Ti Powders for HIVIPP Deposition to Manufacture Targets for Nuclear Cross Section Measurement. Materials. 2023; 16(11):3926. https://doi.org/10.3390/ma16113926

Chicago/Turabian StyleCisternino, Sara, Lucia De Dominicis, Liliana Mou, Juan Esposito, Claudio Gennari, Irene Calliari, and Gaia Pupillo. 2023. "Cryomilling of Isotope-Enriched Ti Powders for HIVIPP Deposition to Manufacture Targets for Nuclear Cross Section Measurement" Materials 16, no. 11: 3926. https://doi.org/10.3390/ma16113926

APA StyleCisternino, S., De Dominicis, L., Mou, L., Esposito, J., Gennari, C., Calliari, I., & Pupillo, G. (2023). Cryomilling of Isotope-Enriched Ti Powders for HIVIPP Deposition to Manufacture Targets for Nuclear Cross Section Measurement. Materials, 16(11), 3926. https://doi.org/10.3390/ma16113926